1443501f4fc87bfce3040362f676650f.ppt

- Количество слайдов: 20

Final Design Review: The Ultimate Tailgate Jonathan Brooks Matthew Piatkowski Spencer Herendeen

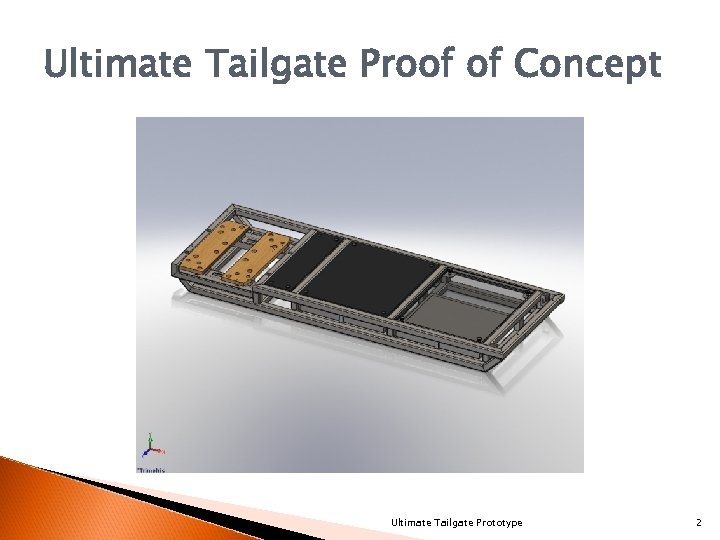

Ultimate Tailgate Proof of Concept Ultimate Tailgate Prototype 2

Agenda Project Background and Scope ◦ Customer Needs ◦ Engineering Specifications ◦ Risk Management Design Changes from MSD I Final System Budget Project Shortfalls Recommendations for future prototypes

Project Background and Scope Project is to create a functional tailgate work surface with ◦ ◦ ◦ Workmate style clamp Auxiliary clamp Storage Bins 120 VAC power 12 VDC power The intention of this project is to generate an initial proof of concept. This is the main concern, and as such drives much of how the project progressed

Customer Needs Meet or exceed stock tailgate performance capabilities Flat work surface, level with truck bed Two clamps: one primary Workmate style, and one auxiliary bar style Two storage drawers Structure to conform to a 2001 Chevrolet Silverado 2500 System capable of providing 120 VAC outlet power, and 12 VDC accessory power System power failsafe to shut down when vehicle is engaged out of park or neutral and when vehicle battery voltage becomes too low. System power to be limited to 10 AAC when vehicle is off and limited to 15 AAC when the vehicle is on.

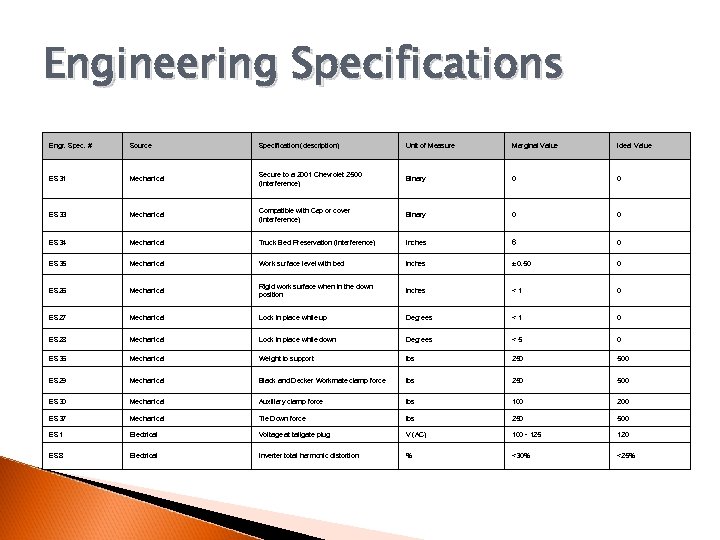

Engineering Specifications Engr. Spec. # Source Specification (description) Unit of Measure Marginal Value Ideal Value ES 31 Mechanical Secure to a 2001 Chevrolet 2500 (interference) Binary 0 0 ES 33 Mechanical Compatible with Cap or cover (interference) Binary 0 0 ES 34 Mechanical Truck Bed Preservation (interference) Inches 6 0 ES 35 Mechanical Work surface level with bed inches ± 0. 50 0 ES 26 Mechanical Rigid work surface when in the down position inches <1 0 ES 27 Mechanical Lock in place while up Degrees <1 0 ES 28 Mechanical Lock in place while down Degrees <5 0 ES 36 Mechanical Weight to support lbs 250 500 ES 29 Mechanical Black and Decker Workmate clamp force lbs 250 500 ES 30 Mechanical Auxiliary clamp force lbs 100 200 ES 37 Mechanical Tie Down force lbs 250 500 ES 1 Electrical Voltage at tailgate plug V (AC) 100 - 125 120 ES 8 Electrical Inverter total harmonic distortion % <30% <25%

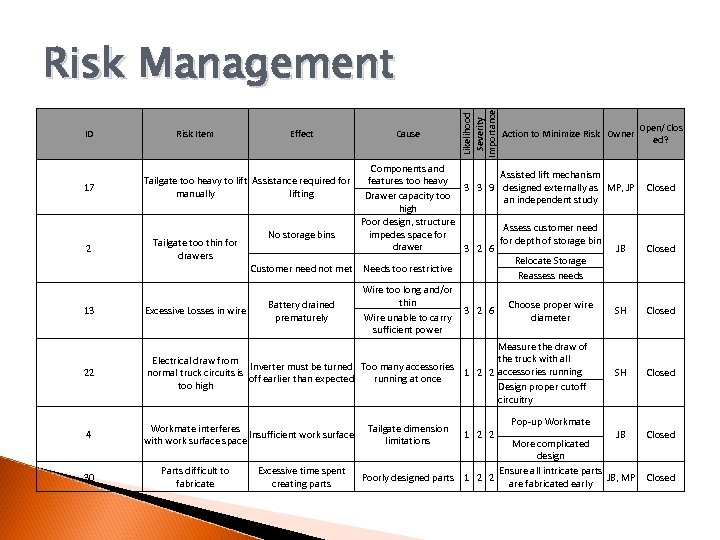

ID 17 2 13 22 4 30 Risk Item Effect Cause Likelihood Severity Importance Risk Management Action to Minimize Risk Owner Components and Assisted lift mechanism features too heavy Tailgate too heavy to lift Assistance required for 3 3 9 designed externally as MP, JP manually lifting Drawer capacity too an independent study high Poor design, structure Assess customer need No storage bins impedes space for depth of storage bin Tailgate too thin for drawer 3 2 6 JB drawers Relocate Storage Customer need not met Needs too restrictive Reassess needs Wire too long and/or thin Battery drained Choose proper wire Excessive Losses in wire 3 2 6 SH prematurely diameter Wire unable to carry sufficient power Measure the draw of the truck with all Electrical draw from Inverter must be turned Too many accessories 1 2 2 accessories running normal truck circuits is off earlier than expected running at once too high Design proper cutoff circuitry Workmate interferes Insufficient work surface with work surface space Parts difficult to fabricate Excessive time spent creating parts Tailgate dimension limitations SH Open/Clos ed? Closed Pop-up Workmate 1 2 2 JB More complicated design Ensure all intricate parts Poorly designed parts 1 2 2 JB, MP are fabricated early Closed

Design Changes Mechanical ◦ Drawer Slides have integrated catch to prevent drawer from opening unexpectedly ◦ Workmate Clamp has added rotation feature Workmate can be rotated in 90 degree increments When operated parallel to the direction of truck, workmate is elevated to allow work to extend into truck bed Workmate dimensions reduced to allow for rotation ◦ Automated actuation added as an independent study to work in conjunction with MSD II P 10811 Drawers shortened to account for automated actuation system ◦ Tube structure made of 0. 083 steel tubing instead of 0. 065 due to availability

Design Changes Electrical ◦ No DC side relays were used in order to save on implementation complexity, safety, and cost ◦ No external low voltage shutdown circuitry was used because the innate inverter circuitry was found to be sufficient ◦ No starter relay was used because the vehicle will draw current away from the inverter to start. The inverter has a shutdown mechanism if the current becomes too low.

Product: Tailgate Frame constructed as tube structure Tubes are 1 -1/4 inch X 0. 083 square mild steel tube stock Tubes are cut to length and MIG welded together to provide required strength External frame dimensions match those of stock tailgate, except thickness which is increased to 4 -1/2 inches to provide additional room for features

Product: Drawers are constructed from 16 guage mild steel sheet Drawer size is 15 X 12 X 2 inches Parts are cut to size with shears and bent if required using a break Parts are MIG welded together Drawer slides are sourced from Ovis Online and are 14 inch 100 lb load capacity Drawer slides are welded to drawer and frame

Product: Workmate style clamp Wood surfaces are milled to size Screw system is constructed on lathe Frame constructed from 16 gauge sheet steel in same fashion as drawers Workmate mounts to frame by quarter turn fasteners allowing easy changing of orientation in 90 degree increments

Product: Auxiliary Clamp Irwin one handed bar clamp purchased from Lowes Slots fabricated from mild steel to allow for insertion into frame for clamping directly to tailgate work surface Clamp modified with stronger dowel pin to allow for mounting to slots welded on frame

Product: Self actuating system Designed as an independent study Provides motors to raise and lower the tailgate electronically Incorporates latching mechanism to prevent tailgate from opening during vehicle operation

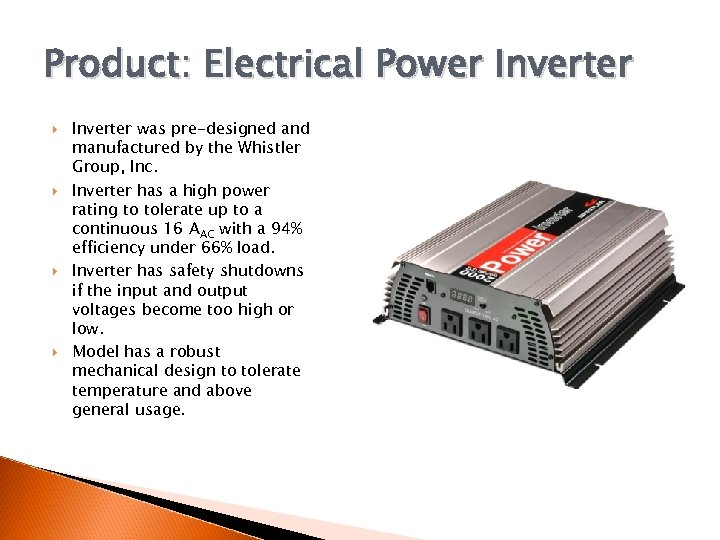

Product: Electrical Power Inverter was pre-designed and manufactured by the Whistler Group, Inc. Inverter has a high power rating to tolerate up to a continuous 16 AAC with a 94% efficiency under 66% load. Inverter has safety shutdowns if the input and output voltages become too high or low. Model has a robust mechanical design to tolerate temperature and above general usage.

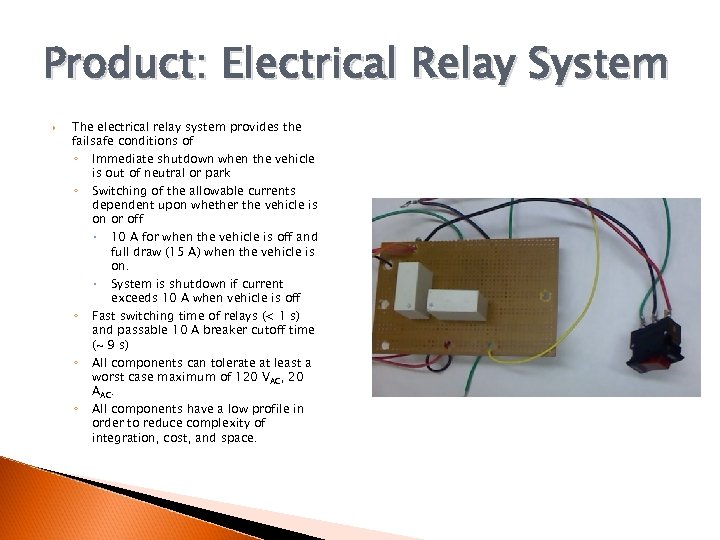

Product: Electrical Relay System The electrical relay system provides the failsafe conditions of ◦ Immediate shutdown when the vehicle is out of neutral or park ◦ Switching of the allowable currents dependent upon whether the vehicle is on or off 10 A for when the vehicle is off and full draw (15 A) when the vehicle is on. System is shutdown if current exceeds 10 A when vehicle is off ◦ Fast switching time of relays (< 1 s) and passable 10 A breaker cutoff time (~ 9 s) ◦ All components can tolerate at least a worst case maximum of 120 VAC, 20 AAC. ◦ All components have a low profile in order to reduce complexity of integration, cost, and space.

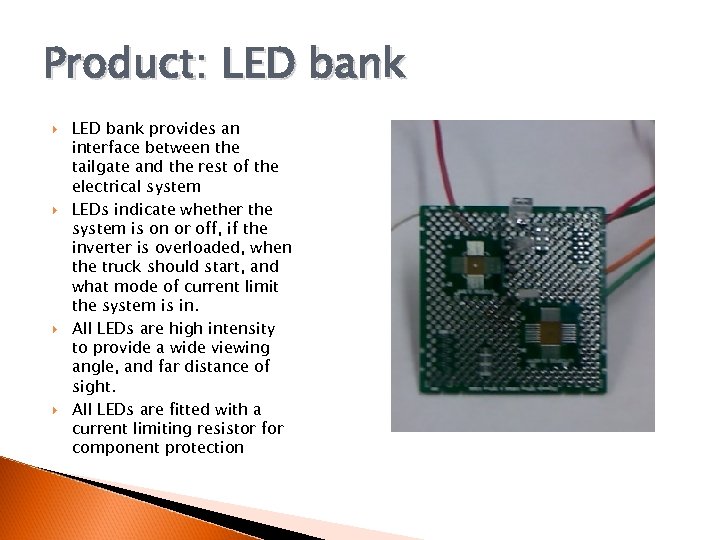

Product: LED bank provides an interface between the tailgate and the rest of the electrical system LEDs indicate whether the system is on or off, if the inverter is overloaded, when the truck should start, and what mode of current limit the system is in. All LEDs are high intensity to provide a wide viewing angle, and far distance of sight. All LEDs are fitted with a current limiting resistor for component protection

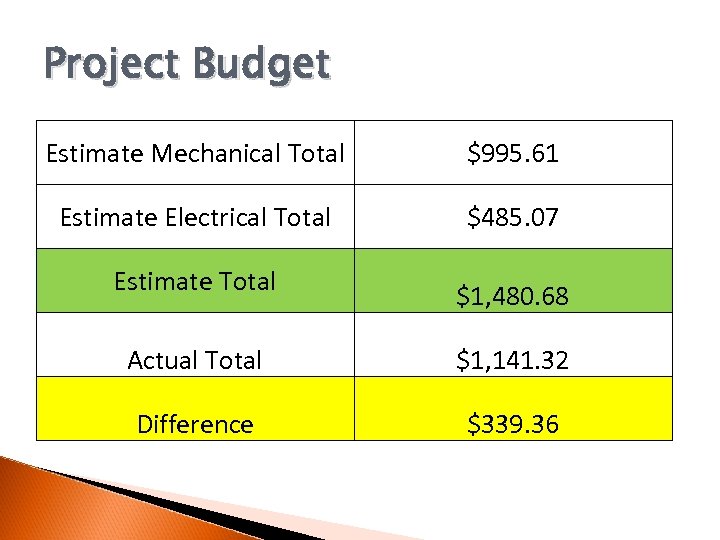

Project Budget Estimate Mechanical Total $995. 61 Estimate Electrical Total $485. 07 Estimate Total $1, 480. 68 Actual Total $1, 141. 32 Difference $339. 36

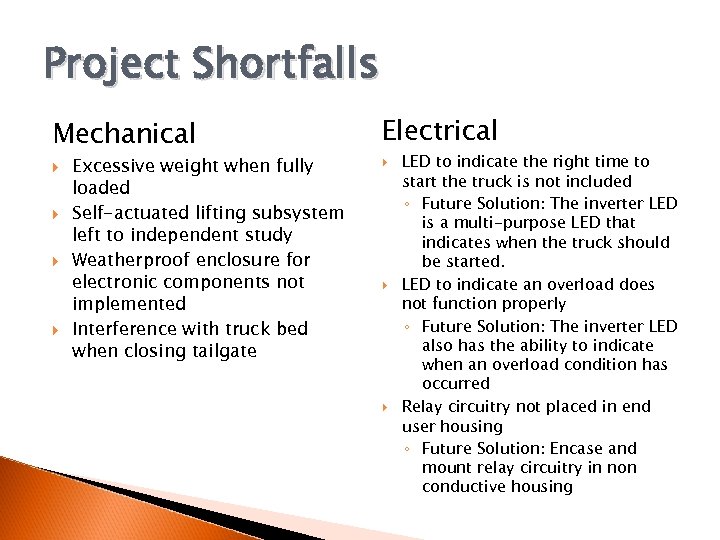

Project Shortfalls Mechanical Electrical Excessive weight when fully loaded Self-actuated lifting subsystem left to independent study Weatherproof enclosure for electronic components not implemented Interference with truck bed when closing tailgate LED to indicate the right time to start the truck is not included ◦ Future Solution: The inverter LED is a multi-purpose LED that indicates when the truck should be started. LED to indicate an overload does not function properly ◦ Future Solution: The inverter LED also has the ability to indicate when an overload condition has occurred Relay circuitry not placed in end user housing ◦ Future Solution: Encase and mount relay circuitry in non conductive housing

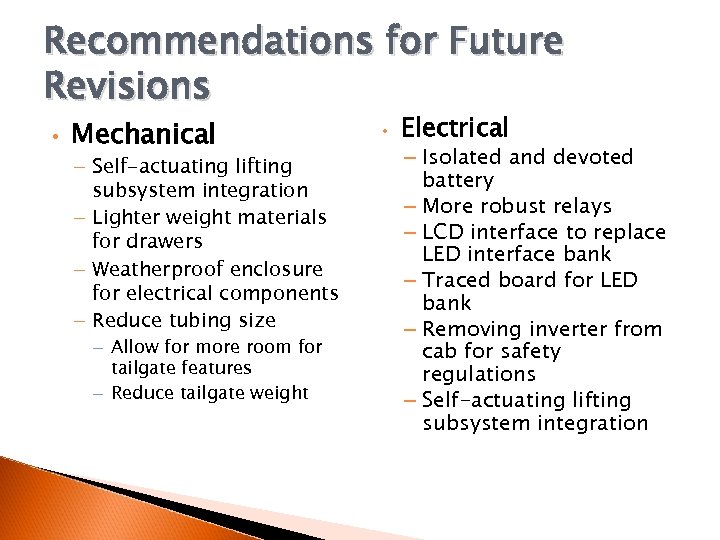

Recommendations for Future Revisions • Mechanical – Self-actuating lifting subsystem integration – Lighter weight materials for drawers – Weatherproof enclosure for electrical components – Reduce tubing size – Allow for more room for tailgate features – Reduce tailgate weight • Electrical – Isolated and devoted battery – More robust relays – LCD interface to replace LED interface bank – Traced board for LED bank – Removing inverter from cab for safety regulations – Self-actuating lifting subsystem integration

1443501f4fc87bfce3040362f676650f.ppt