86e727621f753b9359a3be3a390b171d.ppt

- Количество слайдов: 20

Femtosecond Laser Micromachining of Bio. MEMS l l l Bio. MEMS Lab Mechanical and Aerospace Engineering University of Texas Arlington

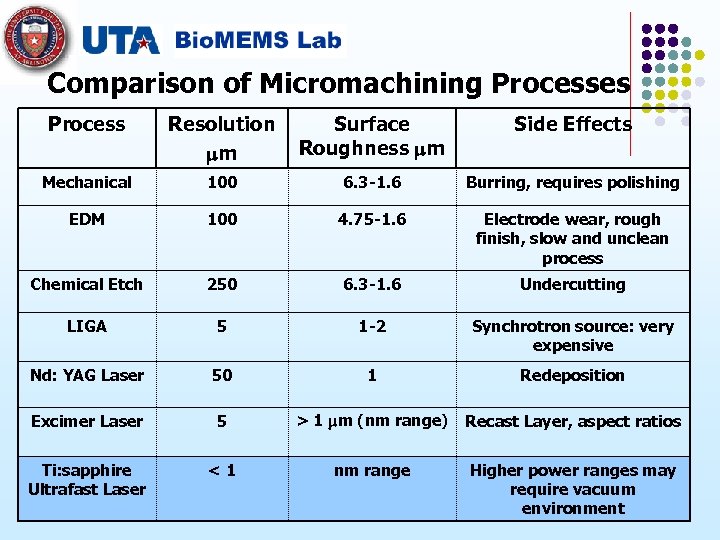

Comparison of Micromachining Processes Process Resolution m Surface Roughness m Side Effects Mechanical 100 6. 3 -1. 6 Burring, requires polishing EDM 100 4. 75 -1. 6 Electrode wear, rough finish, slow and unclean process Chemical Etch 250 6. 3 -1. 6 Undercutting LIGA 5 1 -2 Synchrotron source: very expensive Nd: YAG Laser 50 1 Redeposition Excimer Laser 5 > 1 m (nm range) Recast Layer, aspect ratios Ti: sapphire Ultrafast Laser <1 nm range Higher power ranges may require vacuum environment

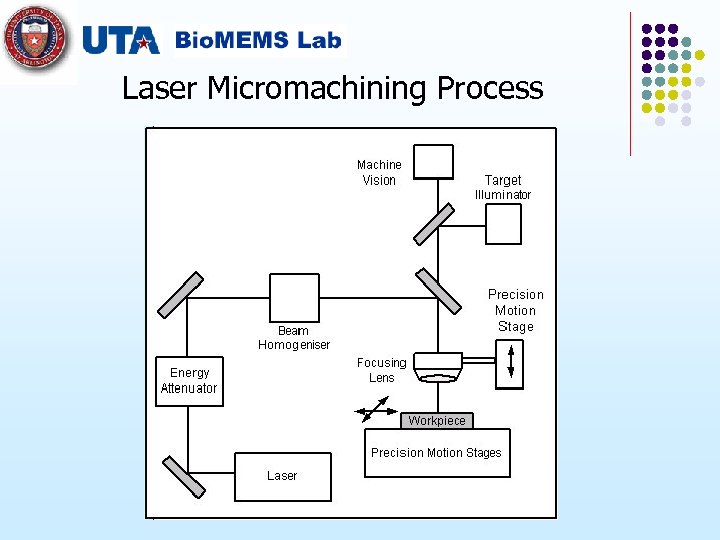

Laser Micromachining Process

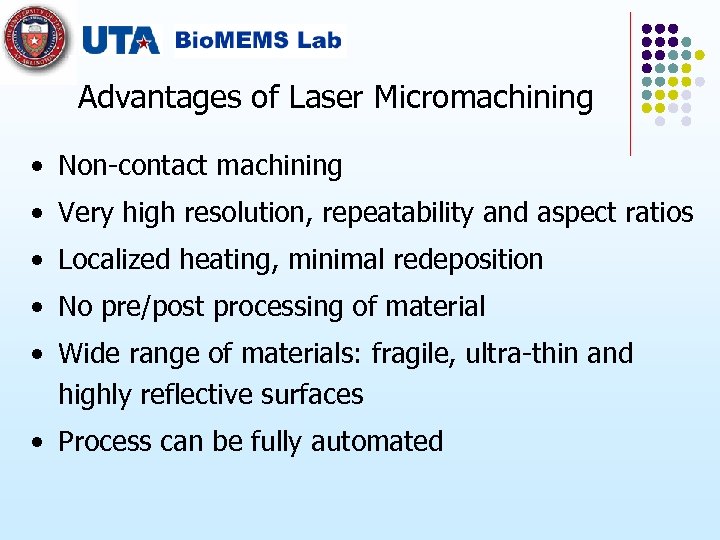

Advantages of Laser Micromachining • Non-contact machining • Very high resolution, repeatability and aspect ratios • Localized heating, minimal redeposition • No pre/post processing of material • Wide range of materials: fragile, ultra-thin and highly reflective surfaces • Process can be fully automated

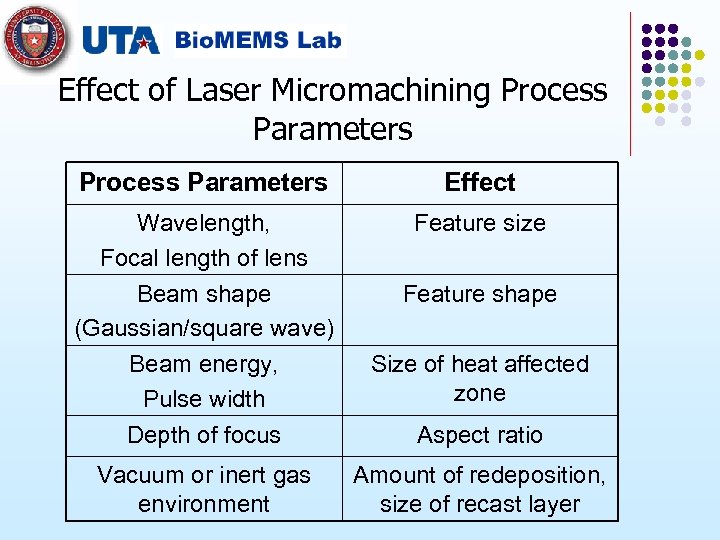

Effect of Laser Micromachining Process Parameters Effect Wavelength, Focal length of lens Beam shape (Gaussian/square wave) Beam energy, Pulse width Depth of focus Feature size Vacuum or inert gas environment Feature shape Size of heat affected zone Aspect ratio Amount of redeposition, size of recast layer

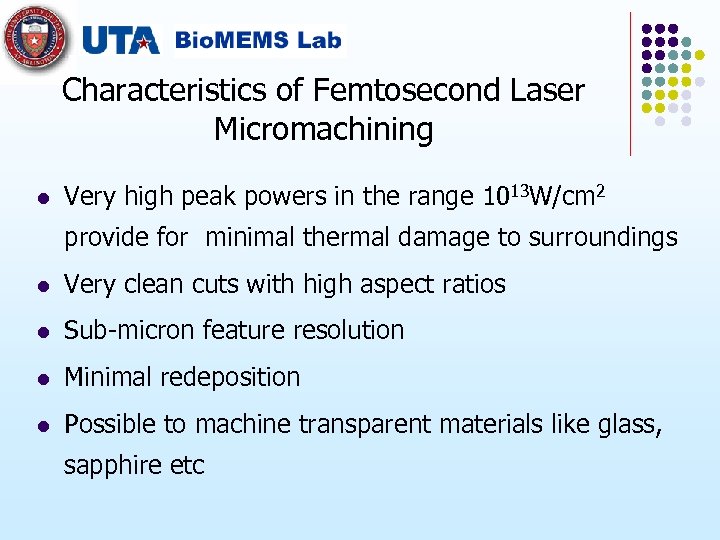

Characteristics of Femtosecond Laser Micromachining l Very high peak powers in the range 1013 W/cm 2 provide for minimal thermal damage to surroundings l Very clean cuts with high aspect ratios l Sub-micron feature resolution l Minimal redeposition l Possible to machine transparent materials like glass, sapphire etc

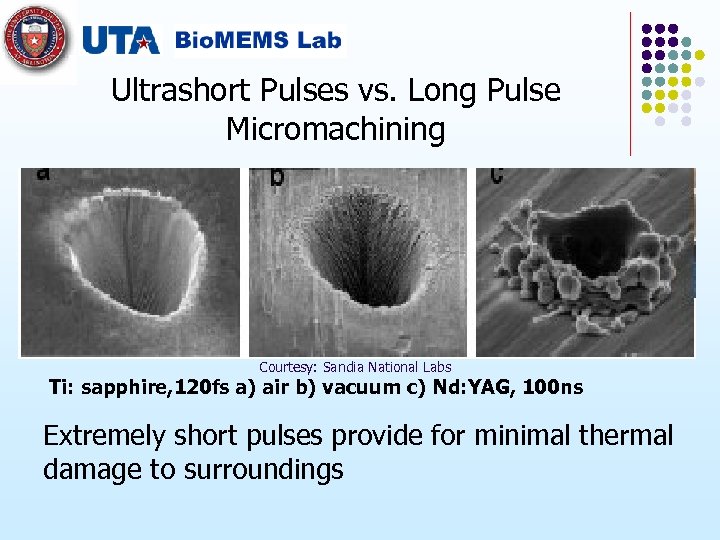

Ultrashort Pulses vs. Long Pulse Micromachining Courtesy: Sandia National Labs Ti: sapphire, 120 fs a) air b) vacuum c) Nd: YAG, 100 ns Extremely short pulses provide for minimal thermal damage to surroundings

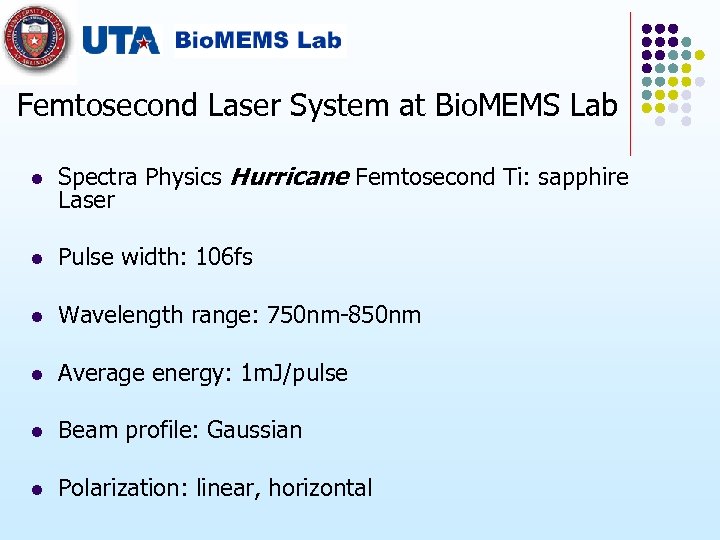

Femtosecond Laser System at Bio. MEMS Lab l Spectra Physics Hurricane Femtosecond Ti: sapphire Laser l Pulse width: 106 fs l Wavelength range: 750 nm-850 nm l l l Average energy: 1 m. J/pulse Beam profile: Gaussian Polarization: linear, horizontal

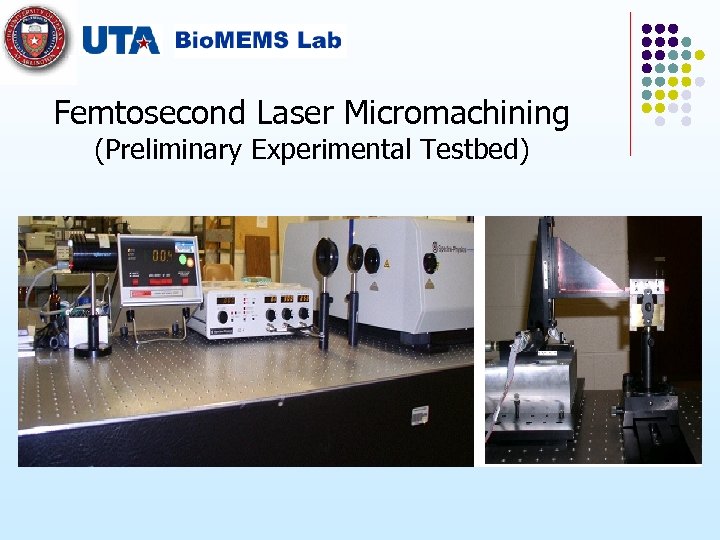

Femtosecond Laser Micromachining (Preliminary Experimental Testbed)

Additional Equipment for Femtosecond Laser Micromachining l Ultra-high precision 3 -axis linear stage assembly by Aerotech Inc. l Ultrafast High Energy Beam Attenuator by Newport Corporation. l Power Meter by Scientech Inc. l 2 GHz Oscilloscope by Hewlett Packard Under development l 10 -3 Torr, 1 m 3 Vacuum Chamber with inert gas and electrical and power ports l Fully automated multiple lens changer l Lab. View based control environment

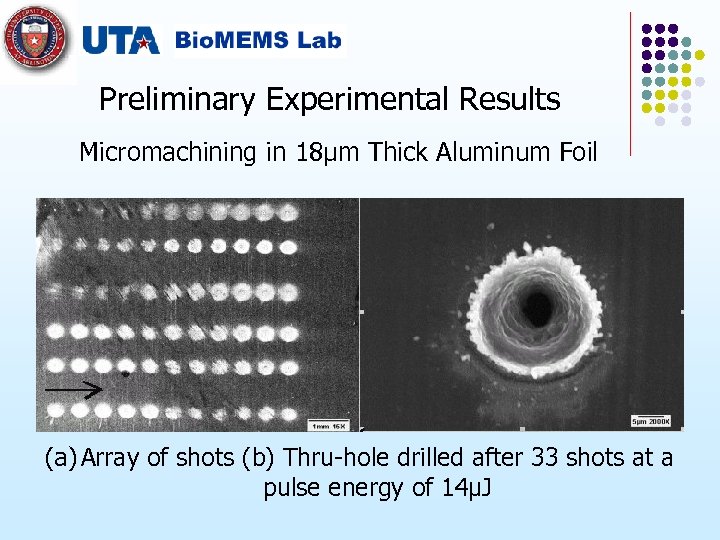

Preliminary Experimental Results Micromachining in 18μm Thick Aluminum Foil (a) Array of shots (b) Thru-hole drilled after 33 shots at a pulse energy of 14μJ

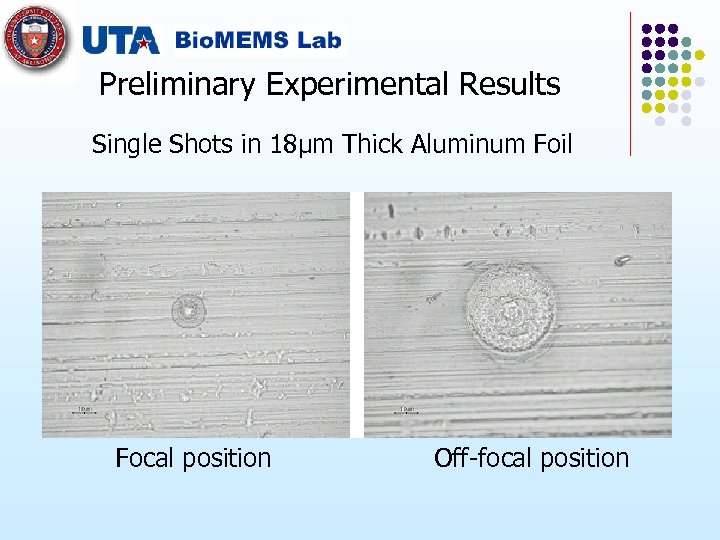

Preliminary Experimental Results Single Shots in 18μm Thick Aluminum Foil Focal position Off-focal position

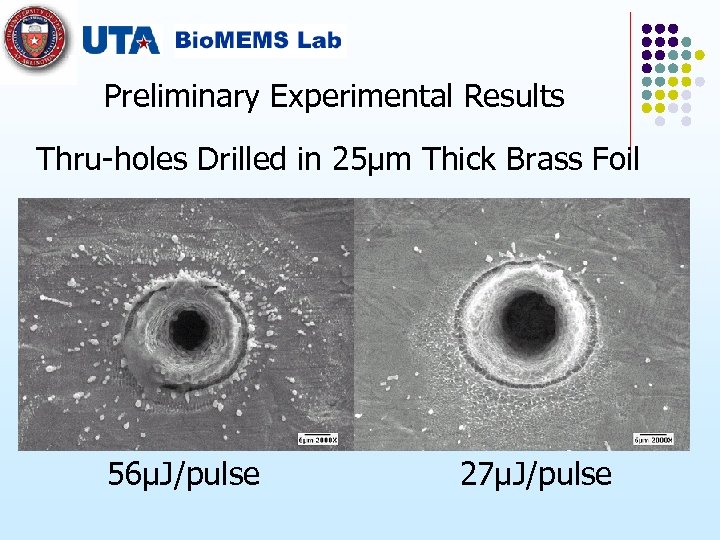

Preliminary Experimental Results Thru-holes Drilled in 25μm Thick Brass Foil 56μJ/pulse 27μJ/pulse

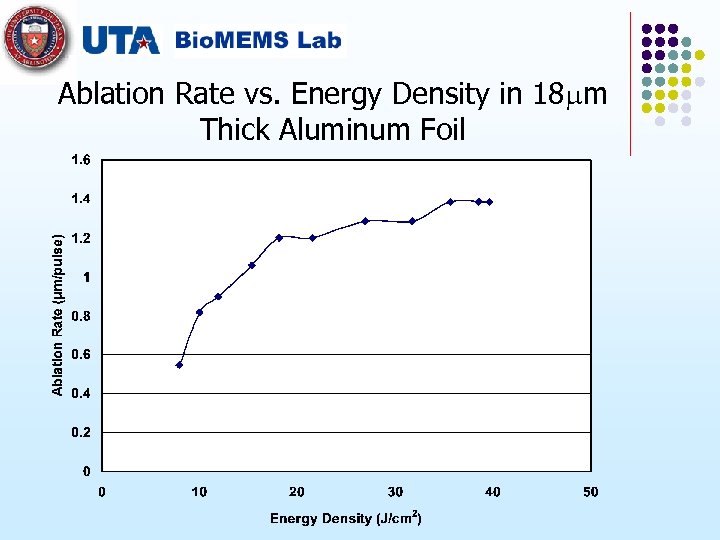

Ablation Rate vs. Energy Density in 18 m Thick Aluminum Foil

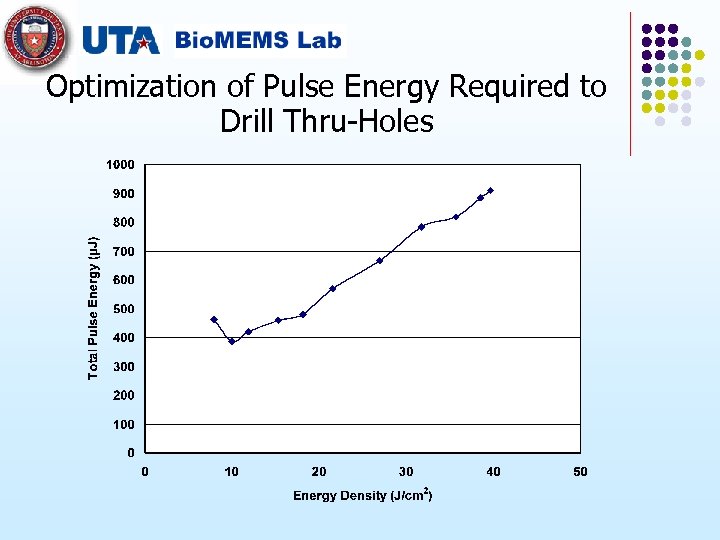

Optimization of Pulse Energy Required to Drill Thru-Holes

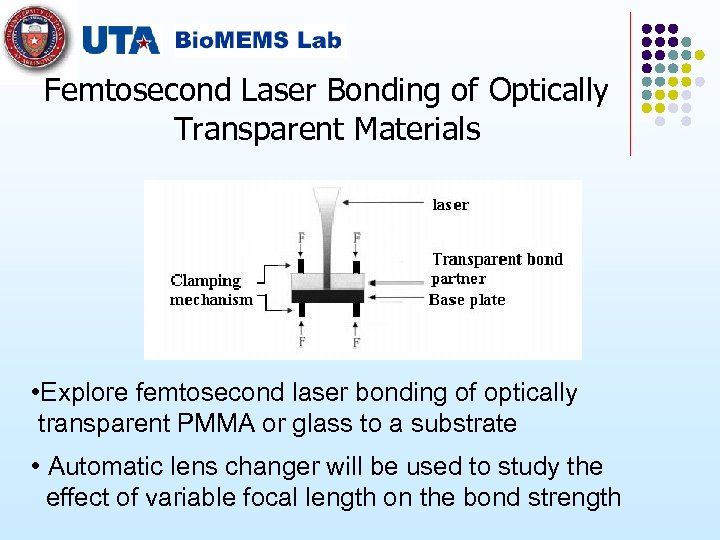

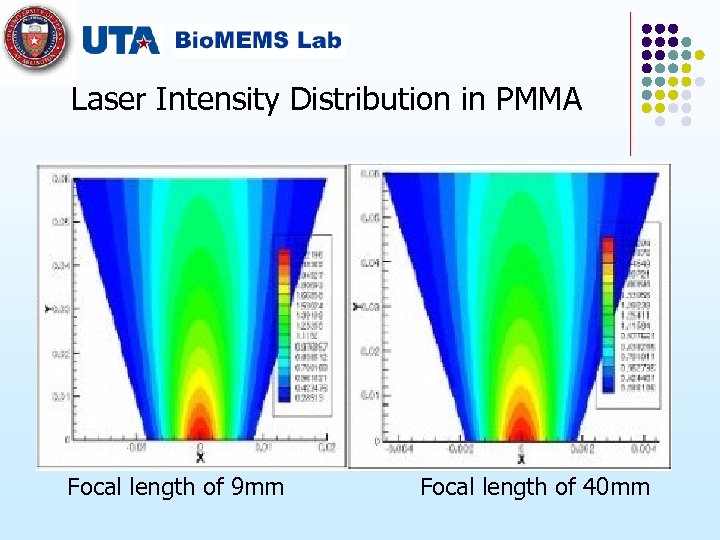

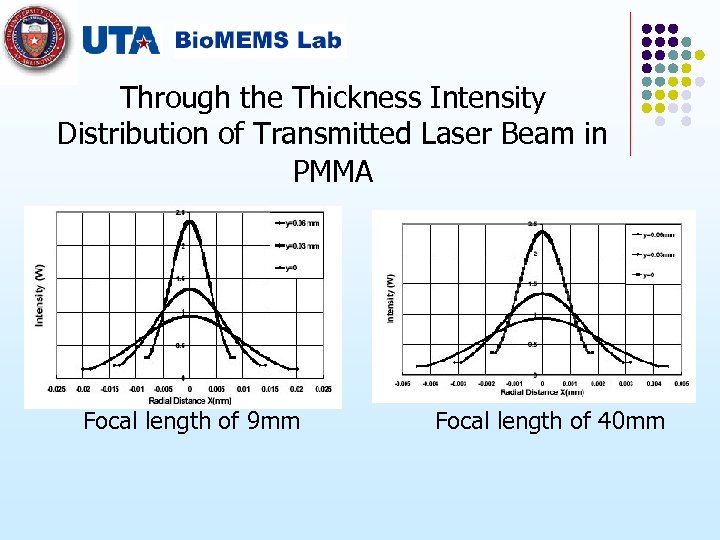

Femtosecond Laser Bonding of Optically Transparent Materials • Explore femtosecond laser bonding of optically transparent PMMA or glass to a substrate • Automatic lens changer will be used to study the effect of variable focal length on the bond strength

Laser Intensity Distribution in PMMA Focal length of 9 mm Focal length of 40 mm

Through the Thickness Intensity Distribution of Transmitted Laser Beam in PMMA Focal length of 9 mm Focal length of 40 mm

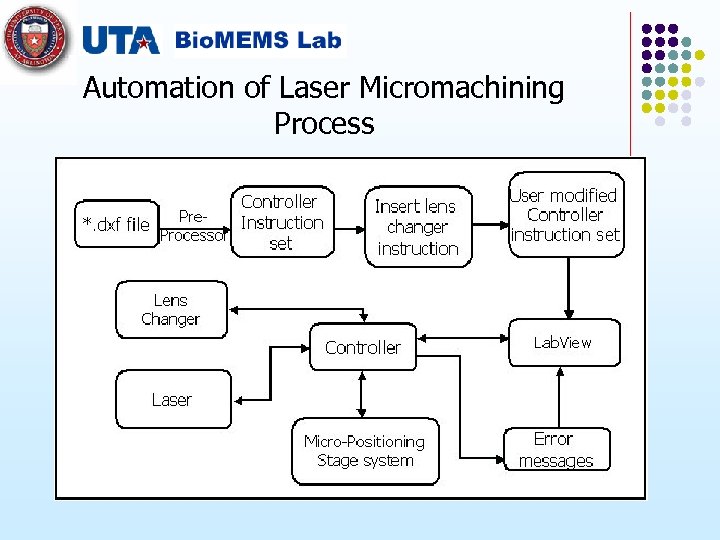

Automation of Laser Micromachining Process

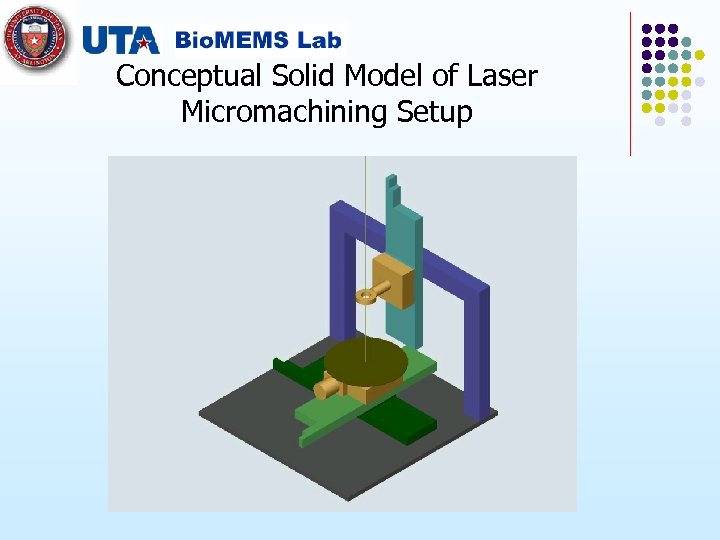

Conceptual Solid Model of Laser Micromachining Setup

86e727621f753b9359a3be3a390b171d.ppt