fcc95ae37f13d66823c3db8d305af6d4.ppt

- Количество слайдов: 94

Everything you wanted to know about Six-Sigma but were afraid to ask! Dave Stewardson - ISRU Ronald Does – The Netherlands Soren Bisgaard - USA Bo Bergman – Sweden Ron Kennet – Israel Oystein Evandt – Norway Xavier Tort-Martorell - Spain

Pro-Enbis All joint authors - presenters- are members of: Pro-Enbis and ENBIS. This presentation is supported by Pro-Enbis a Thematic Network funded under the ‘Growth’ programme of the European Commission’s 5 th Framework research programme - contract number G 6 RT-CT-2001 -05059

ENBIS European Network for Business and Industrial Statistics www. enbis. org

Overview u u u u u Brief resume of Six Sigma - Key concepts - Training - Execution The Scientific Method Project selection “Quotes” Barriers – Overcoming these Critique of ISO 9000 Change programs Real reasons why six-sigma works Simple case study

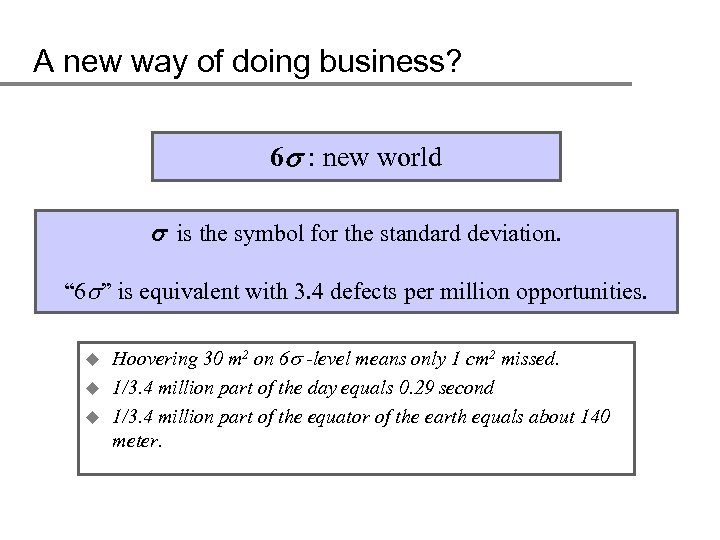

A new way of doing business? 6 : new world is the symbol for the standard deviation. “ 6 s” is equivalent with 3. 4 defects per million opportunities. u u u Hoovering 30 m 2 on 6 s -level means only 1 cm 2 missed. 1/3. 4 million part of the day equals 0. 29 second 1/3. 4 million part of the equator of the earth equals about 140 meter.

Statistical background Some Key measure Target = m

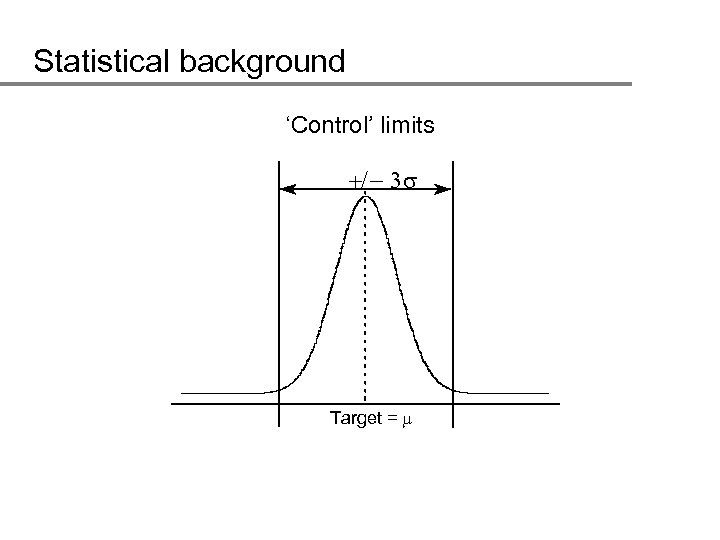

Statistical background ‘Control’ limits +/ - 3 Target = m

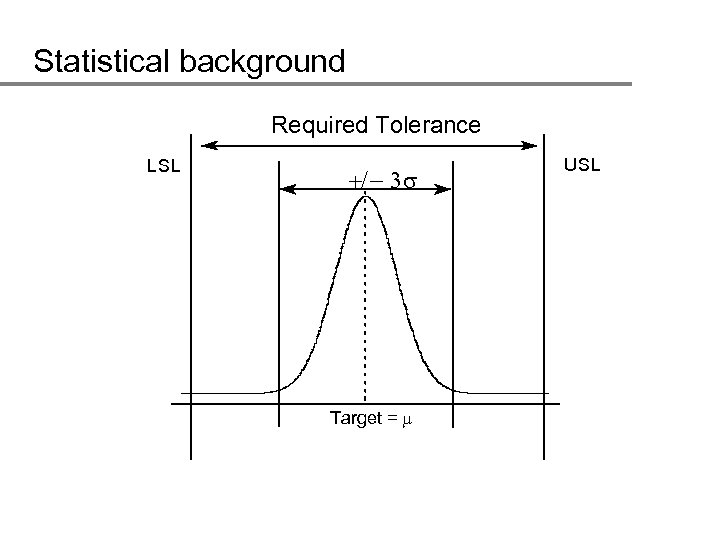

Statistical background Required Tolerance LSL +/ - 3 Target = m USL

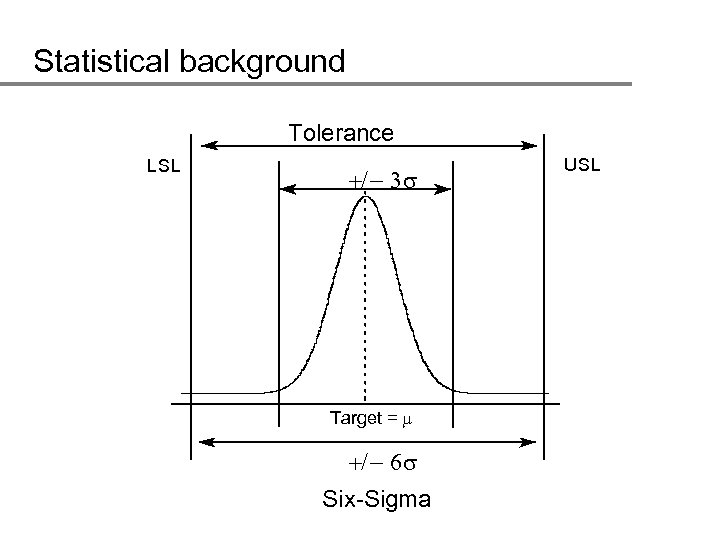

Statistical background Tolerance LSL +/ - 3 Target = m +/ - 6 Six-Sigma USL

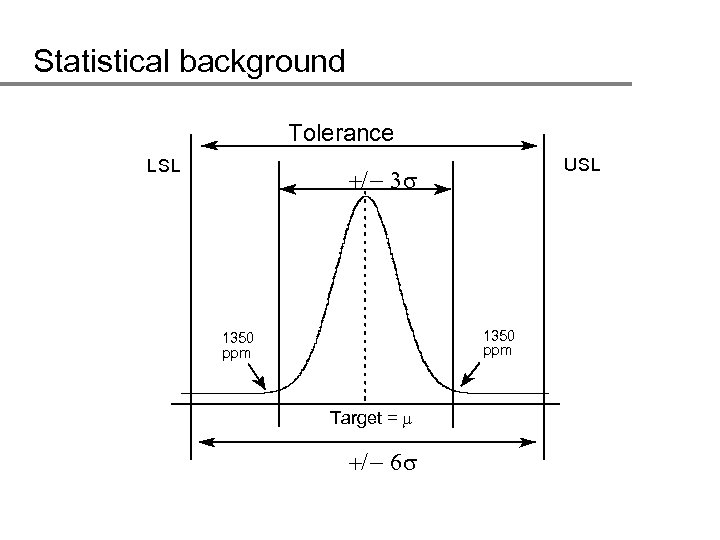

Statistical background Tolerance LSL USL +/ - 3 1350 ppm Target = m +/ - 6

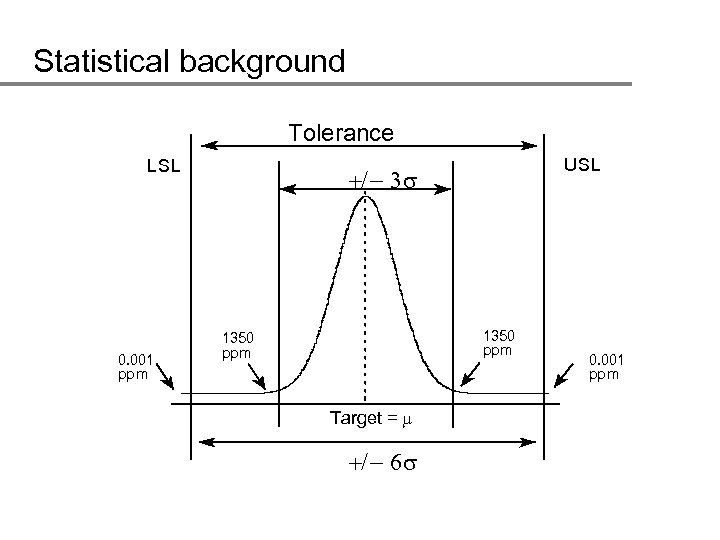

Statistical background Tolerance LSL 0. 001 ppm USL +/ - 3 1350 ppm Target = m +/ - 6 0. 001 ppm

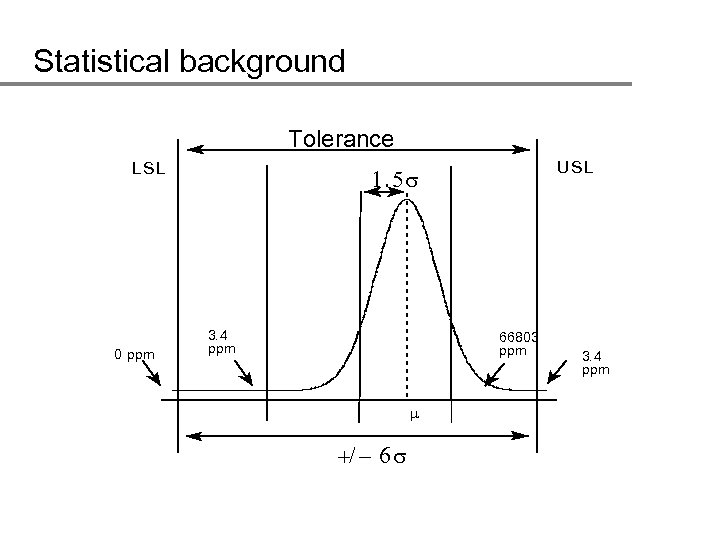

Statistical background But Six-Sigma allows for un-forseen ‘problems’ and longer term issues when calculating failure error or re-work rates Assumes a process ‘shift’

Statistical background Tolerance LSL 0 ppm USL 1. 5 3. 4 ppm 66803 ppm m +/ - 6 3. 4 ppm

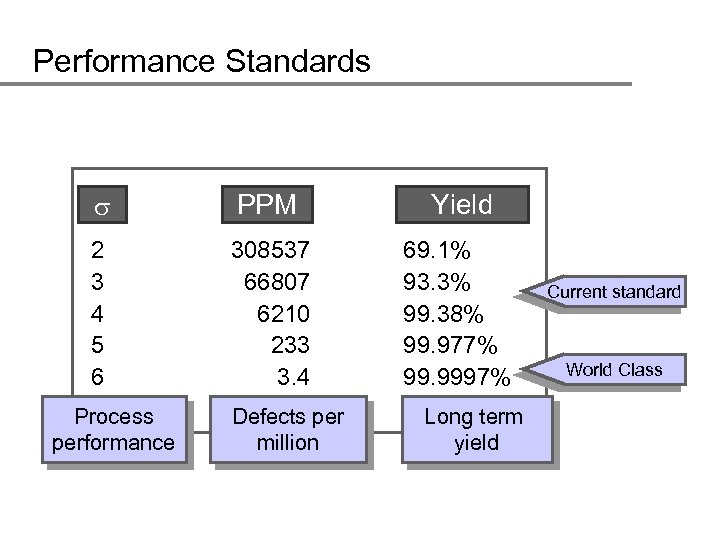

Performance Standards PPM Yield 2 3 4 5 6 308537 66807 6210 233 3. 4 69. 1% 93. 3% 99. 38% 99. 977% 99. 9997% Process performance Defects per million Long term yield Current standard World Class

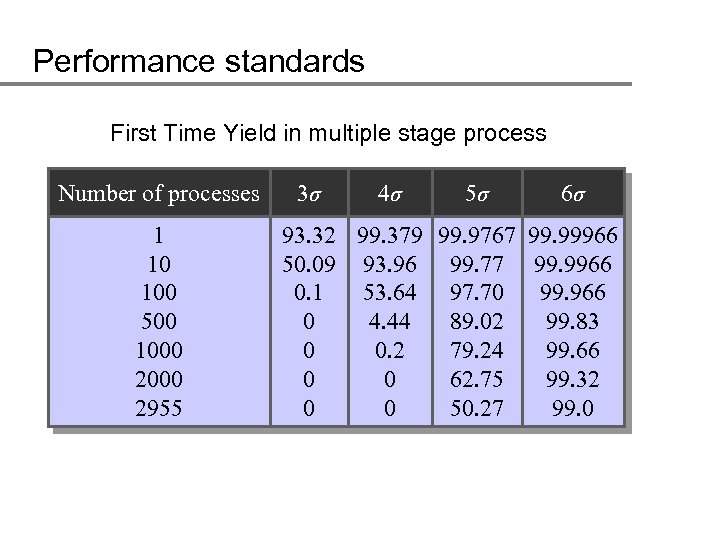

Performance standards First Time Yield in multiple stage process Number of processes 1 10 100 500 1000 2955 3σ 4σ 5σ 6σ 93. 32 99. 379 99. 9767 99. 99966 50. 09 93. 96 99. 77 99. 9966 0. 1 53. 64 97. 70 99. 966 0 4. 44 89. 02 99. 83 0 0. 2 79. 24 99. 66 0 0 62. 75 99. 32 0 0 50. 27 99. 0

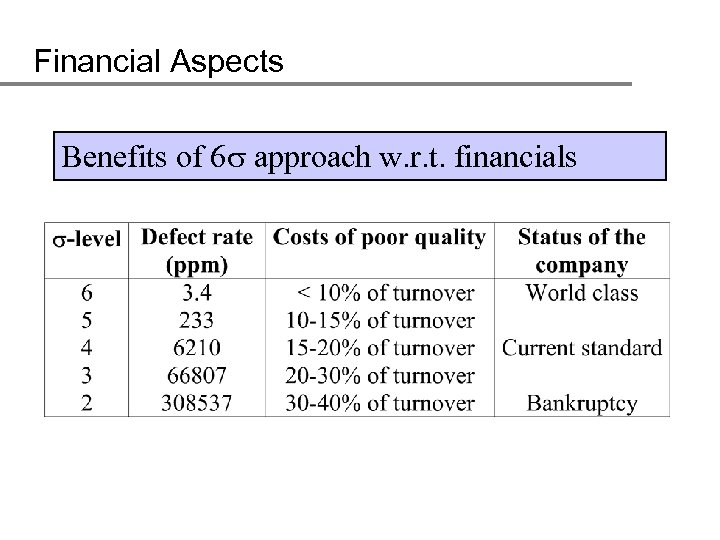

Financial Aspects Benefits of 6 approach w. r. t. financials

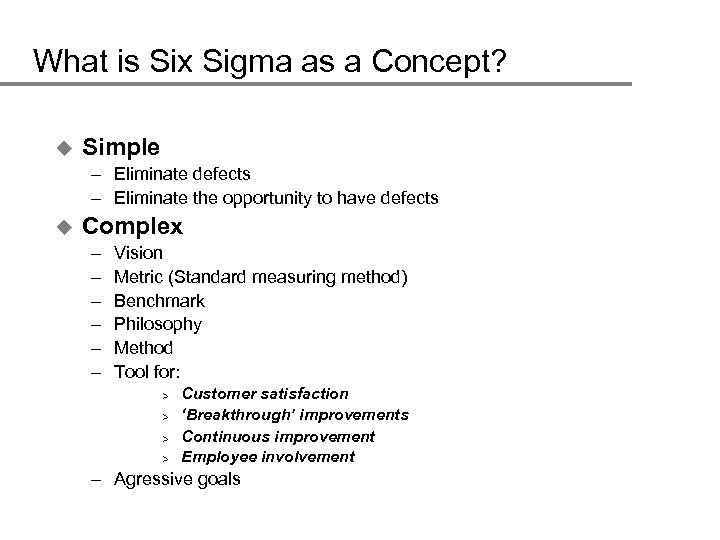

What is Six Sigma as a Concept? u Simple – Eliminate defects – Eliminate the opportunity to have defects u Complex – – – Vision Metric (Standard measuring method) Benchmark Philosophy Method Tool for: > > Customer satisfaction ‘Breakthrough’ improvements Continuous improvement Employee involvement – Agressive goals

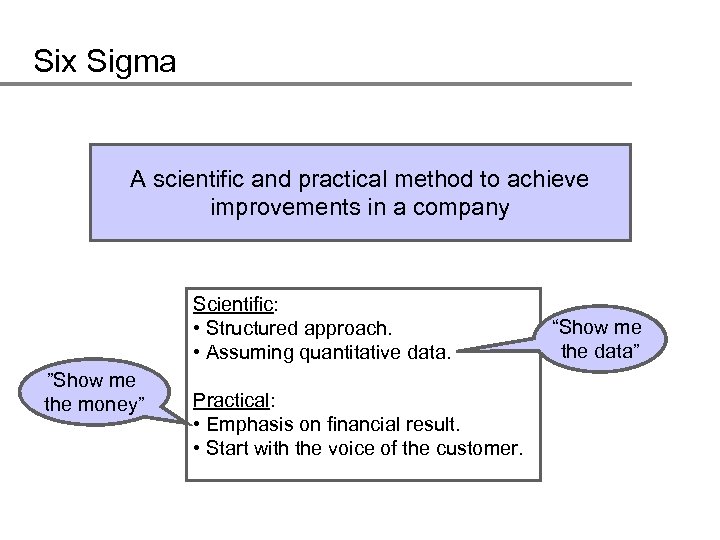

Six Sigma A scientific and practical method to achieve improvements in a company Scientific: • Structured approach. • Assuming quantitative data. ”Show me the money” Practical: • Emphasis on financial result. • Start with the voice of the customer. “Show me the data”

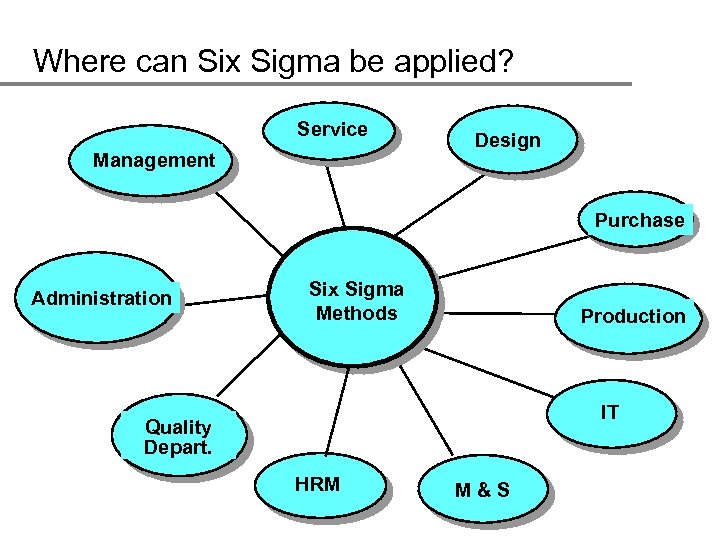

Where can Six Sigma be applied? Service Management Design Purchase Administration Six Sigma Methods Production IT Quality Depart. HRM M&S

GE “Service company”Examples u Approving a credit card application u Installing a turbine u Lending money u Servicing an aircraft engine u Answering a service call for an appliance u Underwriting an insurance policy u Developing software for a new CAT product u Overhauling a locomotive

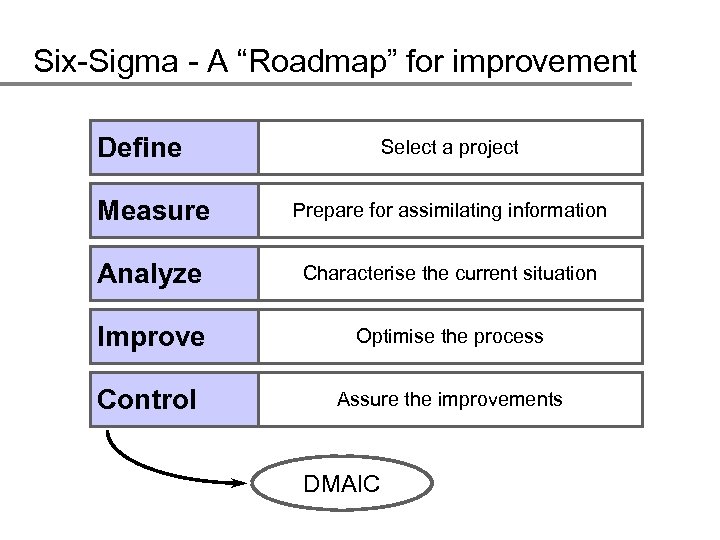

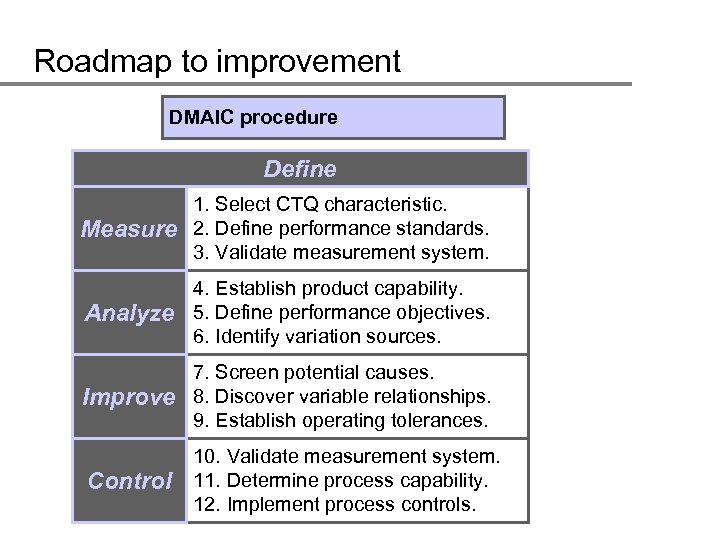

Six-Sigma - A “Roadmap” for improvement Define Select a project Measure Prepare for assimilating information Analyze Characterise the current situation Improve Optimise the process Control Assure the improvements DMAIC

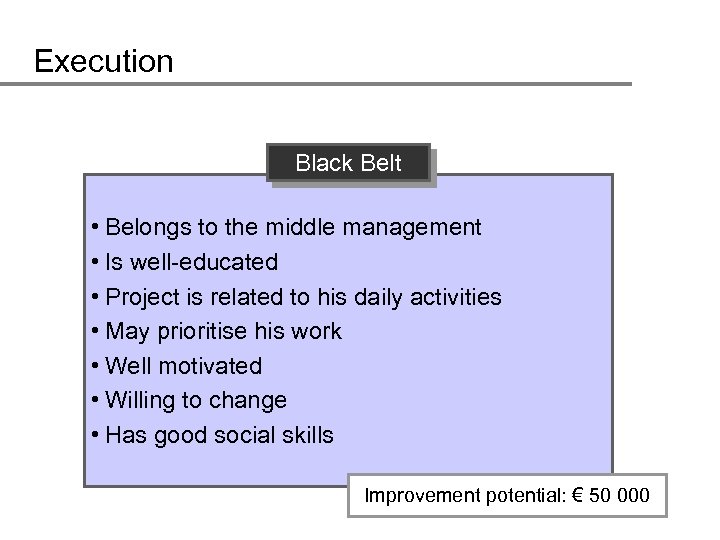

Execution Black Belt • Belongs to the middle management • Is well-educated • Project is related to his daily activities • May prioritise his work • Well motivated • Willing to change • Has good social skills Improvement potential: € 50 000

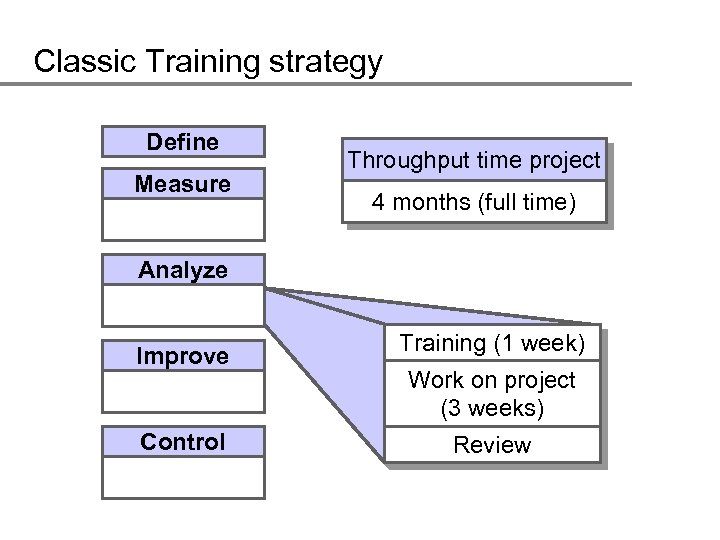

Classic Training strategy Define Measure Throughput time project 4 months (full time) Analyze Improve Control Training (1 week) Work on project (3 weeks) Review

Training In Spain 5 x three day sessions Includes weekend More ‘Homework’ Heaver individual support Fewer advanced methods It is their view that some training is not assimilated by delegates and that some items do not fit the need of some delegates

Training In Poland 5 x 5 day sessions But with 5 weeks between training sessions not 3 weeks Extra Support via on-line materials Individual support stepped up

Training In Sweden 4 x 5 day sessions 3 week gaps as in America Less emphasis on top-down Perceived to be more need for buy-in by staff than in America

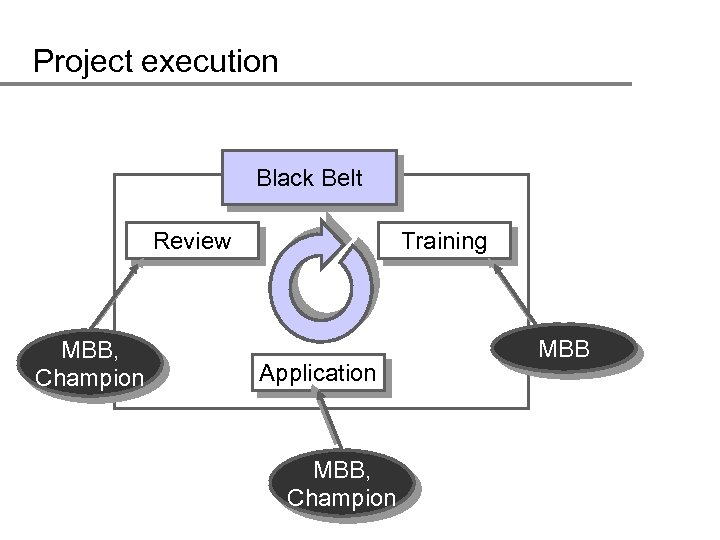

Project execution Black Belt Review MBB, Champion Training Application MBB, Champion MBB

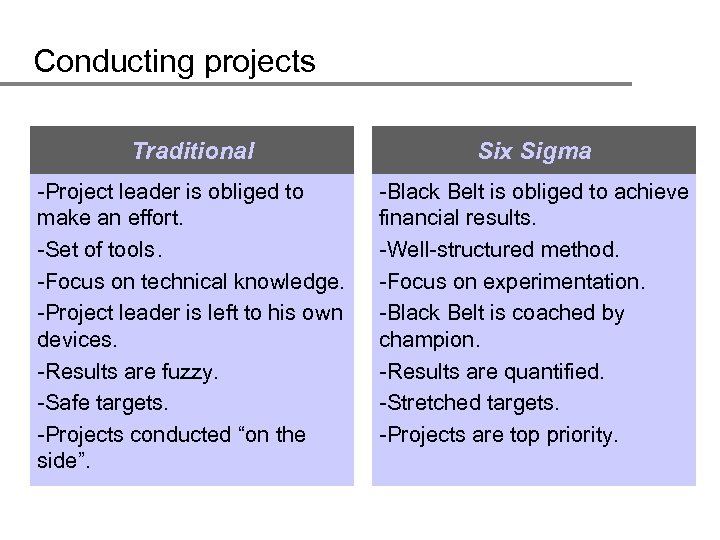

Conducting projects Traditional Six Sigma -Project leader is obliged to make an effort. -Set of tools. -Focus on technical knowledge. -Project leader is left to his own devices. -Results are fuzzy. -Safe targets. -Projects conducted “on the side”. -Black Belt is obliged to achieve financial results. -Well-structured method. -Focus on experimentation. -Black Belt is coached by champion. -Results are quantified. -Stretched targets. -Projects are top priority.

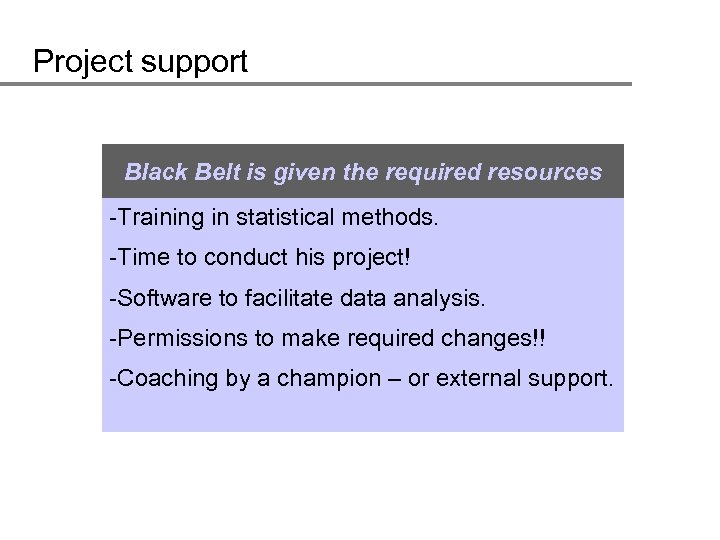

Project support Black Belt is given the required resources -Training in statistical methods. -Time to conduct his project! -Software to facilitate data analysis. -Permissions to make required changes!! -Coaching by a champion – or external support.

Project support In other words the Black Belt is -Empowered. -In the sense that it was always meant! -As theroists have been saying for years!

Roadmap to improvement DMAIC procedure Define Measure 1. Select CTQ characteristic. 2. Define performance standards. 3. Validate measurement system. Analyze 4. Establish product capability. 5. Define performance objectives. 6. Identify variation sources. Improve 7. Screen potential causes. 8. Discover variable relationships. 9. Establish operating tolerances. Control 10. Validate measurement system. 11. Determine process capability. 12. Implement process controls.

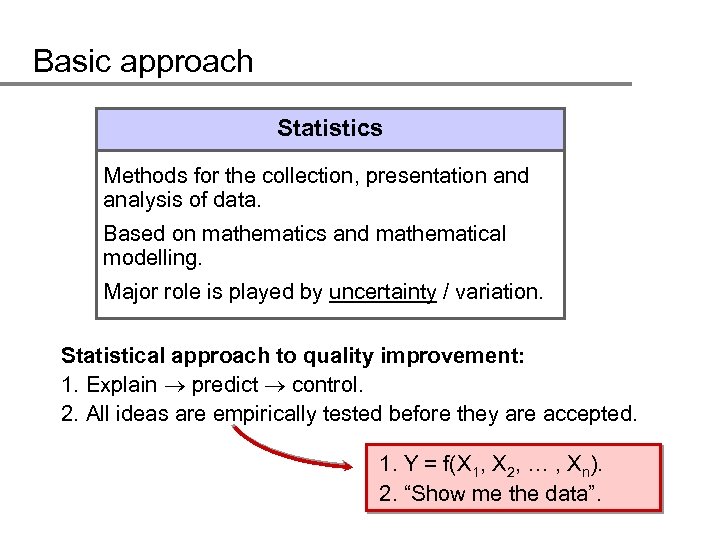

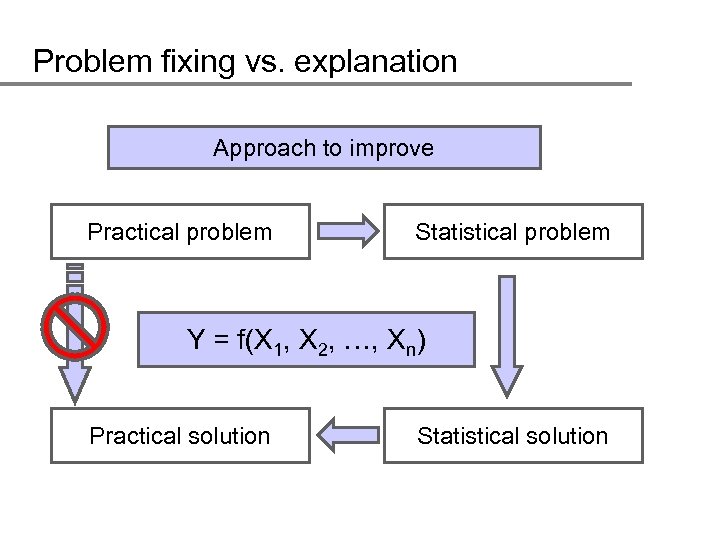

Basic approach Statistics Methods for the collection, presentation and analysis of data. Based on mathematics and mathematical modelling. Major role is played by uncertainty / variation. Statistical approach to quality improvement: 1. Explain predict control. 2. All ideas are empirically tested before they are accepted. 1. Y = f(X 1, X 2, … , Xn). 2. “Show me the data”.

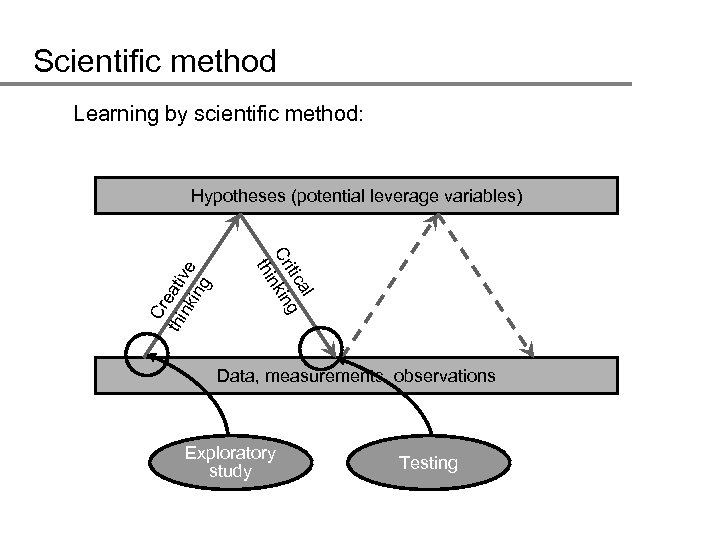

Scientific method Learning by scientific method: al itic g Cr nkin thi Cr thi eativ nk ing e Hypotheses (potential leverage variables) Data, measurements, observations Exploratory study Testing

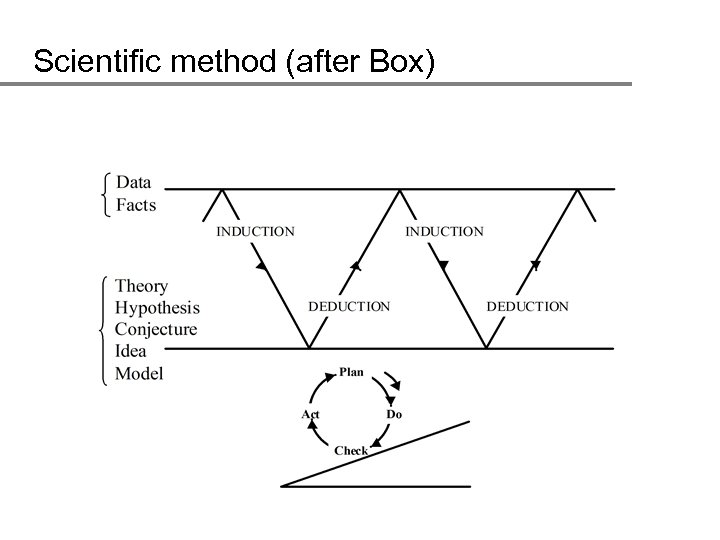

Scientific method (after Box)

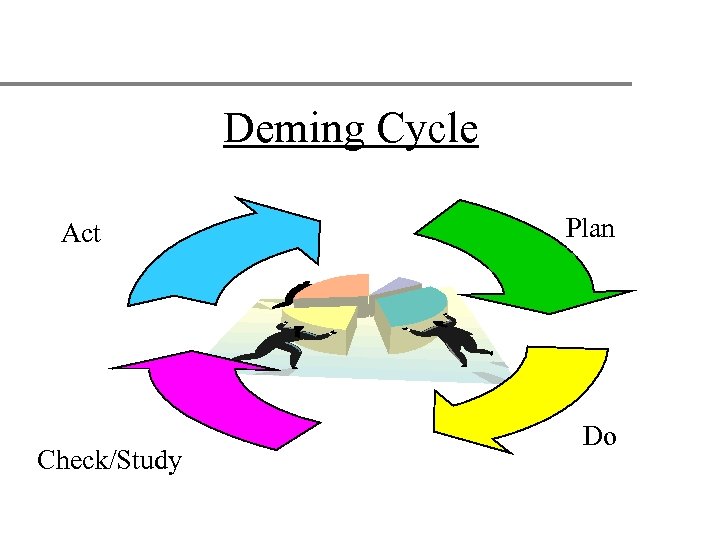

Deming Cycle Act Check/Study Plan Do

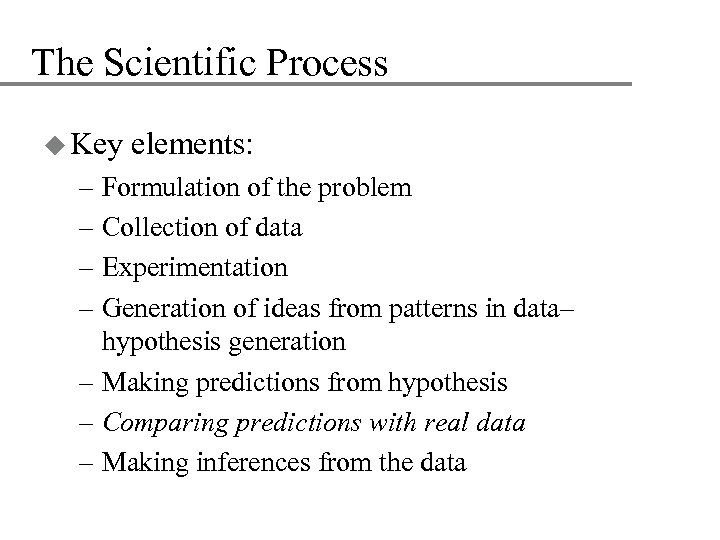

The Scientific Process u Key elements: – Formulation of the problem – Collection of data – Experimentation – Generation of ideas from patterns in data– hypothesis generation – Making predictions from hypothesis – Comparing predictions with real data – Making inferences from the data

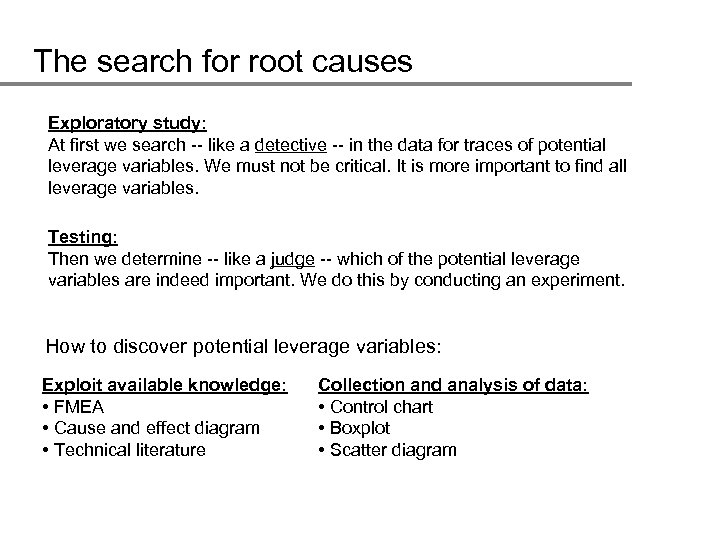

The search for root causes Exploratory study: At first we search -- like a detective -- in the data for traces of potential leverage variables. We must not be critical. It is more important to find all leverage variables. Testing: Then we determine -- like a judge -- which of the potential leverage variables are indeed important. We do this by conducting an experiment. How to discover potential leverage variables: Exploit available knowledge: • FMEA • Cause and effect diagram • Technical literature Collection and analysis of data: • Control chart • Boxplot • Scatter diagram

Problem fixing vs. explanation Approach to improve Practical problem Statistical problem Y = f(X 1, X 2, …, Xn) Practical solution Statistical solution

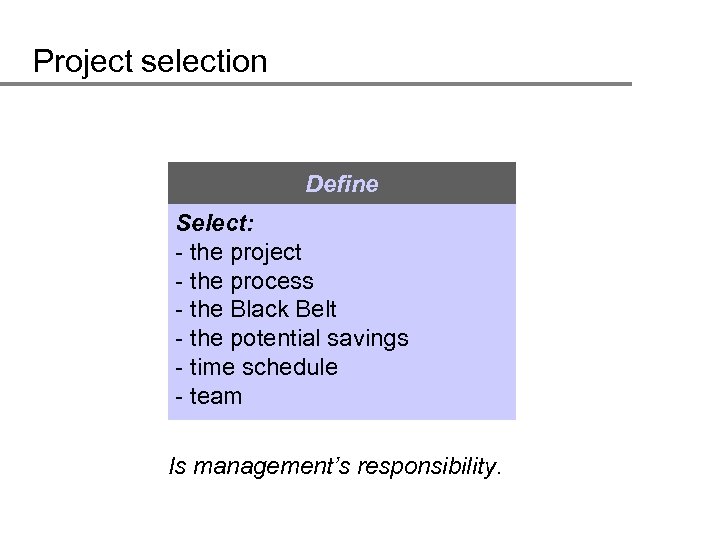

Project selection Define Select: - the project - the process - the Black Belt - the potential savings - time schedule - team Is management’s responsibility.

Project selection Projects may be selected according to: 1. A complete list of requirements of customers. 2. A complete list of costs of poor quality. 3. A complete list of existing problems or targets.

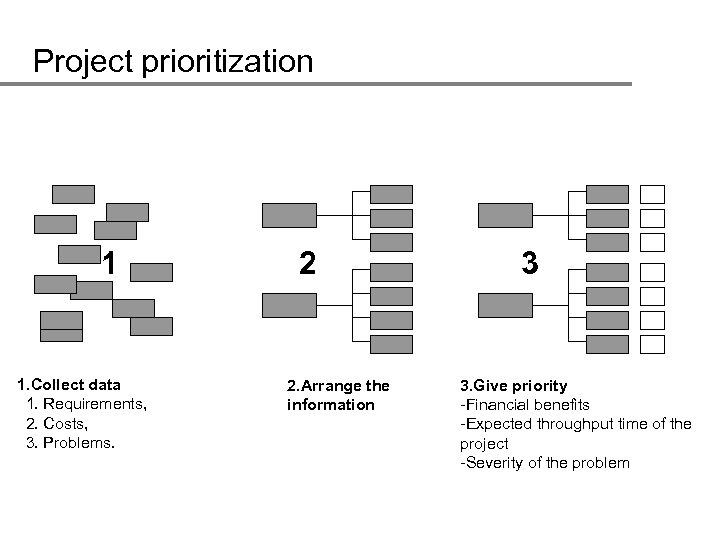

Project prioritization 1 1. Collect data 1. Requirements, 2. Costs, 3. Problems. 2 2. Arrange the information 3 3. Give priority -Financial benefits -Expected throughput time of the project -Severity of the problem

Before a simple case study a few quotes - some important issues - then some why’s?

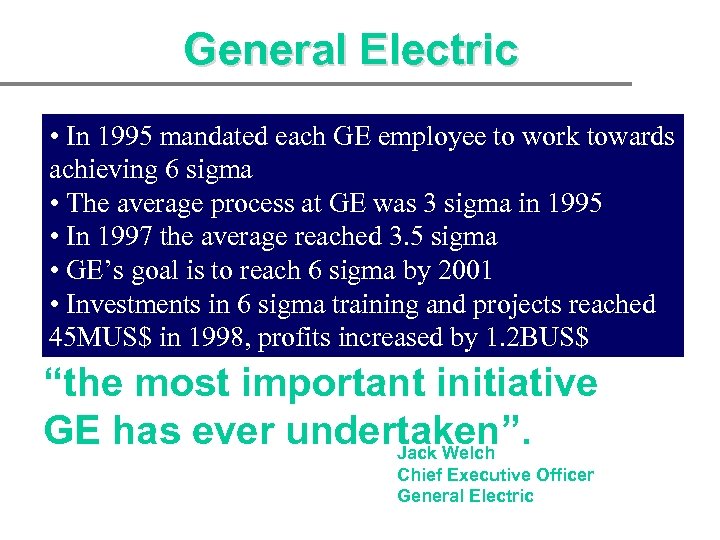

General Electric • In 1995 mandated each GE employee to work towards achieving 6 sigma • The average process at GE was 3 sigma in 1995 • In 1997 the average reached 3. 5 sigma • GE’s goal is to reach 6 sigma by 2001 • Investments in 6 sigma training and projects reached 45 MUS$ in 1998, profits increased by 1. 2 BUS$ “the most important initiative GE has ever undertaken”. Jack Welch Chief Executive Officer General Electric

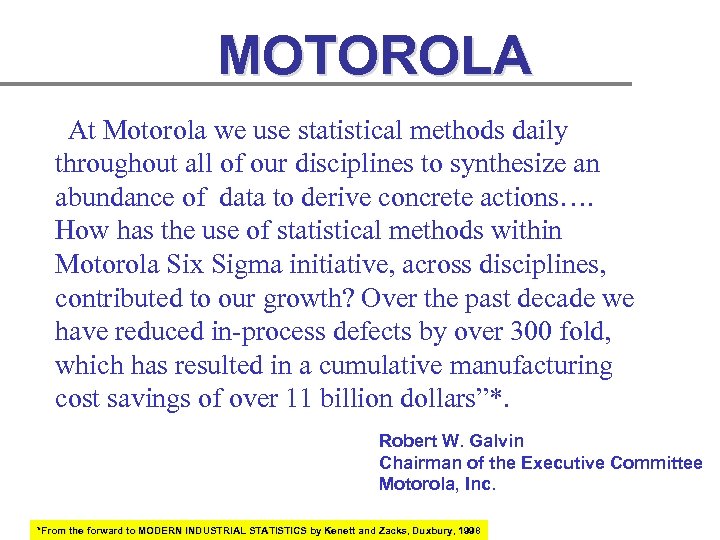

MOTOROLA “At Motorola we use statistical methods daily throughout all of our disciplines to synthesize an abundance of data to derive concrete actions…. How has the use of statistical methods within Motorola Six Sigma initiative, across disciplines, contributed to our growth? Over the past decade we have reduced in-process defects by over 300 fold, which has resulted in a cumulative manufacturing cost savings of over 11 billion dollars”*. Robert W. Galvin Chairman of the Executive Committee Motorola, Inc. *From the forward to MODERN INDUSTRIAL STATISTICS by Kenett and Zacks, Duxbury, 1998 Zacks,

Some more Quotes “Six Sigma is making war on defects” Bill Smith, Motorola “If an employee is not enthusiastic about Six Sigma, GE is simply not the right company for that person” Jack Welch, General Electric “If all we have is spirit, we will lose to the US” President Idei, Sony

Even more Quotes “Six-Sigma is remarkable – it has made managers start to adopt those simple and efficient methods that they have all needed desperately ever since they were developed back in the 1920 s” Translated from Oystein Evandt (Norway) “Six-sigma’s focus on the bottom line provides the missing ingredient in Deming’s philosophy”

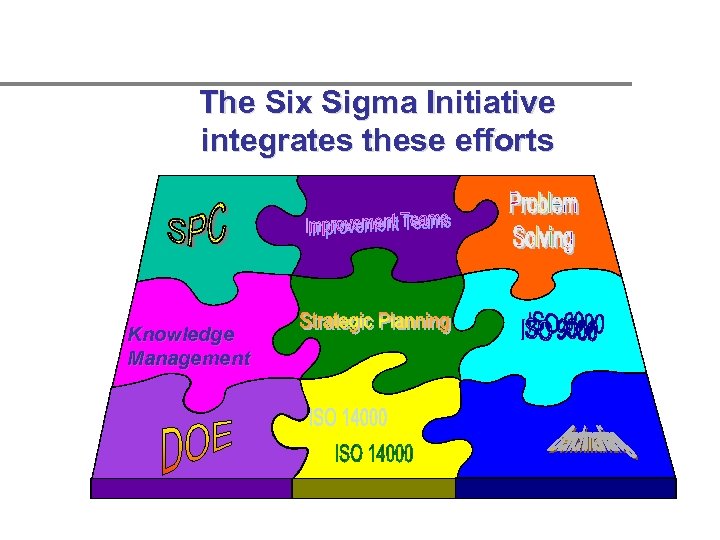

The Six Sigma Initiative integrates these efforts Knowledge Management

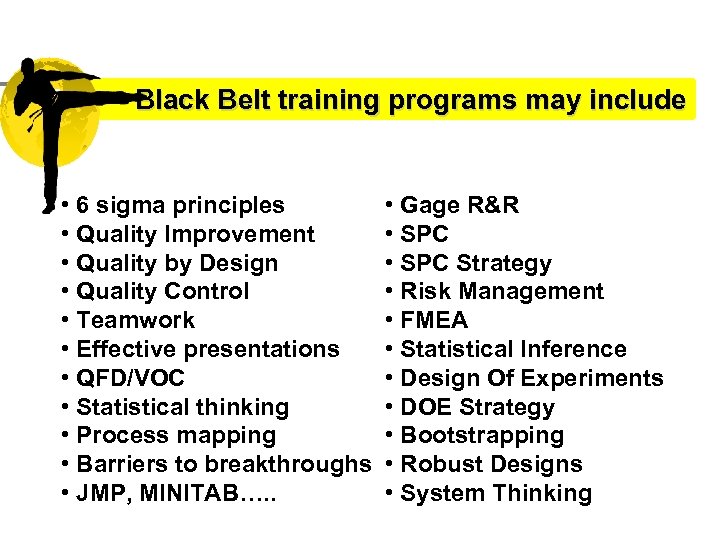

Black Belt training programs may include • 6 sigma principles • Quality Improvement • Quality by Design • Quality Control • Teamwork • Effective presentations • QFD/VOC • Statistical thinking • Process mapping • Barriers to breakthroughs • JMP, MINITAB…. . • Gage R&R • SPC Strategy • Risk Management • FMEA • Statistical Inference • Design Of Experiments • DOE Strategy • Bootstrapping • Robust Designs • System Thinking

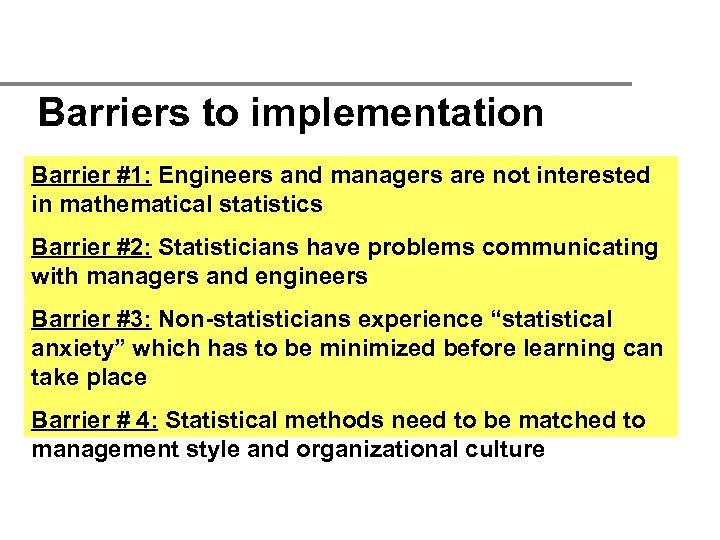

Barriers to implementation Barrier #1: Engineers and managers are not interested in mathematical statistics Barrier #2: Statisticians have problems communicating with managers and engineers Barrier #3: Non-statisticians experience “statistical anxiety” which has to be minimized before learning can take place Barrier # 4: Statistical methods need to be matched to management style and organizational culture

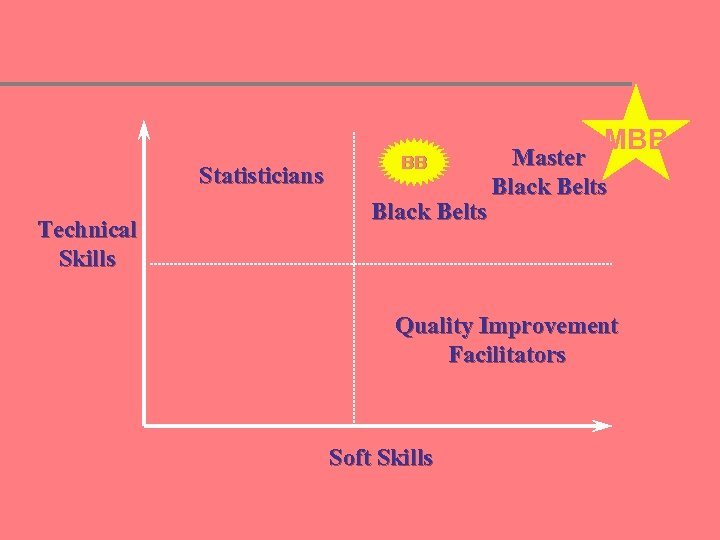

Statisticians Technical Skills BB Black Belts MBB Master Black Belts Quality Improvement Facilitators Soft Skills

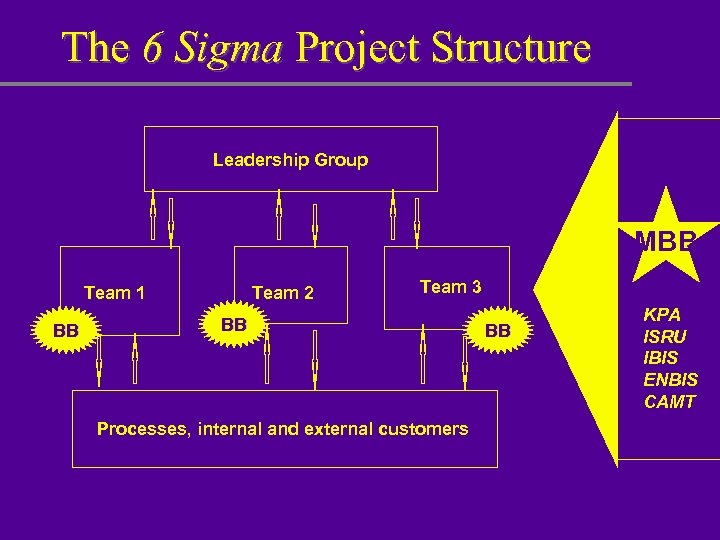

The 6 Sigma Project Structure Leadership Group MBB Team 1 BB Team 2 Team 3 BB Processes, internal and external customers BB KPA ISRU IBIS ENBIS CAMT

Comparing three recent developments in “Quality Management” u. ISO 9000 (-2000) u. EFQM Model u. Quality Improvement and Six Sigma Programs

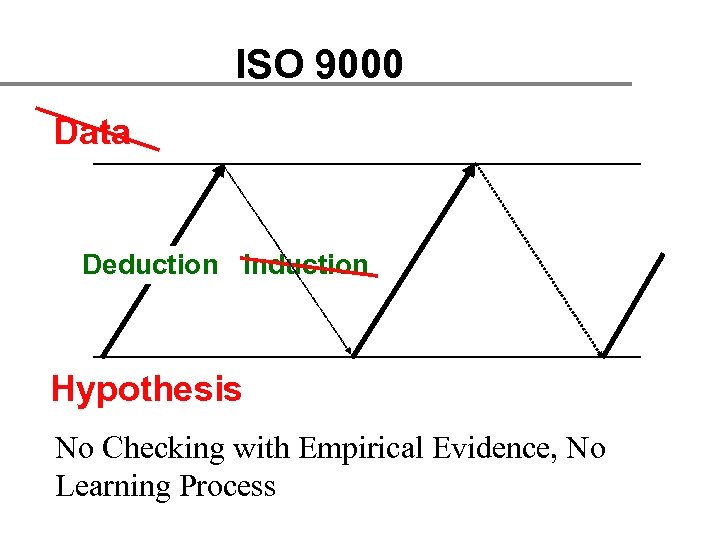

ISO 9000 u Proponents claim that ISO 9000 is a general system for Quality Management u The de facto applications seem to be – an excessive emphasis on Quality Assurance, and – standardization of already existing systems with little attention to Quality Improvement u It would have been better if improvement efforts had preceded standardization

Critique of ISO 9000 u Bureaucratic, large scale u Focus on satisfying auditors, not customers u Certification is the goal; the job is done when certified u Little emphasis on improvement u The return on investment is not transparent u Main driver is: – We need ISO 9000 to become a certified supplier, – Not “we need to be the best and most cost effective supplier to win our customer’s business” u Corrupting influence on the quality profession

EFQM Model u. A tool for assessment: Can measure where we are and how well we are doing u Assessment is a small piece of the bigger scheme of Quality Management: – Planning – Control – Improvement u EFQM provides a tool for assessment, but no tools, training, concepts and managerial approaches for improvement and planning

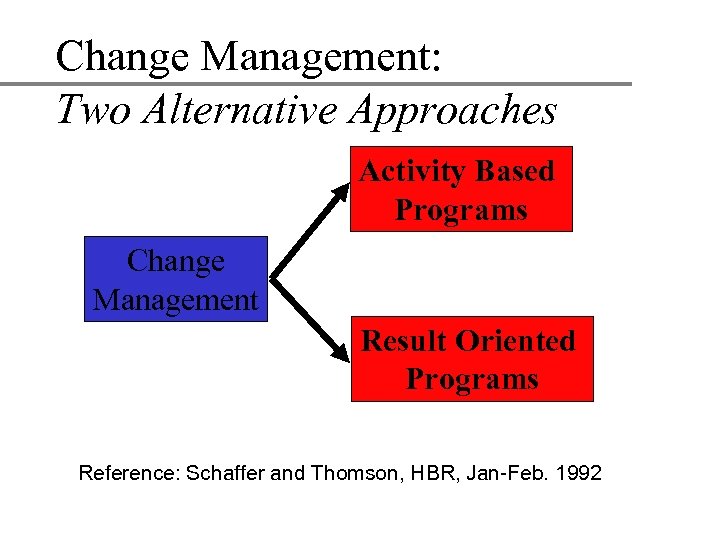

The “Success” of Change Programs? “Performance improvement efforts … have as much impact on operational and financial results as a ceremonial rain dance has on the weather” Schaffer and Thomson, Harvard Business Review (1992)

Change Management: Two Alternative Approaches Activity Based Programs Change Management Result Oriented Programs Reference: Schaffer and Thomson, HBR, Jan-Feb. 1992

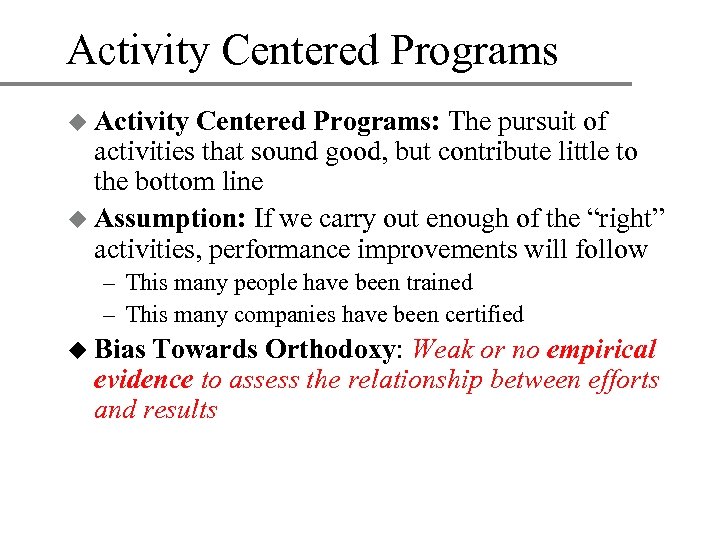

Activity Centered Programs u Activity Centered Programs: The pursuit of activities that sound good, but contribute little to the bottom line u Assumption: If we carry out enough of the “right” activities, performance improvements will follow – This many people have been trained – This many companies have been certified u Bias Towards Orthodoxy: Weak or no empirical evidence to assess the relationship between efforts and results

ISO 9000 Data Deduction Induction Hypothesis No Checking with Empirical Evidence, No Learning Process

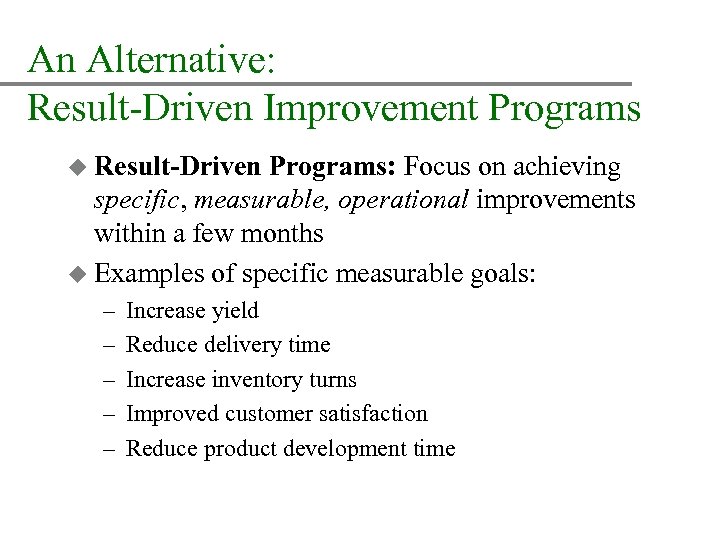

An Alternative: Result-Driven Improvement Programs u Result-Driven Programs: Focus on achieving specific, measurable, operational improvements within a few months u Examples of specific measurable goals: – – – Increase yield Reduce delivery time Increase inventory turns Improved customer satisfaction Reduce product development time

Result Oriented Programs: u. Project based u. Experimental u. Guided by empirical evidence u. Measurable results u. Easier to assess cause and effect u. Cascading strategy

Why Transformation Efforts Fail! u u u John Kotter, Professor, Harvard Business School Leading scholar on Change Management Lists 8 common errors in managing change, two of which are: 1. Not establishing a sense of urgency 2. Not systematically planning for and creating short term wins

Six Sigma Demystified* Six Sigma is TQM in disguise, but this time the focus is: – Alignment of customers, strategy, process and people – Significant measurable business results – Large scale deployment of advanced quality and statistical tools – Data based, quantitative *Adapted from Zinkgraf (1999), Sigma Breakthrough Technologies Inc. , Austin, TX.

Keys to Success* u. Set clear expectations for results u. Measure the progress (metrics) u. Manage for results *Adapted from Zinkgraf (1999), Sigma Breakthrough Technologies Inc. , Austin, TX.

Six Sigma u The precise definition of Six Sigma is not important; the content of the program is u A disciplined quantitative approach for improvement of defined metrics u Can be applied to all business processes, manufacturing, finance and services

Focus of Six Sigma* u Accelerating fast breakthrough performance u Significant financial results in 4 -8 months u Ensuring Six Sigma is an extension of the Corporate culture, not the program of the month u Results first, then culture change! *Adapted from Zinkgraf (1999), Sigma Breakthrough Technologies Inc. , Austin, TX.

Six Sigma: Reasons for Success u The Success at Motorola, GE and Allied. Signal has been attributed to: – Strong leadership (Jack Welch, Larry Bossidy and Bob Galvin personally involved) – Initial focus on operations – Aggressive project selection (potential savings in cost of poor quality > $50, 000/year) – Training the right people

The right way! u Plan for “quick wins” – Find good initial projects - fast wins u Establish resource structure – Make sure you know where it is u Publicise success – Often and continually - blow that trumpet u Embed the skills – Everyone owns successes

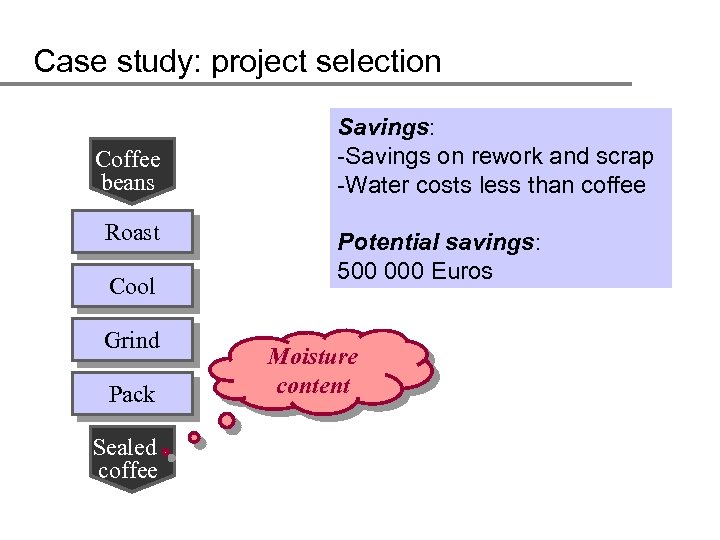

Case study: project selection Coffee beans Roast Cool Grind Pack Sealed coffee Savings: -Savings on rework and scrap -Water costs less than coffee Potential savings: 500 000 Euros Moisture content

Case study: Measure 1. Select the CTQ characteristic 2. Define performance standards 3. Validate measurement system

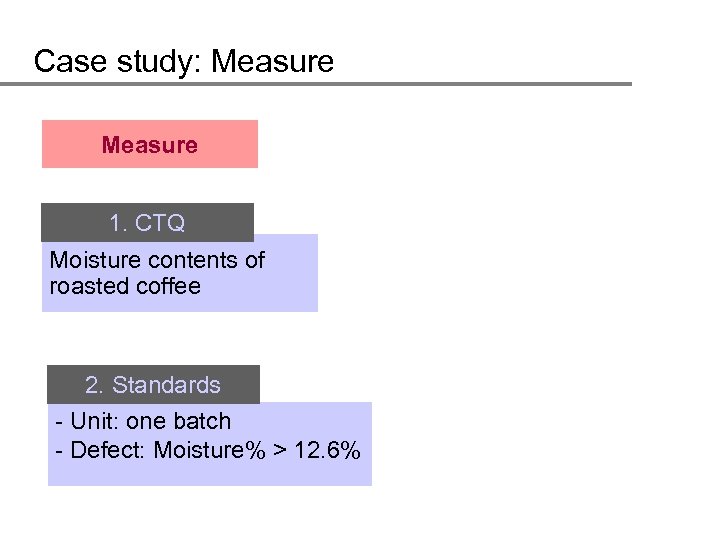

Case study: Measure 1. CTQ Moisture contents of roasted coffee 2. Standards - Unit: one batch - Defect: Moisture% > 12. 6%

Case study: Measure 3. Measurement reliability Gauge R&R study Measurement system too unreliable! So fix it!!

Case study: Analyze 4. Establish product capability 5. Define performance objectives 6. Identify influence factors

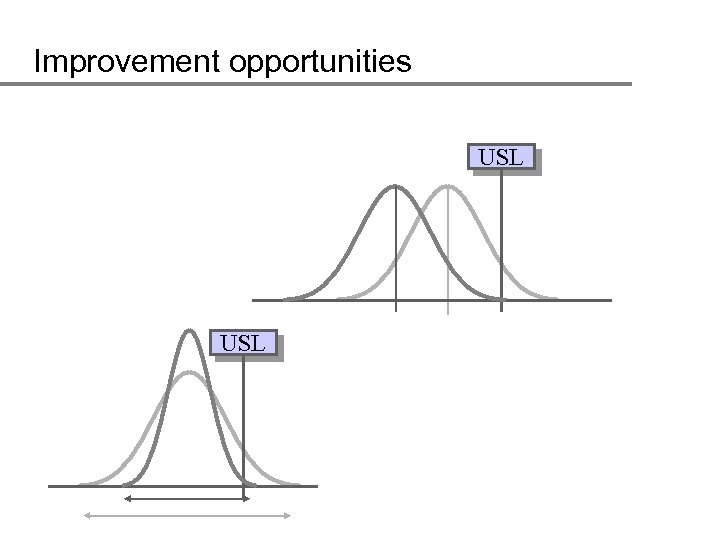

Improvement opportunities USL

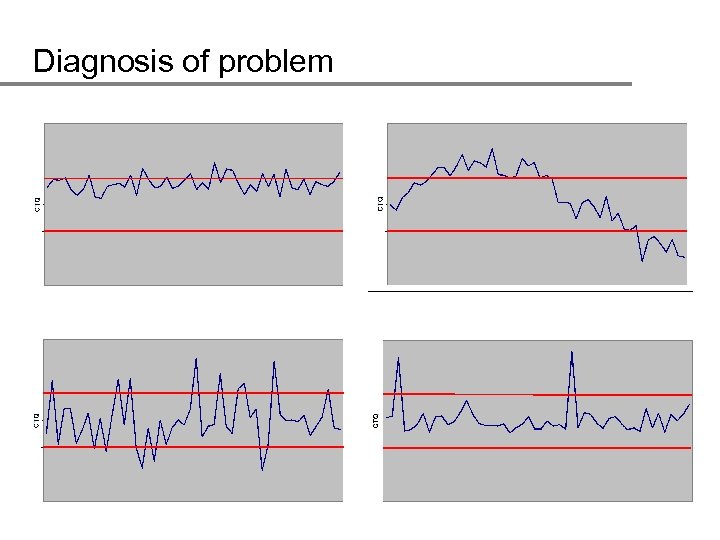

Diagnosis of problem

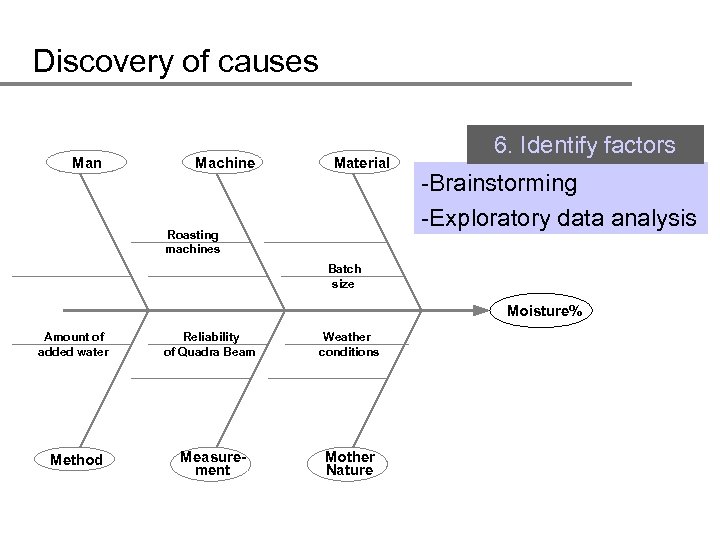

Discovery of causes Man Machine Material Roasting machines 6. Identify factors -Brainstorming -Exploratory data analysis Batch size Moisture% Amount of added water Reliability of Quadra Beam Weather conditions Method Measurement Mother Nature

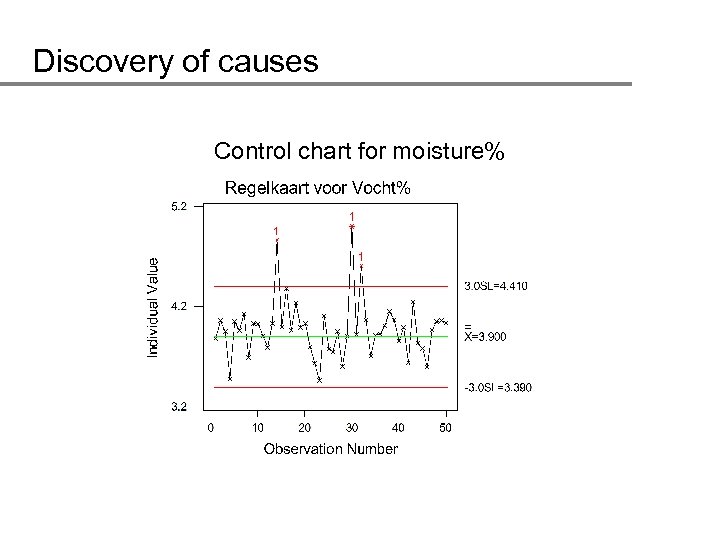

Discovery of causes Control chart for moisture%

A case study Potential influence factors - Roasting machines (Nuisance variable) - Weather conditions (Nuisance variable) - Stagnations in the transport system (Disturbance) - Batch size (Nuisance variable) - Amount of added water (Control variable)

Case study: Improve 7. Screen potential causes 8. Discover variable relationships 9. Establish operating tolerances

Case study: Improve 7. Screen potential causes - Relation between humidity and moisture% not established - Effect of stagnations confirmed - Machine differences confirmed 8. Discover variable relationships Design of Experiments (Do. E)

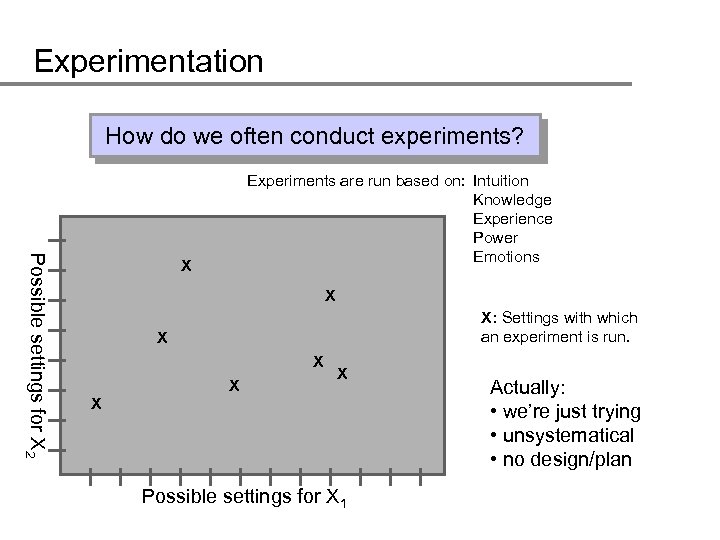

Experimentation How do we often conduct experiments? Possible settings for X 2 Experiments are run based on: Intuition Knowledge Experience Power Emotions X X X: Settings with which an experiment is run. X X X Possible settings for X 1 Actually: • we’re just trying • unsystematical • no design/plan

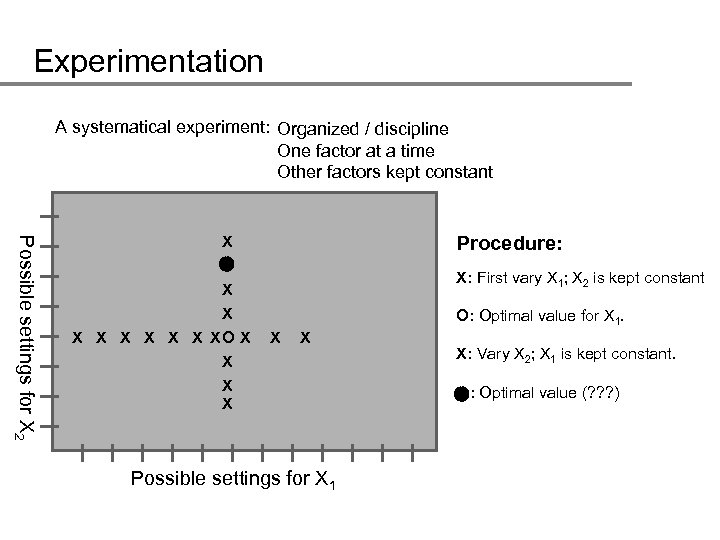

Experimentation A systematical experiment: Organized / discipline One factor at a time Other factors kept constant Possible settings for X 2 Procedure: X X X X XO X X X: First vary X 1; X 2 is kept constant O: Optimal value for X 1. X X Possible settings for X 1 X: Vary X 2; X 1 is kept constant. : Optimal value (? ? ? )

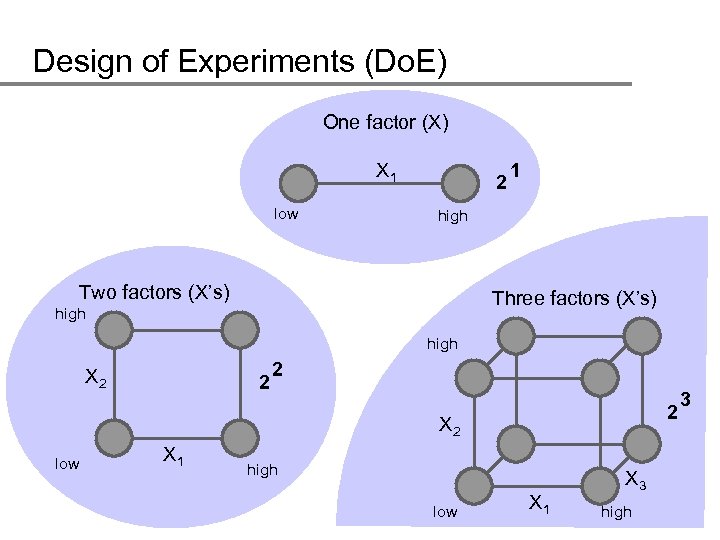

Design of Experiments (Do. E) One factor (X) X 1 low 2 1 high Two factors (X’s) Three factors (X’s) high X 2 2 X 2 low X 1 high low X 1 X 3 high 3

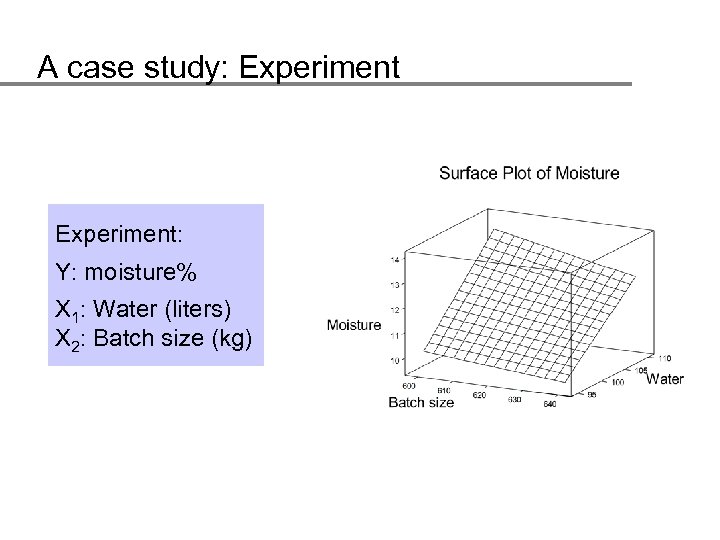

A case study: Experiment: Y: moisture% X 1: Water (liters) X 2: Batch size (kg)

A case study 9. Establish operating tolerances Feedback adjustments for influence of weather conditions

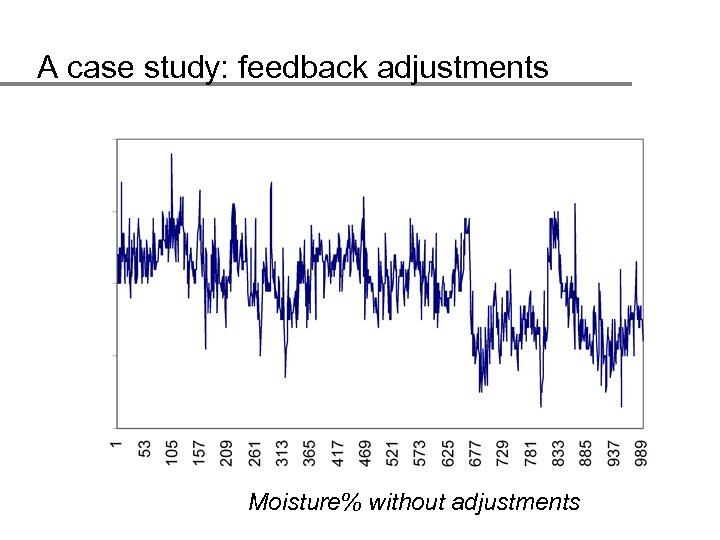

A case study: feedback adjustments Moisture% without adjustments

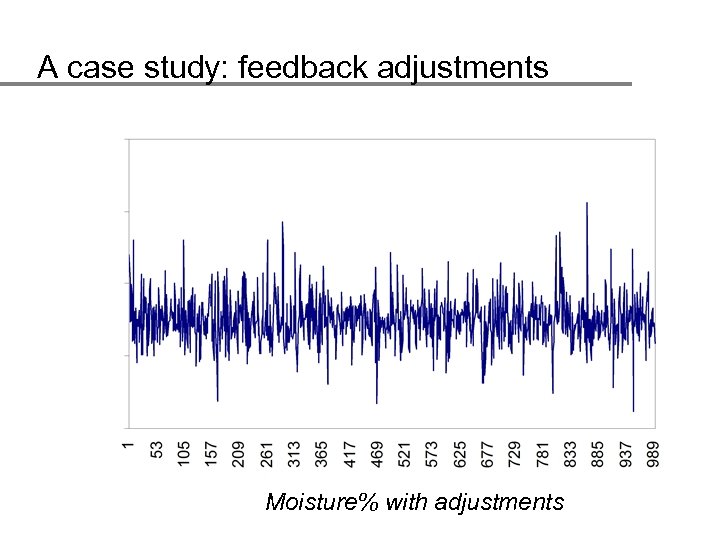

A case study: feedback adjustments Moisture% with adjustments

Case study: Control 10. Validate measurement system (X’s) 11. Determine process capability 12. Implement process controls

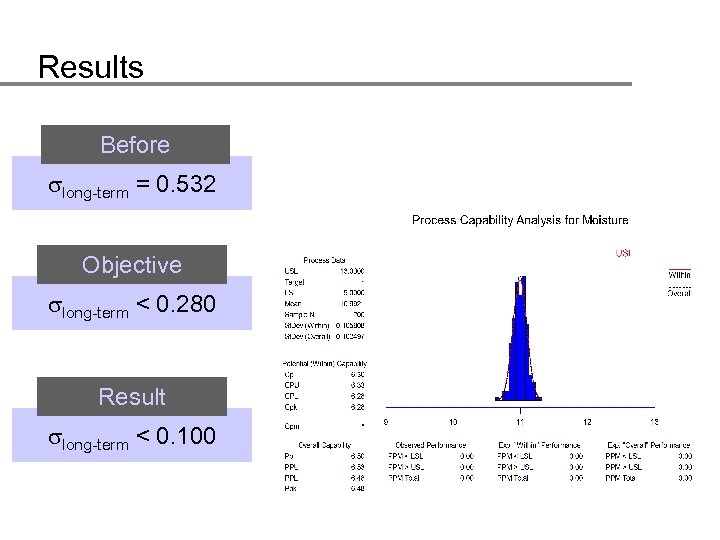

Results Before long-term = 0. 532 Objective long-term < 0. 280 Result long-term < 0. 100

Benefits of this project long-term < 0. 100 Ppk = 1. 5 This enables us to increase the mean to 12. 1% Per 0. 1% coffee: 100 000 Euros saving Benefits of this project: 1 100 000 Euros per year Approved by controller

Case study: control 12. Implement process controls - SPC control loop - Mistake proofing - Control plan - Audit schedule Project closure - Documentation of the results and data. - Results are reported to involved persons. - The follow-up is determined

Six Sigma approach to this project - Step-by-step approach. - Constant testing and double checking. - No problem fixing, but: explanation control. - Interaction of technical knowledge and experimentation methodology. - Good research enables intelligent decision making. - Knowing the financial impact made it easy to find priority for this project.

Re-cap I! u Structured approach – roadmap u Systematic project-based improvement u Plan for “quick wins” – Find good initial projects - fast wins u Publicise success – Often and continually - blow that trumpet u Use modern tools and methods u Empirical evidence based improvement

Re-cap II! u DMAIC is a basic ‘training’ structure u Establish your resource structure – Make sure you know where external help is u Key ingredient is the support for projects - It’s the project that ‘wins’ not the training itself u Fit the training programme around the company needs – not the company around the training u Embed the skills – Everyone owns the successes

fcc95ae37f13d66823c3db8d305af6d4.ppt