7ec13946b6e433fbbbda254c3bb21e59.ppt

- Количество слайдов: 21

Final Optic Research – Progress and Plans M. S. Tillack, J. E. Pulsifer, K. Sequoia HAPL Project Meeting, Georgia Tech 5– 6 February 2004

Final Optic Research – Progress and Plans M. S. Tillack, J. E. Pulsifer, K. Sequoia HAPL Project Meeting, Georgia Tech 5– 6 February 2004

Overview 1. Expanded database on electoplated Al 2. Mechanical and optical improvements 3. Near-term plans – – – Scale-up Distribution of samples Efforts to improve mirror quality Gasdynamic modeling Integration

Overview 1. Expanded database on electoplated Al 2. Mechanical and optical improvements 3. Near-term plans – – – Scale-up Distribution of samples Efforts to improve mirror quality Gasdynamic modeling Integration

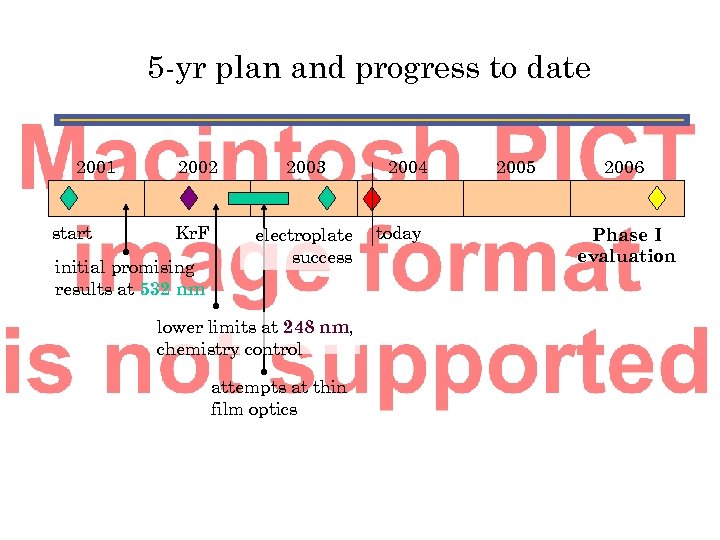

5 -yr plan and progress to date 2001 start 2002 Kr. F initial promising results at 532 nm 2003 electroplate success lower limits at 248 nm, chemistry control attempts at thin film optics 2004 today 2005 2006 Phase I evaluation

5 -yr plan and progress to date 2001 start 2002 Kr. F initial promising results at 532 nm 2003 electroplate success lower limits at 248 nm, chemistry control attempts at thin film optics 2004 today 2005 2006 Phase I evaluation

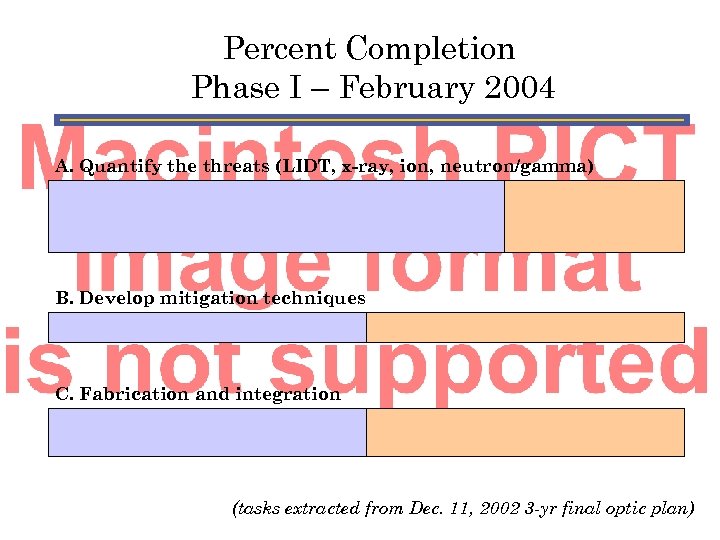

Percent Completion Phase I – February 2004 A. Quantify the threats (LIDT, x-ray, ion, neutron/gamma) B. Develop mitigation techniques C. Fabrication and integration (tasks extracted from Dec. 11, 2002 3 -yr final optic plan)

Percent Completion Phase I – February 2004 A. Quantify the threats (LIDT, x-ray, ion, neutron/gamma) B. Develop mitigation techniques C. Fabrication and integration (tasks extracted from Dec. 11, 2002 3 -yr final optic plan)

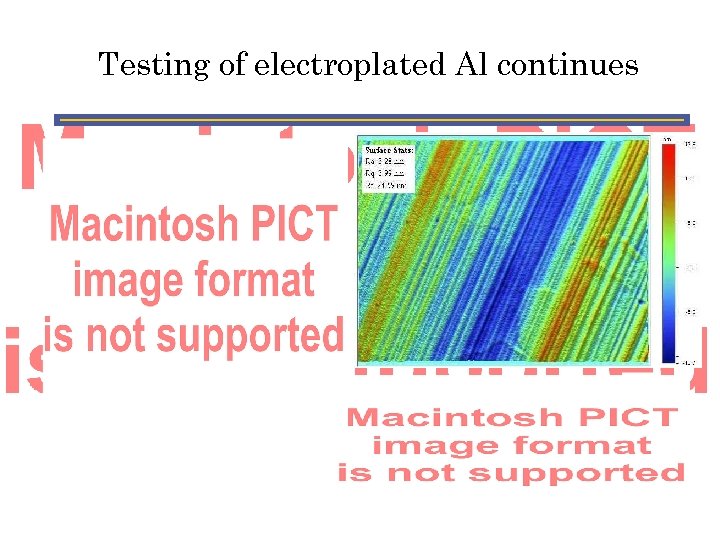

Testing of electroplated Al continues

Testing of electroplated Al continues

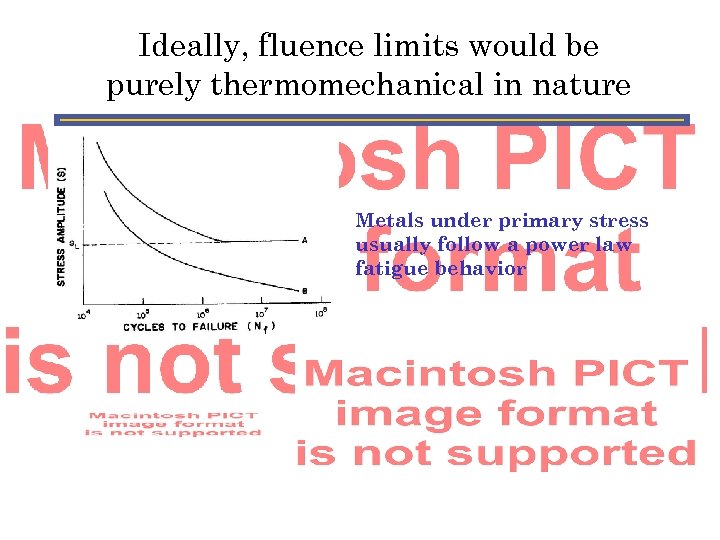

Ideally, fluence limits would be purely thermomechanical in nature Metals under primary stress usually follow a power law fatigue behavior

Ideally, fluence limits would be purely thermomechanical in nature Metals under primary stress usually follow a power law fatigue behavior

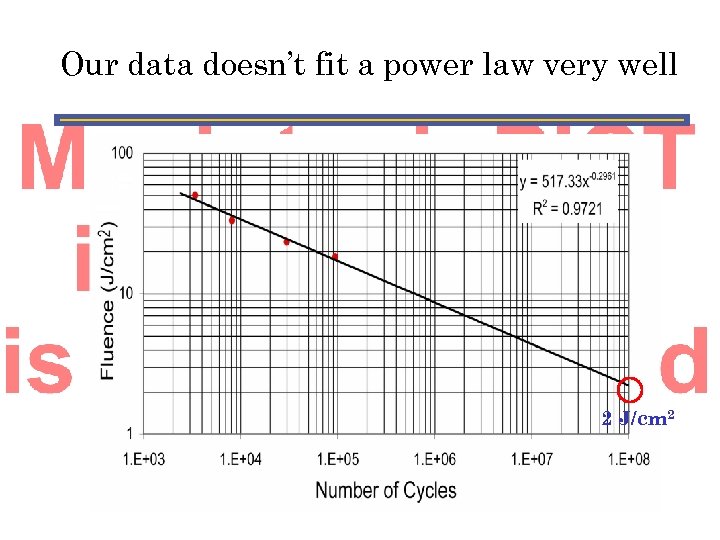

Our data doesn’t fit a power law very well 2 J/cm 2

Our data doesn’t fit a power law very well 2 J/cm 2

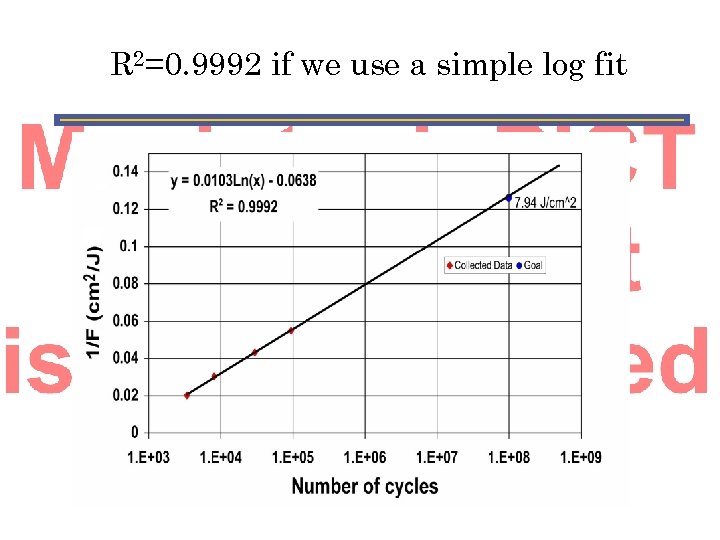

R 2=0. 9992 if we use a simple log fit

R 2=0. 9992 if we use a simple log fit

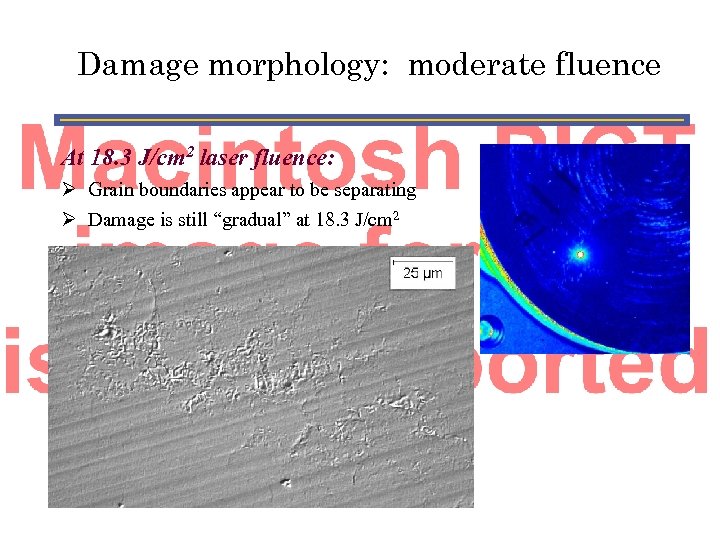

Damage morphology: moderate fluence At 18. 3 J/cm 2 laser fluence: Ø Grain boundaries appear to be separating Ø Damage is still “gradual” at 18. 3 J/cm 2

Damage morphology: moderate fluence At 18. 3 J/cm 2 laser fluence: Ø Grain boundaries appear to be separating Ø Damage is still “gradual” at 18. 3 J/cm 2

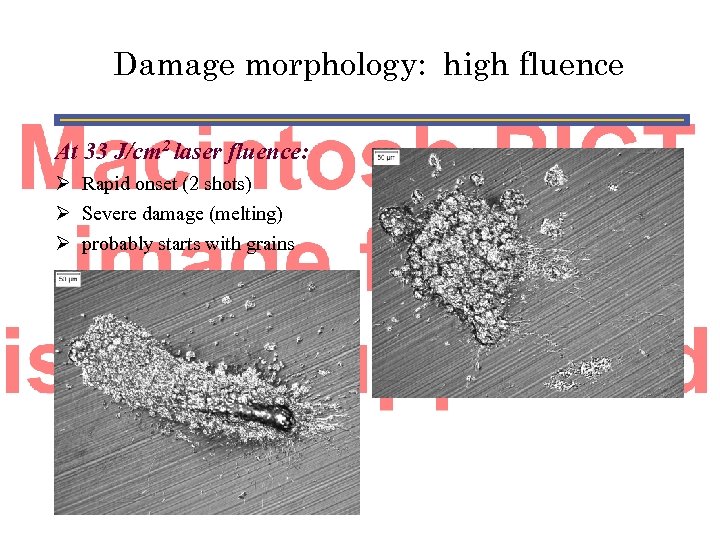

Damage morphology: high fluence At 33 J/cm 2 laser fluence: Ø Rapid onset (2 shots) Ø Severe damage (melting) Ø probably starts with grains

Damage morphology: high fluence At 33 J/cm 2 laser fluence: Ø Rapid onset (2 shots) Ø Severe damage (melting) Ø probably starts with grains

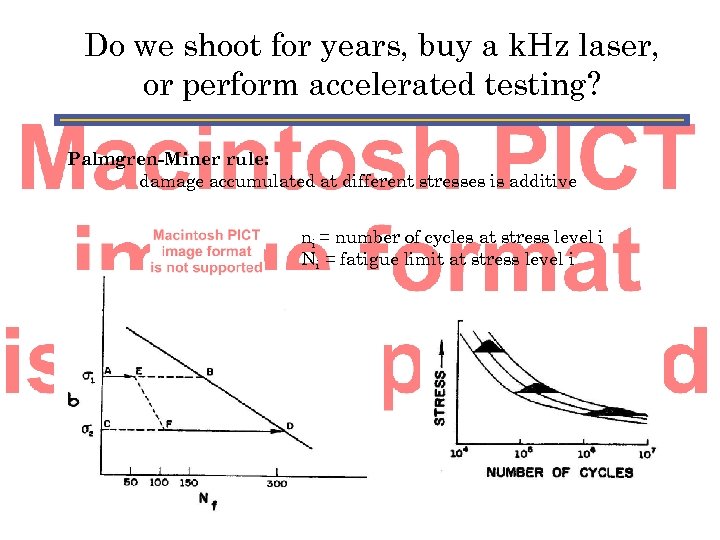

Do we shoot for years, buy a k. Hz laser, or perform accelerated testing? Palmgren-Miner rule: damage accumulated at different stresses is additive ni = number of cycles at stress level i Ni = fatigue limit at stress level i

Do we shoot for years, buy a k. Hz laser, or perform accelerated testing? Palmgren-Miner rule: damage accumulated at different stresses is additive ni = number of cycles at stress level i Ni = fatigue limit at stress level i

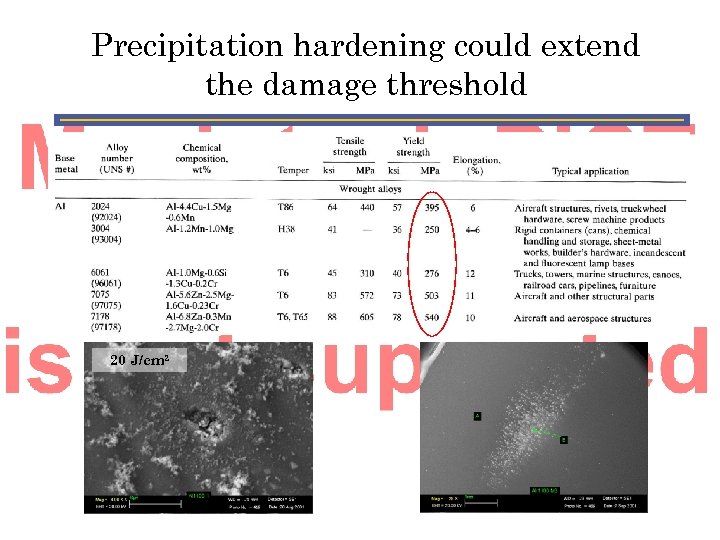

Precipitation hardening could extend the damage threshold 20 J/cm 2

Precipitation hardening could extend the damage threshold 20 J/cm 2

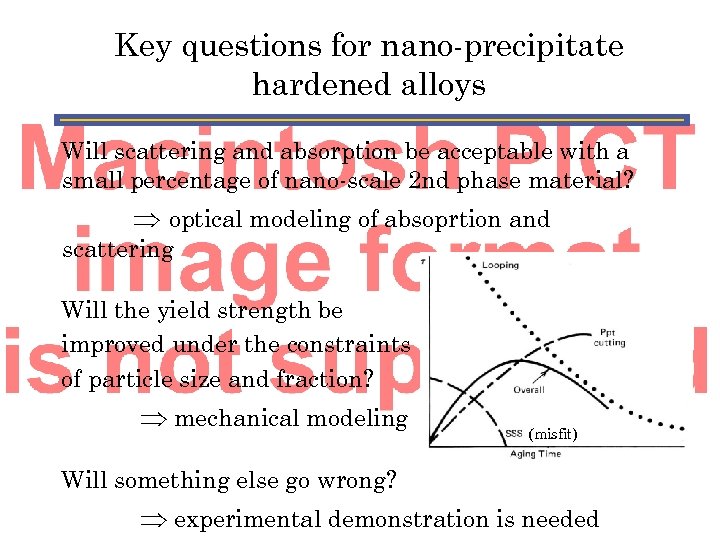

Key questions for nano-precipitate hardened alloys Will scattering and absorption be acceptable with a small percentage of nano-scale 2 nd phase material? optical modeling of absoprtion and scattering Will the yield strength be improved under the constraints of particle size and fraction? mechanical modeling (misfit) Will something else go wrong? experimental demonstration is needed

Key questions for nano-precipitate hardened alloys Will scattering and absorption be acceptable with a small percentage of nano-scale 2 nd phase material? optical modeling of absoprtion and scattering Will the yield strength be improved under the constraints of particle size and fraction? mechanical modeling (misfit) Will something else go wrong? experimental demonstration is needed

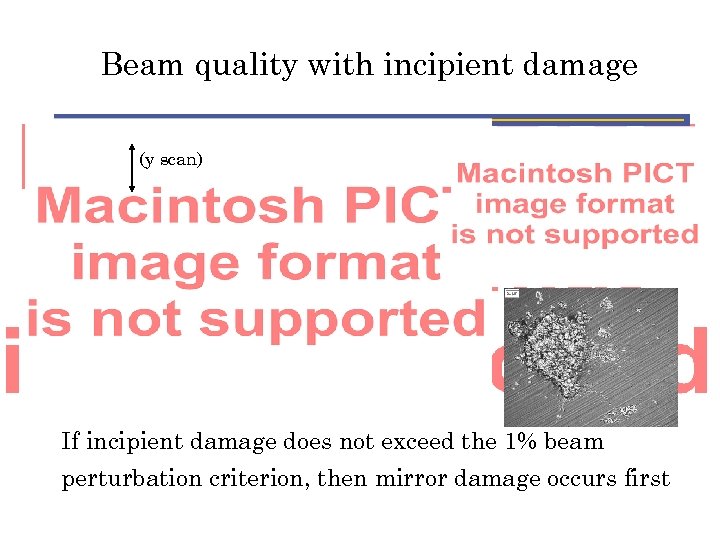

Beam quality with incipient damage (y scan) If incipient damage does not exceed the 1% beam perturbation criterion, then mirror damage occurs first

Beam quality with incipient damage (y scan) If incipient damage does not exceed the 1% beam perturbation criterion, then mirror damage occurs first

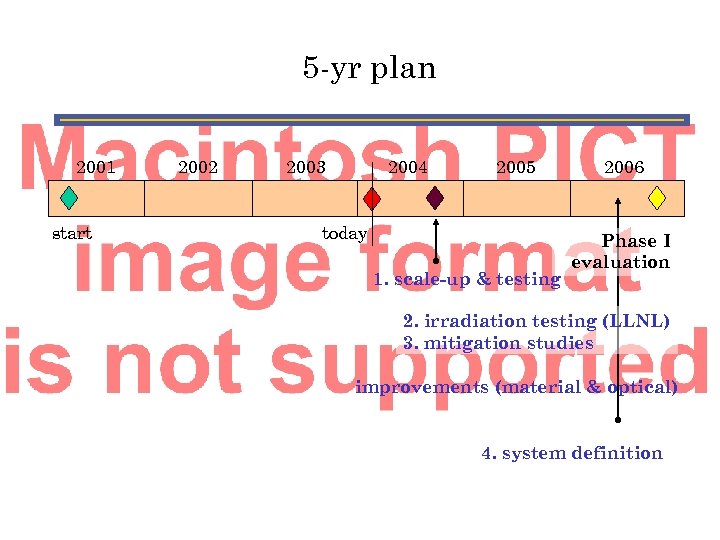

5 -yr plan 2001 start 2002 2003 2004 2005 today 1. scale-up & testing 2006 Phase I evaluation 2. irradiation testing (LLNL) 3. mitigation studies improvements (material & optical) 4. system definition

5 -yr plan 2001 start 2002 2003 2004 2005 today 1. scale-up & testing 2006 Phase I evaluation 2. irradiation testing (LLNL) 3. mitigation studies improvements (material & optical) 4. system definition

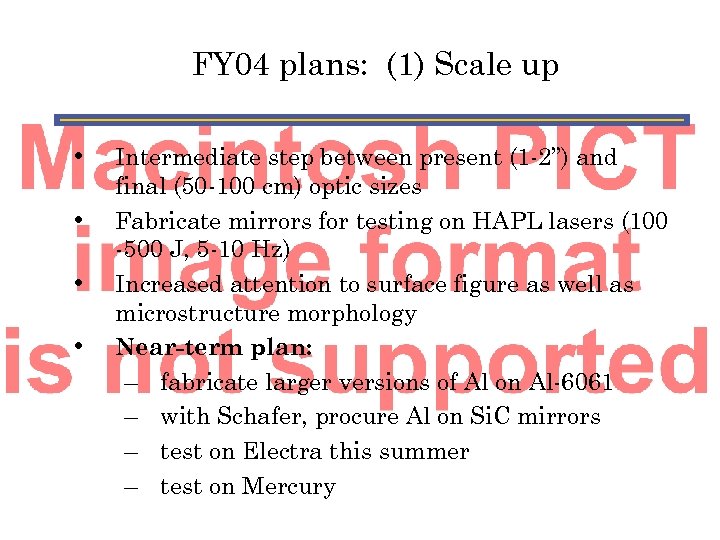

FY 04 plans: (1) Scale up • • Intermediate step between present (1 -2”) and final (50 -100 cm) optic sizes Fabricate mirrors for testing on HAPL lasers (100 -500 J, 5 -10 Hz) Increased attention to surface figure as well as microstructure morphology Near-term plan: – fabricate larger versions of Al on Al-6061 – with Schafer, procure Al on Si. C mirrors – test on Electra this summer – test on Mercury

FY 04 plans: (1) Scale up • • Intermediate step between present (1 -2”) and final (50 -100 cm) optic sizes Fabricate mirrors for testing on HAPL lasers (100 -500 J, 5 -10 Hz) Increased attention to surface figure as well as microstructure morphology Near-term plan: – fabricate larger versions of Al on Al-6061 – with Schafer, procure Al on Si. C mirrors – test on Electra this summer – test on Mercury

FY 04 plans: (2) Sample distribution • Radiation damage tests should use the reference optic – Al on Al-6061 can be obtained in 2 -4 weeks (discussions with Alumiplate and ii-vi are underway) – Al on Si. C tests should wait for validation • • We need protocols for characterization and testing Whoever needs optics, let’s talk.

FY 04 plans: (2) Sample distribution • Radiation damage tests should use the reference optic – Al on Al-6061 can be obtained in 2 -4 weeks (discussions with Alumiplate and ii-vi are underway) – Al on Si. C tests should wait for validation • • We need protocols for characterization and testing Whoever needs optics, let’s talk.

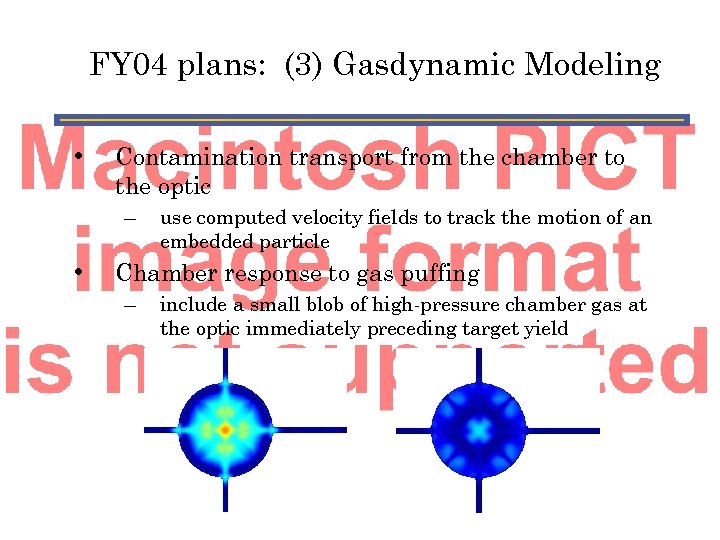

FY 04 plans: (3) Gasdynamic Modeling • Contamination transport from the chamber to the optic – • use computed velocity fields to track the motion of an embedded particle Chamber response to gas puffing – include a small blob of high-pressure chamber gas at the optic immediately preceding target yield

FY 04 plans: (3) Gasdynamic Modeling • Contamination transport from the chamber to the optic – • use computed velocity fields to track the motion of an embedded particle Chamber response to gas puffing – include a small blob of high-pressure chamber gas at the optic immediately preceding target yield

FY 04 plans: (4) Integration • Define the optical system in enough detail to determine whethere are issues requiring R&D, e. g. , – Develop the target/driver interface further (w/ GA) – Specify the beam steering and wavefront control methods (e. g. , where will these be achieved? ) – Cooling and other mechanical design issues • Define the design requirements and reference parameters in greater detail – Design lifetime: 108 shots – Operating temperature: 30˚C – Reflected beam smoothness: 1% (could tolerate more? ) • Need to organize the “final optic working group”

FY 04 plans: (4) Integration • Define the optical system in enough detail to determine whethere are issues requiring R&D, e. g. , – Develop the target/driver interface further (w/ GA) – Specify the beam steering and wavefront control methods (e. g. , where will these be achieved? ) – Cooling and other mechanical design issues • Define the design requirements and reference parameters in greater detail – Design lifetime: 108 shots – Operating temperature: 30˚C – Reflected beam smoothness: 1% (could tolerate more? ) • Need to organize the “final optic working group”

Final Optic Working Group

Final Optic Working Group

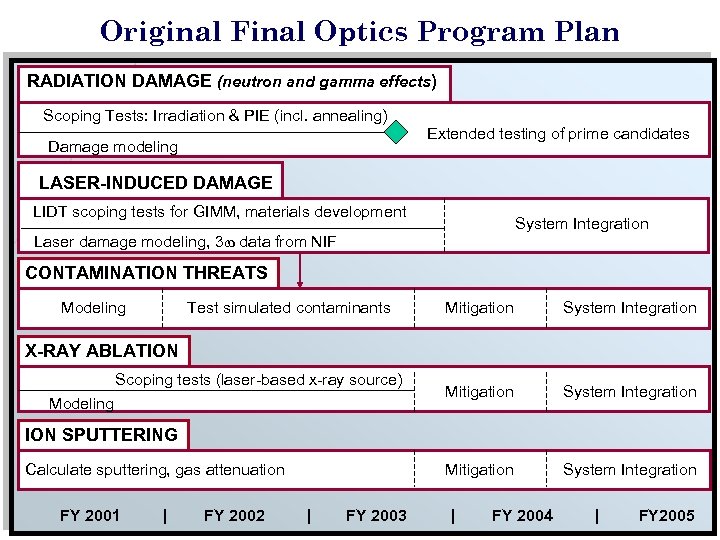

Original Final Optics Program Plan RADIATION DAMAGE (neutron and gamma effects) Scoping Tests: Irradiation & PIE (incl. annealing) Extended testing of prime candidates Damage modeling LASER-INDUCED DAMAGE LIDT scoping tests for GIMM, materials development System Integration Laser damage modeling, 3 w data from NIF CONTAMINATION THREATS Modeling Test simulated contaminants Mitigation System Integration X-RAY ABLATION Scoping tests (laser-based x-ray source) Modeling ION SPUTTERING Calculate sputtering, gas attenuation FY 2001 | FY 2002 | FY 2003 | FY 2004 | FY 2005

Original Final Optics Program Plan RADIATION DAMAGE (neutron and gamma effects) Scoping Tests: Irradiation & PIE (incl. annealing) Extended testing of prime candidates Damage modeling LASER-INDUCED DAMAGE LIDT scoping tests for GIMM, materials development System Integration Laser damage modeling, 3 w data from NIF CONTAMINATION THREATS Modeling Test simulated contaminants Mitigation System Integration X-RAY ABLATION Scoping tests (laser-based x-ray source) Modeling ION SPUTTERING Calculate sputtering, gas attenuation FY 2001 | FY 2002 | FY 2003 | FY 2004 | FY 2005