92837ef2177fa1b287b13776dbcdb0e7.ppt

- Количество слайдов: 30

Fiber Repositioning System Nano. Drop December 11, 2006 Chris Czech Charles Dielmann Mark Howe Dana Kimpton Christopher Sherman

Who is Nano. Drop? § § § Manufacture and sell analytical laboratory equipment worldwide Used in biotechnology, pharmaceutical, and life science fields ND-1000 Spectrophotometer is best known small liquid sample instrument

The ND-1000 § Uses a flash lamp, photospectrometer and proprietary software to quantify nucleic acid, protein, and other biological compound liquid samples

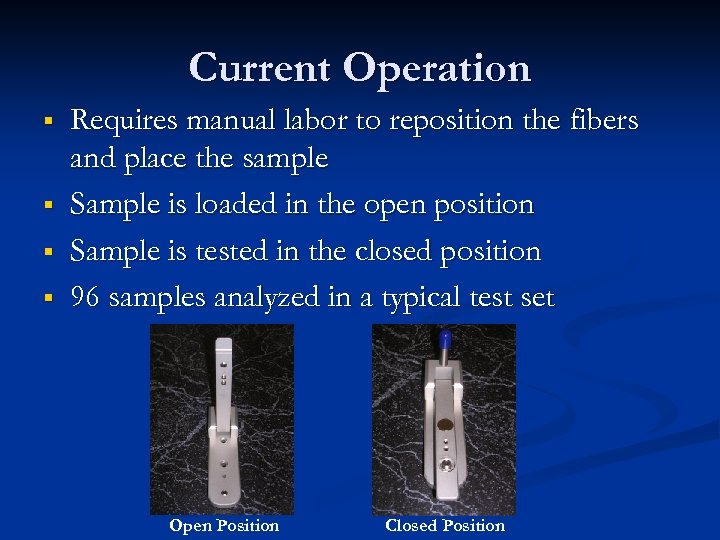

Current Operation § § Requires manual labor to reposition the fibers and place the sample Sample is loaded in the open position Sample is tested in the closed position 96 samples analyzed in a typical test set Open Position Closed Position

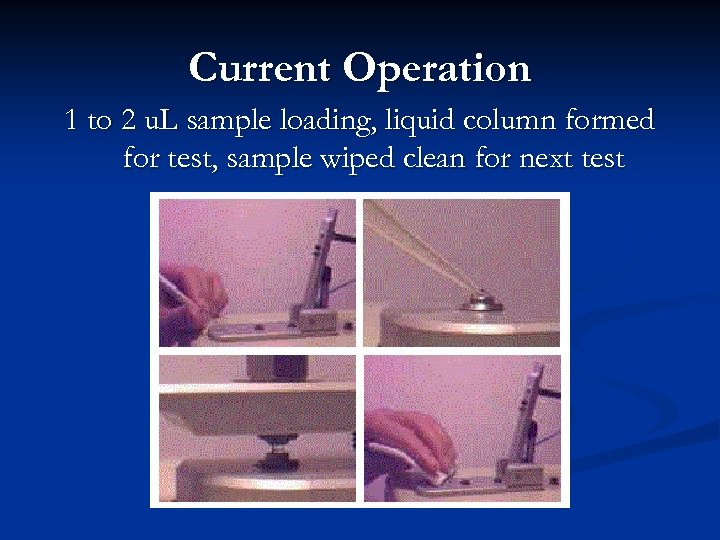

Current Operation 1 to 2 u. L sample loading, liquid column formed for test, sample wiped clean for next test

Project Purpose § Purpose: To expand customer market by eliminating human interaction to test samples by automating the ND-1000 and using a liquid handling robot to place the samples § Objective: Miniaturize and automate the ND-1000's operations for integration into a robotic testing environment. Secondary Objective: Allow for future development of a liquid sample wiping system within the design. §

Customer Wants § § § Repeatable vertical and horizontal alignment No unprotected fibers that could interfere with motion of robot Compatible with Labview Potential for future liquid sample wiping system Ease of loading the liquid sample

Project Metrics § 1) Repeatability: within 1/100 th of an inch vertical and horizontal alignment § 2) Distance between top and bottom pedestals: 2/10, 000 th of an inch § 3) Miniaturize: base dimensions to match the footprint of a 96 well u. L sample plate

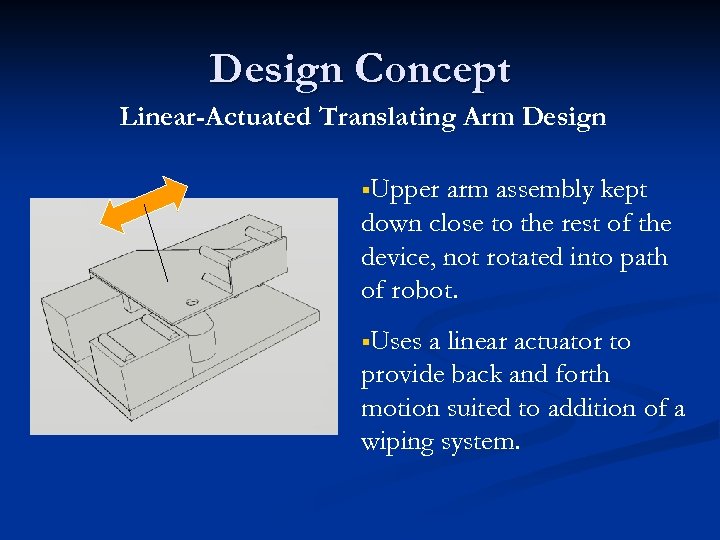

Design Concept Linear-Actuated Translating Arm Design §Upper arm assembly kept down close to the rest of the device, not rotated into path of robot. §Uses a linear actuator to provide back and forth motion suited to addition of a wiping system.

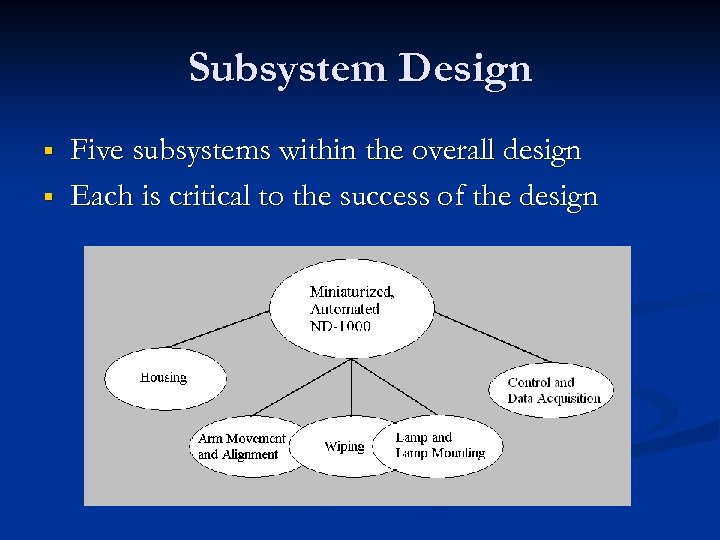

Subsystem Design § § Five subsystems within the overall design Each is critical to the success of the design

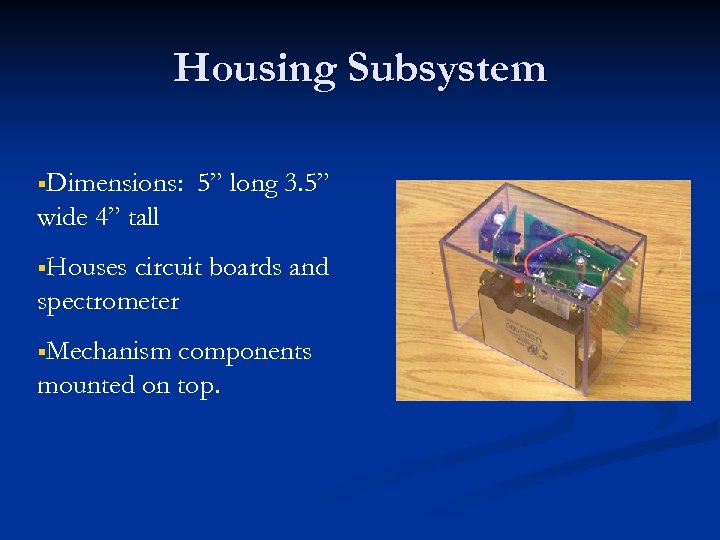

Housing Subsystem §Dimensions: 5” long 3. 5” wide 4” tall §Houses circuit boards and spectrometer §Mechanism components mounted on top.

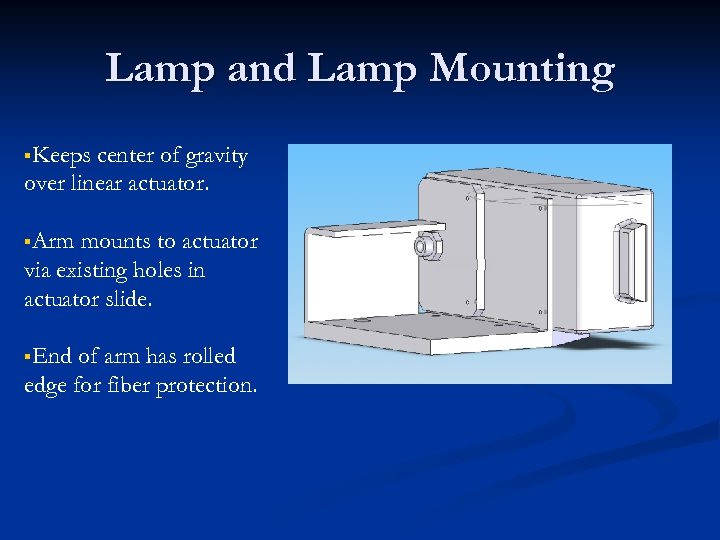

Lamp and Lamp Mounting §Keeps center of gravity over linear actuator. §Arm mounts to actuator via existing holes in actuator slide. §End of arm has rolled edge for fiber protection.

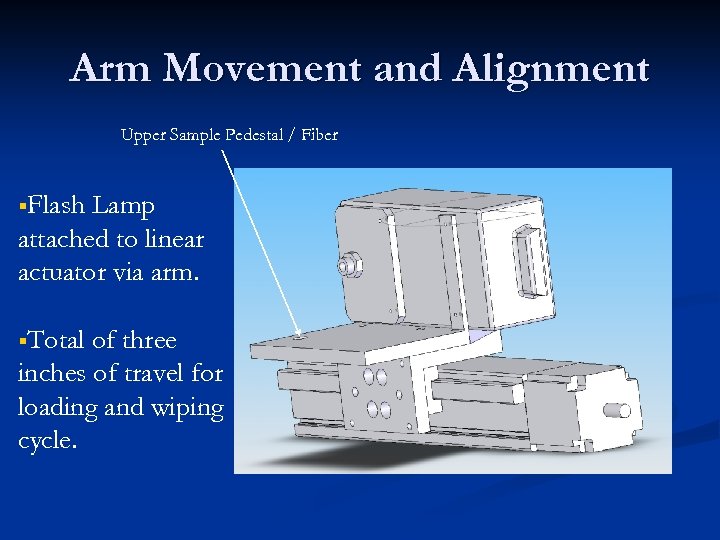

Arm Movement and Alignment Upper Sample Pedestal / Fiber §Flash Lamp attached to linear actuator via arm. §Total of three inches of travel for loading and wiping cycle.

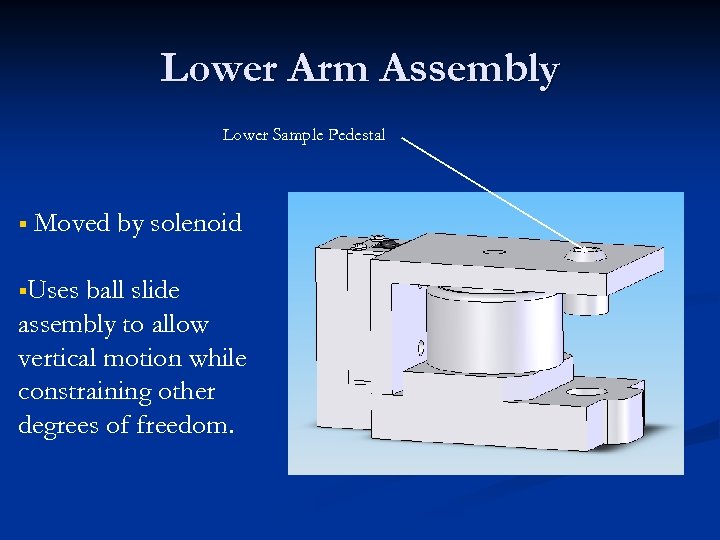

Lower Arm Assembly Lower Sample Pedestal § Moved by solenoid §Uses ball slide assembly to allow vertical motion while constraining other degrees of freedom.

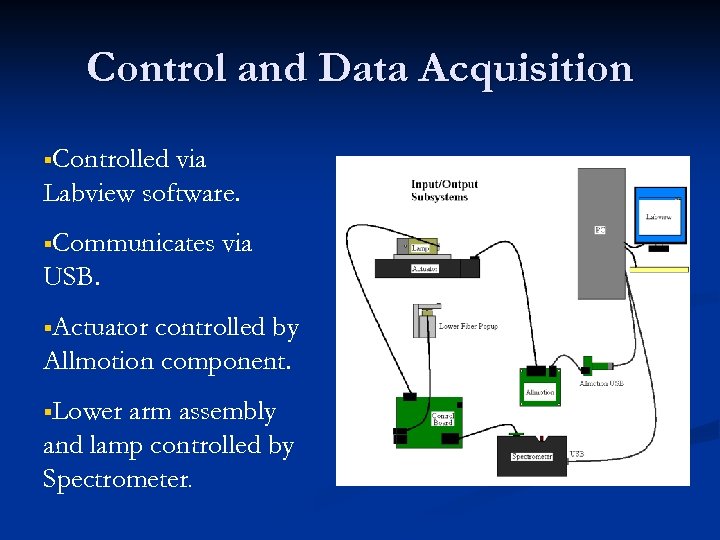

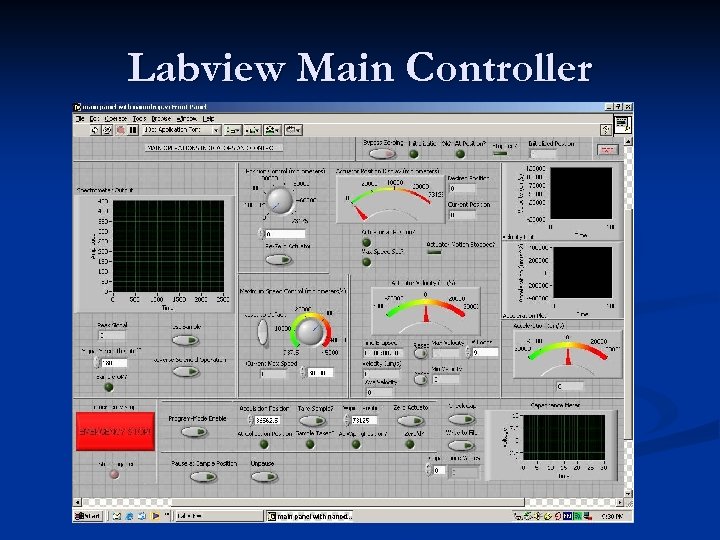

Control and Data Acquisition §Controlled via Labview software. §Communicates via USB. §Actuator controlled by Allmotion component. §Lower arm assembly and lamp controlled by Spectrometer.

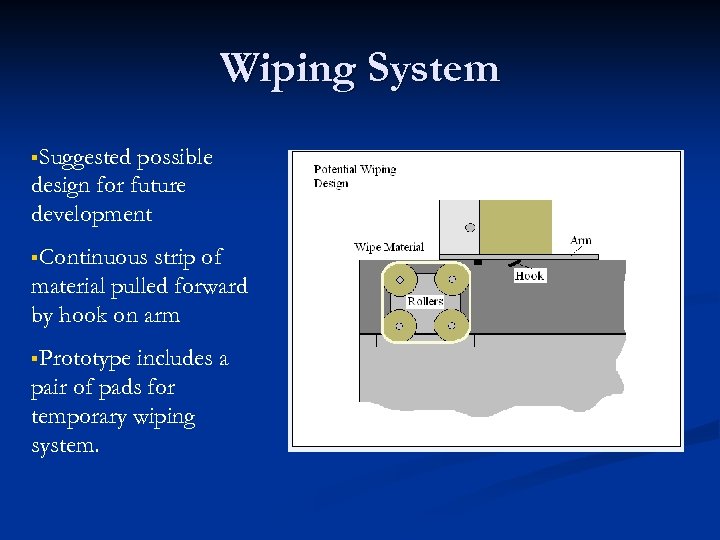

Wiping System §Suggested possible design for future development §Continuous strip of material pulled forward by hook on arm §Prototype includes a pair of pads for temporary wiping system.

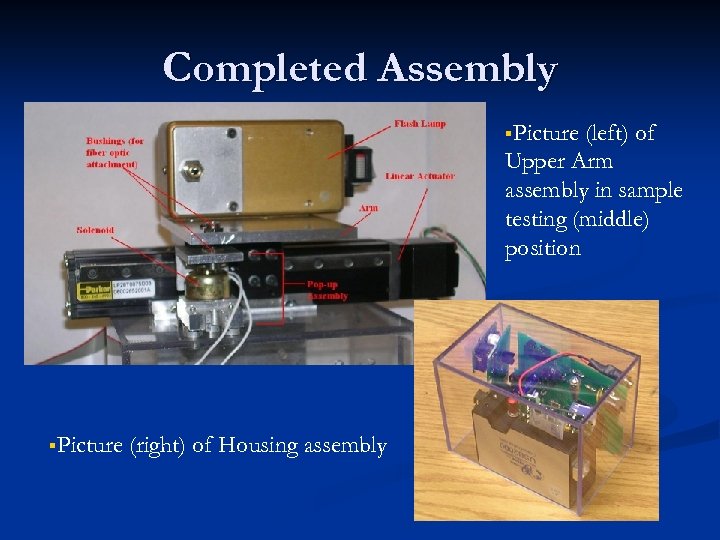

Completed Assembly §Picture (left) of Upper Arm assembly in sample testing (middle) position §Picture (right) of Housing assembly

Video of Prototype

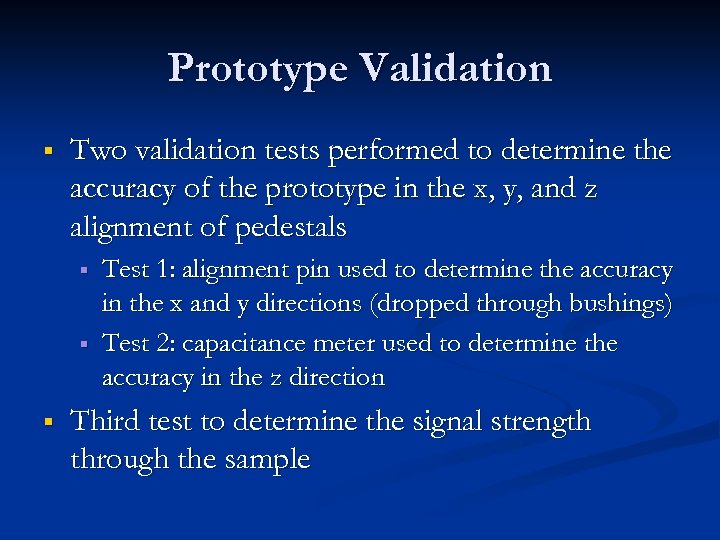

Prototype Validation § Two validation tests performed to determine the accuracy of the prototype in the x, y, and z alignment of pedestals § § § Test 1: alignment pin used to determine the accuracy in the x and y directions (dropped through bushings) Test 2: capacitance meter used to determine the accuracy in the z direction Third test to determine the signal strength through the sample

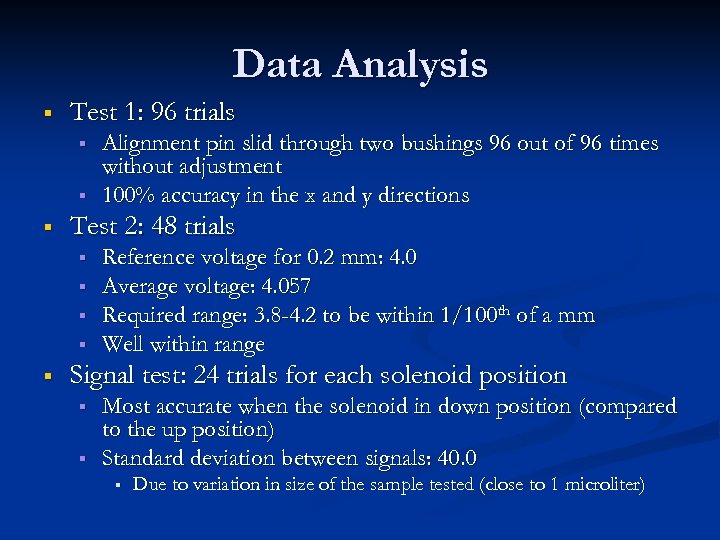

Data Analysis § Test 1: 96 trials § § § Test 2: 48 trials § § § Alignment pin slid through two bushings 96 out of 96 times without adjustment 100% accuracy in the x and y directions Reference voltage for 0. 2 mm: 4. 0 Average voltage: 4. 057 Required range: 3. 8 -4. 2 to be within 1/100 th of a mm Well within range Signal test: 24 trials for each solenoid position § § Most accurate when the solenoid in down position (compared to the up position) Standard deviation between signals: 40. 0 § Due to variation in size of the sample tested (close to 1 microliter)

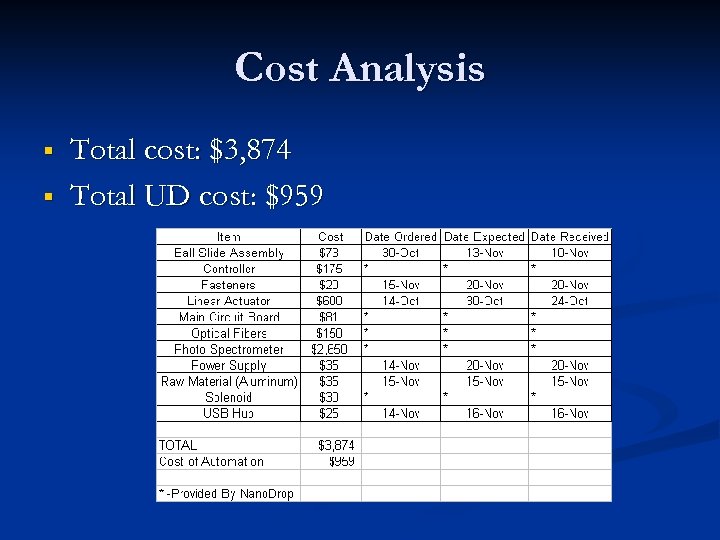

Cost Analysis § § Total cost: $3, 874 Total UD cost: $959

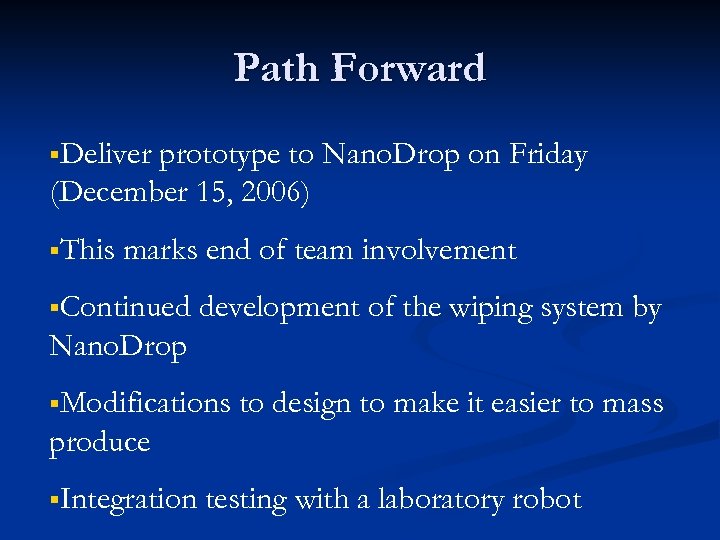

Path Forward §Deliver prototype to Nano. Drop on Friday (December 15, 2006) §This marks end of team involvement §Continued development of the wiping system by Nano. Drop §Modifications to design to make it easier to mass produce §Integration testing with a laboratory robot

Questions?

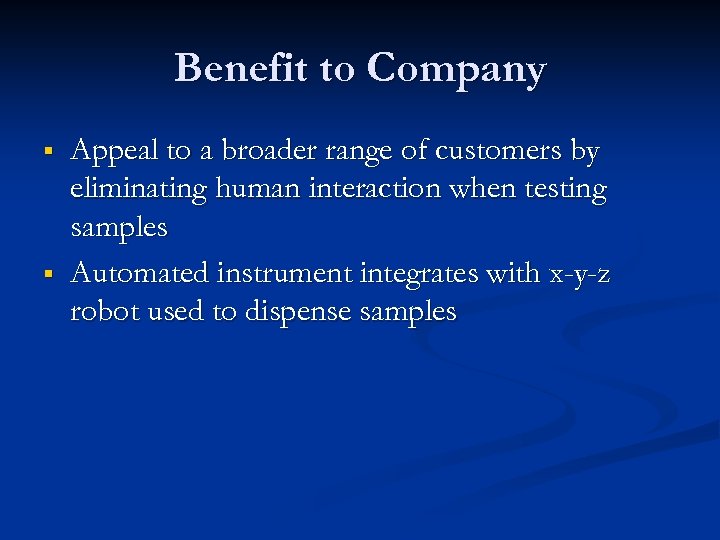

Benefit to Company § § Appeal to a broader range of customers by eliminating human interaction when testing samples Automated instrument integrates with x-y-z robot used to dispense samples

Labview Main Controller

Testing Procedure 1 § Test 1: x-y alignment accuracy § § § § Remove fiber optics from bushings. Start actuator motion. Pause motion at testing position. Drop alignment pin (0. 125” diameter through top bushing (0. 126” diameter). If alignment pin does not drop through bottom bushing, loosen screws that attach the solenoid to the base until pin drops through. Tighten pins in this new position. Record whether pin dropped without adjustment or if adjustment was needed. Resume motion of actuator. Repeat 96 times to simulate a typical testing set.

Testing Procedure 2 n n n n n Mount capacitance meter to the top plate Initiate actuator motion and pause at the testing position Establish 0. 2 mm gap using feeler gage Click check gap on the Labview code and record reading for voltage reference Unpause the actuator motion Initiate motion, pause at sample, check gap, unpause motion Repeat the above step 48 times Write to file Find standard deviation and average of all tests using the reference voltage

Signal Strength Test § 24 tests run with water sample § § § § Place sample on bottom pedestal in popped up position Record the signal strength from the photospectrometer Place sample on bottom pedestal in popped down position Record the signal strength from the photospectrometer 20 tests run without water sample in popped down position Find the standard deviation of the tests

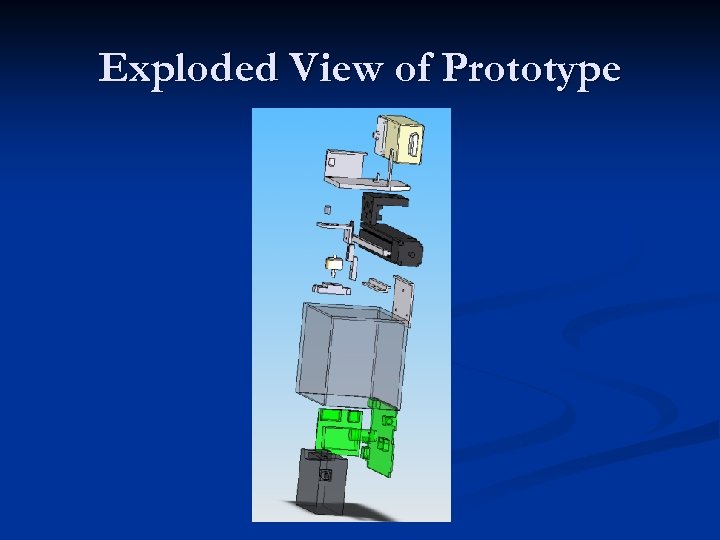

Exploded View of Prototype

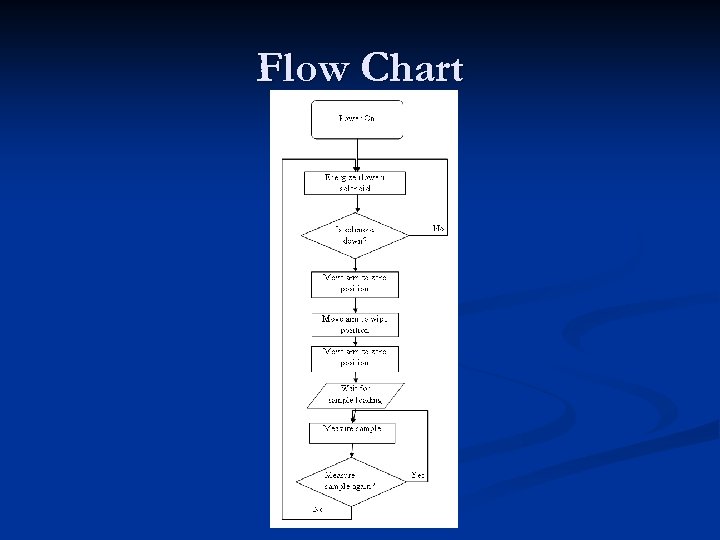

Flow Chart

92837ef2177fa1b287b13776dbcdb0e7.ppt