90d3808e61341856a249c0fcda49ca2a.ppt

- Количество слайдов: 59

FACİLİTİES LAYOUT & MATERİAL HANDLİNG SYSTEMS Prepared by Şevkinaz Gümüşoğlu using different references about POM

FACILITY LAYOUT DEFINED Facility layout can be defined as the process by which the placement of departments, workgroups within departments, workstations, machines, and stockholding points within a facility are determined This process requires the following inputs: Specification of objectives of the system in terms of output and flexibility Estimation of product or service demand on the system Processing requirements in terms of number of operations and amount of flow between departments and work centers Space requirements for the elements in the layout Space availability within the facility itself

Layout decisions are concerned with the arrangement of production, support, customer service and other facilities. Layout can be costly investments, but they effect material (non production cost) handling, capital equipment utilization, inventory storage levels, worker productivity, and even group communications and employee morale. A good layout will be enable materials, people, and information to flow in a safe and efficient manner. For this reason two of the major criteria for selecting and designing a layout are; 1. Materials-handling cost 2. worker effectiveness.

Material- handing cost has often been considered the most important criteria of a layout. Cost are minimized by using belts and conveyors to automate product flows belts and keeping the flow distances as short as possible. Sequential processing activities are usually located in adjacent areas. In service systems such as subways, customer are frequently the material that moves through the system. So the customer service time becomes a relevant variable. Workers effectiveness is an increasingly important criterion in facilities today. Good layouts provide workers with a satisfying job and permit them to work effectively at the highest skill level for which they are being paid. This applies just as much to a office layout (where an engineers might spend unnecessary time delivering memos) as it does to a factory layout (where a machinist might have to walk long distances for tools). Good communications systems and well-placed supporting activity locations are critical to the success of any facility.

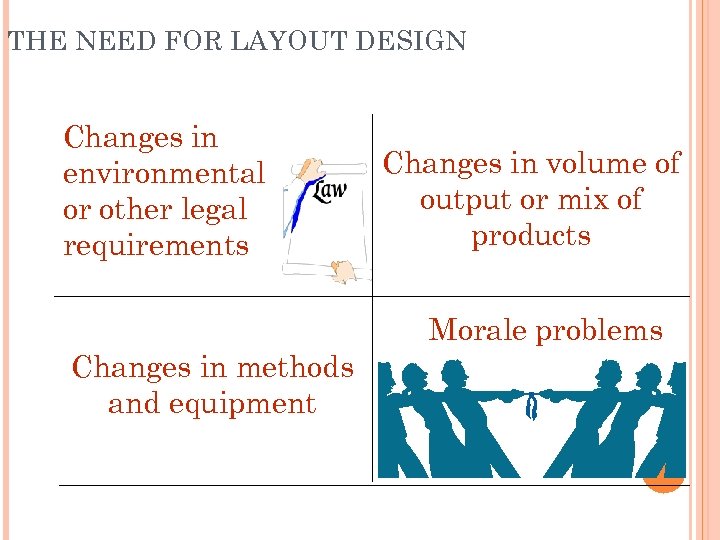

THE NEED FOR LAYOUT DESIGN Changes in environmental or other legal requirements Changes in volume of output or mix of products Morale problems Changes in methods and equipment

LAYOUT RELATİONSHIPS; PRODUCY DESİGN LAYOUT SHEDULED PROCESS DESİGN

TYPES OF LAYOUT Basic types of layouts are Process (functional) layouts Product (line) layouts Fixed position layouts Cellular Layout There are many combinations of these. Flexible production systems are line layouts that use micro processor and robots to gain some of the advantages of functional layouts. The type of layout is generally determined by the following: Type of product: This concerns whether the product is a good or a service, the product design and quality standards and whether the product is produced for stock or for order. Type of production process: This relates to the technology used, the type of materials, handled, and for the means of providing the services. Volume of production: Volume affects the present facility design and capacity utilization, plus provisions for expansion or change.

ARE RELATED WİTH PROCESS TYPES Job shop Batch Assembly line Continuous flow

Facility layout are influenced by the level of automation and cost of manufacturing equipment. Many numerically controlled (CNC) machines and industrial robots perform simple tasks such as drilling hales or welding joints. However, as the number of task performed by automated machinery increases, the machines can become quite large and expensive. In these situations the equipment and configuration significantly influence the layout and product floor. The more advanced systems gaining acceptance in U. S. firms today cellular manufacturing which is building-block step toward flexible manufacturing system. *Manufacturing cells also enable a firm to operate with less work-in-process inventory.

PROCESS LAYOUT: INTERDEPARTMENTAL FLOW Given The flow (number of moves) to and from all departments The cost of moving from one department to another The existing or planned physical layout of the plant Determine The “best” locations for each department, where best means maximizing flow, which minimizing costs

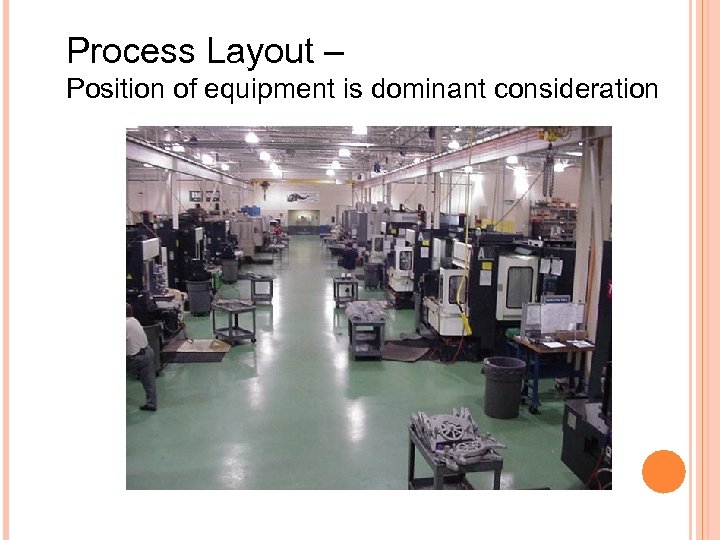

Process Layout – Position of equipment is dominant consideration

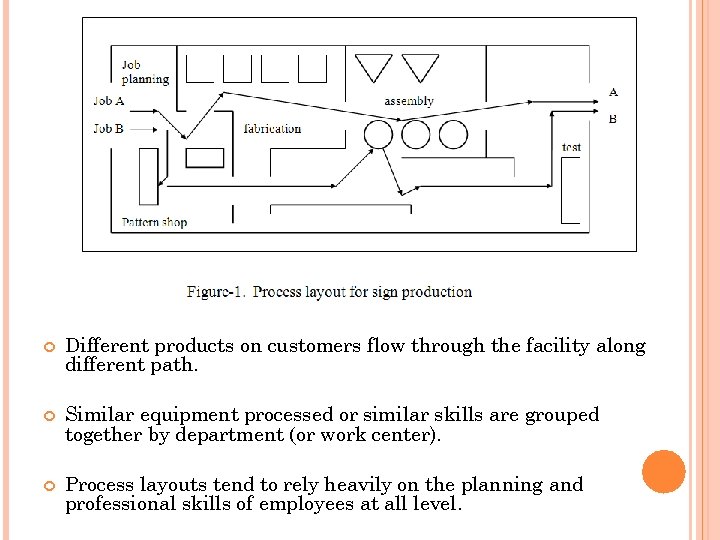

PROCESS LAYOUT Process layouts group the people and equipment performing similar functions, such as x-raying, typing or electroplating. They lend themselves to low volumes of customized jobs and use a variety of general purpose equipment. Work flow is typically intermittent and guided by individual work orders. This figures illustrates a process layout.

PROCESS LAYOUT (JOB SHOP) Product 3 Product 1 Product 2 A B C Product 1 Product 2 Product 3 D E F

Different products on customers flow through the facility along different path. Similar equipment processed or similar skills are grouped together by department (or work center). Process layouts tend to rely heavily on the planning and professional skills of employees at all level.

Some of Advantages of functional layouts Flexible systems for custom work. Less costly general-purpose equipment Enhances job satisfaction (more diversity and challenge) Some of Disadvantages of process layouts Costly materials handling High-cost skilled labor Higher supervision cost Per employee Low equipment utilization More complex production control (for instance, scheduling, inventory, control) These layout problems fall into two basic categories Those involving quantitative decision criteria Those involving qualitative criteria.

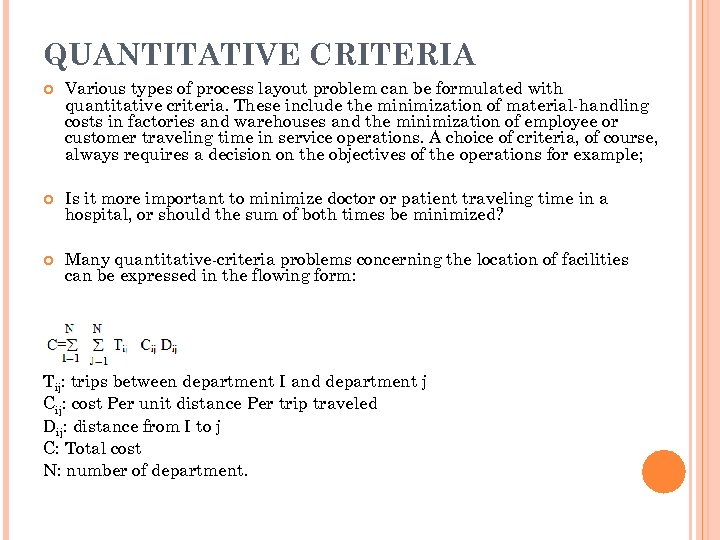

QUANTITATIVE CRITERIA Various types of process layout problem can be formulated with quantitative criteria. These include the minimization of material-handling costs in factories and warehouses and the minimization of employee or customer traveling time in service operations. A choice of criteria, of course, always requires a decision on the objectives of the operations for example; Is it more important to minimize doctor or patient traveling time in a hospital, or should the sum of both times be minimized? Many quantitative-criteria problems concerning the location of facilities can be expressed in the flowing form: Tij: trips between department I and department j Cij: cost Per unit distance Per trip traveled Dij: distance from I to j C: Total cost N: number of department.

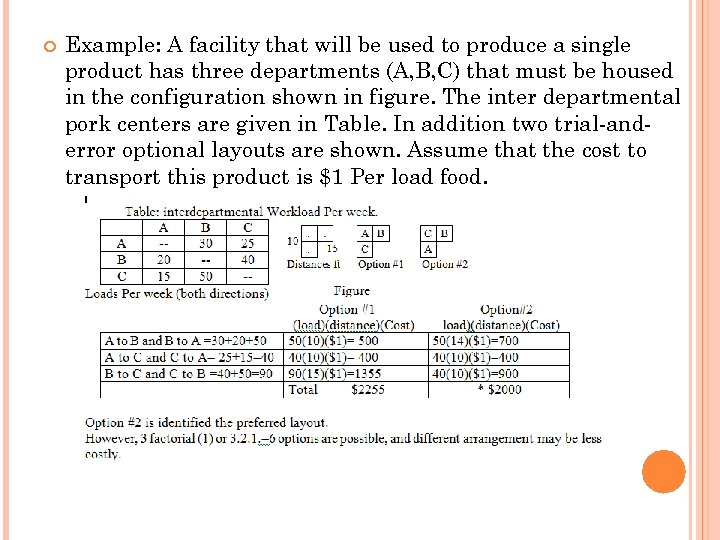

Example: A facility that will be used to produce a single product has three departments (A, B, C) that must be housed in the configuration shown in figure. The inter departmental pork centers are given in Table. In addition two trial-anderror optional layouts are shown. Assume that the cost to transport this product is $1 Per load food.

QUALITATIVE CRITERIA Layout problems involving qualitative criteria occur when relationships between in qualitative terms. In some cases, these qualitative criteria may be more readily available or more appropriate than quantitative criteria. The qualitative location problem has been studied in depth by Muther (1962) who has proposed a method of formulation and solution called SLP (systematic Layout Planning). According to Muther’s approach, the desirability of locating a given department next to any other department is rated by one of the following terms: Absolutely necessary, Especially important, Ordinary closeness okay, Unimportant, undesirable. These qualitative ratings may be based on safety considerations, customer convenience, or approximate flows between departments.

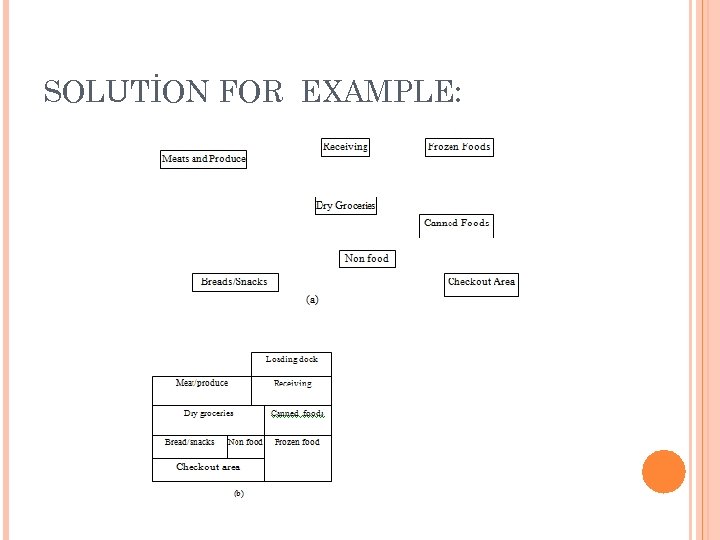

For example, it might be desirable to locate the baby food department near the milk department in a supermarket for convenience of shopping. In these example it is shown for a typical supermarket. The solution is not necessarily an optimal solution but simply a good solution chosen for purposes of illustration. Qualitative layout problems are frequently encountered in the service industries, where customers interact with the facilities. Several computerized approaches are available for developing and analyzing process layouts. Computerized Relative Allocation of Facilities Technique CRAFT (Soft ware) packages program attempts to minimize materialhandling costs by calculating cost a exchanging department. ALDEP and CORELAP programs attempt to maximize a nearness rating within the facility dimension constraints. None of the methods guarantees optimality.

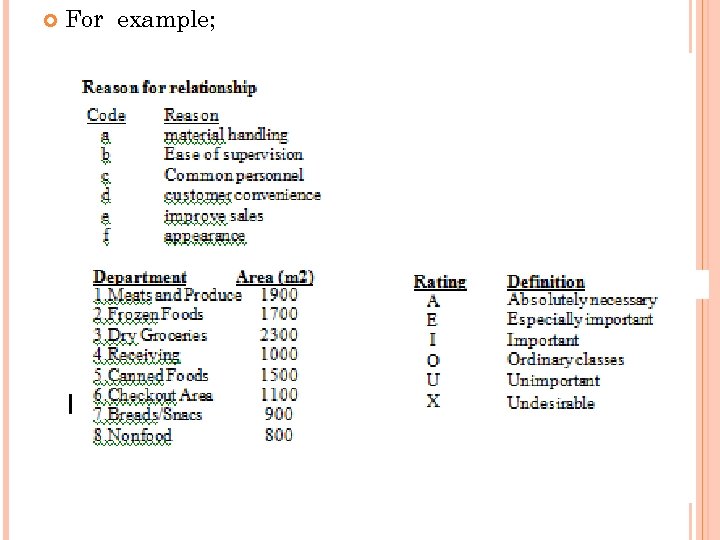

For example;

SOLUTİON FOR EXAMPLE:

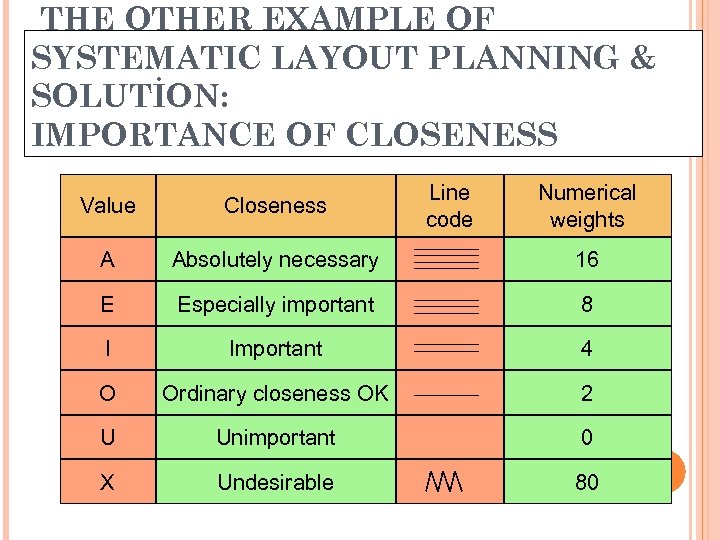

THE OTHER EXAMPLE OF SYSTEMATIC LAYOUT PLANNING & SOLUTİON: IMPORTANCE OF CLOSENESS Line code Numerical weights Value Closeness A Absolutely necessary 16 E Especially important 8 I Important 4 O Ordinary closeness OK 2 U Unimportant 0 X Undesirable 80

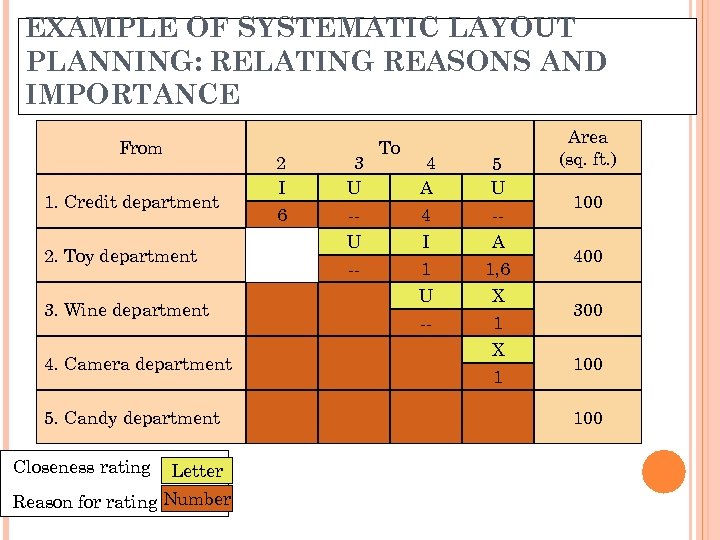

EXAMPLE OF SYSTEMATIC LAYOUT PLANNING: RELATING REASONS AND IMPORTANCE From 1. Credit department 2. Toy department 3. Wine department 4. Camera department 5. Candy department Closeness rating Letter Reason for rating Number 2 I 6 3 U -U -- To 4 A 4 I 1 U -- 5 U -A 1, 6 X 1 Area (sq. ft. ) 100 400 300 100

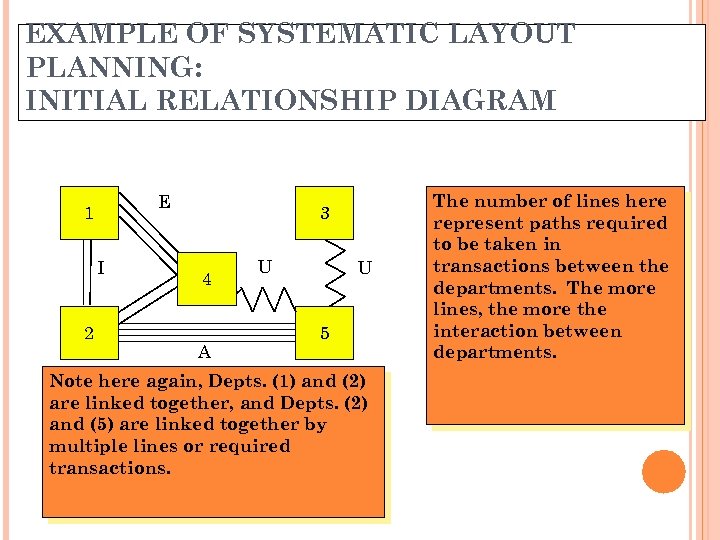

EXAMPLE OF SYSTEMATIC LAYOUT PLANNING: INITIAL RELATIONSHIP DIAGRAM E 1 I 2 3 4 A U U 5 Note here again, Depts. (1) and (2) are linked together, and Depts. (2) and (5) are linked together by multiple lines or required transactions. The number of lines here represent paths required to be taken in transactions between the departments. The more lines, the more the interaction between departments.

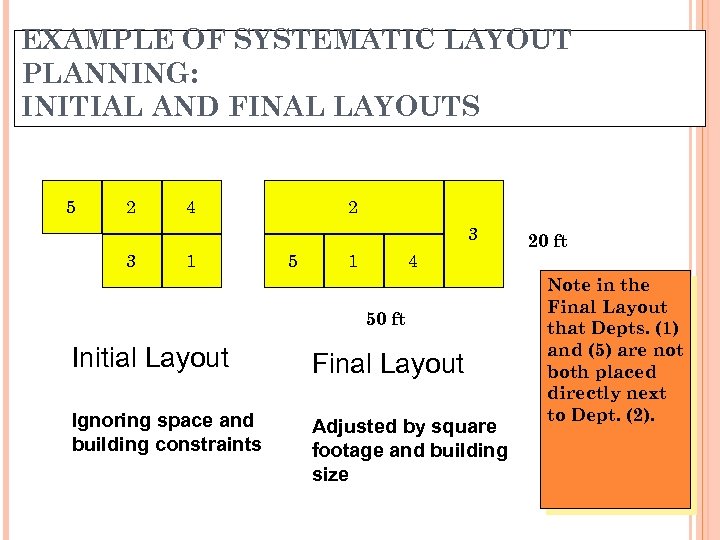

EXAMPLE OF SYSTEMATIC LAYOUT PLANNING: INITIAL AND FINAL LAYOUTS 5 2 4 2 3 3 1 5 1 4 50 ft Initial Layout Final Layout Ignoring space and building constraints Adjusted by square footage and building size 20 ft Note in the Final Layout that Depts. (1) and (5) are not both placed directly next to Dept. (2).

http: //www. youtube. com/watch? v=7 ezj. Hn. OATQs&feature=player_detailp age HTTP: //WWW. YOUTUBE. COM/WATCH? V=2 GBMA TGAGDG&FEATURE=PLAYER_DETAİLPAGE http: //www. youtube. com/watch? v=u. F 4 l 1 Imnc 0 c&fe ature=player_detailpage? http: //www. youtube. com/watch? v=gpp 6 Cv. Cgt. NY&f eature=player_detailpage

HTTP: //WWW. YOUTUBE. COM/WATCH? V=CDM 2 T 952 JYG &FEATURE=PLAYER_DETAİLPAGEP HTTP: //WWW. YOUTUBE. COM/WATCH? V=İ 6 H 7 NFHJ HTY&FEATURE=PLAYER_DETAİLPAGE http: //www. youtube. com/watch? v=Cdm 2 t 952 j. Yg&fe ature=player_detailpage http: //www. youtube. com/watch? v=i 6 H 7 nf. Hj. Ht. Y&featur e=player_detailpageoutube. com/watch? v=Pusv. Vn. C_4 Uc &feature=player_detailpage

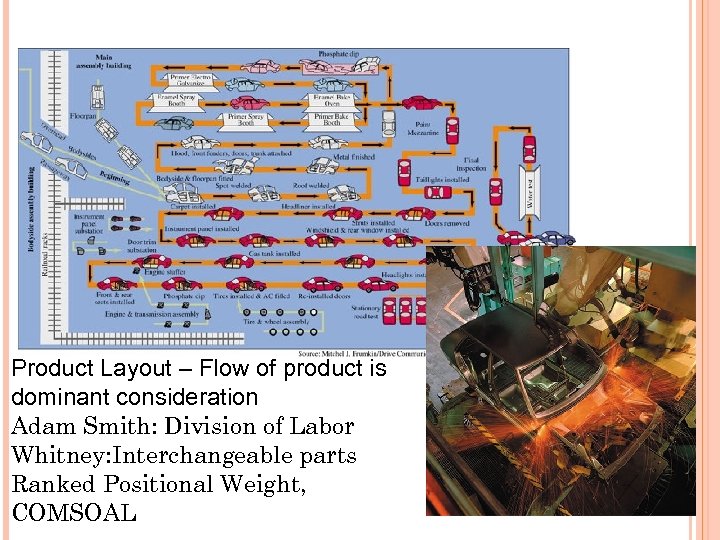

Product Layout – Flow of product is dominant consideration Adam Smith: Division of Labor Whitney: Interchangeable parts Ranked Positional Weight, COMSOAL

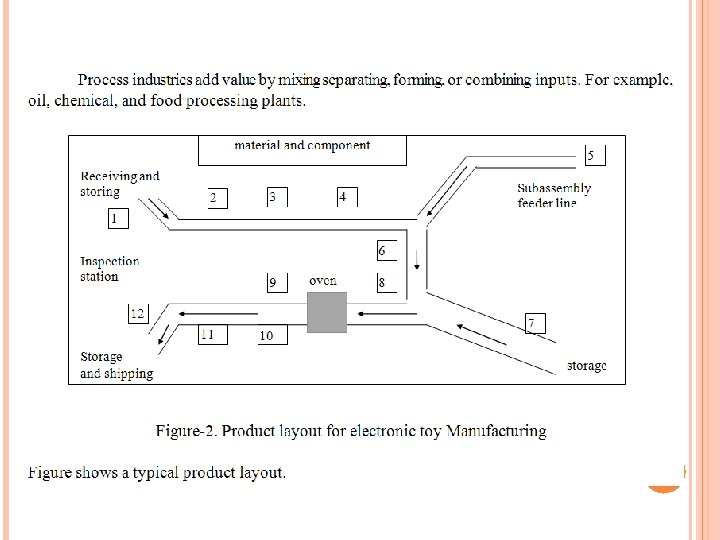

PRODUCT LAYOUT (LINE LAYOUT) Product layouts group the workers and equipment according to the sequence of operations performed on the product or customer. They lend themselves to the use of (assembly line) conveyors and automated equipment to produce large volumes of relatively few items (for instance, refrigerators and freezers). Work flow is typically continuous and guided by standardized instructions. Product layout are used in both discrete manufacturing and in process industry plants. It is important to distinguish process layouts from process industries.

Advantages High utilization of people and equipment Low material-handling cost Low-cost unskilled labor Less work-in-process inventory Disadvantages Inflexible system (unless designed for flexibility) High-cost specialized equipment Interdependent operations Dull, monotonous jobs (unless products are customized or system is flexible) expensive machine investment.

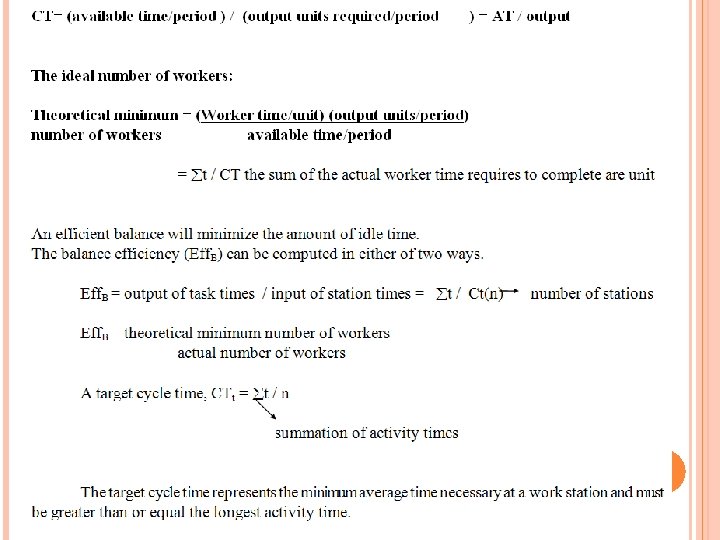

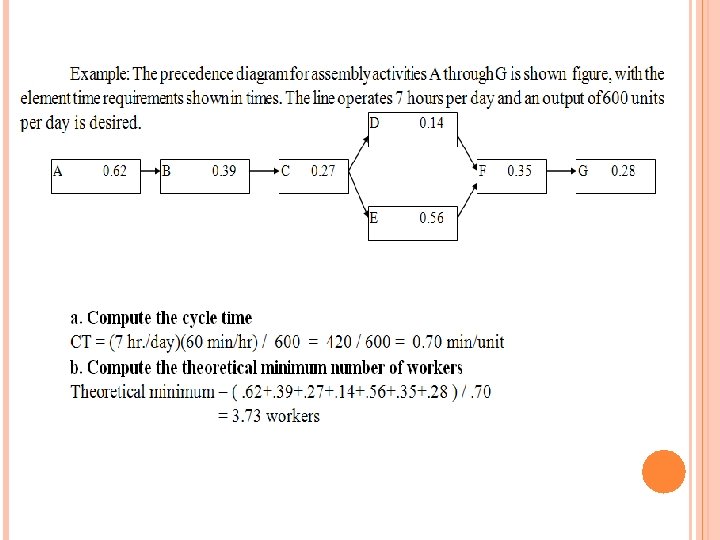

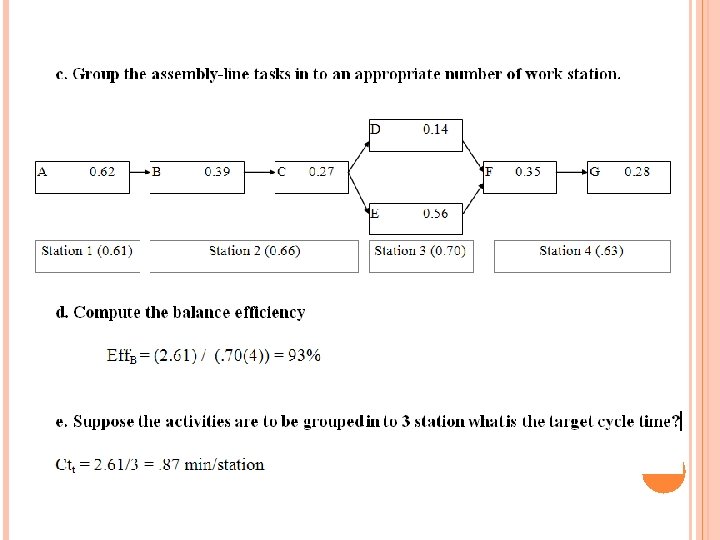

Layout analysis has focused primarily upon these two concerns: Process layout attempt to minimize material-handling costs by arranging departmental sizes and locations according to the volume and flow rate of products. Product layout attempt to maximize worker effectiveness by grouping sequential work activities in to work stations that field a high utilization of labor and equipment with a minimum of idle time. Line balancing is the apportionment of sequential work activities in to work stations in order to gain a high utilization of labor and equipment and therefore minimize idle time in product layouts. Compatible work activities are combined in to approximately equal time groupings that do not violate precedence relationships. The length of work time that a component is available at each work station is the cycle time, CT.

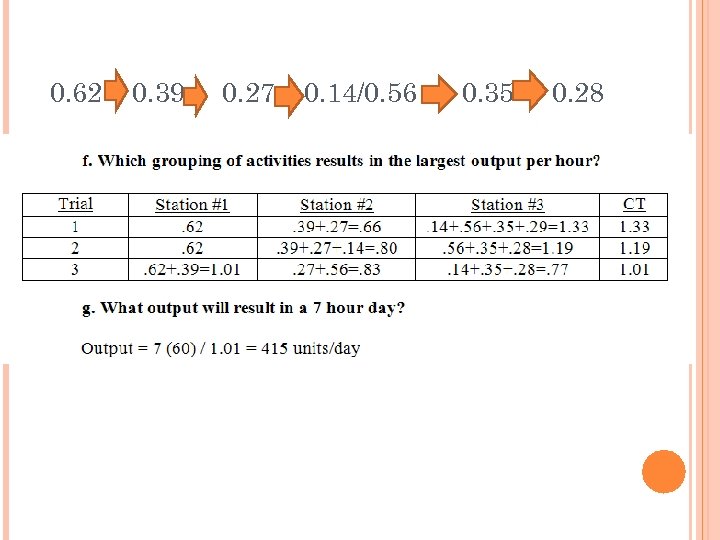

0. 62 0. 39 0. 27 0. 14/0. 56 0. 35 0. 28

FIXED POSITION LAYOUT Question: What are our primary considerations for a fixed position layout? Answer: Arranging materials and equipment concentrically around the production point in their order of use.

FIXED-POSITION LAYOUTS They are arrangements where labor, materials, and equipment are brought to the work side. They apply to construction, farming, mining, and other activities that must be completed in a particular place. Project activities can take advantage of network techniques (CPM and RERT) for planning and control. Manufacturing Cells Manufacturing cells are smaller groups of machines that are arranged according to a similarity in the operations performed. A close grouping of equipment for performing a sequence of operations on multiple units of a component or family of similar components or products is called manufacturing a cell.

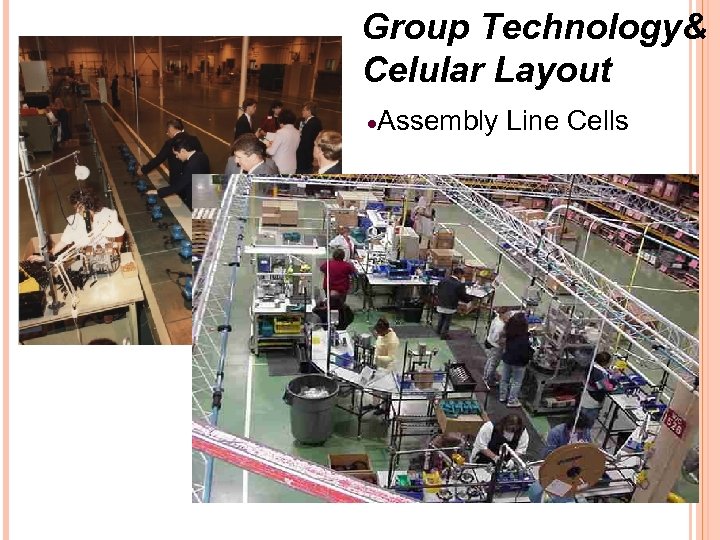

Group Technology& Celular Layout ·Assembly Line Cells

http: //www. youtube. com/watch? v=Dk. NVht. OCcr. E&feature=player_de tailpage HTTP: //WWW. YOUTUBE. COM/WATCH? V=WBPY 34 JCMOS&FEATURE=PLAYER_DETAİLPAGE http: //www. youtube. com/watch? v=i. Y 0 o. BGo 0 W 4&feature=player_detailpage

CELLULAR LAYOUTS Cellular Production Layout in which machines are grouped into a cell that can process items that have similar processing requirements Group Technology The grouping into part families of items with similar design or manufacturing characteristics

BENEFITS OF GROUP TECHNOLOGY Changeover setup time reduced for tooling and equipment Automation may be possible Operator may be specially trained with improved expertise Quality of output improved In-process inventory reduced Productivity improved Lead time reduced Improved human relations

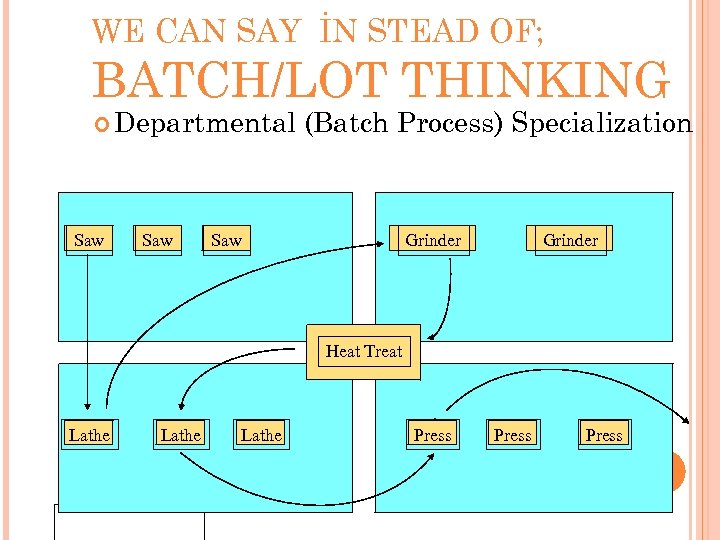

WE CAN SAY İN STEAD OF; BATCH/LOT THINKING Departmental Saw (Batch Process) Specialization Saw Grinder Heat Treat Lathe Press

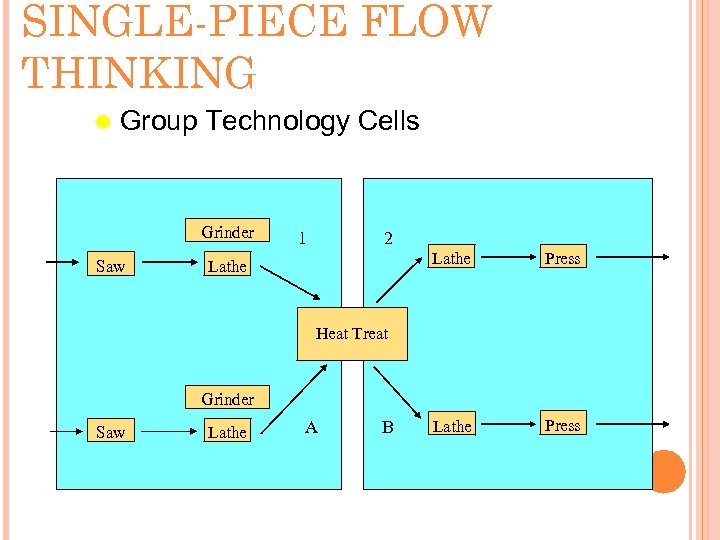

SINGLE-PIECE FLOW THINKING ® Group Technology Cells Grinder Saw 1 2 Lathe Press Heat Treat Grinder Saw Lathe A B

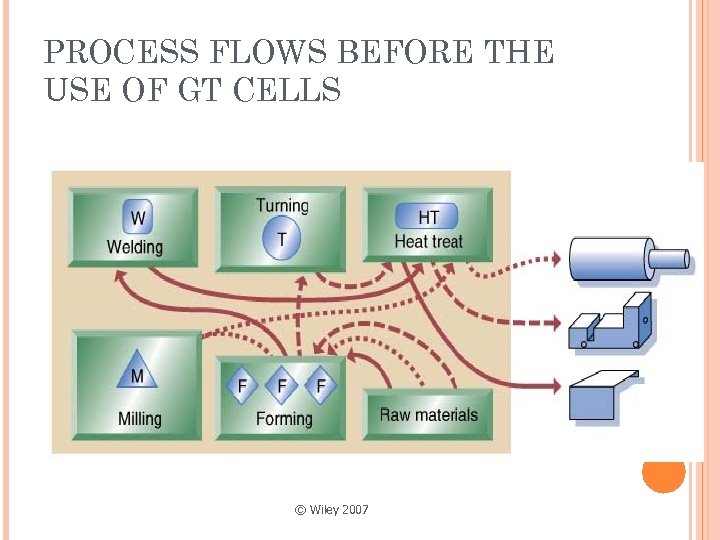

PROCESS FLOWS BEFORE THE USE OF GT CELLS © Wiley 2007

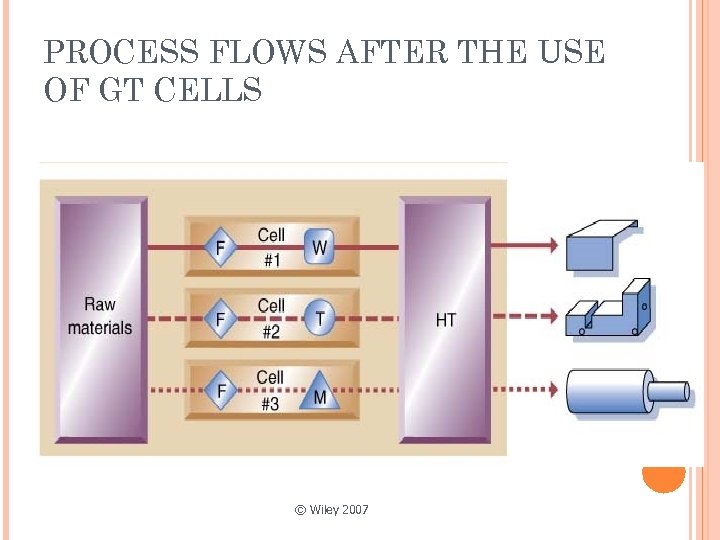

PROCESS FLOWS AFTER THE USE OF GT CELLS © Wiley 2007

Use of cellular manufacturing-affords advantages beyond reduction of the distances that parts must be moved between machines. Since movement reduces and is there fore not expensive parts do not have to be moved in large batches to spread the cost of a move over a number of units. Frequently parts are processed one by one through the steps of production, making the throughput time short and the work-in-process inventory low. Cells are typically connected with material handling equipment so that these cost are reduced. The use of cells in repetitive manufacturing plants greatly enhances just-in-time production methods. In companies that hove a large variety of parts, group technology is often helpful in selecting appropriate families of pants that can be run in cell. Figure-3 is represented it. They can be expended to words a FMS by adding a supervisory computer and machines.

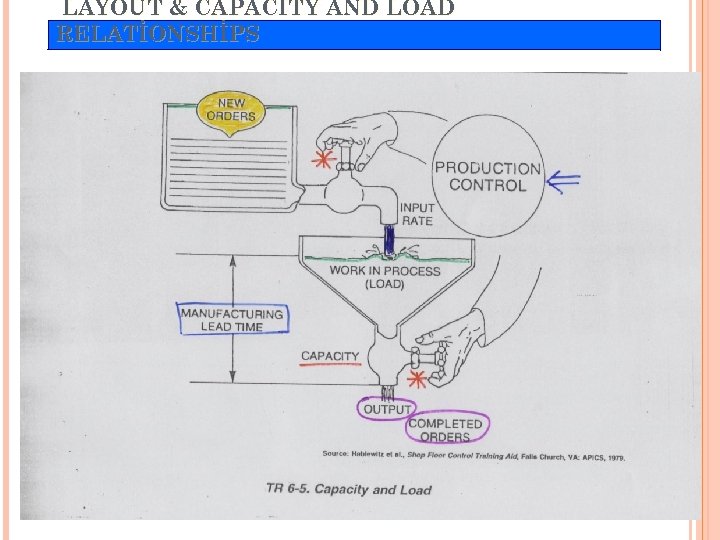

LAYOUT & CAPACITY AND LOAD RELATİONSHİPS “TR 6 -5 Capacitiy and load” eklenecek!

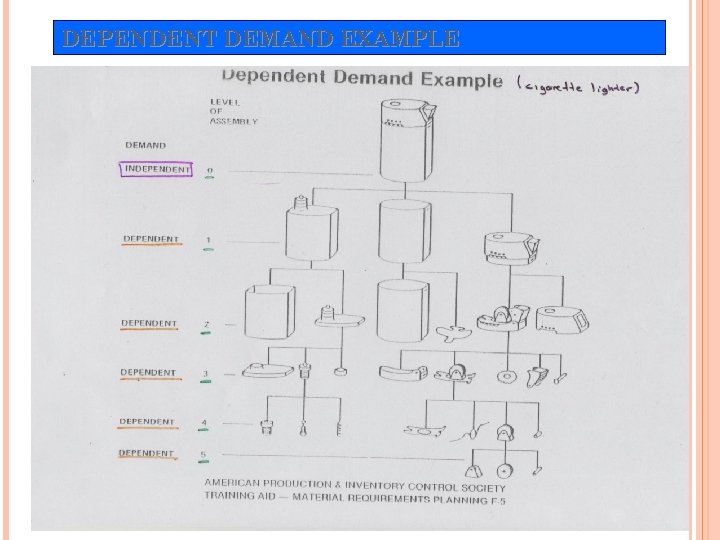

DEPENDENT DEMAND EXAMPLE

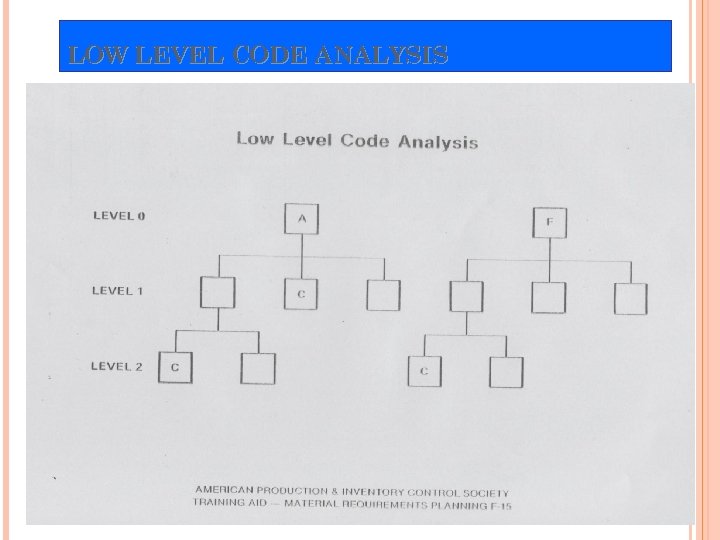

LOW LEVEL CODE ANALYSIS

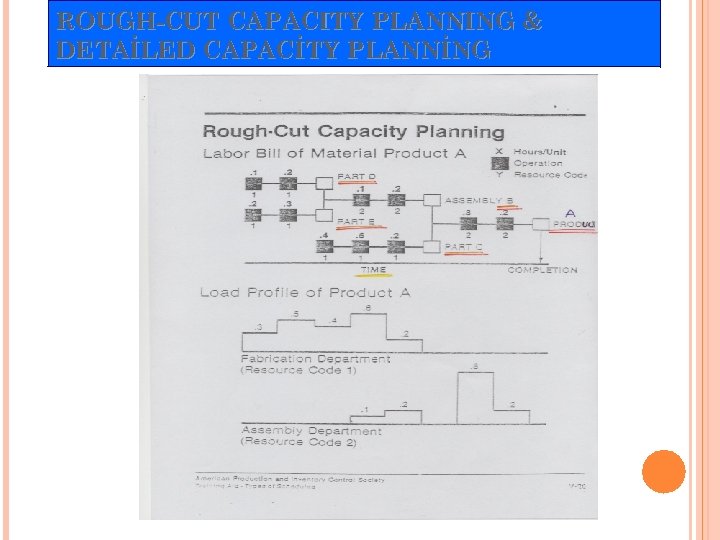

ROUGH-CUT CAPACITY PLANNING & DETAİLED CAPACİTY PLANNİNG

SERVICE FACİLİTİES LAYOUTS Warehouse and storage layouts Retail layouts Office layouts Hospital layout Fast Food Layout Hotel and Motel Layout Car Rental Layout SPA & Healthcare Layout

8 -54 İN THE SERVICES SECTOR Designing Physical Surroundings to Affect Employee and Customer Behavior Ambient Conditions: background characteristics such as noise level, music, lighting, temperature, and scent. Spatial Layout and Functionality: reception area, circulation paths of employees and customers, and focal points. Signs, Symbols, and Artifacts: selection, orientation, location, and size of objects.

OFFICE LAYOUTS Human interaction and communication are the primary considerations in office layouts People who need to interact frequently should be close to each other One key layout tradeoff is between closeness and privacy

OFFICE LAYOUTS Open concept offices promote understanding and trust. A few closed rooms are needed for private discussions, such as personnel matters. Moveable walls provide flexibility to change the layout when needed.

OFFICE LAYOUT EXAMPLE Hi-tech company – provides equipment and materials for rapid product design and manufacturing Open office plan Conference room Areas for informal meetings Product showroom for customers Cyber café and fitness center for employees

THE OTHER EXAMPLES • http: //www. authorstream. com/Presentation/Sudiksha 65030 -Facility-Layout-Lecture-Notes-Innovations. Mc. Donalds-Supermarket-Retail-Education-pptpowerpoint/

THANKS!!!

90d3808e61341856a249c0fcda49ca2a.ppt