4dbf90896d1416df6c74c88666ecd983.ppt

- Количество слайдов: 50

Fire Safety Engineering & Structures in Fire Workshop at Indian Institute of Science 9 -13 August, 2010 Bangalore India Structural Fire Engineering – Design Approaches Organisers: CS Manohar and Ananth Ramaswamy Indian Institute of Science Speakers: Jose Torero, Asif Usmani and Martin Gillie The University of Edinburgh Funding and Sponsorship:

Fire Safety Engineering & Structures in Fire Workshop at Indian Institute of Science 9 -13 August, 2010 Bangalore India Structural Fire Engineering – Design Approaches Organisers: CS Manohar and Ananth Ramaswamy Indian Institute of Science Speakers: Jose Torero, Asif Usmani and Martin Gillie The University of Edinburgh Funding and Sponsorship:

Structural design for fire u PRESCRIPTIVE APPROACH u. Structural elements protected to remain under a certain temperature u. Fire scenario so that they retain adequate strength and stiffness to continue to carry loads. This has been the traditional approach. u PERFORMANCE BASED DESIGN APPROACH u. Engineer must show structure meets certain criteria u. Requires understanding of behaviour

Structural design for fire u PRESCRIPTIVE APPROACH u. Structural elements protected to remain under a certain temperature u. Fire scenario so that they retain adequate strength and stiffness to continue to carry loads. This has been the traditional approach. u PERFORMANCE BASED DESIGN APPROACH u. Engineer must show structure meets certain criteria u. Requires understanding of behaviour

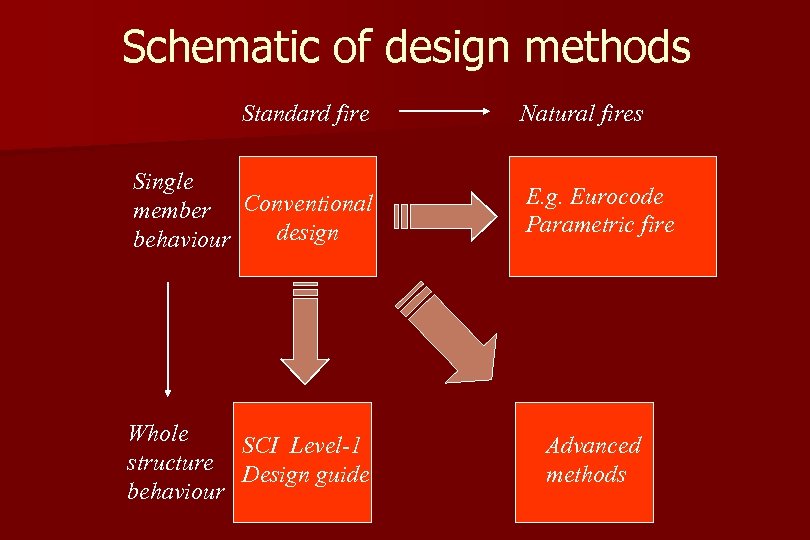

Schematic of design methods Standard fire Natural fires Single member Conventional design behaviour E. g. Eurocode Parametric fire Whole SCI Level-1 structure Design guide behaviour Advanced methods

Schematic of design methods Standard fire Natural fires Single member Conventional design behaviour E. g. Eurocode Parametric fire Whole SCI Level-1 structure Design guide behaviour Advanced methods

Eurocodes n n n n Replacing British (and other) Standards (for all structural design) 9 Codes Eurocode 1 - actions Eurocode 2 - concrete Eurocode 3 - steel Eurocode 4 - composite Etc All available online via the library website

Eurocodes n n n n Replacing British (and other) Standards (for all structural design) 9 Codes Eurocode 1 - actions Eurocode 2 - concrete Eurocode 3 - steel Eurocode 4 - composite Etc All available online via the library website

Eurocode 1 n Covers “actions” for all design n n Part 1 -2 covers fire actions Allows for n Provides background information on – Various parts and sections – Standard fire curve – Natural fires – Computer analysis of fires – Parametric fires – Fire load densities – etc

Eurocode 1 n Covers “actions” for all design n n Part 1 -2 covers fire actions Allows for n Provides background information on – Various parts and sections – Standard fire curve – Natural fires – Computer analysis of fires – Parametric fires – Fire load densities – etc

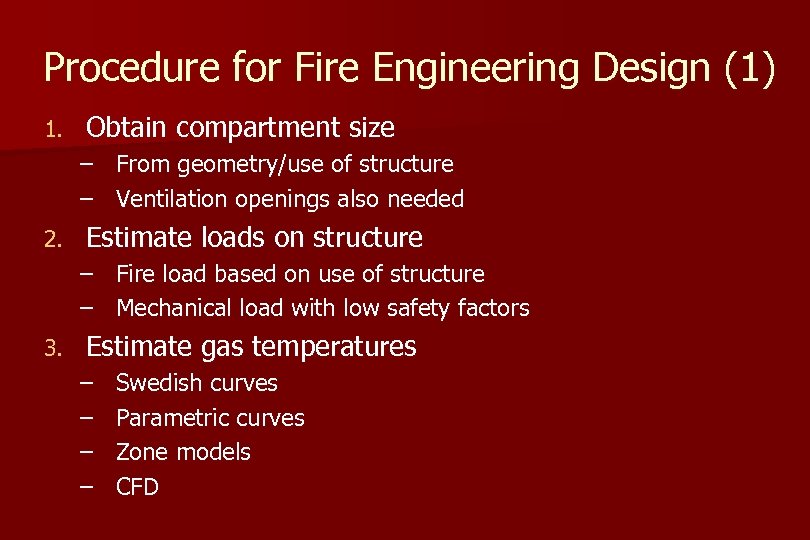

Procedure for Fire Engineering Design (1) 1. Obtain compartment size – From geometry/use of structure – Ventilation openings also needed 2. Estimate loads on structure – Fire load based on use of structure – Mechanical load with low safety factors 3. Estimate gas temperatures – – Swedish curves Parametric curves Zone models CFD

Procedure for Fire Engineering Design (1) 1. Obtain compartment size – From geometry/use of structure – Ventilation openings also needed 2. Estimate loads on structure – Fire load based on use of structure – Mechanical load with low safety factors 3. Estimate gas temperatures – – Swedish curves Parametric curves Zone models CFD

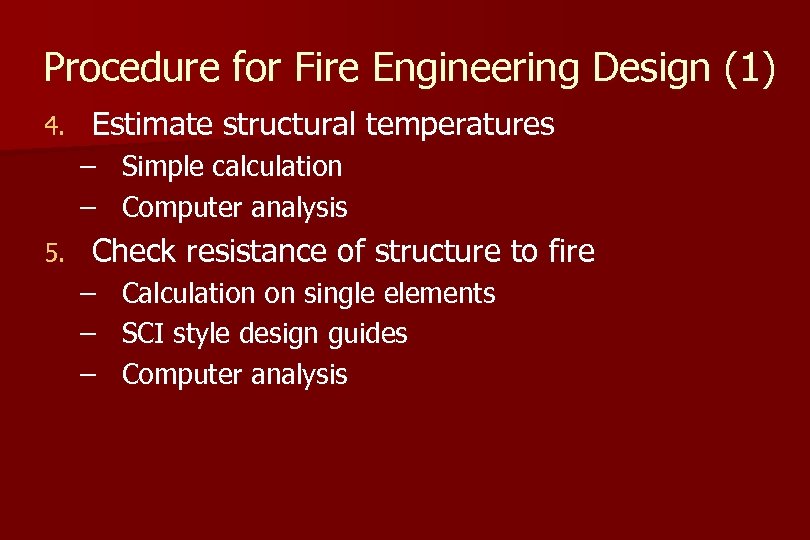

Procedure for Fire Engineering Design (1) 4. Estimate structural temperatures – Simple calculation – Computer analysis 5. Check resistance of structure to fire – – – Calculation on single elements SCI style design guides Computer analysis

Procedure for Fire Engineering Design (1) 4. Estimate structural temperatures – Simple calculation – Computer analysis 5. Check resistance of structure to fire – – – Calculation on single elements SCI style design guides Computer analysis

Loads for Fire Design

Loads for Fire Design

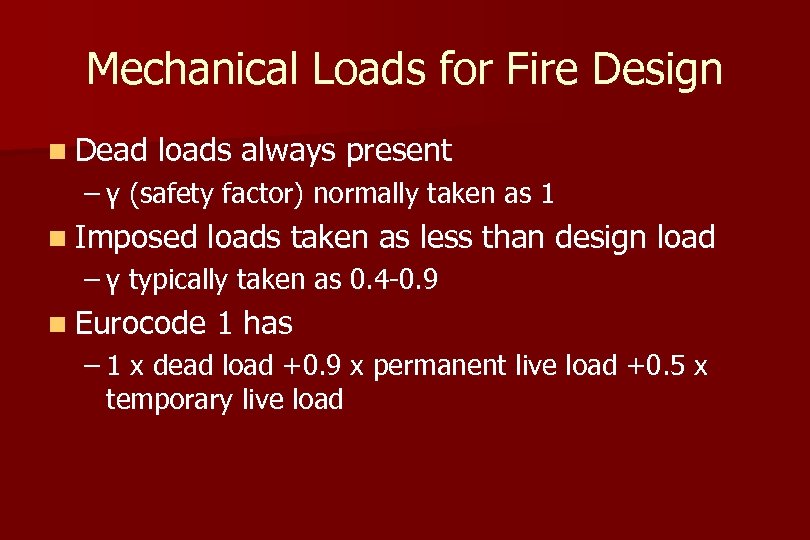

Mechanical Loads for Fire Design n Dead loads always present – γ (safety factor) normally taken as 1 n Imposed loads taken as less than design load – γ typically taken as 0. 4 -0. 9 n Eurocode 1 has – 1 x dead load +0. 9 x permanent live load +0. 5 x temporary live load

Mechanical Loads for Fire Design n Dead loads always present – γ (safety factor) normally taken as 1 n Imposed loads taken as less than design load – γ typically taken as 0. 4 -0. 9 n Eurocode 1 has – 1 x dead load +0. 9 x permanent live load +0. 5 x temporary live load

Fire Loads n Measure of the combustible material in a fire compartment – Normally measured in MJ/m 2 floor area – REMEMBER temperature calculations often use total surface area of compartment n In design adjusted for – – – n Compartment area “Fire activation risk” Etc Extract from Eurocode available

Fire Loads n Measure of the combustible material in a fire compartment – Normally measured in MJ/m 2 floor area – REMEMBER temperature calculations often use total surface area of compartment n In design adjusted for – – – n Compartment area “Fire activation risk” Etc Extract from Eurocode available

Estimating Compartment Temperatures

Estimating Compartment Temperatures

Temperatures in compartment fires n Need to know atmosphere temperatures in order to estimate structural temperatures n Simple approach uses energy balance in a compartment n Swedish method the most common (from physics) n Similar curves in parametric form in the Eurocode 1 Part 2 (curve fire to Swedish method)

Temperatures in compartment fires n Need to know atmosphere temperatures in order to estimate structural temperatures n Simple approach uses energy balance in a compartment n Swedish method the most common (from physics) n Similar curves in parametric form in the Eurocode 1 Part 2 (curve fire to Swedish method)

Compartment Fires

Compartment Fires

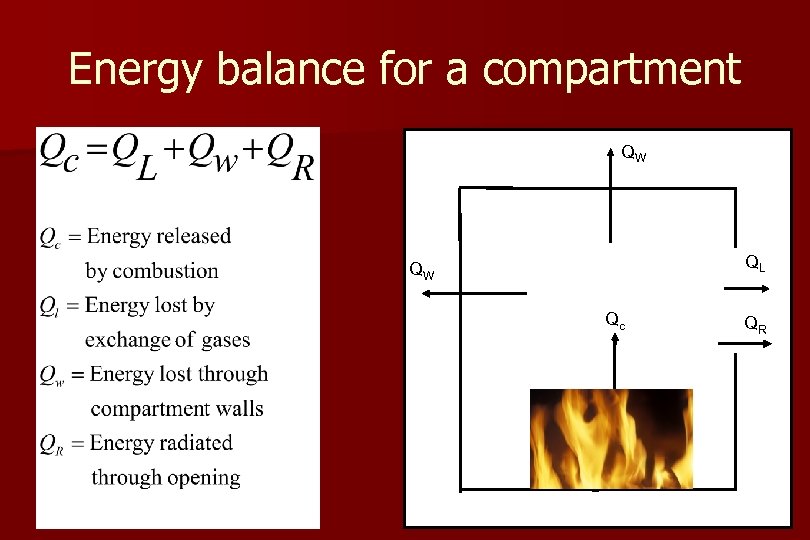

Energy balance for a compartment QW QL QW Qc QR

Energy balance for a compartment QW QL QW Qc QR

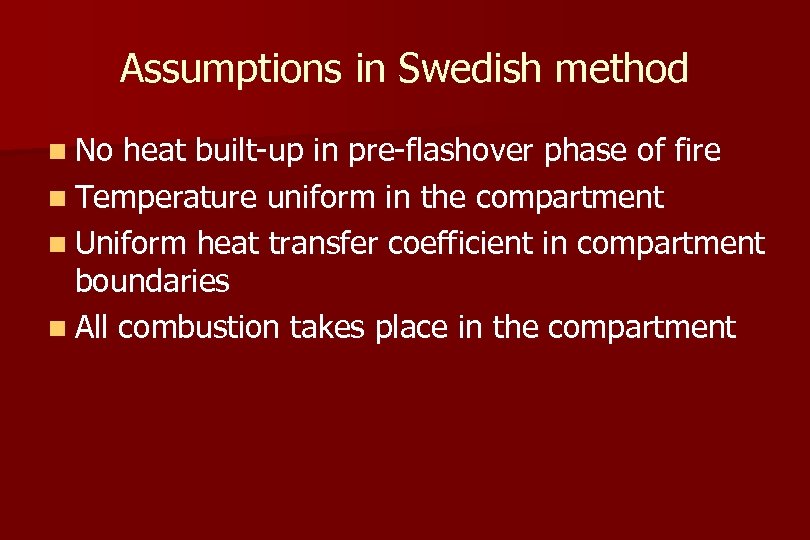

Assumptions in Swedish method n No heat built-up in pre-flashover phase of fire n Temperature uniform in the compartment n Uniform heat transfer coefficient in compartment boundaries n All combustion takes place in the compartment

Assumptions in Swedish method n No heat built-up in pre-flashover phase of fire n Temperature uniform in the compartment n Uniform heat transfer coefficient in compartment boundaries n All combustion takes place in the compartment

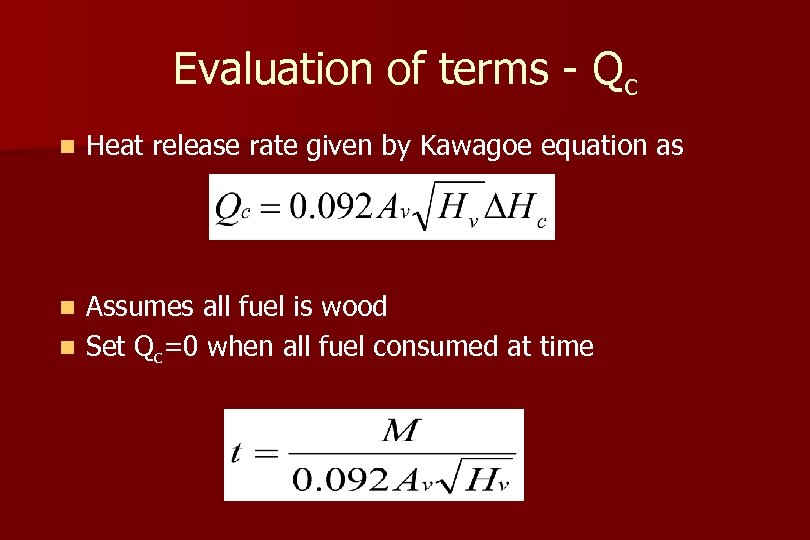

Evaluation of terms - Qc n Heat release rate given by Kawagoe equation as Assumes all fuel is wood n Set Qc=0 when all fuel consumed at time n

Evaluation of terms - Qc n Heat release rate given by Kawagoe equation as Assumes all fuel is wood n Set Qc=0 when all fuel consumed at time n

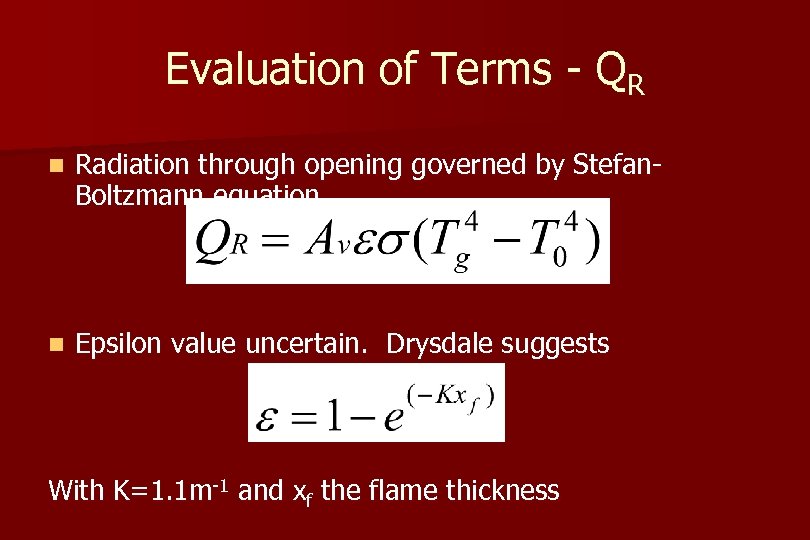

Evaluation of Terms - QR n Radiation through opening governed by Stefan. Boltzmann equation n Epsilon value uncertain. Drysdale suggests With K=1. 1 m-1 and xf the flame thickness

Evaluation of Terms - QR n Radiation through opening governed by Stefan. Boltzmann equation n Epsilon value uncertain. Drysdale suggests With K=1. 1 m-1 and xf the flame thickness

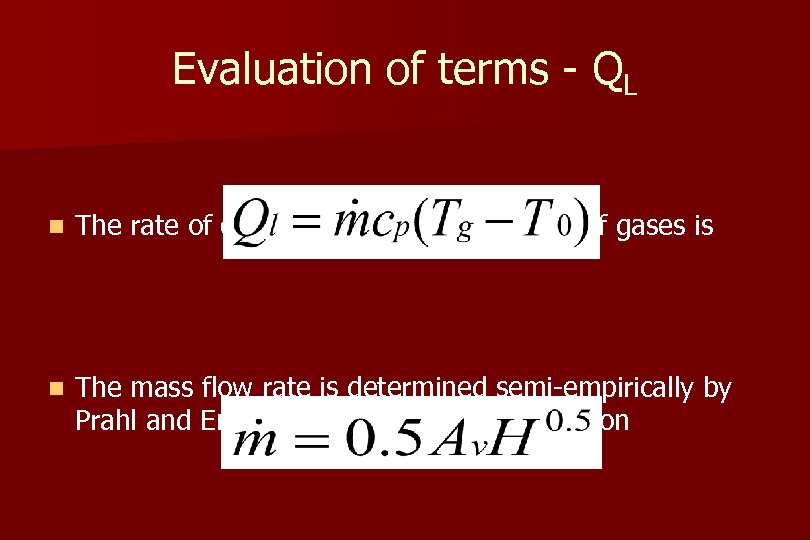

Evaluation of terms - QL n The rate of energy loss due to exchange of gases is n The mass flow rate is determined semi-empirically by Prahl and Emmons using Bernoulli’s equation

Evaluation of terms - QL n The rate of energy loss due to exchange of gases is n The mass flow rate is determined semi-empirically by Prahl and Emmons using Bernoulli’s equation

Evaluation of terms - QW n Convection into wall n Conduction through wall n Convection out of wall n Not steady state

Evaluation of terms - QW n Convection into wall n Conduction through wall n Convection out of wall n Not steady state

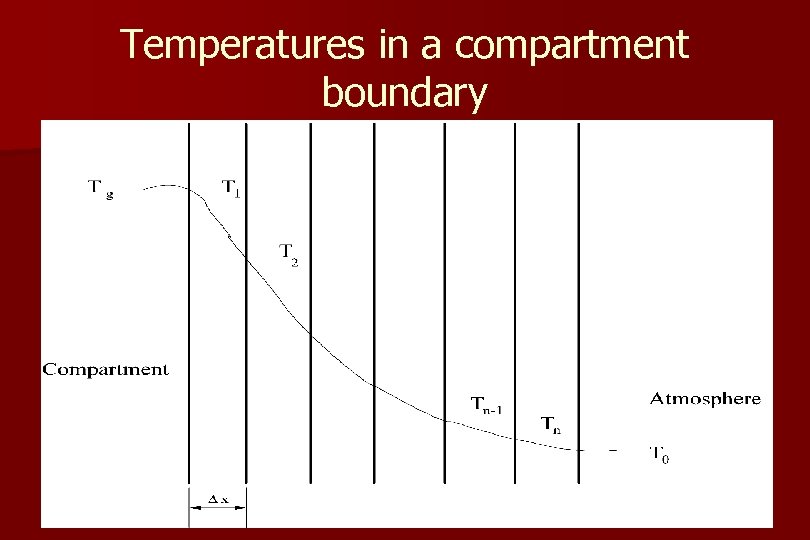

Temperatures in a compartment boundary

Temperatures in a compartment boundary

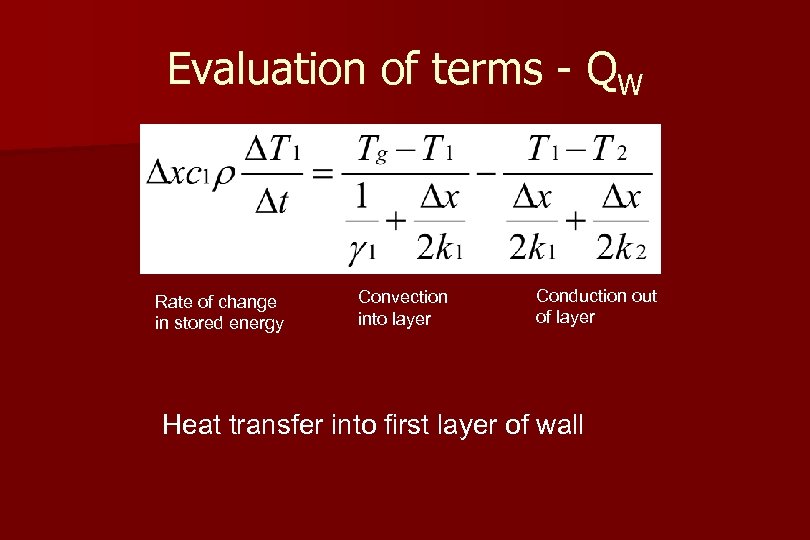

Evaluation of terms - QW Rate of change in stored energy Convection into layer Conduction out of layer Heat transfer into first layer of wall

Evaluation of terms - QW Rate of change in stored energy Convection into layer Conduction out of layer Heat transfer into first layer of wall

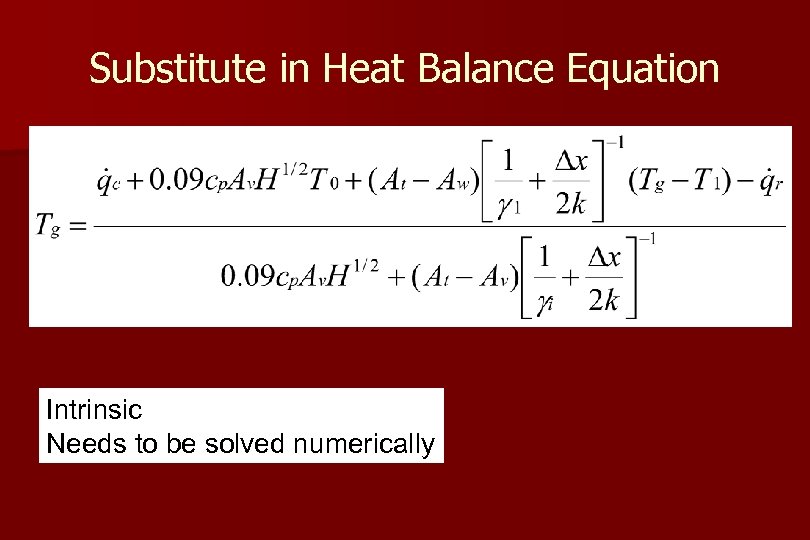

Substitute in Heat Balance Equation Intrinsic Needs to be solved numerically

Substitute in Heat Balance Equation Intrinsic Needs to be solved numerically

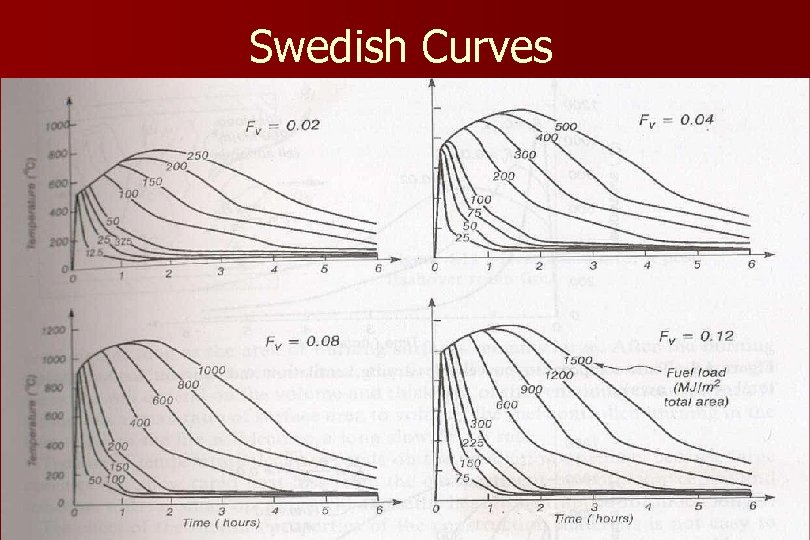

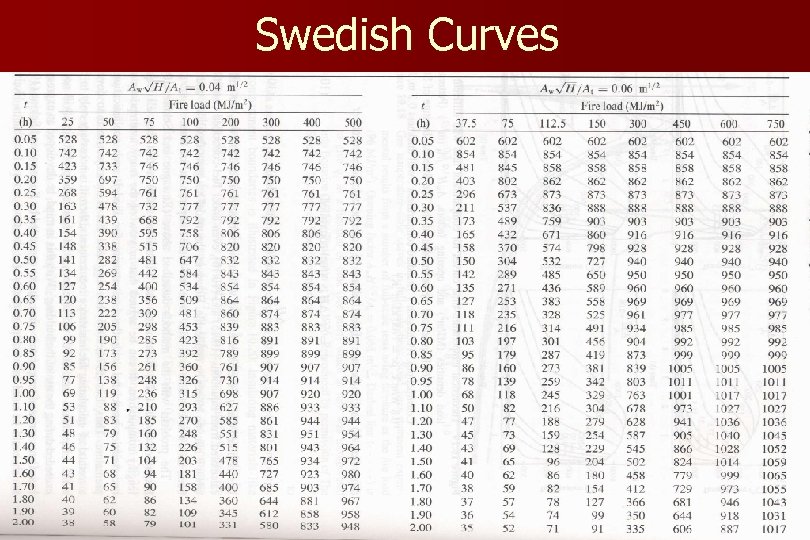

Swedish Curves

Swedish Curves

Swedish Curves

Swedish Curves

Swedish Curves n NOTE: Fire load calculated based on TOTAL surface area of the compartment n Implicit nature awkward

Swedish Curves n NOTE: Fire load calculated based on TOTAL surface area of the compartment n Implicit nature awkward

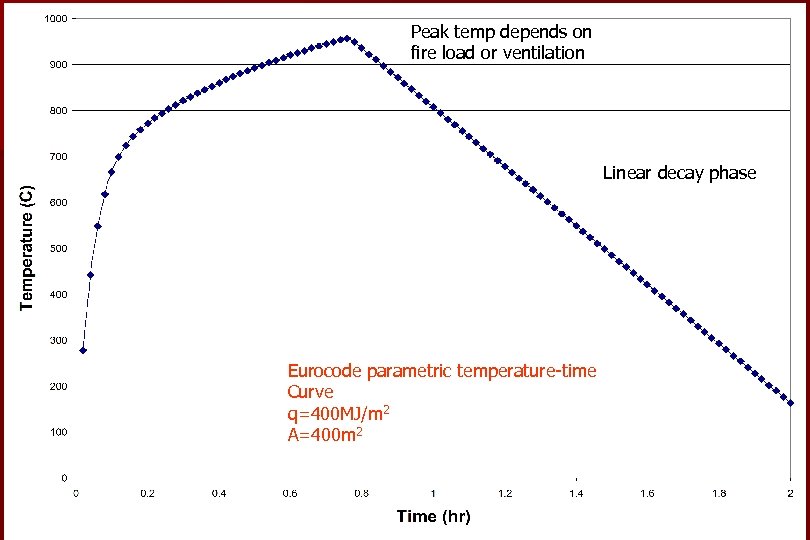

Parametric T-t Curves n Used in Eurocodes n Avoid implicit nature of Swedish Curves – Growth curve based on opening factor – Peak temperature (time) based on fuel load – Linear decay curve

Parametric T-t Curves n Used in Eurocodes n Avoid implicit nature of Swedish Curves – Growth curve based on opening factor – Peak temperature (time) based on fuel load – Linear decay curve

Peak temp depends on fire load or ventilation Linear decay phase Eurocode parametric temperature-time Curve q=400 MJ/m 2 A=400 m 2

Peak temp depends on fire load or ventilation Linear decay phase Eurocode parametric temperature-time Curve q=400 MJ/m 2 A=400 m 2

STEEL STRUCTURES

STEEL STRUCTURES

General Actions on structure in fire < Strength of structure in fire

General Actions on structure in fire < Strength of structure in fire

Spray protection: £ 6/m 2 1 hour, wet trade, poor application in winter conditions

Spray protection: £ 6/m 2 1 hour, wet trade, poor application in winter conditions

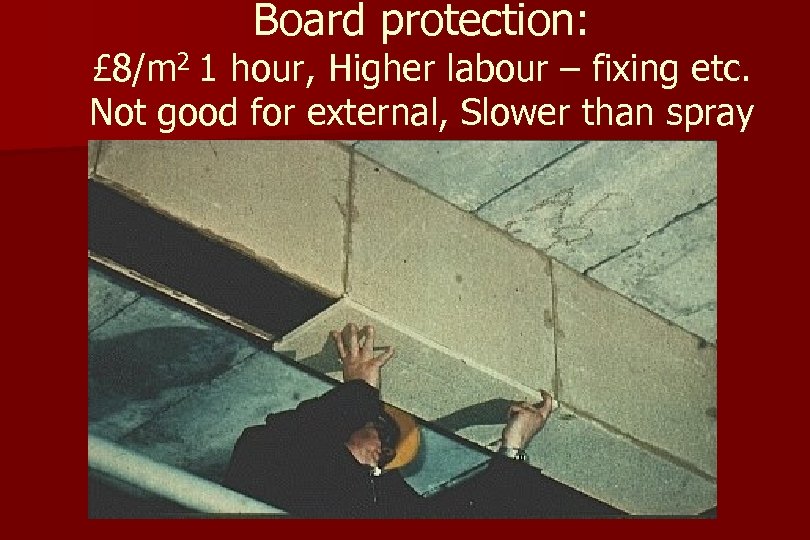

Board protection: £ 8/m 2 1 hour, Higher labour – fixing etc. Not good for external, Slower than spray

Board protection: £ 8/m 2 1 hour, Higher labour – fixing etc. Not good for external, Slower than spray

Blanket: same price as boarding, poor appearance, dry trade

Blanket: same price as boarding, poor appearance, dry trade

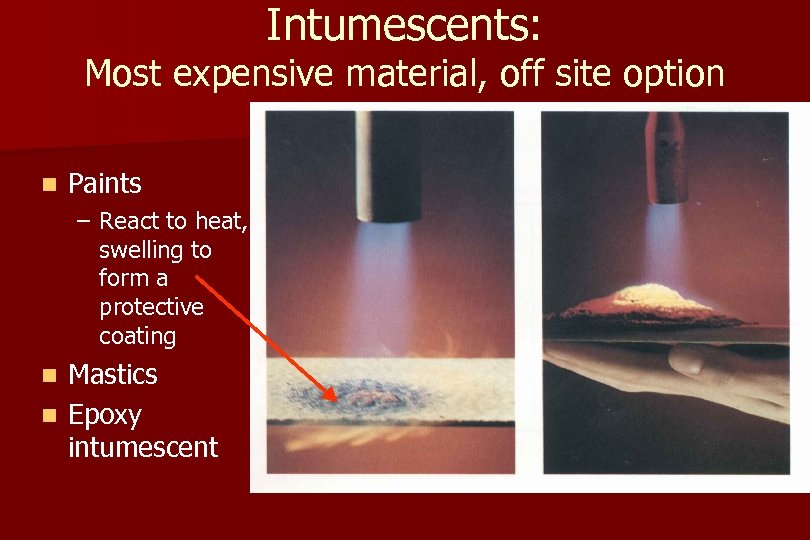

Intumescents: Most expensive material, off site option n Paints – React to heat, swelling to form a protective coating Mastics n Epoxy intumescent n

Intumescents: Most expensive material, off site option n Paints – React to heat, swelling to form a protective coating Mastics n Epoxy intumescent n

Off site intumescent n Plates and bolts need to be cleaned, primed and painted on site n Bolt caps recently introduced to the market n Aiming for a completely offsite product

Off site intumescent n Plates and bolts need to be cleaned, primed and painted on site n Bolt caps recently introduced to the market n Aiming for a completely offsite product

Why contractor may propose off-site application: n Faster construction n Cost savings n Reduction in site disruption n Improved safety n Better QA n Environmental n Where site access is limited

Why contractor may propose off-site application: n Faster construction n Cost savings n Reduction in site disruption n Improved safety n Better QA n Environmental n Where site access is limited

Disadvantages of off site application n Careful handling required n Mechanical damage n Coat connections once erected n Damaged by through deck stud welding n Water-based systems are not sufficiently durable for off-site application

Disadvantages of off site application n Careful handling required n Mechanical damage n Coat connections once erected n Damaged by through deck stud welding n Water-based systems are not sufficiently durable for off-site application

Automated application process at ENOB Ltd

Automated application process at ENOB Ltd

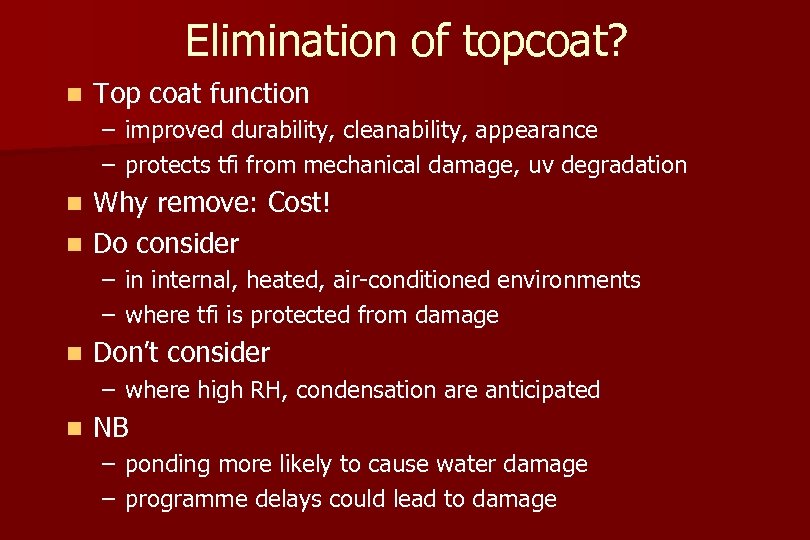

Elimination of topcoat? n Top coat function – improved durability, cleanability, appearance – protects tfi from mechanical damage, uv degradation Why remove: Cost! n Do consider n – in internal, heated, air-conditioned environments – where tfi is protected from damage n Don’t consider – where high RH, condensation are anticipated n NB – ponding more likely to cause water damage – programme delays could lead to damage

Elimination of topcoat? n Top coat function – improved durability, cleanability, appearance – protects tfi from mechanical damage, uv degradation Why remove: Cost! n Do consider n – in internal, heated, air-conditioned environments – where tfi is protected from damage n Don’t consider – where high RH, condensation are anticipated n NB – ponding more likely to cause water damage – programme delays could lead to damage

Appearance on site (without top coat)

Appearance on site (without top coat)

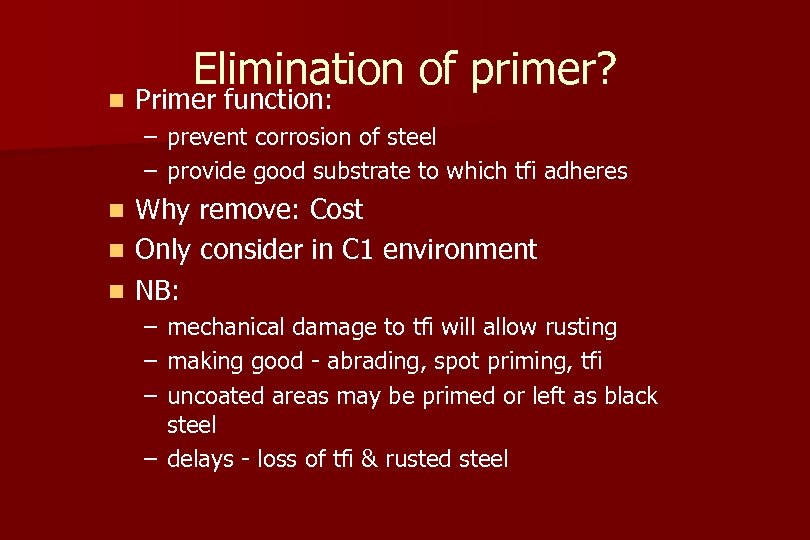

n Elimination of primer? Primer function: – prevent corrosion of steel – provide good substrate to which tfi adheres n n n Why remove: Cost Only consider in C 1 environment NB: – mechanical damage to tfi will allow rusting – making good - abrading, spot priming, tfi – uncoated areas may be primed or left as black steel – delays - loss of tfi & rusted steel

n Elimination of primer? Primer function: – prevent corrosion of steel – provide good substrate to which tfi adheres n n n Why remove: Cost Only consider in C 1 environment NB: – mechanical damage to tfi will allow rusting – making good - abrading, spot priming, tfi – uncoated areas may be primed or left as black steel – delays - loss of tfi & rusted steel

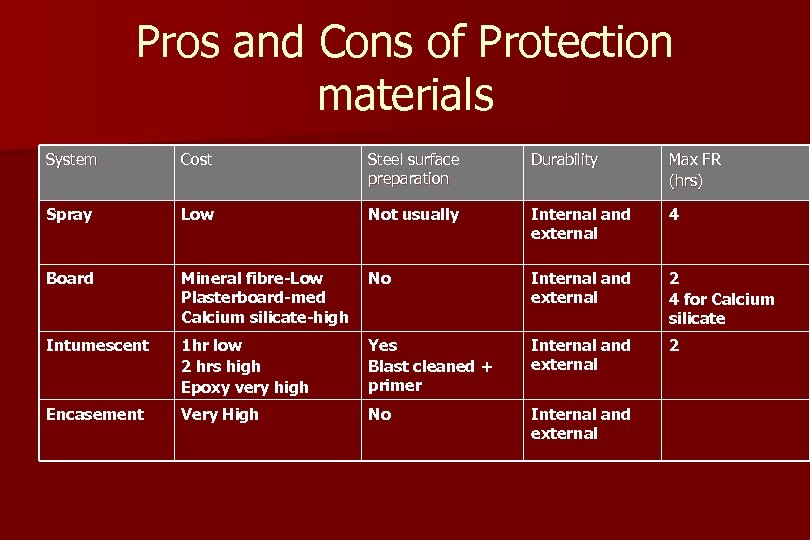

Pros and Cons of Protection materials System Cost Steel surface preparation Durability Max FR (hrs) Spray Low Not usually Internal and external 4 Board Mineral fibre-Low Plasterboard-med Calcium silicate-high No Internal and external 2 4 for Calcium silicate Intumescent 1 hr low 2 hrs high Epoxy very high Yes Blast cleaned + primer Internal and external 2 Encasement Very High No Internal and external

Pros and Cons of Protection materials System Cost Steel surface preparation Durability Max FR (hrs) Spray Low Not usually Internal and external 4 Board Mineral fibre-Low Plasterboard-med Calcium silicate-high No Internal and external 2 4 for Calcium silicate Intumescent 1 hr low 2 hrs high Epoxy very high Yes Blast cleaned + primer Internal and external 2 Encasement Very High No Internal and external

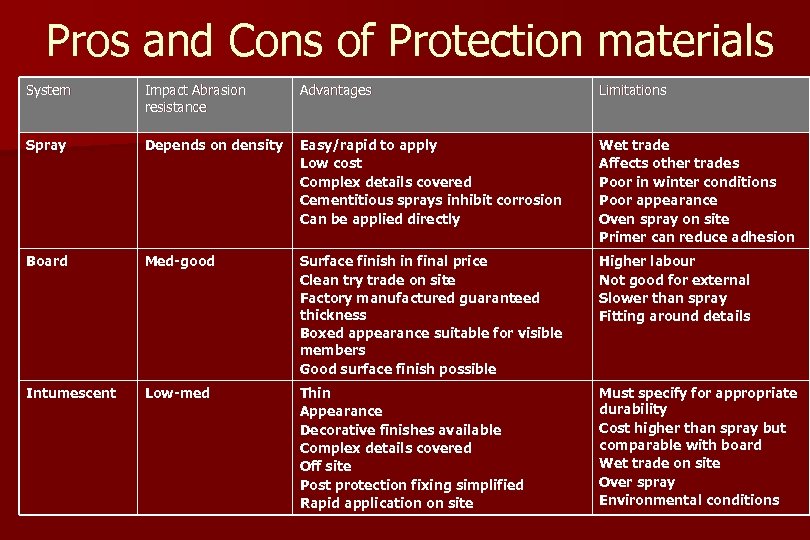

Pros and Cons of Protection materials System Impact Abrasion resistance Advantages Limitations Spray Depends on density Easy/rapid to apply Low cost Complex details covered Cementitious sprays inhibit corrosion Can be applied directly Wet trade Affects other trades Poor in winter conditions Poor appearance Oven spray on site Primer can reduce adhesion Board Med-good Surface finish in final price Clean try trade on site Factory manufactured guaranteed thickness Boxed appearance suitable for visible members Good surface finish possible Higher labour Not good for external Slower than spray Fitting around details Intumescent Low-med Thin Appearance Decorative finishes available Complex details covered Off site Post protection fixing simplified Rapid application on site Must specify for appropriate durability Cost higher than spray but comparable with board Wet trade on site Over spray Environmental conditions

Pros and Cons of Protection materials System Impact Abrasion resistance Advantages Limitations Spray Depends on density Easy/rapid to apply Low cost Complex details covered Cementitious sprays inhibit corrosion Can be applied directly Wet trade Affects other trades Poor in winter conditions Poor appearance Oven spray on site Primer can reduce adhesion Board Med-good Surface finish in final price Clean try trade on site Factory manufactured guaranteed thickness Boxed appearance suitable for visible members Good surface finish possible Higher labour Not good for external Slower than spray Fitting around details Intumescent Low-med Thin Appearance Decorative finishes available Complex details covered Off site Post protection fixing simplified Rapid application on site Must specify for appropriate durability Cost higher than spray but comparable with board Wet trade on site Over spray Environmental conditions

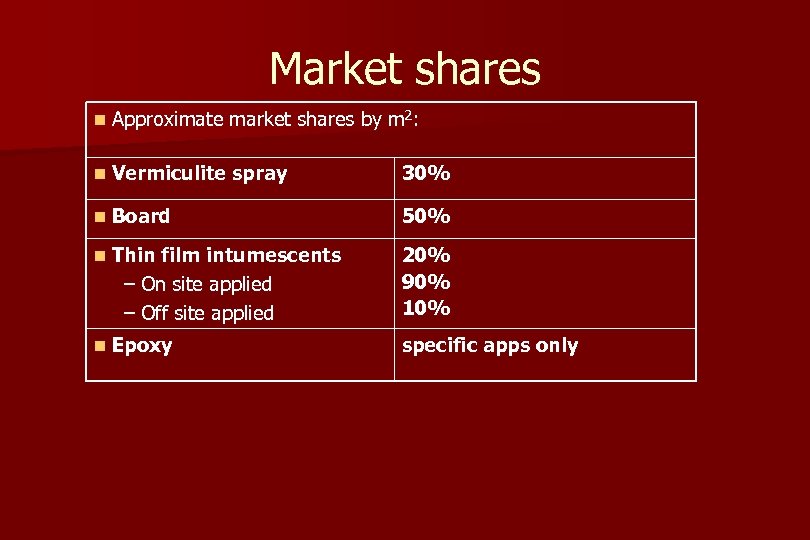

Market shares n Approximate market shares by m 2: n Vermiculite spray 30% n Board 50% n Thin film intumescents – On site applied – Off site applied 20% 90% 10% n Epoxy specific apps only

Market shares n Approximate market shares by m 2: n Vermiculite spray 30% n Board 50% n Thin film intumescents – On site applied – Off site applied 20% 90% 10% n Epoxy specific apps only

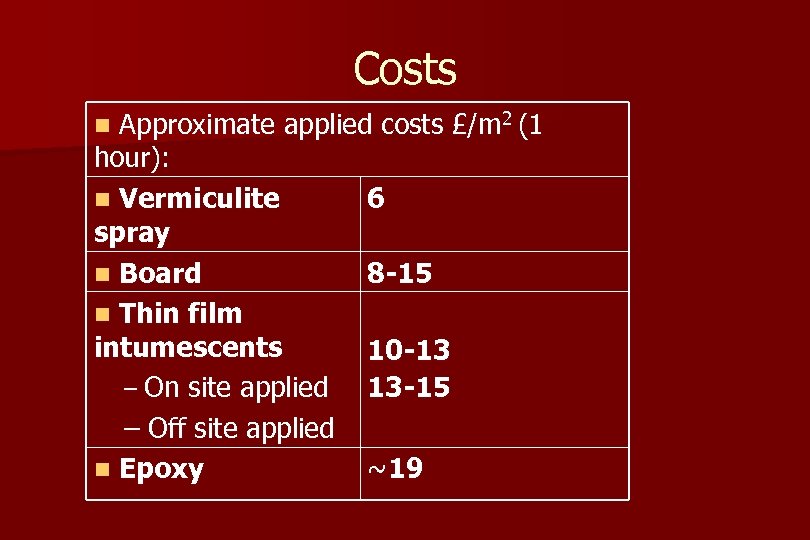

Costs Approximate applied costs £/m 2 (1 hour): n Vermiculite 6 spray n Board 8 -15 n Thin film intumescents 10 -13 13 -15 – On site applied – Off site applied n Epoxy ~19 n

Costs Approximate applied costs £/m 2 (1 hour): n Vermiculite 6 spray n Board 8 -15 n Thin film intumescents 10 -13 13 -15 – On site applied – Off site applied n Epoxy ~19 n

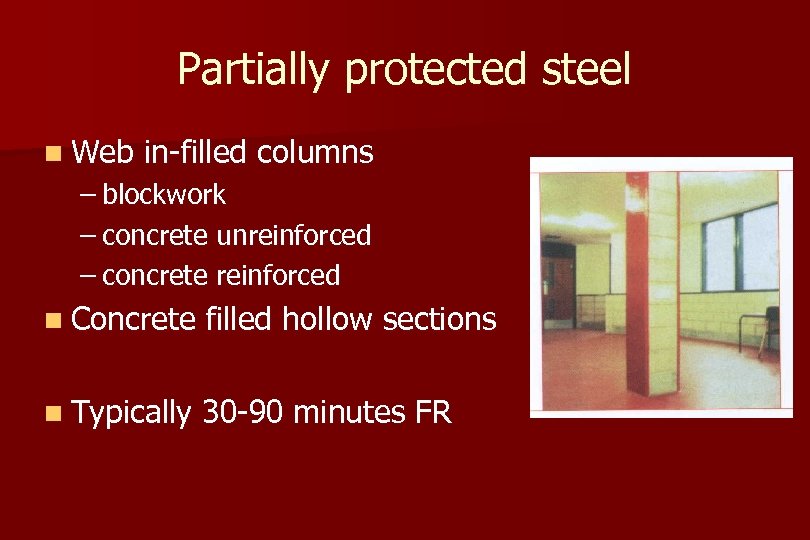

Partially protected steel n Web in-filled columns – blockwork – concrete unreinforced – concrete reinforced n Concrete filled hollow sections n Typically 30 -90 minutes FR

Partially protected steel n Web in-filled columns – blockwork – concrete unreinforced – concrete reinforced n Concrete filled hollow sections n Typically 30 -90 minutes FR

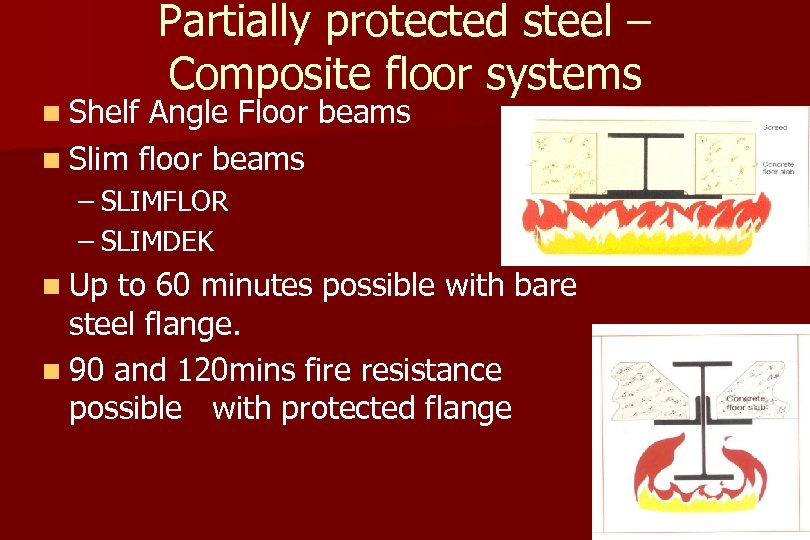

n Shelf Partially protected steel – Composite floor systems Angle Floor beams n Slim floor beams – SLIMFLOR – SLIMDEK n Up to 60 minutes possible with bare steel flange. n 90 and 120 mins fire resistance possible with protected flange

n Shelf Partially protected steel – Composite floor systems Angle Floor beams n Slim floor beams – SLIMFLOR – SLIMDEK n Up to 60 minutes possible with bare steel flange. n 90 and 120 mins fire resistance possible with protected flange

Hidden costs n The quality of finish – decorative finishes are more expensive n Difficulty or ease of access, manpower, time on site n Size of project n Location of project e. g. tall congested city centre n Type, size and weight of steel section

Hidden costs n The quality of finish – decorative finishes are more expensive n Difficulty or ease of access, manpower, time on site n Size of project n Location of project e. g. tall congested city centre n Type, size and weight of steel section

CONCRETE STRUCTURES

CONCRETE STRUCTURES

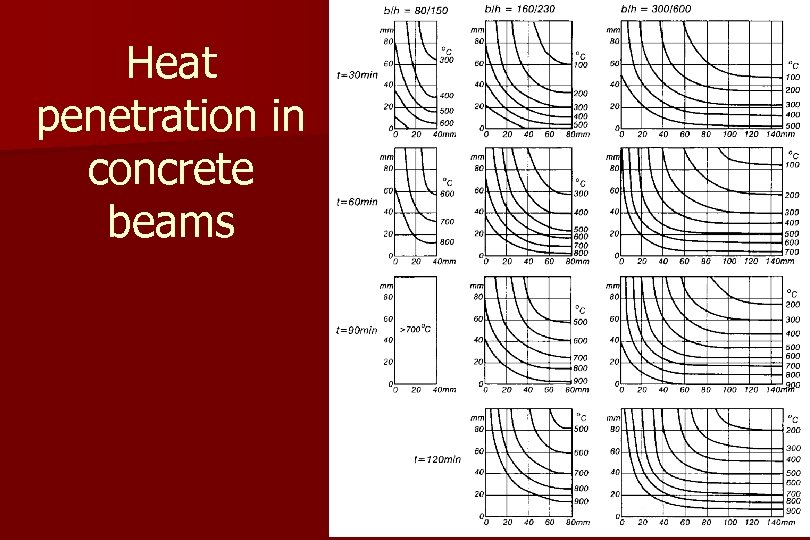

Heat penetration in concrete beams

Heat penetration in concrete beams

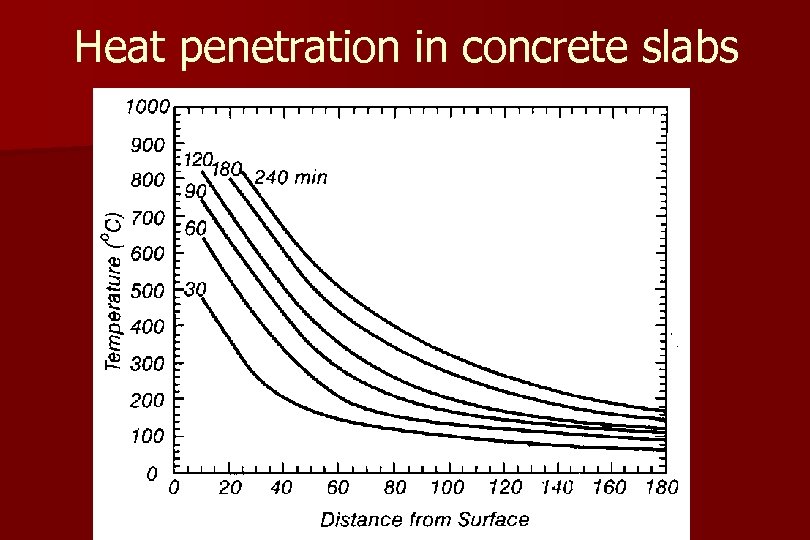

Heat penetration in concrete slabs (mm)

Heat penetration in concrete slabs (mm)