4cfaee0d7de38e588aafc1c781d0d2ea.ppt

- Количество слайдов: 31

FAME Blended Diesel Fuel Specification in Japan Vehicle Fuel Quality Workshop Petron Mega Plaza Makati City, Metro Manila Katsuro FURUI Fuel & Lubricant committee Japan Automobile Manufacturers Association 1

Outline 1. 2. 3. 4. Fuel Quality Impact on Vehicle Characteristics of FAME and Diesel Fuel Specification in Europe METI FAME Conformity Tests 4. 1 Properties of Test FAME 4. 2 FAME Properties to be remarked 4. 3 Summary of Test Results 4. 4 Key Properties 4. 5 Development of New Oxidation Stability Tests 4. 6 Remained Issues 5. Fuel Regulation for B 5 in Japan 6. Future Plan of METI 2

1. Fuel Quality Impact on Vehicle Safety ü ü Corrosion and degradation of rubber material Ø Fuel leakage Damage to fuel system and engine Ø Sudden stop and Engine broken Environment ü Damage on After treatment System, Impacts on Air Fuel Management and Deposits etc. Ø Emission Increase Performance ü Impacts on Air Fuel Management and deposits etc. Ø Poor driveability and Engine stall 3

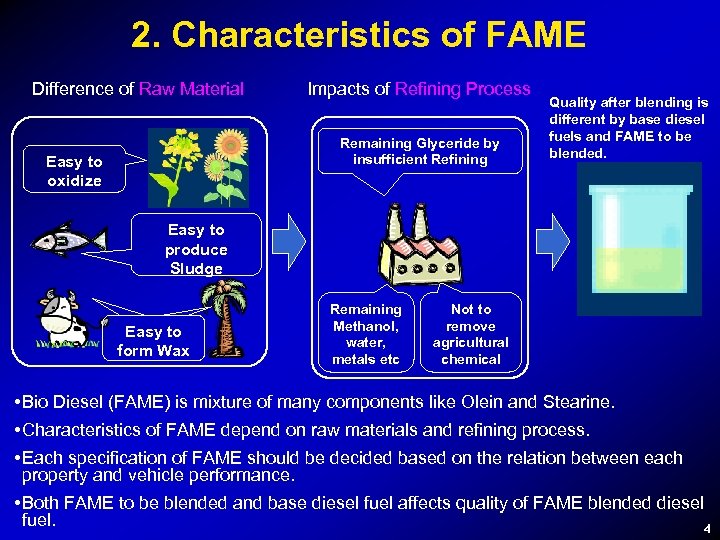

2. Characteristics of FAME Difference of Raw Material Impacts of Refining Process Remaining Glyceride by insufficient Refining Easy to oxidize Quality after blending is different by base diesel fuels and FAME to be blended. Easy to produce Sludge Easy to form Wax Remaining Methanol, water, metals etc Not to remove agricultural chemical • Bio Diesel (FAME) is mixture of many components like Olein and Stearine. • Characteristics of FAME depend on raw materials and refining process. • Each specification of FAME should be decided based on the relation between each property and vehicle performance. • Both FAME to be blended and base diesel fuel affects quality of FAME blended diesel fuel. 4

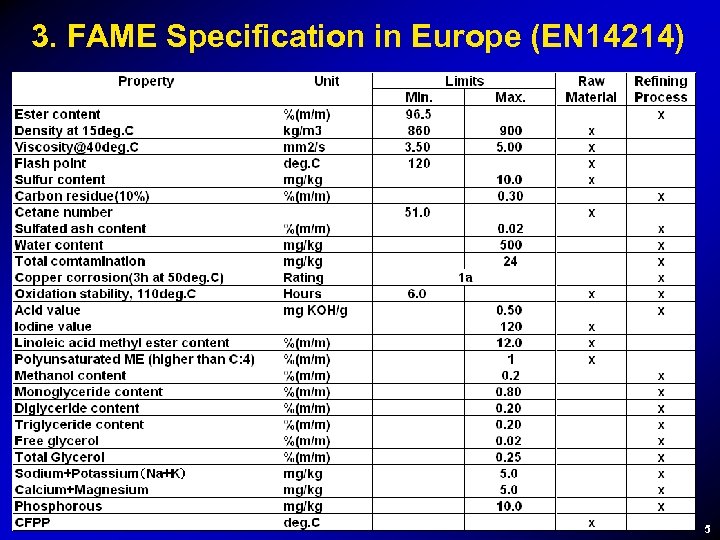

3. FAME Specification in Europe (EN 14214) 5

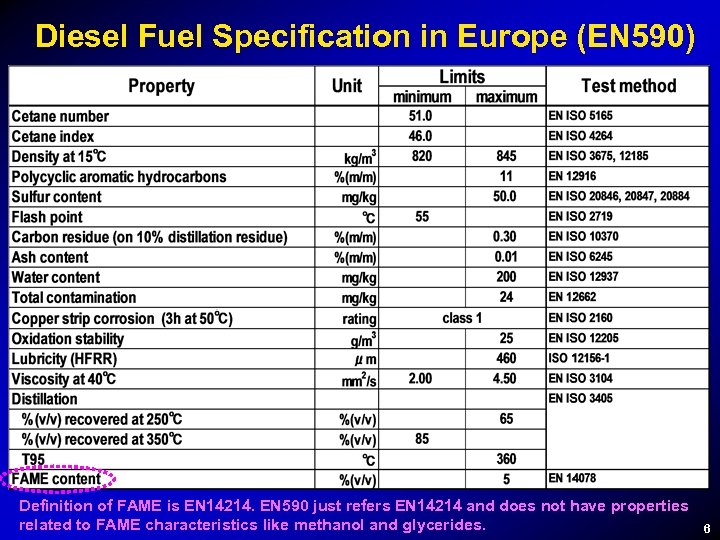

Diesel Fuel Specification in Europe (EN 590) Definition of FAME is EN 14214. EN 590 just refers EN 14214 and does not have properties related to FAME characteristics like methanol and glycerides. 6

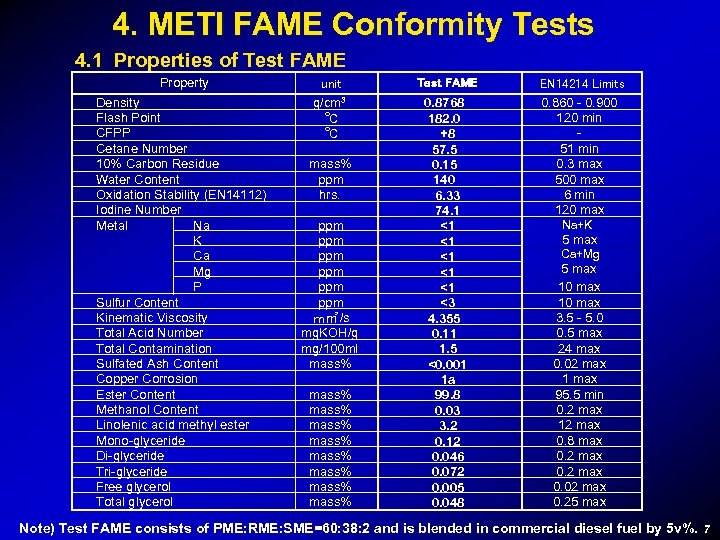

4. METI FAME Conformity Tests 4. 1 Properties of Test FAME Property Density Flash Point CFPP Cetane Number 10% Carbon Residue Water Content Oxidation Stability (EN 14112) Iodine Number Metal Na K Ca Mg P Sulfur Content Kinematic Viscosity Total Acid Number Total Contamination Sulfated Ash Content Copper Corrosion Ester Content Methanol Content Linolenic acid methyl ester Mono-glyceride Di-glyceride Tri-glyceride Free glycerol Total glycerol unit g/cm 3 ℃ ℃ mass% ppm hrs. ppm ppm ppm m㎡ /s mg. KOH/g mg/100 ml mass% mass% mass% Test FAME 0. 8768 182. 0 +8 57. 5 0. 15 140 6. 33 74. 1 <1 <1 <3 4. 355 0. 11 1. 5 <0. 001 1 a 99. 8 0. 03 3. 2 0. 12 0. 046 0. 072 0. 005 0. 048 EN 14214 Limits 0. 860 - 0. 900 120 min 51 min 0. 3 max 500 max 6 min 120 max Na+K 5 max Ca+Mg 5 max 10 max 3. 5 - 5. 0 0. 5 max 24 max 0. 02 max 1 max 95. 5 min 0. 2 max 12 max 0. 8 max 0. 2 max 0. 02 max 0. 25 max Note) Test FAME consists of PME: RME: SME=60: 38: 2 and is blended in commercial diesel fuel by 5 v%. 7

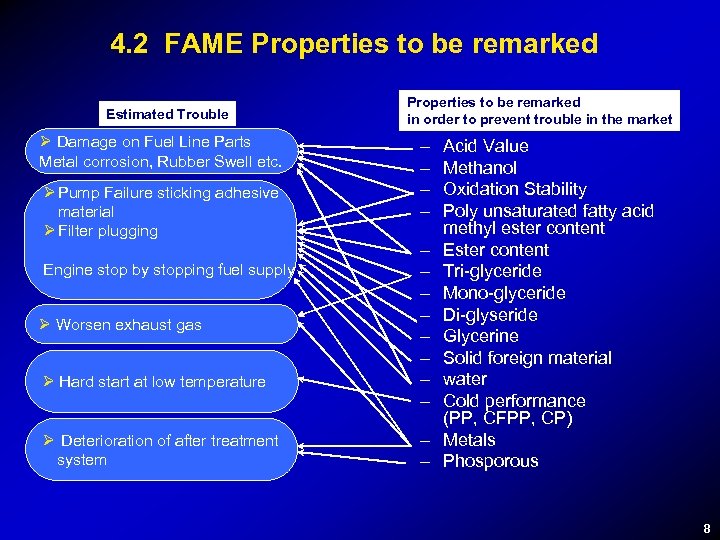

4. 2 FAME Properties to be remarked Estimated Trouble Ø Damage on Fuel Line Parts Metal corrosion, Rubber Swell etc. Ø Pump Failure sticking adhesive material Ø Filter plugging Engine stop by stopping fuel supply Ø Worsen exhaust gas Ø Hard start at low temperature Ø Deterioration of after treatment system Properties to be remarked in order to prevent trouble in the market – – – – Acid Value Methanol Oxidation Stability Poly unsaturated fatty acid methyl ester content Ester content Tri-glyceride Mono-glyceride Di-glyseride Glycerine Solid foreign material water Cold performance (PP, CFPP, CP) Metals Phosporous 8

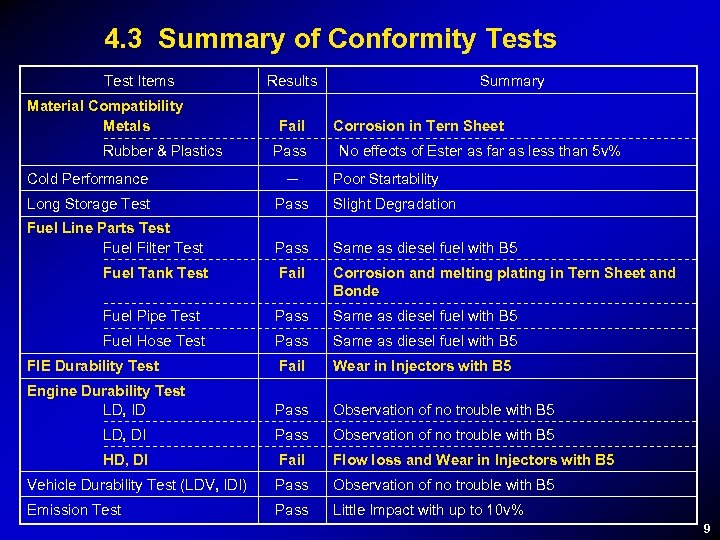

4. 3 Summary of Conformity Tests Test Items Material Compatibility Metals Rubber & Plastics Results Fail Pass Summary Corrosion in Tern Sheet No effects of Ester as far as less than 5 v% Cold Performance - Poor Startability Long Storage Test Pass Slight Degradation Fuel Line Parts Test Fuel Filter Test Pass Same as diesel fuel with B 5 Fuel Tank Test Fail Corrosion and melting plating in Tern Sheet and Bonde Fuel Pipe Test Pass Same as diesel fuel with B 5 Fuel Hose Test Pass Same as diesel fuel with B 5 FIE Durability Test Fail Wear in Injectors with B 5 Engine Durability Test LD, ID Pass Observation of no trouble with B 5 LD, DI Pass Observation of no trouble with B 5 HD, DI Fail Flow loss and Wear in Injectors with B 5 Vehicle Durability Test (LDV, IDI) Pass Observation of no trouble with B 5 Emission Test Pass Little Impact with up to 10 v% 9

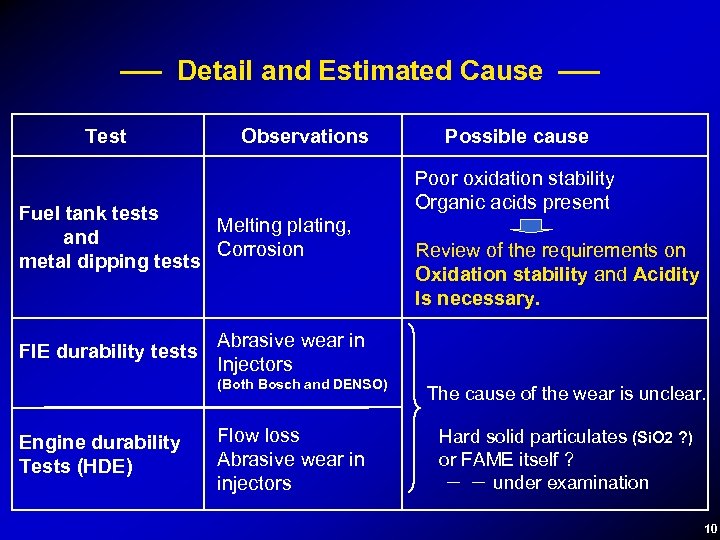

Detail and Estimated Cause Test Observations Fuel tank tests Melting plating, and Corrosion metal dipping tests FIE durability tests Poor oxidation stability Organic acids present Review of the requirements on Oxidation stability and Acidity Is necessary. Abrasive wear in Injectors (Both Bosch and DENSO) Engine durability Tests (HDE) Possible cause Flow loss Abrasive wear in injectors The cause of the wear is unclear. Hard solid particulates (Si. O 2 ? ) or FAME itself ? - - under examination 10

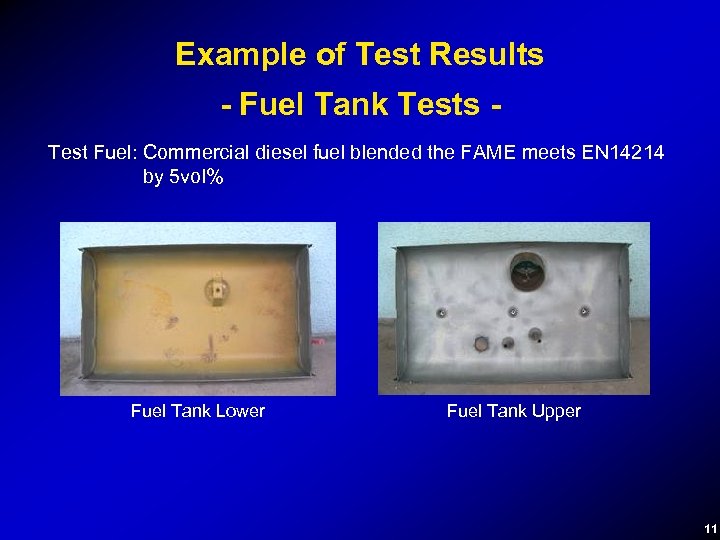

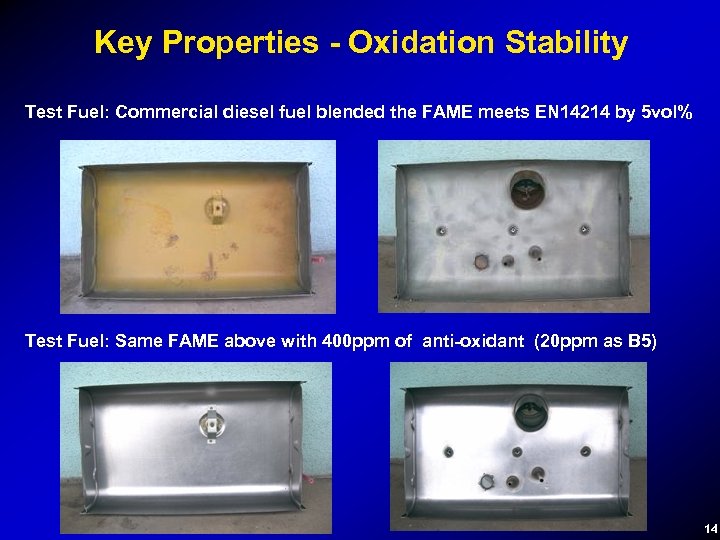

Example of Test Results - Fuel Tank Tests Test Fuel: Commercial diesel fuel blended the FAME meets EN 14214 by 5 vol% Fuel Tank Lower Fuel Tank Upper 11

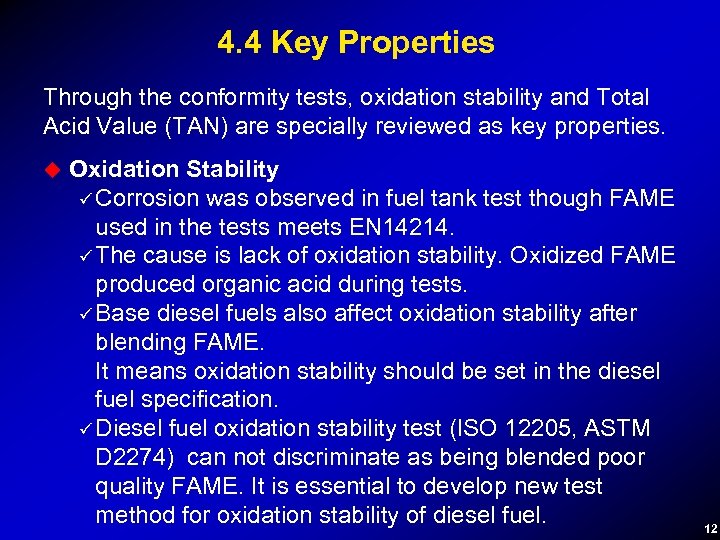

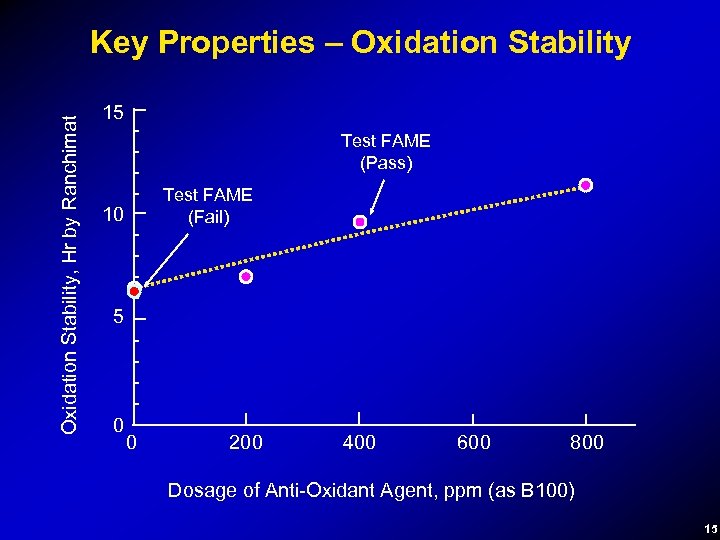

4. 4 Key Properties Through the conformity tests, oxidation stability and Total Acid Value (TAN) are specially reviewed as key properties. u Oxidation Stability ü Corrosion was observed in fuel tank test though FAME used in the tests meets EN 14214. ü The cause is lack of oxidation stability. Oxidized FAME produced organic acid during tests. ü Base diesel fuels also affect oxidation stability after blending FAME. It means oxidation stability should be set in the diesel fuel specification. ü Diesel fuel oxidation stability test (ISO 12205, ASTM D 2274) can not discriminate as being blended poor quality FAME. It is essential to develop new test method for oxidation stability of diesel fuel. 12

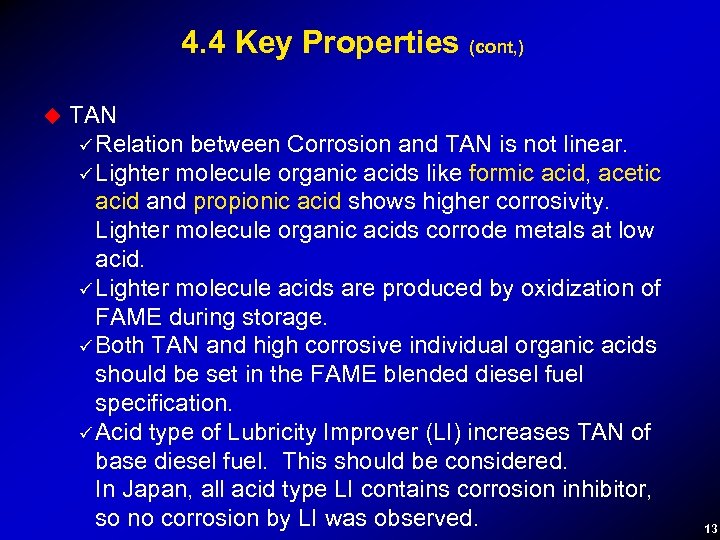

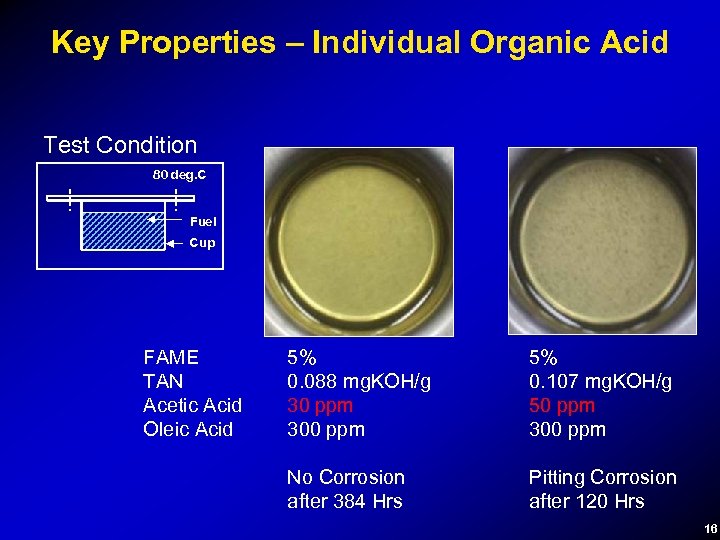

4. 4 Key Properties (cont, ) u TAN ü Relation between Corrosion and TAN is not linear. ü Lighter molecule organic acids like formic acid, acetic acid and propionic acid shows higher corrosivity. Lighter molecule organic acids corrode metals at low acid. ü Lighter molecule acids are produced by oxidization of FAME during storage. ü Both TAN and high corrosive individual organic acids should be set in the FAME blended diesel fuel specification. ü Acid type of Lubricity Improver (LI) increases TAN of base diesel fuel. This should be considered. In Japan, all acid type LI contains corrosion inhibitor, so no corrosion by LI was observed. 13

Key Properties - Oxidation Stability Test Fuel: Commercial diesel fuel blended the FAME meets EN 14214 by 5 vol% Test Fuel: Same FAME above with 400 ppm of anti-oxidant (20 ppm as B 5) 14

Oxidation Stability, Hr by Ranchimat Key Properties – Oxidation Stability 15 Test FAME (Pass) Test FAME (Fail) 10 5 0 0 200 400 600 800 Dosage of Anti-Oxidant Agent, ppm (as B 100) 15

Key Properties – Individual Organic Acid Test Condition 80 deg. C Fuel Cup FAME TAN Acetic Acid Oleic Acid 5% 0. 088 mg. KOH/g 30 ppm 300 ppm 5% 0. 107 mg. KOH/g 50 ppm 300 ppm No Corrosion after 384 Hrs Pitting Corrosion after 120 Hrs 16

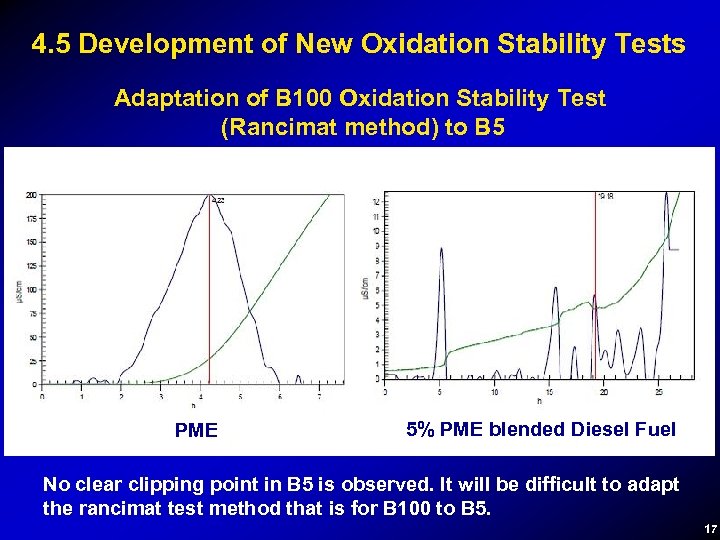

4. 5 Development of New Oxidation Stability Tests Adaptation of B 100 Oxidation Stability Test (Rancimat method) to B 5 PME 5% PME blended Diesel Fuel No clear clipping point in B 5 is observed. It will be difficult to adapt the rancimat test method that is for B 100 to B 5. 17

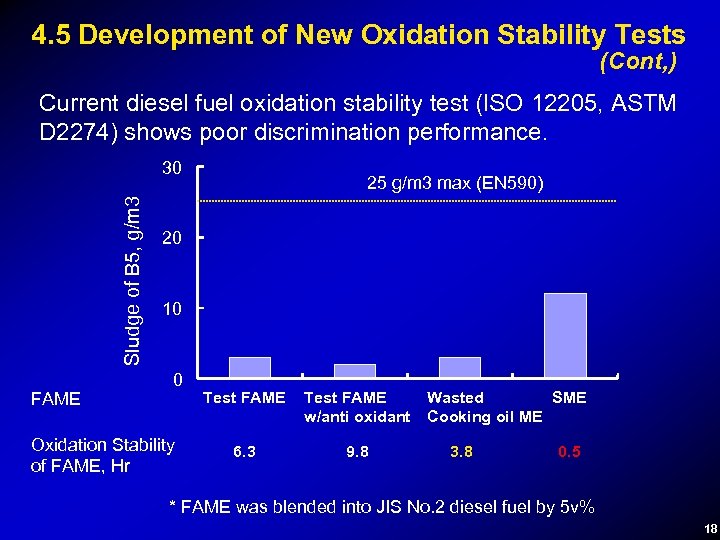

4. 5 Development of New Oxidation Stability Tests (Cont, ) Current diesel fuel oxidation stability test (ISO 12205, ASTM D 2274) shows poor discrimination performance. Sludge of B 5, g/m 3 30 FAME 25 g/m 3 max (EN 590) 20 10 0 Oxidation Stability of FAME, Hr Test FAME w/anti oxidant 6. 3 9. 8 Wasted SME Cooking oil ME 3. 8 0. 5 * FAME was blended into JIS No. 2 diesel fuel by 5 v% 18

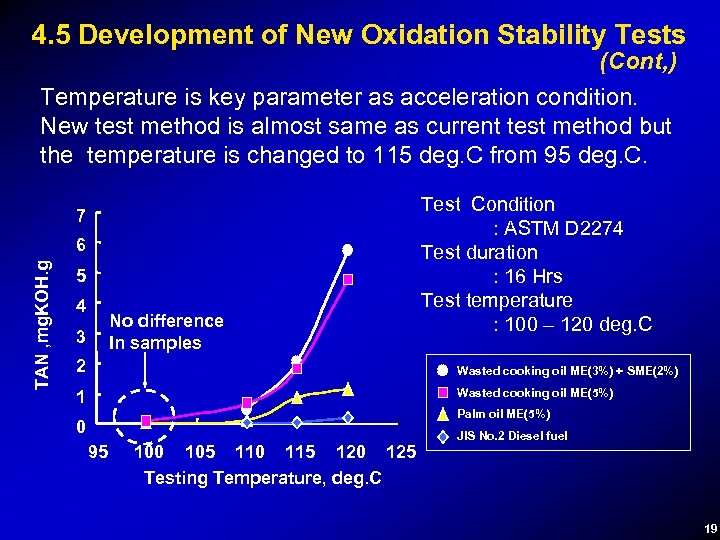

4. 5 Development of New Oxidation Stability Tests (Cont, ) Temperature is key parameter as acceleration condition. New test method is almost same as current test method but the temperature is changed to 115 deg. C from 95 deg. C. 7 TAN , mg. KOH. g 6 5 4 No difference In samples 3 Test Condition : ASTM D 2274 Test duration : 16 Hrs Test temperature : 100 – 120 deg. C 2 Wasted cooking oil ME(3%) + SME(2%) 1 Wasted cooking oil ME(5%) Palm oil ME(5%) 0 95 100 105 110 115 120 125 Testing Temperature, deg. C JIS No. 2 Diesel fuel 19

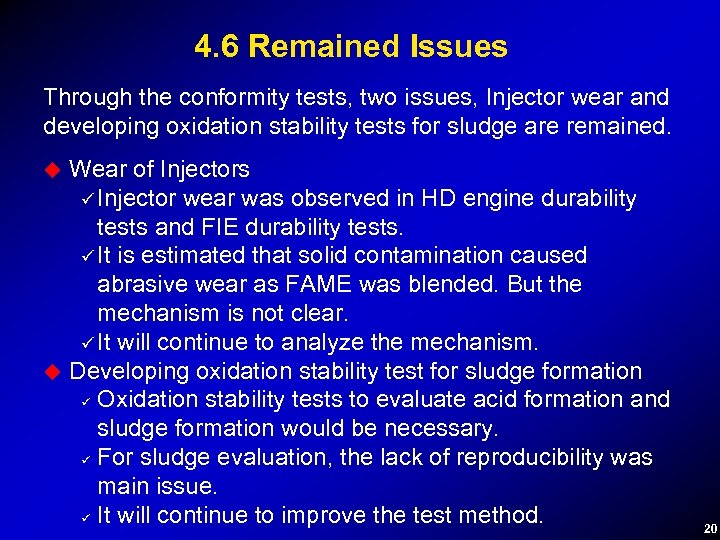

4. 6 Remained Issues Through the conformity tests, two issues, Injector wear and developing oxidation stability tests for sludge are remained. Wear of Injectors ü Injector wear was observed in HD engine durability tests and FIE durability tests. ü It is estimated that solid contamination caused abrasive wear as FAME was blended. But the mechanism is not clear. ü It will continue to analyze the mechanism. u Developing oxidation stability test for sludge formation ü Oxidation stability tests to evaluate acid formation and sludge formation would be necessary. ü For sludge evaluation, the lack of reproducibility was main issue. ü It will continue to improve the test method. u 20

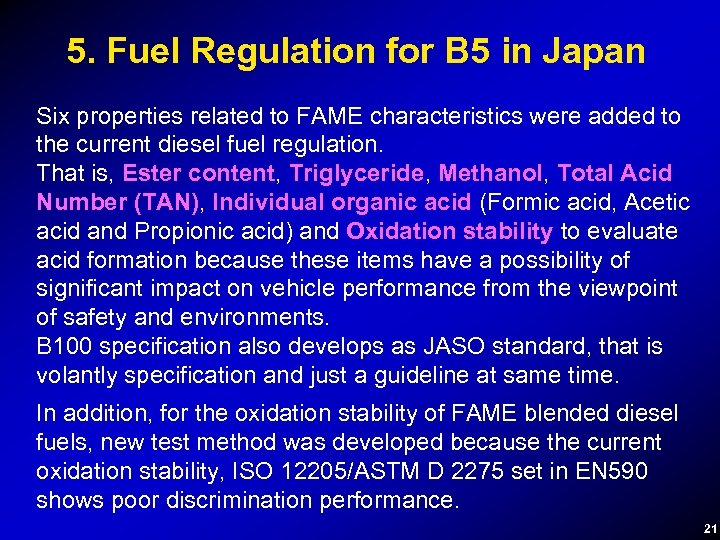

5. Fuel Regulation for B 5 in Japan Six properties related to FAME characteristics were added to the current diesel fuel regulation. That is, Ester content, Triglyceride, Methanol, Total Acid Number (TAN), Individual organic acid (Formic acid, Acetic acid and Propionic acid) and Oxidation stability to evaluate acid formation because these items have a possibility of significant impact on vehicle performance from the viewpoint of safety and environments. B 100 specification also develops as JASO standard, that is volantly specification and just a guideline at same time. In addition, for the oxidation stability of FAME blended diesel fuels, new test method was developed because the current oxidation stability, ISO 12205/ASTM D 2275 set in EN 590 shows poor discrimination performance. 21

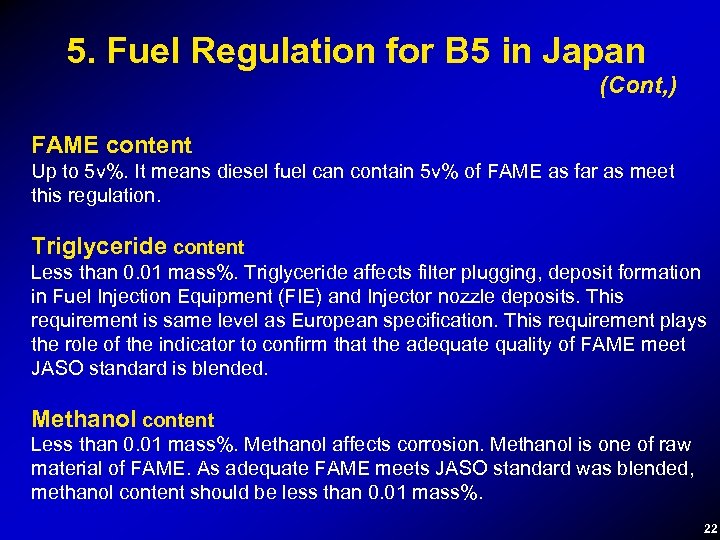

5. Fuel Regulation for B 5 in Japan (Cont, ) FAME content Up to 5 v%. It means diesel fuel can contain 5 v% of FAME as far as meet this regulation. Triglyceride content Less than 0. 01 mass%. Triglyceride affects filter plugging, deposit formation in Fuel Injection Equipment (FIE) and Injector nozzle deposits. This requirement is same level as European specification. This requirement plays the role of the indicator to confirm that the adequate quality of FAME meet JASO standard is blended. Methanol content Less than 0. 01 mass%. Methanol affects corrosion. Methanol is one of raw material of FAME. As adequate FAME meets JASO standard was blended, methanol content should be less than 0. 01 mass%. 22

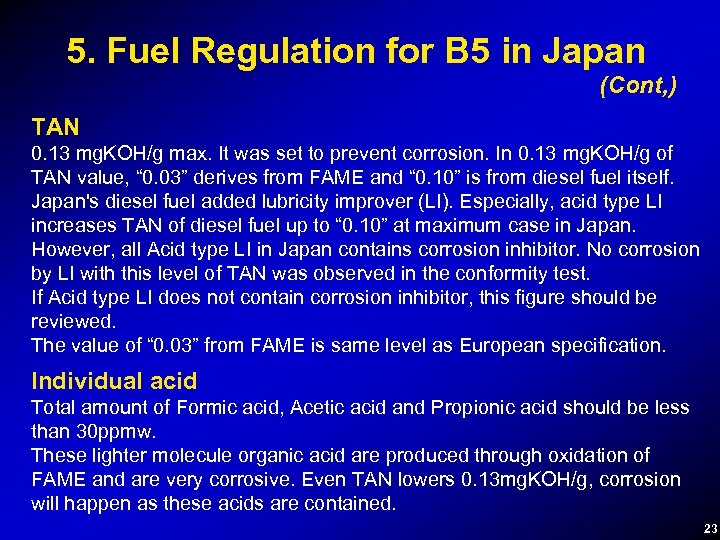

5. Fuel Regulation for B 5 in Japan (Cont, ) TAN 0. 13 mg. KOH/g max. It was set to prevent corrosion. In 0. 13 mg. KOH/g of TAN value, “ 0. 03” derives from FAME and “ 0. 10” is from diesel fuel itself. Japan's diesel fuel added lubricity improver (LI). Especially, acid type LI increases TAN of diesel fuel up to “ 0. 10” at maximum case in Japan. However, all Acid type LI in Japan contains corrosion inhibitor. No corrosion by LI with this level of TAN was observed in the conformity test. If Acid type LI does not contain corrosion inhibitor, this figure should be reviewed. The value of “ 0. 03” from FAME is same level as European specification. Individual acid Total amount of Formic acid, Acetic acid and Propionic acid should be less than 30 ppmw. These lighter molecule organic acid are produced through oxidation of FAME and are very corrosive. Even TAN lowers 0. 13 mg. KOH/g, corrosion will happen as these acids are contained. 23

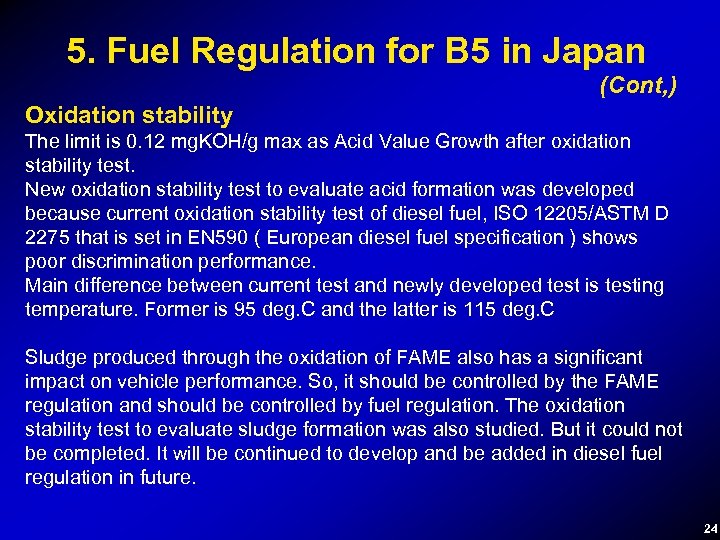

5. Fuel Regulation for B 5 in Japan (Cont, ) Oxidation stability The limit is 0. 12 mg. KOH/g max as Acid Value Growth after oxidation stability test. New oxidation stability test to evaluate acid formation was developed because current oxidation stability test of diesel fuel, ISO 12205/ASTM D 2275 that is set in EN 590 ( European diesel fuel specification ) shows poor discrimination performance. Main difference between current test and newly developed test is testing temperature. Former is 95 deg. C and the latter is 115 deg. C Sludge produced through the oxidation of FAME also has a significant impact on vehicle performance. So, it should be controlled by the FAME regulation and should be controlled by fuel regulation. The oxidation stability test to evaluate sludge formation was also studied. But it could not be completed. It will be continued to develop and be added in diesel fuel regulation in future. 24

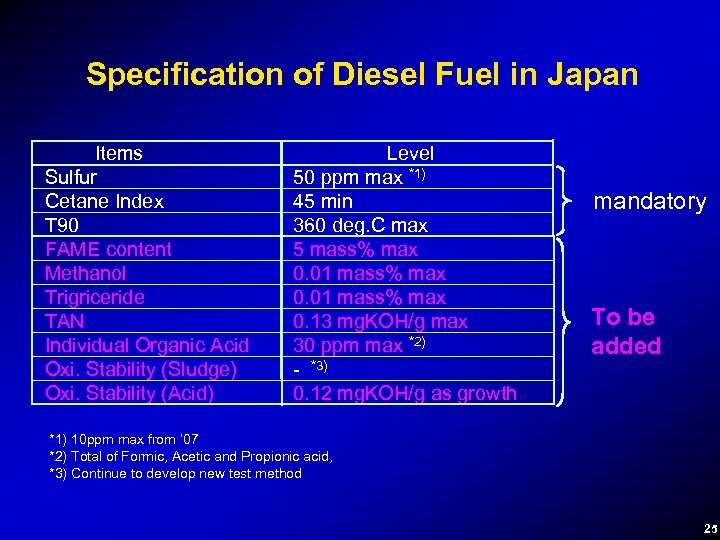

Specification of Diesel Fuel in Japan Items Sulfur Cetane Index T 90 FAME content Methanol Trigriceride TAN Individual Organic Acid Oxi. Stability (Sludge) Oxi. Stability (Acid) Level 50 ppm max *1) 45 min 360 deg. C max 5 mass% max 0. 01 mass% max 0. 13 mg. KOH/g max 30 ppm max *2) - *3) 0. 12 mg. KOH/g as growth mandatory To be added *1) 10 ppm max from ’ 07 *2) Total of Formic, Acetic and Propionic acid, *3) Continue to develop new test method 25

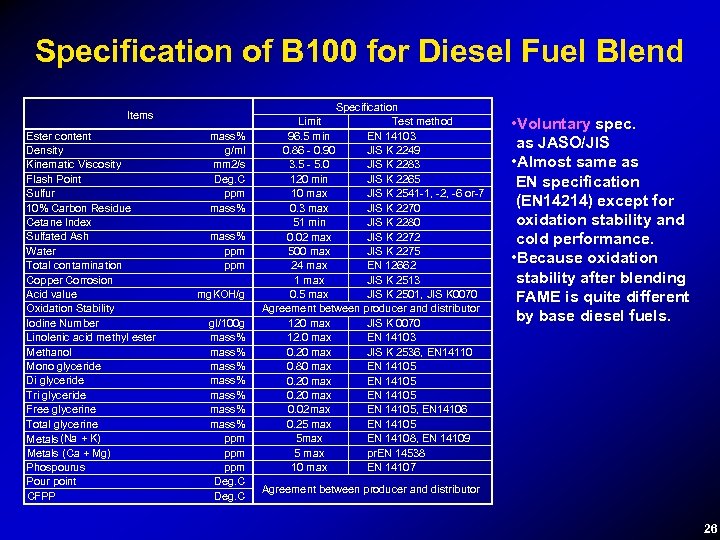

Specification of B 100 for Diesel Fuel Blend Items Ester content Density Kinematic Viscosity Flash Point Sulfur 10% Carbon Residue Cetane Index Sulfated Ash Water Total contamination Copper Corrosion Acid value Oxidation Stability Iodine Number Linolenic acid methyl ester Methanol Mono glyceride Di glyceride Tri glyceride Free glycerine Total glycerine Metals (Na + K) Metals (Ca + Mg) Phospourus Pour point CFPP mass% g/ml mm 2/s Deg. C ppm mass% ppm mg. KOH/g g. I/100 g mass% mass% ppm ppm Deg. C Specification Limit Test method 96. 5 min EN 14103 0. 86 - 0. 90 JIS K 2249 3. 5 - 5. 0 JIS K 2283 120 min JIS K 2265 10 max JIS K 2541 -1, -2, -6 or-7 0. 3 max JIS K 2270 51 min JIS K 2280 0. 02 max JIS K 2272 500 max JIS K 2275 24 max EN 12662 1 max JIS K 2513 0. 5 max JIS K 2501, JIS K 0070 Agreement between producer and distributor 120 max JIS K 0070 12. 0 max EN 14103 0. 20 max JIS K 2536, EN 14110 0. 80 max EN 14105 0. 20 max EN 14105 0. 02 max EN 14105, EN 14106 0. 25 max EN 14105 5 max EN 14108, EN 14109 5 max pr. EN 14538 10 max EN 14107 • Voluntary spec. as JASO/JIS • Almost same as EN specification (EN 14214) except for oxidation stability and cold performance. • Because oxidation stability after blending FAME is quite different by base diesel fuels. Agreement between producer and distributor 26

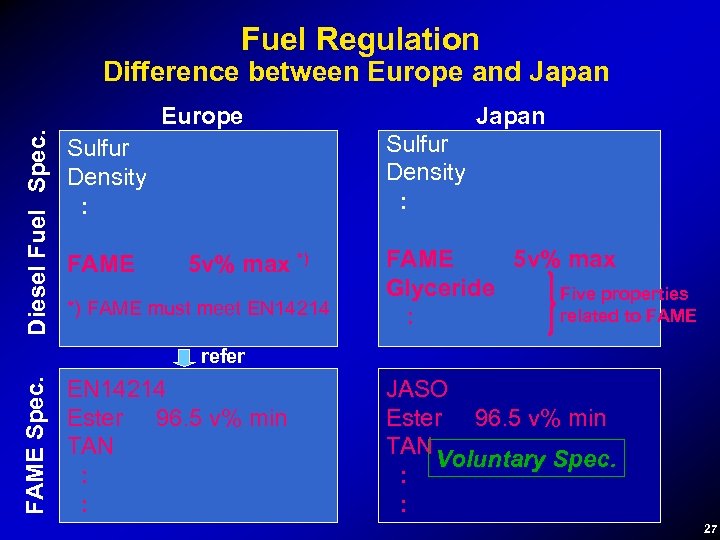

Fuel Regulation Difference between Europe and Japan Diesel Fuel Spec. Europe Sulfur Density : FAME Japan 5 v% max *) *) FAME must meet EN 14214 FAME 5 v% max Glyceride Five properties related to FAME : FAME Spec. refer EN 14214 Ester 96. 5 v% min TAN : : JASO Ester 96. 5 v% min TAN Voluntary Spec. : : 27

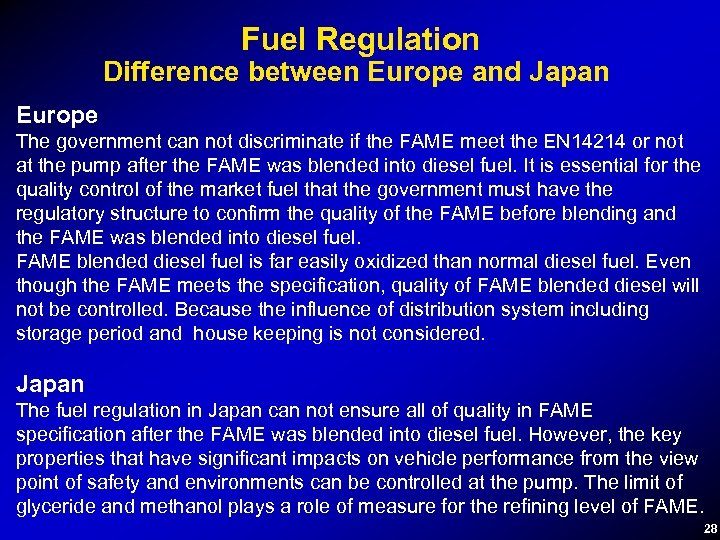

Fuel Regulation Difference between Europe and Japan Europe The government can not discriminate if the FAME meet the EN 14214 or not at the pump after the FAME was blended into diesel fuel. It is essential for the quality control of the market fuel that the government must have the regulatory structure to confirm the quality of the FAME before blending and the FAME was blended into diesel fuel. FAME blended diesel fuel is far easily oxidized than normal diesel fuel. Even though the FAME meets the specification, quality of FAME blended diesel will not be controlled. Because the influence of distribution system including storage period and house keeping is not considered. Japan The fuel regulation in Japan can not ensure all of quality in FAME specification after the FAME was blended into diesel fuel. However, the key properties that have significant impacts on vehicle performance from the view point of safety and environments can be controlled at the pump. The limit of glyceride and methanol plays a role of measure for the refining level of FAME. 28

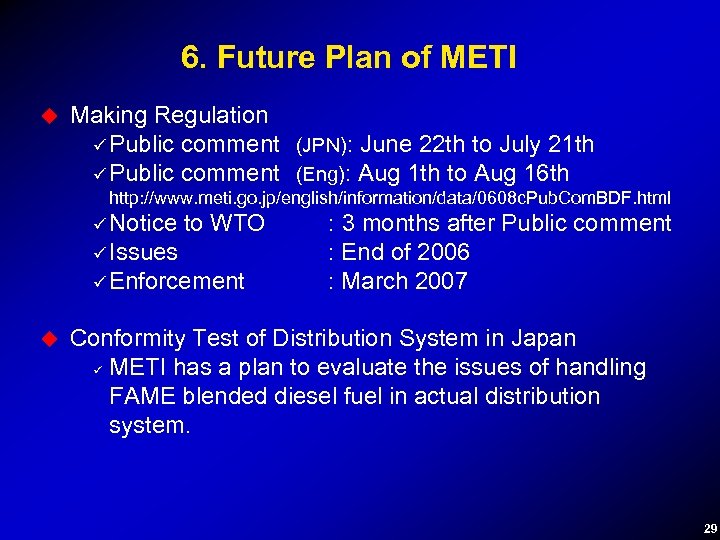

6. Future Plan of METI u Making Regulation ü Public comment (JPN): June 22 th to July 21 th ü Public comment (Eng): Aug 1 th to Aug 16 th http: //www. meti. go. jp/english/information/data/0608 c. Pub. Com. BDF. html ü Notice to WTO ü Issues ü Enforcement u : 3 months after Public comment : End of 2006 : March 2007 Conformity Test of Distribution System in Japan ü METI has a plan to evaluate the issues of handling FAME blended diesel fuel in actual distribution system. 29

JAMA Recommendation Diesel fuel specification blended FAME in Japan was decided based on technical studies for more than two years testing. Ø The expenses for the studies amount to more than 400 million JPY and main research institutes and associations in Japan participated ( METI, AIST, JARI, JAMA, JPI, PAJ ). Ø JAMA strongly recommend the governments to adopt Japanese specification. Ø B 100 specification is not enough to ensure the quality of FAME blended diesel fuels at the pump because base diesel fuels also affects oxidation stability of FAME blended diesel fuels. Ø 30

JAMA Recommendation (Cont, ) Good house keeping and management in distribution system would be necessary because FAME blended diesel adsorb moisture and oxidized easily. Ø Japan’s diesel fuel regulation and B 100 specification is for up to 5 v% of FAME blending. As introduction of more than 5 v% of FAME is discussing, both diesel fuel and B 100 specification should be reviewed based on technical data. Ø It will be more preferable to utilize "BTL (Biomass To Liquid)" or "Hydrotreated Vegetable Oil" as compared to the use of FAME from the technical view points. Ø 31

4cfaee0d7de38e588aafc1c781d0d2ea.ppt