6c761db2ec179c580b05095483c96981.ppt

- Количество слайдов: 43

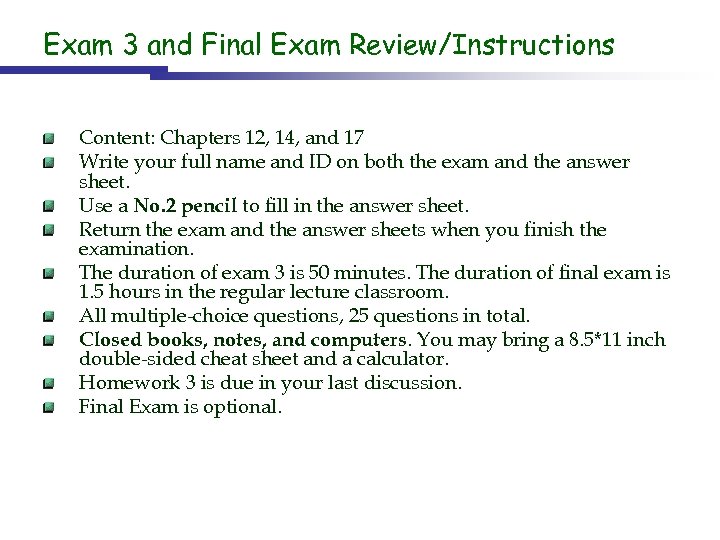

Exam 3 and Final Exam Review/Instructions Content: Chapters 12, 14, and 17 Write your full name and ID on both the exam and the answer sheet. Use a No. 2 pencil to fill in the answer sheet. Return the exam and the answer sheets when you finish the examination. The duration of exam 3 is 50 minutes. The duration of final exam is 1. 5 hours in the regular lecture classroom. All multiple-choice questions, 25 questions in total. Closed books, notes, and computers. You may bring a 8. 5*11 inch double-sided cheat sheet and a calculator. Homework 3 is due in your last discussion. Final Exam is optional.

Exam 3 and Final Exam Review/Instructions Content: Chapters 12, 14, and 17 Write your full name and ID on both the exam and the answer sheet. Use a No. 2 pencil to fill in the answer sheet. Return the exam and the answer sheets when you finish the examination. The duration of exam 3 is 50 minutes. The duration of final exam is 1. 5 hours in the regular lecture classroom. All multiple-choice questions, 25 questions in total. Closed books, notes, and computers. You may bring a 8. 5*11 inch double-sided cheat sheet and a calculator. Homework 3 is due in your last discussion. Final Exam is optional.

CHAPTER 12 Inventory Management

CHAPTER 12 Inventory Management

Contents Inventory Management? Inventory Reasons for holding/avoiding inventory Objective of inventory management Continuous (perpetual) inventory counting system Constant demand lead time : EOQ Model Uncertain demand constant lead time Single-Period Model (newsboy Problem) Economic Production Model (EPQ) –not required for exam 3 and final exam

Contents Inventory Management? Inventory Reasons for holding/avoiding inventory Objective of inventory management Continuous (perpetual) inventory counting system Constant demand lead time : EOQ Model Uncertain demand constant lead time Single-Period Model (newsboy Problem) Economic Production Model (EPQ) –not required for exam 3 and final exam

Inventory: A stock or store of goods. Inventory is created when receiving rate exceeds usage rate incoming raw material exceeds production consumption production exceeds demand Inventory can be measured in physical units money

Inventory: A stock or store of goods. Inventory is created when receiving rate exceeds usage rate incoming raw material exceeds production consumption production exceeds demand Inventory can be measured in physical units money

Why might we want to build inventories? a. Customer service: For customers that have immediate or seasonal demands, finished goods inventory can speed up delivery and reduce stockouts and backorders. b. Ordering costs: Costs associated with purchasing, follow-up, receiving, and paperwork are incurred each time an order is placed. By ordering in larger quantities, the resulting inventory provides a means of obtaining and handling materials in economic lot sizes. c. Setup costs: Production orders have similar costs associated with each setup, and machines may be unproductive for several hours each time the product is switched. > Labor and time to make changeover > May include scrap and rework

Why might we want to build inventories? a. Customer service: For customers that have immediate or seasonal demands, finished goods inventory can speed up delivery and reduce stockouts and backorders. b. Ordering costs: Costs associated with purchasing, follow-up, receiving, and paperwork are incurred each time an order is placed. By ordering in larger quantities, the resulting inventory provides a means of obtaining and handling materials in economic lot sizes. c. Setup costs: Production orders have similar costs associated with each setup, and machines may be unproductive for several hours each time the product is switched. > Labor and time to make changeover > May include scrap and rework

Why might we want to build inventories? (cont’d) c. Stabilizing output rates: Inventories can be used to cover peaks in demand, level production activities, stabilize employment, and improve labor relations. d. Transportation costs: Transportation costs can be reduced by building inventories and shipping full truckloads. e. Quantity discounts. Ordering large quantities can provide a hedge against future price increases and provide a means to obtain quantity discounts.

Why might we want to build inventories? (cont’d) c. Stabilizing output rates: Inventories can be used to cover peaks in demand, level production activities, stabilize employment, and improve labor relations. d. Transportation costs: Transportation costs can be reduced by building inventories and shipping full truckloads. e. Quantity discounts. Ordering large quantities can provide a hedge against future price increases and provide a means to obtain quantity discounts.

Why might we want to avoid inventories? a. Collectively called “inventory holding cost. ” The cost to keep an item on hand for a year typically ranges from 25 percent to 40 percent of the item’s value. b. Cost components • Interest or opportunity cost of capital — time value of money • Storage and handling—warehouse facilities and labor • Taxes and insurance—usually proportional to inventory value • Shrinkage - Pilferage - Obsolescence - Deterioration

Why might we want to avoid inventories? a. Collectively called “inventory holding cost. ” The cost to keep an item on hand for a year typically ranges from 25 percent to 40 percent of the item’s value. b. Cost components • Interest or opportunity cost of capital — time value of money • Storage and handling—warehouse facilities and labor • Taxes and insurance—usually proportional to inventory value • Shrinkage - Pilferage - Obsolescence - Deterioration

Objective of Inventory Management To achieve satisfactory levels of customer service while keeping inventory costs within reasonable bounds Right goods, right place, right time, right quantity Goal: matching supply with demand!

Objective of Inventory Management To achieve satisfactory levels of customer service while keeping inventory costs within reasonable bounds Right goods, right place, right time, right quantity Goal: matching supply with demand!

Basic Inventory Management Questions How much to order When to order? Purchase Order Description Qty. Microwave 1000

Basic Inventory Management Questions How much to order When to order? Purchase Order Description Qty. Microwave 1000

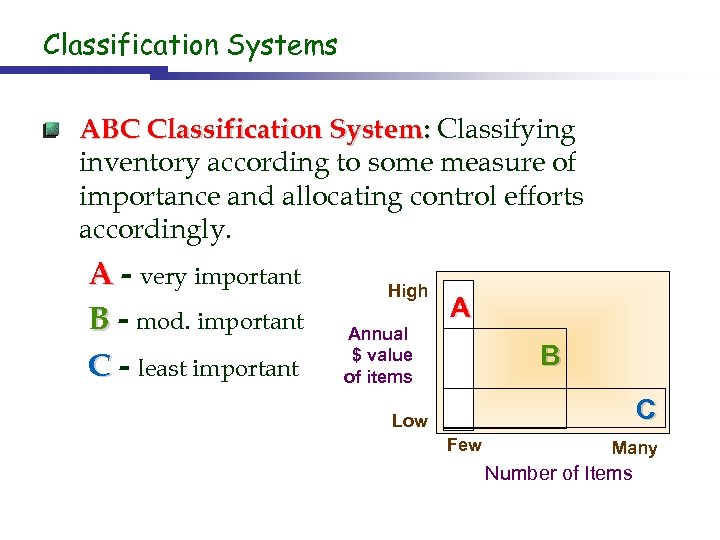

Classification Systems ABC Classification System: Classifying inventory according to some measure of importance and allocating control efforts accordingly. A - very important B - mod. important C - least important High Annual $ value of items A B C Low Few Many Number of Items

Classification Systems ABC Classification System: Classifying inventory according to some measure of importance and allocating control efforts accordingly. A - very important B - mod. important C - least important High Annual $ value of items A B C Low Few Many Number of Items

Uses of ABC Approach Class A typically contains about 10 -20% of the items and 60 -70% of the annual dollar value Receive close attention: frequent reviews make sure customer service levels Class C contains about 50 -60% of the items, but only 10 -15% of the dollar value Receive only loose control, usually order in large quantities Class B is between the two extremes

Uses of ABC Approach Class A typically contains about 10 -20% of the items and 60 -70% of the annual dollar value Receive close attention: frequent reviews make sure customer service levels Class C contains about 50 -60% of the items, but only 10 -15% of the dollar value Receive only loose control, usually order in large quantities Class B is between the two extremes

Continuous (perpetual) System with Constant Demand Lead Time – EOQ (basic)

Continuous (perpetual) System with Constant Demand Lead Time – EOQ (basic)

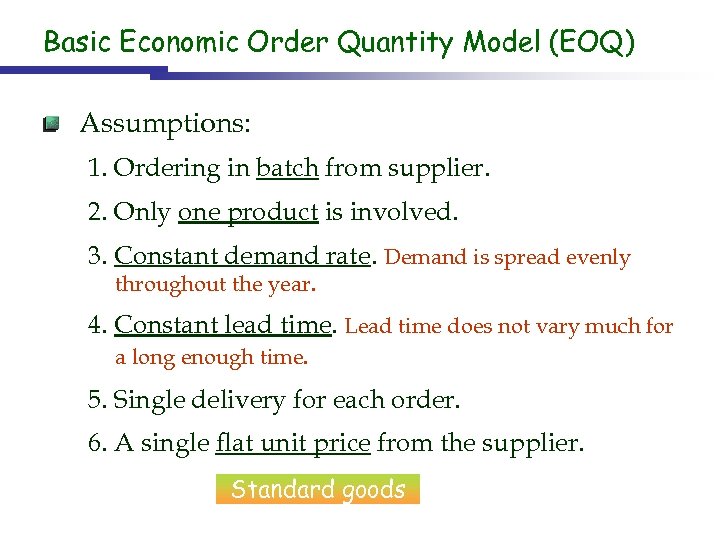

Basic Economic Order Quantity Model (EOQ) Assumptions: 1. Ordering in batch from supplier. 2. Only one product is involved. 3. Constant demand rate. Demand is spread evenly throughout the year. 4. Constant lead time. Lead time does not vary much for a long enough time. 5. Single delivery for each order. 6. A single flat unit price from the supplier. Standard goods

Basic Economic Order Quantity Model (EOQ) Assumptions: 1. Ordering in batch from supplier. 2. Only one product is involved. 3. Constant demand rate. Demand is spread evenly throughout the year. 4. Constant lead time. Lead time does not vary much for a long enough time. 5. Single delivery for each order. 6. A single flat unit price from the supplier. Standard goods

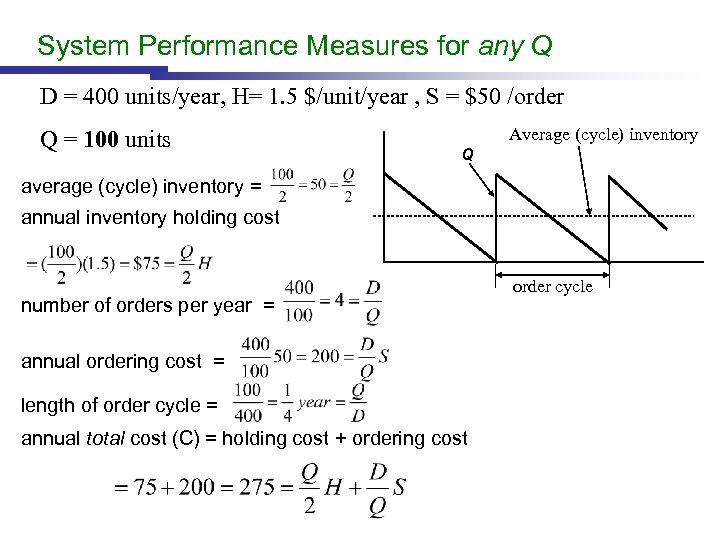

System Performance Measures for any Q D = 400 units/year, H= 1. 5 $/unit/year , S = $50 /order Q = 100 units Average (cycle) inventory Q average (cycle) inventory = annual inventory holding cost number of orders per year = annual ordering cost = length of order cycle = annual total cost (C) = holding cost + ordering cost order cycle

System Performance Measures for any Q D = 400 units/year, H= 1. 5 $/unit/year , S = $50 /order Q = 100 units Average (cycle) inventory Q average (cycle) inventory = annual inventory holding cost number of orders per year = annual ordering cost = length of order cycle = annual total cost (C) = holding cost + ordering cost order cycle

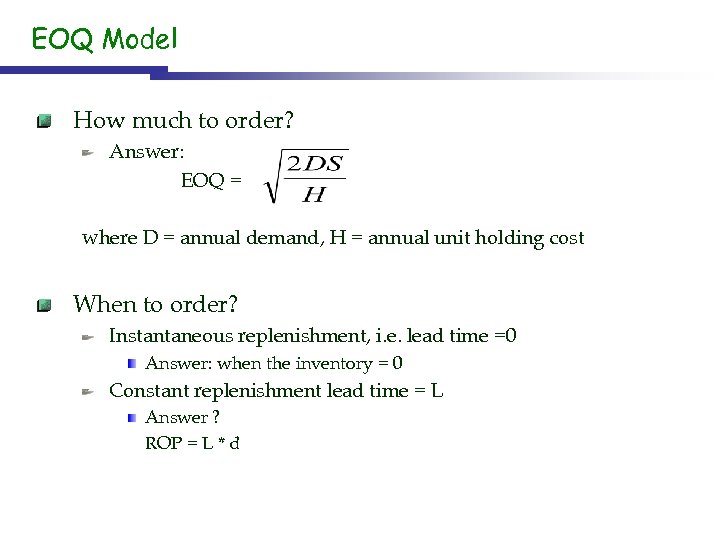

EOQ Model How much to order? Answer: EOQ = where D = annual demand, H = annual unit holding cost When to order? Instantaneous replenishment, i. e. lead time =0 Answer: when the inventory = 0 Constant replenishment lead time = L Answer ? ROP = L * d

EOQ Model How much to order? Answer: EOQ = where D = annual demand, H = annual unit holding cost When to order? Instantaneous replenishment, i. e. lead time =0 Answer: when the inventory = 0 Constant replenishment lead time = L Answer ? ROP = L * d

Continuous (perpetual) System with Uncertain Demand Constant Lead Time

Continuous (perpetual) System with Uncertain Demand Constant Lead Time

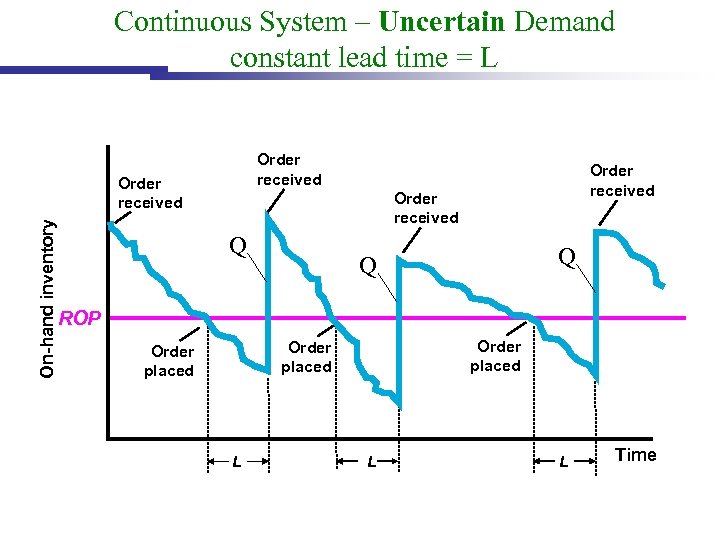

Continuous System – Uncertain Demand constant lead time = L Order received On-hand inventory Order received Q Q Q ROP Order placed L L L Time

Continuous System – Uncertain Demand constant lead time = L Order received On-hand inventory Order received Q Q Q ROP Order placed L L L Time

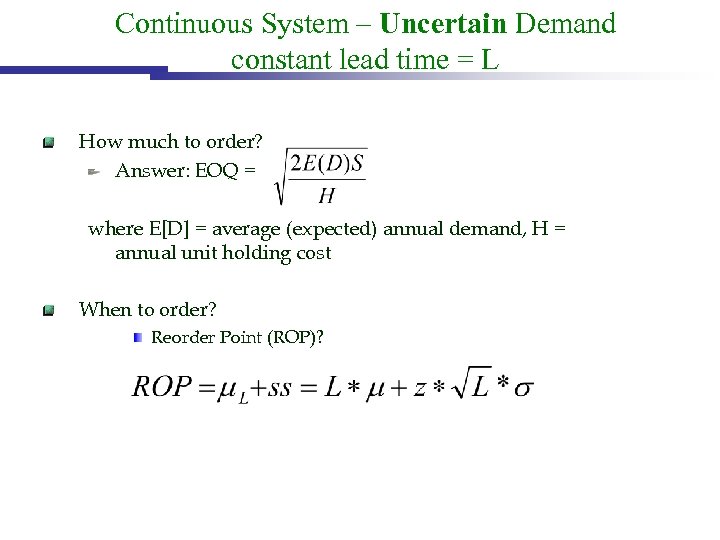

Continuous System – Uncertain Demand constant lead time = L How much to order? Answer: EOQ = where E[D] = average (expected) annual demand, H = annual unit holding cost When to order? Reorder Point (ROP)?

Continuous System – Uncertain Demand constant lead time = L How much to order? Answer: EOQ = where E[D] = average (expected) annual demand, H = annual unit holding cost When to order? Reorder Point (ROP)?

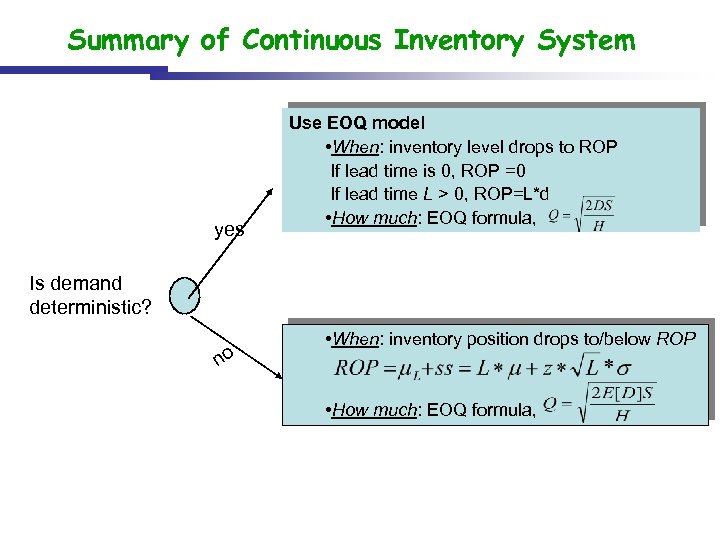

Summary of Continuous Inventory System yes Use EOQ model • When: inventory level drops to ROP If lead time is 0, ROP =0 If lead time L > 0, ROP=L*d • How much: EOQ formula, Is demand deterministic? no • When: inventory position drops to/below ROP • How much: EOQ formula,

Summary of Continuous Inventory System yes Use EOQ model • When: inventory level drops to ROP If lead time is 0, ROP =0 If lead time L > 0, ROP=L*d • How much: EOQ formula, Is demand deterministic? no • When: inventory position drops to/below ROP • How much: EOQ formula,

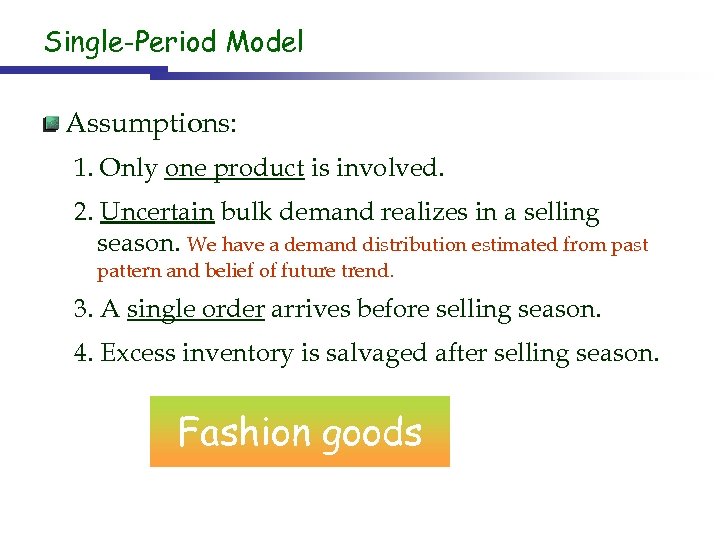

Single-Period Model Assumptions: 1. Only one product is involved. 2. Uncertain bulk demand realizes in a selling season. We have a demand distribution estimated from past pattern and belief of future trend. 3. A single order arrives before selling season. 4. Excess inventory is salvaged after selling season. Fashion goods

Single-Period Model Assumptions: 1. Only one product is involved. 2. Uncertain bulk demand realizes in a selling season. We have a demand distribution estimated from past pattern and belief of future trend. 3. A single order arrives before selling season. 4. Excess inventory is salvaged after selling season. Fashion goods

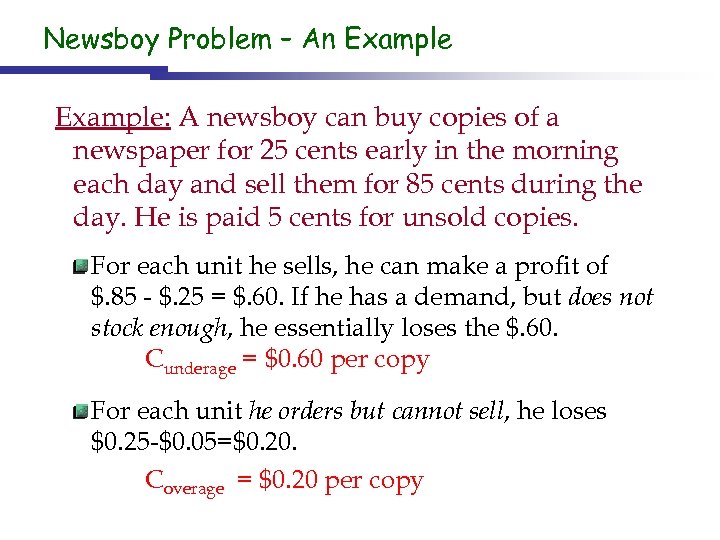

Newsboy Problem – An Example: A newsboy can buy copies of a newspaper for 25 cents early in the morning each day and sell them for 85 cents during the day. He is paid 5 cents for unsold copies. For each unit he sells, he can make a profit of $. 85 - $. 25 = $. 60. If he has a demand, but does not stock enough, he essentially loses the $. 60. Cunderage = $0. 60 per copy For each unit he orders but cannot sell, he loses $0. 25 -$0. 05=$0. 20. Coverage = $0. 20 per copy

Newsboy Problem – An Example: A newsboy can buy copies of a newspaper for 25 cents early in the morning each day and sell them for 85 cents during the day. He is paid 5 cents for unsold copies. For each unit he sells, he can make a profit of $. 85 - $. 25 = $. 60. If he has a demand, but does not stock enough, he essentially loses the $. 60. Cunderage = $0. 60 per copy For each unit he orders but cannot sell, he loses $0. 25 -$0. 05=$0. 20. Coverage = $0. 20 per copy

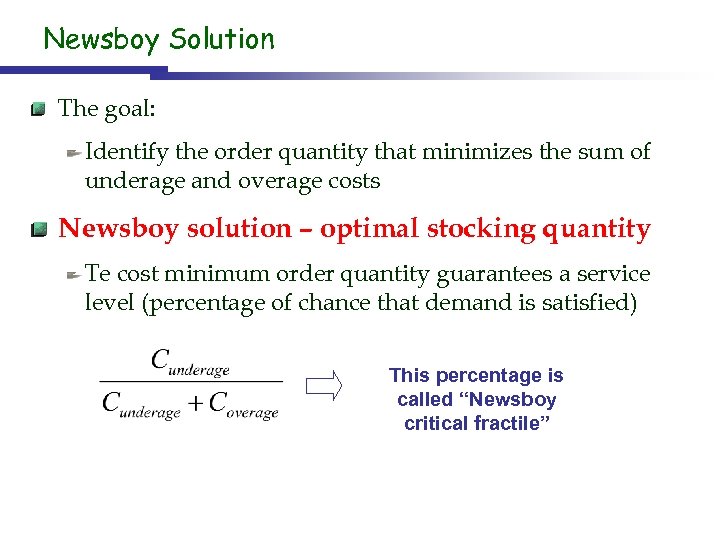

Newsboy Solution The goal: Identify the order quantity that minimizes the sum of underage and overage costs Newsboy solution – optimal stocking quantity Te cost minimum order quantity guarantees a service level (percentage of chance that demand is satisfied) This percentage is called “Newsboy critical fractile”

Newsboy Solution The goal: Identify the order quantity that minimizes the sum of underage and overage costs Newsboy solution – optimal stocking quantity Te cost minimum order quantity guarantees a service level (percentage of chance that demand is satisfied) This percentage is called “Newsboy critical fractile”

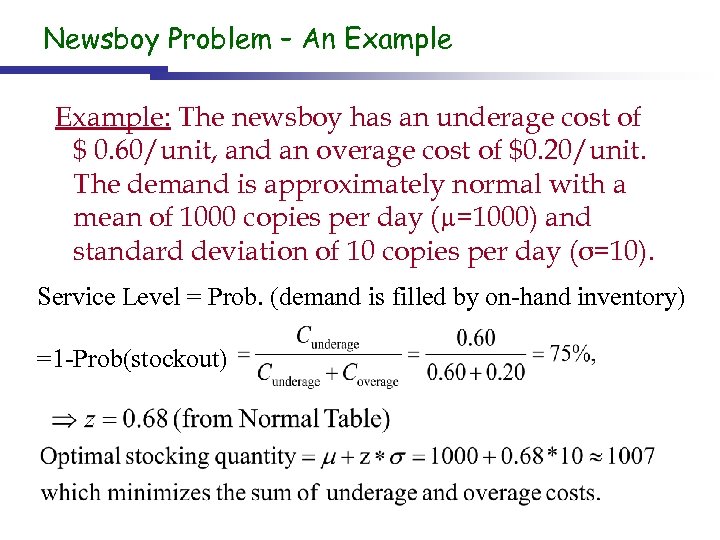

Newsboy Problem – An Example: The newsboy has an underage cost of $ 0. 60/unit, and an overage cost of $0. 20/unit. The demand is approximately normal with a mean of 1000 copies per day (µ=1000) and standard deviation of 10 copies per day (σ=10). Service Level = Prob. (demand is filled by on-hand inventory) =1 -Prob(stockout)

Newsboy Problem – An Example: The newsboy has an underage cost of $ 0. 60/unit, and an overage cost of $0. 20/unit. The demand is approximately normal with a mean of 1000 copies per day (µ=1000) and standard deviation of 10 copies per day (σ=10). Service Level = Prob. (demand is filled by on-hand inventory) =1 -Prob(stockout)

CHAPTER 14 MRP and ERP

CHAPTER 14 MRP and ERP

Contents Basic concepts in MRP and ERP. Independent demand, dependent demand master production schedule, bill of materials, product structure tree, inventory record, etc. Problem Solving Prepare MRP for end products, subassemblies and components

Contents Basic concepts in MRP and ERP. Independent demand, dependent demand master production schedule, bill of materials, product structure tree, inventory record, etc. Problem Solving Prepare MRP for end products, subassemblies and components

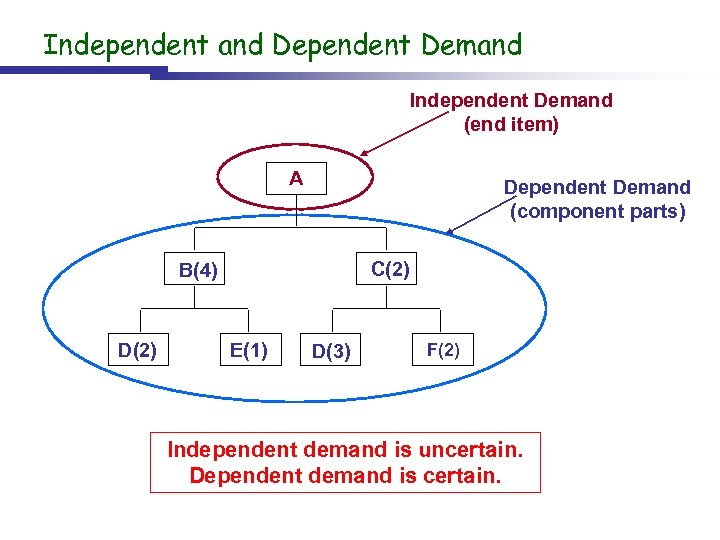

Independent and Dependent Demand Independent Demand (end item) A Dependent Demand (component parts) C(2) B(4) D(2) E(1) D(3) F(2) Independent demand is uncertain. Dependent demand is certain.

Independent and Dependent Demand Independent Demand (end item) A Dependent Demand (component parts) C(2) B(4) D(2) E(1) D(3) F(2) Independent demand is uncertain. Dependent demand is certain.

Dependant vs. Independent Demand Independent demand: Demand for end items. demand Dependent demand: Demand for items that are demand subassemblies or component parts to be used in production of finished goods. Once the independent demand is known, the dependent demand can be determined. Require a different inventory management technique from Chapter 12

Dependant vs. Independent Demand Independent demand: Demand for end items. demand Dependent demand: Demand for items that are demand subassemblies or component parts to be used in production of finished goods. Once the independent demand is known, the dependent demand can be determined. Require a different inventory management technique from Chapter 12

Material requirements planning (MRP): (MRP) Computer-based information system that translates master schedule requirements for end items into time-phased requirements for subassemblies, components, and raw materials. MRP works backward from the due date using lead times and other information to determine when and how much to order.

Material requirements planning (MRP): (MRP) Computer-based information system that translates master schedule requirements for end items into time-phased requirements for subassemblies, components, and raw materials. MRP works backward from the due date using lead times and other information to determine when and how much to order.

MPR Inputs 1. A master production schedule 2. A Bill of Materials 3. An inventory records file ure ct t uc rod P e e Tr tru S es m L Ti ad e

MPR Inputs 1. A master production schedule 2. A Bill of Materials 3. An inventory records file ure ct t uc rod P e e Tr tru S es m L Ti ad e

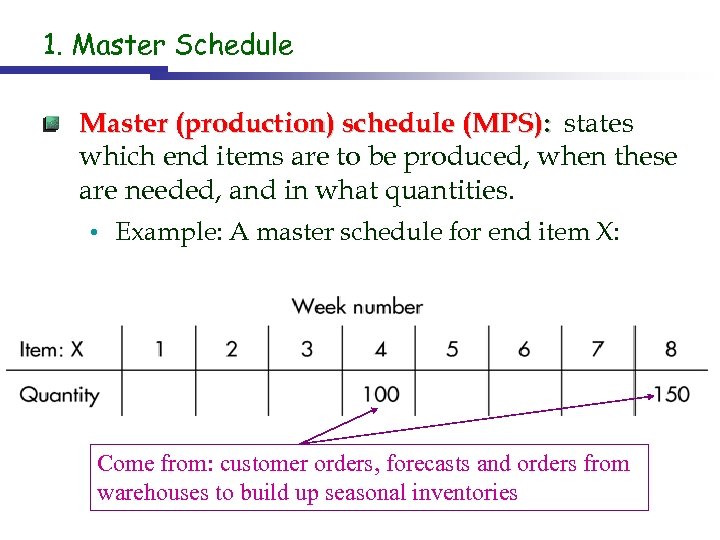

1. Master Schedule Master (production) schedule (MPS): states which end items are to be produced, when these are needed, and in what quantities. • Example: A master schedule for end item X: Come from: customer orders, forecasts and orders from warehouses to build up seasonal inventories

1. Master Schedule Master (production) schedule (MPS): states which end items are to be produced, when these are needed, and in what quantities. • Example: A master schedule for end item X: Come from: customer orders, forecasts and orders from warehouses to build up seasonal inventories

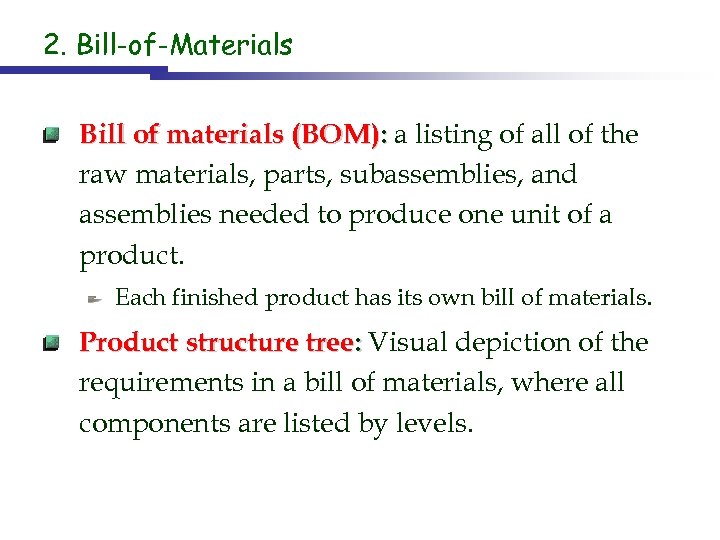

2. Bill-of-Materials Bill of materials (BOM): a listing of all of the raw materials, parts, subassemblies, and assemblies needed to produce one unit of a product. Each finished product has its own bill of materials. Product structure tree: Visual depiction of the requirements in a bill of materials, where all components are listed by levels.

2. Bill-of-Materials Bill of materials (BOM): a listing of all of the raw materials, parts, subassemblies, and assemblies needed to produce one unit of a product. Each finished product has its own bill of materials. Product structure tree: Visual depiction of the requirements in a bill of materials, where all components are listed by levels.

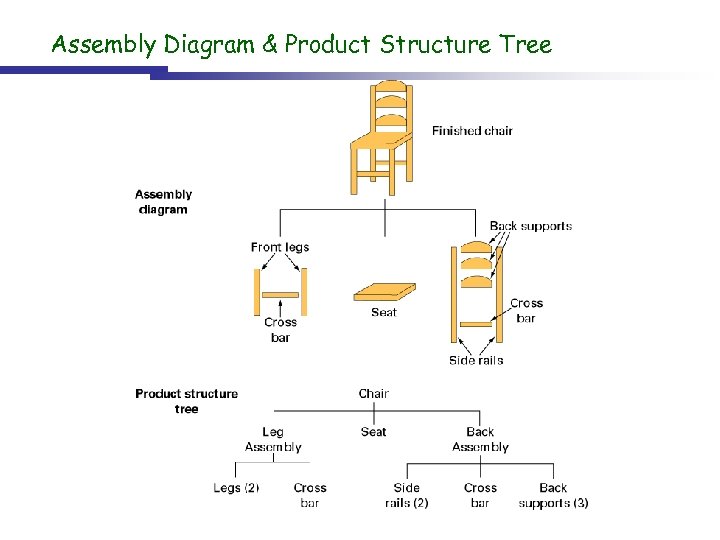

Assembly Diagram & Product Structure Tree

Assembly Diagram & Product Structure Tree

3. Inventory Records File Inventory records: includes information on the status of each item by time period: • • • Gross requirements Scheduled receipts Expected amount on hand Lead time Lot size policy And more …

3. Inventory Records File Inventory records: includes information on the status of each item by time period: • • • Gross requirements Scheduled receipts Expected amount on hand Lead time Lot size policy And more …

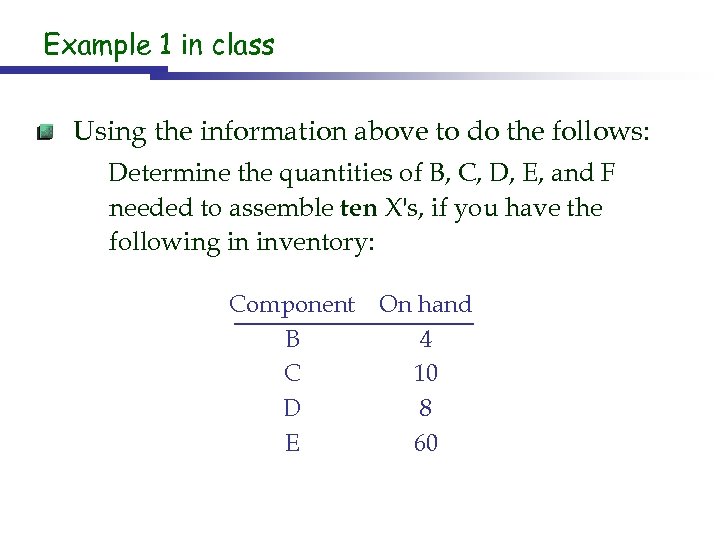

Example 1 in class Using the information above to do the follows: Determine the quantities of B, C, D, E, and F needed to assemble ten X's, if you have the following in inventory: Component On hand B 4 C 10 D 8 E 60

Example 1 in class Using the information above to do the follows: Determine the quantities of B, C, D, E, and F needed to assemble ten X's, if you have the following in inventory: Component On hand B 4 C 10 D 8 E 60

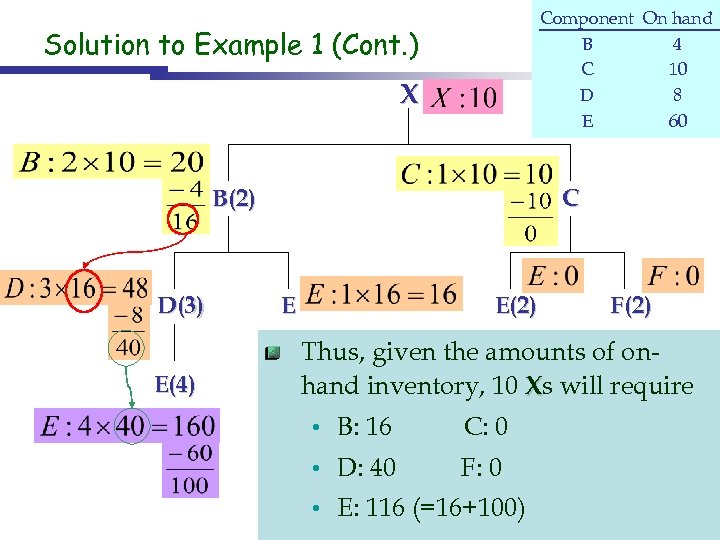

Component On hand B 4 C 10 D 8 E 60 Solution to Example 1 (Cont. ) X B(2) D(3) E(4) C E E(2) F(2) Thus, given the amounts of onhand inventory, 10 Xs will require • B: 16 C: 0 • D: 40 F: 0 • E: 116 (=16+100)

Component On hand B 4 C 10 D 8 E 60 Solution to Example 1 (Cont. ) X B(2) D(3) E(4) C E E(2) F(2) Thus, given the amounts of onhand inventory, 10 Xs will require • B: 16 C: 0 • D: 40 F: 0 • E: 116 (=16+100)

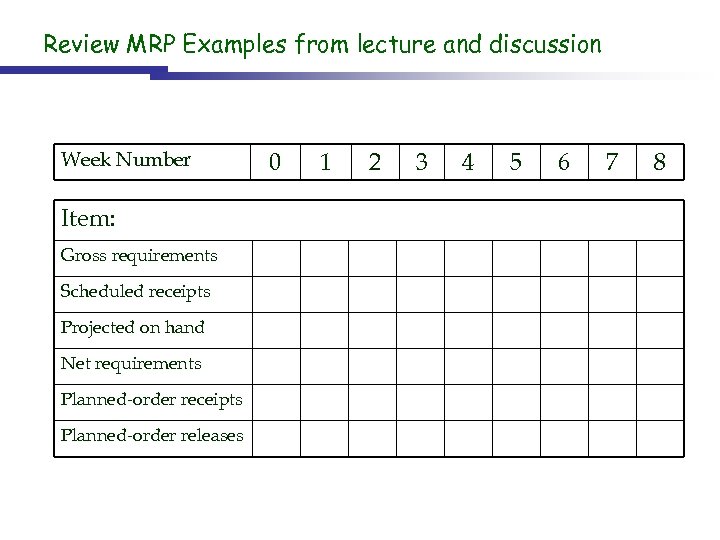

Review MRP Examples from lecture and discussion Week Number Item: Gross requirements Scheduled receipts Projected on hand Net requirements Planned-order receipts Planned-order releases 0 1 2 3 4 5 6 7 8

Review MRP Examples from lecture and discussion Week Number Item: Gross requirements Scheduled receipts Projected on hand Net requirements Planned-order receipts Planned-order releases 0 1 2 3 4 5 6 7 8

Project Management Chapter 17

Project Management Chapter 17

Contents Basic concepts in Project Mgmt. PERT, critical path, ES, EF, LS, LF, Slack… Problem Solving Identify critical path(s) Calculate ES, EF, LS, LF for each activity Crash a project Calculate probabilistic time estimates (not required for exam 3 and final exam)

Contents Basic concepts in Project Mgmt. PERT, critical path, ES, EF, LS, LF, Slack… Problem Solving Identify critical path(s) Calculate ES, EF, LS, LF for each activity Crash a project Calculate probabilistic time estimates (not required for exam 3 and final exam)

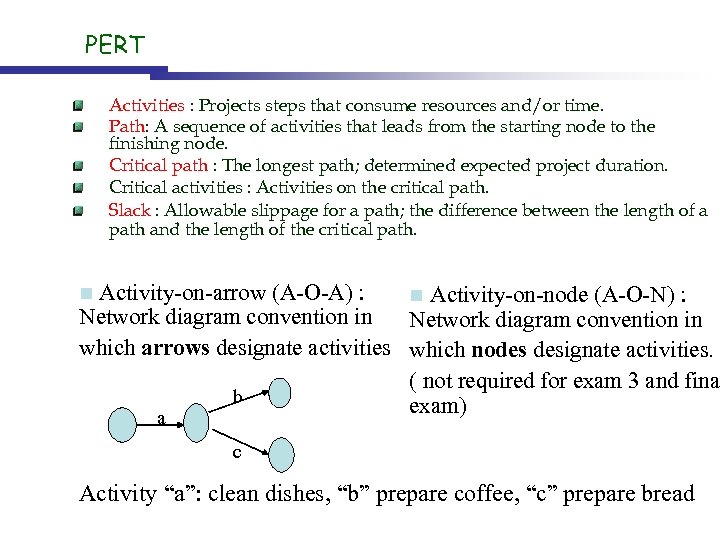

PERT Activities : Projects steps that consume resources and/or time. Path: A sequence of activities that leads from the starting node to the finishing node. Critical path : The longest path; determined expected project duration. Critical activities : Activities on the critical path. Slack : Allowable slippage for a path; the difference between the length of a path and the length of the critical path. Activity-on-arrow (A-O-A) : n Activity-on-node (A-O-N) : Network diagram convention in which arrows designate activities which nodes designate activities. ( not required for exam 3 and fina b exam) n a c Activity “a”: clean dishes, “b” prepare coffee, “c” prepare bread

PERT Activities : Projects steps that consume resources and/or time. Path: A sequence of activities that leads from the starting node to the finishing node. Critical path : The longest path; determined expected project duration. Critical activities : Activities on the critical path. Slack : Allowable slippage for a path; the difference between the length of a path and the length of the critical path. Activity-on-arrow (A-O-A) : n Activity-on-node (A-O-N) : Network diagram convention in which arrows designate activities which nodes designate activities. ( not required for exam 3 and fina b exam) n a c Activity “a”: clean dishes, “b” prepare coffee, “c” prepare bread

Deterministic Time Estimates ES : the earliest time activity can start, assuming all preceding activities start as early as possible. EF : the earliest time activity can finish. LS : the latest time the activity can start and not delay the project. LF : the latest time the activity can finish and not delay the project. Slack=LS-ES or LF-EF

Deterministic Time Estimates ES : the earliest time activity can start, assuming all preceding activities start as early as possible. EF : the earliest time activity can finish. LS : the latest time the activity can start and not delay the project. LF : the latest time the activity can finish and not delay the project. Slack=LS-ES or LF-EF

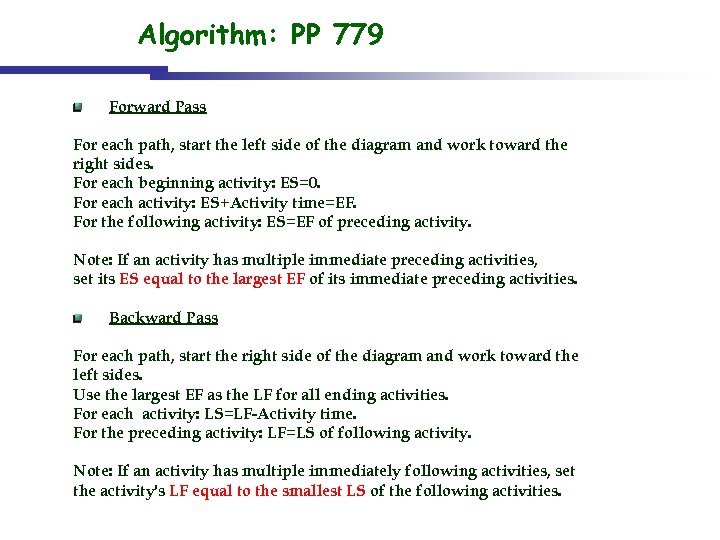

Algorithm: PP 779 Forward Pass For each path, start the left side of the diagram and work toward the right sides. For each beginning activity: ES=0. For each activity: ES+Activity time=EF. For the following activity: ES=EF of preceding activity. Note: If an activity has multiple immediate preceding activities, set its ES equal to the largest EF of its immediate preceding activities. Backward Pass For each path, start the right side of the diagram and work toward the left sides. Use the largest EF as the LF for all ending activities. For each activity: LS=LF-Activity time. For the preceding activity: LF=LS of following activity. Note: If an activity has multiple immediately following activities, set the activity's LF equal to the smallest LS of the following activities.

Algorithm: PP 779 Forward Pass For each path, start the left side of the diagram and work toward the right sides. For each beginning activity: ES=0. For each activity: ES+Activity time=EF. For the following activity: ES=EF of preceding activity. Note: If an activity has multiple immediate preceding activities, set its ES equal to the largest EF of its immediate preceding activities. Backward Pass For each path, start the right side of the diagram and work toward the left sides. Use the largest EF as the LF for all ending activities. For each activity: LS=LF-Activity time. For the preceding activity: LF=LS of following activity. Note: If an activity has multiple immediately following activities, set the activity's LF equal to the smallest LS of the following activities.

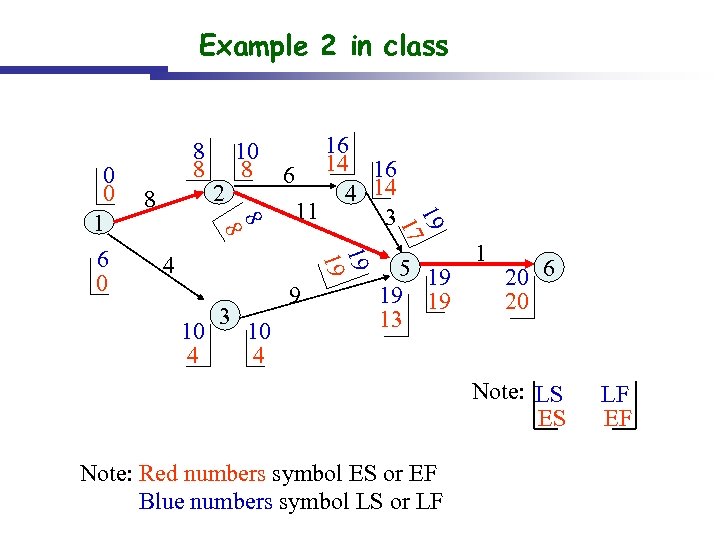

Example 2 in class 2 16 6 14 16 4 14 11 3 19 17 8 19 19 6 0 8 10 8 8 0 0 1 8 8 4 10 4 3 9 10 4 5 19 19 19 13 1 20 6 20 Note: LS ES Note: Red numbers symbol ES or EF Blue numbers symbol LS or LF LF EF

Example 2 in class 2 16 6 14 16 4 14 11 3 19 17 8 19 19 6 0 8 10 8 8 0 0 1 8 8 4 10 4 3 9 10 4 5 19 19 19 13 1 20 6 20 Note: LS ES Note: Red numbers symbol ES or EF Blue numbers symbol LS or LF LF EF

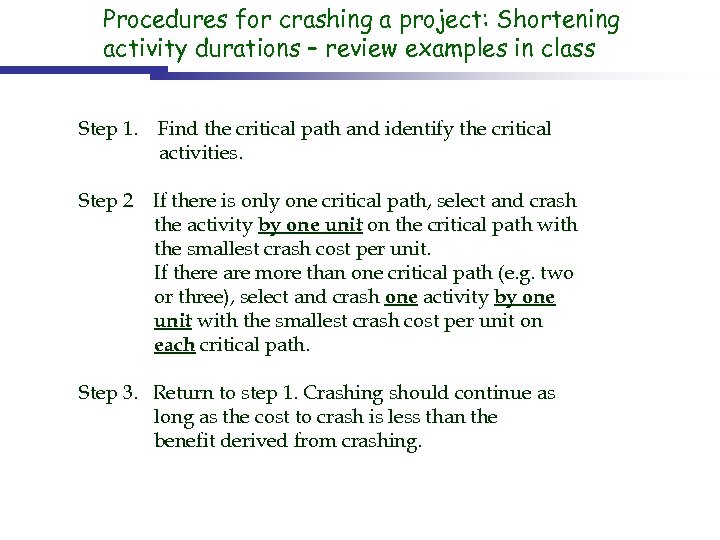

Procedures for crashing a project: Shortening activity durations – review examples in class Step 1. Find the critical path and identify the critical activities. Step 2 If there is only one critical path, select and crash the activity by one unit on the critical path with the smallest crash cost per unit. If there are more than one critical path (e. g. two or three), select and crash one activity by one unit with the smallest crash cost per unit on each critical path. Step 3. Return to step 1. Crashing should continue as long as the cost to crash is less than the benefit derived from crashing.

Procedures for crashing a project: Shortening activity durations – review examples in class Step 1. Find the critical path and identify the critical activities. Step 2 If there is only one critical path, select and crash the activity by one unit on the critical path with the smallest crash cost per unit. If there are more than one critical path (e. g. two or three), select and crash one activity by one unit with the smallest crash cost per unit on each critical path. Step 3. Return to step 1. Crashing should continue as long as the cost to crash is less than the benefit derived from crashing.