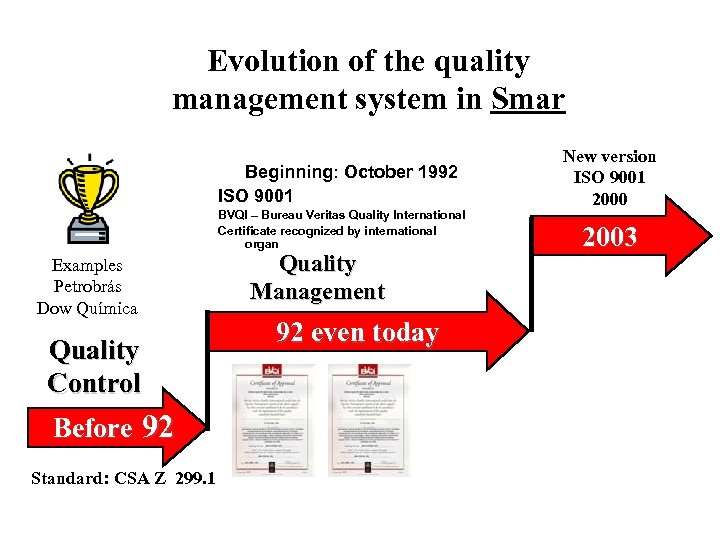

Evolution of the quality management system in Smar Beginning: October 1992 ISO 9001 BVQI – Bureau Veritas Quality International Certificate recognized by international organ Examples Petrobrás Dow Química Quality Control Before 92 Standard: CSA Z 299. 1 Quality Management 92 even today New version ISO 9001 2000 2003

Evolution of the quality management system in Smar Beginning: October 1992 ISO 9001 BVQI – Bureau Veritas Quality International Certificate recognized by international organ Examples Petrobrás Dow Química Quality Control Before 92 Standard: CSA Z 299. 1 Quality Management 92 even today New version ISO 9001 2000 2003

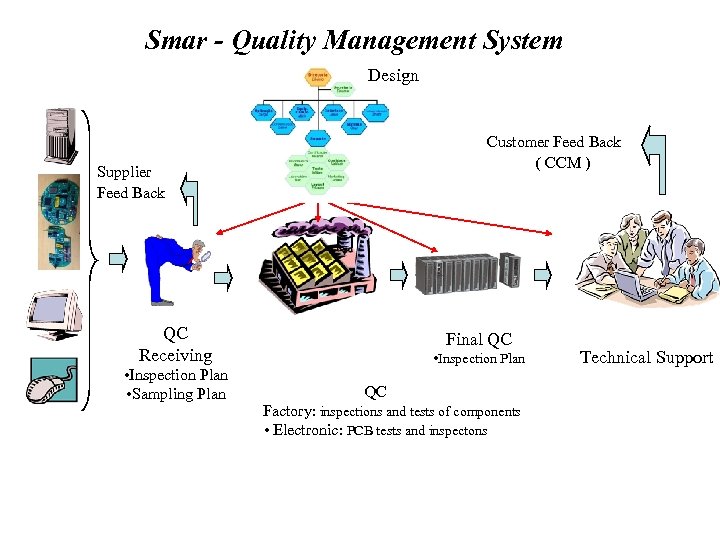

Smar - Quality Management System Design Customer Feed Back ( CCM ) Supplier Feed Back QC Receiving • Inspection Plan • Sampling Plan Final QC • Inspection Plan QC Factory: inspections and tests of components • Electronic: PCB tests and inspectons Technical Support

Smar - Quality Management System Design Customer Feed Back ( CCM ) Supplier Feed Back QC Receiving • Inspection Plan • Sampling Plan Final QC • Inspection Plan QC Factory: inspections and tests of components • Electronic: PCB tests and inspectons Technical Support

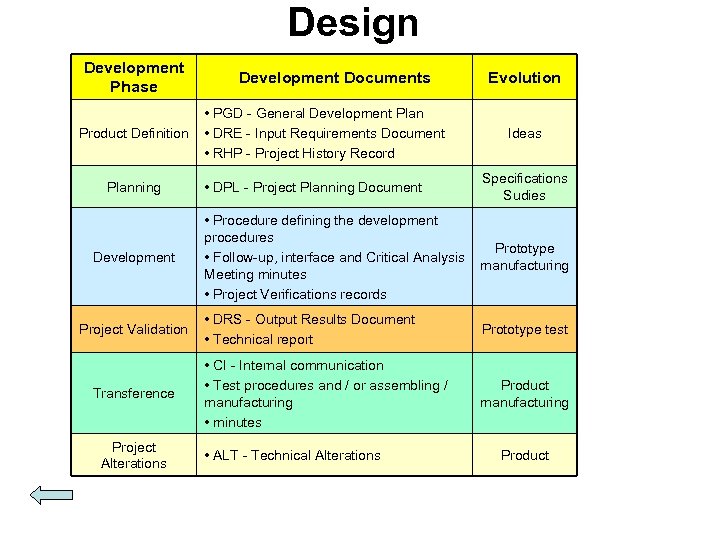

Design Development Phase Product Definition Planning Development Project Validation Transference Project Alterations Development Documents • PGD - General Development Plan • DRE - Input Requirements Document • RHP - Project History Record Evolution Ideas • DPL - Project Planning Document Specifications Sudies • Procedure defining the development procedures • Follow-up, interface and Critical Analysis Meeting minutes • Project Verifications records Prototype manufacturing • DRS - Output Results Document • Technical report Prototype test • CI - Internal communication • Test procedures and / or assembling / manufacturing • minutes Product manufacturing • ALT - Technical Alterations Product

Design Development Phase Product Definition Planning Development Project Validation Transference Project Alterations Development Documents • PGD - General Development Plan • DRE - Input Requirements Document • RHP - Project History Record Evolution Ideas • DPL - Project Planning Document Specifications Sudies • Procedure defining the development procedures • Follow-up, interface and Critical Analysis Meeting minutes • Project Verifications records Prototype manufacturing • DRS - Output Results Document • Technical report Prototype test • CI - Internal communication • Test procedures and / or assembling / manufacturing • minutes Product manufacturing • ALT - Technical Alterations Product

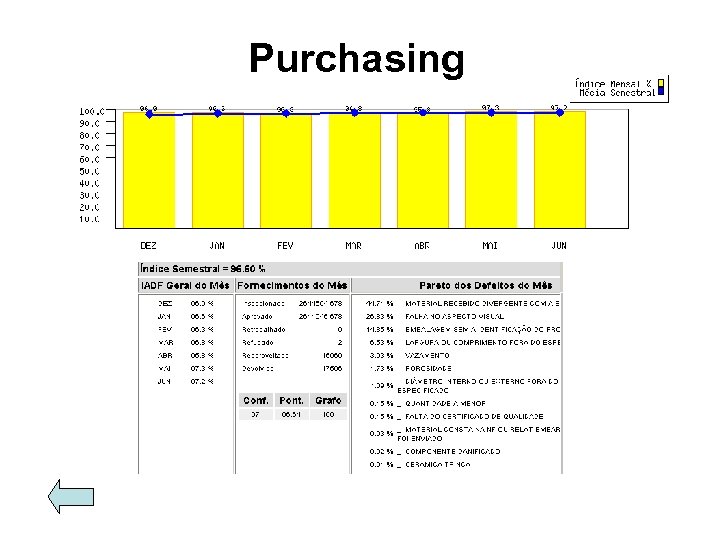

Purchasing

Purchasing

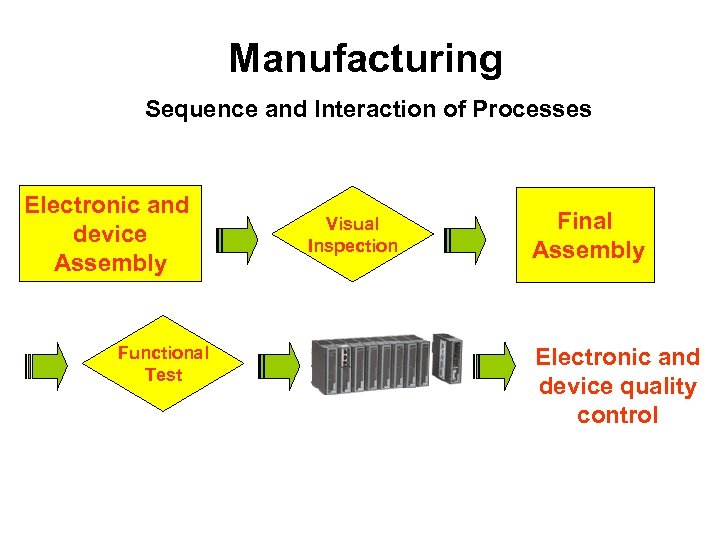

Manufacturing Sequence and Interaction of Processes Electronic and device Assembly Functional Test Visual Inspection Final Assembly Electronic and device quality control

Manufacturing Sequence and Interaction of Processes Electronic and device Assembly Functional Test Visual Inspection Final Assembly Electronic and device quality control

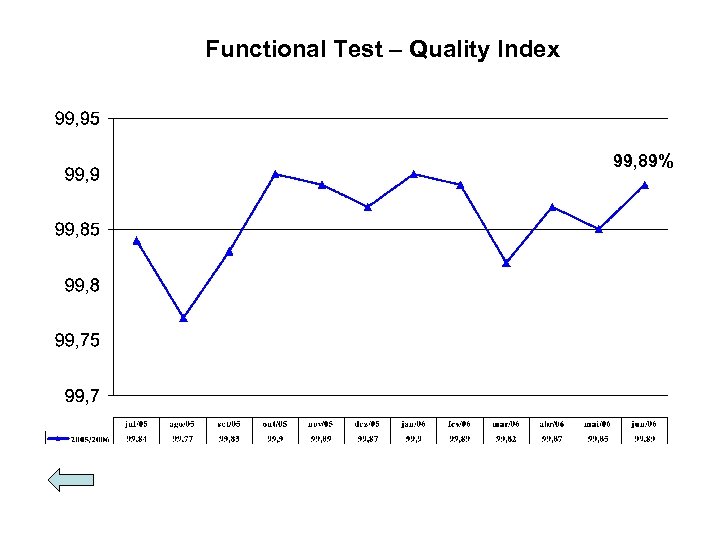

Functional Test – Quality Index 99, 89%

Functional Test – Quality Index 99, 89%

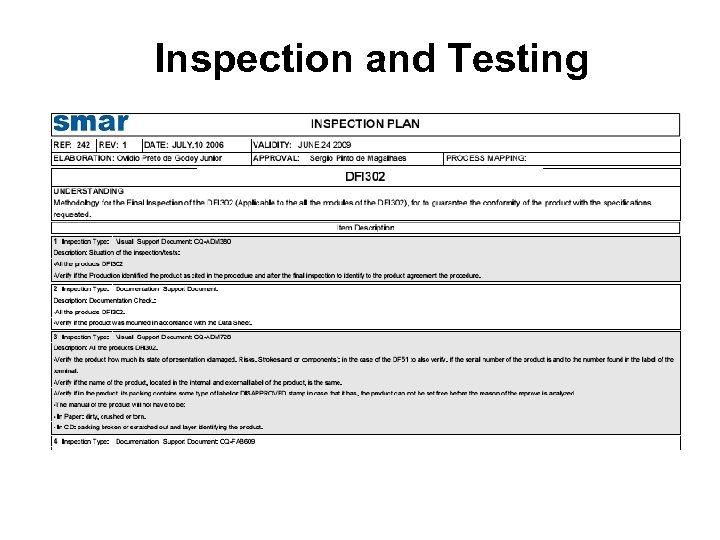

Inspection and Testing

Inspection and Testing

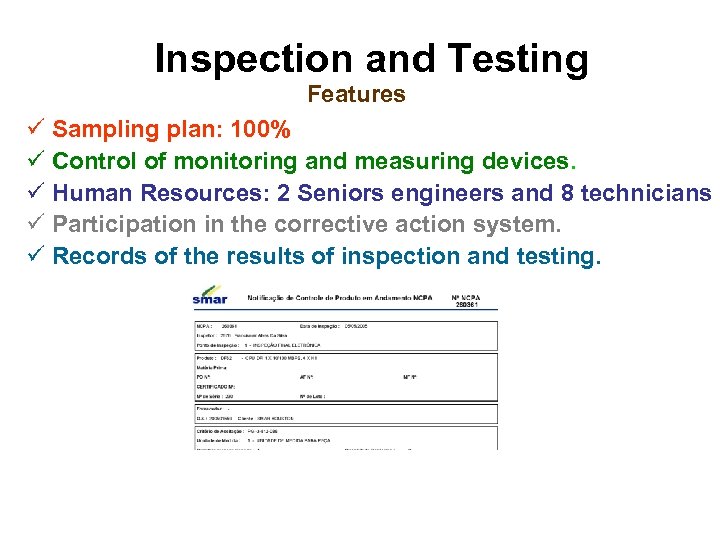

Inspection and Testing Features ü Sampling plan: 100% ü Control of monitoring and measuring devices. ü Human Resources: 2 Seniors engineers and 8 technicians ü Participation in the corrective action system. ü Records of the results of inspection and testing.

Inspection and Testing Features ü Sampling plan: 100% ü Control of monitoring and measuring devices. ü Human Resources: 2 Seniors engineers and 8 technicians ü Participation in the corrective action system. ü Records of the results of inspection and testing.

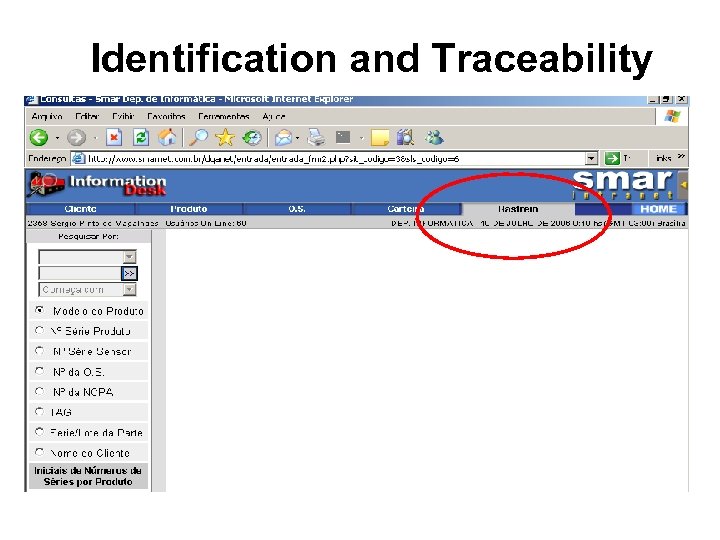

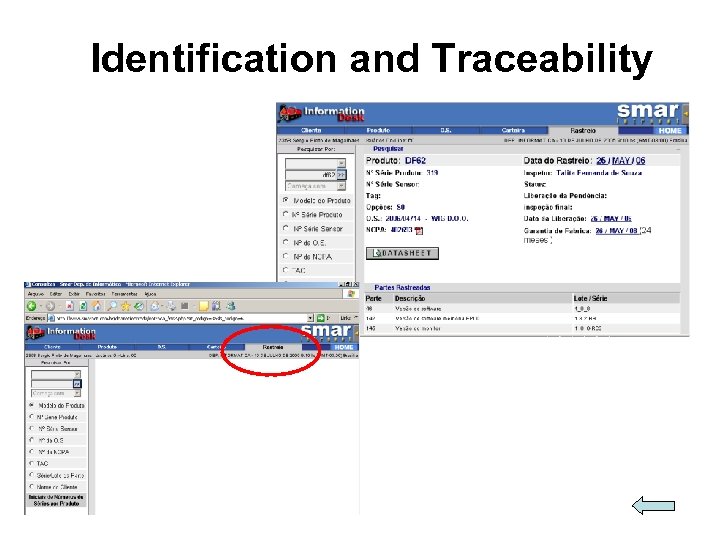

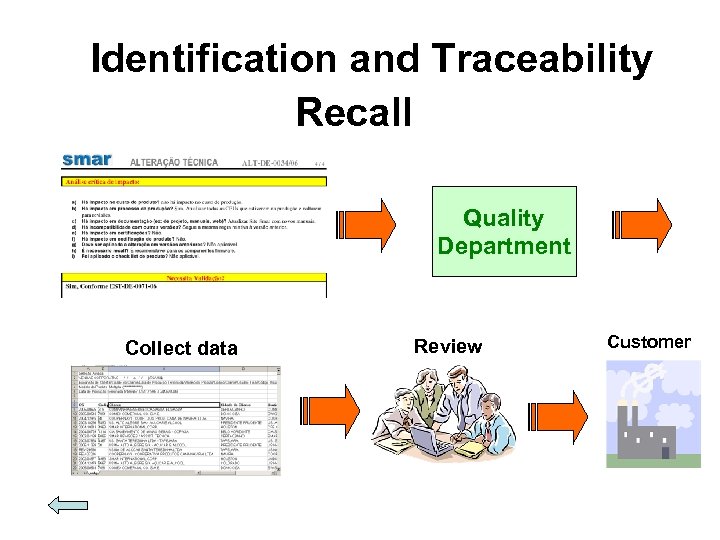

Identification and Traceability

Identification and Traceability

Identification and Traceability

Identification and Traceability

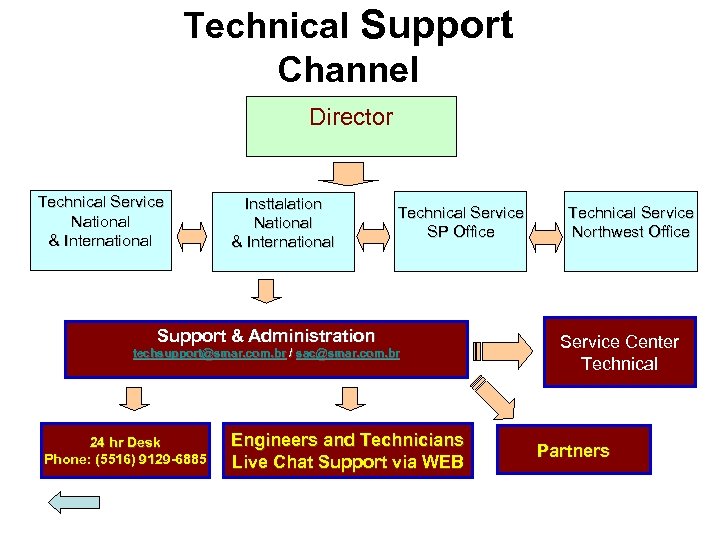

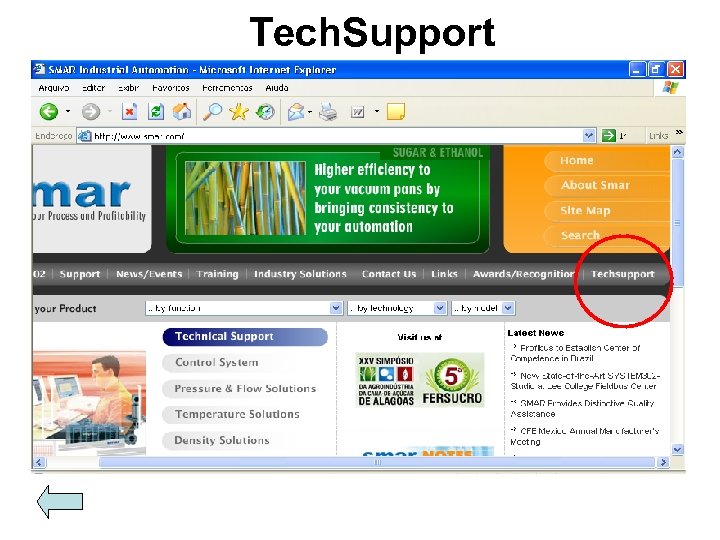

Technical Support Channel Director Technical Service National & International Insttalation National & International Technical Service SP Office Support & Administration techsupport@smar. com. br / sac@smar. com. br 24 hr Desk Phone: (5516) 9129 -6885 Engineers and Technicians Live Chat Support via WEB Technical Service Northwest Office Service Center Technical Partners

Technical Support Channel Director Technical Service National & International Insttalation National & International Technical Service SP Office Support & Administration techsupport@smar. com. br / sac@smar. com. br 24 hr Desk Phone: (5516) 9129 -6885 Engineers and Technicians Live Chat Support via WEB Technical Service Northwest Office Service Center Technical Partners

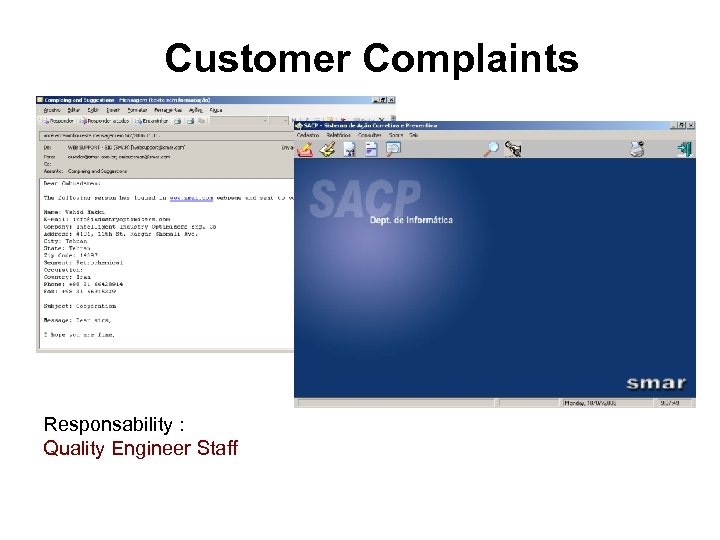

Customer Complaints

Customer Complaints

Customer Complaints Responsability : Quality Engineer Staff

Customer Complaints Responsability : Quality Engineer Staff

Tech. Support

Tech. Support

Identification and Traceability Recall Quality Department Collect data Review Customer

Identification and Traceability Recall Quality Department Collect data Review Customer