a072a3ec87da3698328b938acb87169f.ppt

- Количество слайдов: 65

Federal Transit Administration’s Bus Testing Program Steering Committee Meeting March 28 th, 2013 University Park, PA Operated by: Thomas D. Larson, Pennsylvania Transportation Institute Altoona Bus Testing and Research Center Pennsylvania Transportation Institute College of Engineering The Pennsylvania State University

Purpose of Meeting • Steering committee members include: – Transit bus manufactures – Transit industry manufacturers – Transit agency professionals – Experts from national labs – FTA Personnel • Meeting objectives: – Review current program – Suggest improvements to tests, policies and procedures – Present and discuss MAP-21 changes

Altoona Bus Research and Testing Center 2237 Old Route 220 N Duncansville, PA

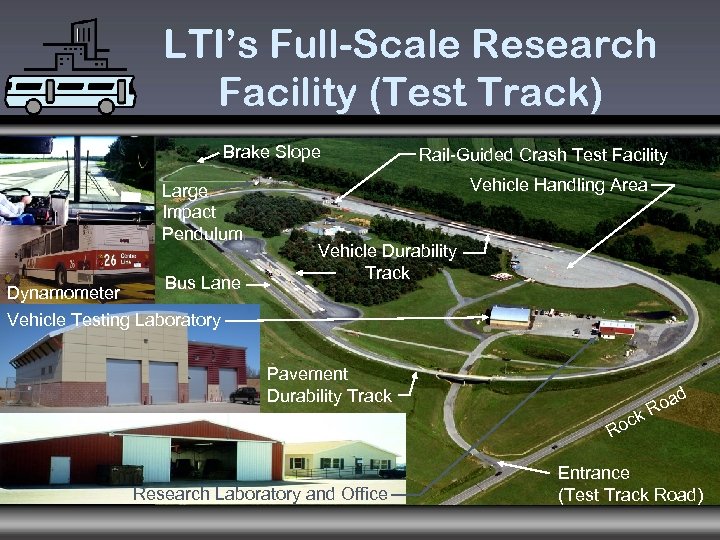

LTI’s Full-Scale Research Facility (Test Track) Brake Slope Large Impact Pendulum Dynamometer Bus Lane Rail-Guided Crash Test Facility Vehicle Handling Area Vehicle Durability Track Vehicle Testing Laboratory Pavement Durability Track ock R Research Laboratory and Office d oa R Entrance (Test Track Road)

The Bus Testing Law • STURRA – Established center (1989) – Required testing of new model buses to be purchased with Federal funding – Established test categories (based on early 1980’s First Article Bus Testing Plan, i. e. , White Book) • ISTEA – Provided 80% test fee funded by FTA – Provided 20% test fee funded by entity having vehicle tested – Expanded test categories • TEA 21 – Provided funding until 2004 • SAFETEA-LU – Provides continued funding • MAP-21 – Establishes pass/fail requirement

Definition of a Bus? • 49 Code of Federal Regulations, part 665. 5 – “a rubber-tired automotive vehicle used for the provision of mass transportation service by or for a recipient. ”

Testing Determinations • Independent of testing center • Made by FTA – FTA Program Manager: Mr. Greg Rymarz – Reasonable approach based on “family of vehicles” – Consistent, qualified engineering support • Booz Allen & Hamilton

Full Testing • Explicitly required when a new bus model has not been tested previously at the Altoona Bus Research and Testing Center

Partial Testing • Applies to previously-tested models only • Required for – “Major change in chassis or components” • Might be required when a change – Potentially impacts structural integrity – Potentially impacts safety characteristics

Altoona’s Testing Plan • Standardized • Based on minimum expected vehicle service life or mileage • Minimum performance criteria proposed • Mandated pass/fail provision • In addition to FMVSS requirements

The Tests • Eight evaluation categories – Maintainability – Reliability – Safety-Braking – Performance – Structural Integrity and Durability – Fuel Economy – Noise – Emissions

Data Reported • Comprehensive Final Test Report – Comprehensive report for each model tested – Format standardized for ease of comparison between competing models – Objective results – Pass/fail provision mandated by MAP-21 – Descriptions of all problems/failures encountered – Data intended for use during procurement process

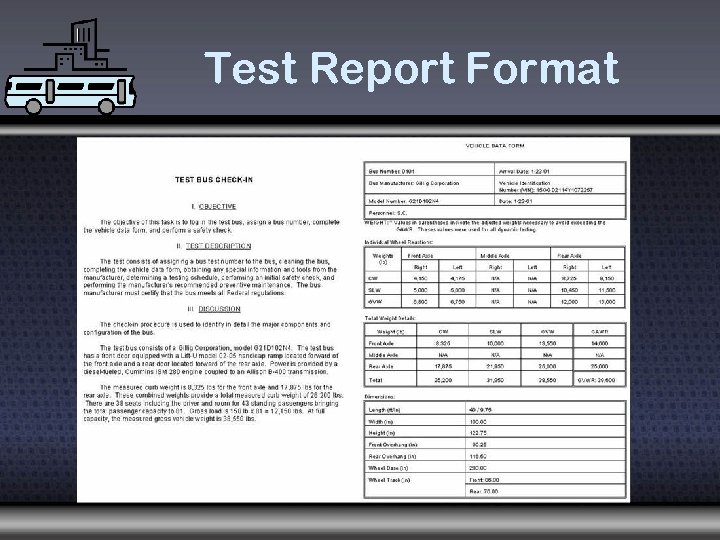

Test Report Format

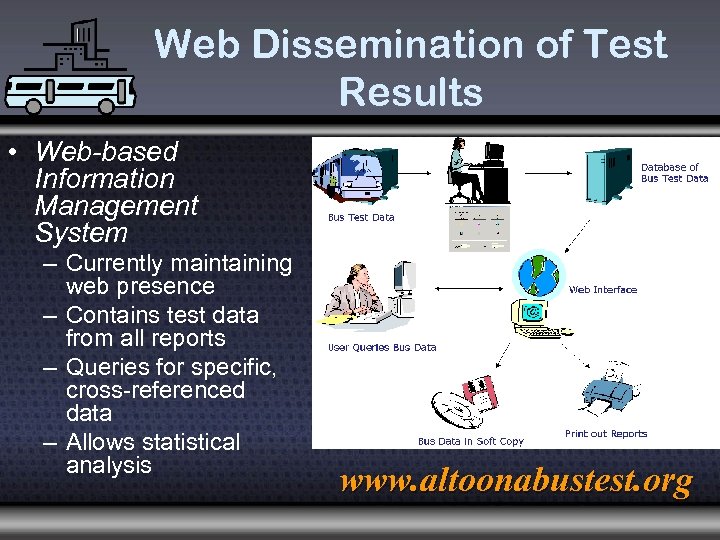

Web Dissemination of Test Results • Web-based Information Management System – Currently maintaining web presence – Contains test data from all reports – Queries for specific, cross-referenced data – Allows statistical analysis www. altoonabustest. org

Web Update • Administrative site allows timely updates by authorized personnel.

Web Presence

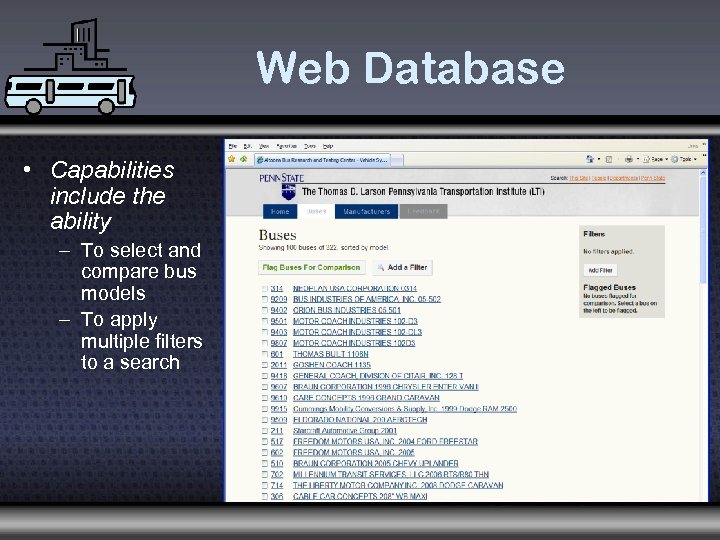

Web Database • Capabilities include the ability – To select and compare bus models – To apply multiple filters to a search

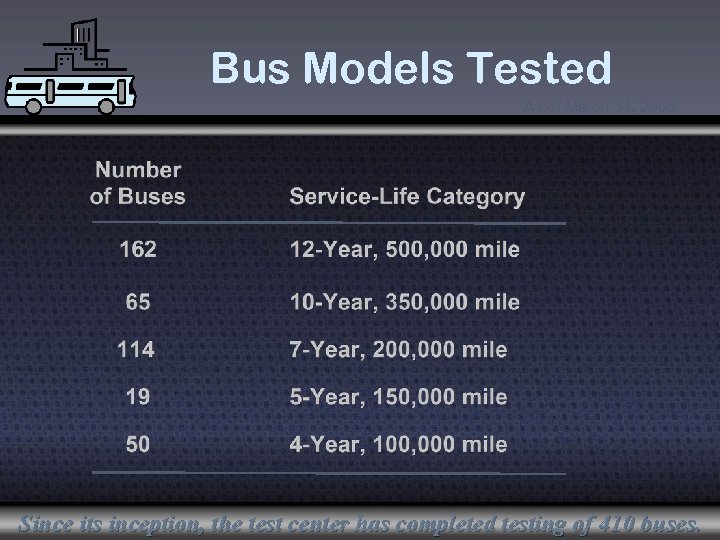

Bus Models Tested As of March 31, 2008 Since its inception, the test center has completed testing of 410 buses.

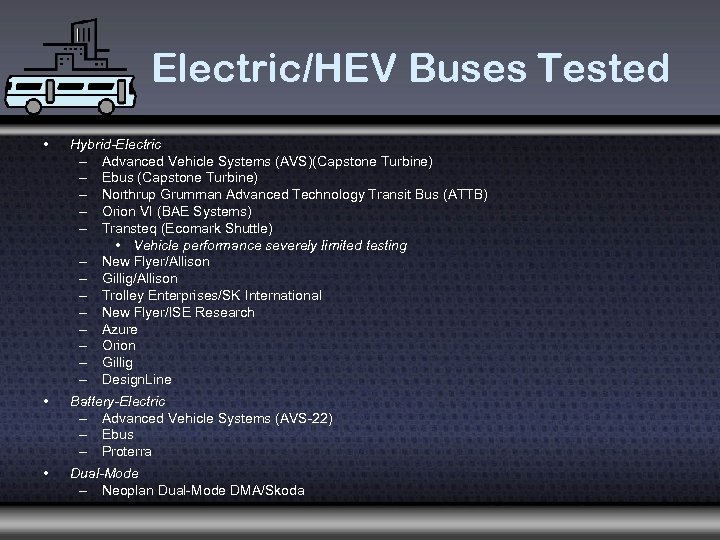

Electric/HEV Buses Tested • Hybrid-Electric – Advanced Vehicle Systems (AVS)(Capstone Turbine) – Ebus (Capstone Turbine) – Northrup Grumman Advanced Technology Transit Bus (ATTB) – Orion VI (BAE Systems) – Transteq (Ecomark Shuttle) • Vehicle performance severely limited testing – New Flyer/Allison – Gillig/Allison – Trolley Enterprises/SK International – New Flyer/ISE Research – Azure – Orion – Gillig – Design. Line • Battery-Electric – Advanced Vehicle Systems (AVS-22) – Ebus – Proterra • Dual-Mode – Neoplan Dual-Mode DMA/Skoda

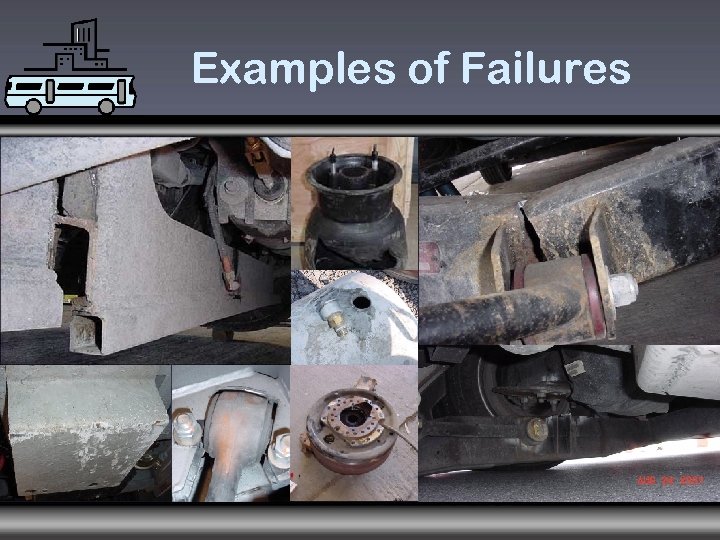

Failures Encountered • Majority of failures encountered – – – – – Chassis/structure Suspension Engine/drive train Exhaust/emissions Electrical Air conditioning/heating Brakes Steering Fuel Systems Seats/Lifts/Doors/Windows

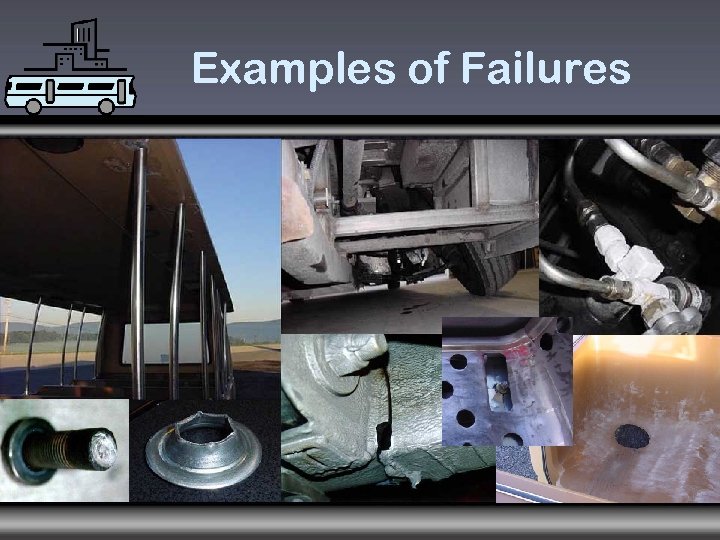

Examples of Failures

Examples of Failures

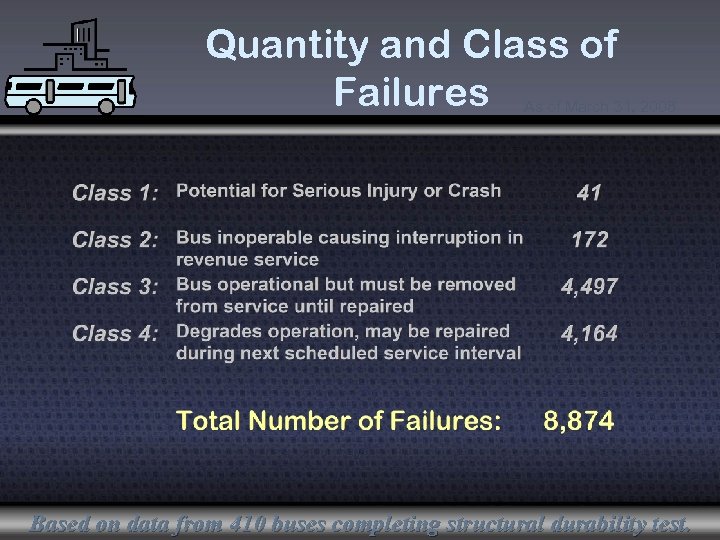

Quantity and Class of Failures As of March 31, 2008 Based on data from 410 buses completing structural durability test.

An Ambitious Beginning • Technical and regulatory changes since 1990 (ADA, Clean Air, etc. ) – Deployment of new technologies • Alternative fuels/Fuel cells • Battery and hybrid-electric buses • Advanced materials-SS and light weight composites • Electronic controls/multiplexed systems • Advanced engines (diesel, gas, turbine, etc. ) • Advanced after-treatment including urea injection, SCR catalysts, etc. – Evaluating new technologies • Bus testing played prominent role – Identifying “teething” problems – Helping to correct problems early in production cycle – Emissions testing – Brake testing – Pass/fail criteria

Safety Benefits • Detect defects directly related to safety of transitriding public Examples: – Bus Fires – Cracked CNG cylinder support brackets • High-pressure fuel cylinder detachment – – – CNG fuel system cracks/leaks Fuel tank leaks Fire detection/suppression system failures High current electrical short circuits Broken steering/suspension components • Loss of vehicle control

Making a Positive Impact • Testing raises the bar – Requires better reliability and performance • Manufacturers – Opportunity to correct deficiencies (without public disclosure) • Transit agencies – Use test results to • Manage risk during procurement • Modify maintenance schedules

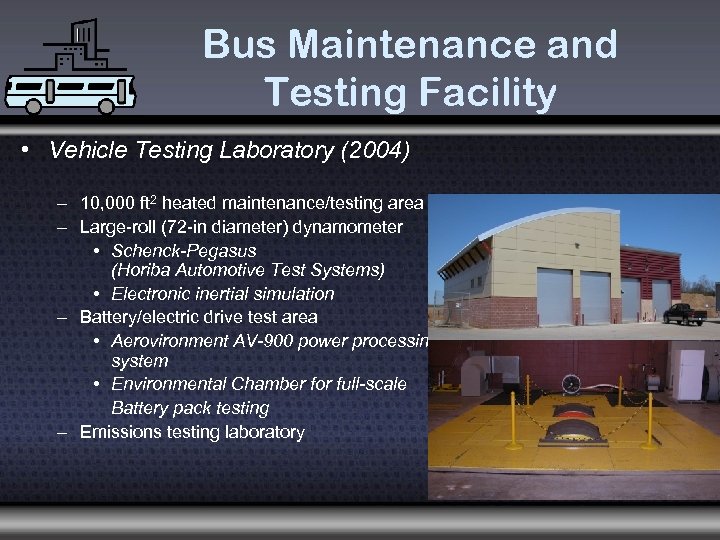

Expansion of Testing Program • Facility Modifications Since 2000 – Accommodate new tests – Accommodate advanced technology buses • New Facilities – Brake slope – Emissions Lab – Battery testing/simulation • Power processing systems – Hydrogen fueling station • Completed spring 2006

Bus Maintenance and Testing Facility • Vehicle Testing Laboratory (2004) – 10, 000 ft 2 heated maintenance/testing area – Large-roll (72 -in diameter) dynamometer • Schenck-Pegasus (Horiba Automotive Test Systems) • Electronic inertial simulation – Battery/electric drive test area • Aerovironment AV-900 power processing system • Environmental Chamber for full-scale Battery pack testing – Emissions testing laboratory

Regulatory Changes • FTA Final Rule Published October 5 th 2009 Testing of Overloaded Buses Emissions and Brake Testing • FTA Withdrew the 175 lb person requirement in December 2012 • MAP-21 Requires Pass/Fail • Federal Register: 49 CFR Part 665 • Go to : www. regulations. gov to view or post comments to the docket

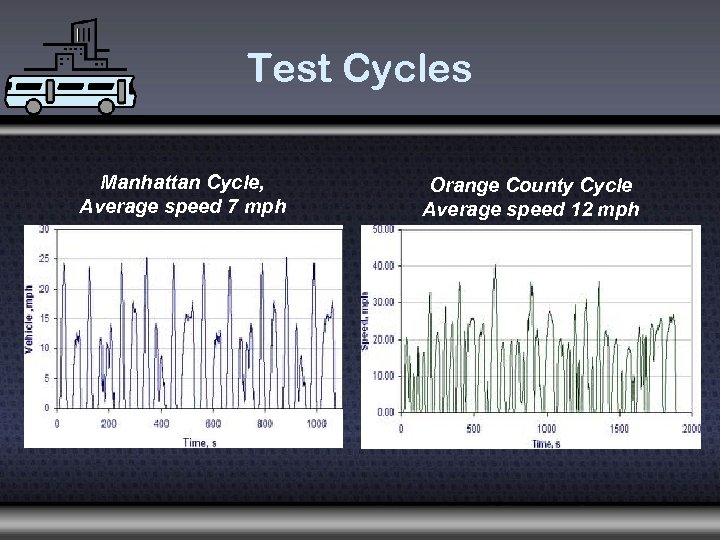

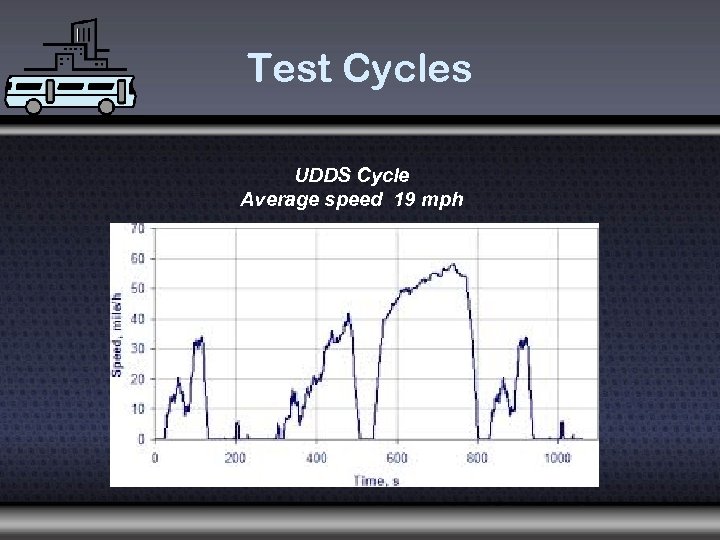

Proposed Changes to tests • Perform fuel economy tests on chassis dynamometer. • Replace current fuel economy cycles (CBD, Arterial, Commuter) with cycles used for emissions tests: (Manhattan, Orange County, and UDDS)

Bus Testing—Into the Future • Predicting continued significant advancement in new bus technologies (i. e. , Bus Rapid Transit) – Driving Factors • • • Safety and security Better performance, efficiency, reliability Enhanced service Advancements in materials systems Increased integration of advanced systems • Anticipating future changes in industry • Looking forward to meeting challenges • Bus Testing Steering Committee

Information Greg Rymarz, FTA Program Manager Phone: 202 -366 -6410 Email: gregory. rymarz@dot. gov • David J. Klinikowski, Program Director Phone: 814 -863 -1898 Email: dklinikowski@engr. psu. edu • Robert R. Reifsteck, Altoona Manager Phone: 814 -695 -4067 Email: rreifsteck@engr. psu. edu

Brake Testing Update Larson Transportation Institute Bus Research and Testing Center Steering Committee Meeting Allen Homan 27 March 2013

Mid-Sized Buses 180 160 Distance (feet) 140 120 45 Dry 40 Dry 20 Wet 100 80 60 40 20 0 0 5 10 15 Number of Buses 20 25 30

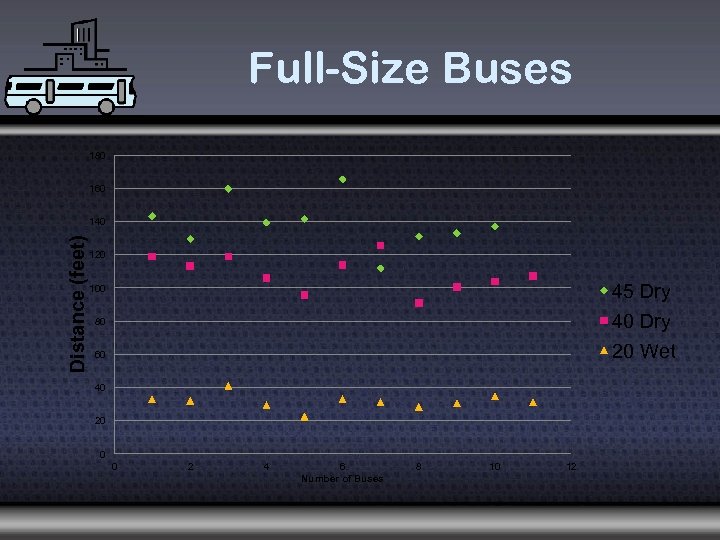

Full-Size Buses 180 160 Distance (feet) 140 120 45 Dry 40 Dry 20 Wet 100 80 60 40 20 0 0 2 4 6 Number of Buses 8 10 12

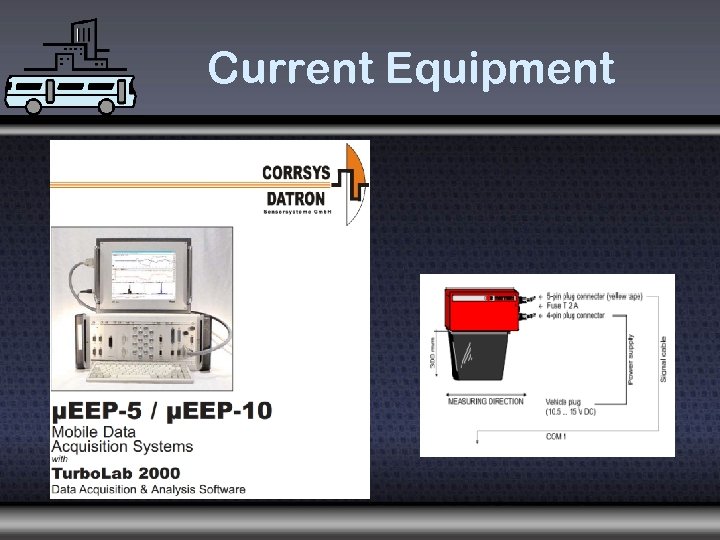

Current Equipment

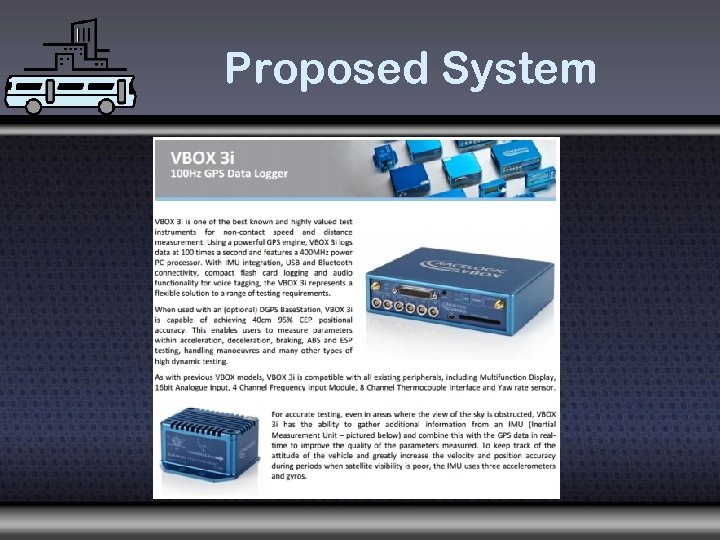

Proposed System

Questions? Allen Homan (814) 863 -8011 ahoman@engr. psu. edu

Emissions Testing Update Larson Transportation Institute Bus Research and Testing Center Steering Committee Meeting Dr. Suresh Iyer 27 March 2013

Overview • 2005 – Decided on concept of full scale dilution tunnel • 2006 – Finalized specifications • 2007 - Identified potential suppliers • 2008 – Placed orders • 2009 – Modified facilities, equipment delivered and commissioned • 2010 – Started emissions tests on buses • 2011 – Received ISO 17025 laboratory accreditation from A 2 LA • 2010 to 2012 – Performed emissions tests on 44 buses

Buses Tested 2010 -2012 Year Tested Fuel Type Diesel CNG Gasoline Propane Artic 40’ 30’ Cutaway 2010 7 4 2 0 0 4 2 7 2011 8 6 2 1 1 3 1 12 2012 4 7 2 1 0 6 0 8 Total 19 17 6 2 1 13 3 27 44 Bus Type 44

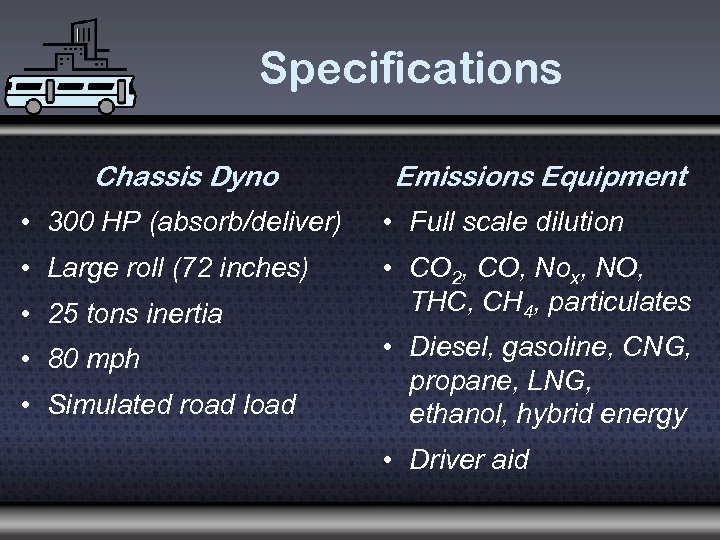

Specifications Chassis Dyno Emissions Equipment • 300 HP (absorb/deliver) • Full scale dilution • Large roll (72 inches) • CO 2, CO, Nox, NO, THC, CH 4, particulates • 25 tons inertia • 80 mph • Simulated road load • Diesel, gasoline, CNG, propane, LNG, ethanol, hybrid energy • Driver aid

Capabilities • Gaseous Emissions (dilute continuous, dilute bag, and raw) – – CO 2 CO THC and CH 4 NOx and NO • Particulates (PM) – Secondary air conditioned for dilution • Up to 3 phases in one test • Fuel consumption by carbon balance

Advantages • Less sensitive to ambient conditions – Conditioned air to dilution tunnel – Conditioned air to engine intake • Two banks of emissions analyzers – Simultaneous dilute and raw exhaust measurements (check) – Reliability • Large roll (dyno) reduces tire flexure (and tire heating) during tests • Absorbed power (dyno) is fed back into the grid

Heavy-Duty Dynamometer

Emissions Testing Facility-Overview

Midsize Bus under Test

Midsize Bus under Test

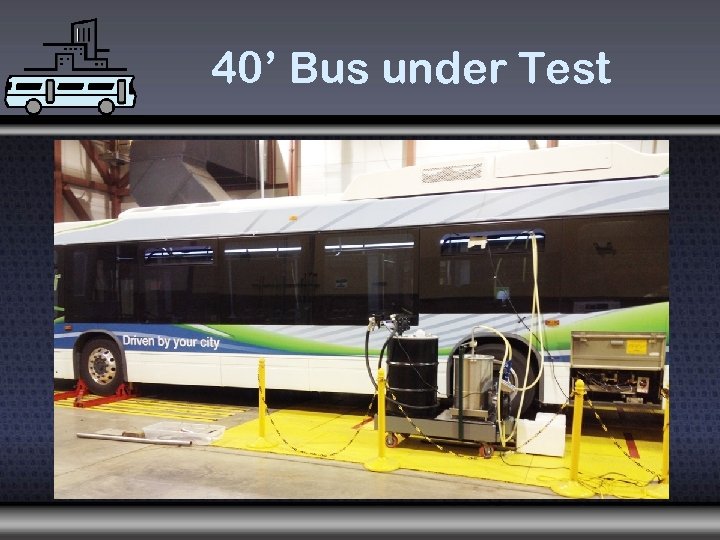

40’ Bus under Test

40’ Bus under Test

Test Cycles Manhattan Cycle, Average speed 7 mph Orange County Cycle Average speed 12 mph

Test Cycles UDDS Cycle Average speed 19 mph

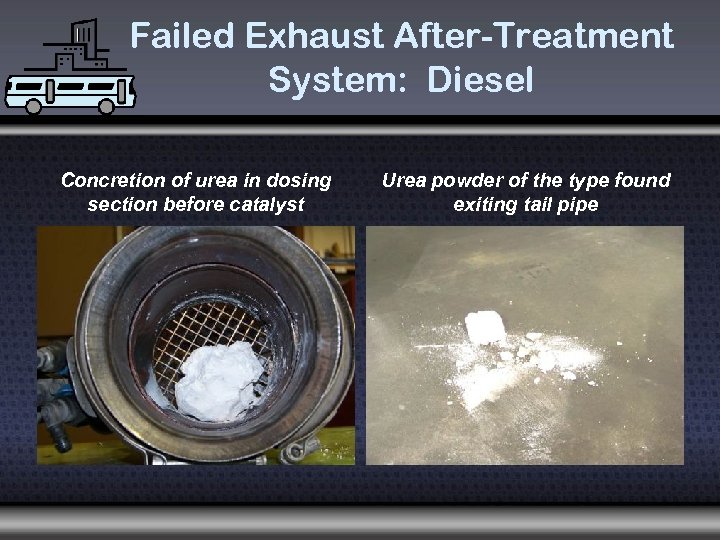

Failed Exhaust After-Treatment System: Diesel Concretion of urea in dosing section before catalyst Urea powder of the type found exiting tail pipe

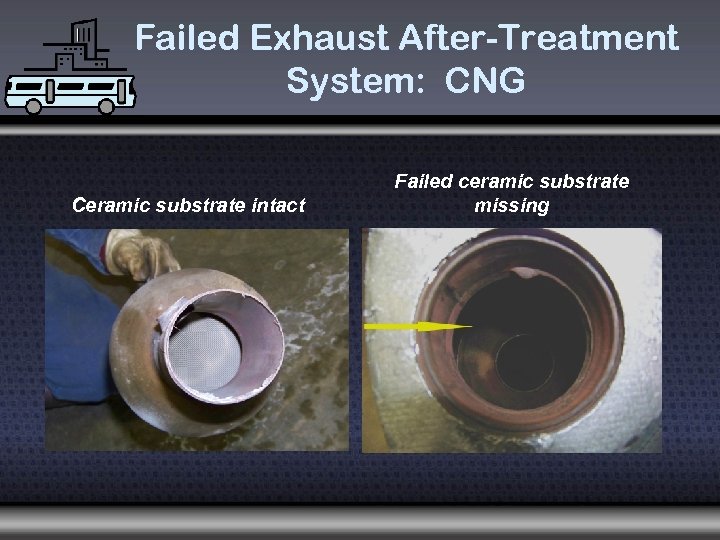

Failed Exhaust After-Treatment System: CNG Ceramic substrate intact Failed ceramic substrate missing

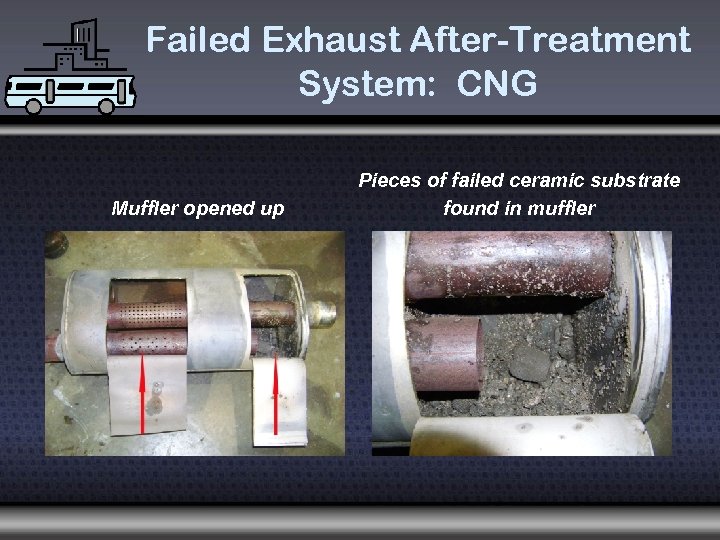

Failed Exhaust After-Treatment System: CNG Muffler opened up Pieces of failed ceramic substrate found in muffler

Comparative Test with WVU Equipment • Compared with WVU Transportable Chassis Dyno and Emissions Lab • Simultaneous data collection and independent analysis – Analyzer results were within experimental error – Mobility and reliability of WVU system resulted in delays during set up and testing – Stationary PSU system is automated and easy to operate

Uncertainty in Emissions Measurement • Summer project 2012 • Experimental uncertainty only • Relate sub-system uncertainty • Three methods – Raw exhaust - continuous – Dilute bag – collected during test • Manuscript of a journal paper in progress

Future • Investigate sensitivity of species to method of measurement • Ammonia and NO 2 analyzers • Upgrade to 500 HP dyno

Questions? Dr. Suresh Iyer (814) 865 -2327 suiyer@engr. psu. edu

Battery Application Technology Testing Energy Research Laboratory (BATTERY) Timothy Cleary 28 March 2013

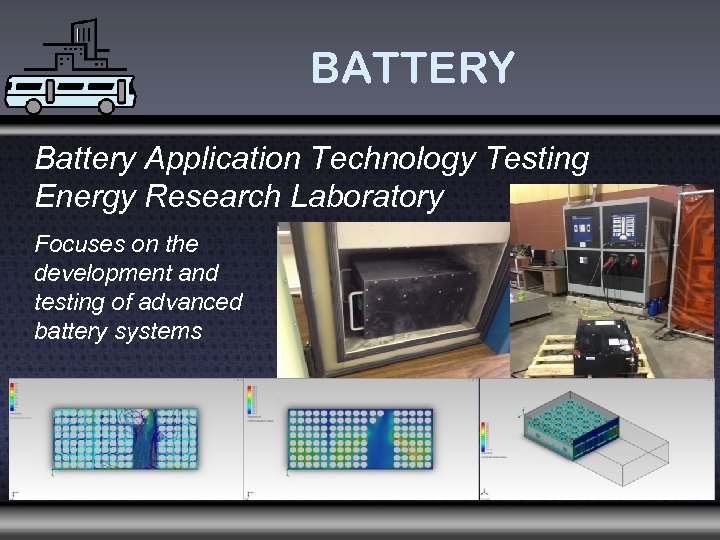

BATTERY Battery Application Technology Testing Energy Research Laboratory Focuses on the development and testing of advanced battery systems

BATTERY Projects • Thermal Management, SOC and SOH Estimation of a Large format Lithium-Titanate Battery System Designed for Heavy Vehicle Applications with Fast Charging Sponsor: U. S. Dept. of Transportation/Mineta National Transit Research Consortium • Thermal Design Validation, Control Optimization and Energy Storage Evaluation of an Experimental Electric Locomotive Sponsor: U. S. Dept. of Transportation/Norfolk Southern • Bus Testing Support – Future Battery Safety / Crash Testing

BATTERY Facilities • Aero. Vironment - AV 900 & ABC 150 Bi-Directional Load Capability AV 900 ABC 150 Power +/- 250 k. W +/- 125 k. W Current +/- 1000 ADC +/- 530 ADC Voltage 8 to 900 VDC 8 to 495 VDC

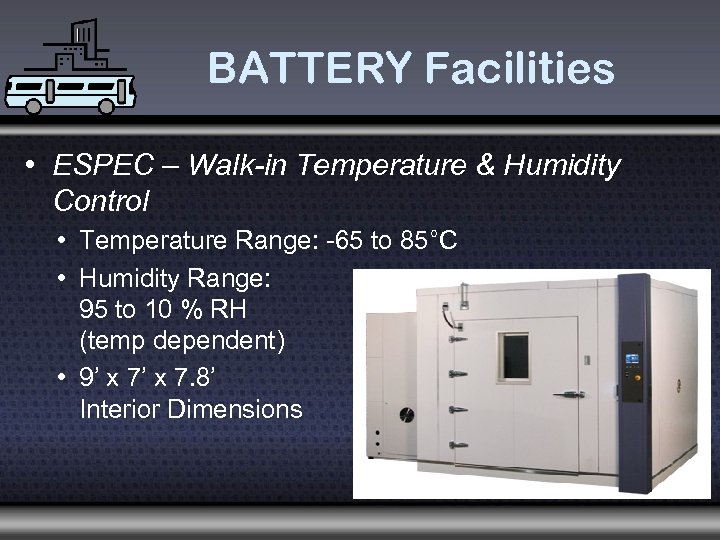

BATTERY Facilities • ESPEC – Walk-in Temperature & Humidity Control • Temperature Range: -65 to 85°C • Humidity Range: 95 to 10 % RH (temp dependent) • 9’ x 7. 8’ Interior Dimensions

Questions? Mr. Timothy Cleary (814) 865 -0500 tcleary@engr. psu. edu

a072a3ec87da3698328b938acb87169f.ppt