EWM-cold. Arc® Low energy short arc © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 1 08. 2008

EWM-cold. Arc® Low energy short arc © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 1 08. 2008

The cold arc. . . the impossible made possible! Overview ● ● ● Principle, solution and material transfer of the EWM-cold. Arc® Heat-reduced welding of the thinnest possible panels Low-heat brazing with Cu. Si and low-melting zinc brazing wire Mixed connections Manual and automatic MAG standard applications © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 2 08. 2008

The cold arc. . . the impossible made possible! Overview ● ● ● Principle, solution and material transfer of the EWM-cold. Arc® Heat-reduced welding of the thinnest possible panels Low-heat brazing with Cu. Si and low-melting zinc brazing wire Mixed connections Manual and automatic MAG standard applications © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 2 08. 2008

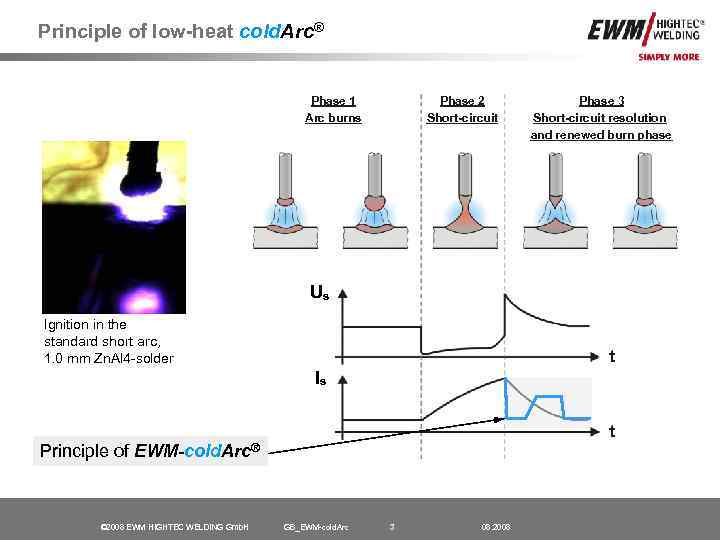

Principle of low-heat cold. Arc® Phase 1 Arc burns Phase 2 Short-circuit Phase 3 Short-circuit resolution and renewed burn phase Us Ignition in the standard short arc, 1. 0 mm Zn. Al 4 -solder t Is t Principle of EWM-cold. Arc® © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 3 08. 2008

Principle of low-heat cold. Arc® Phase 1 Arc burns Phase 2 Short-circuit Phase 3 Short-circuit resolution and renewed burn phase Us Ignition in the standard short arc, 1. 0 mm Zn. Al 4 -solder t Is t Principle of EWM-cold. Arc® © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 3 08. 2008

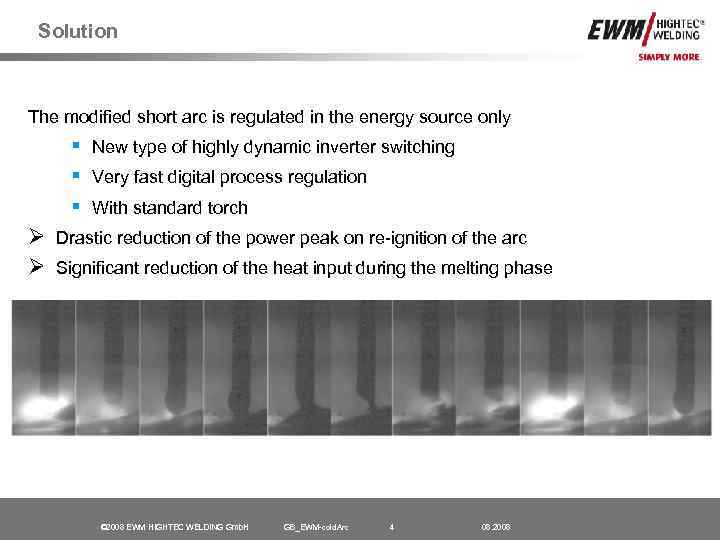

Solution The modified short arc is regulated in the energy source only § New type of highly dynamic inverter switching § Very fast digital process regulation § With standard torch Ø Drastic reduction of the power peak on re-ignition of the arc Ø Significant reduction of the heat input during the melting phase © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 4 08. 2008

Solution The modified short arc is regulated in the energy source only § New type of highly dynamic inverter switching § Very fast digital process regulation § With standard torch Ø Drastic reduction of the power peak on re-ignition of the arc Ø Significant reduction of the heat input during the melting phase © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 4 08. 2008

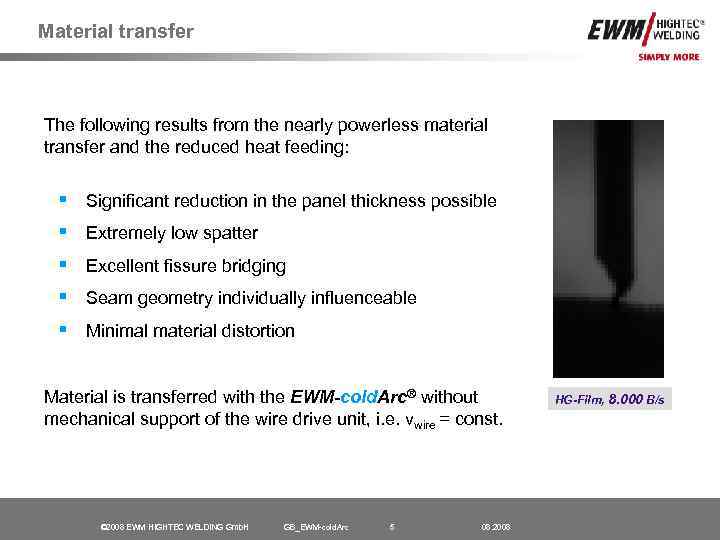

Material transfer The following results from the nearly powerless material transfer and the reduced heat feeding: § § § Significant reduction in the panel thickness possible Extremely low spatter Excellent fissure bridging Seam geometry individually influenceable Minimal material distortion Material is transferred with the EWM-cold. Arc® without mechanical support of the wire drive unit, i. e. vwire = const. © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 5 08. 2008 HG-Film, 8. 000 B/s

Material transfer The following results from the nearly powerless material transfer and the reduced heat feeding: § § § Significant reduction in the panel thickness possible Extremely low spatter Excellent fissure bridging Seam geometry individually influenceable Minimal material distortion Material is transferred with the EWM-cold. Arc® without mechanical support of the wire drive unit, i. e. vwire = const. © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 5 08. 2008 HG-Film, 8. 000 B/s

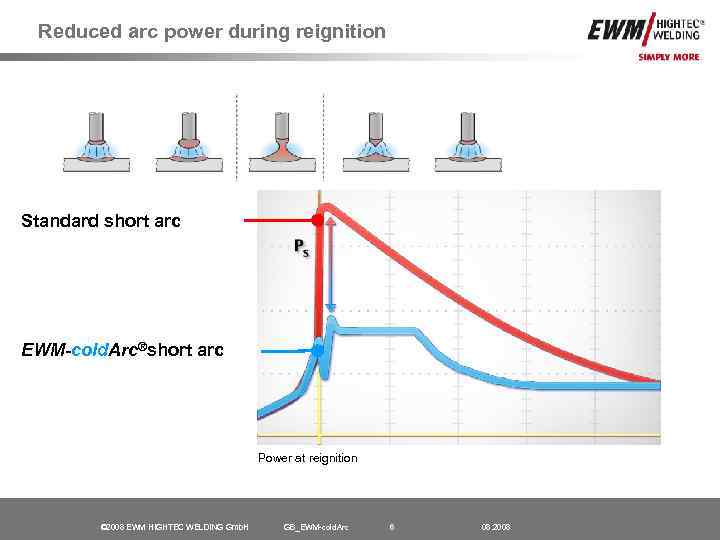

Reduced arc power during reignition Standard short arc EWM-cold. Arc®short arc Power at reignition © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 6 08. 2008

Reduced arc power during reignition Standard short arc EWM-cold. Arc®short arc Power at reignition © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 6 08. 2008

![voltage [V] Arc types RLB eed) hsp Hig ( ILB SLB ILB = Pulsed voltage [V] Arc types RLB eed) hsp Hig ( ILB SLB ILB = Pulsed](https://present5.com/presentation/37136695_184547197/image-7.jpg) voltage [V] Arc types RLB eed) hsp Hig ( ILB SLB ILB = Pulsed arc KLB = Short arc ÜLB = Transition arc SLB = Spray arc RLB = Rotating arc (Highspeed) rc orce. A f KLB ® rc cold. A ÜLB ® amperage [A] © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 7 08. 2008

voltage [V] Arc types RLB eed) hsp Hig ( ILB SLB ILB = Pulsed arc KLB = Short arc ÜLB = Transition arc SLB = Spray arc RLB = Rotating arc (Highspeed) rc orce. A f KLB ® rc cold. A ÜLB ® amperage [A] © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 7 08. 2008

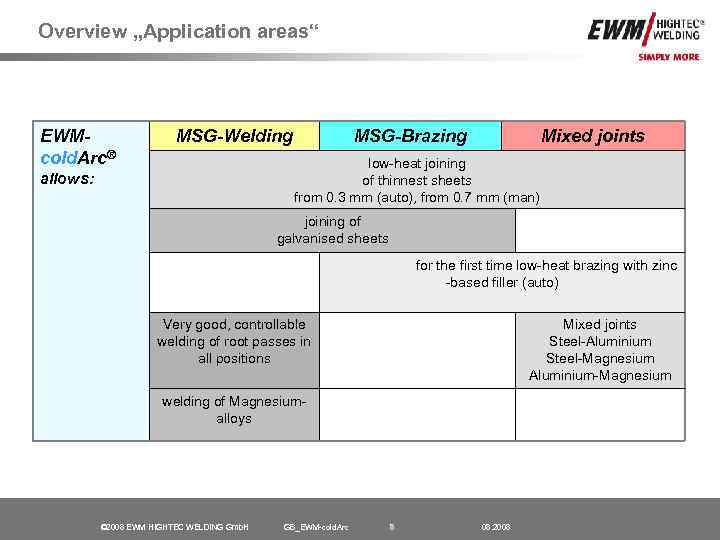

Overview „Application areas“ EWMcold. Arc® MSG-Welding MSG-Brazing Mixed joints low-heat joining of thinnest sheets from 0. 3 mm (auto), from 0. 7 mm (man) allows: joining of galvanised sheets for the first time low-heat brazing with zinc -based filler (auto) Very good, controllable welding of root passes in all positions Mixed joints Steel-Aluminium Steel-Magnesium Aluminium-Magnesium welding of Magnesiumalloys © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 8 08. 2008

Overview „Application areas“ EWMcold. Arc® MSG-Welding MSG-Brazing Mixed joints low-heat joining of thinnest sheets from 0. 3 mm (auto), from 0. 7 mm (man) allows: joining of galvanised sheets for the first time low-heat brazing with zinc -based filler (auto) Very good, controllable welding of root passes in all positions Mixed joints Steel-Aluminium Steel-Magnesium Aluminium-Magnesium welding of Magnesiumalloys © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 8 08. 2008

![Available characteristic curves MSG-Welding material sheet thickness (mm) gas wire Ø [mm] wire material Available characteristic curves MSG-Welding material sheet thickness (mm) gas wire Ø [mm] wire material](https://present5.com/presentation/37136695_184547197/image-9.jpg) Available characteristic curves MSG-Welding material sheet thickness (mm) gas wire Ø [mm] wire material application Steel 0. 2/0. 3 – 1. 5 (2. 0) 82% Argon + 18% CO 2 0. 8; 1. 0; 1. 2 like material auto Steel 0. 7 - 1, 5 (2. 0) 82% Argon + 18% CO 2 0. 8; 1. 0; 1. 2 like material man Steel 0. 2/0. 3 – 1. 5 (2. 0) 100% CO 2 0. 8; 1. 0; 1. 2 like material auto Steel 0. 7 – 1. 5 (2. 0) 100% CO 2 0. 8; 1. 0; 1. 2 like material man Cr. Ni-Steel 0. 2/0. 3 – 2. 5 97, 5% Argon + 2, 5% CO 2 0. 8; 1. 0; 1. 2 like material auto Cr. Ni-Steel 0. 7 – 2. 5 97, 5% Argon + 2, 5% CO 2 0. 8; 1. 0; 1. 2 like material man © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 9 08. 2008

Available characteristic curves MSG-Welding material sheet thickness (mm) gas wire Ø [mm] wire material application Steel 0. 2/0. 3 – 1. 5 (2. 0) 82% Argon + 18% CO 2 0. 8; 1. 0; 1. 2 like material auto Steel 0. 7 - 1, 5 (2. 0) 82% Argon + 18% CO 2 0. 8; 1. 0; 1. 2 like material man Steel 0. 2/0. 3 – 1. 5 (2. 0) 100% CO 2 0. 8; 1. 0; 1. 2 like material auto Steel 0. 7 – 1. 5 (2. 0) 100% CO 2 0. 8; 1. 0; 1. 2 like material man Cr. Ni-Steel 0. 2/0. 3 – 2. 5 97, 5% Argon + 2, 5% CO 2 0. 8; 1. 0; 1. 2 like material auto Cr. Ni-Steel 0. 7 – 2. 5 97, 5% Argon + 2, 5% CO 2 0. 8; 1. 0; 1. 2 like material man © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 9 08. 2008

![Available characteristic curves MSG-Brazing material sheet thickness (mm) gas wire Ø [mm] wire material Available characteristic curves MSG-Brazing material sheet thickness (mm) gas wire Ø [mm] wire material](https://present5.com/presentation/37136695_184547197/image-10.jpg) Available characteristic curves MSG-Brazing material sheet thickness (mm) gas wire Ø [mm] wire material application Steel 0. 2/0. 3 – 1. 5 (2. 0) 100% Argon 0. 8; 1. 0; 1. 2 Cu. Si/Cu. Al/Al. Bz 8 auto Steel 0. 7 – 1. 5 (2. 0) 100% Argon 0. 8; 1. 0; 1. 2 Cu. Si/Cu. Al/Al. Bz 8 man Steel 0. 2/0. 3 – 1. 5 (2. 0) 99% Argon + 1% CO 2 (S 1) 0. 8; 1. 0; 1. 2 Cu. Si/Cu. Al/Al. Bz 8 auto Steel 0. 7 – 1. 5 (2. 0) 99% Argon + 1% CO 2 (S 1) 0. 8; 1. 0; 1. 2 Cu. Si/Cu. Al/Al. Bz 8 man St zinced 0. 2/0. 3 – 1. 5 (2. 0) 100% Argon 0. 8; 1. 0; 1. 2 Cu. Si/Cu. Al/Al. Bz 8 auto St zinced 0. 7 – 1. 5 (2. 0) 100% Argon 0. 8; 1. 0; 1. 2 Cu. Si/Cu. Al/Al. Bz 8 man St zinced 0. 2/0. 3 – 1. 5 (2. 0) 99% Argon + 1% CO 2 (S 1) 0. 8; 1. 0; 1. 2 Cu. Si/Cu. Al/Al. Bz 8 auto St zinced 0. 7 – 1. 5 (2. 0) 99% Argon + 1% CO 2 (S 1) 0. 8; 1. 0; 1. 2 Cu. Si/Cu. Al/Al. Bz 8 man © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 10 08. 2008

Available characteristic curves MSG-Brazing material sheet thickness (mm) gas wire Ø [mm] wire material application Steel 0. 2/0. 3 – 1. 5 (2. 0) 100% Argon 0. 8; 1. 0; 1. 2 Cu. Si/Cu. Al/Al. Bz 8 auto Steel 0. 7 – 1. 5 (2. 0) 100% Argon 0. 8; 1. 0; 1. 2 Cu. Si/Cu. Al/Al. Bz 8 man Steel 0. 2/0. 3 – 1. 5 (2. 0) 99% Argon + 1% CO 2 (S 1) 0. 8; 1. 0; 1. 2 Cu. Si/Cu. Al/Al. Bz 8 auto Steel 0. 7 – 1. 5 (2. 0) 99% Argon + 1% CO 2 (S 1) 0. 8; 1. 0; 1. 2 Cu. Si/Cu. Al/Al. Bz 8 man St zinced 0. 2/0. 3 – 1. 5 (2. 0) 100% Argon 0. 8; 1. 0; 1. 2 Cu. Si/Cu. Al/Al. Bz 8 auto St zinced 0. 7 – 1. 5 (2. 0) 100% Argon 0. 8; 1. 0; 1. 2 Cu. Si/Cu. Al/Al. Bz 8 man St zinced 0. 2/0. 3 – 1. 5 (2. 0) 99% Argon + 1% CO 2 (S 1) 0. 8; 1. 0; 1. 2 Cu. Si/Cu. Al/Al. Bz 8 auto St zinced 0. 7 – 1. 5 (2. 0) 99% Argon + 1% CO 2 (S 1) 0. 8; 1. 0; 1. 2 Cu. Si/Cu. Al/Al. Bz 8 man © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 10 08. 2008

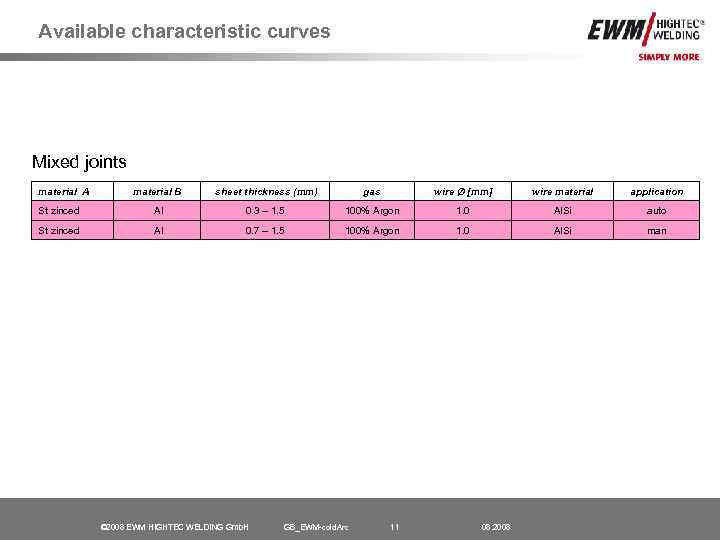

Available characteristic curves Mixed joints material A material B sheet thickness (mm) gas wire Ø [mm] wire material application St zinced Al 0. 3 – 1. 5 100% Argon 1. 0 Al. Si auto St zinced Al 0. 7 – 1. 5 100% Argon 1. 0 Al. Si man © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 11 08. 2008

Available characteristic curves Mixed joints material A material B sheet thickness (mm) gas wire Ø [mm] wire material application St zinced Al 0. 3 – 1. 5 100% Argon 1. 0 Al. Si auto St zinced Al 0. 7 – 1. 5 100% Argon 1. 0 Al. Si man © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 11 08. 2008

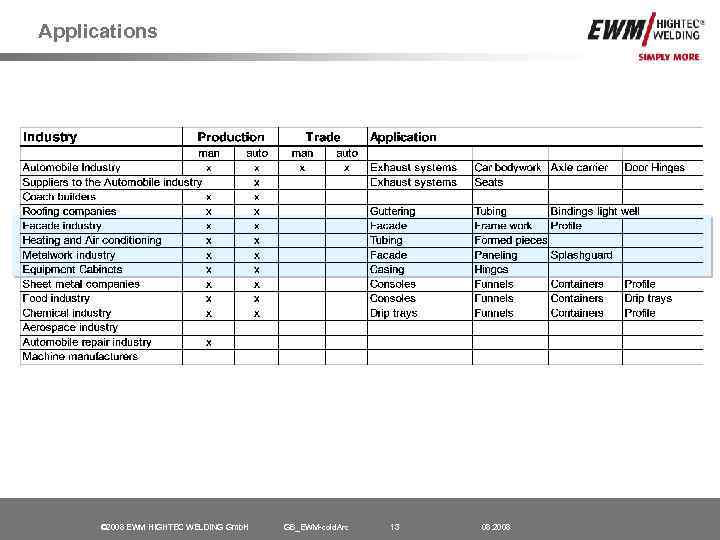

Applications in Production and repair in the manual processes Industry Automobile Industry Suppliers to the Automobile industry Coach builders Roofing companies Facade industry Heating and Air conditioning Metalwork industry Equipment Cabinets – Switch Cabinets Sheet metal companies Food industry Chemical industry Aerospace industry Automobile repair industry Machine manufacturers © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 12 08. 2008

Applications in Production and repair in the manual processes Industry Automobile Industry Suppliers to the Automobile industry Coach builders Roofing companies Facade industry Heating and Air conditioning Metalwork industry Equipment Cabinets – Switch Cabinets Sheet metal companies Food industry Chemical industry Aerospace industry Automobile repair industry Machine manufacturers © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 12 08. 2008

Applications © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 13 08. 2008

Applications © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 13 08. 2008

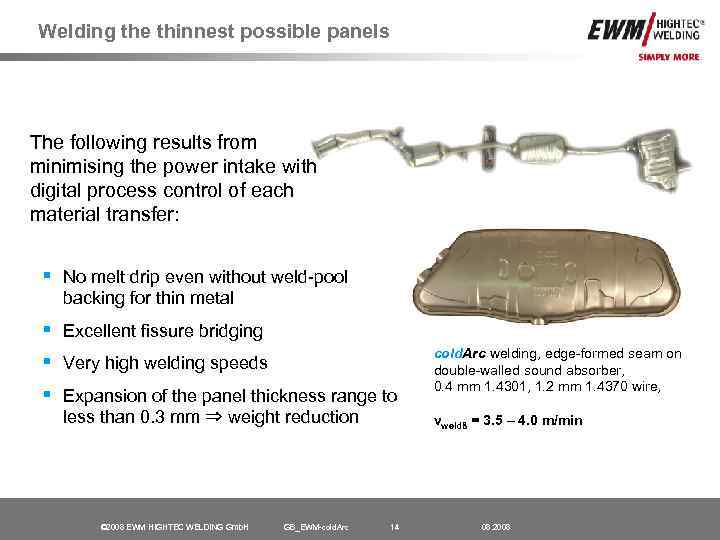

Welding the thinnest possible panels The following results from minimising the power intake with digital process control of each material transfer: § No melt drip even without weld-pool backing for thin metal § Excellent fissure bridging § Very high welding speeds § Expansion of the panel thickness range to less than 0. 3 mm ⇒ weight reduction © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc welding, edge-formed seam on double-walled sound absorber, 0. 4 mm 1. 4301, 1. 2 mm 1. 4370 wire, vweldß = 3. 5 – 4. 0 m/min 14 08. 2008

Welding the thinnest possible panels The following results from minimising the power intake with digital process control of each material transfer: § No melt drip even without weld-pool backing for thin metal § Excellent fissure bridging § Very high welding speeds § Expansion of the panel thickness range to less than 0. 3 mm ⇒ weight reduction © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc welding, edge-formed seam on double-walled sound absorber, 0. 4 mm 1. 4301, 1. 2 mm 1. 4370 wire, vweldß = 3. 5 – 4. 0 m/min 14 08. 2008

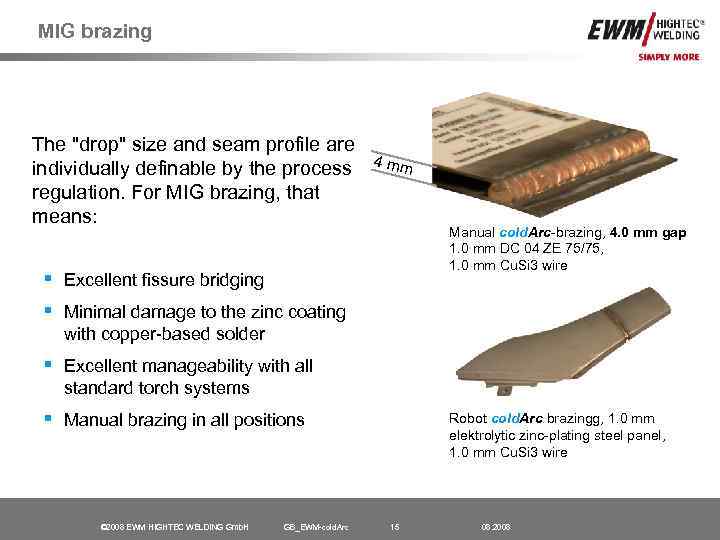

MIG brazing The "drop" size and seam profile are individually definable by the process 4 mm regulation. For MIG brazing, that means: § Excellent fissure bridging § Minimal damage to the zinc coating Manual cold. Arc-brazing, 4. 0 mm gap 1. 0 mm DC 04 ZE 75/75, 1. 0 mm Cu. Si 3 wire with copper-based solder § Excellent manageability with all standard torch systems § Manual brazing in all positions © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc Robot cold. Arc brazingg, 1. 0 mm elektrolytic zinc-plating steel panel, 1. 0 mm Cu. Si 3 wire 15 08. 2008

MIG brazing The "drop" size and seam profile are individually definable by the process 4 mm regulation. For MIG brazing, that means: § Excellent fissure bridging § Minimal damage to the zinc coating Manual cold. Arc-brazing, 4. 0 mm gap 1. 0 mm DC 04 ZE 75/75, 1. 0 mm Cu. Si 3 wire with copper-based solder § Excellent manageability with all standard torch systems § Manual brazing in all positions © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc Robot cold. Arc brazingg, 1. 0 mm elektrolytic zinc-plating steel panel, 1. 0 mm Cu. Si 3 wire 15 08. 2008

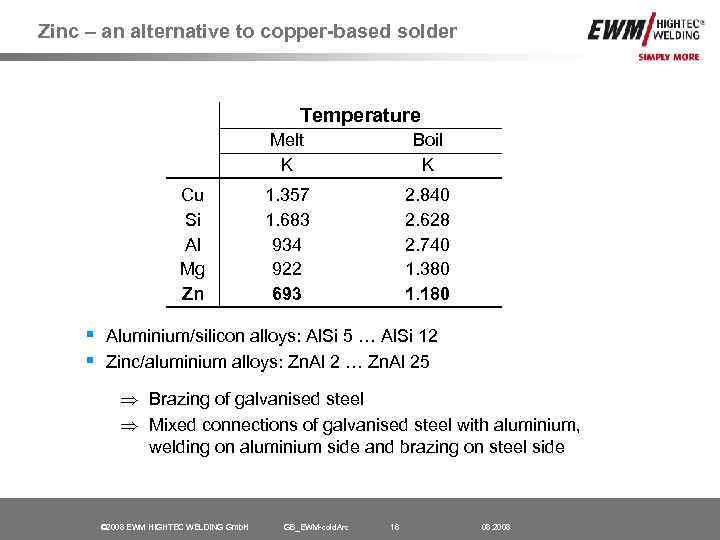

Zinc – an alternative to copper-based solder Temperature Melt K Cu Si Al Mg Zn Boil K 1. 357 1. 683 934 922 693 2. 840 2. 628 2. 740 1. 380 1. 180 § Aluminium/silicon alloys: Al. Si 5 … Al. Si 12 § Zinc/aluminium alloys: Zn. Al 2 … Zn. Al 25 Þ Brazing of galvanised steel Þ Mixed connections of galvanised steel with aluminium, welding on aluminium side and brazing on steel side © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 16 08. 2008

Zinc – an alternative to copper-based solder Temperature Melt K Cu Si Al Mg Zn Boil K 1. 357 1. 683 934 922 693 2. 840 2. 628 2. 740 1. 380 1. 180 § Aluminium/silicon alloys: Al. Si 5 … Al. Si 12 § Zinc/aluminium alloys: Zn. Al 2 … Zn. Al 25 Þ Brazing of galvanised steel Þ Mixed connections of galvanised steel with aluminium, welding on aluminium side and brazing on steel side © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 16 08. 2008

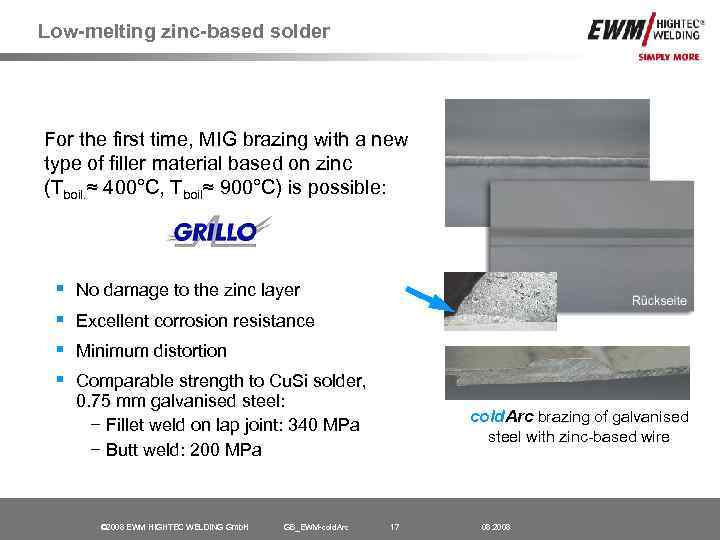

Low-melting zinc-based solder For the first time, MIG brazing with a new type of filler material based on zinc (Tboil. ≈ 400°C, Tboil≈ 900°C) is possible: § § No damage to the zinc layer Excellent corrosion resistance Minimum distortion Comparable strength to Cu. Si solder, 0. 75 mm galvanised steel: − Fillet weld on lap joint: 340 MPa − Butt weld: 200 MPa © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc brazing of galvanised steel with zinc-based wire 17 08. 2008

Low-melting zinc-based solder For the first time, MIG brazing with a new type of filler material based on zinc (Tboil. ≈ 400°C, Tboil≈ 900°C) is possible: § § No damage to the zinc layer Excellent corrosion resistance Minimum distortion Comparable strength to Cu. Si solder, 0. 75 mm galvanised steel: − Fillet weld on lap joint: 340 MPa − Butt weld: 200 MPa © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc brazing of galvanised steel with zinc-based wire 17 08. 2008

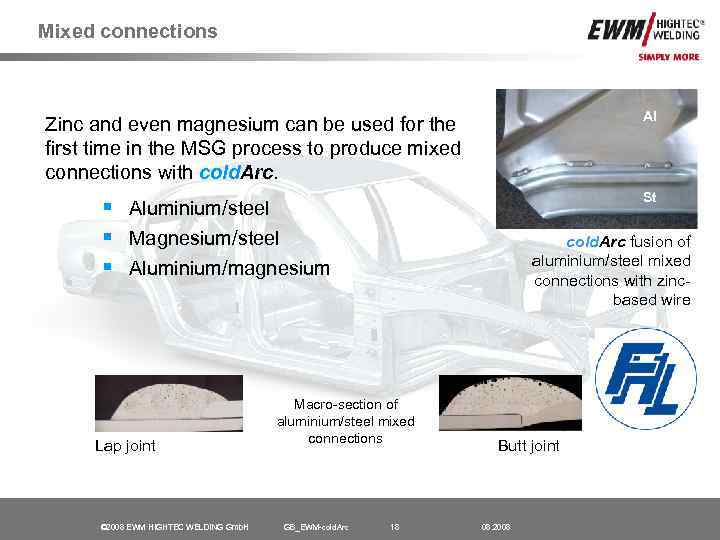

Mixed connections Al Zinc and even magnesium can be used for the first time in the MSG process to produce mixed connections with cold. Arc. St § Aluminium/steel § Magnesium/steel § Aluminium/magnesium Lap joint © 2008 EWM HIGHTEC WELDING Gmb. H cold. Arc fusion of aluminium/steel mixed connections with zincbased wire Macro-section of aluminium/steel mixed connections GB_EWM-cold. Arc 18 Butt joint 08. 2008

Mixed connections Al Zinc and even magnesium can be used for the first time in the MSG process to produce mixed connections with cold. Arc. St § Aluminium/steel § Magnesium/steel § Aluminium/magnesium Lap joint © 2008 EWM HIGHTEC WELDING Gmb. H cold. Arc fusion of aluminium/steel mixed connections with zincbased wire Macro-section of aluminium/steel mixed connections GB_EWM-cold. Arc 18 Butt joint 08. 2008

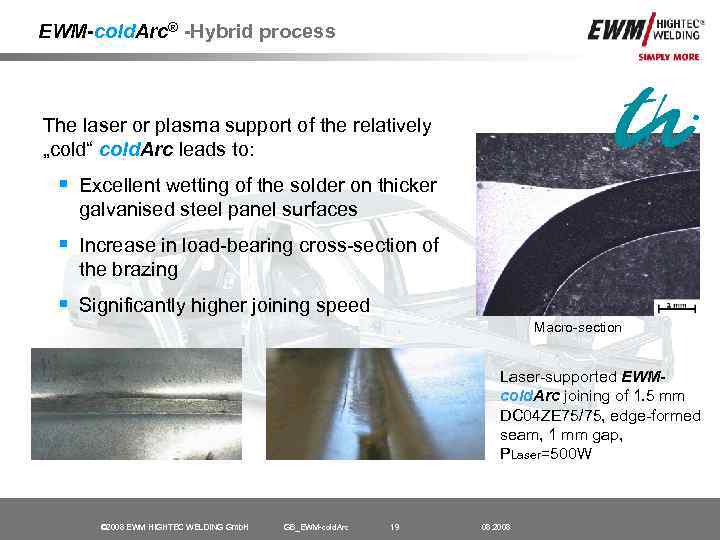

EWM-cold. Arc® -Hybrid process The laser or plasma support of the relatively „cold“ cold. Arc leads to: § Excellent wetting of the solder on thicker galvanised steel panel surfaces § Increase in load-bearing cross-section of the brazing § Significantly higher joining speed Macro-section Laser-supported EWMcold. Arc joining of 1. 5 mm DC 04 ZE 75/75, edge-formed seam, 1 mm gap, PLaser=500 W © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 19 08. 2008

EWM-cold. Arc® -Hybrid process The laser or plasma support of the relatively „cold“ cold. Arc leads to: § Excellent wetting of the solder on thicker galvanised steel panel surfaces § Increase in load-bearing cross-section of the brazing § Significantly higher joining speed Macro-section Laser-supported EWMcold. Arc joining of 1. 5 mm DC 04 ZE 75/75, edge-formed seam, 1 mm gap, PLaser=500 W © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 19 08. 2008

Варианты применения EWM-cold. Arc® пайка Оцинкованная сталь 0, 7 мм Угловой шов со сваркой внахлестку, цинковая проволока 1, 0 мм Смешанное соединение "алюминий-сталь", 0, 7 мм оцинкованная сталь и 1, 0 мм Al. Mg Угловой шов со сваркой внахлестку, цинковая проволока 1, 0 мм Смешанное соединение "алюминий-сталь", 1, 0 мм Al. Mg и 0, 7 мм оцинкованная сталь Угловой шов со сваркой внахлестку, проволока Al. Si 5 1, 0 мм © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 20 08. 2008

Варианты применения EWM-cold. Arc® пайка Оцинкованная сталь 0, 7 мм Угловой шов со сваркой внахлестку, цинковая проволока 1, 0 мм Смешанное соединение "алюминий-сталь", 0, 7 мм оцинкованная сталь и 1, 0 мм Al. Mg Угловой шов со сваркой внахлестку, цинковая проволока 1, 0 мм Смешанное соединение "алюминий-сталь", 1, 0 мм Al. Mg и 0, 7 мм оцинкованная сталь Угловой шов со сваркой внахлестку, проволока Al. Si 5 1, 0 мм © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 20 08. 2008

Варианты применения EWM-cold. Arc® сварка Стальной лист 1, 0 мм Соединение встык, зазор 1 мм, проволока G 4 Si 1 1, 0 мм Лист Cr. Ni 0, 5 мм Угловой шов со сваркой внахлестку, проволока Cr. Ni 1, 0 мм © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 21 08. 2008

Варианты применения EWM-cold. Arc® сварка Стальной лист 1, 0 мм Соединение встык, зазор 1 мм, проволока G 4 Si 1 1, 0 мм Лист Cr. Ni 0, 5 мм Угловой шов со сваркой внахлестку, проволока Cr. Ni 1, 0 мм © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 21 08. 2008

Стандартные конфигурации аппаратов Автоматическое выполнение работ PHOENIX DRIVE 4 ROB Горелка для роботизирован ной сварки Выполнение работ вручную Источник тока © 2008 EWM HIGHTEC WELDING Gmb. H PHOENIX DRIVE 4 L P GB_EWM-cold. Arc 22 Горелка для ручной сварки 08. 2008

Стандартные конфигурации аппаратов Автоматическое выполнение работ PHOENIX DRIVE 4 ROB Горелка для роботизирован ной сварки Выполнение работ вручную Источник тока © 2008 EWM HIGHTEC WELDING Gmb. H PHOENIX DRIVE 4 L P GB_EWM-cold. Arc 22 Горелка для ручной сварки 08. 2008

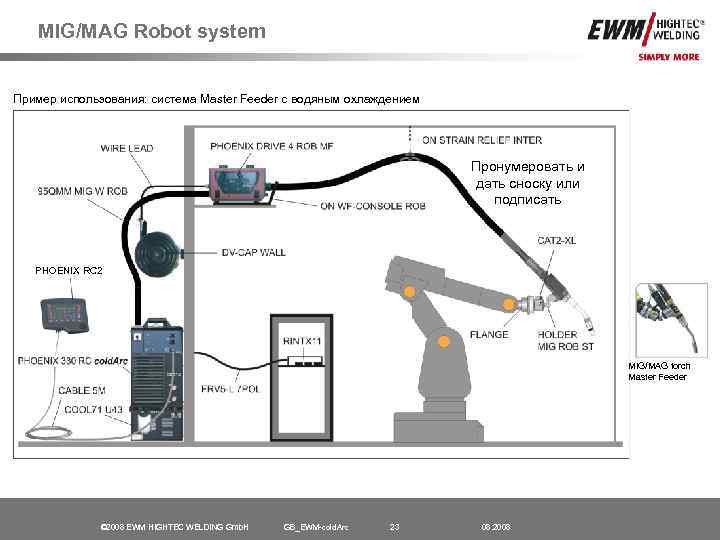

MIG/MAG Robot system Пример использования: система Master Feeder с водяным охлаждением Пронумеровать и дать сноску или подписать PHOENIX RC 2 MIG/MAG torch Master Feeder © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 23 08. 2008

MIG/MAG Robot system Пример использования: система Master Feeder с водяным охлаждением Пронумеровать и дать сноску или подписать PHOENIX RC 2 MIG/MAG torch Master Feeder © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 23 08. 2008

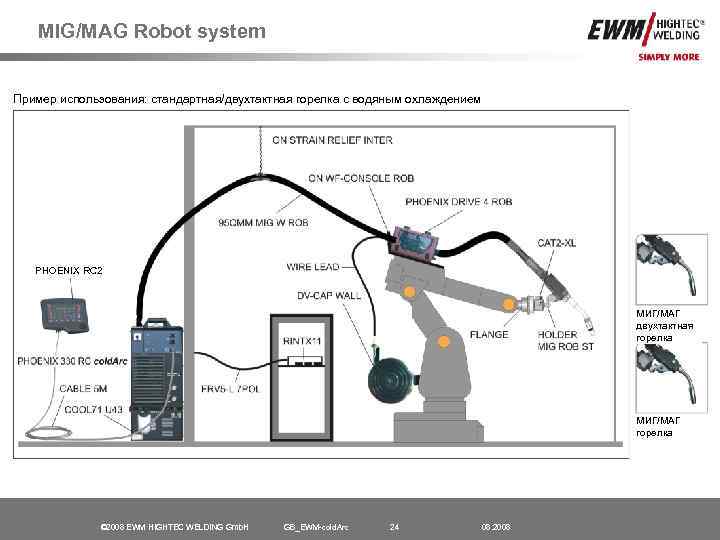

MIG/MAG Robot system Пример использования: стандартная/двухтактная горелка с водяным охлаждением PHOENIX RC 2 МИГ/МАГ двухтактная горелка МИГ/МАГ горелка © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 24 08. 2008

MIG/MAG Robot system Пример использования: стандартная/двухтактная горелка с водяным охлаждением PHOENIX RC 2 МИГ/МАГ двухтактная горелка МИГ/МАГ горелка © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 24 08. 2008

Спасибо за внимание © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 25 08. 2008

Спасибо за внимание © 2008 EWM HIGHTEC WELDING Gmb. H GB_EWM-cold. Arc 25 08. 2008