d72157e437568b4874667a8994281ca1.ppt

- Количество слайдов: 28

FCP-Modify – High level Process & Illustrative Examples Gary Williamson Openreach LLU Technical Development Manager Version 1 – 15 th April 2013

FCP-Modify – High level Process & Illustrative Examples Gary Williamson Openreach LLU Technical Development Manager Version 1 – 15 th April 2013

Introduction § FCP-Modify is about getting more from existing LLU infrastructure through rejuvenation and in-life upgrade: § May be considered for any existing ‘pre-FCP’ Po. P type. § Firm order acceptance is always subject to survey. For some Po. Ps, physical expansion may not be possible due to the presence of surrounding equipment belonging to other customers or BT. Openreach will offer what is possible for customer consideration. § Can help improve service continuity through greater power resilience. § Offers more for the customer – eg ‘Customer Use Cabinet’ (Cu. C). § Lowers DC energy costs due to >95% power efficiency (cf 89%-92%) § Can help customers to prepare for consolidation of their LLU estates.

Introduction § FCP-Modify is about getting more from existing LLU infrastructure through rejuvenation and in-life upgrade: § May be considered for any existing ‘pre-FCP’ Po. P type. § Firm order acceptance is always subject to survey. For some Po. Ps, physical expansion may not be possible due to the presence of surrounding equipment belonging to other customers or BT. Openreach will offer what is possible for customer consideration. § Can help improve service continuity through greater power resilience. § Offers more for the customer – eg ‘Customer Use Cabinet’ (Cu. C). § Lowers DC energy costs due to >95% power efficiency (cf 89%-92%) § Can help customers to prepare for consolidation of their LLU estates.

Key Points 1. It is important that: 1. Prior to APO placement there is a customer / Openreach dialogue to agree and document the customer requirements to be met. 2. Following receipt of an APO in which multiple similar Po. Ps are to be upgraded, the work is undertaken as a programme. This will help to ensure consistency of delivery for the customer. 3. Customers have a person who is the primary point of contact for FCP-Modify orders over the end-to-end delivery process. 2. A ‘rack face’ map will be created for added cabinets and added rack spaces. This will help the required positions of ethernet fibre and equipment to be thought through and defined by the customer. 3. In some cases the APO survey will find that there is insufficient suitable space and/or ac mains power capacity to satisfy the customer’s requirement. Openreach will seek to offer an alternative based on what appears feasible.

Key Points 1. It is important that: 1. Prior to APO placement there is a customer / Openreach dialogue to agree and document the customer requirements to be met. 2. Following receipt of an APO in which multiple similar Po. Ps are to be upgraded, the work is undertaken as a programme. This will help to ensure consistency of delivery for the customer. 3. Customers have a person who is the primary point of contact for FCP-Modify orders over the end-to-end delivery process. 2. A ‘rack face’ map will be created for added cabinets and added rack spaces. This will help the required positions of ethernet fibre and equipment to be thought through and defined by the customer. 3. In some cases the APO survey will find that there is insufficient suitable space and/or ac mains power capacity to satisfy the customer’s requirement. Openreach will seek to offer an alternative based on what appears feasible.

Definitions – Categorisation for APO § FCP-New Build is the provision of a new Po. P in response to a customer order. § FCP-Modify is the means to upgrade an existing ‘pre-FCP’ LLU Po. P such that is subsequently treated as an FCP installation for billing and future upgrade path purposes. § § § Will always include provision of at least one new FCP DC Power System. Will always replace any existing Openreach maintained DC system(s). Is not offered in ‘AC Only’ form. May include additional rack space units (RSUs), Customer Use Cabinets and HDF racks. Is always subject to survey for space and ac power supply capacity reasons. Is always the subject of customer requirements document produced by the Openreach LLU Technical Development Team for customer approval and having an solution code. § FCP-Refresh applies to an existing FCP installation for the incremental increase or decrease of power capacity and/or the provision of additional features within the original physical footprint / expected future maximum power envelope (eg Add an HDF / HDF sub-racks, supply and install a Customer Use Cabinet). Does not entail re-engineering of the Po. P. § FCP-Augment will entail re-engineering of an in-life FCP Po. P to increase its spatial and/or maximum power capacity envelope beyond the original expected future maximum. § LLU-Regrade applies to any Non-FCP LLU Po. P and encompasses changes of a minor engineering nature within the existing design limits of the relevant product type.

Definitions – Categorisation for APO § FCP-New Build is the provision of a new Po. P in response to a customer order. § FCP-Modify is the means to upgrade an existing ‘pre-FCP’ LLU Po. P such that is subsequently treated as an FCP installation for billing and future upgrade path purposes. § § § Will always include provision of at least one new FCP DC Power System. Will always replace any existing Openreach maintained DC system(s). Is not offered in ‘AC Only’ form. May include additional rack space units (RSUs), Customer Use Cabinets and HDF racks. Is always subject to survey for space and ac power supply capacity reasons. Is always the subject of customer requirements document produced by the Openreach LLU Technical Development Team for customer approval and having an solution code. § FCP-Refresh applies to an existing FCP installation for the incremental increase or decrease of power capacity and/or the provision of additional features within the original physical footprint / expected future maximum power envelope (eg Add an HDF / HDF sub-racks, supply and install a Customer Use Cabinet). Does not entail re-engineering of the Po. P. § FCP-Augment will entail re-engineering of an in-life FCP Po. P to increase its spatial and/or maximum power capacity envelope beyond the original expected future maximum. § LLU-Regrade applies to any Non-FCP LLU Po. P and encompasses changes of a minor engineering nature within the existing design limits of the relevant product type.

Customer Requirements Definition The embedded document is the blank template to be completed for each new customer requirement that arises. One document may apply to many or few LLU Po. Ps of a given type. Dialogue with the customer may entail a degree of iteration as actual requirements are confirmed and the associated indicative pricing is understood. Once agreed, a PDF version of the Customer Requirements Definition paper will be stored and made available for use by the Openreach Plan & Build and EIPB teams. Each approved requirement will result in a “Solution Code”. The customer will then be able to place APOs quoting the solution code on one or many occasions.

Customer Requirements Definition The embedded document is the blank template to be completed for each new customer requirement that arises. One document may apply to many or few LLU Po. Ps of a given type. Dialogue with the customer may entail a degree of iteration as actual requirements are confirmed and the associated indicative pricing is understood. Once agreed, a PDF version of the Customer Requirements Definition paper will be stored and made available for use by the Openreach Plan & Build and EIPB teams. Each approved requirement will result in a “Solution Code”. The customer will then be able to place APOs quoting the solution code on one or many occasions.

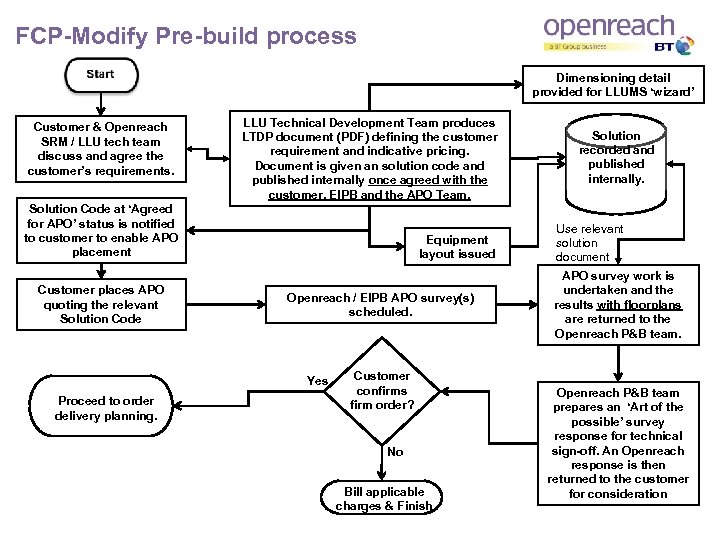

FCP-Modify Pre-build process Dimensioning detail provided for LLUMS ‘wizard’ Customer & Openreach SRM / LLU tech team discuss and agree the customer’s requirements. LLU Technical Development Team produces LTDP document (PDF) defining the customer requirement and indicative pricing. Document is given an solution code and published internally once agreed with the customer, EIPB and the APO Team. Solution Code at ‘Agreed for APO’ status is notified to customer to enable APO placement Customer places APO quoting the relevant Solution Code Equipment layout issued Openreach / EIPB APO survey(s) scheduled. Yes Proceed to order delivery planning. Customer confirms firm order? No Bill applicable charges & Finish Solution recorded and published internally. Use relevant solution document APO survey work is undertaken and the results with floorplans are returned to the Openreach P&B team prepares an ‘Art of the possible’ survey response for technical sign-off. An Openreach response is then returned to the customer for consideration

FCP-Modify Pre-build process Dimensioning detail provided for LLUMS ‘wizard’ Customer & Openreach SRM / LLU tech team discuss and agree the customer’s requirements. LLU Technical Development Team produces LTDP document (PDF) defining the customer requirement and indicative pricing. Document is given an solution code and published internally once agreed with the customer, EIPB and the APO Team. Solution Code at ‘Agreed for APO’ status is notified to customer to enable APO placement Customer places APO quoting the relevant Solution Code Equipment layout issued Openreach / EIPB APO survey(s) scheduled. Yes Proceed to order delivery planning. Customer confirms firm order? No Bill applicable charges & Finish Solution recorded and published internally. Use relevant solution document APO survey work is undertaken and the results with floorplans are returned to the Openreach P&B team prepares an ‘Art of the possible’ survey response for technical sign-off. An Openreach response is then returned to the customer for consideration

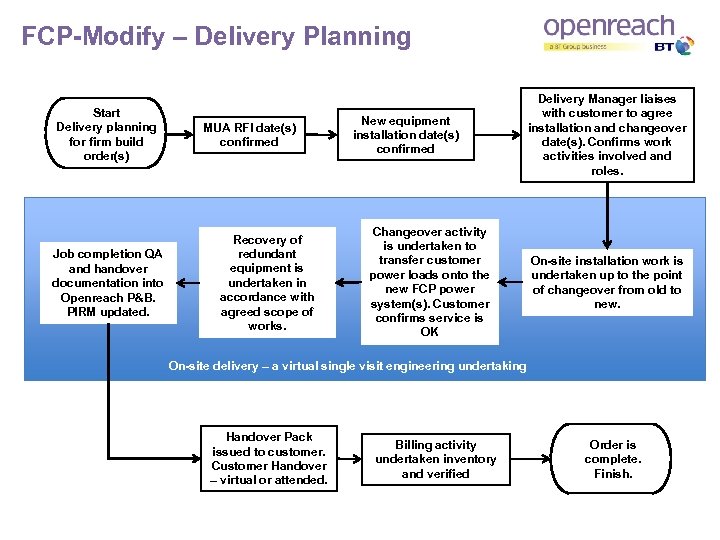

FCP-Modify – Delivery Planning Start Delivery planning for firm build order(s) Job completion QA and handover documentation into Openreach P&B. PIRM updated. MUA RFI date(s) confirmed Recovery of redundant equipment is undertaken in accordance with agreed scope of works. New equipment installation date(s) confirmed Changeover activity is undertaken to transfer customer power loads onto the new FCP power system(s). Customer confirms service is OK Delivery Manager liaises with customer to agree installation and changeover date(s). Confirms work activities involved and roles. On-site installation work is undertaken up to the point of changeover from old to new. On-site delivery – a virtual single visit engineering undertaking Handover Pack issued to customer. Customer Handover – virtual or attended. Billing activity undertaken inventory and verified Order is complete. Finish.

FCP-Modify – Delivery Planning Start Delivery planning for firm build order(s) Job completion QA and handover documentation into Openreach P&B. PIRM updated. MUA RFI date(s) confirmed Recovery of redundant equipment is undertaken in accordance with agreed scope of works. New equipment installation date(s) confirmed Changeover activity is undertaken to transfer customer power loads onto the new FCP power system(s). Customer confirms service is OK Delivery Manager liaises with customer to agree installation and changeover date(s). Confirms work activities involved and roles. On-site installation work is undertaken up to the point of changeover from old to new. On-site delivery – a virtual single visit engineering undertaking Handover Pack issued to customer. Customer Handover – virtual or attended. Billing activity undertaken inventory and verified Order is complete. Finish.

Annex 1 provides examples of possible FCP-Modify requirements – this is not exhaustive

Annex 1 provides examples of possible FCP-Modify requirements – this is not exhaustive

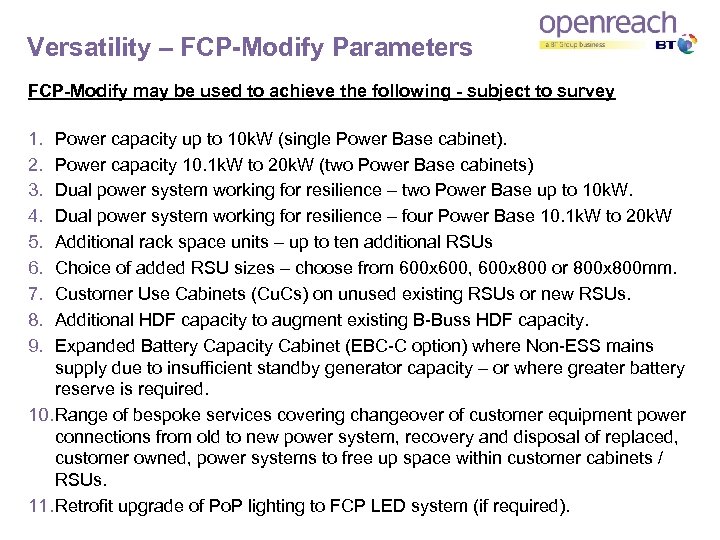

Versatility – FCP-Modify Parameters FCP-Modify may be used to achieve the following - subject to survey 1. 2. 3. 4. 5. 6. 7. 8. 9. Power capacity up to 10 k. W (single Power Base cabinet). Power capacity 10. 1 k. W to 20 k. W (two Power Base cabinets) Dual power system working for resilience – two Power Base up to 10 k. W. Dual power system working for resilience – four Power Base 10. 1 k. W to 20 k. W Additional rack space units – up to ten additional RSUs Choice of added RSU sizes – choose from 600 x 600, 600 x 800 or 800 x 800 mm. Customer Use Cabinets (Cu. Cs) on unused existing RSUs or new RSUs. Additional HDF capacity to augment existing B-Buss HDF capacity. Expanded Battery Capacity Cabinet (EBC-C option) where Non-ESS mains supply due to insufficient standby generator capacity – or where greater battery reserve is required. 10. Range of bespoke services covering changeover of customer equipment power connections from old to new power system, recovery and disposal of replaced, customer owned, power systems to free up space within customer cabinets / RSUs. 11. Retrofit upgrade of Po. P lighting to FCP LED system (if required).

Versatility – FCP-Modify Parameters FCP-Modify may be used to achieve the following - subject to survey 1. 2. 3. 4. 5. 6. 7. 8. 9. Power capacity up to 10 k. W (single Power Base cabinet). Power capacity 10. 1 k. W to 20 k. W (two Power Base cabinets) Dual power system working for resilience – two Power Base up to 10 k. W. Dual power system working for resilience – four Power Base 10. 1 k. W to 20 k. W Additional rack space units – up to ten additional RSUs Choice of added RSU sizes – choose from 600 x 600, 600 x 800 or 800 x 800 mm. Customer Use Cabinets (Cu. Cs) on unused existing RSUs or new RSUs. Additional HDF capacity to augment existing B-Buss HDF capacity. Expanded Battery Capacity Cabinet (EBC-C option) where Non-ESS mains supply due to insufficient standby generator capacity – or where greater battery reserve is required. 10. Range of bespoke services covering changeover of customer equipment power connections from old to new power system, recovery and disposal of replaced, customer owned, power systems to free up space within customer cabinets / RSUs. 11. Retrofit upgrade of Po. P lighting to FCP LED system (if required).

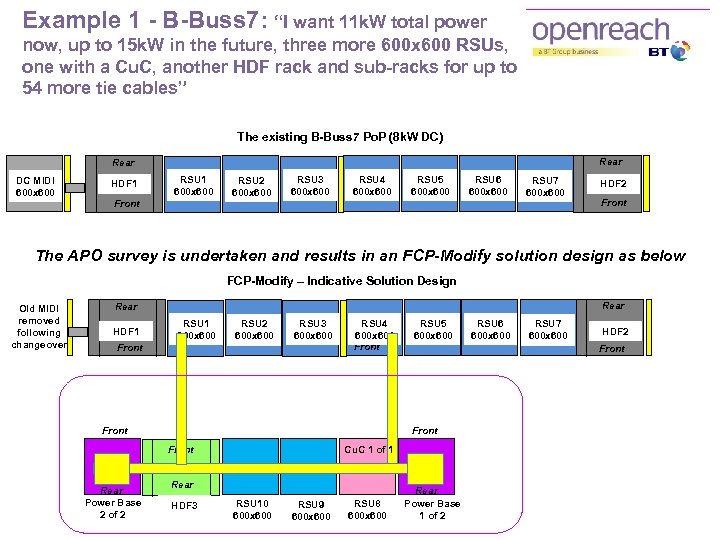

Example 1 - B-Buss 7: “I want 11 k. W total power now, up to 15 k. W in the future, three more 600 x 600 RSUs, one with a Cu. C, another HDF rack and sub-racks for up to 54 more tie cables” The existing B-Buss 7 Po. P (8 k. W DC) Rear DC MIDI 600 x 600 HDF 1 RSU 1 600 x 600 RSU 2 600 x 600 RSU 3 600 x 600 RSU 4 600 x 600 RSU 5 600 x 600 RSU 6 600 x 600 RSU 7 600 x 600 Front HDF 2 Front The APO survey is undertaken and results in an FCP-Modify solution design as below FCP-Modify – Indicative Solution Design Old MIDI removed following changeover Rear HDF 1 RSU 1 600 x 600 RSU 2 600 x 600 RSU 3 600 x 600 Front RSU 4 600 x 600 Front Cu. C 1 of 1 Rear HDF 3 RSU 10 600 x 600 RSU 9 600 x 600 RSU 8 600 x 600 RSU 6 600 x 600 RSU 7 600 x 600 HDF 2 Front Rear Power Base 2 of 2 RSU 5 600 x 600 Rear Power Base 1 of 2

Example 1 - B-Buss 7: “I want 11 k. W total power now, up to 15 k. W in the future, three more 600 x 600 RSUs, one with a Cu. C, another HDF rack and sub-racks for up to 54 more tie cables” The existing B-Buss 7 Po. P (8 k. W DC) Rear DC MIDI 600 x 600 HDF 1 RSU 1 600 x 600 RSU 2 600 x 600 RSU 3 600 x 600 RSU 4 600 x 600 RSU 5 600 x 600 RSU 6 600 x 600 RSU 7 600 x 600 Front HDF 2 Front The APO survey is undertaken and results in an FCP-Modify solution design as below FCP-Modify – Indicative Solution Design Old MIDI removed following changeover Rear HDF 1 RSU 1 600 x 600 RSU 2 600 x 600 RSU 3 600 x 600 Front RSU 4 600 x 600 Front Cu. C 1 of 1 Rear HDF 3 RSU 10 600 x 600 RSU 9 600 x 600 RSU 8 600 x 600 RSU 6 600 x 600 RSU 7 600 x 600 HDF 2 Front Rear Power Base 2 of 2 RSU 5 600 x 600 Rear Power Base 1 of 2

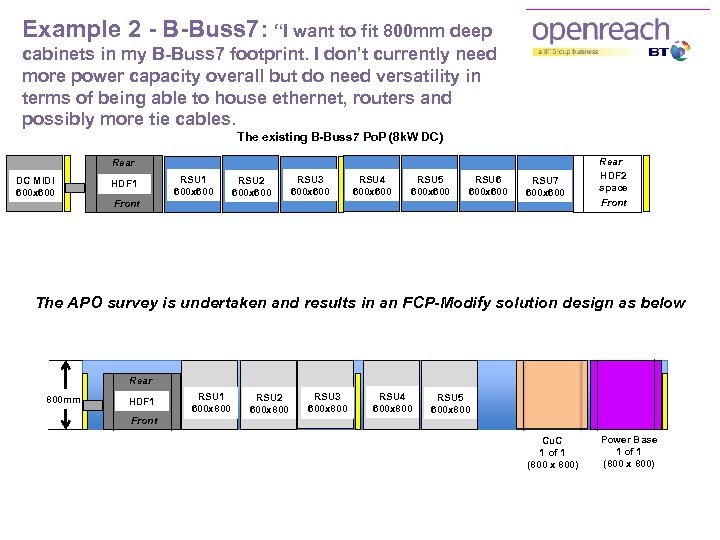

Example 2 - B-Buss 7: “I want to fit 800 mm deep cabinets in my B-Buss 7 footprint. I don’t currently need more power capacity overall but do need versatility in terms of being able to house ethernet, routers and possibly more tie cables. The existing B-Buss 7 Po. P (8 k. W DC) Rear DC MIDI 600 x 600 HDF 1 RSU 1 600 x 600 RSU 2 600 x 600 RSU 3 600 x 600 RSU 4 600 x 600 RSU 5 600 x 600 RSU 6 600 x 600 RSU 7 600 x 600 Front Rear HDF 2 space Front The APO survey is undertaken and results in an FCP-Modify solution design as below Rear 800 mm HDF 1 RSU 1 600 x 800 RSU 2 600 x 800 RSU 3 600 x 800 RSU 4 600 x 800 RSU 5 600 x 800 Front Cu. C 1 of 1 (800 x 800) Power Base 1 of 1 (800 x 800)

Example 2 - B-Buss 7: “I want to fit 800 mm deep cabinets in my B-Buss 7 footprint. I don’t currently need more power capacity overall but do need versatility in terms of being able to house ethernet, routers and possibly more tie cables. The existing B-Buss 7 Po. P (8 k. W DC) Rear DC MIDI 600 x 600 HDF 1 RSU 1 600 x 600 RSU 2 600 x 600 RSU 3 600 x 600 RSU 4 600 x 600 RSU 5 600 x 600 RSU 6 600 x 600 RSU 7 600 x 600 Front Rear HDF 2 space Front The APO survey is undertaken and results in an FCP-Modify solution design as below Rear 800 mm HDF 1 RSU 1 600 x 800 RSU 2 600 x 800 RSU 3 600 x 800 RSU 4 600 x 800 RSU 5 600 x 800 Front Cu. C 1 of 1 (800 x 800) Power Base 1 of 1 (800 x 800)

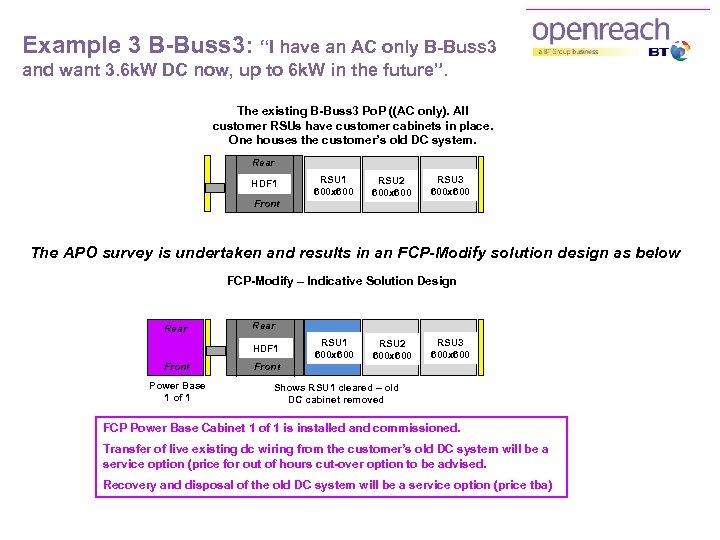

Example 3 B-Buss 3: “I have an AC only B-Buss 3 and want 3. 6 k. W DC now, up to 6 k. W in the future”. The existing B-Buss 3 Po. P ((AC only). All customer RSUs have customer cabinets in place. One houses the customer’s old DC system. Rear HDF 1 RSU 1 600 x 600 RSU 2 600 x 600 RSU 3 600 x 600 Front The APO survey is undertaken and results in an FCP-Modify solution design as below FCP-Modify – Indicative Solution Design Rear HDF 1 Front Power Base 1 of 1 RSU 1 600 x 600 RSU 2 600 x 600 RSU 3 600 x 600 Front Shows RSU 1 cleared – old DC cabinet removed FCP Power Base Cabinet 1 of 1 is installed and commissioned. Transfer of live existing dc wiring from the customer’s old DC system will be a service option (price for out of hours cut-over option to be advised. Recovery and disposal of the old DC system will be a service option (price tba)

Example 3 B-Buss 3: “I have an AC only B-Buss 3 and want 3. 6 k. W DC now, up to 6 k. W in the future”. The existing B-Buss 3 Po. P ((AC only). All customer RSUs have customer cabinets in place. One houses the customer’s old DC system. Rear HDF 1 RSU 1 600 x 600 RSU 2 600 x 600 RSU 3 600 x 600 Front The APO survey is undertaken and results in an FCP-Modify solution design as below FCP-Modify – Indicative Solution Design Rear HDF 1 Front Power Base 1 of 1 RSU 1 600 x 600 RSU 2 600 x 600 RSU 3 600 x 600 Front Shows RSU 1 cleared – old DC cabinet removed FCP Power Base Cabinet 1 of 1 is installed and commissioned. Transfer of live existing dc wiring from the customer’s old DC system will be a service option (price for out of hours cut-over option to be advised. Recovery and disposal of the old DC system will be a service option (price tba)

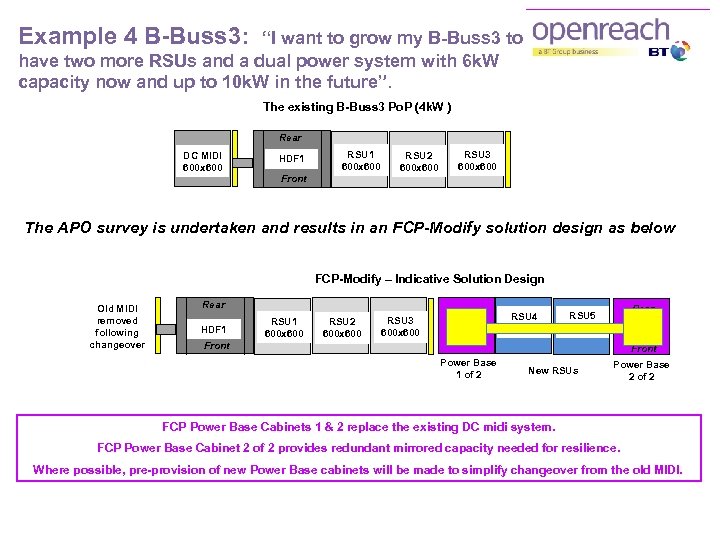

Example 4 B-Buss 3: “I want to grow my B-Buss 3 to have two more RSUs and a dual power system with 6 k. W capacity now and up to 10 k. W in the future”. The existing B-Buss 3 Po. P (4 k. W ) Rear DC MIDI 600 x 600 HDF 1 RSU 1 600 x 600 RSU 2 600 x 600 RSU 3 600 x 600 Front The APO survey is undertaken and results in an FCP-Modify solution design as below FCP-Modify – Indicative Solution Design Old MIDI removed following changeover Rear HDF 1 RSU 1 600 x 600 RSU 2 600 x 600 RSU 4 600 x 600 RSU 3 600 x 600 Rear RSU 5 600 x 600 Front Power Base 1 of 2 New RSUs Power Base 2 of 2 FCP Power Base Cabinets 1 & 2 replace the existing DC midi system. FCP Power Base Cabinet 2 of 2 provides redundant mirrored capacity needed for resilience. Where possible, pre-provision of new Power Base cabinets will be made to simplify changeover from the old MIDI.

Example 4 B-Buss 3: “I want to grow my B-Buss 3 to have two more RSUs and a dual power system with 6 k. W capacity now and up to 10 k. W in the future”. The existing B-Buss 3 Po. P (4 k. W ) Rear DC MIDI 600 x 600 HDF 1 RSU 1 600 x 600 RSU 2 600 x 600 RSU 3 600 x 600 Front The APO survey is undertaken and results in an FCP-Modify solution design as below FCP-Modify – Indicative Solution Design Old MIDI removed following changeover Rear HDF 1 RSU 1 600 x 600 RSU 2 600 x 600 RSU 4 600 x 600 RSU 3 600 x 600 Rear RSU 5 600 x 600 Front Power Base 1 of 2 New RSUs Power Base 2 of 2 FCP Power Base Cabinets 1 & 2 replace the existing DC midi system. FCP Power Base Cabinet 2 of 2 provides redundant mirrored capacity needed for resilience. Where possible, pre-provision of new Power Base cabinets will be made to simplify changeover from the old MIDI.

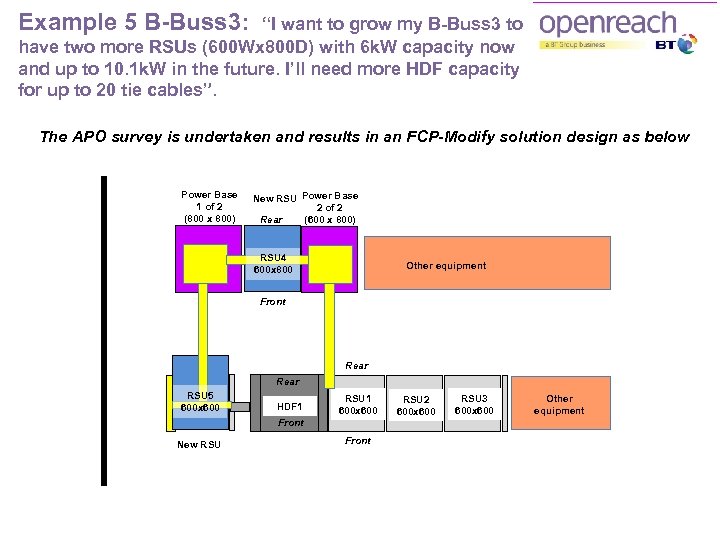

Example 5 B-Buss 3: “I want to grow my B-Buss 3 to have two more RSUs (600 Wx 800 D) with 6 k. W capacity now and up to 10. 1 k. W in the future. I’ll need more HDF capacity for up to 20 tie cables”. The APO survey is undertaken and results in an FCP-Modify solution design as below Power Base 1 of 2 (800 x 800) New RSU Power Base 2 of 2 (600 x 800) Rear RSU 4 600 x 800 Other equipment Front Rear RSU 5 600 x 600 HDF 1 RSU 1 600 x 600 Front New RSU Front RSU 2 600 x 600 RSU 3 600 x 600 Other equipment

Example 5 B-Buss 3: “I want to grow my B-Buss 3 to have two more RSUs (600 Wx 800 D) with 6 k. W capacity now and up to 10. 1 k. W in the future. I’ll need more HDF capacity for up to 20 tie cables”. The APO survey is undertaken and results in an FCP-Modify solution design as below Power Base 1 of 2 (800 x 800) New RSU Power Base 2 of 2 (600 x 800) Rear RSU 4 600 x 800 Other equipment Front Rear RSU 5 600 x 600 HDF 1 RSU 1 600 x 600 Front New RSU Front RSU 2 600 x 600 RSU 3 600 x 600 Other equipment

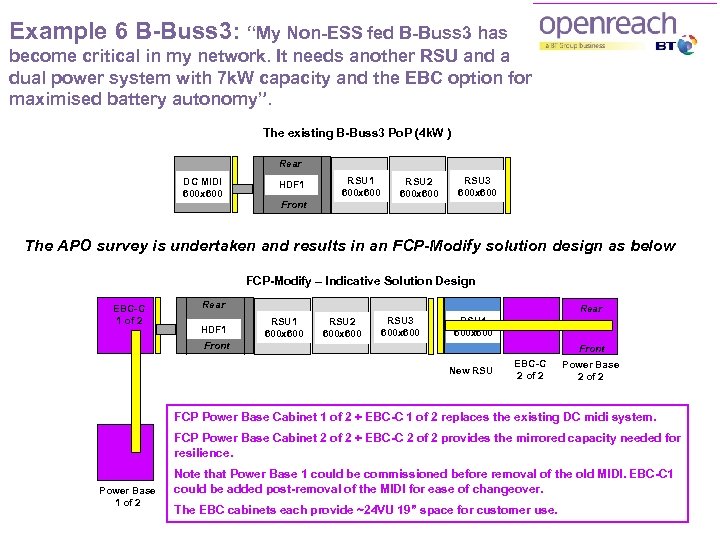

Example 6 B-Buss 3: “My Non-ESS fed B-Buss 3 has become critical in my network. It needs another RSU and a dual power system with 7 k. W capacity and the EBC option for maximised battery autonomy”. The existing B-Buss 3 Po. P (4 k. W ) Rear DC MIDI 600 x 600 HDF 1 RSU 1 600 x 600 RSU 2 600 x 600 RSU 3 600 x 600 Front The APO survey is undertaken and results in an FCP-Modify solution design as below FCP-Modify – Indicative Solution Design EBC-C 1 of 2 Rear HDF 1 Rear RSU 1 600 x 600 RSU 2 600 x 600 RSU 3 600 x 600 RSU 4 600 x 600 Front New RSU EBC-C 2 of 2 Power Base 2 of 2 FCP Power Base Cabinet 1 of 2 + EBC-C 1 of 2 replaces the existing DC midi system. FCP Power Base Cabinet 2 of 2 + EBC-C 2 of 2 provides the mirrored capacity needed for resilience. Power Base 1 of 2 Note that Power Base 1 could be commissioned before removal of the old MIDI. EBC-C 1 could be added post-removal of the MIDI for ease of changeover. The EBC cabinets each provide ~24 VU 19” space for customer use.

Example 6 B-Buss 3: “My Non-ESS fed B-Buss 3 has become critical in my network. It needs another RSU and a dual power system with 7 k. W capacity and the EBC option for maximised battery autonomy”. The existing B-Buss 3 Po. P (4 k. W ) Rear DC MIDI 600 x 600 HDF 1 RSU 1 600 x 600 RSU 2 600 x 600 RSU 3 600 x 600 Front The APO survey is undertaken and results in an FCP-Modify solution design as below FCP-Modify – Indicative Solution Design EBC-C 1 of 2 Rear HDF 1 Rear RSU 1 600 x 600 RSU 2 600 x 600 RSU 3 600 x 600 RSU 4 600 x 600 Front New RSU EBC-C 2 of 2 Power Base 2 of 2 FCP Power Base Cabinet 1 of 2 + EBC-C 1 of 2 replaces the existing DC midi system. FCP Power Base Cabinet 2 of 2 + EBC-C 2 of 2 provides the mirrored capacity needed for resilience. Power Base 1 of 2 Note that Power Base 1 could be commissioned before removal of the old MIDI. EBC-C 1 could be added post-removal of the MIDI for ease of changeover. The EBC cabinets each provide ~24 VU 19” space for customer use.

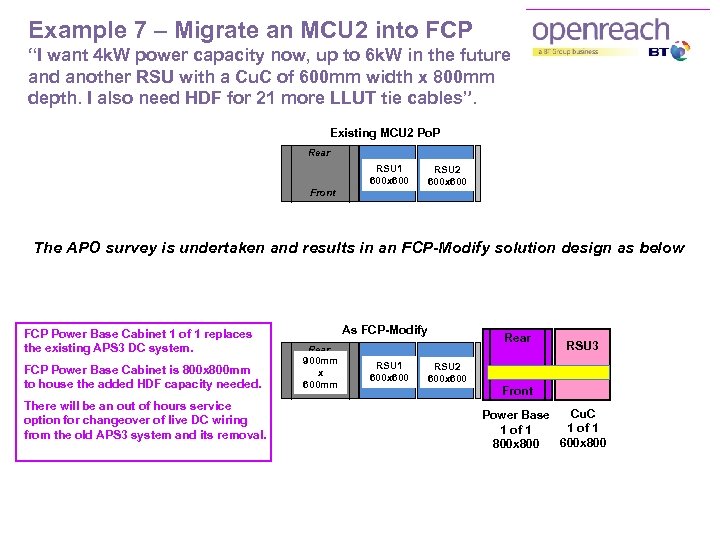

Example 7 – Migrate an MCU 2 into FCP “I want 4 k. W power capacity now, up to 6 k. W in the future and another RSU with a Cu. C of 600 mm width x 800 mm depth. I also need HDF for 21 more LLUT tie cables”. Existing MCU 2 Po. P Rear RSU 1 600 x 600 RSU 2 600 x 600 Front The APO survey is undertaken and results in an FCP-Modify solution design as below FCP Power Base Cabinet 1 of 1 replaces the existing APS 3 DC system. FCP Power Base Cabinet is 800 x 800 mm to house the added HDF capacity needed. There will be an out of hours service option for changeover of live DC wiring from the old APS 3 system and its removal. As FCP-Modify Rear 900 mm x 600 mm Front RSU 1 600 x 600 Rear RSU 3 RSU 2 600 x 600 Front Cu. C Power Base 1 of 1 600 x 800 x 800

Example 7 – Migrate an MCU 2 into FCP “I want 4 k. W power capacity now, up to 6 k. W in the future and another RSU with a Cu. C of 600 mm width x 800 mm depth. I also need HDF for 21 more LLUT tie cables”. Existing MCU 2 Po. P Rear RSU 1 600 x 600 RSU 2 600 x 600 Front The APO survey is undertaken and results in an FCP-Modify solution design as below FCP Power Base Cabinet 1 of 1 replaces the existing APS 3 DC system. FCP Power Base Cabinet is 800 x 800 mm to house the added HDF capacity needed. There will be an out of hours service option for changeover of live DC wiring from the old APS 3 system and its removal. As FCP-Modify Rear 900 mm x 600 mm Front RSU 1 600 x 600 Rear RSU 3 RSU 2 600 x 600 Front Cu. C Power Base 1 of 1 600 x 800 x 800

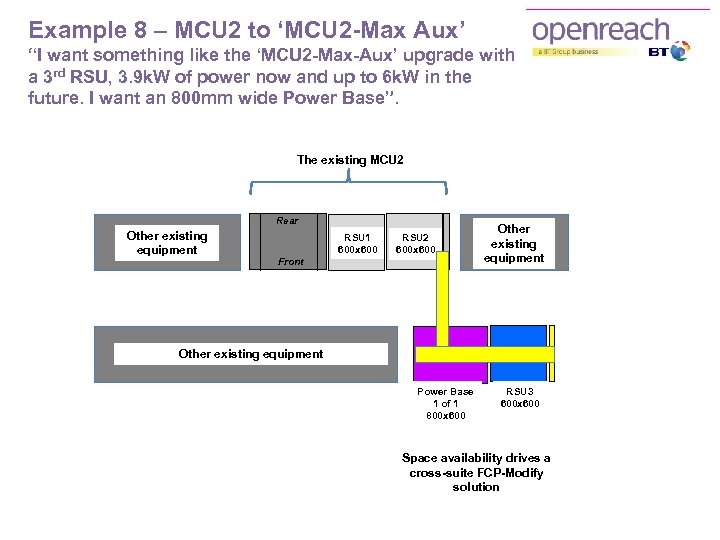

Example 8 – MCU 2 to ‘MCU 2 -Max Aux’ “I want something like the ‘MCU 2 -Max-Aux’ upgrade with a 3 rd RSU, 3. 9 k. W of power now and up to 6 k. W in the future. I want an 800 mm wide Power Base”. The existing MCU 2 Rear Other existing equipment RSU 1 600 x 600 RSU 2 600 x 600 Front Other existing equipment Power Base 1 of 1 800 x 600 RSU 3 600 x 600 Space availability drives a cross-suite FCP-Modify solution

Example 8 – MCU 2 to ‘MCU 2 -Max Aux’ “I want something like the ‘MCU 2 -Max-Aux’ upgrade with a 3 rd RSU, 3. 9 k. W of power now and up to 6 k. W in the future. I want an 800 mm wide Power Base”. The existing MCU 2 Rear Other existing equipment RSU 1 600 x 600 RSU 2 600 x 600 Front Other existing equipment Power Base 1 of 1 800 x 600 RSU 3 600 x 600 Space availability drives a cross-suite FCP-Modify solution

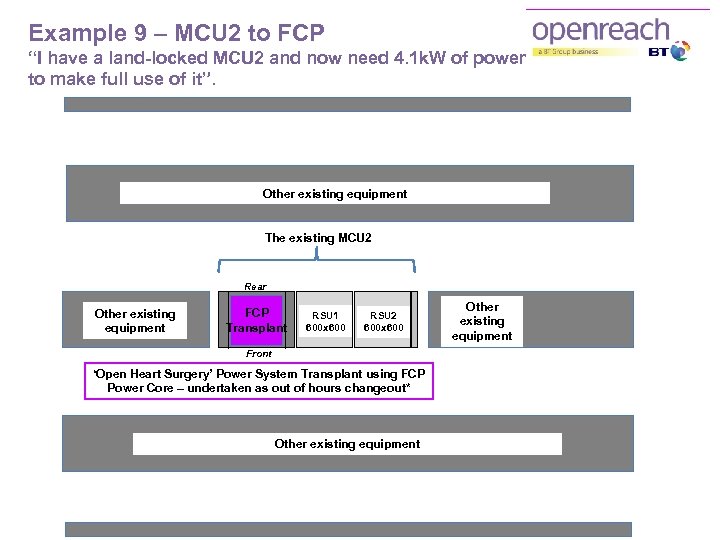

Example 9 – MCU 2 to FCP “I have a land-locked MCU 2 and now need 4. 1 k. W of power to make full use of it”. Other existing equipment The existing MCU 2 Rear Other existing equipment FCP Transplant RSU 1 600 x 600 RSU 2 600 x 600 Front ‘Open Heart Surgery’ Power System Transplant using FCP Power Core – undertaken as out of hours changeout* Other existing equipment

Example 9 – MCU 2 to FCP “I have a land-locked MCU 2 and now need 4. 1 k. W of power to make full use of it”. Other existing equipment The existing MCU 2 Rear Other existing equipment FCP Transplant RSU 1 600 x 600 RSU 2 600 x 600 Front ‘Open Heart Surgery’ Power System Transplant using FCP Power Core – undertaken as out of hours changeout* Other existing equipment

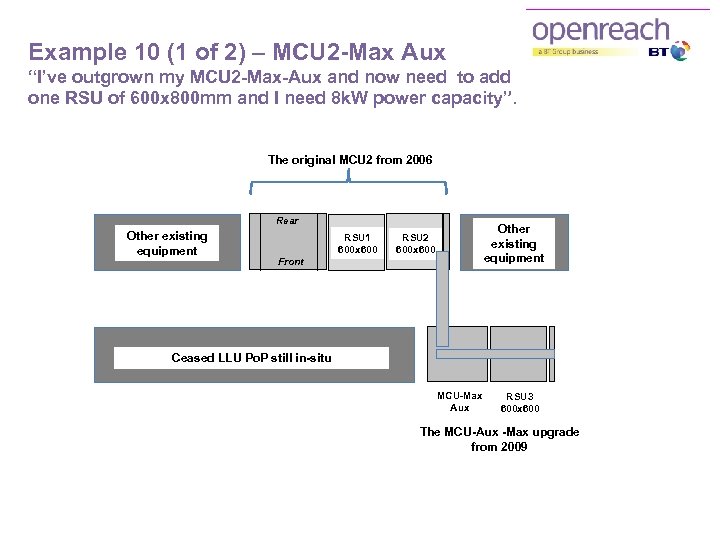

Example 10 (1 of 2) – MCU 2 -Max Aux “I’ve outgrown my MCU 2 -Max-Aux and now need to add one RSU of 600 x 800 mm and I need 8 k. W power capacity”. The original MCU 2 from 2006 Rear Other existing equipment RSU 1 600 x 600 Other existing equipment RSU 2 600 x 600 Front Ceased LLU Po. P still in-situ MCU-Max Aux RSU 3 600 x 600 The MCU-Aux -Max upgrade from 2009

Example 10 (1 of 2) – MCU 2 -Max Aux “I’ve outgrown my MCU 2 -Max-Aux and now need to add one RSU of 600 x 800 mm and I need 8 k. W power capacity”. The original MCU 2 from 2006 Rear Other existing equipment RSU 1 600 x 600 Other existing equipment RSU 2 600 x 600 Front Ceased LLU Po. P still in-situ MCU-Max Aux RSU 3 600 x 600 The MCU-Aux -Max upgrade from 2009

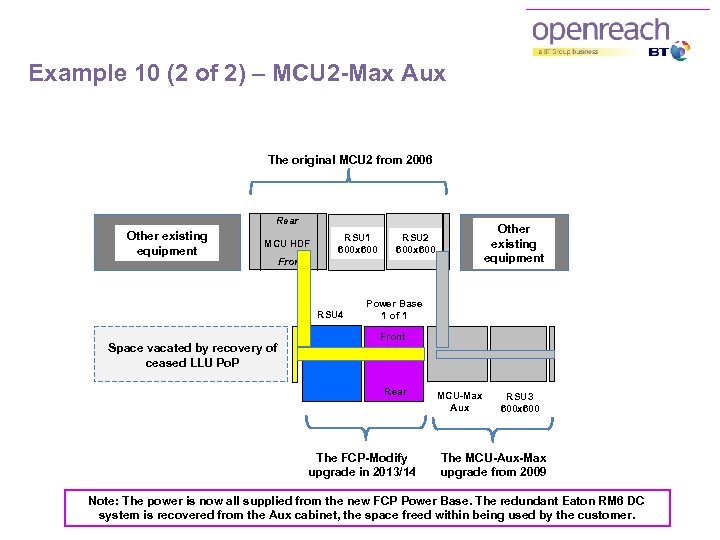

Example 10 (2 of 2) – MCU 2 -Max Aux The original MCU 2 from 2006 Rear Other existing equipment MCU HDF RSU 1 600 x 600 Front RSU 4 Space vacated by recovery of ceased LLU Po. P Other existing equipment RSU 2 600 x 600 Power Base 1 of 1 Front Rear The FCP-Modify upgrade in 2013/14 MCU-Max Aux RSU 3 600 x 600 The MCU-Aux-Max upgrade from 2009 Note: The power is now all supplied from the new FCP Power Base. The redundant Eaton RM 6 DC system is recovered from the Aux cabinet, the space freed within being used by the customer.

Example 10 (2 of 2) – MCU 2 -Max Aux The original MCU 2 from 2006 Rear Other existing equipment MCU HDF RSU 1 600 x 600 Front RSU 4 Space vacated by recovery of ceased LLU Po. P Other existing equipment RSU 2 600 x 600 Power Base 1 of 1 Front Rear The FCP-Modify upgrade in 2013/14 MCU-Max Aux RSU 3 600 x 600 The MCU-Aux-Max upgrade from 2009 Note: The power is now all supplied from the new FCP Power Base. The redundant Eaton RM 6 DC system is recovered from the Aux cabinet, the space freed within being used by the customer.

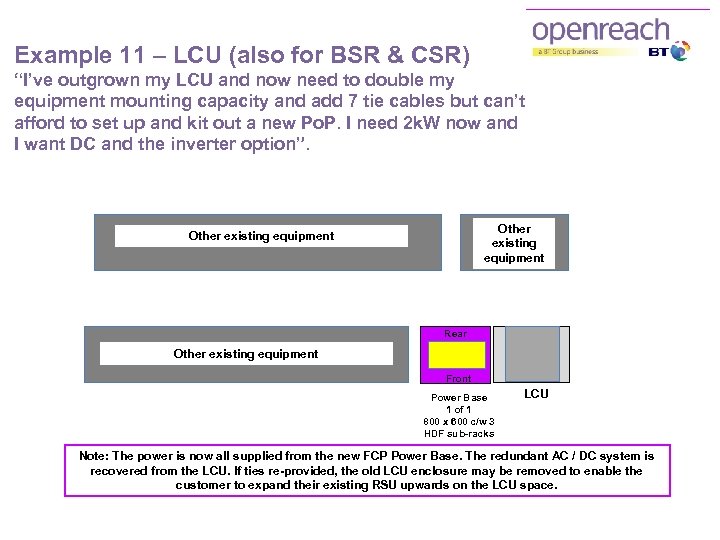

Example 11 – LCU (also for BSR & CSR) “I’ve outgrown my LCU and now need to double my equipment mounting capacity and add 7 tie cables but can’t afford to set up and kit out a new Po. P. I need 2 k. W now and I want DC and the inverter option”. Other existing equipment Rear Other existing equipment Front Power Base 1 of 1 800 x 600 c/w 3 HDF sub-racks LCU Note: The power is now all supplied from the new FCP Power Base. The redundant AC / DC system is recovered from the LCU. If ties re-provided, the old LCU enclosure may be removed to enable the customer to expand their existing RSU upwards on the LCU space.

Example 11 – LCU (also for BSR & CSR) “I’ve outgrown my LCU and now need to double my equipment mounting capacity and add 7 tie cables but can’t afford to set up and kit out a new Po. P. I need 2 k. W now and I want DC and the inverter option”. Other existing equipment Rear Other existing equipment Front Power Base 1 of 1 800 x 600 c/w 3 HDF sub-racks LCU Note: The power is now all supplied from the new FCP Power Base. The redundant AC / DC system is recovered from the LCU. If ties re-provided, the old LCU enclosure may be removed to enable the customer to expand their existing RSU upwards on the LCU space.

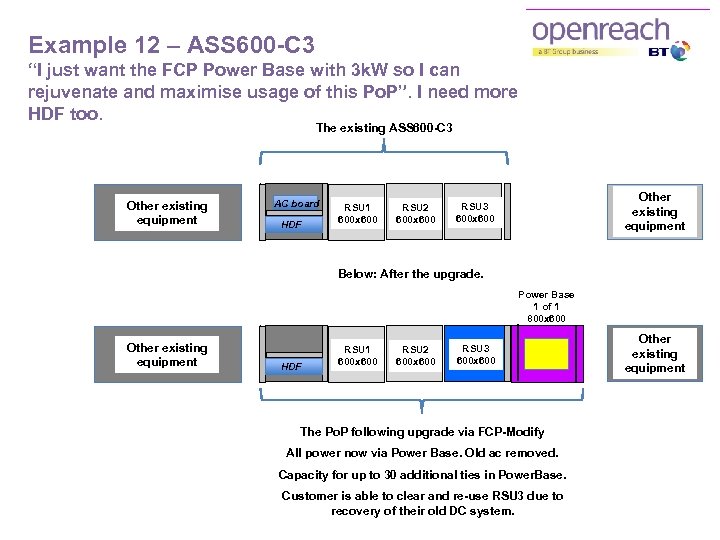

Example 12 – ASS 600 -C 3 “I just want the FCP Power Base with 3 k. W so I can rejuvenate and maximise usage of this Po. P”. I need more HDF too. The existing ASS 600 -C 3 Other existing equipment AC board HDF RSU 1 600 x 600 RSU 2 600 x 600 Other existing equipment RSU 3 600 x 600 Below: After the upgrade. Power Base 1 of 1 800 x 600 Other existing equipment HDF RSU 1 600 x 600 RSU 2 600 x 600 RSU 3 600 x 600 The Po. P following upgrade via FCP-Modify All power now via Power Base. Old ac removed. Capacity for up to 30 additional ties in Power. Base. Customer is able to clear and re-use RSU 3 due to recovery of their old DC system. Other existing equipment

Example 12 – ASS 600 -C 3 “I just want the FCP Power Base with 3 k. W so I can rejuvenate and maximise usage of this Po. P”. I need more HDF too. The existing ASS 600 -C 3 Other existing equipment AC board HDF RSU 1 600 x 600 RSU 2 600 x 600 Other existing equipment RSU 3 600 x 600 Below: After the upgrade. Power Base 1 of 1 800 x 600 Other existing equipment HDF RSU 1 600 x 600 RSU 2 600 x 600 RSU 3 600 x 600 The Po. P following upgrade via FCP-Modify All power now via Power Base. Old ac removed. Capacity for up to 30 additional ties in Power. Base. Customer is able to clear and re-use RSU 3 due to recovery of their old DC system. Other existing equipment

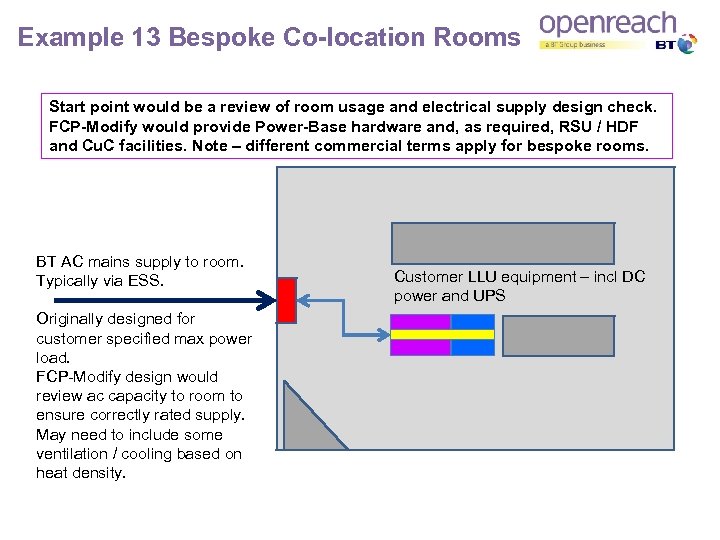

Example 13 Bespoke Co-location Rooms Start point would be a review of room usage and electrical supply design check. FCP-Modify would provide Power-Base hardware and, as required, RSU / HDF and Cu. C facilities. Note – different commercial terms apply for bespoke rooms. BT AC mains supply to room. Typically via ESS. Originally designed for customer specified max power load. FCP-Modify design would review ac capacity to room to ensure correctly rated supply. May need to include some ventilation / cooling based on heat density. Customer LLU equipment – incl DC power and UPS

Example 13 Bespoke Co-location Rooms Start point would be a review of room usage and electrical supply design check. FCP-Modify would provide Power-Base hardware and, as required, RSU / HDF and Cu. C facilities. Note – different commercial terms apply for bespoke rooms. BT AC mains supply to room. Typically via ESS. Originally designed for customer specified max power load. FCP-Modify design would review ac capacity to room to ensure correctly rated supply. May need to include some ventilation / cooling based on heat density. Customer LLU equipment – incl DC power and UPS

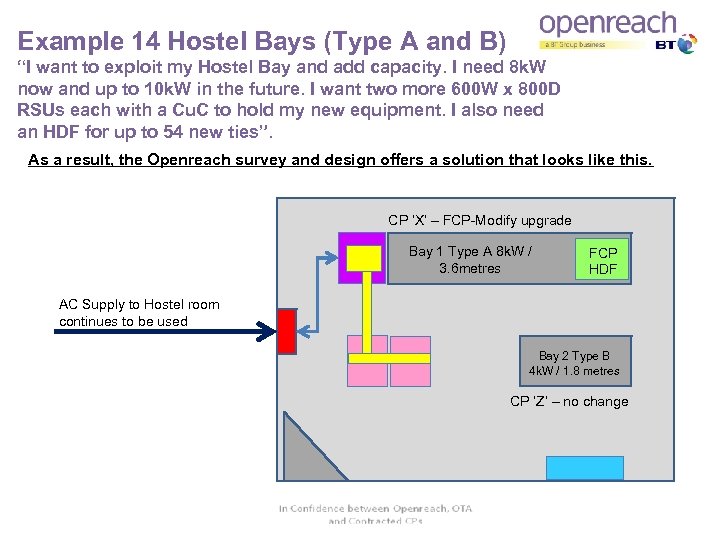

Example 14 Hostel Bays (Type A and B) “I want to exploit my Hostel Bay and add capacity. I need 8 k. W now and up to 10 k. W in the future. I want two more 600 W x 800 D RSUs each with a Cu. C to hold my new equipment. I also need an HDF for up to 54 new ties”. As a result, the Openreach survey and design offers a solution that looks like this. CP ‘X’ – FCP-Modify upgrade Bay 1 Type A 8 k. W / 3. 6 metres FCP HDF AC Supply to Hostel room continues to be used Bay 2 Type B 4 k. W / 1. 8 metres CP ‘Z’ – no change

Example 14 Hostel Bays (Type A and B) “I want to exploit my Hostel Bay and add capacity. I need 8 k. W now and up to 10 k. W in the future. I want two more 600 W x 800 D RSUs each with a Cu. C to hold my new equipment. I also need an HDF for up to 54 new ties”. As a result, the Openreach survey and design offers a solution that looks like this. CP ‘X’ – FCP-Modify upgrade Bay 1 Type A 8 k. W / 3. 6 metres FCP HDF AC Supply to Hostel room continues to be used Bay 2 Type B 4 k. W / 1. 8 metres CP ‘Z’ – no change

Annex 2 ‘FCP-Refresh’ high level APO process ‘FCP-Augment’ ‘LLU Regrade’ Further work is to be undertaken on these.

Annex 2 ‘FCP-Refresh’ high level APO process ‘FCP-Augment’ ‘LLU Regrade’ Further work is to be undertaken on these.

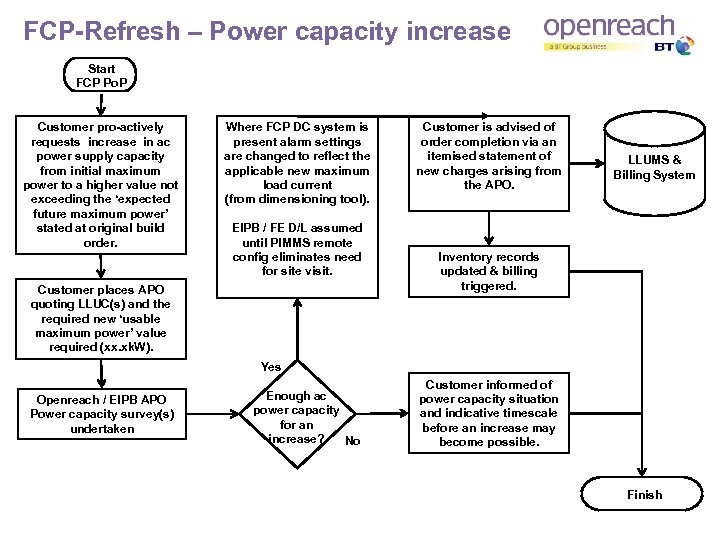

FCP-Refresh – Power capacity increase Start FCP Po. P Customer pro-actively requests increase in ac power supply capacity from initial maximum power to a higher value not exceeding the ‘expected future maximum power’ stated at original build order. Where FCP DC system is present alarm settings are changed to reflect the applicable new maximum load current (from dimensioning tool). EIPB / FE D/L assumed until PIMMS remote config eliminates need for site visit. Customer places APO quoting LLUC(s) and the required new ‘usable maximum power’ value required (xx. xk. W). Customer is advised of order completion via an itemised statement of new charges arising from the APO. LLUMS & Billing System Inventory records updated & billing triggered. Yes Openreach / EIPB APO Power capacity survey(s) undertaken Enough ac power capacity for an increase? No Customer informed of power capacity situation and indicative timescale before an increase may become possible. Finish

FCP-Refresh – Power capacity increase Start FCP Po. P Customer pro-actively requests increase in ac power supply capacity from initial maximum power to a higher value not exceeding the ‘expected future maximum power’ stated at original build order. Where FCP DC system is present alarm settings are changed to reflect the applicable new maximum load current (from dimensioning tool). EIPB / FE D/L assumed until PIMMS remote config eliminates need for site visit. Customer places APO quoting LLUC(s) and the required new ‘usable maximum power’ value required (xx. xk. W). Customer is advised of order completion via an itemised statement of new charges arising from the APO. LLUMS & Billing System Inventory records updated & billing triggered. Yes Openreach / EIPB APO Power capacity survey(s) undertaken Enough ac power capacity for an increase? No Customer informed of power capacity situation and indicative timescale before an increase may become possible. Finish

FCP-Augment (applies to in-life FCP Po. P that originated as a new build or via FCP-Modify). • Process would be similar to FCP-Modify and begin with a customer requirements definition exercise to ensure that the need / indicative pricing is documented and agreed. • APO placed as the customer’s authority to proceed. • APO survey would be undertaken for each Po. P in scope. • Response to customer based on ‘art of the possible’. • Customer firm order decision. • Delivery planning, date setting, installation, QA. • Handover to customer. • Billing & inventory.

FCP-Augment (applies to in-life FCP Po. P that originated as a new build or via FCP-Modify). • Process would be similar to FCP-Modify and begin with a customer requirements definition exercise to ensure that the need / indicative pricing is documented and agreed. • APO placed as the customer’s authority to proceed. • APO survey would be undertaken for each Po. P in scope. • Response to customer based on ‘art of the possible’. • Customer firm order decision. • Delivery planning, date setting, installation, QA. • Handover to customer. • Billing & inventory.

LLU-Regrades (‘Minor-works’) In scope: - MCU-Max & Aux: 4. 95 k. W to 6. 6 k. W (rectifier infill) B-Buss 3: 4. 4 k. W to 6. 6 k. W (rectifier / battery infill) Additional DC sub-distribution connected to existing DC system Additional AC sub-distribution connected into existing AC system. MCU 1 to MCU 2 (+1 rectifier & +5 HDF sub-racks + RSU#2 if space). B-Buss 7 Supplementary HDF rack B-Buss 7 to B-Buss 3 downgrade Inverter tower Non-ESS to ESS transfer Retrofit sub-meter. HDF sub-rack provision into available space in or adjacent to the Po. P. Note: The above is not and exhaustive listing – further low-capex re-grade solutions of a minor engineering nature may be added.

LLU-Regrades (‘Minor-works’) In scope: - MCU-Max & Aux: 4. 95 k. W to 6. 6 k. W (rectifier infill) B-Buss 3: 4. 4 k. W to 6. 6 k. W (rectifier / battery infill) Additional DC sub-distribution connected to existing DC system Additional AC sub-distribution connected into existing AC system. MCU 1 to MCU 2 (+1 rectifier & +5 HDF sub-racks + RSU#2 if space). B-Buss 7 Supplementary HDF rack B-Buss 7 to B-Buss 3 downgrade Inverter tower Non-ESS to ESS transfer Retrofit sub-meter. HDF sub-rack provision into available space in or adjacent to the Po. P. Note: The above is not and exhaustive listing – further low-capex re-grade solutions of a minor engineering nature may be added.