17dd446941a85d57fdf1cb8e7af4e93f.ppt

- Количество слайдов: 18

FDM/FEM System-level Analysis of Heat Pipes and LHPs in Modern CAD Environments Aerospace Thermal Control Workshop 2005 Brent Cullimore, Jane Baumann brent. cullimore@crtech. com C&R Technologies, Inc. www. crtech. com 9 Red Fox Lane Littleton CO 80127 -5710 USA Phone 303. 971. 0292 Fax 303. 971. 0035

FDM/FEM System-level Analysis of Heat Pipes and LHPs in Modern CAD Environments Aerospace Thermal Control Workshop 2005 Brent Cullimore, Jane Baumann brent. cullimore@crtech. com C&R Technologies, Inc. www. crtech. com 9 Red Fox Lane Littleton CO 80127 -5710 USA Phone 303. 971. 0292 Fax 303. 971. 0035

The Need for Analysis l The user’s confidence in any technology is based in part on its predictability ü The ability to model predictable behavior ü The ability to bound unpredictable behavior l l Must have compatibility with industry standard thermal analysis tools, including radiation/orbital analyzers Should be able to integrate with concurrent engineering methods such as CAD and structural/FEM

The Need for Analysis l The user’s confidence in any technology is based in part on its predictability ü The ability to model predictable behavior ü The ability to bound unpredictable behavior l l Must have compatibility with industry standard thermal analysis tools, including radiation/orbital analyzers Should be able to integrate with concurrent engineering methods such as CAD and structural/FEM

How Not to Model a Heat Pipe: Common Misconceptions l “Full two-phase thermohydraulic modeling is required” ü Overkill with respect to heat pipe modeling at the system level ü Applicable thermohydraulic solvers are available for detailed modeling, but uncertainties in inputs can be quite large l “Heat pipes can be represented by solid bars with an artificially high thermal conductivity” ü Disruptive to the numerical solution (especially in transient analyses) ü Unlike a highly conductive bar, a heat pipe’s axial resistance is independent of transport length: not even anisotropic materials approximate this behavior ü No information is gleaned regarding limits, design margin l “Heat pipes can be modeled as a large conductor” ü Analyst shouldn’t assume which sections will absorb heat and which will reject it ü Heat pipes can exhibit up to a two-fold difference in convection coefficients between evaporation and condensation

How Not to Model a Heat Pipe: Common Misconceptions l “Full two-phase thermohydraulic modeling is required” ü Overkill with respect to heat pipe modeling at the system level ü Applicable thermohydraulic solvers are available for detailed modeling, but uncertainties in inputs can be quite large l “Heat pipes can be represented by solid bars with an artificially high thermal conductivity” ü Disruptive to the numerical solution (especially in transient analyses) ü Unlike a highly conductive bar, a heat pipe’s axial resistance is independent of transport length: not even anisotropic materials approximate this behavior ü No information is gleaned regarding limits, design margin l “Heat pipes can be modeled as a large conductor” ü Analyst shouldn’t assume which sections will absorb heat and which will reject it ü Heat pipes can exhibit up to a two-fold difference in convection coefficients between evaporation and condensation

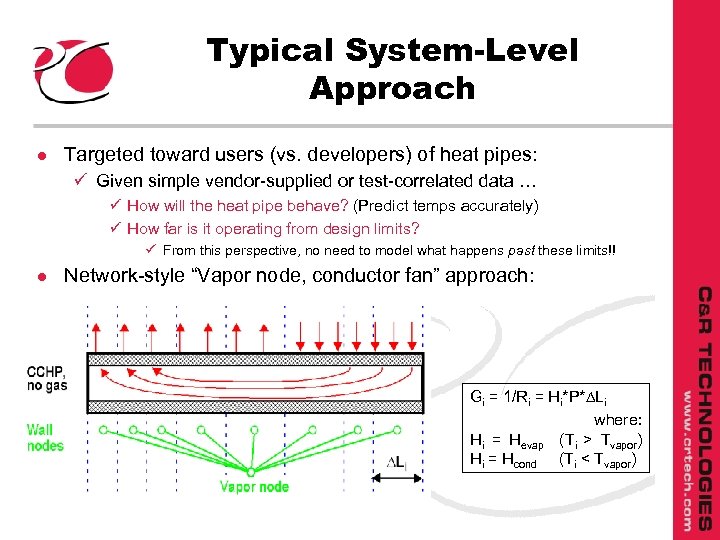

Typical System-Level Approach l Targeted toward users (vs. developers) of heat pipes: ü Given simple vendor-supplied or test-correlated data … ü How will the heat pipe behave? (Predict temps accurately) ü How far is it operating from design limits? ü From this perspective, no need to model what happens past these limits!! l Network-style “Vapor node, conductor fan” approach: Gi = 1/Ri = Hi*P*DLi where: Hi = Hevap (Ti > Tvapor) Hi = Hcond (Ti < Tvapor)

Typical System-Level Approach l Targeted toward users (vs. developers) of heat pipes: ü Given simple vendor-supplied or test-correlated data … ü How will the heat pipe behave? (Predict temps accurately) ü How far is it operating from design limits? ü From this perspective, no need to model what happens past these limits!! l Network-style “Vapor node, conductor fan” approach: Gi = 1/Ri = Hi*P*DLi where: Hi = Hevap (Ti > Tvapor) Hi = Hcond (Ti < Tvapor)

Next Level: QLeff l Checking Power-Length Product Limits ü Sum energies along pipe, looking for peak capacity: QLeff = maxi | [ Si( Qi/2 + Sj=0, i-1 Qj ) DLi ] | ü Can be compared with vendor-supplied QLeff as a function of temperature, tilt l What matters is verifying margin, not modeling deprime ü Exception: start-up of liquid metal pipes (methods available)

Next Level: QLeff l Checking Power-Length Product Limits ü Sum energies along pipe, looking for peak capacity: QLeff = maxi | [ Si( Qi/2 + Sj=0, i-1 Qj ) DLi ] | ü Can be compared with vendor-supplied QLeff as a function of temperature, tilt l What matters is verifying margin, not modeling deprime ü Exception: start-up of liquid metal pipes (methods available)

Noncondensible Gas l Gas Front Modeling (VCHP or gas-blocked CCHP) ü Amount of gas (in gmol, kmol, or lbmol) must be known or guessed (can be a variable for automated correlation) ü Gas front modeled in 1 D: “flat front” ü Iteratively find the location of the gas front ü Sum gas masses from reservoir end (or cold end). For a perfect gas: * mgas = Si {(P-Psat, i)*DLi*Apipe/(Rgas*Ti)} ü Block condensation in proportion to the gas content for each section ü Provides sizing verification for VCHP, degradation for CCHP ______ * Real gases may be used with full FLUINT FPROP blocks

Noncondensible Gas l Gas Front Modeling (VCHP or gas-blocked CCHP) ü Amount of gas (in gmol, kmol, or lbmol) must be known or guessed (can be a variable for automated correlation) ü Gas front modeled in 1 D: “flat front” ü Iteratively find the location of the gas front ü Sum gas masses from reservoir end (or cold end). For a perfect gas: * mgas = Si {(P-Psat, i)*DLi*Apipe/(Rgas*Ti)} ü Block condensation in proportion to the gas content for each section ü Provides sizing verification for VCHP, degradation for CCHP ______ * Real gases may be used with full FLUINT FPROP blocks

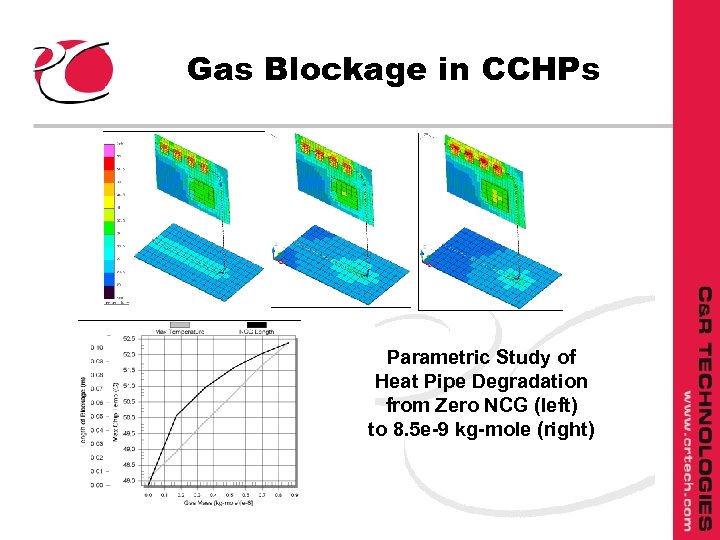

Gas Blockage in CCHPs Parametric Study of Heat Pipe Degradation from Zero NCG (left) to 8. 5 e-9 kg-mole (right)

Gas Blockage in CCHPs Parametric Study of Heat Pipe Degradation from Zero NCG (left) to 8. 5 e-9 kg-mole (right)

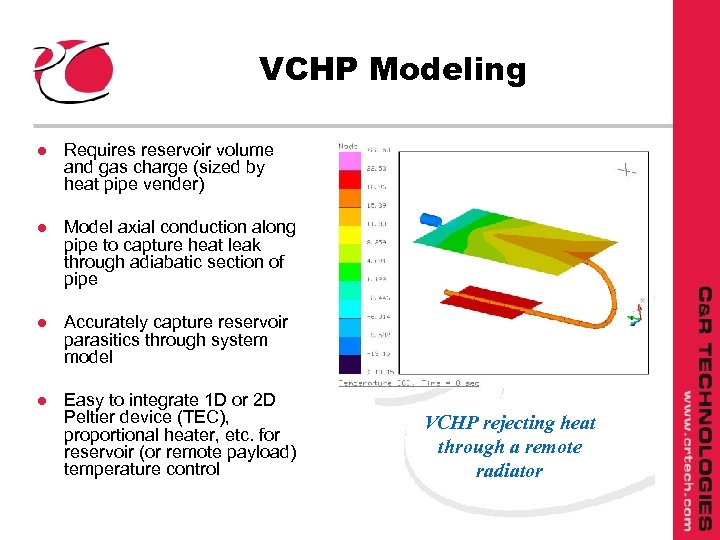

VCHP Modeling l Requires reservoir volume and gas charge (sized by heat pipe vender) l Model axial conduction along pipe to capture heat leak through adiabatic section of pipe l Accurately capture reservoir parasitics through system model l Easy to integrate 1 D or 2 D Peltier device (TEC), proportional heater, etc. for reservoir (or remote payload) temperature control VCHP rejecting heat through a remote radiator

VCHP Modeling l Requires reservoir volume and gas charge (sized by heat pipe vender) l Model axial conduction along pipe to capture heat leak through adiabatic section of pipe l Accurately capture reservoir parasitics through system model l Easy to integrate 1 D or 2 D Peltier device (TEC), proportional heater, etc. for reservoir (or remote payload) temperature control VCHP rejecting heat through a remote radiator

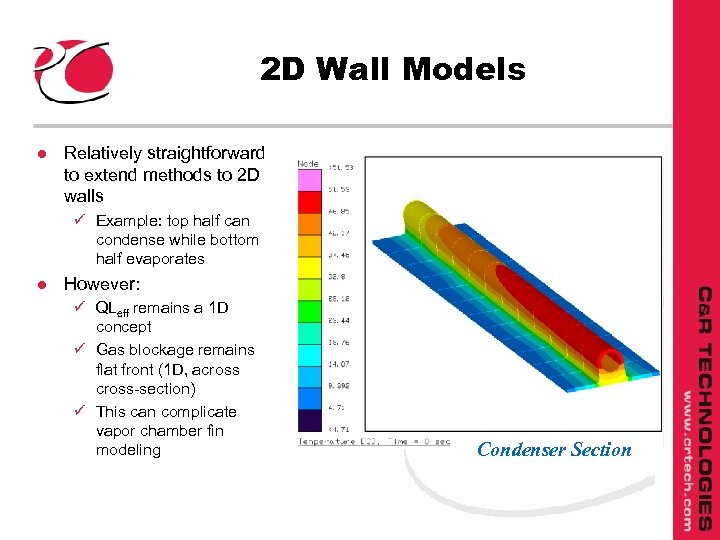

2 D Wall Models l Relatively straightforward to extend methods to 2 D walls ü Example: top half can condense while bottom half evaporates l However: ü QLeff remains a 1 D concept ü Gas blockage remains flat front (1 D, across-section) ü This can complicate vapor chamber fin modeling Condenser Section

2 D Wall Models l Relatively straightforward to extend methods to 2 D walls ü Example: top half can condense while bottom half evaporates l However: ü QLeff remains a 1 D concept ü Gas blockage remains flat front (1 D, across-section) ü This can complicate vapor chamber fin modeling Condenser Section

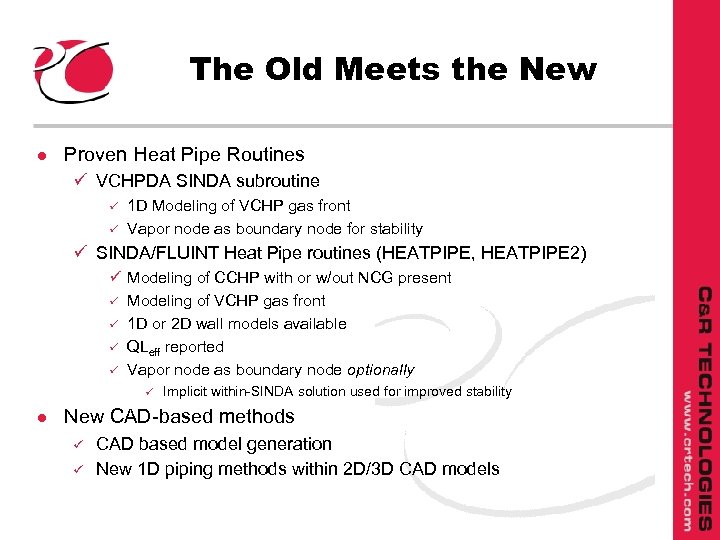

The Old Meets the New l Proven Heat Pipe Routines ü VCHPDA SINDA subroutine ü ü 1 D Modeling of VCHP gas front Vapor node as boundary node for stability ü SINDA/FLUINT Heat Pipe routines (HEATPIPE, HEATPIPE 2) ü Modeling of CCHP with or w/out NCG present ü Modeling of VCHP gas front ü 1 D or 2 D wall models available ü QLeff reported ü Vapor node as boundary node optionally ü l Implicit within-SINDA solution used for improved stability New CAD-based methods ü ü CAD based model generation New 1 D piping methods within 2 D/3 D CAD models

The Old Meets the New l Proven Heat Pipe Routines ü VCHPDA SINDA subroutine ü ü 1 D Modeling of VCHP gas front Vapor node as boundary node for stability ü SINDA/FLUINT Heat Pipe routines (HEATPIPE, HEATPIPE 2) ü Modeling of CCHP with or w/out NCG present ü Modeling of VCHP gas front ü 1 D or 2 D wall models available ü QLeff reported ü Vapor node as boundary node optionally ü l Implicit within-SINDA solution used for improved stability New CAD-based methods ü ü CAD based model generation New 1 D piping methods within 2 D/3 D CAD models

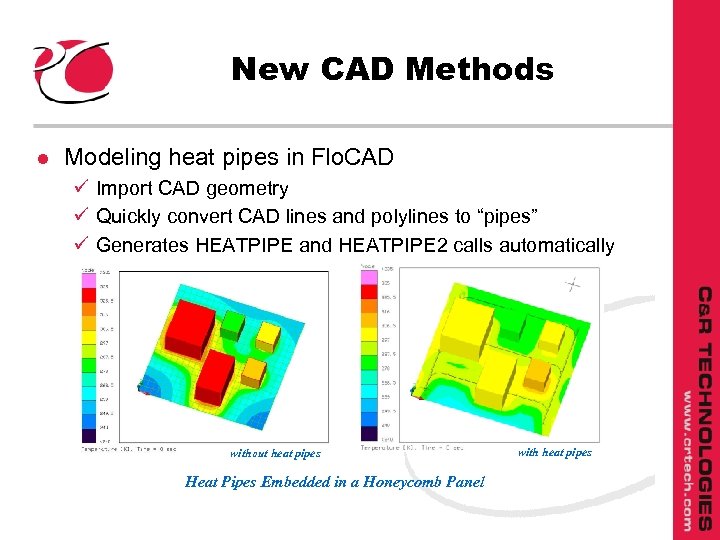

New CAD Methods l Modeling heat pipes in Flo. CAD ü Import CAD geometry ü Quickly convert CAD lines and polylines to “pipes” ü Generates HEATPIPE and HEATPIPE 2 calls automatically without heat pipes Heat Pipes Embedded in a Honeycomb Panel with heat pipes

New CAD Methods l Modeling heat pipes in Flo. CAD ü Import CAD geometry ü Quickly convert CAD lines and polylines to “pipes” ü Generates HEATPIPE and HEATPIPE 2 calls automatically without heat pipes Heat Pipes Embedded in a Honeycomb Panel with heat pipes

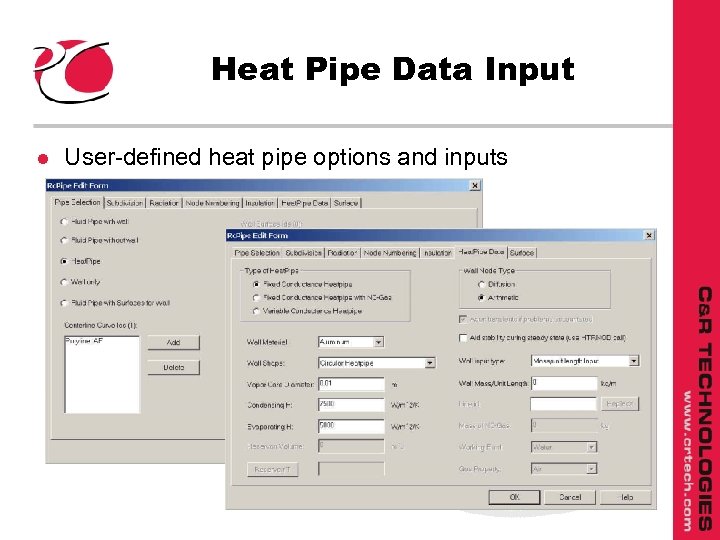

Heat Pipe Data Input l User-defined heat pipe options and inputs

Heat Pipe Data Input l User-defined heat pipe options and inputs

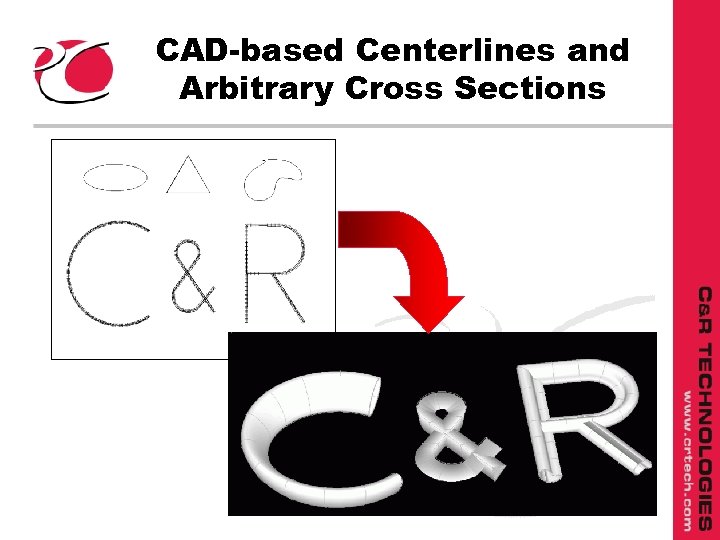

CAD-based Centerlines and Arbitrary Cross Sections

CAD-based Centerlines and Arbitrary Cross Sections

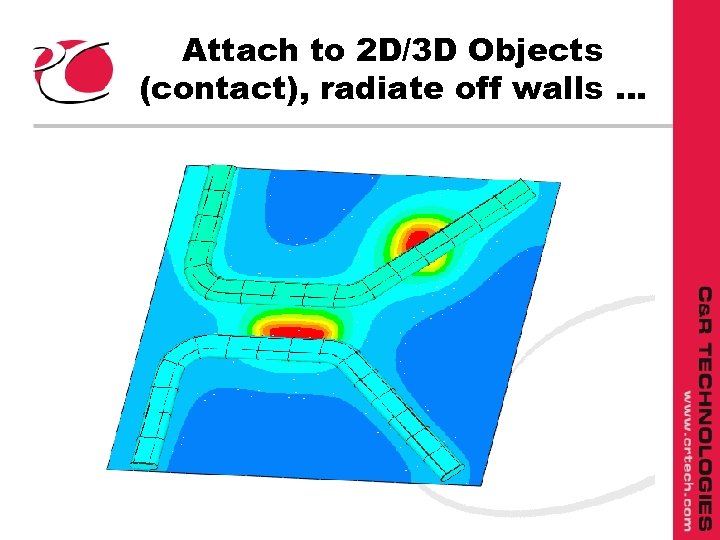

Attach to 2 D/3 D Objects (contact), radiate off walls …

Attach to 2 D/3 D Objects (contact), radiate off walls …

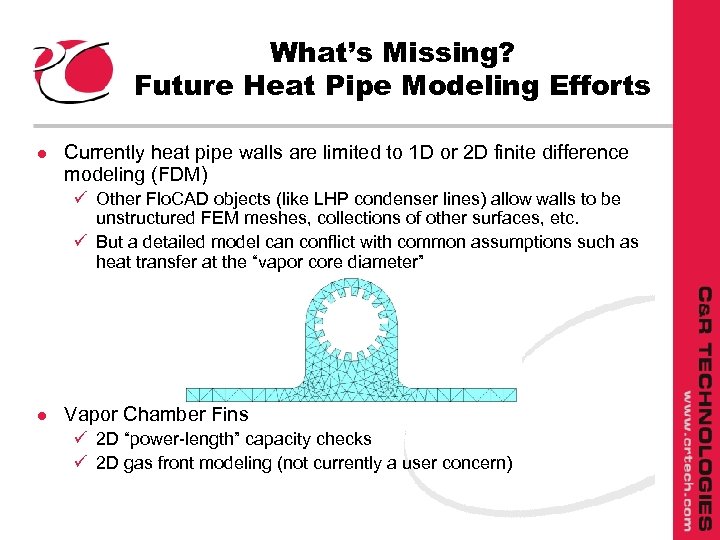

What’s Missing? Future Heat Pipe Modeling Efforts l Currently heat pipe walls are limited to 1 D or 2 D finite difference modeling (FDM) ü Other Flo. CAD objects (like LHP condenser lines) allow walls to be unstructured FEM meshes, collections of other surfaces, etc. ü But a detailed model can conflict with common assumptions such as heat transfer at the “vapor core diameter” l Vapor Chamber Fins ü 2 D “power-length” capacity checks ü 2 D gas front modeling (not currently a user concern)

What’s Missing? Future Heat Pipe Modeling Efforts l Currently heat pipe walls are limited to 1 D or 2 D finite difference modeling (FDM) ü Other Flo. CAD objects (like LHP condenser lines) allow walls to be unstructured FEM meshes, collections of other surfaces, etc. ü But a detailed model can conflict with common assumptions such as heat transfer at the “vapor core diameter” l Vapor Chamber Fins ü 2 D “power-length” capacity checks ü 2 D gas front modeling (not currently a user concern)

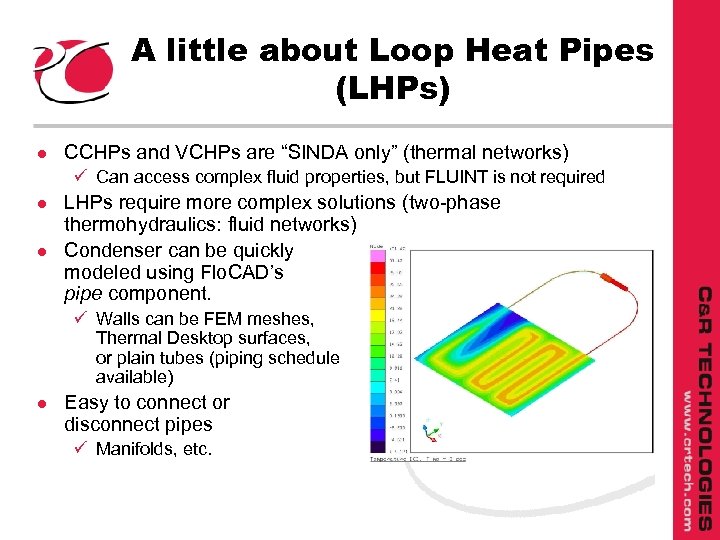

A little about Loop Heat Pipes (LHPs) l CCHPs and VCHPs are “SINDA only” (thermal networks) ü Can access complex fluid properties, but FLUINT is not required l l LHPs require more complex solutions (two-phase thermohydraulics: fluid networks) Condenser can be quickly modeled using Flo. CAD’s pipe component. ü Walls can be FEM meshes, Thermal Desktop surfaces, or plain tubes (piping schedule available) l Easy to connect or disconnect pipes ü Manifolds, etc.

A little about Loop Heat Pipes (LHPs) l CCHPs and VCHPs are “SINDA only” (thermal networks) ü Can access complex fluid properties, but FLUINT is not required l l LHPs require more complex solutions (two-phase thermohydraulics: fluid networks) Condenser can be quickly modeled using Flo. CAD’s pipe component. ü Walls can be FEM meshes, Thermal Desktop surfaces, or plain tubes (piping schedule available) l Easy to connect or disconnect pipes ü Manifolds, etc.

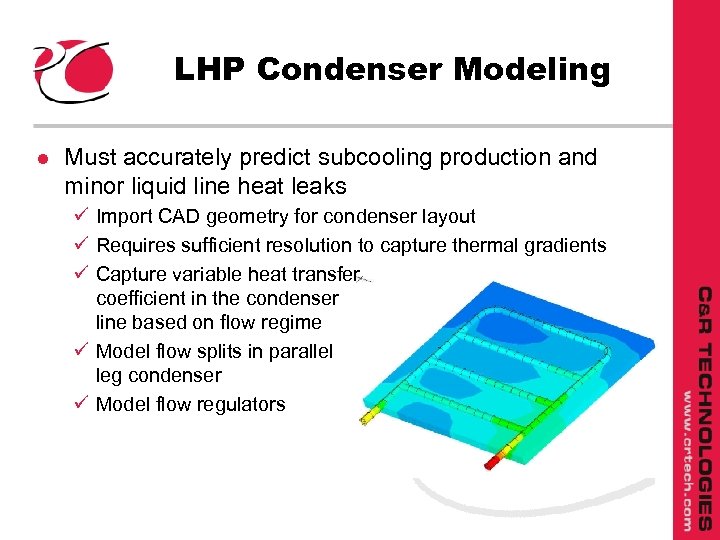

LHP Condenser Modeling l Must accurately predict subcooling production and minor liquid line heat leaks ü Import CAD geometry for condenser layout ü Requires sufficient resolution to capture thermal gradients ü Capture variable heat transfer coefficient in the condenser line based on flow regime ü Model flow splits in parallel leg condenser ü Model flow regulators

LHP Condenser Modeling l Must accurately predict subcooling production and minor liquid line heat leaks ü Import CAD geometry for condenser layout ü Requires sufficient resolution to capture thermal gradients ü Capture variable heat transfer coefficient in the condenser line based on flow regime ü Model flow splits in parallel leg condenser ü Model flow regulators

Conclusions l Heat pipes and LHPs are can be easily modeled at the system-level ü Heat pipes: using modern incarnations of “trusted” methods ü LHPs: using off-the-shelf, validated thermohydraulic solutions l New CAD methods permit models to be developed in a fraction of the time compared with traditional techniques

Conclusions l Heat pipes and LHPs are can be easily modeled at the system-level ü Heat pipes: using modern incarnations of “trusted” methods ü LHPs: using off-the-shelf, validated thermohydraulic solutions l New CAD methods permit models to be developed in a fraction of the time compared with traditional techniques