60bd5db038341a31fffae85886e099b3.ppt

- Количество слайдов: 32

Estimating – Methods and Practise A discussion paper Ó Galorath Incorporated 2003

Estimating – Methods and Practise A discussion paper Ó Galorath Incorporated 2003

Estimate defined es·ti·mate (es′ti mit), n. an approximate judgment or calculation, as of the value or amount of something a prediction that is equally likely to be above or below the actual result (Tom De. Marco) Ó Galorath Inc. 2003 All Rights Reserved

Estimate defined es·ti·mate (es′ti mit), n. an approximate judgment or calculation, as of the value or amount of something a prediction that is equally likely to be above or below the actual result (Tom De. Marco) Ó Galorath Inc. 2003 All Rights Reserved

Estimating – why ? Conceptual design • Which way • Feature / function implications • Budget setting • Feature / function trade offs • Bid no / bid evaluation System / assembly level • Trade studies • What if Detail design • Target cost modelling • Design to cost • Value analysis Part level • Should cost models • Supplier cost modelling • Make buy decisions • Process selection • Material implications

Estimating – why ? Conceptual design • Which way • Feature / function implications • Budget setting • Feature / function trade offs • Bid no / bid evaluation System / assembly level • Trade studies • What if Detail design • Target cost modelling • Design to cost • Value analysis Part level • Should cost models • Supplier cost modelling • Make buy decisions • Process selection • Material implications

The estimating environment

The estimating environment

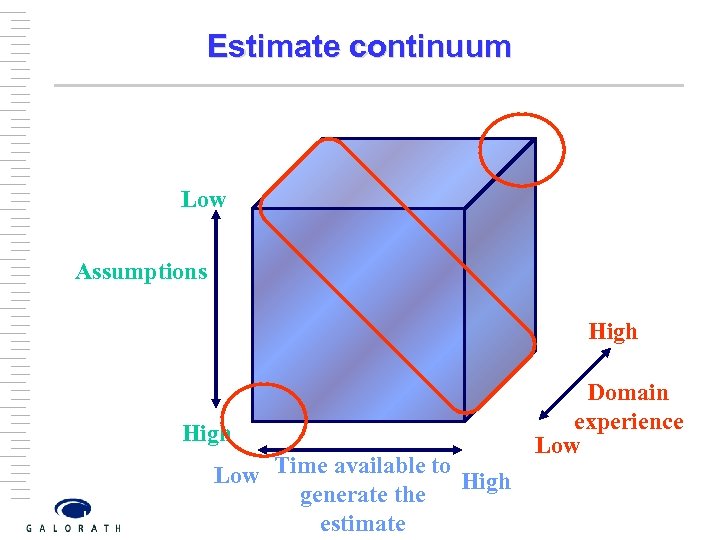

Estimate continuum Low Assumptions High Low Time available to High generate the estimate Domain experience Low

Estimate continuum Low Assumptions High Low Time available to High generate the estimate Domain experience Low

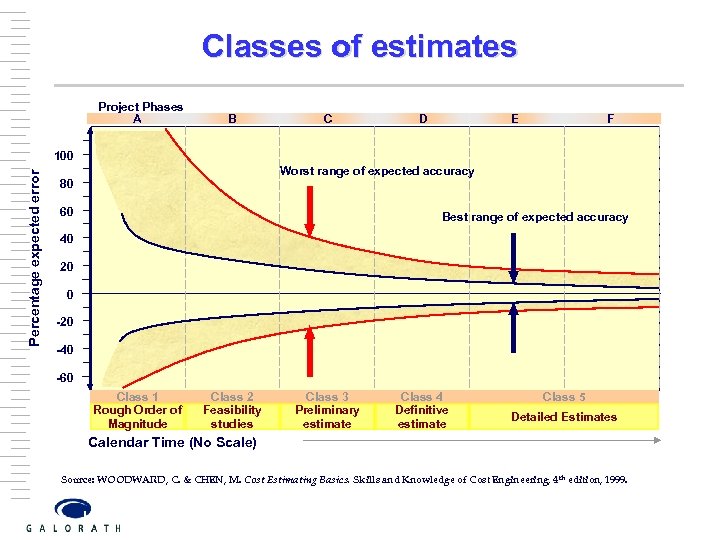

Classes of estimates Project Phases A B C D E F Percentage expected error 100 Worst range of expected accuracy 80 60 Best range of expected accuracy 40 20 0 -20 -40 -60 Class 1 Rough Order of Magnitude Class 2 Feasibility studies Class 3 Preliminary estimate Class 4 Definitive estimate Class 5 Detailed Estimates Calendar Time (No Scale) Source: WOODWARD, C. & CHEN, M. Cost Estimating Basics. Skills and Knowledge of Cost Engineering, 4 th edition, 1999.

Classes of estimates Project Phases A B C D E F Percentage expected error 100 Worst range of expected accuracy 80 60 Best range of expected accuracy 40 20 0 -20 -40 -60 Class 1 Rough Order of Magnitude Class 2 Feasibility studies Class 3 Preliminary estimate Class 4 Definitive estimate Class 5 Detailed Estimates Calendar Time (No Scale) Source: WOODWARD, C. & CHEN, M. Cost Estimating Basics. Skills and Knowledge of Cost Engineering, 4 th edition, 1999.

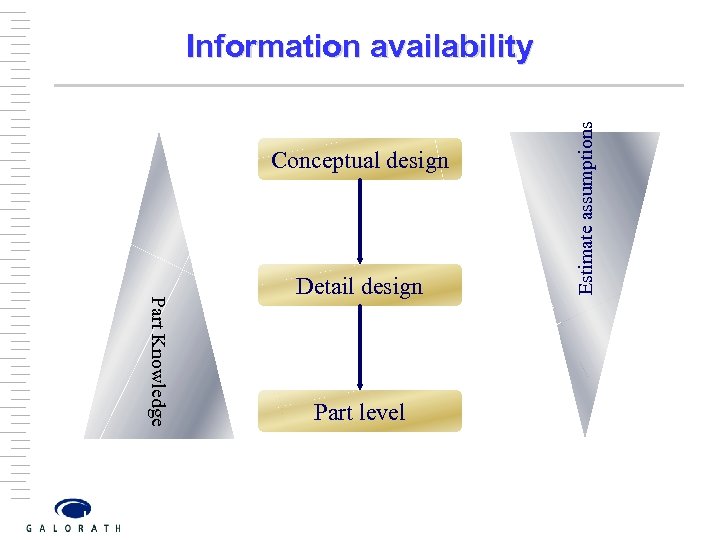

Conceptual design Part Knowledge Detail design Part level Estimate assumptions Information availability

Conceptual design Part Knowledge Detail design Part level Estimate assumptions Information availability

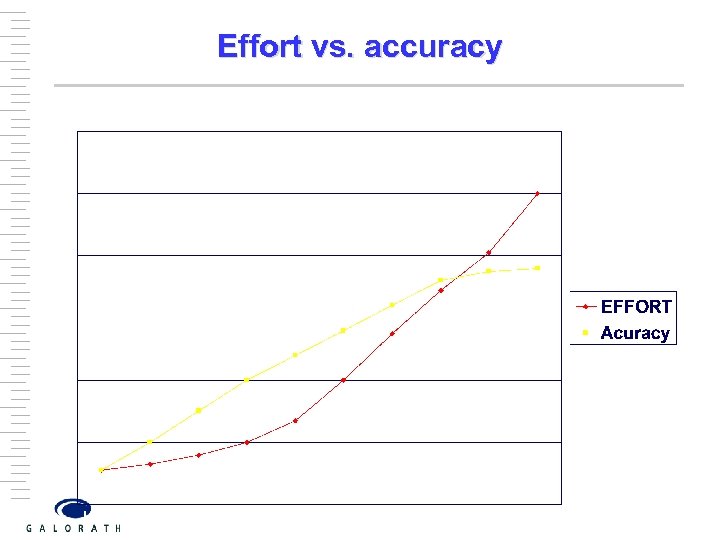

Effort vs. accuracy

Effort vs. accuracy

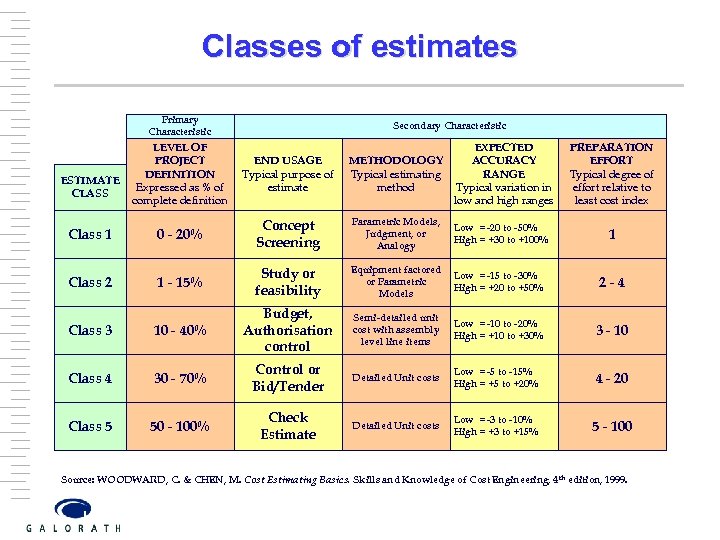

Classes of estimates Primary Characteristic Secondary Characteristic LEVEL OF PROJECT DEFINITION Expressed as % of complete definition END USAGE Typical purpose of estimate METHODOLOGY Typical estimating method EXPECTED ACCURACY RANGE Typical variation in low and high ranges Class 1 0 - 20% Concept Screening Parametric Models, Judgment, or Analogy Low = -20 to -50% High = +30 to +100% 1 Class 2 1 - 15% Study or feasibility Equipment factored or Parametric Models Low = -15 to -30% High = +20 to +50% 2 -4 Class 3 10 - 40% Budget, Authorisation control Semi-detailed unit cost with assembly level line items Low = -10 to -20% High = +10 to +30% 3 - 10 Class 4 30 - 70% Control or Bid/Tender Detailed Unit costs Low = -5 to -15% High = +5 to +20% 4 - 20 Class 5 50 - 100% Check Estimate Detailed Unit costs Low = -3 to -10% High = +3 to +15% 5 - 100 ESTIMATE CLASS PREPARATION EFFORT Typical degree of effort relative to least cost index Source: WOODWARD, C. & CHEN, M. Cost Estimating Basics. Skills and Knowledge of Cost Engineering, 4 th edition, 1999.

Classes of estimates Primary Characteristic Secondary Characteristic LEVEL OF PROJECT DEFINITION Expressed as % of complete definition END USAGE Typical purpose of estimate METHODOLOGY Typical estimating method EXPECTED ACCURACY RANGE Typical variation in low and high ranges Class 1 0 - 20% Concept Screening Parametric Models, Judgment, or Analogy Low = -20 to -50% High = +30 to +100% 1 Class 2 1 - 15% Study or feasibility Equipment factored or Parametric Models Low = -15 to -30% High = +20 to +50% 2 -4 Class 3 10 - 40% Budget, Authorisation control Semi-detailed unit cost with assembly level line items Low = -10 to -20% High = +10 to +30% 3 - 10 Class 4 30 - 70% Control or Bid/Tender Detailed Unit costs Low = -5 to -15% High = +5 to +20% 4 - 20 Class 5 50 - 100% Check Estimate Detailed Unit costs Low = -3 to -10% High = +3 to +15% 5 - 100 ESTIMATE CLASS PREPARATION EFFORT Typical degree of effort relative to least cost index Source: WOODWARD, C. & CHEN, M. Cost Estimating Basics. Skills and Knowledge of Cost Engineering, 4 th edition, 1999.

How do we estimate

How do we estimate

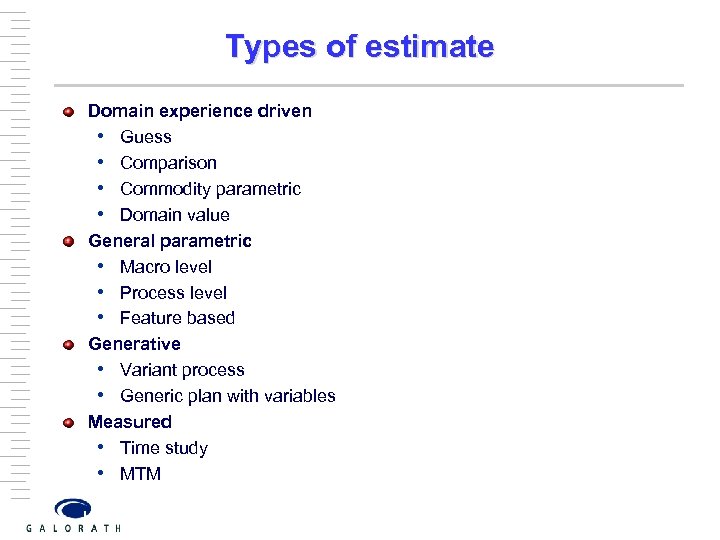

Types of estimate Domain experience driven • Guess • Comparison • Commodity parametric • Domain value General parametric • Macro level • Process level • Feature based Generative • Variant process • Generic plan with variables Measured • Time study • MTM

Types of estimate Domain experience driven • Guess • Comparison • Commodity parametric • Domain value General parametric • Macro level • Process level • Feature based Generative • Variant process • Generic plan with variables Measured • Time study • MTM

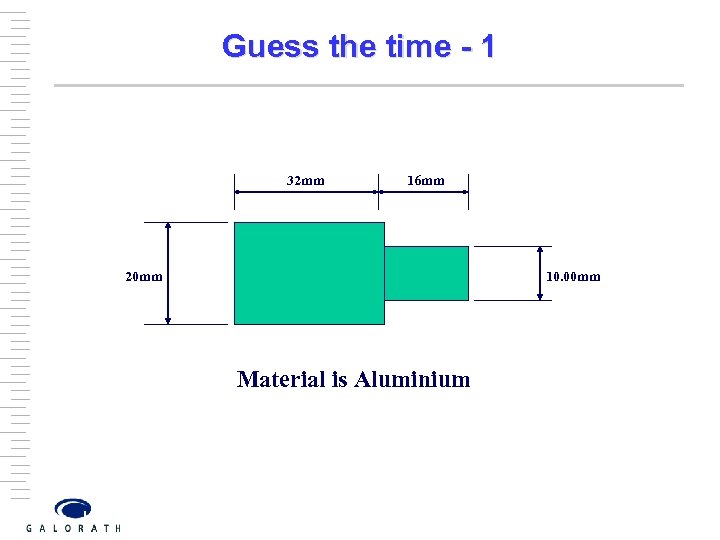

Guess the time - 1 32 mm 16 mm 20 mm 10. 00 mm Material is Aluminium

Guess the time - 1 32 mm 16 mm 20 mm 10. 00 mm Material is Aluminium

Guess the time - 1 - Results Time dependent on domain knowledge • Accuracy • Volume • Process Time dependant on level of detail Add some more information Does this change your estimate?

Guess the time - 1 - Results Time dependent on domain knowledge • Accuracy • Volume • Process Time dependant on level of detail Add some more information Does this change your estimate?

Guess the time - 2

Guess the time - 2

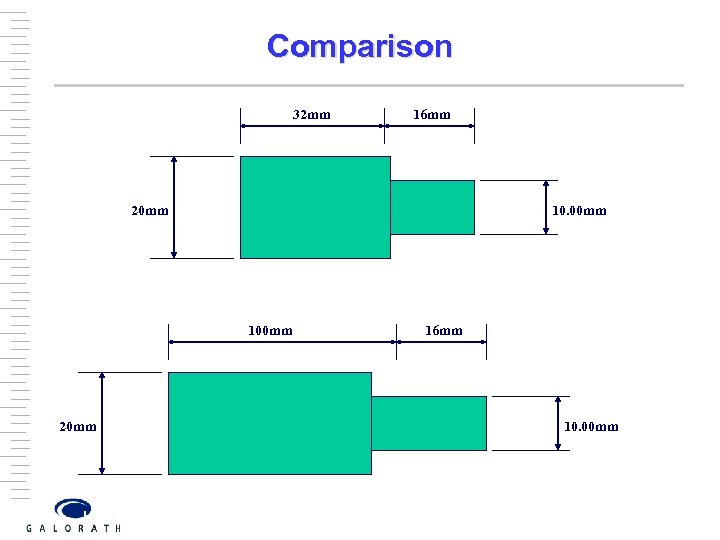

Comparison 32 mm 16 mm 20 mm 10. 00 mm 100 mm 20 mm 16 mm 10. 00 mm

Comparison 32 mm 16 mm 20 mm 10. 00 mm 100 mm 20 mm 16 mm 10. 00 mm

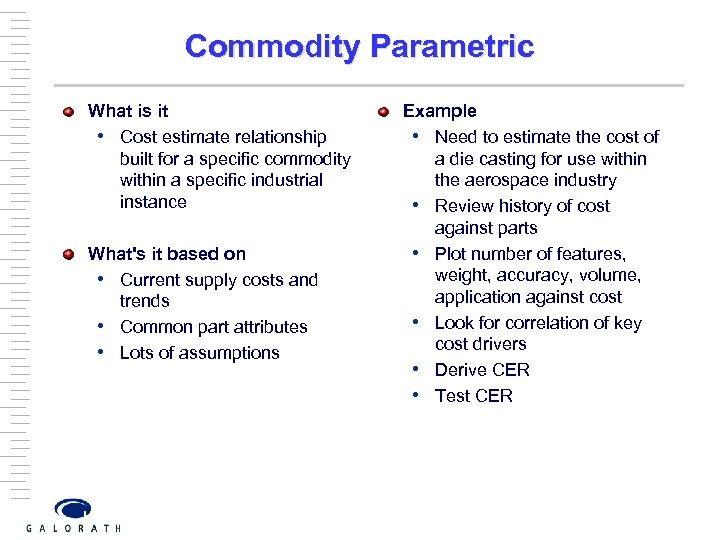

Commodity Parametric What is it • Cost estimate relationship built for a specific commodity within a specific industrial instance What's it based on • Current supply costs and trends • Common part attributes • Lots of assumptions Example • Need to estimate the cost of a die casting for use within the aerospace industry • Review history of cost against parts • Plot number of features, weight, accuracy, volume, application against cost • Look for correlation of key cost drivers • Derive CER • Test CER

Commodity Parametric What is it • Cost estimate relationship built for a specific commodity within a specific industrial instance What's it based on • Current supply costs and trends • Common part attributes • Lots of assumptions Example • Need to estimate the cost of a die casting for use within the aerospace industry • Review history of cost against parts • Plot number of features, weight, accuracy, volume, application against cost • Look for correlation of key cost drivers • Derive CER • Test CER

Macro Level Parametric Estimating Little knowledge of details / high assumptions Estimates based on high level information • Weight • Boards • Complexity Quicker than manual methods Able to estimate without cost data Should be calibrated to local environment Can/Should include Development, Production, Logistics, Operations, & Support Costs all in one model Should include sensitivity and risk analysis

Macro Level Parametric Estimating Little knowledge of details / high assumptions Estimates based on high level information • Weight • Boards • Complexity Quicker than manual methods Able to estimate without cost data Should be calibrated to local environment Can/Should include Development, Production, Logistics, Operations, & Support Costs all in one model Should include sensitivity and risk analysis

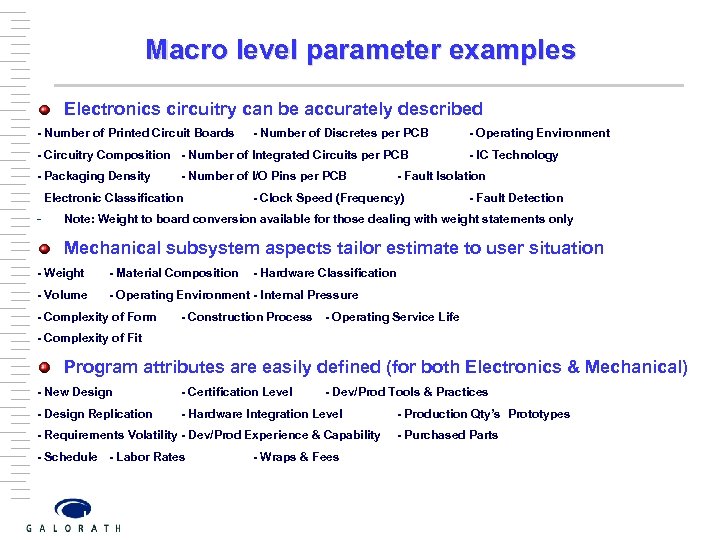

Macro level parameter examples Electronics circuitry can be accurately described - Number of Printed Circuit Boards - Number of Discretes per PCB - Circuitry Composition - Number of Integrated Circuits per PCB - Packaging Density - Number of I/O Pins per PCB Electronic Classification - - Operating Environment - IC Technology - Fault Isolation - Clock Speed (Frequency) - Fault Detection Note: Weight to board conversion available for those dealing with weight statements only Mechanical subsystem aspects tailor estimate to user situation - Weight - Material Composition - Volume - Operating Environment - Internal Pressure - Complexity of Form - Hardware Classification - Construction Process - Operating Service Life - Complexity of Fit Program attributes are easily defined (for both Electronics & Mechanical) - New Design - Certification Level - Dev/Prod Tools & Practices - Design Replication - Hardware Integration Level - Requirements Volatility - Dev/Prod Experience & Capability - Schedule - Labor Rates - Wraps & Fees - Production Qty’s Prototypes - Purchased Parts

Macro level parameter examples Electronics circuitry can be accurately described - Number of Printed Circuit Boards - Number of Discretes per PCB - Circuitry Composition - Number of Integrated Circuits per PCB - Packaging Density - Number of I/O Pins per PCB Electronic Classification - - Operating Environment - IC Technology - Fault Isolation - Clock Speed (Frequency) - Fault Detection Note: Weight to board conversion available for those dealing with weight statements only Mechanical subsystem aspects tailor estimate to user situation - Weight - Material Composition - Volume - Operating Environment - Internal Pressure - Complexity of Form - Hardware Classification - Construction Process - Operating Service Life - Complexity of Fit Program attributes are easily defined (for both Electronics & Mechanical) - New Design - Certification Level - Dev/Prod Tools & Practices - Design Replication - Hardware Integration Level - Requirements Volatility - Dev/Prod Experience & Capability - Schedule - Labor Rates - Wraps & Fees - Production Qty’s Prototypes - Purchased Parts

Process based parametric estimating Based on mathematically derived CER’s Estimates based on generic manufacturing details Production methods evaluated Should be calibrated to local environment Includes sensitivity and risk analysis Should produce an acceptable range for the items / assembly Process knowledge but no time Good part data available but no time Need to run multiple trade studies

Process based parametric estimating Based on mathematically derived CER’s Estimates based on generic manufacturing details Production methods evaluated Should be calibrated to local environment Includes sensitivity and risk analysis Should produce an acceptable range for the items / assembly Process knowledge but no time Good part data available but no time Need to run multiple trade studies

Generative estimating Deterministic Base on formulas Detailed process plan • Speeds • Feeds • Precise removal rates • Scrap rates Virtual factory model for suppliers Can add new process models Tends to be in-house verified data

Generative estimating Deterministic Base on formulas Detailed process plan • Speeds • Feeds • Precise removal rates • Scrap rates Virtual factory model for suppliers Can add new process models Tends to be in-house verified data

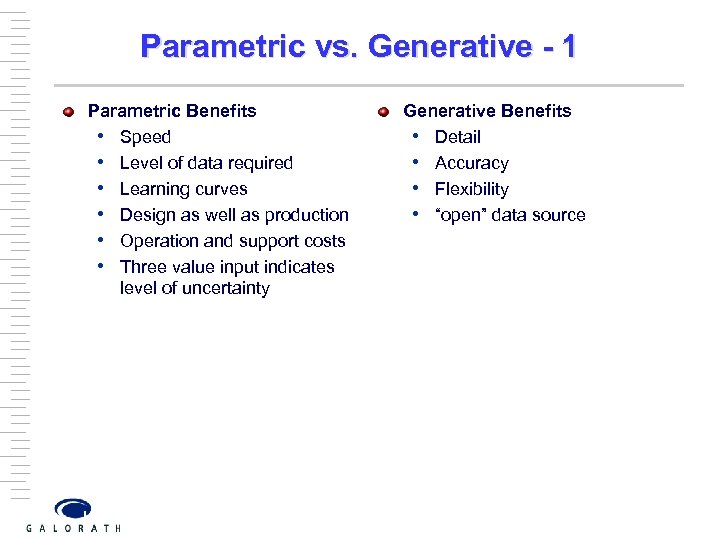

Parametric vs. Generative - 1 Parametric Benefits • Speed • Level of data required • Learning curves • Design as well as production • Operation and support costs • Three value input indicates level of uncertainty Generative Benefits • Detail • Accuracy • Flexibility • “open” data source

Parametric vs. Generative - 1 Parametric Benefits • Speed • Level of data required • Learning curves • Design as well as production • Operation and support costs • Three value input indicates level of uncertainty Generative Benefits • Detail • Accuracy • Flexibility • “open” data source

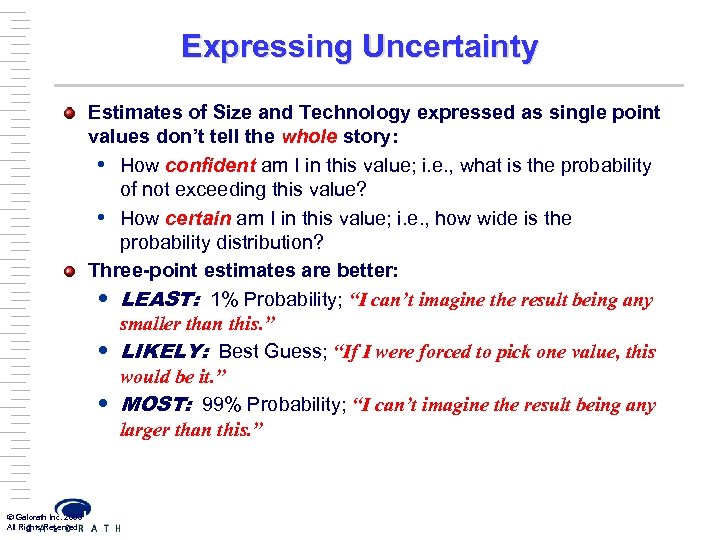

Expressing Uncertainty Estimates of Size and Technology expressed as single point values don’t tell the whole story: • How confident am I in this value; i. e. , what is the probability of not exceeding this value? • How certain am I in this value; i. e. , how wide is the probability distribution? Three-point estimates are better: • LEAST: 1% Probability; “I can’t imagine the result being any smaller than this. ” • LIKELY: Best Guess; “If I were forced to pick one value, this would be it. ” • MOST: 99% Probability; “I can’t imagine the result being any larger than this. ” Ó Galorath Inc. 2003 All Rights Reserved

Expressing Uncertainty Estimates of Size and Technology expressed as single point values don’t tell the whole story: • How confident am I in this value; i. e. , what is the probability of not exceeding this value? • How certain am I in this value; i. e. , how wide is the probability distribution? Three-point estimates are better: • LEAST: 1% Probability; “I can’t imagine the result being any smaller than this. ” • LIKELY: Best Guess; “If I were forced to pick one value, this would be it. ” • MOST: 99% Probability; “I can’t imagine the result being any larger than this. ” Ó Galorath Inc. 2003 All Rights Reserved

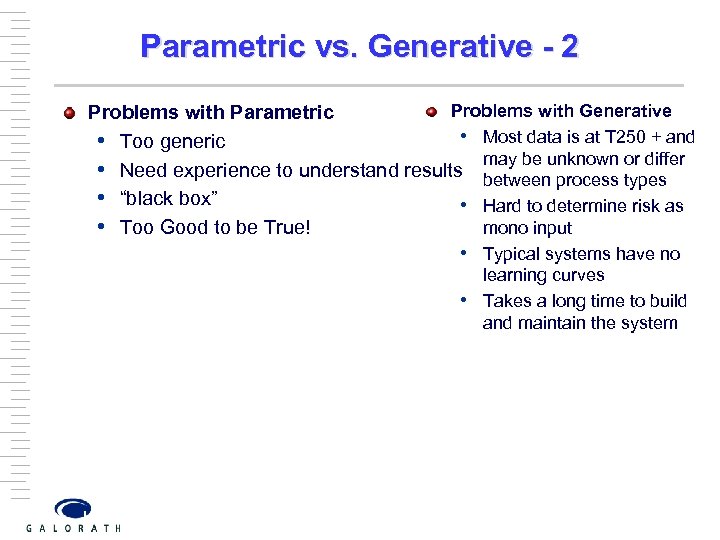

Parametric vs. Generative - 2 Problems with Generative Problems with Parametric • Most data is at T 250 + and • Too generic may be unknown or differ • Need experience to understand results between process types • “black box” • Hard to determine risk as mono input • Too Good to be True! • Typical systems have no learning curves • Takes a long time to build and maintain the system

Parametric vs. Generative - 2 Problems with Generative Problems with Parametric • Most data is at T 250 + and • Too generic may be unknown or differ • Need experience to understand results between process types • “black box” • Hard to determine risk as mono input • Too Good to be True! • Typical systems have no learning curves • Takes a long time to build and maintain the system

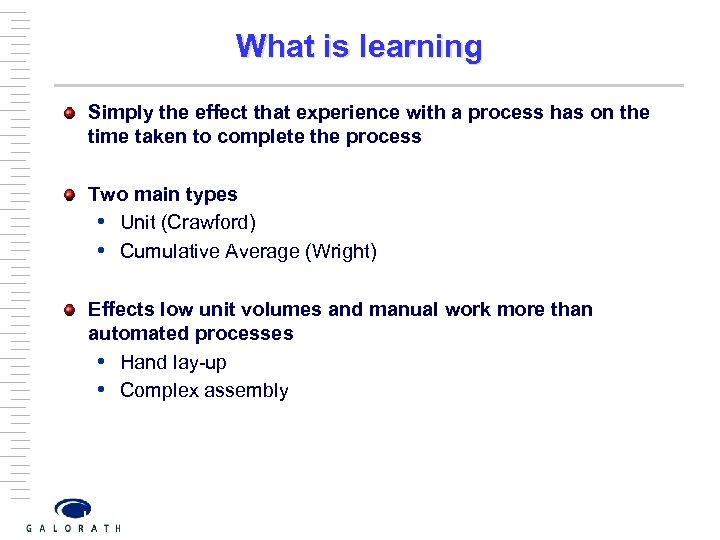

What is learning Simply the effect that experience with a process has on the time taken to complete the process Two main types • Unit (Crawford) • Cumulative Average (Wright) Effects low unit volumes and manual work more than automated processes • Hand lay-up • Complex assembly

What is learning Simply the effect that experience with a process has on the time taken to complete the process Two main types • Unit (Crawford) • Cumulative Average (Wright) Effects low unit volumes and manual work more than automated processes • Hand lay-up • Complex assembly

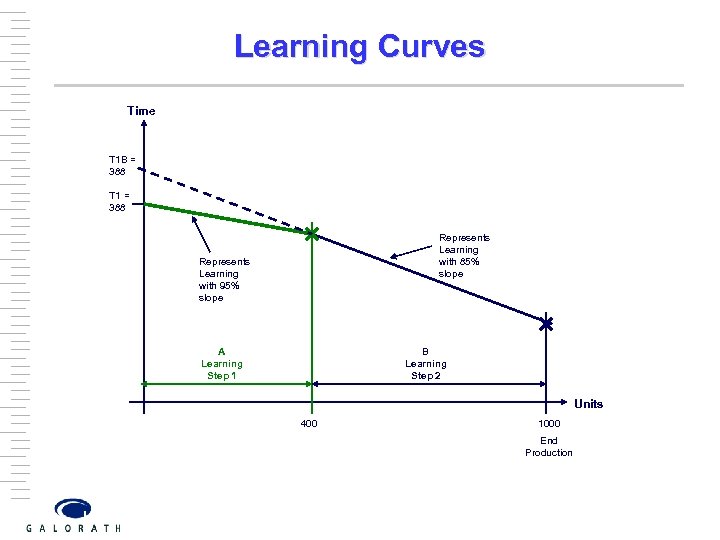

Learning Curves Time T 1 B = 388 T 1 = 388 Represents Learning with 85% slope Represents Learning with 95% slope A Learning Step 1 B Learning Step 2 Units 400 1000 End Production

Learning Curves Time T 1 B = 388 T 1 = 388 Represents Learning with 85% slope Represents Learning with 95% slope A Learning Step 1 B Learning Step 2 Units 400 1000 End Production

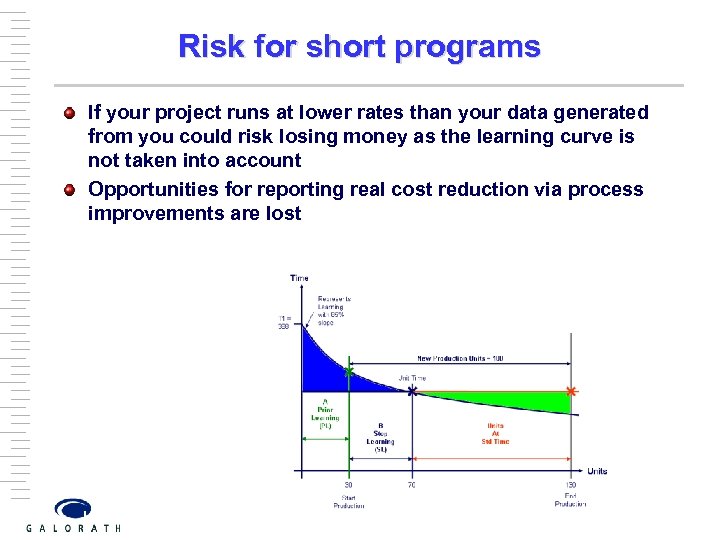

Risk for short programs If your project runs at lower rates than your data generated from you could risk losing money as the learning curve is not taken into account Opportunities for reporting real cost reduction via process improvements are lost

Risk for short programs If your project runs at lower rates than your data generated from you could risk losing money as the learning curve is not taken into account Opportunities for reporting real cost reduction via process improvements are lost

What should you be using?

What should you be using?

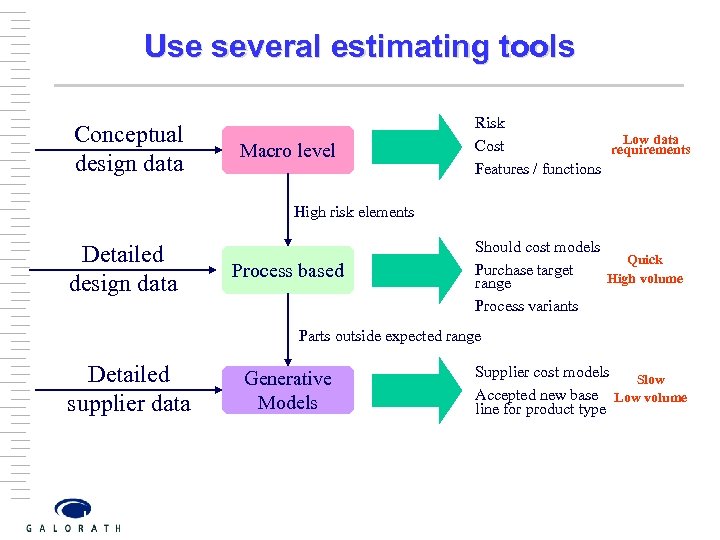

Use several estimating tools Conceptual design data Macro level Risk Low data Cost requirements Features / functions High risk elements Detailed design data Process based Should cost models Quick Purchase target High volume range Process variants Parts outside expected range Detailed supplier data Generative Models Supplier cost models Slow Accepted new base Low volume line for product type

Use several estimating tools Conceptual design data Macro level Risk Low data Cost requirements Features / functions High risk elements Detailed design data Process based Should cost models Quick Purchase target High volume range Process variants Parts outside expected range Detailed supplier data Generative Models Supplier cost models Slow Accepted new base Low volume line for product type

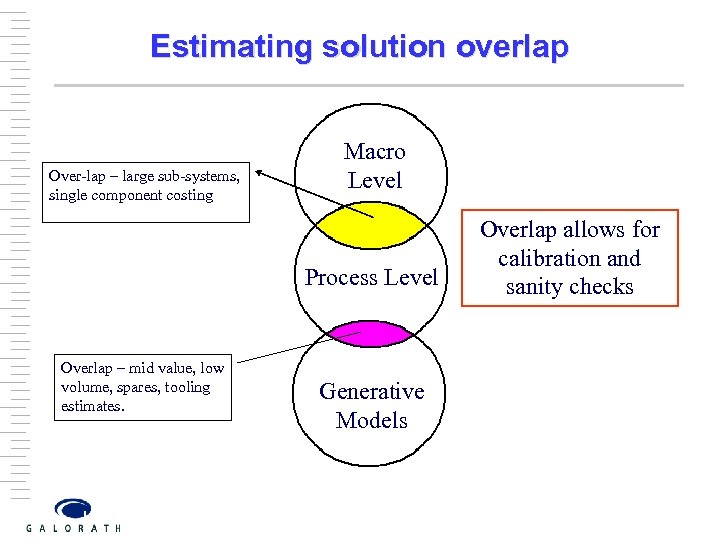

Estimating solution overlap Over-lap – large sub-systems, single component costing Macro Level Process Level Overlap – mid value, low volume, spares, tooling estimates. Generative Models Overlap allows for calibration and sanity checks

Estimating solution overlap Over-lap – large sub-systems, single component costing Macro Level Process Level Overlap – mid value, low volume, spares, tooling estimates. Generative Models Overlap allows for calibration and sanity checks

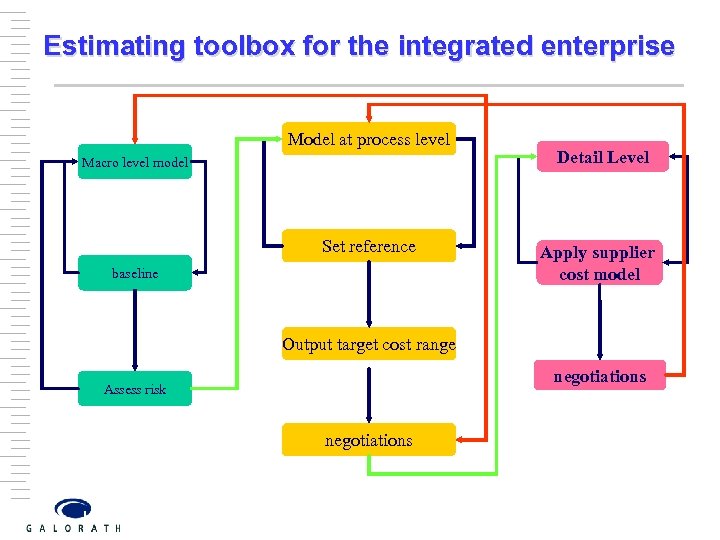

Estimating toolbox for the integrated enterprise Model at process level Macro level model Set reference baseline Detail Level Apply supplier cost model Output target cost range negotiations Assess risk negotiations

Estimating toolbox for the integrated enterprise Model at process level Macro level model Set reference baseline Detail Level Apply supplier cost model Output target cost range negotiations Assess risk negotiations

Benefits of multiple tool approach Use appropriate estimating technology at each stage of the product life cycle Top-down Parametric tool can be used with the minimum of process knowledge Bottom-up parametric tool allows fast accurate ranges to be established for family groups Generative modelling will establish base lines for supplier modelling Pyramid approach supports ALL the company cost engineering needs Use for sanity check and calibration between models Increased confidence and overall capability

Benefits of multiple tool approach Use appropriate estimating technology at each stage of the product life cycle Top-down Parametric tool can be used with the minimum of process knowledge Bottom-up parametric tool allows fast accurate ranges to be established for family groups Generative modelling will establish base lines for supplier modelling Pyramid approach supports ALL the company cost engineering needs Use for sanity check and calibration between models Increased confidence and overall capability

Last but not least Remember • No matter how long you spend • How much you discuss with your colleagues • Who you involve • How experienced you are Estimates are always wrong! Our task is to understand how wrong and to make sure our organisation is wise to the risks and assumptions

Last but not least Remember • No matter how long you spend • How much you discuss with your colleagues • Who you involve • How experienced you are Estimates are always wrong! Our task is to understand how wrong and to make sure our organisation is wise to the risks and assumptions