40a9e3570dc3778b54c1ad3a237f4de5.ppt

- Количество слайдов: 41

Experts in Chem-Feed and Water Treatment Pro. Minent Pro. Mix Polymer System Customer Training – April 2009 Presented by Ed Thomas

Experts in Chem-Feed and Water Treatment Pro. Minent Pro. Mix Polymer System Customer Training – April 2009 Presented by Ed Thomas

Today's Agenda Experts in Chem-Feed and Water Treatment Pro. Mix Market Overview The Players Our Direction Sales strategy and focus Initial offering Competition Selling Against The Competition Pro. Mix System Looking Ahead

Today's Agenda Experts in Chem-Feed and Water Treatment Pro. Mix Market Overview The Players Our Direction Sales strategy and focus Initial offering Competition Selling Against The Competition Pro. Mix System Looking Ahead

The Market Experts in Chem-Feed and Water Treatment § US polymer feed market 30 -35 million annually § Stranco had 10 -12 million § Dynablend 6 -7 million (Growing) § The smaller players 15 -20 million § 300 -400 polymer projects bidding annually § Typically 15 -150 k § 16, 500 wastewater treatment plants in US § 156, 000 drinking water systems in US § Canada – Indachem ~ 300 k – 60/40 municipal/industrial § W&T 300 -400 K

The Market Experts in Chem-Feed and Water Treatment § US polymer feed market 30 -35 million annually § Stranco had 10 -12 million § Dynablend 6 -7 million (Growing) § The smaller players 15 -20 million § 300 -400 polymer projects bidding annually § Typically 15 -150 k § 16, 500 wastewater treatment plants in US § 156, 000 drinking water systems in US § Canada – Indachem ~ 300 k – 60/40 municipal/industrial § W&T 300 -400 K

The Players Experts in Chem-Feed and Water Treatment § Siemens/Stranco/W&T Polyblend § Neptune § Dynablend § Komax § Semblex § Jet Wet (Dyna-Jet) § Acrison § Chemflow § Excell § Norchem § Hummix § Enpro § New Dynablend

The Players Experts in Chem-Feed and Water Treatment § Siemens/Stranco/W&T Polyblend § Neptune § Dynablend § Komax § Semblex § Jet Wet (Dyna-Jet) § Acrison § Chemflow § Excell § Norchem § Hummix § Enpro § New Dynablend

Siemens Experts in Chem-Feed and Water Treatment § Polyblend § Market leader? § Losing of Key People § Slipping on Submittals, Deliveries § Losing application experience § Production Problems § Reps Dissatisfaction § 1 st & 2 nd tier reps § Municipal stronger than industrial

Siemens Experts in Chem-Feed and Water Treatment § Polyblend § Market leader? § Losing of Key People § Slipping on Submittals, Deliveries § Losing application experience § Production Problems § Reps Dissatisfaction § 1 st & 2 nd tier reps § Municipal stronger than industrial

Siemens Experts in Chem-Feed and Water Treatment

Siemens Experts in Chem-Feed and Water Treatment

Acrison Experts in Chem-Feed and Water Treatment § Liquid Polymer & Dry feed Systems § Complete dry feed line § Solid reputation in engineered projects § Lack flexibility § Has 1 st & 2 nd tier reps § Municipal stronger than industrial

Acrison Experts in Chem-Feed and Water Treatment § Liquid Polymer & Dry feed Systems § Complete dry feed line § Solid reputation in engineered projects § Lack flexibility § Has 1 st & 2 nd tier reps § Municipal stronger than industrial

Acrison Experts in Chem-Feed and Water Treatment § Liquid Polymer & Dry feed Systems § Complete dry feed line § Solid reputation in engineered projects § Lack flexibility § Has 1 st & 2 nd tier reps § Municipal stronger than industrial

Acrison Experts in Chem-Feed and Water Treatment § Liquid Polymer & Dry feed Systems § Complete dry feed line § Solid reputation in engineered projects § Lack flexibility § Has 1 st & 2 nd tier reps § Municipal stronger than industrial

Acrison Experts in Chem-Feed and Water Treatment

Acrison Experts in Chem-Feed and Water Treatment

Neptune Experts in Chem-Feed and Water Treatment § Dynablend, Komax, Semblex, Dyna-Jet § Confusing Market § Reps bidding against themselves § Have not settled on product direction § Municipal & industrial

Neptune Experts in Chem-Feed and Water Treatment § Dynablend, Komax, Semblex, Dyna-Jet § Confusing Market § Reps bidding against themselves § Have not settled on product direction § Municipal & industrial

Neptune Experts in Chem-Feed and Water Treatment

Neptune Experts in Chem-Feed and Water Treatment

Chemflow Experts in Chem-Feed and Water Treatment § Have not settled on product direction § Industrial focus § Trying to play in municipal market § No strong rep force § Questionable Quality Control § Good application experience

Chemflow Experts in Chem-Feed and Water Treatment § Have not settled on product direction § Industrial focus § Trying to play in municipal market § No strong rep force § Questionable Quality Control § Good application experience

Chemflow Experts in Chem-Feed and Water Treatment

Chemflow Experts in Chem-Feed and Water Treatment

Norchem Experts in Chem-Feed and Water Treatment § Industrial focus § Strong in paper market § Does not bid municipal § Products/company on market?

Norchem Experts in Chem-Feed and Water Treatment § Industrial focus § Strong in paper market § Does not bid municipal § Products/company on market?

Norchem Experts in Chem-Feed and Water Treatment

Norchem Experts in Chem-Feed and Water Treatment

Excell – Hummix – Enpro – (New Dynablend) Experts in Chem-Feed and Water Treatment § § § § Smaller players Play in all markets No real rep force Cherry pick opportunities Low ball bidders New Dynablend establishing rep force Enpro has original PB designer on retainer – New patent

Excell – Hummix – Enpro – (New Dynablend) Experts in Chem-Feed and Water Treatment § § § § Smaller players Play in all markets No real rep force Cherry pick opportunities Low ball bidders New Dynablend establishing rep force Enpro has original PB designer on retainer – New patent

Focus on Today Experts in Chem-Feed and Water Treatment Primary focus on short term targets Municipal retrofit Industrial end users OEM’s Chem Vendors

Focus on Today Experts in Chem-Feed and Water Treatment Primary focus on short term targets Municipal retrofit Industrial end users OEM’s Chem Vendors

Target Strategy Experts in Chem-Feed and Water Treatment Quick close projects to develop installation list Promote “try & buy” Conduct polymer & product seminars Maintain high market visibility Demo Program

Target Strategy Experts in Chem-Feed and Water Treatment Quick close projects to develop installation list Promote “try & buy” Conduct polymer & product seminars Maintain high market visibility Demo Program

Pro. Mix Basic Unit Experts in Chem-Feed and Water Treatment Initial Offering – Where does it fit? Potential applications for present size systems include: Municipal Clarifier Applications up to about 5 MGD Small rotary drum thickener applications Small gravity belt thickeners applications Most 1 meter belt press applications Phosphorus Removal Applications Digester Sludge thickening Drying Beds

Pro. Mix Basic Unit Experts in Chem-Feed and Water Treatment Initial Offering – Where does it fit? Potential applications for present size systems include: Municipal Clarifier Applications up to about 5 MGD Small rotary drum thickener applications Small gravity belt thickeners applications Most 1 meter belt press applications Phosphorus Removal Applications Digester Sludge thickening Drying Beds

Pro. Mix Basic Unit Experts in Chem-Feed and Water Treatment Initial Offering – Where does it fit? Potential applications for present size systems include: Municipal Clarifier Applications up to about 5 MGD Small rotary drum thickener applications Small gravity belt thickeners applications Most 1 meter belt press applications Phosphorus Removal Applications Digester Sludge thickening Drying Beds

Pro. Mix Basic Unit Experts in Chem-Feed and Water Treatment Initial Offering – Where does it fit? Potential applications for present size systems include: Municipal Clarifier Applications up to about 5 MGD Small rotary drum thickener applications Small gravity belt thickeners applications Most 1 meter belt press applications Phosphorus Removal Applications Digester Sludge thickening Drying Beds

Pro. Mix Basic Unit Experts in Chem-Feed and Water Treatment Initial Offering – Where does it fit? Potential applications for present size systems include: Industrial Clarifier Applications up to about 5 MGD Dynasand Filters – Continuous backwashing sand filters Inclined Plate Separators Pressure Filter polishing Phosphorus Removal Applications Digester Sludge thickening Small Centrifuges (refinery oily waste) Potable Water make-up plant Plating Industry wastewater

Pro. Mix Basic Unit Experts in Chem-Feed and Water Treatment Initial Offering – Where does it fit? Potential applications for present size systems include: Industrial Clarifier Applications up to about 5 MGD Dynasand Filters – Continuous backwashing sand filters Inclined Plate Separators Pressure Filter polishing Phosphorus Removal Applications Digester Sludge thickening Small Centrifuges (refinery oily waste) Potable Water make-up plant Plating Industry wastewater

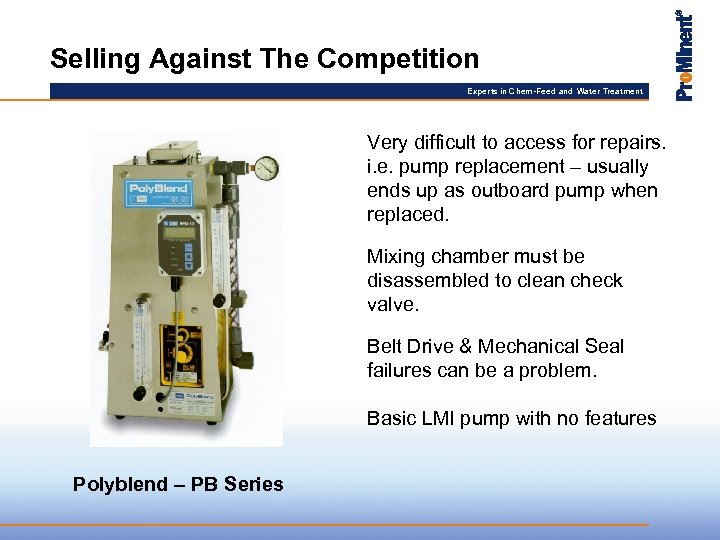

Selling Against The Competition Experts in Chem-Feed and Water Treatment Very difficult to access for repairs. i. e. pump replacement – usually ends up as outboard pump when replaced. Mixing chamber must be disassembled to clean check valve. Belt Drive & Mechanical Seal failures can be a problem. Basic LMI pump with no features Polyblend – PB Series

Selling Against The Competition Experts in Chem-Feed and Water Treatment Very difficult to access for repairs. i. e. pump replacement – usually ends up as outboard pump when replaced. Mixing chamber must be disassembled to clean check valve. Belt Drive & Mechanical Seal failures can be a problem. Basic LMI pump with no features Polyblend – PB Series

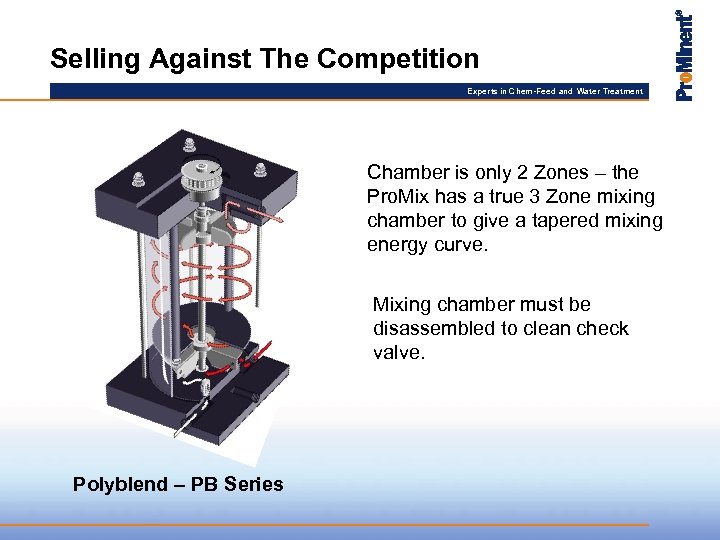

Selling Against The Competition Experts in Chem-Feed and Water Treatment Chamber is only 2 Zones – the Pro. Mix has a true 3 Zone mixing chamber to give a tapered mixing energy curve. Mixing chamber must be disassembled to clean check valve. Polyblend – PB Series

Selling Against The Competition Experts in Chem-Feed and Water Treatment Chamber is only 2 Zones – the Pro. Mix has a true 3 Zone mixing chamber to give a tapered mixing energy curve. Mixing chamber must be disassembled to clean check valve. Polyblend – PB Series

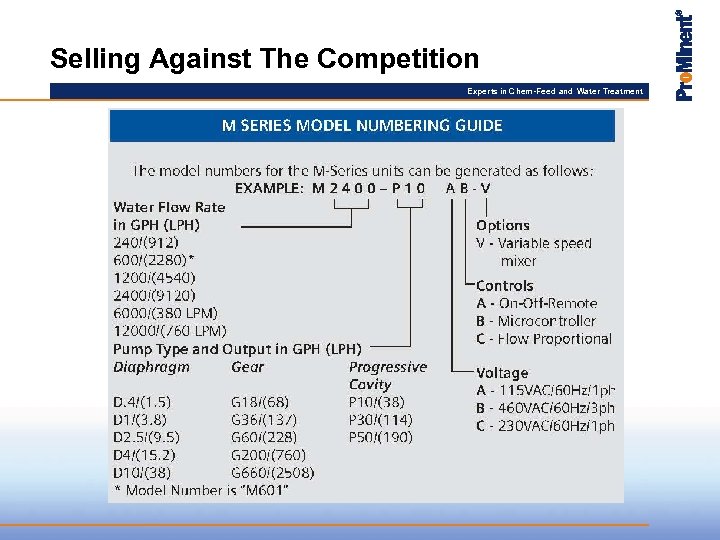

Selling Against The Competition Experts in Chem-Feed and Water Treatment

Selling Against The Competition Experts in Chem-Feed and Water Treatment

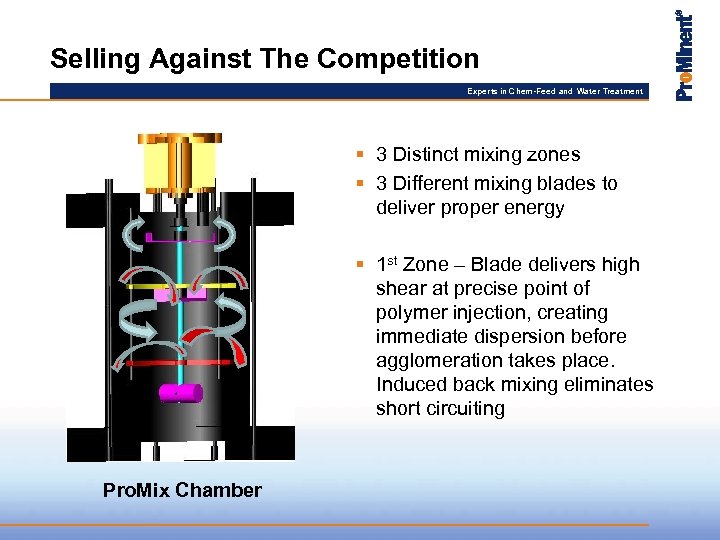

Selling Against The Competition Experts in Chem-Feed and Water Treatment § 3 Distinct mixing zones § 3 Different mixing blades to deliver proper energy § 1 st Zone – Blade delivers high shear at precise point of polymer injection, creating immediate dispersion before agglomeration takes place. Induced back mixing eliminates short circuiting Pro. Mix Chamber

Selling Against The Competition Experts in Chem-Feed and Water Treatment § 3 Distinct mixing zones § 3 Different mixing blades to deliver proper energy § 1 st Zone – Blade delivers high shear at precise point of polymer injection, creating immediate dispersion before agglomeration takes place. Induced back mixing eliminates short circuiting Pro. Mix Chamber

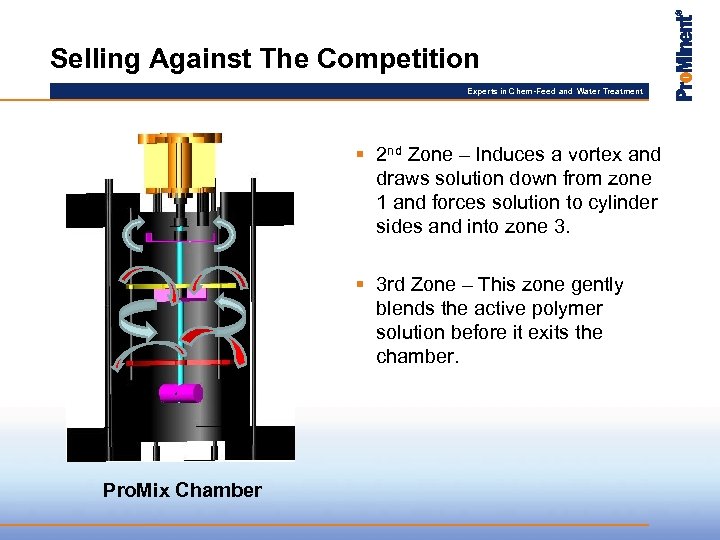

Selling Against The Competition Experts in Chem-Feed and Water Treatment § 2 nd Zone – Induces a vortex and draws solution down from zone 1 and forces solution to cylinder sides and into zone 3. § 3 rd Zone – This zone gently blends the active polymer solution before it exits the chamber. Pro. Mix Chamber

Selling Against The Competition Experts in Chem-Feed and Water Treatment § 2 nd Zone – Induces a vortex and draws solution down from zone 1 and forces solution to cylinder sides and into zone 3. § 3 rd Zone – This zone gently blends the active polymer solution before it exits the chamber. Pro. Mix Chamber

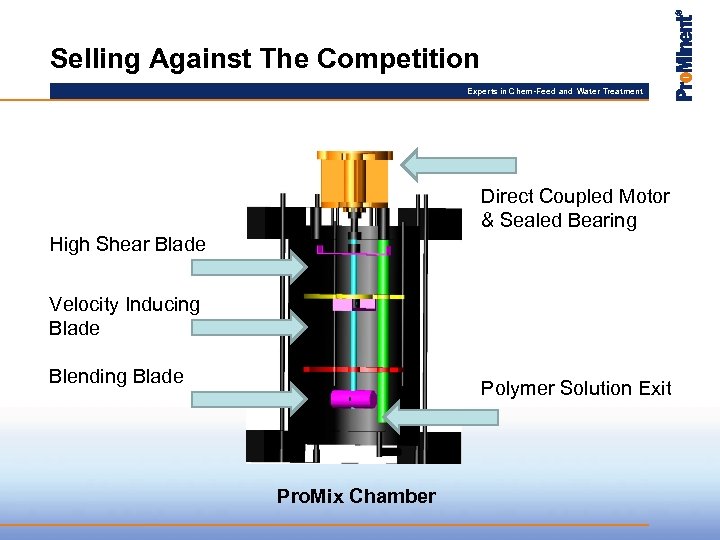

Selling Against The Competition Experts in Chem-Feed and Water Treatment Direct Coupled Motor & Sealed Bearing High Shear Blade Velocity Inducing Blade Blending Blade Polymer Solution Exit Pro. Mix Chamber

Selling Against The Competition Experts in Chem-Feed and Water Treatment Direct Coupled Motor & Sealed Bearing High Shear Blade Velocity Inducing Blade Blending Blade Polymer Solution Exit Pro. Mix Chamber

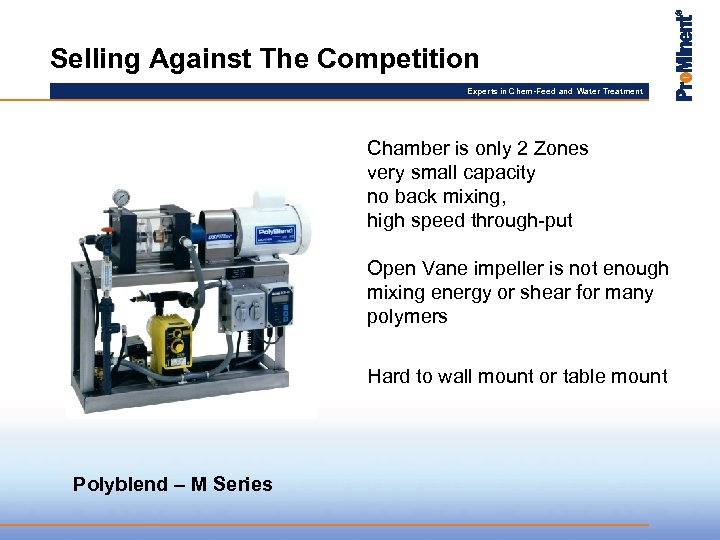

Selling Against The Competition Experts in Chem-Feed and Water Treatment Chamber is only 2 Zones very small capacity no back mixing, high speed through-put Open Vane impeller is not enough mixing energy or shear for many polymers Hard to wall mount or table mount Polyblend – M Series

Selling Against The Competition Experts in Chem-Feed and Water Treatment Chamber is only 2 Zones very small capacity no back mixing, high speed through-put Open Vane impeller is not enough mixing energy or shear for many polymers Hard to wall mount or table mount Polyblend – M Series

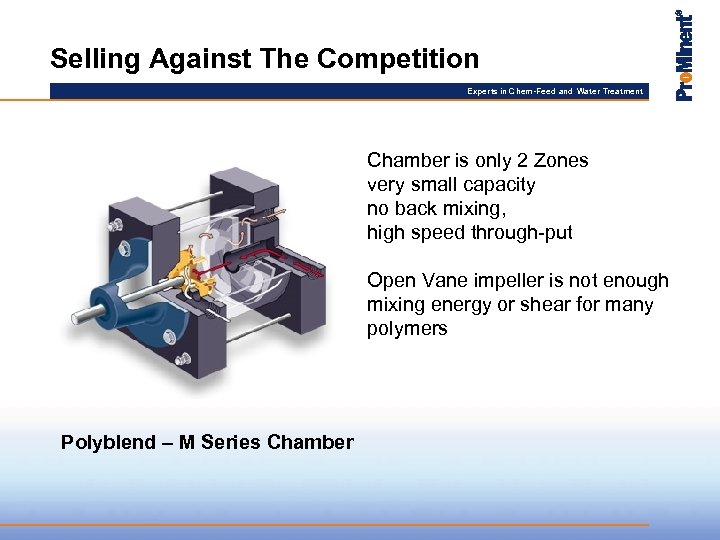

Selling Against The Competition Experts in Chem-Feed and Water Treatment Chamber is only 2 Zones very small capacity no back mixing, high speed through-put Open Vane impeller is not enough mixing energy or shear for many polymers Polyblend – M Series Chamber

Selling Against The Competition Experts in Chem-Feed and Water Treatment Chamber is only 2 Zones very small capacity no back mixing, high speed through-put Open Vane impeller is not enough mixing energy or shear for many polymers Polyblend – M Series Chamber

Selling Against The Competition Experts in Chem-Feed and Water Treatment Dynablend – Gaining Market share from Stranco Now owned and manufactured under the Neptune roof – along with Komax, Semblex, and Jet Wet. Most of the reps don’t understand polymer activation technology, but have made inroads bidding Stranco specs over the years Dynablend

Selling Against The Competition Experts in Chem-Feed and Water Treatment Dynablend – Gaining Market share from Stranco Now owned and manufactured under the Neptune roof – along with Komax, Semblex, and Jet Wet. Most of the reps don’t understand polymer activation technology, but have made inroads bidding Stranco specs over the years Dynablend

Selling Against The Competition Experts in Chem-Feed and Water Treatment Flow and pressure fluctuations have a direct effect on the energy available for polymer activation. Booster pumps are essential in most applications. Uses a concentric chamber to produce a centrifuge effect to try and separate undispersed agglomerates back into the incoming mixing water…. it’s too late to correct at that point. Dynablend

Selling Against The Competition Experts in Chem-Feed and Water Treatment Flow and pressure fluctuations have a direct effect on the energy available for polymer activation. Booster pumps are essential in most applications. Uses a concentric chamber to produce a centrifuge effect to try and separate undispersed agglomerates back into the incoming mixing water…. it’s too late to correct at that point. Dynablend

Selling Against The Competition Experts in Chem-Feed and Water Treatment Units are primarily in the municipal market sold on price alone, usually walk away in cases of performance trials. Little effort to develop a very strong industrial rep force. Dynablend

Selling Against The Competition Experts in Chem-Feed and Water Treatment Units are primarily in the municipal market sold on price alone, usually walk away in cases of performance trials. Little effort to develop a very strong industrial rep force. Dynablend

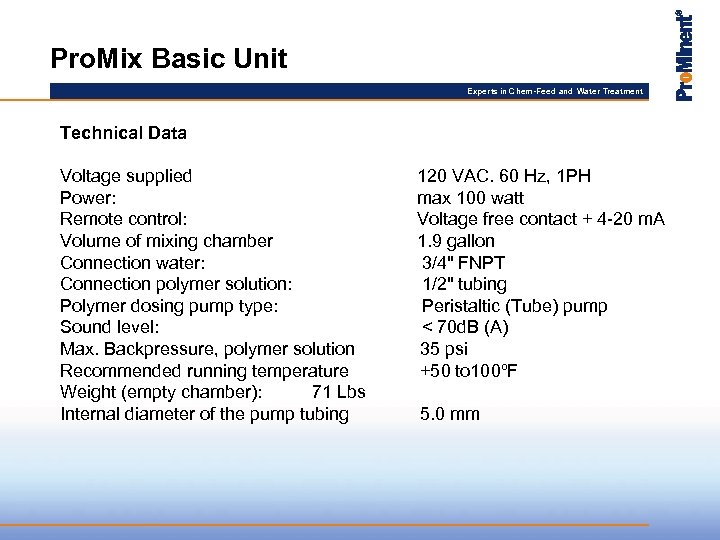

Pro. Mix Basic Unit Experts in Chem-Feed and Water Treatment Technical Data Voltage supplied 120 VAC. 60 Hz, 1 PH Power: max 100 watt Remote control: Voltage free contact + 4 -20 m. A Volume of mixing chamber 1. 9 gallon Connection water: 3/4" FNPT Connection polymer solution: 1/2" tubing Polymer dosing pump type: Peristaltic (Tube) pump Sound level: < 70 d. B (A) Max. Backpressure, polymer solution 35 psi Recommended running temperature +50 to 100ºF Weight (empty chamber): 71 Lbs Internal diameter of the pump tubing 5. 0 mm

Pro. Mix Basic Unit Experts in Chem-Feed and Water Treatment Technical Data Voltage supplied 120 VAC. 60 Hz, 1 PH Power: max 100 watt Remote control: Voltage free contact + 4 -20 m. A Volume of mixing chamber 1. 9 gallon Connection water: 3/4" FNPT Connection polymer solution: 1/2" tubing Polymer dosing pump type: Peristaltic (Tube) pump Sound level: < 70 d. B (A) Max. Backpressure, polymer solution 35 psi Recommended running temperature +50 to 100ºF Weight (empty chamber): 71 Lbs Internal diameter of the pump tubing 5. 0 mm

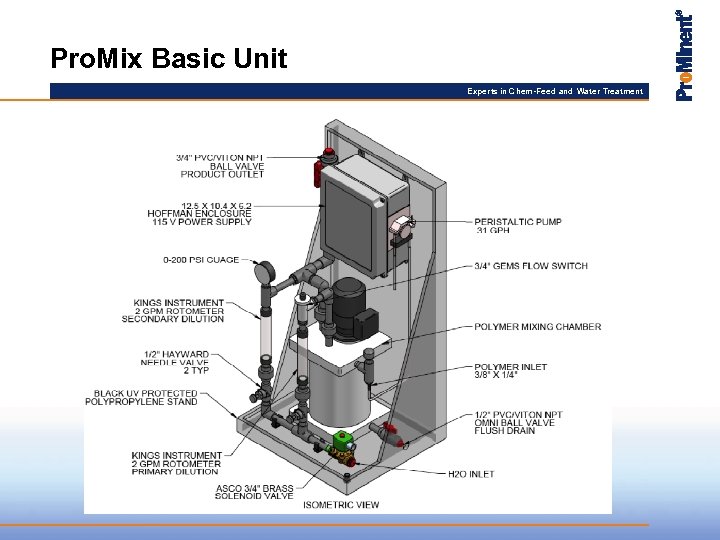

Pro. Mix Basic Unit Experts in Chem-Feed and Water Treatment

Pro. Mix Basic Unit Experts in Chem-Feed and Water Treatment

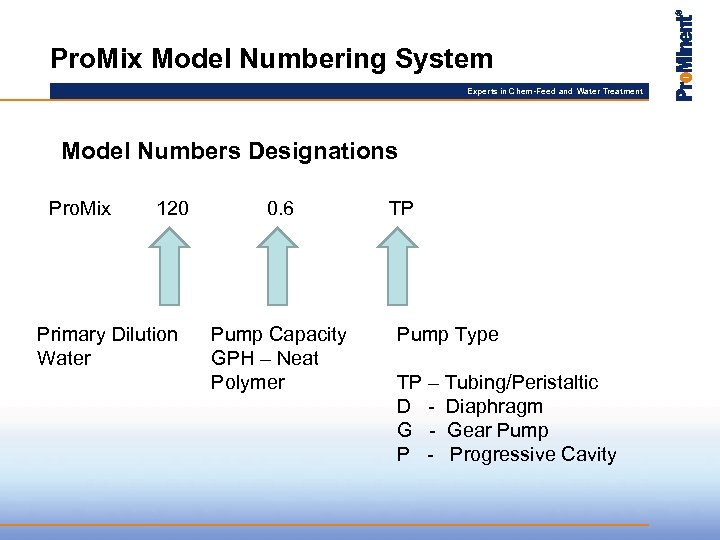

Pro. Mix Model Numbering System Experts in Chem-Feed and Water Treatment Model Numbers Designations Pro. Mix 120 0. 6 TP Primary Dilution Water Pump Capacity GPH – Neat Polymer Pump Type TP – Tubing/Peristaltic D - Diaphragm G - Gear Pump P - Progressive Cavity

Pro. Mix Model Numbering System Experts in Chem-Feed and Water Treatment Model Numbers Designations Pro. Mix 120 0. 6 TP Primary Dilution Water Pump Capacity GPH – Neat Polymer Pump Type TP – Tubing/Peristaltic D - Diaphragm G - Gear Pump P - Progressive Cavity

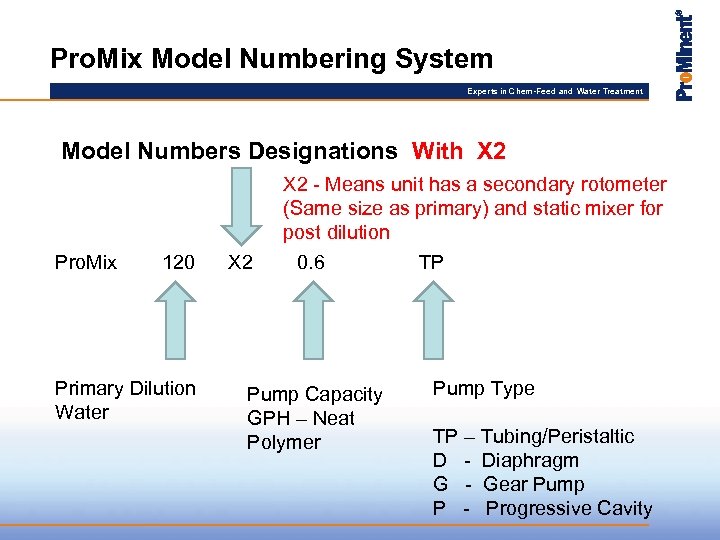

Pro. Mix Model Numbering System Experts in Chem-Feed and Water Treatment Model Numbers Designations With X 2 - Means unit has a secondary rotometer (Same size as primary) and static mixer for post dilution Pro. Mix 120 X 2 0. 6 TP Primary Dilution Water Pump Capacity GPH – Neat Polymer Pump Type TP – Tubing/Peristaltic D - Diaphragm G - Gear Pump P - Progressive Cavity

Pro. Mix Model Numbering System Experts in Chem-Feed and Water Treatment Model Numbers Designations With X 2 - Means unit has a secondary rotometer (Same size as primary) and static mixer for post dilution Pro. Mix 120 X 2 0. 6 TP Primary Dilution Water Pump Capacity GPH – Neat Polymer Pump Type TP – Tubing/Peristaltic D - Diaphragm G - Gear Pump P - Progressive Cavity

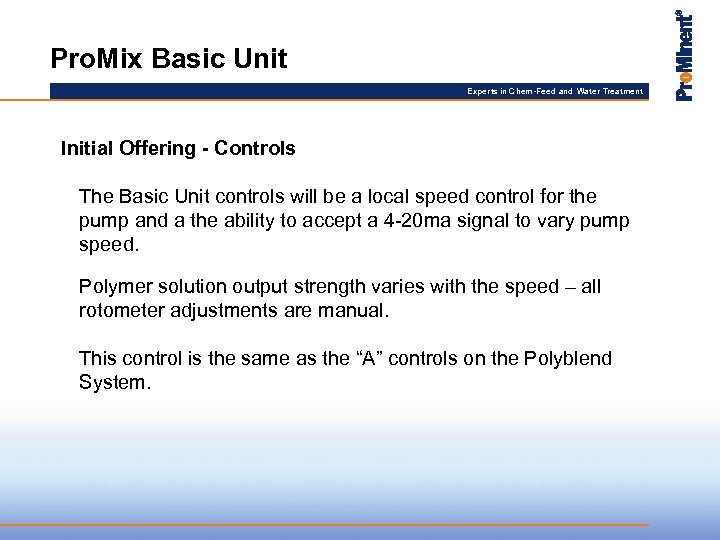

Pro. Mix Basic Unit Experts in Chem-Feed and Water Treatment Initial Offering - Controls The Basic Unit controls will be a local speed control for the pump and a the ability to accept a 4 -20 ma signal to vary pump speed. Polymer solution output strength varies with the speed – all rotometer adjustments are manual. This control is the same as the “A” controls on the Polyblend System.

Pro. Mix Basic Unit Experts in Chem-Feed and Water Treatment Initial Offering - Controls The Basic Unit controls will be a local speed control for the pump and a the ability to accept a 4 -20 ma signal to vary pump speed. Polymer solution output strength varies with the speed – all rotometer adjustments are manual. This control is the same as the “A” controls on the Polyblend System.

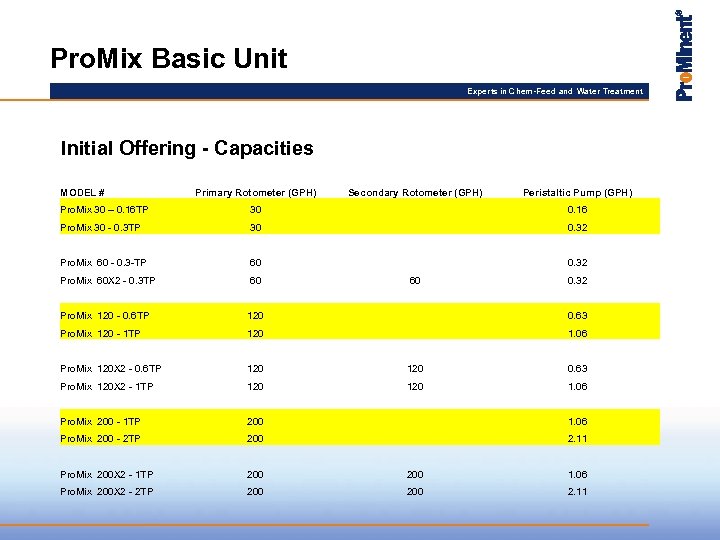

Pro. Mix Basic Unit Experts in Chem-Feed and Water Treatment Initial Offering - Capacities MODEL # Primary Rotometer (GPH) Secondary Rotometer (GPH) Peristaltic Pump (GPH) Pro. Mix 30 – 0. 16 TP 30 0. 16 Pro. Mix 30 - 0. 3 TP 30 Pro. Mix 60 - 0. 3 -TP 60 Pro. Mix 60 X 2 - 0. 3 TP 60 60 0. 32 Pro. Mix 120 - 0. 6 TP 120 0. 63 Pro. Mix 120 - 1 TP 120 1. 06 Pro. Mix 120 X 2 - 0. 6 TP 120 0. 63 Pro. Mix 120 X 2 - 1 TP 120 1. 06 Pro. Mix 200 - 1 TP 200 1. 06 Pro. Mix 200 - 2 TP 200 2. 11 Pro. Mix 200 X 2 - 1 TP 200 1. 06 Pro. Mix 200 X 2 - 2 TP 200 2. 11 0. 32

Pro. Mix Basic Unit Experts in Chem-Feed and Water Treatment Initial Offering - Capacities MODEL # Primary Rotometer (GPH) Secondary Rotometer (GPH) Peristaltic Pump (GPH) Pro. Mix 30 – 0. 16 TP 30 0. 16 Pro. Mix 30 - 0. 3 TP 30 Pro. Mix 60 - 0. 3 -TP 60 Pro. Mix 60 X 2 - 0. 3 TP 60 60 0. 32 Pro. Mix 120 - 0. 6 TP 120 0. 63 Pro. Mix 120 - 1 TP 120 1. 06 Pro. Mix 120 X 2 - 0. 6 TP 120 0. 63 Pro. Mix 120 X 2 - 1 TP 120 1. 06 Pro. Mix 200 - 1 TP 200 1. 06 Pro. Mix 200 - 2 TP 200 2. 11 Pro. Mix 200 X 2 - 1 TP 200 1. 06 Pro. Mix 200 X 2 - 2 TP 200 2. 11 0. 32

Pro. Mix The Future Experts in Chem-Feed and Water Treatment Several Control Variations Full integration of Pro. Minent Pumps Larger Capacities Dual Feed Systems Complete Line of Accessories Engineering Sizing and Selection Tools White Papers & Case Histories

Pro. Mix The Future Experts in Chem-Feed and Water Treatment Several Control Variations Full integration of Pro. Minent Pumps Larger Capacities Dual Feed Systems Complete Line of Accessories Engineering Sizing and Selection Tools White Papers & Case Histories

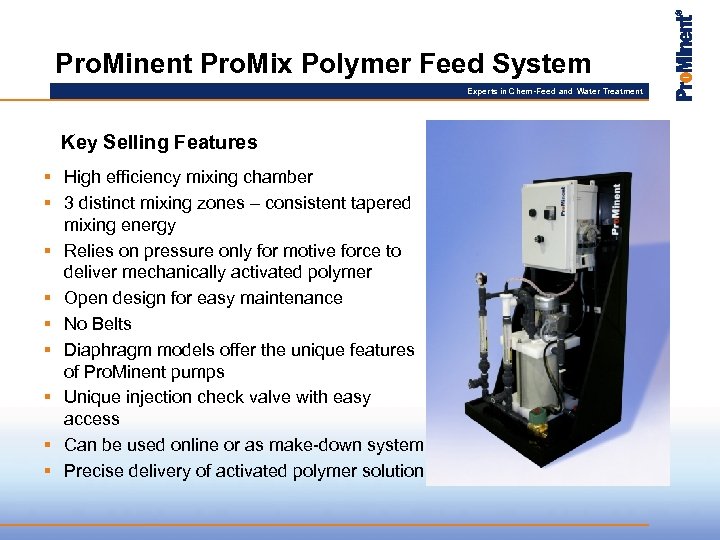

Pro. Minent Pro. Mix Polymer Feed System Experts in Chem-Feed and Water Treatment Key Selling Features § High efficiency mixing chamber § 3 distinct mixing zones – consistent tapered mixing energy § Relies on pressure only for motive force to deliver mechanically activated polymer § Open design for easy maintenance § No Belts § Diaphragm models offer the unique features of Pro. Minent pumps § Unique injection check valve with easy access § Can be used online or as make-down system § Precise delivery of activated polymer solution

Pro. Minent Pro. Mix Polymer Feed System Experts in Chem-Feed and Water Treatment Key Selling Features § High efficiency mixing chamber § 3 distinct mixing zones – consistent tapered mixing energy § Relies on pressure only for motive force to deliver mechanically activated polymer § Open design for easy maintenance § No Belts § Diaphragm models offer the unique features of Pro. Minent pumps § Unique injection check valve with easy access § Can be used online or as make-down system § Precise delivery of activated polymer solution

Pro. Minent Pro. Mix Polymer Feed System Experts in Chem-Feed and Water Treatment § § § § MORE Performance LESS Operating Cost MORE Reliability LESS Maintenance MORE Simplicity LESS Headaches MORE Controls LESS Attention

Pro. Minent Pro. Mix Polymer Feed System Experts in Chem-Feed and Water Treatment § § § § MORE Performance LESS Operating Cost MORE Reliability LESS Maintenance MORE Simplicity LESS Headaches MORE Controls LESS Attention