53302321e490f7e081f5743308f35f5e.ppt

- Количество слайдов: 18

Fast Casters - Formal Design Review March 2, 2006 Rene Chen Byron Hsu Kimberly Kam Kelsey Vandermeulen Lisa Witmer 3/2/2006

Fast Casters - Formal Design Review March 2, 2006 Rene Chen Byron Hsu Kimberly Kam Kelsey Vandermeulen Lisa Witmer 3/2/2006

Brief Update n Speed Skate Blade n n Titanium blade will likely shatter Final Decision n 3/2/2006 3 D printed bone scaffold 2

Brief Update n Speed Skate Blade n n Titanium blade will likely shatter Final Decision n 3/2/2006 3 D printed bone scaffold 2

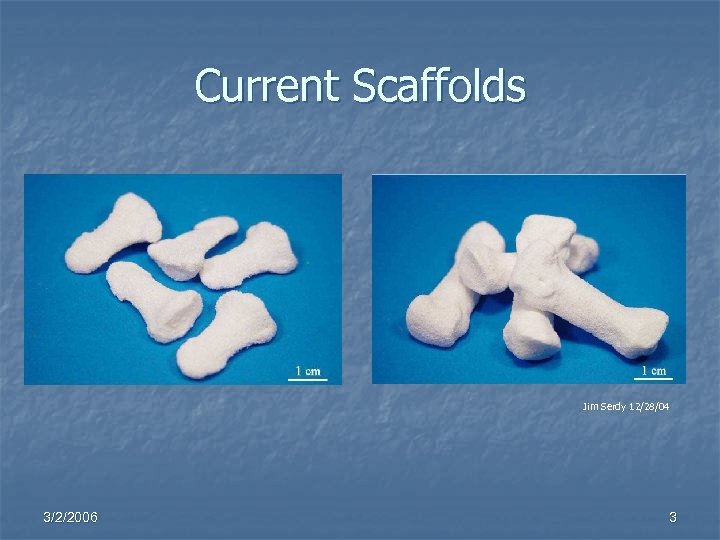

Current Scaffolds Jim Serdy 12/28/04 3/2/2006 3

Current Scaffolds Jim Serdy 12/28/04 3/2/2006 3

Project Goal Improve the mechanical properties of bone scaffolds through optimizing the composition of the printing powder 3/2/2006 4

Project Goal Improve the mechanical properties of bone scaffolds through optimizing the composition of the printing powder 3/2/2006 4

Desired Scaffold Properties: Biocompatibility n Materials candidates PLGA – poly lactic acid-co-glycolic acid n PCL – poly caprolactone n TCP – tricalcium phosphate n HA – hydroxyapatite n 3/2/2006 5

Desired Scaffold Properties: Biocompatibility n Materials candidates PLGA – poly lactic acid-co-glycolic acid n PCL – poly caprolactone n TCP – tricalcium phosphate n HA – hydroxyapatite n 3/2/2006 5

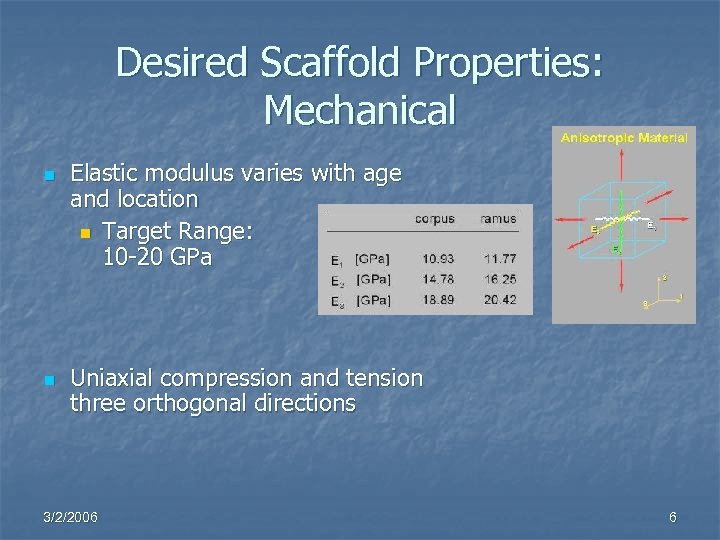

Desired Scaffold Properties: Mechanical n n Elastic modulus varies with age and location n Target Range: 10 -20 GPa Uniaxial compression and tension three orthogonal directions 3/2/2006 6

Desired Scaffold Properties: Mechanical n n Elastic modulus varies with age and location n Target Range: 10 -20 GPa Uniaxial compression and tension three orthogonal directions 3/2/2006 6

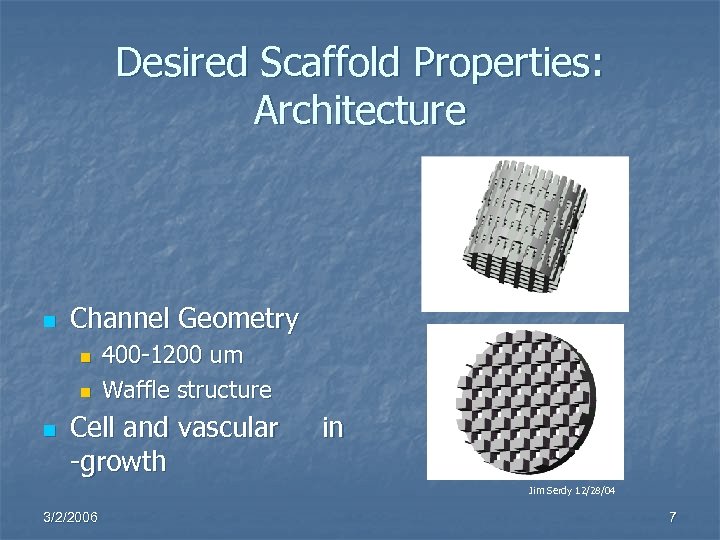

Desired Scaffold Properties: Architecture n Channel Geometry n n n 400 -1200 um Waffle structure Cell and vascular -growth in Jim Serdy 12/28/04 3/2/2006 7

Desired Scaffold Properties: Architecture n Channel Geometry n n n 400 -1200 um Waffle structure Cell and vascular -growth in Jim Serdy 12/28/04 3/2/2006 7

Current MIT Research n n Jim Serdy Lab of Manufacturing and Productivity n Has been working with bone scaffolds n MGH and Cleveland Clinic Agreed to supervise our work in his lab n Our work will explore areas of his interest as well 3/2/2006 8

Current MIT Research n n Jim Serdy Lab of Manufacturing and Productivity n Has been working with bone scaffolds n MGH and Cleveland Clinic Agreed to supervise our work in his lab n Our work will explore areas of his interest as well 3/2/2006 8

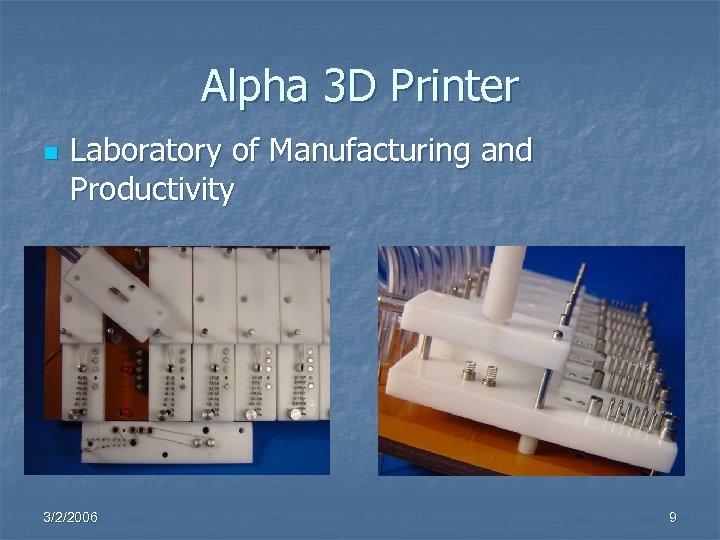

Alpha 3 D Printer n Laboratory of Manufacturing and Productivity 3/2/2006 9

Alpha 3 D Printer n Laboratory of Manufacturing and Productivity 3/2/2006 9

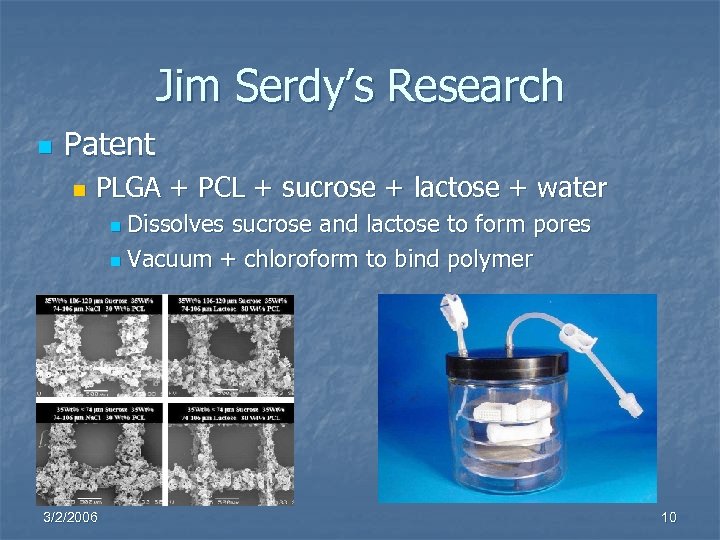

Jim Serdy’s Research n Patent n PLGA + PCL + sucrose + lactose + water Dissolves sucrose and lactose to form pores n Vacuum + chloroform to bind polymer n 3/2/2006 10

Jim Serdy’s Research n Patent n PLGA + PCL + sucrose + lactose + water Dissolves sucrose and lactose to form pores n Vacuum + chloroform to bind polymer n 3/2/2006 10

Improvements n n Bone scaffold is too soft/compliant Increase the stiffness by incorporation of higher TCP concentrataions 3/2/2006 11

Improvements n n Bone scaffold is too soft/compliant Increase the stiffness by incorporation of higher TCP concentrataions 3/2/2006 11

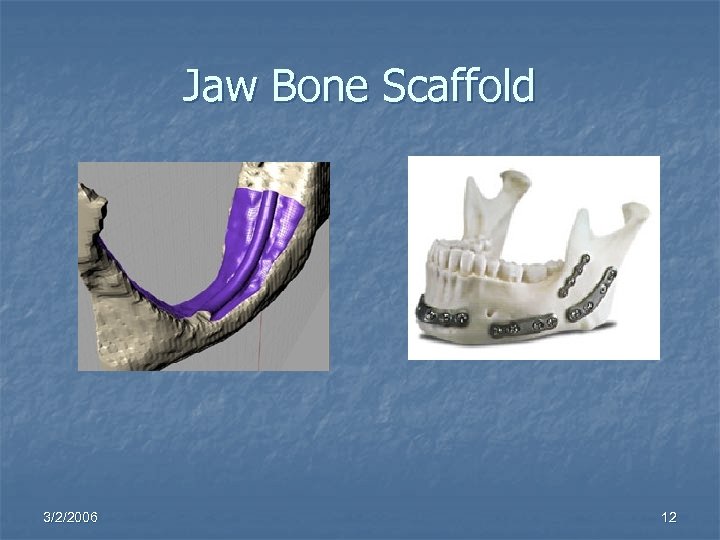

Jaw Bone Scaffold 3/2/2006 12

Jaw Bone Scaffold 3/2/2006 12

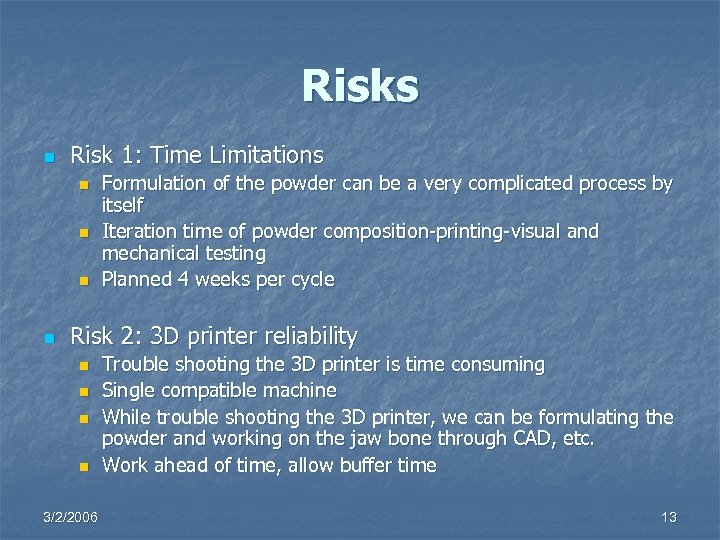

Risks n Risk 1: Time Limitations n n Formulation of the powder can be a very complicated process by itself Iteration time of powder composition-printing-visual and mechanical testing Planned 4 weeks per cycle Risk 2: 3 D printer reliability n n 3/2/2006 Trouble shooting the 3 D printer is time consuming Single compatible machine While trouble shooting the 3 D printer, we can be formulating the powder and working on the jaw bone through CAD, etc. Work ahead of time, allow buffer time 13

Risks n Risk 1: Time Limitations n n Formulation of the powder can be a very complicated process by itself Iteration time of powder composition-printing-visual and mechanical testing Planned 4 weeks per cycle Risk 2: 3 D printer reliability n n 3/2/2006 Trouble shooting the 3 D printer is time consuming Single compatible machine While trouble shooting the 3 D printer, we can be formulating the powder and working on the jaw bone through CAD, etc. Work ahead of time, allow buffer time 13

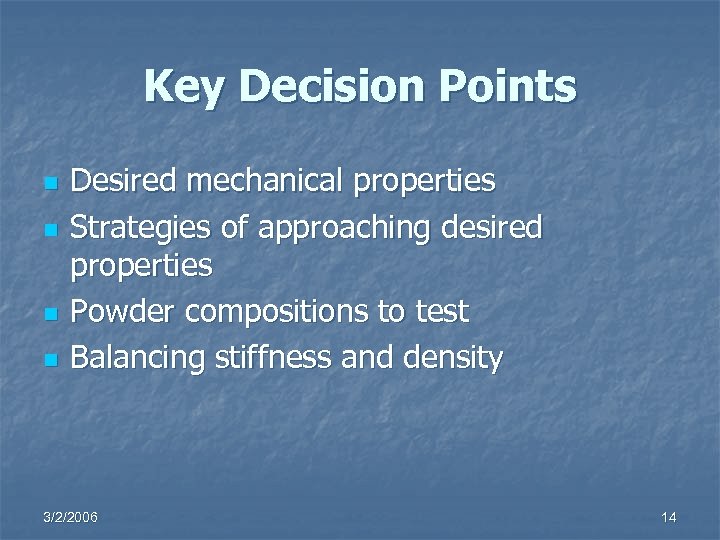

Key Decision Points n n Desired mechanical properties Strategies of approaching desired properties Powder compositions to test Balancing stiffness and density 3/2/2006 14

Key Decision Points n n Desired mechanical properties Strategies of approaching desired properties Powder compositions to test Balancing stiffness and density 3/2/2006 14

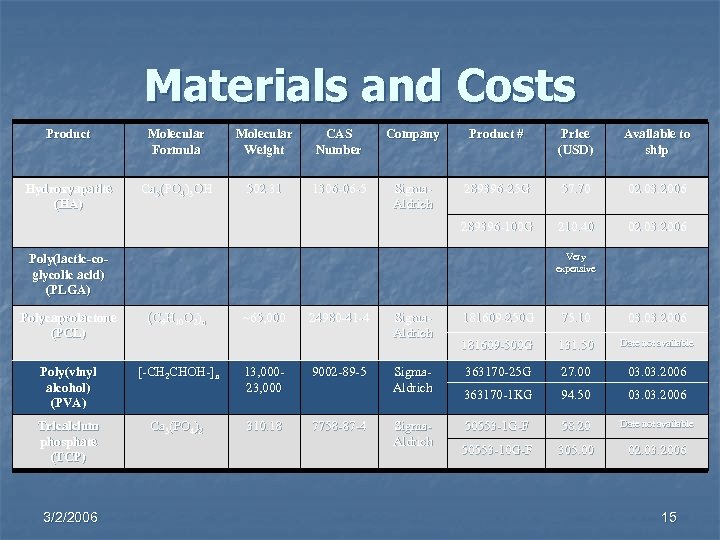

Materials and Costs Product Molecular Formula Molecular Weight CAS Number Company Product # Price (USD) Available to ship Hydroxyapatite (HA) Ca 5(PO 4)3 OH 502. 31 1306 -06 -5 Sigma. Aldrich 289396 -25 G 57. 70 02. 03. 2006 289396 -100 G 210. 40 02. 03. 2006 Very expensive Poly(lactic-coglycolic acid) (PLGA) Polycaprolactone (PCL) (C 6 H 10 O 2)n Poly(vinyl alcohol) (PVA) [-CH 2 CHOH-]n Tricalcium phosphate (TCP) Ca 3(PO 4)2 3/2/2006 ~65, 000 24980 -41 -4 13, 00023, 000 9002 -89 -5 310. 18 7758 -87 -4 Sigma. Aldrich 181609 -250 G 75. 10 03. 2006 181609 -500 G 131. 50 Date not available 363170 -25 G 27. 00 03. 2006 363170 -1 KG 94. 50 03. 2006 50553 -1 G-F 58. 20 Date not available 50553 -10 G-F 305. 00 02. 03. 2006 15

Materials and Costs Product Molecular Formula Molecular Weight CAS Number Company Product # Price (USD) Available to ship Hydroxyapatite (HA) Ca 5(PO 4)3 OH 502. 31 1306 -06 -5 Sigma. Aldrich 289396 -25 G 57. 70 02. 03. 2006 289396 -100 G 210. 40 02. 03. 2006 Very expensive Poly(lactic-coglycolic acid) (PLGA) Polycaprolactone (PCL) (C 6 H 10 O 2)n Poly(vinyl alcohol) (PVA) [-CH 2 CHOH-]n Tricalcium phosphate (TCP) Ca 3(PO 4)2 3/2/2006 ~65, 000 24980 -41 -4 13, 00023, 000 9002 -89 -5 310. 18 7758 -87 -4 Sigma. Aldrich 181609 -250 G 75. 10 03. 2006 181609 -500 G 131. 50 Date not available 363170 -25 G 27. 00 03. 2006 363170 -1 KG 94. 50 03. 2006 50553 -1 G-F 58. 20 Date not available 50553 -10 G-F 305. 00 02. 03. 2006 15

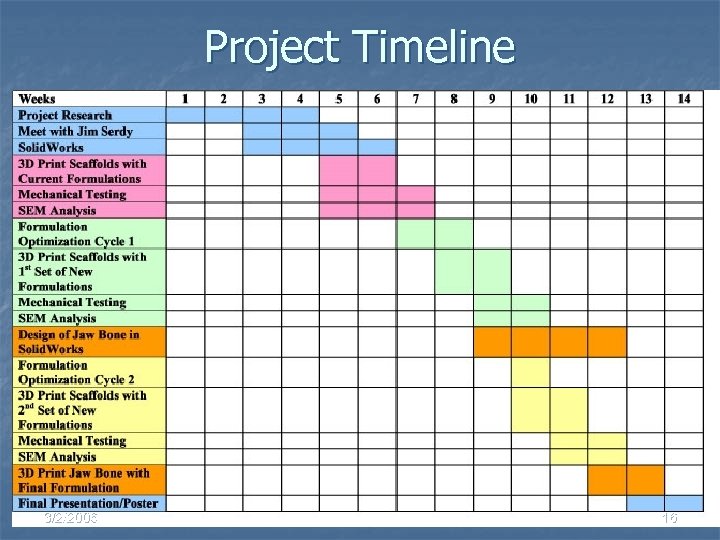

Project Timeline 3/2/2006 16

Project Timeline 3/2/2006 16

Resources n 3 D Printer: James Serdy’s lab Productivity n n Room 35 -011 Laboratory for Manufacturing and Workstations for using Solidworks and Ansys: Room 8 -241 SEM: Room 13 -4139? 3/2/2006 17

Resources n 3 D Printer: James Serdy’s lab Productivity n n Room 35 -011 Laboratory for Manufacturing and Workstations for using Solidworks and Ansys: Room 8 -241 SEM: Room 13 -4139? 3/2/2006 17

Thank You Questions? 3/2/2006 18

Thank You Questions? 3/2/2006 18