2ce406d578f2bc39ba77ae94fd011f5b.ppt

- Количество слайдов: 12

FEDIAF Code of Practice for the Manufacture of Safe Pet Food TRAINING PACKAGE Introduction

FEDIAF Code of Practice for the Manufacture of Safe Pet Food TRAINING PACKAGE Introduction

What is FEDIAF? European Pet Food Industry Federation representing the National Pet Food Industry Associations of the EU, Bosnia Croatia, Norway, Russia, Serbia and Switzerland

What is FEDIAF? European Pet Food Industry Federation representing the National Pet Food Industry Associations of the EU, Bosnia Croatia, Norway, Russia, Serbia and Switzerland

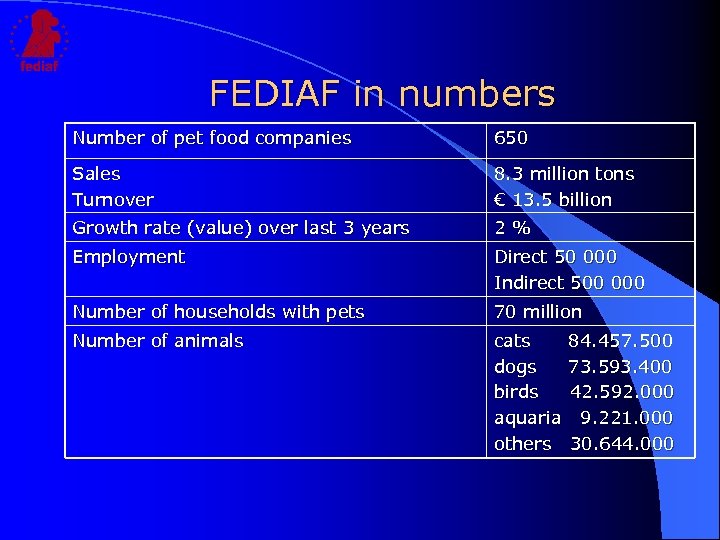

FEDIAF in numbers Number of pet food companies 650 Sales Turnover 8. 3 million tons € 13. 5 billion Growth rate (value) over last 3 years 2% Employment Direct 50 000 Indirect 500 000 Number of households with pets 70 million Number of animals cats dogs birds aquaria others 84. 457. 500 73. 593. 400 42. 592. 000 9. 221. 000 30. 644. 000

FEDIAF in numbers Number of pet food companies 650 Sales Turnover 8. 3 million tons € 13. 5 billion Growth rate (value) over last 3 years 2% Employment Direct 50 000 Indirect 500 000 Number of households with pets 70 million Number of animals cats dogs birds aquaria others 84. 457. 500 73. 593. 400 42. 592. 000 9. 221. 000 30. 644. 000

Prime objective of FEDIAF Feeding pet animals with safe pet food for a long healthy life

Prime objective of FEDIAF Feeding pet animals with safe pet food for a long healthy life

What is the FEDIAF Code? Guide of good manufacturing practices first adopted in 2001

What is the FEDIAF Code? Guide of good manufacturing practices first adopted in 2001

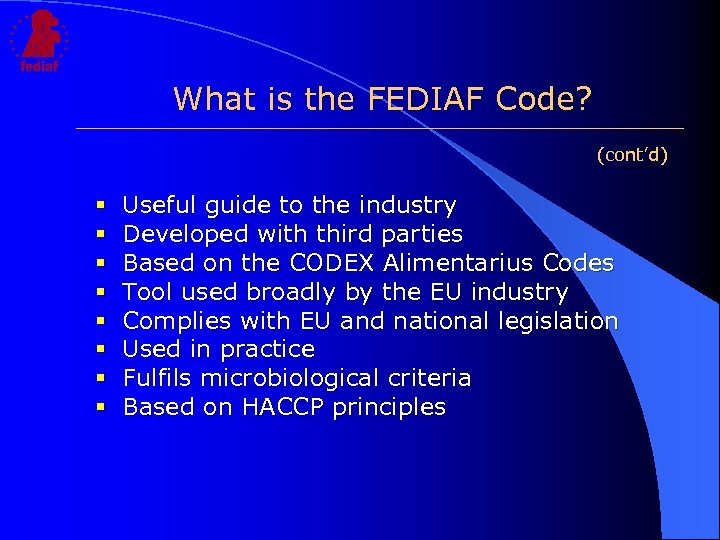

What is the FEDIAF Code? (cont’d) § § § § Useful guide to the industry Developed with third parties Based on the CODEX Alimentarius Codes Tool used broadly by the EU industry Complies with EU and national legislation Used in practice Fulfils microbiological criteria Based on HACCP principles

What is the FEDIAF Code? (cont’d) § § § § Useful guide to the industry Developed with third parties Based on the CODEX Alimentarius Codes Tool used broadly by the EU industry Complies with EU and national legislation Used in practice Fulfils microbiological criteria Based on HACCP principles

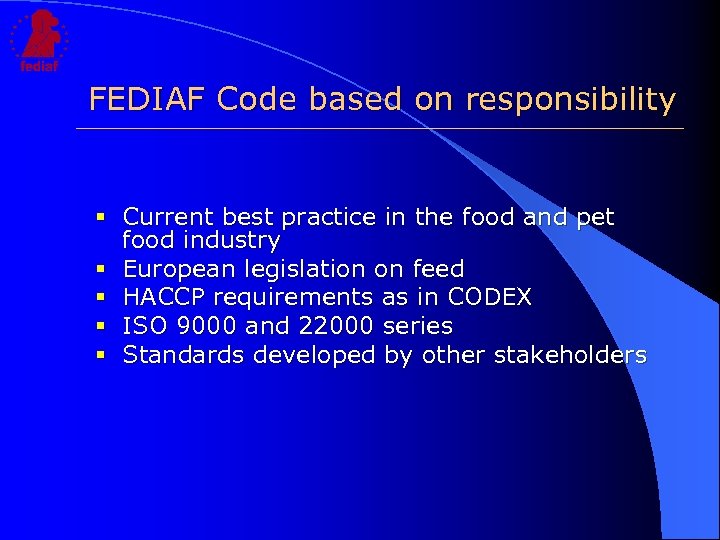

FEDIAF Code based on responsibility § Current best practice in the food and pet food industry § European legislation on feed § HACCP requirements as in CODEX § ISO 9000 and 22000 series § Standards developed by other stakeholders

FEDIAF Code based on responsibility § Current best practice in the food and pet food industry § European legislation on feed § HACCP requirements as in CODEX § ISO 9000 and 22000 series § Standards developed by other stakeholders

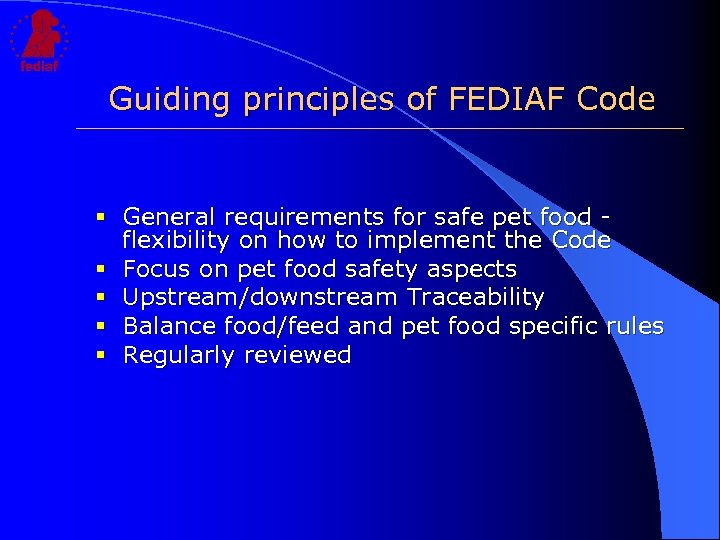

Guiding principles of FEDIAF Code § General requirements for safe pet food flexibility on how to implement the Code § Focus on pet food safety aspects § Upstream/downstream Traceability § Balance food/feed and pet food specific rules § Regularly reviewed

Guiding principles of FEDIAF Code § General requirements for safe pet food flexibility on how to implement the Code § Focus on pet food safety aspects § Upstream/downstream Traceability § Balance food/feed and pet food specific rules § Regularly reviewed

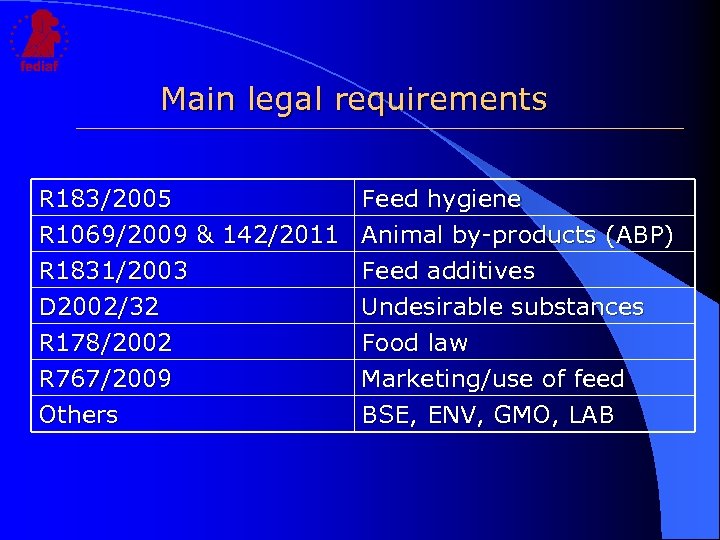

Main legal requirements R 183/2005 Feed hygiene R 1069/2009 & 142/2011 Animal by-products (ABP) R 1831/2003 Feed additives D 2002/32 Undesirable substances R 178/2002 Food law R 767/2009 Marketing/use of feed Others BSE, ENV, GMO, LAB

Main legal requirements R 183/2005 Feed hygiene R 1069/2009 & 142/2011 Animal by-products (ABP) R 1831/2003 Feed additives D 2002/32 Undesirable substances R 178/2002 Food law R 767/2009 Marketing/use of feed Others BSE, ENV, GMO, LAB

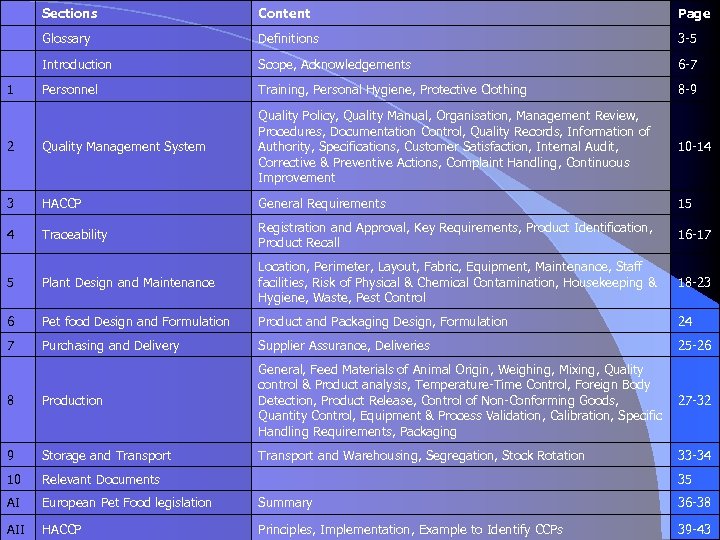

Sections Content Page Glossary Definitions 3 -5 Introduction Scope, Acknowledgements 6 -7 1 Personnel Training, Personal Hygiene, Protective Clothing 8 -9 2 Quality Management System Quality Policy, Quality Manual, Organisation, Management Review, Procedures, Documentation Control, Quality Records, Information of Authority, Specifications, Customer Satisfaction, Internal Audit, Corrective & Preventive Actions, Complaint Handling, Continuous Improvement 10 -14 3 HACCP General Requirements 15 4 Traceability Registration and Approval, Key Requirements, Product Identification, Product Recall 16 -17 5 Plant Design and Maintenance Location, Perimeter, Layout, Fabric, Equipment, Maintenance, Staff facilities, Risk of Physical & Chemical Contamination, Housekeeping & Hygiene, Waste, Pest Control 18 -23 6 Pet food Design and Formulation Product and Packaging Design, Formulation 24 7 Purchasing and Delivery Supplier Assurance, Deliveries 25 -26 8 Production General, Feed Materials of Animal Origin, Weighing, Mixing, Quality control & Product analysis, Temperature-Time Control, Foreign Body Detection, Product Release, Control of Non-Conforming Goods, 27 -32 Quantity Control, Equipment & Process Validation, Calibration, Specific Handling Requirements, Packaging 9 Storage and Transport and Warehousing, Segregation, Stock Rotation 33 -34 10 Relevant Documents 35 AI European Pet Food legislation Summary 36 -38 AII HACCP Principles, Implementation, Example to Identify CCPs 39 -43

Sections Content Page Glossary Definitions 3 -5 Introduction Scope, Acknowledgements 6 -7 1 Personnel Training, Personal Hygiene, Protective Clothing 8 -9 2 Quality Management System Quality Policy, Quality Manual, Organisation, Management Review, Procedures, Documentation Control, Quality Records, Information of Authority, Specifications, Customer Satisfaction, Internal Audit, Corrective & Preventive Actions, Complaint Handling, Continuous Improvement 10 -14 3 HACCP General Requirements 15 4 Traceability Registration and Approval, Key Requirements, Product Identification, Product Recall 16 -17 5 Plant Design and Maintenance Location, Perimeter, Layout, Fabric, Equipment, Maintenance, Staff facilities, Risk of Physical & Chemical Contamination, Housekeeping & Hygiene, Waste, Pest Control 18 -23 6 Pet food Design and Formulation Product and Packaging Design, Formulation 24 7 Purchasing and Delivery Supplier Assurance, Deliveries 25 -26 8 Production General, Feed Materials of Animal Origin, Weighing, Mixing, Quality control & Product analysis, Temperature-Time Control, Foreign Body Detection, Product Release, Control of Non-Conforming Goods, 27 -32 Quantity Control, Equipment & Process Validation, Calibration, Specific Handling Requirements, Packaging 9 Storage and Transport and Warehousing, Segregation, Stock Rotation 33 -34 10 Relevant Documents 35 AI European Pet Food legislation Summary 36 -38 AII HACCP Principles, Implementation, Example to Identify CCPs 39 -43

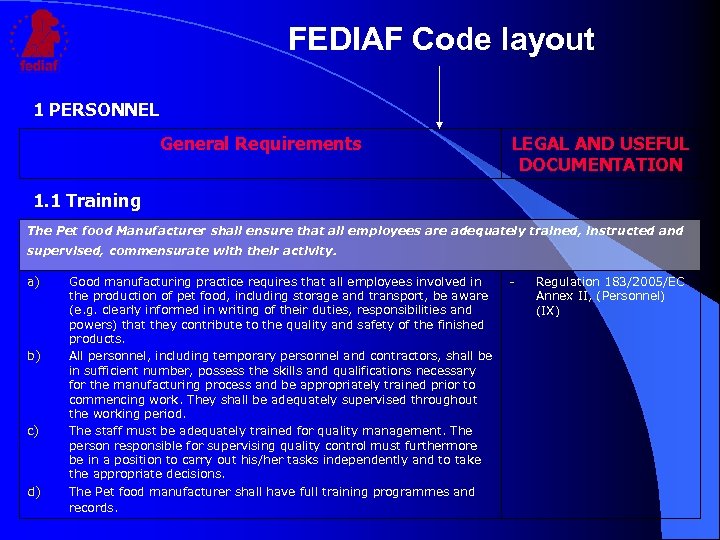

FEDIAF Code layout 1 PERSONNEL General Requirements LEGAL AND USEFUL DOCUMENTATION 1. 1 Training The Pet food Manufacturer shall ensure that all employees are adequately trained, instructed and supervised, commensurate with their activity. a) b) c) d) Good manufacturing practice requires that all employees involved in the production of pet food, including storage and transport, be aware (e. g. clearly informed in writing of their duties, responsibilities and powers) that they contribute to the quality and safety of the finished products. All personnel, including temporary personnel and contractors, shall be in sufficient number, possess the skills and qualifications necessary for the manufacturing process and be appropriately trained prior to commencing work. They shall be adequately supervised throughout the working period. The staff must be adequately trained for quality management. The person responsible for supervising quality control must furthermore be in a position to carry out his/her tasks independently and to take the appropriate decisions. The Pet food manufacturer shall have full training programmes and records. - Regulation 183/2005/EC Annex II, (Personnel) (IX)

FEDIAF Code layout 1 PERSONNEL General Requirements LEGAL AND USEFUL DOCUMENTATION 1. 1 Training The Pet food Manufacturer shall ensure that all employees are adequately trained, instructed and supervised, commensurate with their activity. a) b) c) d) Good manufacturing practice requires that all employees involved in the production of pet food, including storage and transport, be aware (e. g. clearly informed in writing of their duties, responsibilities and powers) that they contribute to the quality and safety of the finished products. All personnel, including temporary personnel and contractors, shall be in sufficient number, possess the skills and qualifications necessary for the manufacturing process and be appropriately trained prior to commencing work. They shall be adequately supervised throughout the working period. The staff must be adequately trained for quality management. The person responsible for supervising quality control must furthermore be in a position to carry out his/her tasks independently and to take the appropriate decisions. The Pet food manufacturer shall have full training programmes and records. - Regulation 183/2005/EC Annex II, (Personnel) (IX)

Consultation of third parties FEFAC (EU Farm Feed Federation) BRC (British Retail Consortium) BEUC (EU Consumer Association) CIES (Food Safety Initiative) IFS (International Food Standards) Euro. Commerce (EU Retail Federation) Lloyd’s Register of Quality Assurance FVO (Food and Veterinary Office) EFSA (European Food Safety Authority) National Authorities National Organisations

Consultation of third parties FEFAC (EU Farm Feed Federation) BRC (British Retail Consortium) BEUC (EU Consumer Association) CIES (Food Safety Initiative) IFS (International Food Standards) Euro. Commerce (EU Retail Federation) Lloyd’s Register of Quality Assurance FVO (Food and Veterinary Office) EFSA (European Food Safety Authority) National Authorities National Organisations