db2a97126f9b1ec49d93b498e92c6c81.ppt

- Количество слайдов: 36

Executive Overview EX-201 Ready. Resourceful. Responsive! 1

Executive Overview EX-201 Ready. Resourceful. Responsive! 1

Agenda NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Course Mission Statement ERP Overview Major Terms & Concepts SMART Integrated Scenarios SAP Repair Cycle Demonstration 2

Agenda NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Course Mission Statement ERP Overview Major Terms & Concepts SMART Integrated Scenarios SAP Repair Cycle Demonstration 2

Course Mission Statement NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS To provide the tools to understand ERP and its impacts to the Navy and to demonstrate a real-world scenario of the Navy’s use of ERP. In other words: “To know the right questions to ask and to understand the answers given. ” 3

Course Mission Statement NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS To provide the tools to understand ERP and its impacts to the Navy and to demonstrate a real-world scenario of the Navy’s use of ERP. In other words: “To know the right questions to ask and to understand the answers given. ” 3

NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS ERP Overview 4

NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS ERP Overview 4

ERP Overview Outline NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Why ERP? What’s our approach? What investment is required? What will it buy the Navy? 5

ERP Overview Outline NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Why ERP? What’s our approach? What investment is required? What will it buy the Navy? 5

Why ERP? NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS ERP is NOT about IT or software! ERP is about how business is done Reengineer business processes Establish common data and practices Establish Single Entry – Single Source Reduce number of applications Establish End-to-End process connectivity Comply with Federal financial standards Enable effective implementation of Activity Based Costing (ABC) 6

Why ERP? NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS ERP is NOT about IT or software! ERP is about how business is done Reengineer business processes Establish common data and practices Establish Single Entry – Single Source Reduce number of applications Establish End-to-End process connectivity Comply with Federal financial standards Enable effective implementation of Activity Based Costing (ABC) 6

Relationship to Existing Systems NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Provides backbone to leverage best commercial business practices Replaces legacy systems requiring upgrades Capitalizes on Navy, Other Services, and DOD Investments Provides the means to achieve common ashore / afloat processes Enhances speed and accuracy in decision making Enables e. Business extensions 7

Relationship to Existing Systems NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Provides backbone to leverage best commercial business practices Replaces legacy systems requiring upgrades Capitalizes on Navy, Other Services, and DOD Investments Provides the means to achieve common ashore / afloat processes Enhances speed and accuracy in decision making Enables e. Business extensions 7

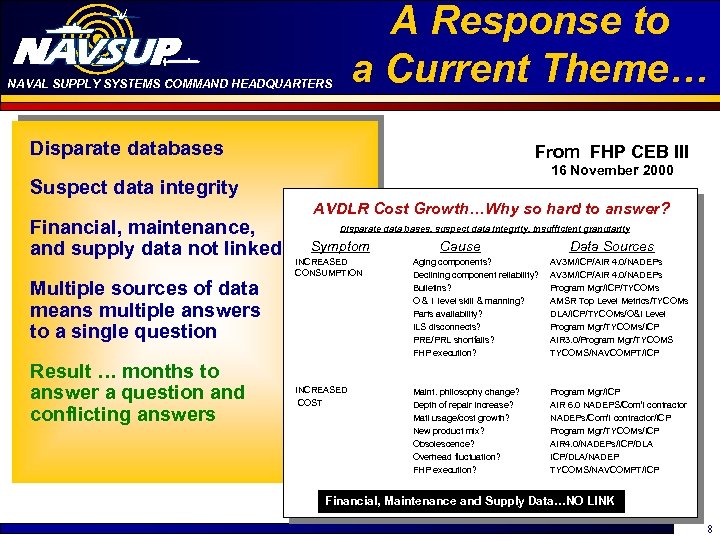

A Response to a Current Theme… NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Disparate databases From FHP CEB III 16 November 2000 Suspect data integrity Financial, maintenance, and supply data not linked Multiple sources of data means multiple answers to a single question Result … months to answer a question and conflicting answers AVDLR Cost Growth…Why so hard to answer? Disparate data bases, suspect data integrity, insufficient granularity Symptom Cause Data Sources INCREASED CONSUMPTION Aging components? Declining component reliability? Bulletins? O & I level skill & manning? Parts availability? ILS disconnects? PRE/PRL shortfalls? FHP execution? AV 3 M/ICP/AIR 4. 0/NADEPs Program Mgr/ICP/TYCOMs AMSR Top Level Metrics/TYCOMs DLA/ICP/TYCOMs/O&I Level Program Mgr/TYCOMs/ICP AIR 3. 0/Program Mgr/TYCOMS/NAVCOMPT/ICP INCREASED COST Maint. philosophy change? Depth of repair increase? Matl usage/cost growth? New product mix? Obsolescence? Overhead fluctuation? FHP execution? Program Mgr/ICP AIR 6. 0 NADEPS/Com’l contractor NADEPs/Com’l contractor/ICP Program Mgr/TYCOMs/ICP AIR 4. 0/NADEPs/ICP/DLA/NADEP TYCOMS/NAVCOMPT/ICP Financial, Maintenance and Supply Data…NO LINK 8

A Response to a Current Theme… NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Disparate databases From FHP CEB III 16 November 2000 Suspect data integrity Financial, maintenance, and supply data not linked Multiple sources of data means multiple answers to a single question Result … months to answer a question and conflicting answers AVDLR Cost Growth…Why so hard to answer? Disparate data bases, suspect data integrity, insufficient granularity Symptom Cause Data Sources INCREASED CONSUMPTION Aging components? Declining component reliability? Bulletins? O & I level skill & manning? Parts availability? ILS disconnects? PRE/PRL shortfalls? FHP execution? AV 3 M/ICP/AIR 4. 0/NADEPs Program Mgr/ICP/TYCOMs AMSR Top Level Metrics/TYCOMs DLA/ICP/TYCOMs/O&I Level Program Mgr/TYCOMs/ICP AIR 3. 0/Program Mgr/TYCOMS/NAVCOMPT/ICP INCREASED COST Maint. philosophy change? Depth of repair increase? Matl usage/cost growth? New product mix? Obsolescence? Overhead fluctuation? FHP execution? Program Mgr/ICP AIR 6. 0 NADEPS/Com’l contractor NADEPs/Com’l contractor/ICP Program Mgr/TYCOMs/ICP AIR 4. 0/NADEPs/ICP/DLA/NADEP TYCOMS/NAVCOMPT/ICP Financial, Maintenance and Supply Data…NO LINK 8

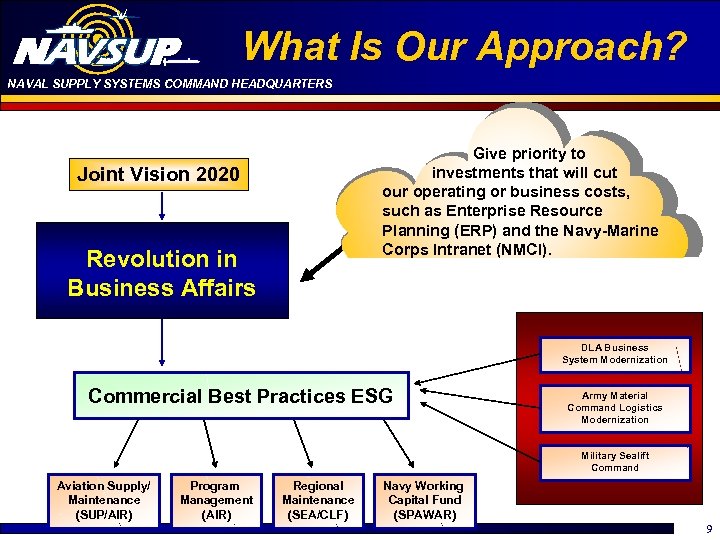

What Is Our Approach? NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Give priority to investments that will cut our operating or business costs, such as Enterprise Resource Planning (ERP) and the Navy-Marine Corps Intranet (NMCI). Joint Vision 2020 Revolution in Business Affairs DLA Business System Modernization Commercial Best Practices ESG Army Material Command Logistics Modernization Military Sealift Command Aviation Supply/ Maintenance (SUP/AIR) Program Management (AIR) Regional Maintenance (SEA/CLF) Navy Working Capital Fund (SPAWAR) 9

What Is Our Approach? NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Give priority to investments that will cut our operating or business costs, such as Enterprise Resource Planning (ERP) and the Navy-Marine Corps Intranet (NMCI). Joint Vision 2020 Revolution in Business Affairs DLA Business System Modernization Commercial Best Practices ESG Army Material Command Logistics Modernization Military Sealift Command Aviation Supply/ Maintenance (SUP/AIR) Program Management (AIR) Regional Maintenance (SEA/CLF) Navy Working Capital Fund (SPAWAR) 9

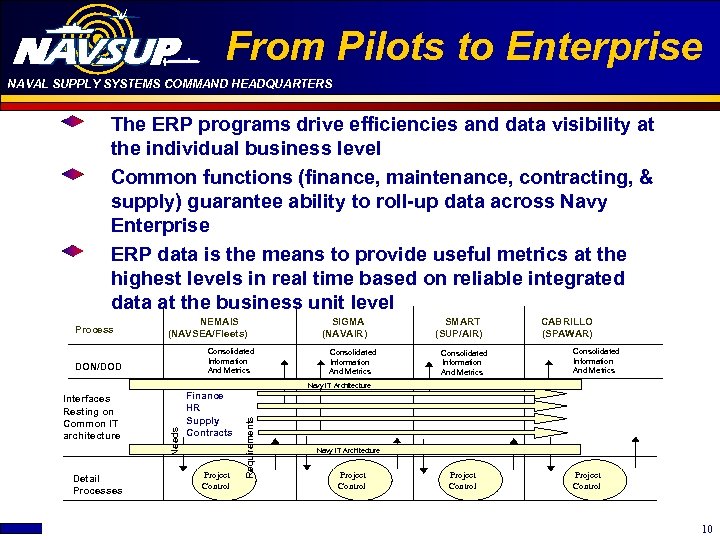

From Pilots to Enterprise NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS The ERP programs drive efficiencies and data visibility at the individual business level Common functions (finance, maintenance, contracting, & supply) guarantee ability to roll-up data across Navy Enterprise ERP data is the means to provide useful metrics at the highest levels in real time based on reliable integrated data at the business unit level Process NEMAIS (NAVSEA/Fleets) Consolidated Information And Metrics DON/DOD SIGMA (NAVAIR) Consolidated Information And Metrics SMART (SUP/AIR) Consolidated Information And Metrics CABRILLO (SPAWAR) Consolidated Information And Metrics Detail Processes Project Control Requirements Interfaces Resting on Common IT architecture Needs Navy IT Architecture Finance HR Supply Contracts Navy IT Architecture Project Control 10

From Pilots to Enterprise NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS The ERP programs drive efficiencies and data visibility at the individual business level Common functions (finance, maintenance, contracting, & supply) guarantee ability to roll-up data across Navy Enterprise ERP data is the means to provide useful metrics at the highest levels in real time based on reliable integrated data at the business unit level Process NEMAIS (NAVSEA/Fleets) Consolidated Information And Metrics DON/DOD SIGMA (NAVAIR) Consolidated Information And Metrics SMART (SUP/AIR) Consolidated Information And Metrics CABRILLO (SPAWAR) Consolidated Information And Metrics Detail Processes Project Control Requirements Interfaces Resting on Common IT architecture Needs Navy IT Architecture Finance HR Supply Contracts Navy IT Architecture Project Control 10

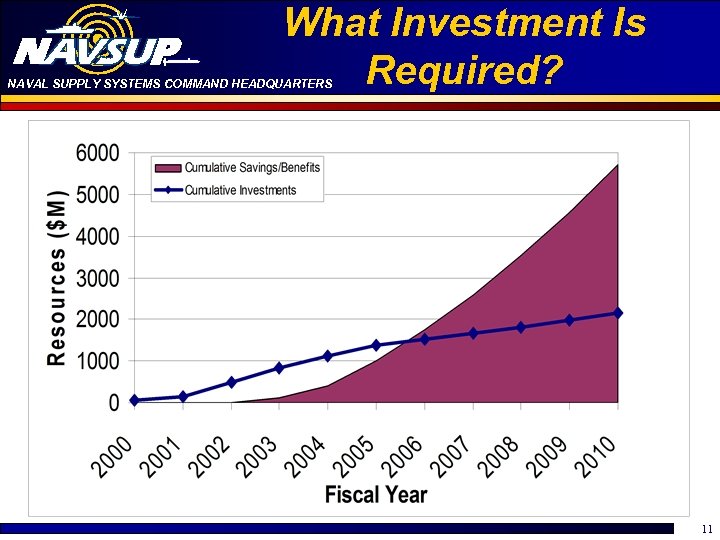

What Investment Is Required? NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS 11

What Investment Is Required? NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS 11

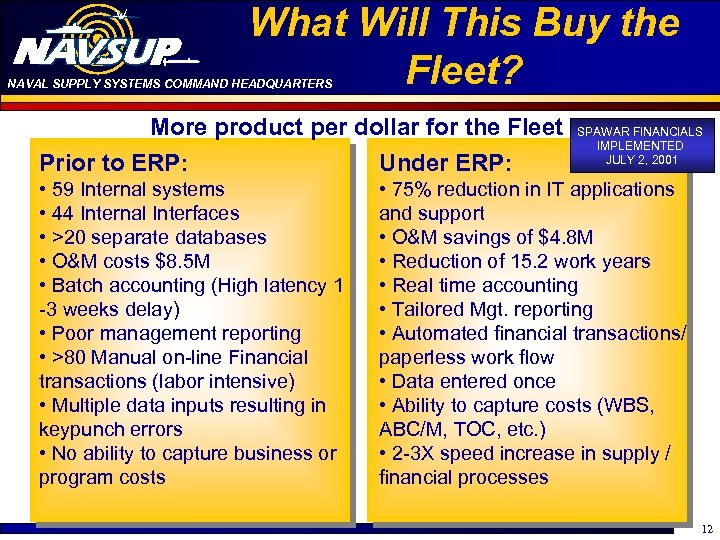

What Will This Buy the Fleet? NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS More product per dollar for the Fleet SPAWAR FINANCIALS IMPLEMENTED JULY 2, 2001 Prior to ERP: Under ERP: • 59 Internal systems • 44 Internal Interfaces • >20 separate databases • O&M costs $8. 5 M • Batch accounting (High latency 1 -3 weeks delay) • Poor management reporting • >80 Manual on-line Financial transactions (labor intensive) • Multiple data inputs resulting in keypunch errors • No ability to capture business or program costs • 75% reduction in IT applications and support • O&M savings of $4. 8 M • Reduction of 15. 2 work years • Real time accounting • Tailored Mgt. reporting • Automated financial transactions/ paperless work flow • Data entered once • Ability to capture costs (WBS, ABC/M, TOC, etc. ) • 2 -3 X speed increase in supply / financial processes 12

What Will This Buy the Fleet? NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS More product per dollar for the Fleet SPAWAR FINANCIALS IMPLEMENTED JULY 2, 2001 Prior to ERP: Under ERP: • 59 Internal systems • 44 Internal Interfaces • >20 separate databases • O&M costs $8. 5 M • Batch accounting (High latency 1 -3 weeks delay) • Poor management reporting • >80 Manual on-line Financial transactions (labor intensive) • Multiple data inputs resulting in keypunch errors • No ability to capture business or program costs • 75% reduction in IT applications and support • O&M savings of $4. 8 M • Reduction of 15. 2 work years • Real time accounting • Tailored Mgt. reporting • Automated financial transactions/ paperless work flow • Data entered once • Ability to capture costs (WBS, ABC/M, TOC, etc. ) • 2 -3 X speed increase in supply / financial processes 12

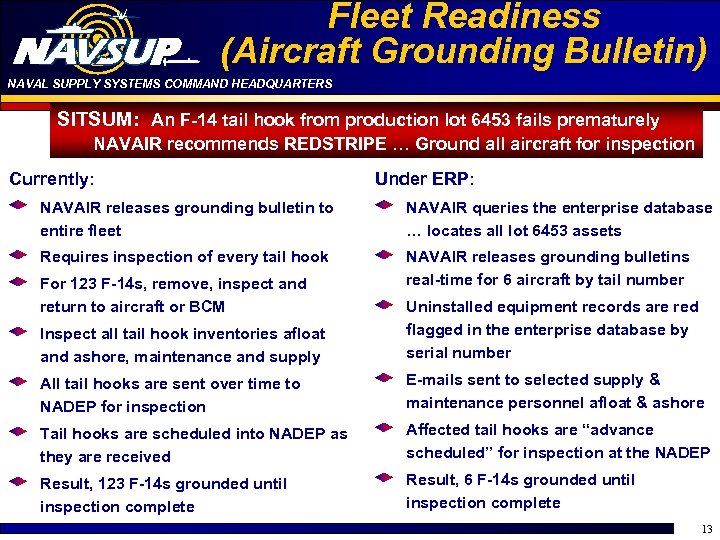

Fleet Readiness (Aircraft Grounding Bulletin) NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS SITSUM: An F-14 tail hook from production lot 6453 fails prematurely NAVAIR recommends REDSTRIPE … Ground all aircraft for inspection Currently: Under ERP: NAVAIR releases grounding bulletin to entire fleet NAVAIR queries the enterprise database … locates all lot 6453 assets Requires inspection of every tail hook NAVAIR releases grounding bulletins real-time for 6 aircraft by tail number For 123 F-14 s, remove, inspect and return to aircraft or BCM Inspect all tail hook inventories afloat and ashore, maintenance and supply Uninstalled equipment records are red flagged in the enterprise database by serial number All tail hooks are sent over time to NADEP for inspection E-mails sent to selected supply & maintenance personnel afloat & ashore Tail hooks are scheduled into NADEP as they are received Affected tail hooks are “advance scheduled” for inspection at the NADEP Result, 123 F-14 s grounded until inspection complete Result, 6 F-14 s grounded until inspection complete 13

Fleet Readiness (Aircraft Grounding Bulletin) NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS SITSUM: An F-14 tail hook from production lot 6453 fails prematurely NAVAIR recommends REDSTRIPE … Ground all aircraft for inspection Currently: Under ERP: NAVAIR releases grounding bulletin to entire fleet NAVAIR queries the enterprise database … locates all lot 6453 assets Requires inspection of every tail hook NAVAIR releases grounding bulletins real-time for 6 aircraft by tail number For 123 F-14 s, remove, inspect and return to aircraft or BCM Inspect all tail hook inventories afloat and ashore, maintenance and supply Uninstalled equipment records are red flagged in the enterprise database by serial number All tail hooks are sent over time to NADEP for inspection E-mails sent to selected supply & maintenance personnel afloat & ashore Tail hooks are scheduled into NADEP as they are received Affected tail hooks are “advance scheduled” for inspection at the NADEP Result, 123 F-14 s grounded until inspection complete Result, 6 F-14 s grounded until inspection complete 13

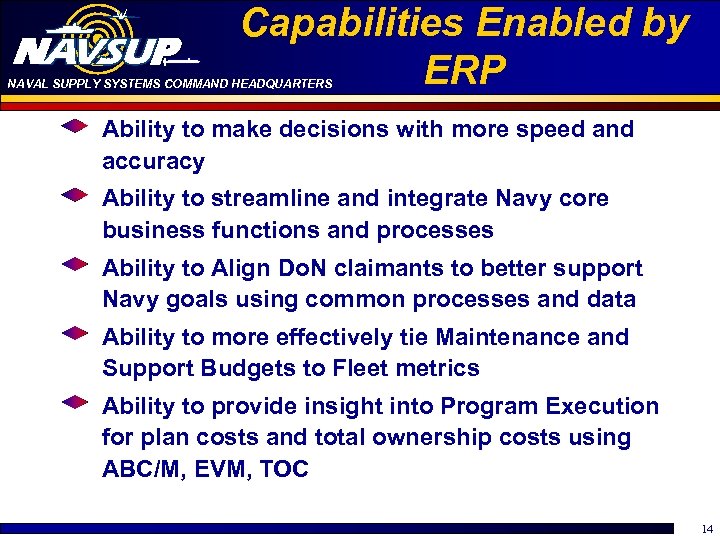

Capabilities Enabled by ERP NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Ability to make decisions with more speed and accuracy Ability to streamline and integrate Navy core business functions and processes Ability to Align Do. N claimants to better support Navy goals using common processes and data Ability to more effectively tie Maintenance and Support Budgets to Fleet metrics Ability to provide insight into Program Execution for plan costs and total ownership costs using ABC/M, EVM, TOC 14

Capabilities Enabled by ERP NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Ability to make decisions with more speed and accuracy Ability to streamline and integrate Navy core business functions and processes Ability to Align Do. N claimants to better support Navy goals using common processes and data Ability to more effectively tie Maintenance and Support Budgets to Fleet metrics Ability to provide insight into Program Execution for plan costs and total ownership costs using ABC/M, EVM, TOC 14

NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Major Terms & Concepts 15

NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Major Terms & Concepts 15

Master Data NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Consistent and common data elements stored in tables that are necessary to process transactions across all modules of SAP. 16

Master Data NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Consistent and common data elements stored in tables that are necessary to process transactions across all modules of SAP. 16

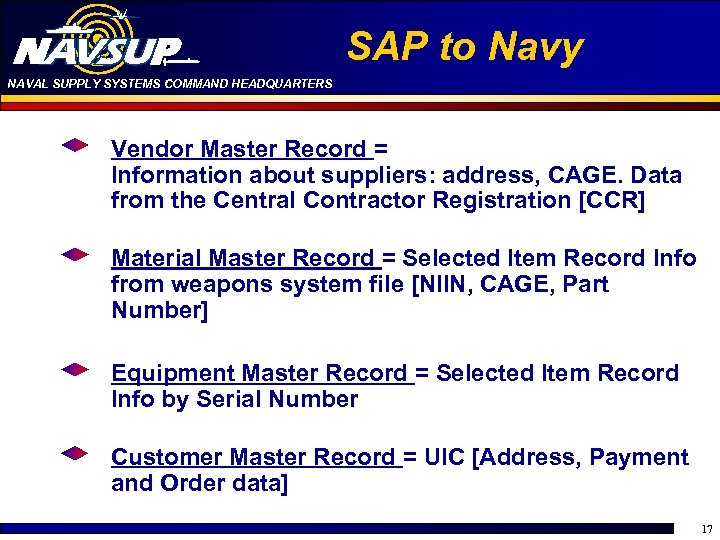

SAP to Navy NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Vendor Master Record = Information about suppliers: address, CAGE. Data from the Central Contractor Registration [CCR] Material Master Record = Selected Item Record Info from weapons system file [NIIN, CAGE, Part Number] Equipment Master Record = Selected Item Record Info by Serial Number Customer Master Record = UIC [Address, Payment and Order data] 17

SAP to Navy NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Vendor Master Record = Information about suppliers: address, CAGE. Data from the Central Contractor Registration [CCR] Material Master Record = Selected Item Record Info from weapons system file [NIIN, CAGE, Part Number] Equipment Master Record = Selected Item Record Info by Serial Number Customer Master Record = UIC [Address, Payment and Order data] 17

Hierarchies NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Structures of master data ordered to reflect organizational requirements for posting and reporting. 18

Hierarchies NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Structures of master data ordered to reflect organizational requirements for posting and reporting. 18

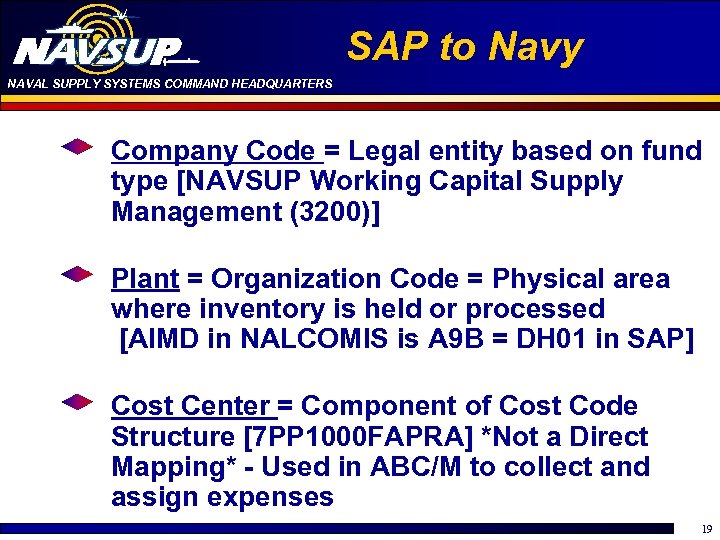

SAP to Navy NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Company Code = Legal entity based on fund type [NAVSUP Working Capital Supply Management (3200)] Plant = Organization Code = Physical area where inventory is held or processed [AIMD in NALCOMIS is A 9 B = DH 01 in SAP] Cost Center = Component of Cost Code Structure [7 PP 1000 FAPRA] *Not a Direct Mapping* - Used in ABC/M to collect and assign expenses 19

SAP to Navy NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Company Code = Legal entity based on fund type [NAVSUP Working Capital Supply Management (3200)] Plant = Organization Code = Physical area where inventory is held or processed [AIMD in NALCOMIS is A 9 B = DH 01 in SAP] Cost Center = Component of Cost Code Structure [7 PP 1000 FAPRA] *Not a Direct Mapping* - Used in ABC/M to collect and assign expenses 19

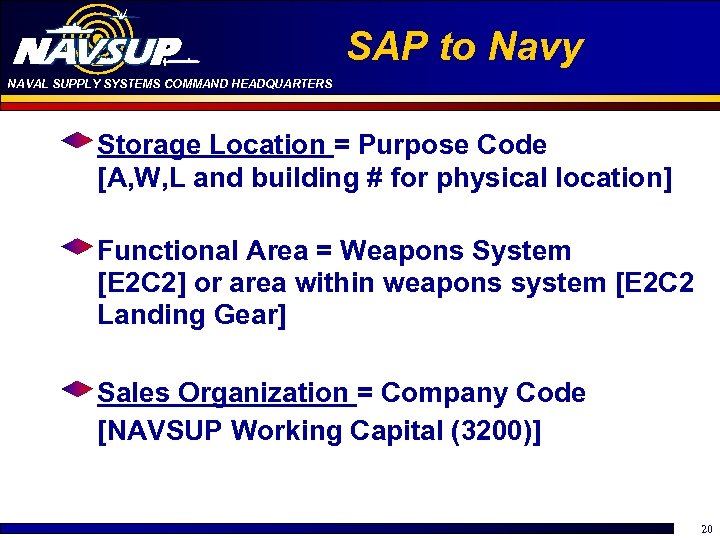

SAP to Navy NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Storage Location = Purpose Code [A, W, L and building # for physical location] Functional Area = Weapons System [E 2 C 2] or area within weapons system [E 2 C 2 Landing Gear] Sales Organization = Company Code [NAVSUP Working Capital (3200)] 20

SAP to Navy NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Storage Location = Purpose Code [A, W, L and building # for physical location] Functional Area = Weapons System [E 2 C 2] or area within weapons system [E 2 C 2 Landing Gear] Sales Organization = Company Code [NAVSUP Working Capital (3200)] 20

SAP to Navy NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Division = Organizational Code [Aviation Repairable, Aviation Consumable, Maritime Repairable, Maritime Consumable, Non-Navy Consumable] Functional Location = No current Navy Equivalent. For pilot, mapped to actual location of work center where equipment is installed [RADCOM Test Bench] 21

SAP to Navy NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Division = Organizational Code [Aviation Repairable, Aviation Consumable, Maritime Repairable, Maritime Consumable, Non-Navy Consumable] Functional Location = No current Navy Equivalent. For pilot, mapped to actual location of work center where equipment is installed [RADCOM Test Bench] 21

![SAP to Navy NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Purchasing Organization = Navy Activity [NAVICP-PHIL/MECH] SAP to Navy NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Purchasing Organization = Navy Activity [NAVICP-PHIL/MECH]](https://present5.com/presentation/db2a97126f9b1ec49d93b498e92c6c81/image-22.jpg) SAP to Navy NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Purchasing Organization = Navy Activity [NAVICP-PHIL/MECH] Purchase Groups = Contract Specialists [grouped by IWST] Maintenance Order = Maintenance Action Form [MAF] 22

SAP to Navy NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Purchasing Organization = Navy Activity [NAVICP-PHIL/MECH] Purchase Groups = Contract Specialists [grouped by IWST] Maintenance Order = Maintenance Action Form [MAF] 22

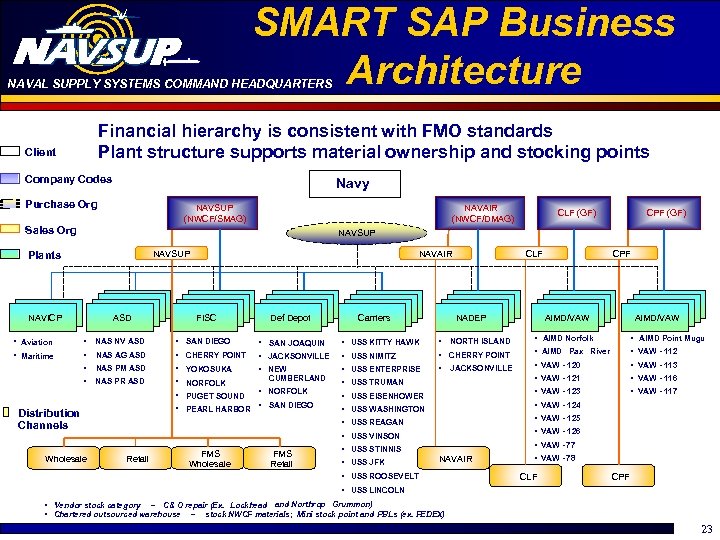

SMART SAP Business Architecture NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Financial hierarchy is consistent with FMO standards Plant structure supports material ownership and stocking points Client Company Codes Navy Purchase Org NAVSUP (NWCF/SMAG) Sales Org NAVAIR (NWCF/DMAG) CLF (GF) CPF (GF) NAVSUP Plants NAVSUP ASD ASD ASD NAVICP • Aviation • • Maritime • NAS NV ASD NAS AG ASD • NAS PM ASD • NAS PR ASD ASD FISC • SAN DIEGO • CHERRY POINT CLF ASD ASD Carriers ASD ASD NADEP • SAN JOAQUIN • USS KITTY HAWK • NORTH ISLAND • AIMD Norfolk • AIMD Point Mugu • JACKSONVILLE • USS NIMITZ • CHERRY POINT • AIMD Pax River • VAW - 112 • • VAW - 120 • VAW - 113 • VAW - 121 • VAW - 116 • VAW - 123 • VAW - 117 • YOKOSUKA • NORFOLK • NEW CUMBERLAND • SAN DIEGO • NORFOLK • USS ENTERPRISE JACKSONVILLE • USS TRUMAN • USS EISENHOWER • USS WASHINGTON Retail • USS STINNIS • USS JFK AIMD Atlanta • ASD ASD AIMD/VAW AIMD Atsugi • VAW - 125 • VAW - 126 • USS VINSON FMS Retail • ASD ASD AIMD/VAW • VAW - 124 • USS REAGAN FMS Wholesale CPF ASD ASD Def Depot • PUGET SOUND • PEARL HARBOR Distribution Channels Wholesale NAVAIR • VAW - 77 NAVAIR • USS ROOSEVELT • VAW - 78 CLF CPF • USS LINCOLN • Vendor stock category – C& O repair (Ex. Lockhead and Northrop Grummon) • Chartered outsourced warehouse – stock NWCF materials; Mini stock point and PBLs (ex. FEDEX) 23

SMART SAP Business Architecture NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Financial hierarchy is consistent with FMO standards Plant structure supports material ownership and stocking points Client Company Codes Navy Purchase Org NAVSUP (NWCF/SMAG) Sales Org NAVAIR (NWCF/DMAG) CLF (GF) CPF (GF) NAVSUP Plants NAVSUP ASD ASD ASD NAVICP • Aviation • • Maritime • NAS NV ASD NAS AG ASD • NAS PM ASD • NAS PR ASD ASD FISC • SAN DIEGO • CHERRY POINT CLF ASD ASD Carriers ASD ASD NADEP • SAN JOAQUIN • USS KITTY HAWK • NORTH ISLAND • AIMD Norfolk • AIMD Point Mugu • JACKSONVILLE • USS NIMITZ • CHERRY POINT • AIMD Pax River • VAW - 112 • • VAW - 120 • VAW - 113 • VAW - 121 • VAW - 116 • VAW - 123 • VAW - 117 • YOKOSUKA • NORFOLK • NEW CUMBERLAND • SAN DIEGO • NORFOLK • USS ENTERPRISE JACKSONVILLE • USS TRUMAN • USS EISENHOWER • USS WASHINGTON Retail • USS STINNIS • USS JFK AIMD Atlanta • ASD ASD AIMD/VAW AIMD Atsugi • VAW - 125 • VAW - 126 • USS VINSON FMS Retail • ASD ASD AIMD/VAW • VAW - 124 • USS REAGAN FMS Wholesale CPF ASD ASD Def Depot • PUGET SOUND • PEARL HARBOR Distribution Channels Wholesale NAVAIR • VAW - 77 NAVAIR • USS ROOSEVELT • VAW - 78 CLF CPF • USS LINCOLN • Vendor stock category – C& O repair (Ex. Lockhead and Northrop Grummon) • Chartered outsourced warehouse – stock NWCF materials; Mini stock point and PBLs (ex. FEDEX) 23

NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS SMART Integrated Scenarios 24

NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS SMART Integrated Scenarios 24

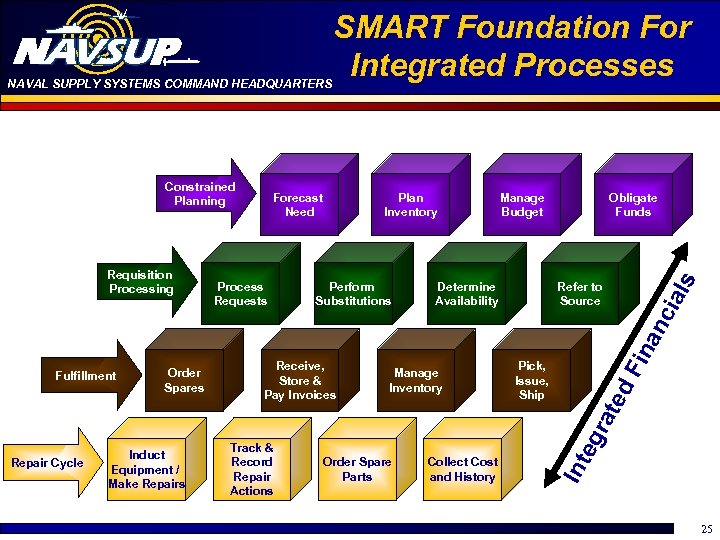

Process Requests Plan Inventory Perform Substitutions Manage Budget Determine Availability Obligate Funds Refer to Source Receive, Store & Pay Invoices Manage Inventory Pick, Issue, Ship ed Order Spares Induct Equipment / Make Repairs Track & Record Repair Actions Order Spare Parts Collect Cost and History Int Repair Cycle eg rat Fulfillment Fin an Requisition Processing Forecast Need ls Constrained Planning cia NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS SMART Foundation For Integrated Processes 25

Process Requests Plan Inventory Perform Substitutions Manage Budget Determine Availability Obligate Funds Refer to Source Receive, Store & Pay Invoices Manage Inventory Pick, Issue, Ship ed Order Spares Induct Equipment / Make Repairs Track & Record Repair Actions Order Spare Parts Collect Cost and History Int Repair Cycle eg rat Fulfillment Fin an Requisition Processing Forecast Need ls Constrained Planning cia NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS SMART Foundation For Integrated Processes 25

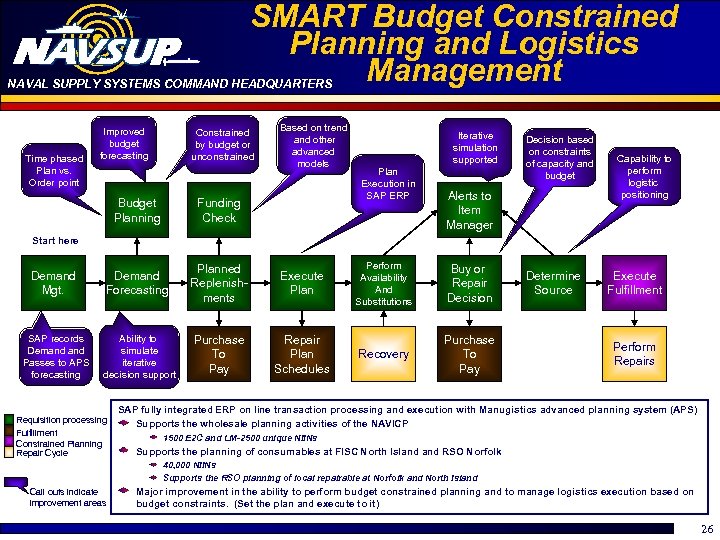

SMART Budget Constrained Planning and Logistics Management NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Time phased Plan vs. Order point Improved budget forecasting Constrained by budget or unconstrained Based on trend and other advanced models Budget Planning Funding Check Demand Mgt. Demand Forecasting Planned Replenishments Execute Plan SAP records Demand Passes to APS forecasting Ability to simulate iterative decision support Purchase To Pay Repair Plan Schedules Iterative simulation supported Plan Execution in SAP ERP Decision based on constraints of capacity and budget Alerts to Item Manager Capability to perform logistic positioning Start here Requisition processing Fulfillment Constrained Planning Repair Cycle Perform Availability And Substitutions Buy or Repair Decision Recovery Purchase To Pay Determine Source Execute Fulfillment Perform Repairs SAP fully integrated ERP on line transaction processing and execution with Manugistics advanced planning system (APS) Supports the wholesale planning activities of the NAVICP 1500 E 2 C and LM-2500 unique NIINs Supports the planning of consumables at FISC North Island RSO Norfolk 40, 000 NIINs Supports the RSO planning of local repairable at Norfolk and North Island Call outs indicate improvement areas Major improvement in the ability to perform budget constrained planning and to manage logistics execution based on budget constraints. (Set the plan and execute to it) 26

SMART Budget Constrained Planning and Logistics Management NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Time phased Plan vs. Order point Improved budget forecasting Constrained by budget or unconstrained Based on trend and other advanced models Budget Planning Funding Check Demand Mgt. Demand Forecasting Planned Replenishments Execute Plan SAP records Demand Passes to APS forecasting Ability to simulate iterative decision support Purchase To Pay Repair Plan Schedules Iterative simulation supported Plan Execution in SAP ERP Decision based on constraints of capacity and budget Alerts to Item Manager Capability to perform logistic positioning Start here Requisition processing Fulfillment Constrained Planning Repair Cycle Perform Availability And Substitutions Buy or Repair Decision Recovery Purchase To Pay Determine Source Execute Fulfillment Perform Repairs SAP fully integrated ERP on line transaction processing and execution with Manugistics advanced planning system (APS) Supports the wholesale planning activities of the NAVICP 1500 E 2 C and LM-2500 unique NIINs Supports the planning of consumables at FISC North Island RSO Norfolk 40, 000 NIINs Supports the RSO planning of local repairable at Norfolk and North Island Call outs indicate improvement areas Major improvement in the ability to perform budget constrained planning and to manage logistics execution based on budget constraints. (Set the plan and execute to it) 26

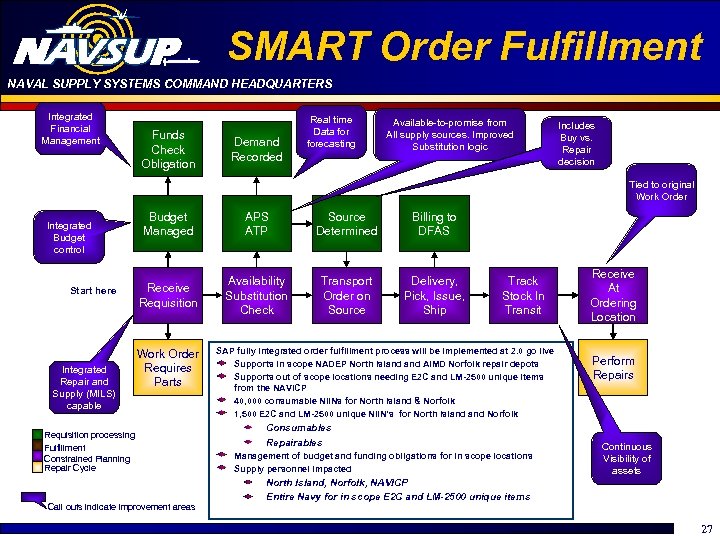

SMART Order Fulfillment NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Integrated Financial Management Funds Check Obligation Demand Recorded Real time Data forecasting Available-to-promise from All supply sources. Improved Substitution logic Includes Buy vs. Repair decision Tied to original Work Order Integrated Budget control Start here Integrated Repair and Supply (MILS) capable Budget Managed APS ATP Source Determined Billing to DFAS Receive Requisition Availability Substitution Check Transport Order on Source Delivery, Pick, Issue, Ship Work Order Requires Parts Requisition processing Fulfillment Constrained Planning Repair Cycle Call outs indicate improvement areas Track Stock In Transit SAP fully integrated order fulfillment process will be implemented at 2. 0 go live Supports in scope NADEP North Island AIMD Norfolk repair depots Supports out of scope locations needing E 2 C and LM-2500 unique items from the NAVICP 40, 000 consumable NIINs for North Island & Norfolk 1, 500 E 2 C and LM-2500 unique NIIN’s for North Island Norfolk Consumables Repairables Management of budget and funding obligations for in scope locations Supply personnel impacted Receive At Ordering Location Perform Repairs Continuous Visibility of assets North Island, Norfolk, NAVICP Entire Navy for in scope E 2 C and LM-2500 unique items 27

SMART Order Fulfillment NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Integrated Financial Management Funds Check Obligation Demand Recorded Real time Data forecasting Available-to-promise from All supply sources. Improved Substitution logic Includes Buy vs. Repair decision Tied to original Work Order Integrated Budget control Start here Integrated Repair and Supply (MILS) capable Budget Managed APS ATP Source Determined Billing to DFAS Receive Requisition Availability Substitution Check Transport Order on Source Delivery, Pick, Issue, Ship Work Order Requires Parts Requisition processing Fulfillment Constrained Planning Repair Cycle Call outs indicate improvement areas Track Stock In Transit SAP fully integrated order fulfillment process will be implemented at 2. 0 go live Supports in scope NADEP North Island AIMD Norfolk repair depots Supports out of scope locations needing E 2 C and LM-2500 unique items from the NAVICP 40, 000 consumable NIINs for North Island & Norfolk 1, 500 E 2 C and LM-2500 unique NIIN’s for North Island Norfolk Consumables Repairables Management of budget and funding obligations for in scope locations Supply personnel impacted Receive At Ordering Location Perform Repairs Continuous Visibility of assets North Island, Norfolk, NAVICP Entire Navy for in scope E 2 C and LM-2500 unique items 27

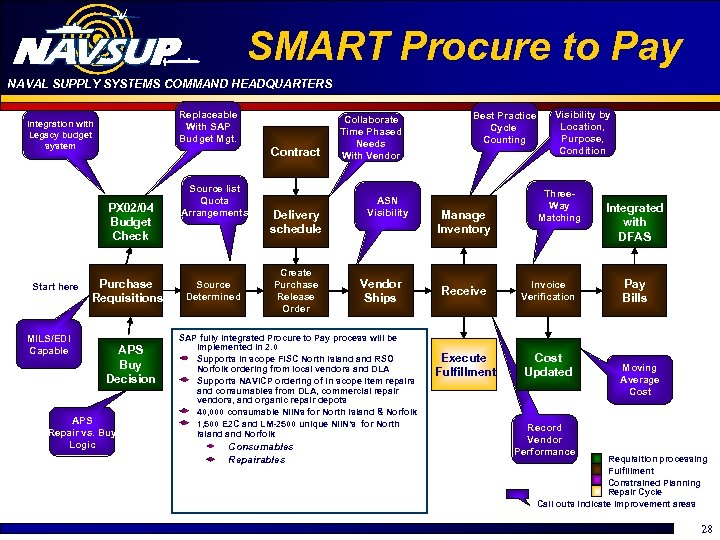

SMART Procure to Pay NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Replaceable With SAP Budget Mgt. Integration with Legacy budget system Contract PX 02/04 Budget Check Start here MILS/EDI Capable Purchase Requisitions APS Buy Decision APS Repair vs. Buy Logic Source list Quota Arrangements Source Determined Delivery schedule Create Purchase Release Order Collaborate Time Phased Needs With Vendor ASN Visibility Vendor Ships SAP fully integrated Procure to Pay process will be implemented in 2. 0 Supports in scope FISC North Island RSO Norfolk ordering from local vendors and DLA Supports NAVICP ordering of in scope item repairs and consumables from DLA, commercial repair vendors, and organic repair depots 40, 000 consumable NIINs for North Island & Norfolk 1, 500 E 2 C and LM-2500 unique NIIN’s for North Island Norfolk Consumables Repairables Best Practice Cycle Counting Manage Inventory Visibility by Location, Purpose, Condition Three. Way Matching Receive Invoice Verification Execute Fulfillment Cost Updated Integrated with DFAS Pay Bills Moving Average Cost Record Vendor Performance Requisition processing Fulfillment Constrained Planning Repair Cycle Call outs indicate improvement areas 28

SMART Procure to Pay NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Replaceable With SAP Budget Mgt. Integration with Legacy budget system Contract PX 02/04 Budget Check Start here MILS/EDI Capable Purchase Requisitions APS Buy Decision APS Repair vs. Buy Logic Source list Quota Arrangements Source Determined Delivery schedule Create Purchase Release Order Collaborate Time Phased Needs With Vendor ASN Visibility Vendor Ships SAP fully integrated Procure to Pay process will be implemented in 2. 0 Supports in scope FISC North Island RSO Norfolk ordering from local vendors and DLA Supports NAVICP ordering of in scope item repairs and consumables from DLA, commercial repair vendors, and organic repair depots 40, 000 consumable NIINs for North Island & Norfolk 1, 500 E 2 C and LM-2500 unique NIIN’s for North Island Norfolk Consumables Repairables Best Practice Cycle Counting Manage Inventory Visibility by Location, Purpose, Condition Three. Way Matching Receive Invoice Verification Execute Fulfillment Cost Updated Integrated with DFAS Pay Bills Moving Average Cost Record Vendor Performance Requisition processing Fulfillment Constrained Planning Repair Cycle Call outs indicate improvement areas 28

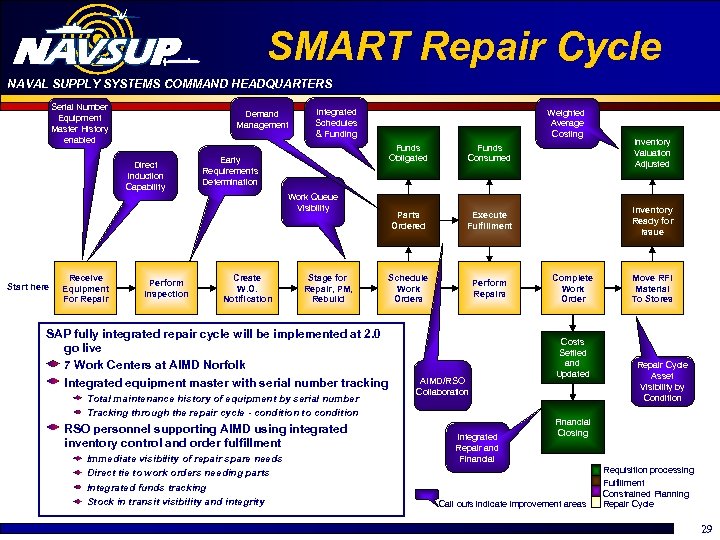

SMART Repair Cycle NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Serial Number Equipment Master History enabled Demand Management Direct Induction Capability Start here Receive Equipment For Repair Perform Inspection Integrated Schedules & Funding Funds Obligated Early Requirements Determination Work Queue Visibility Create W. O. Notification Stage for Repair, PM, Rebuild SAP fully integrated repair cycle will be implemented at 2. 0 go live 7 Work Centers at AIMD Norfolk Integrated equipment master with serial number tracking Total maintenance history of equipment by serial number Tracking through the repair cycle - condition to condition RSO personnel supporting AIMD using integrated inventory control and order fulfillment Immediate visibility of repair spare needs Direct tie to work orders needing parts Integrated funds tracking Stock in transit visibility and integrity Weighted Average Costing Funds Consumed Inventory Valuation Adjusted Parts Ordered Execute Fulfillment Inventory Ready for Issue Schedule Work Orders Perform Repairs AIMD/RSO Collaboration Integrated Repair and Financial Complete Work Order Costs Settled and Updated Move RFI Material To Stores Repair Cycle Asset Visibility by Condition Financial Closing Call outs indicate improvement areas Requisition processing Fulfillment Constrained Planning Repair Cycle 29

SMART Repair Cycle NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Serial Number Equipment Master History enabled Demand Management Direct Induction Capability Start here Receive Equipment For Repair Perform Inspection Integrated Schedules & Funding Funds Obligated Early Requirements Determination Work Queue Visibility Create W. O. Notification Stage for Repair, PM, Rebuild SAP fully integrated repair cycle will be implemented at 2. 0 go live 7 Work Centers at AIMD Norfolk Integrated equipment master with serial number tracking Total maintenance history of equipment by serial number Tracking through the repair cycle - condition to condition RSO personnel supporting AIMD using integrated inventory control and order fulfillment Immediate visibility of repair spare needs Direct tie to work orders needing parts Integrated funds tracking Stock in transit visibility and integrity Weighted Average Costing Funds Consumed Inventory Valuation Adjusted Parts Ordered Execute Fulfillment Inventory Ready for Issue Schedule Work Orders Perform Repairs AIMD/RSO Collaboration Integrated Repair and Financial Complete Work Order Costs Settled and Updated Move RFI Material To Stores Repair Cycle Asset Visibility by Condition Financial Closing Call outs indicate improvement areas Requisition processing Fulfillment Constrained Planning Repair Cycle 29

NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS SAP Repair Cycle Demonstration 30

NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS SAP Repair Cycle Demonstration 30

SAP Repair Cycle Demonstration NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Repair Cycle addresses the repair of a component at the AIMD level. Checks will be performed for funds availability, material availability, interchangeability, and source selection before an order is created to issue a RFI part and move the COND F part to the repair location. At the repair location, a work order is created, the COND F part is repaired and transferred back to supply as RFI. Financial reports are generated to show repair costs and billing status for this repair. 31

SAP Repair Cycle Demonstration NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Repair Cycle addresses the repair of a component at the AIMD level. Checks will be performed for funds availability, material availability, interchangeability, and source selection before an order is created to issue a RFI part and move the COND F part to the repair location. At the repair location, a work order is created, the COND F part is repaired and transferred back to supply as RFI. Financial reports are generated to show repair costs and billing status for this repair. 31

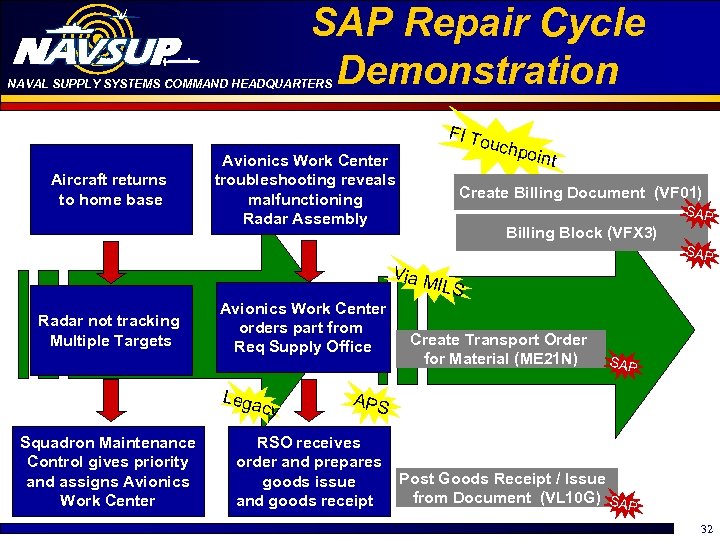

SAP Repair Cycle Demonstration NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS FI To Aircraft returns to home base Avionics Work Center troubleshooting reveals malfunctioning Radar Assembly uchp oint Create Billing Document (VF 01) SAP Billing Block (VFX 3) SAP Via M ILS Radar not tracking Multiple Targets Avionics Work Center orders part from Req Supply Office Lega cy Squadron Maintenance Control gives priority and assigns Avionics Work Center Create Transport Order for Material (ME 21 N) SAP APS RSO receives order and prepares goods issue and goods receipt Post Goods Receipt / Issue from Document (VL 10 G) SAP 32

SAP Repair Cycle Demonstration NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS FI To Aircraft returns to home base Avionics Work Center troubleshooting reveals malfunctioning Radar Assembly uchp oint Create Billing Document (VF 01) SAP Billing Block (VFX 3) SAP Via M ILS Radar not tracking Multiple Targets Avionics Work Center orders part from Req Supply Office Lega cy Squadron Maintenance Control gives priority and assigns Avionics Work Center Create Transport Order for Material (ME 21 N) SAP APS RSO receives order and prepares goods issue and goods receipt Post Goods Receipt / Issue from Document (VL 10 G) SAP 32

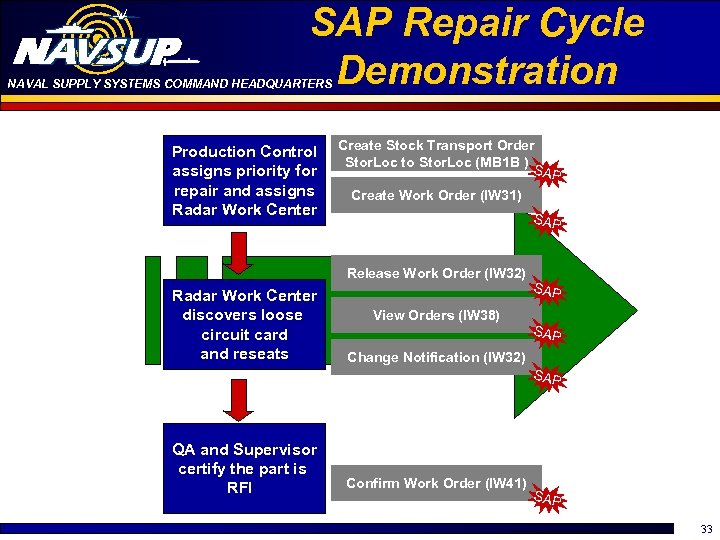

SAP Repair Cycle Demonstration NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Production Control assigns priority for repair and assigns Radar Work Center Create Stock Transport Order Stor. Loc to Stor. Loc (MB 1 B ) SAP Create Work Order (IW 31) SAP Release Work Order (IW 32) Radar Work Center discovers loose circuit card and reseats View Orders (IW 38) SAP Change Notification (IW 32) SAP QA and Supervisor certify the part is RFI Confirm Work Order (IW 41) SAP 33

SAP Repair Cycle Demonstration NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Production Control assigns priority for repair and assigns Radar Work Center Create Stock Transport Order Stor. Loc to Stor. Loc (MB 1 B ) SAP Create Work Order (IW 31) SAP Release Work Order (IW 32) Radar Work Center discovers loose circuit card and reseats View Orders (IW 38) SAP Change Notification (IW 32) SAP QA and Supervisor certify the part is RFI Confirm Work Order (IW 41) SAP 33

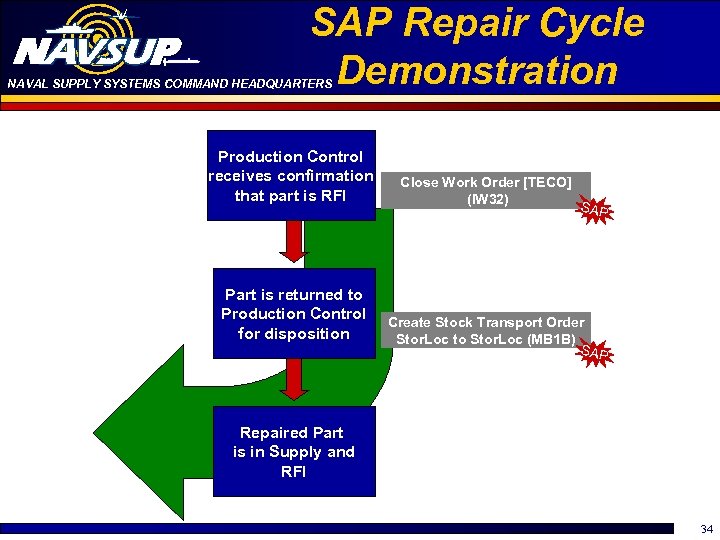

SAP Repair Cycle Demonstration NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Production Control receives confirmation that part is RFI Part is returned to Production Control for disposition Close Work Order [TECO] (IW 32) SAP Create Stock Transport Order Stor. Loc to Stor. Loc (MB 1 B) SAP Repaired Part is in Supply and RFI 34

SAP Repair Cycle Demonstration NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS Production Control receives confirmation that part is RFI Part is returned to Production Control for disposition Close Work Order [TECO] (IW 32) SAP Create Stock Transport Order Stor. Loc to Stor. Loc (MB 1 B) SAP Repaired Part is in Supply and RFI 34

Summary NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS ERP Overview Reengineer business processes Establish common data and practices Establish Single Entry – Single Source Reduce number of applications Establish End-to-End process connectivity Comply with Federal financial standards Enable effective implementation of Activity Based Costing (ABC) Major Terms & Concepts SMART Integrated Scenarios Constrained Planning Order Fulfillment Procure to Pay Repair Cycle SAP Repair Cycle Demonstration 35

Summary NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS ERP Overview Reengineer business processes Establish common data and practices Establish Single Entry – Single Source Reduce number of applications Establish End-to-End process connectivity Comply with Federal financial standards Enable effective implementation of Activity Based Costing (ABC) Major Terms & Concepts SMART Integrated Scenarios Constrained Planning Order Fulfillment Procure to Pay Repair Cycle SAP Repair Cycle Demonstration 35

NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS 36

NAVAL SUPPLY SYSTEMS COMMAND HEADQUARTERS 36