dec1715a08975371fd72f46e474ef630.ppt

- Количество слайдов: 53

Essentials of Fire Fighting 6 th Edition Firefighter II Chapter 16 — Fire Streams

Essentials of Fire Fighting 6 th Edition Firefighter II Chapter 16 — Fire Streams

Learning Objective 1 Describe the methods by which fire fighting foam prevents or controls a hazard. 16– 1

Learning Objective 1 Describe the methods by which fire fighting foam prevents or controls a hazard. 16– 1

Learning Objective 2 Identify foam concentrates. 16– 2

Learning Objective 2 Identify foam concentrates. 16– 2

Learning Objective 3 Explain the factors that impact foam expansion and selection. 16– 3

Learning Objective 3 Explain the factors that impact foam expansion and selection. 16– 3

Learning Objective 4 Describe methods by which foam may be proportioned. 16– 4

Learning Objective 4 Describe methods by which foam may be proportioned. 16– 4

DISCUSSION QUESTION Why is foam used in conjunction with water as an extinguishing agent? 16– 5

DISCUSSION QUESTION Why is foam used in conjunction with water as an extinguishing agent? 16– 5

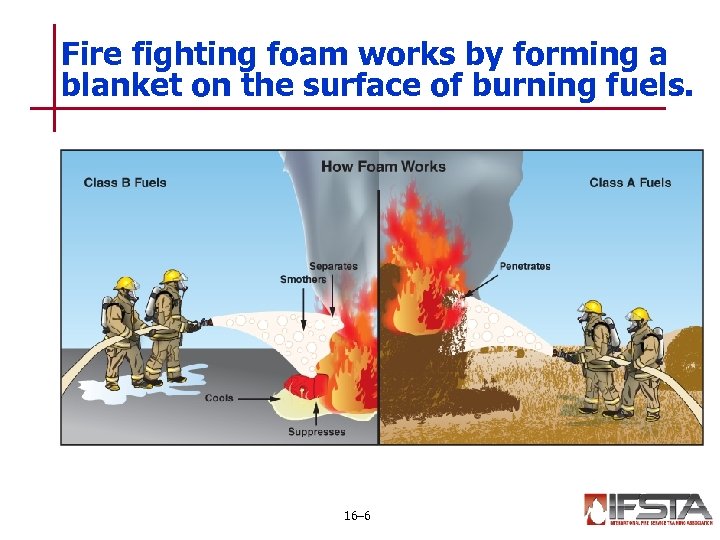

Fire fighting foam works by forming a blanket on the surface of burning fuels. 16– 6

Fire fighting foam works by forming a blanket on the surface of burning fuels. 16– 6

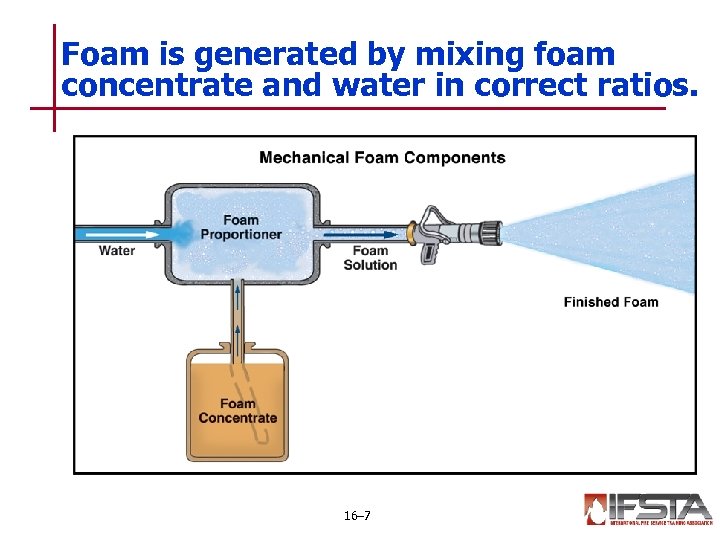

Foam is generated by mixing foam concentrate and water in correct ratios. 16– 7

Foam is generated by mixing foam concentrate and water in correct ratios. 16– 7

Foam expansion is a key characteristic when choosing applications for foam. • Increase in volume when aerated • Depends on • Type of concentrate used • Accurate proportioning • Quality of concentrate • Method of aeration 16– 8

Foam expansion is a key characteristic when choosing applications for foam. • Increase in volume when aerated • Depends on • Type of concentrate used • Accurate proportioning • Quality of concentrate • Method of aeration 16– 8

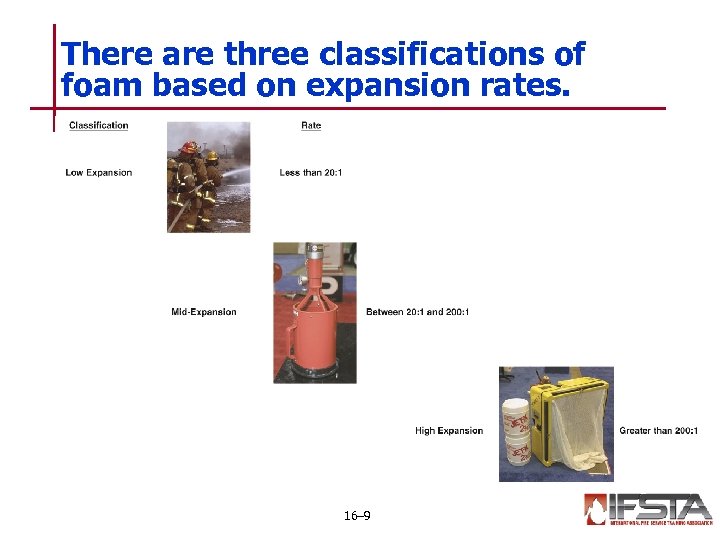

There are three classifications of foam based on expansion rates. 16– 9

There are three classifications of foam based on expansion rates. 16– 9

Foam concentrates must match the fuel to which they are applied to be effective. • Foam for • Class B • Class A not designed for Class B polar solvents may be used on hydrocarbon ONLY if manufacture r states designed for hydrocarbon will not extinguish polar solvents 16– 10 • Incompatibi lity factor makes selection important

Foam concentrates must match the fuel to which they are applied to be effective. • Foam for • Class B • Class A not designed for Class B polar solvents may be used on hydrocarbon ONLY if manufacture r states designed for hydrocarbon will not extinguish polar solvents 16– 10 • Incompatibi lity factor makes selection important

CAUTION Failing to match the proper foam concentrate to the burning fuel will result in an unsuccessful extinguishing attempt and could endanger firefighters. Likewise, mixing different types of foam together can result in substandard quality foam. 16– 11

CAUTION Failing to match the proper foam concentrate to the burning fuel will result in an unsuccessful extinguishing attempt and could endanger firefighters. Likewise, mixing different types of foam together can result in substandard quality foam. 16– 11

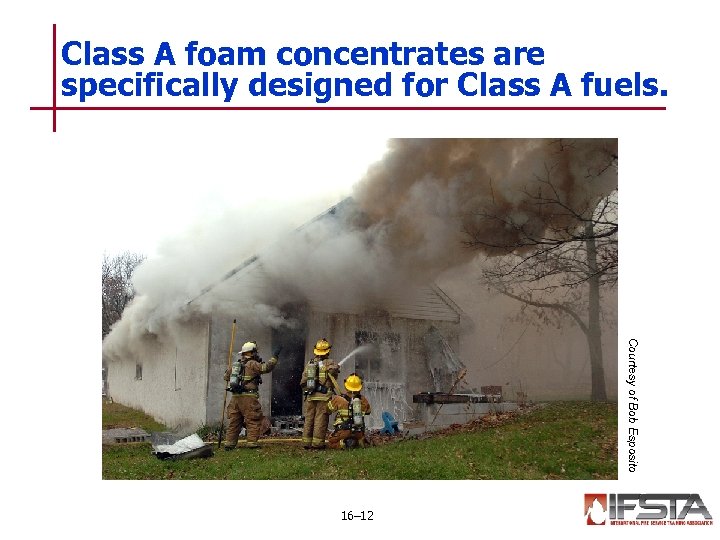

Class A foam concentrates are specifically designed for Class A fuels. Courtesy of Bob Esposito 16– 12

Class A foam concentrates are specifically designed for Class A fuels. Courtesy of Bob Esposito 16– 12

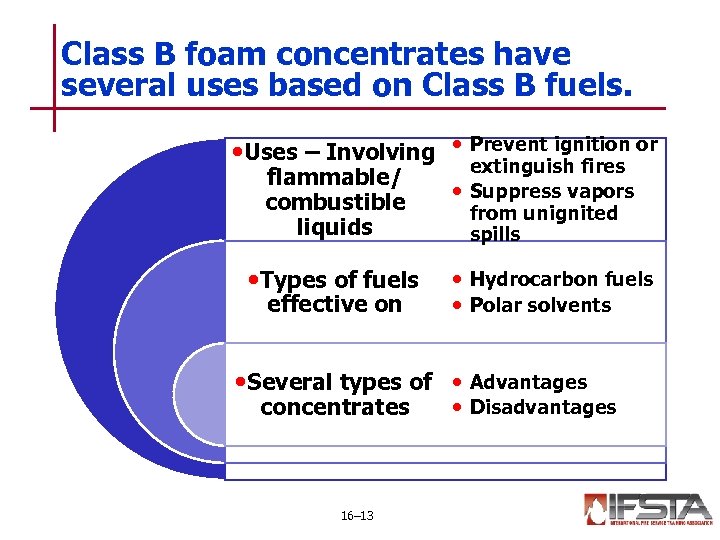

Class B foam concentrates have several uses based on Class B fuels. • Uses – Involving • flammable/ combustible liquids • Types of fuels effective on Prevent ignition or extinguish fires • Suppress vapors from unignited spills • Hydrocarbon fuels • Polar solvents • Several types of • concentrates 16– 13 Advantages • Disadvantages

Class B foam concentrates have several uses based on Class B fuels. • Uses – Involving • flammable/ combustible liquids • Types of fuels effective on Prevent ignition or extinguish fires • Suppress vapors from unignited spills • Hydrocarbon fuels • Polar solvents • Several types of • concentrates 16– 13 Advantages • Disadvantages

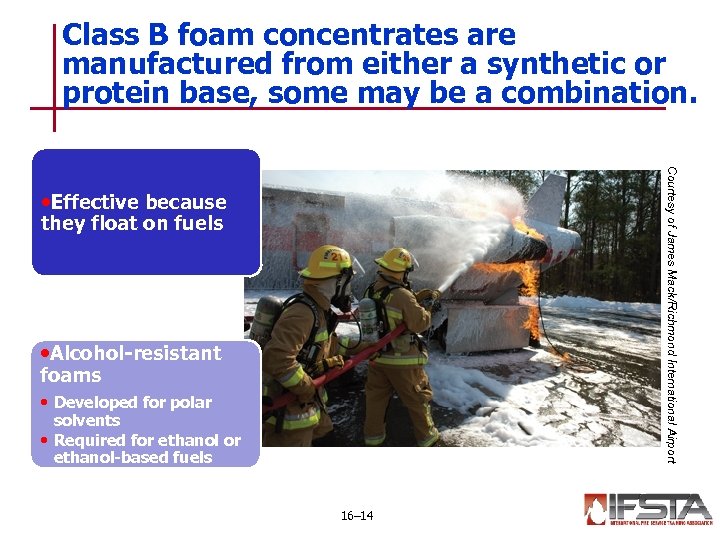

Class B foam concentrates are manufactured from either a synthetic or protein base, some may be a combination. Courtesy of James Mack/Richmond International Airport • Effective because they float on fuels • Alcohol-resistant foams • Developed for polar solvents • Required for ethanol-based fuels 16– 14

Class B foam concentrates are manufactured from either a synthetic or protein base, some may be a combination. Courtesy of James Mack/Richmond International Airport • Effective because they float on fuels • Alcohol-resistant foams • Developed for polar solvents • Required for ethanol-based fuels 16– 14

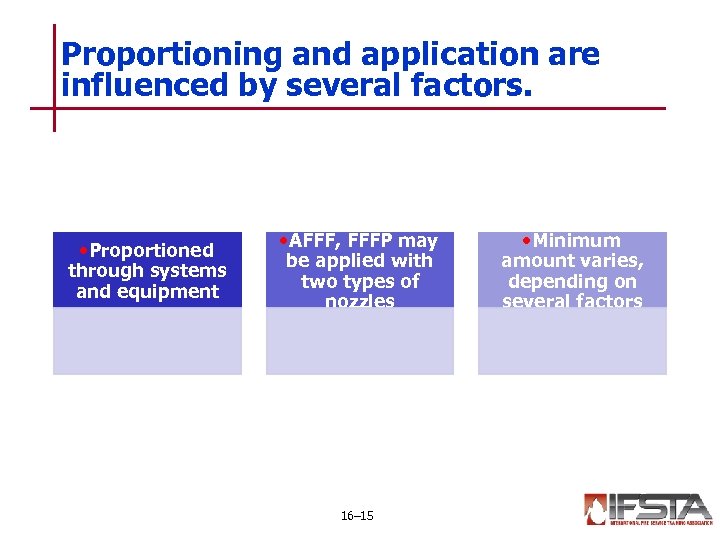

Proportioning and application are influenced by several factors. • Proportioned through systems and equipment • AFFF, FFFP may be applied with two types of nozzles 16– 15 • Minimum amount varies, depending on several factors

Proportioning and application are influenced by several factors. • Proportioned through systems and equipment • AFFF, FFFP may be applied with two types of nozzles 16– 15 • Minimum amount varies, depending on several factors

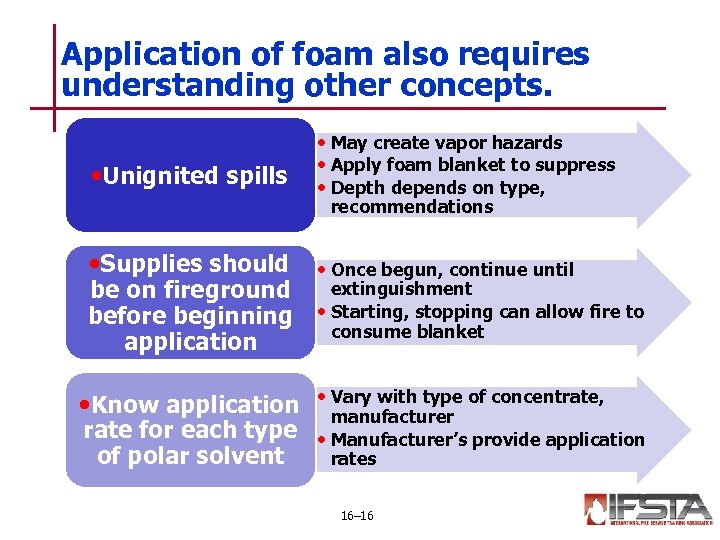

Application of foam also requires understanding other concepts. • Unignited spills • May create vapor hazards • Apply foam blanket to suppress • Depth depends on type, recommendations • Supplies should be on fireground before beginning application • Know application rate for each type of polar solvent • Once begun, continue until extinguishment • Starting, stopping can allow fire to consume blanket • Vary with type of concentrate, manufacturer • Manufacturer’s provide application rates 16– 16

Application of foam also requires understanding other concepts. • Unignited spills • May create vapor hazards • Apply foam blanket to suppress • Depth depends on type, recommendations • Supplies should be on fireground before beginning application • Know application rate for each type of polar solvent • Once begun, continue until extinguishment • Starting, stopping can allow fire to consume blanket • Vary with type of concentrate, manufacturer • Manufacturer’s provide application rates 16– 16

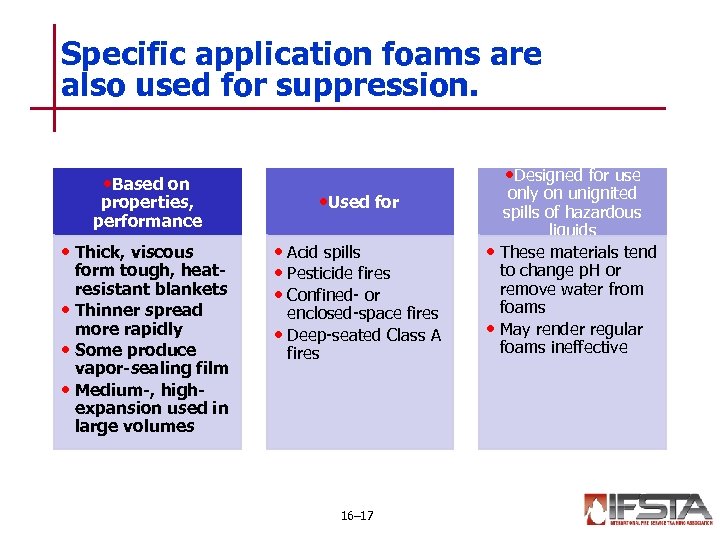

Specific application foams are also used for suppression. • Based on properties, performance • Thick, viscous form tough, heatresistant blankets • Thinner spread more rapidly • Some produce vapor-sealing film • Medium-, highexpansion used in large volumes • Designed for use • Used for • Acid spills • Pesticide fires • Confined- or enclosed-space fires • Deep-seated Class A fires 16– 17 only on unignited spills of hazardous liquids • These materials tend to change p. H or remove water from foams • May render regular foams ineffective

Specific application foams are also used for suppression. • Based on properties, performance • Thick, viscous form tough, heatresistant blankets • Thinner spread more rapidly • Some produce vapor-sealing film • Medium-, highexpansion used in large volumes • Designed for use • Used for • Acid spills • Pesticide fires • Confined- or enclosed-space fires • Deep-seated Class A fires 16– 17 only on unignited spills of hazardous liquids • These materials tend to change p. H or remove water from foams • May render regular foams ineffective

REVIEW QUESTIONS How does fire fighting foam prevent or control a hazard? What are the types of foam concentrates used in the fire service? 16– 18

REVIEW QUESTIONS How does fire fighting foam prevent or control a hazard? What are the types of foam concentrates used in the fire service? 16– 18

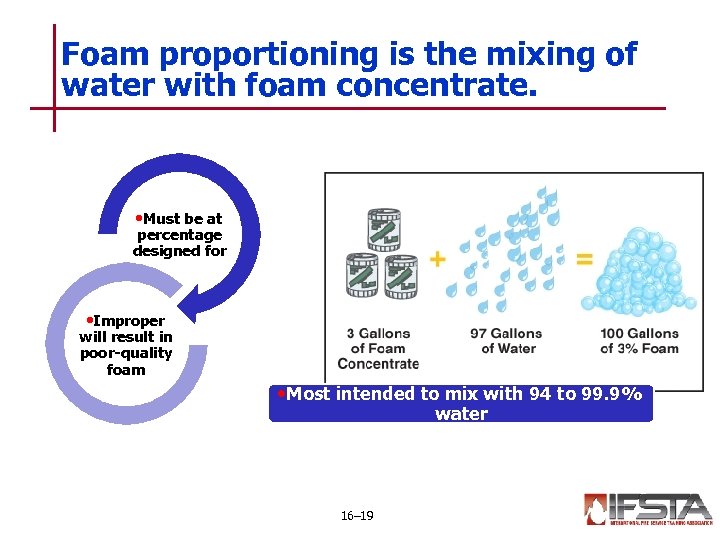

Foam proportioning is the mixing of water with foam concentrate. • Must be at percentage designed for • Improper will result in poor-quality foam • Most intended to mix with 94 to 99. 9% water 16– 19

Foam proportioning is the mixing of water with foam concentrate. • Must be at percentage designed for • Improper will result in poor-quality foam • Most intended to mix with 94 to 99. 9% water 16– 19

Proportioning percentages depend on several factors. • Cla ss A • Dry (thick) • Can be adjusted within limits • Most mixed in proportions of 1 percent or less 16– 20 foam – Higher percentage • Wet (thin) foam – Lower percentage (Cont. )

Proportioning percentages depend on several factors. • Cla ss A • Dry (thick) • Can be adjusted within limits • Most mixed in proportions of 1 percent or less 16– 20 foam – Higher percentage • Wet (thin) foam – Lower percentage (Cont. )

Proportioning percentages depend on several factors. • Cla ss B • Mixed in proportions from 1 to 6 percent • May be multipurpose • Hydrocarbons – 3 percent rate • Polar solvents – 6 percent rate • Always follow manufacturer’s recommendatio ns 16– 21

Proportioning percentages depend on several factors. • Cla ss B • Mixed in proportions from 1 to 6 percent • May be multipurpose • Hydrocarbons – 3 percent rate • Polar solvents – 6 percent rate • Always follow manufacturer’s recommendatio ns 16– 21

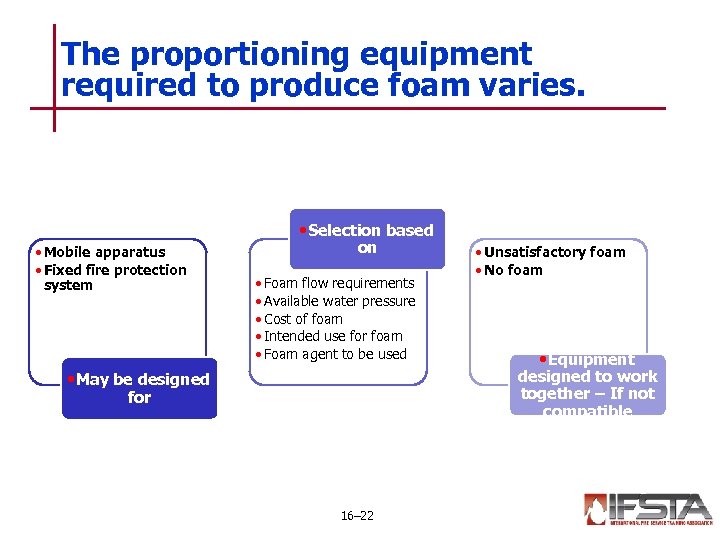

The proportioning equipment required to produce foam varies. • Selection based • Mobile apparatus • Fixed fire protection system on • Foam flow requirements • Available water pressure • Cost of foam • Intended use for foam • Foam agent to be used • Unsatisfactory foam • No foam • Equipment designed to work together – If not compatible • May be designed for 16– 22

The proportioning equipment required to produce foam varies. • Selection based • Mobile apparatus • Fixed fire protection system on • Foam flow requirements • Available water pressure • Cost of foam • Intended use for foam • Foam agent to be used • Unsatisfactory foam • No foam • Equipment designed to work together – If not compatible • May be designed for 16– 22

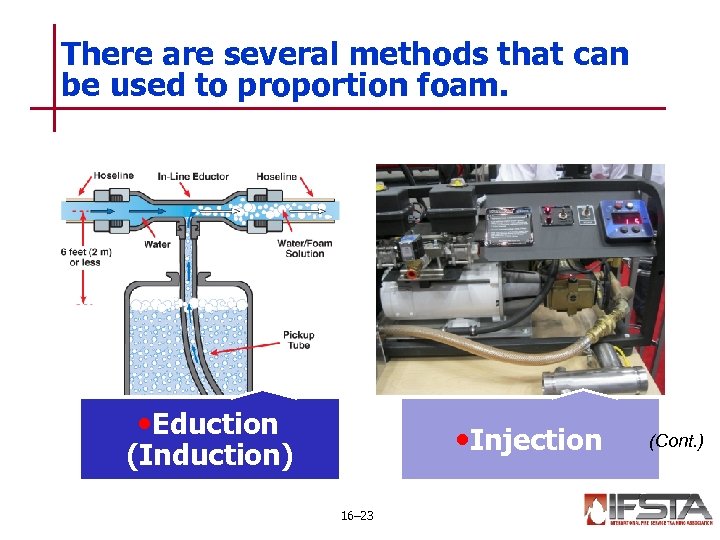

There are several methods that can be used to proportion foam. • Eduction • Injection (Induction) 16– 23 (Cont. )

There are several methods that can be used to proportion foam. • Eduction • Injection (Induction) 16– 23 (Cont. )

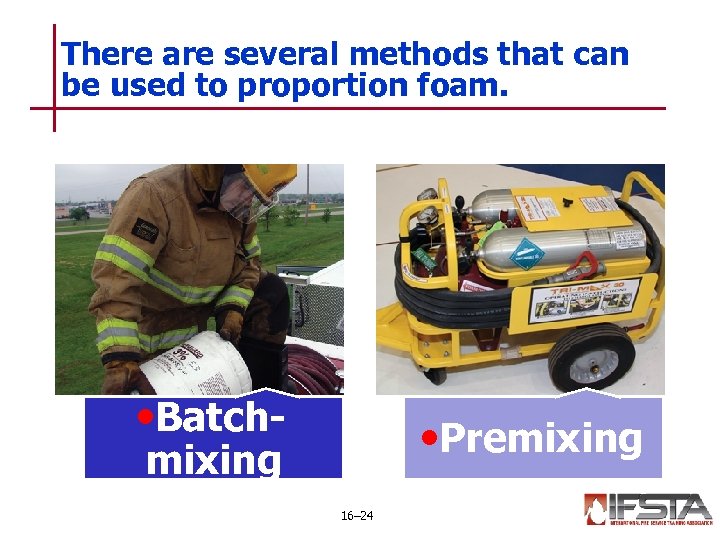

There are several methods that can be used to proportion foam. • Batch- • Premixing 16– 24

There are several methods that can be used to proportion foam. • Batch- • Premixing 16– 24

REVIEW QUESTION Which methods can be used to proportion foam? 16– 25

REVIEW QUESTION Which methods can be used to proportion foam? 16– 25

Learning Objective 5 Explain the advantages and disadvantages of various foam proportioners, delivery devices, and generating systems. 16– 26

Learning Objective 5 Explain the advantages and disadvantages of various foam proportioners, delivery devices, and generating systems. 16– 26

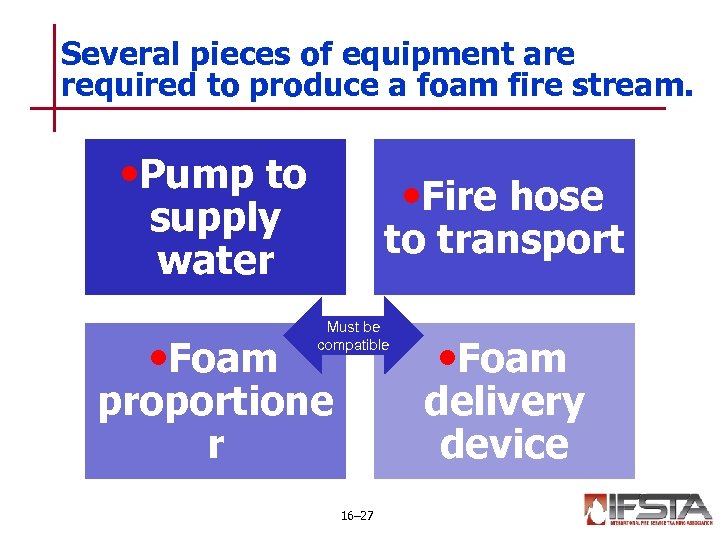

Several pieces of equipment are required to produce a foam fire stream. • Pump to • Fire hose supply water • Foam to transport Must be compatible proportione r • Foam delivery device 16– 27

Several pieces of equipment are required to produce a foam fire stream. • Pump to • Fire hose supply water • Foam to transport Must be compatible proportione r • Foam delivery device 16– 27

An effective foam stream results from two processes working together. • Foam- generating system/nozzle • Air • Foam solution • To produce finished foam • Foam concentrate • Water • To form solution • Foam proportioning 16– 28

An effective foam stream results from two processes working together. • Foam- generating system/nozzle • Air • Foam solution • To produce finished foam • Foam concentrate • Water • To form solution • Foam proportioning 16– 28

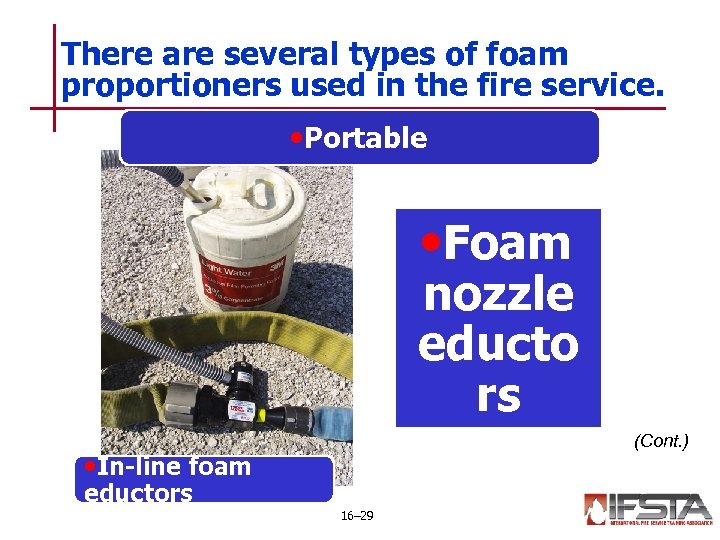

There are several types of foam proportioners used in the fire service. • Portable • Foam nozzle educto rs (Cont. ) • In-line foam eductors 16– 29

There are several types of foam proportioners used in the fire service. • Portable • Foam nozzle educto rs (Cont. ) • In-line foam eductors 16– 29

There are several types of foam proportioners used in the fire service. • Apparatus-mounted (Cont. ) 16– 30

There are several types of foam proportioners used in the fire service. • Apparatus-mounted (Cont. ) 16– 30

DISCUSSION QUESTION Which types of apparatus-mounted foam proportioning systems are used in your jurisdiction(s)? 16– 31

DISCUSSION QUESTION Which types of apparatus-mounted foam proportioning systems are used in your jurisdiction(s)? 16– 31

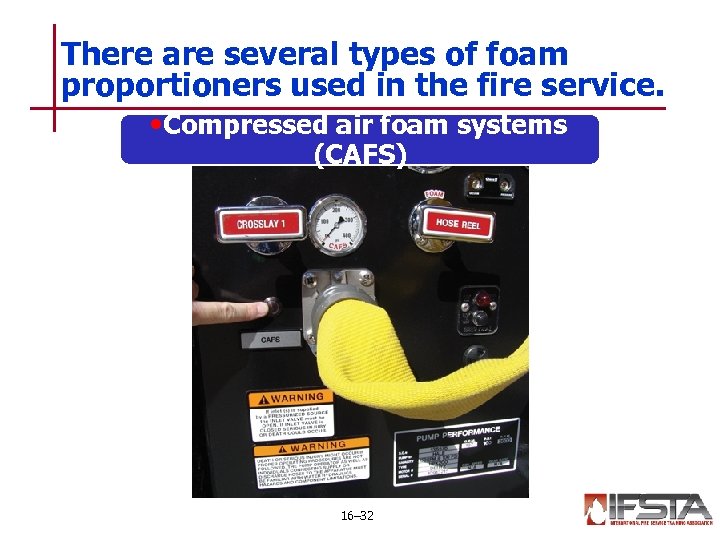

There are several types of foam proportioners used in the fire service. • Compressed air foam systems (CAFS) 16– 32

There are several types of foam proportioners used in the fire service. • Compressed air foam systems (CAFS) 16– 32

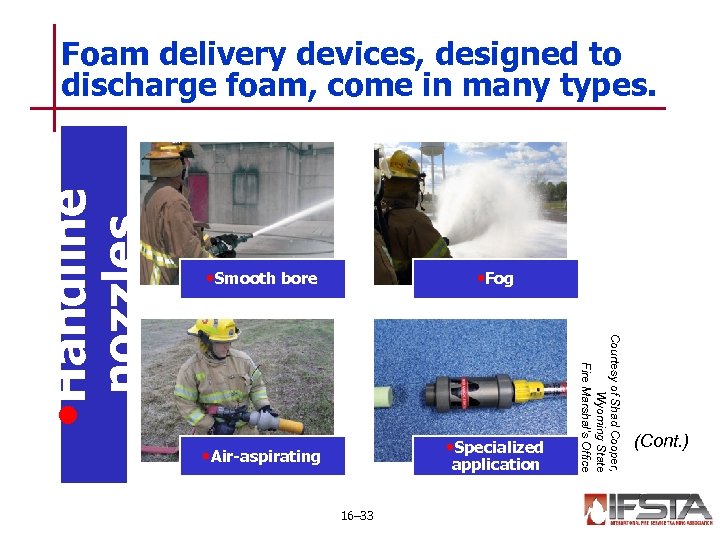

nozzles • Smooth bore • Fog • Air-aspirating • Specialized application 16– 33 Courtesy of Shad Cooper, Wyoming State Fire Marshal’s Office • Handline Foam delivery devices, designed to discharge foam, come in many types. (Cont. )

nozzles • Smooth bore • Fog • Air-aspirating • Specialized application 16– 33 Courtesy of Shad Cooper, Wyoming State Fire Marshal’s Office • Handline Foam delivery devices, designed to discharge foam, come in many types. (Cont. )

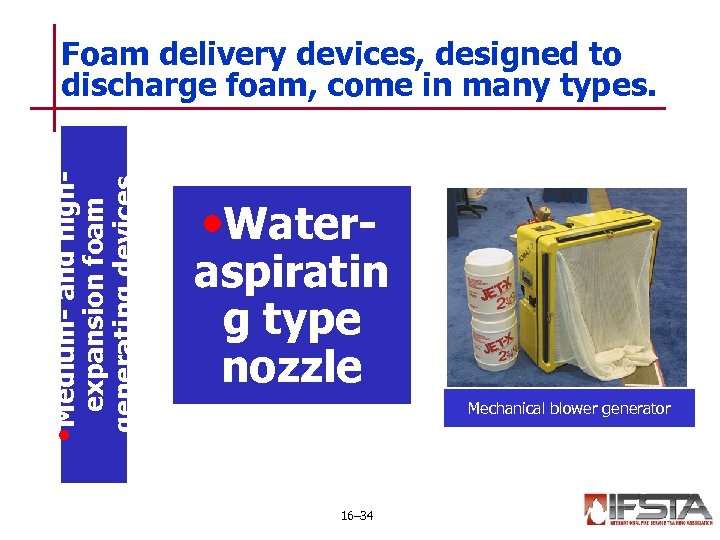

expansion foam generating devices • Medium- and high- Foam delivery devices, designed to discharge foam, come in many types. • Water- aspiratin g type nozzle Mechanical blower generator 16– 34

expansion foam generating devices • Medium- and high- Foam delivery devices, designed to discharge foam, come in many types. • Water- aspiratin g type nozzle Mechanical blower generator 16– 34

REVIEW QUESTION What are the advantages of each type of foam delivery device? 16– 35

REVIEW QUESTION What are the advantages of each type of foam delivery device? 16– 35

Learning Objective 6 Identify causes of poor foam production. 16– 36

Learning Objective 6 Identify causes of poor foam production. 16– 36

Assembling a foam fire stream system requires understanding several concepts. • Make adjustmen ts • Correctly assemble system • Locate problem areas 16– 37

Assembling a foam fire stream system requires understanding several concepts. • Make adjustmen ts • Correctly assemble system • Locate problem areas 16– 37

There are some common reasons for foam failure you should recognize. • Eductor, • Air leaks at nozzle flow ratings do not match fittings • Improper • Nozzle not cleaning causing clogs fully open 16– 38 (Cont. )

There are some common reasons for foam failure you should recognize. • Eductor, • Air leaks at nozzle flow ratings do not match fittings • Improper • Nozzle not cleaning causing clogs fully open 16– 38 (Cont. )

There are some common reasons for foam failure you should recognize. • Hose lay on discharge side of eductor too long • Hose kinked • Mixing different types of foam concentrate in same tank • Nozzle too far above eductor 16– 39

There are some common reasons for foam failure you should recognize. • Hose lay on discharge side of eductor too long • Hose kinked • Mixing different types of foam concentrate in same tank • Nozzle too far above eductor 16– 39

REVIEW QUESTION What are some possible causes of poor foam production? 16– 40

REVIEW QUESTION What are some possible causes of poor foam production? 16– 40

Learning Objective 7 Distinguish among various foam application techniques. 16– 41

Learning Objective 7 Distinguish among various foam application techniques. 16– 41

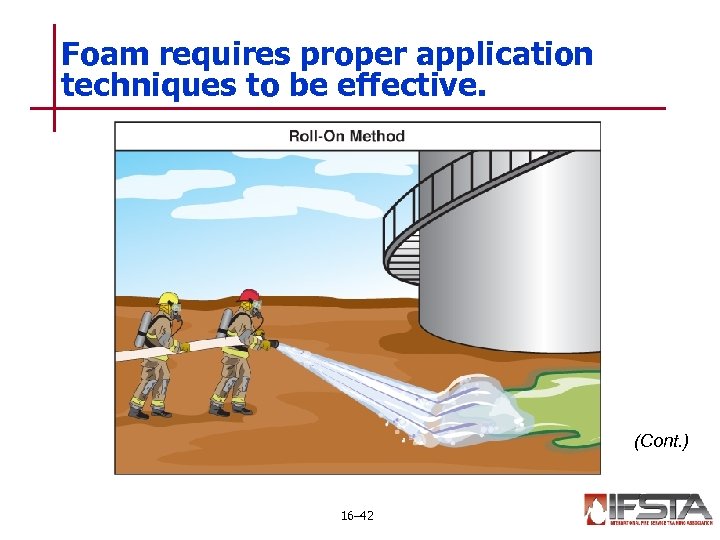

Foam requires proper application techniques to be effective. (Cont. ) 16– 42

Foam requires proper application techniques to be effective. (Cont. ) 16– 42

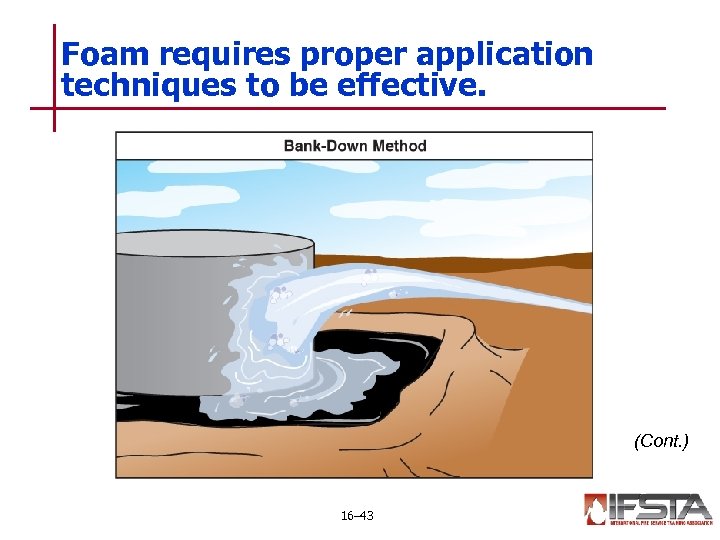

Foam requires proper application techniques to be effective. (Cont. ) 16– 43

Foam requires proper application techniques to be effective. (Cont. ) 16– 43

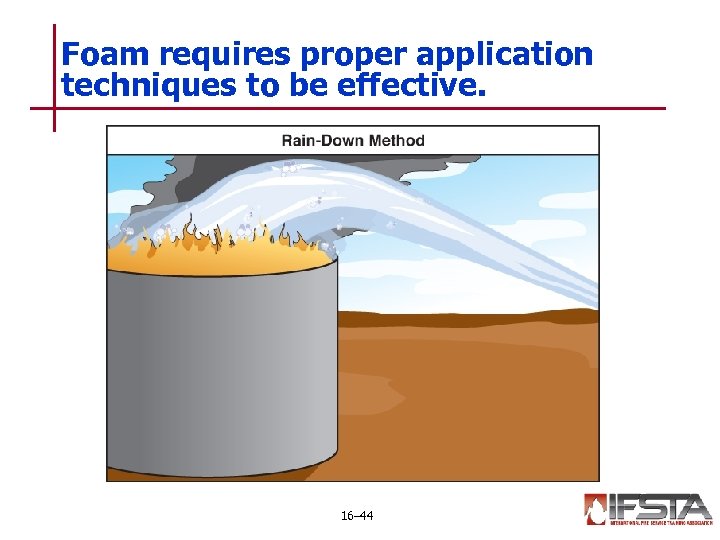

Foam requires proper application techniques to be effective. 16– 44

Foam requires proper application techniques to be effective. 16– 44

REVIEW QUESTION What are three main types of foam application techniques and how do they work? 16– 45

REVIEW QUESTION What are three main types of foam application techniques and how do they work? 16– 45

Learning Objective 8 Identify foam hazards and ways to control them. 16– 46

Learning Objective 8 Identify foam hazards and ways to control them. 16– 46

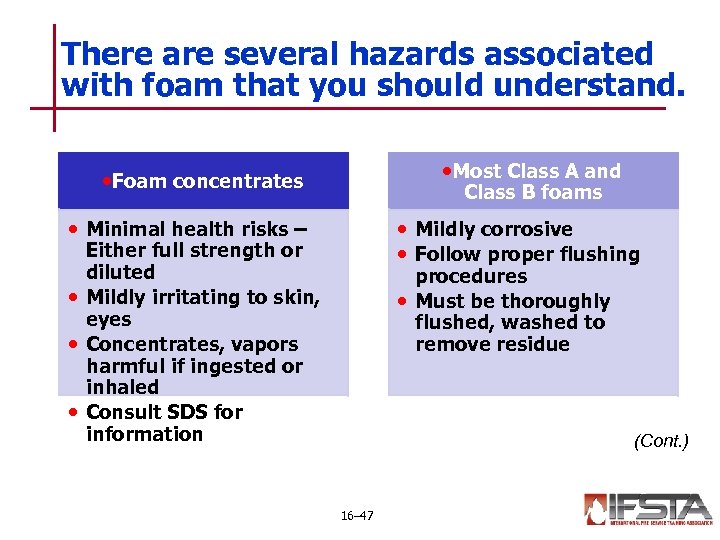

There are several hazards associated with foam that you should understand. • Most Class A and • Foam concentrates Class B foams • Minimal health risks – • Mildly corrosive • Follow proper flushing Either full strength or diluted • Mildly irritating to skin, eyes • Concentrates, vapors harmful if ingested or inhaled • Consult SDS for information procedures • Must be thoroughly flushed, washed to remove residue (Cont. ) 16– 47

There are several hazards associated with foam that you should understand. • Most Class A and • Foam concentrates Class B foams • Minimal health risks – • Mildly corrosive • Follow proper flushing Either full strength or diluted • Mildly irritating to skin, eyes • Concentrates, vapors harmful if ingested or inhaled • Consult SDS for information procedures • Must be thoroughly flushed, washed to remove residue (Cont. ) 16– 47

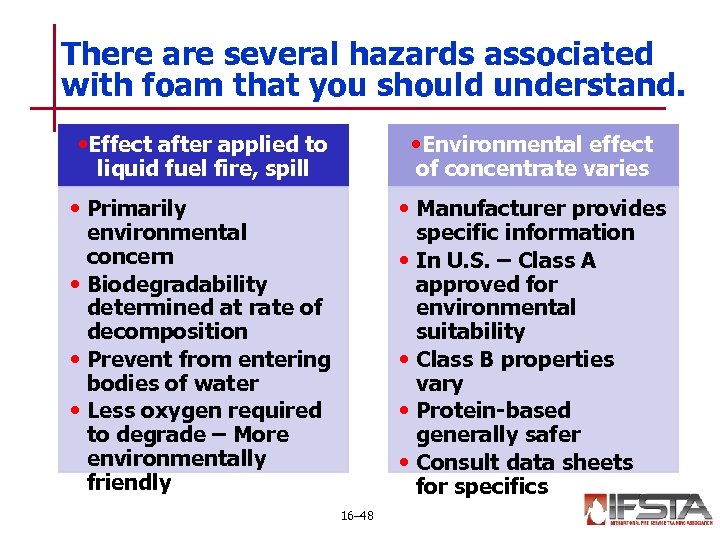

There are several hazards associated with foam that you should understand. • Effect after applied to • Environmental effect liquid fuel fire, spill of concentrate varies • Primarily • Manufacturer provides environmental concern • Biodegradability determined at rate of decomposition • Prevent from entering bodies of water • Less oxygen required to degrade – More environmentally friendly • • 16– 48 specific information In U. S. – Class A approved for environmental suitability Class B properties vary Protein-based generally safer Consult data sheets for specifics

There are several hazards associated with foam that you should understand. • Effect after applied to • Environmental effect liquid fuel fire, spill of concentrate varies • Primarily • Manufacturer provides environmental concern • Biodegradability determined at rate of decomposition • Prevent from entering bodies of water • Less oxygen required to degrade – More environmentally friendly • • 16– 48 specific information In U. S. – Class A approved for environmental suitability Class B properties vary Protein-based generally safer Consult data sheets for specifics

REVIEW QUESTION How can firefighters work to mitigate foam hazards? 16– 49

REVIEW QUESTION How can firefighters work to mitigate foam hazards? 16– 49

Summary • Firefighters must know the differences between the types of foam used by their departments. • They must know how to generate foam. • They must know how to apply foam most effectively. 16– 50

Summary • Firefighters must know the differences between the types of foam used by their departments. • They must know how to generate foam. • They must know how to apply foam most effectively. 16– 50

Learning Objective 9 Place a foam line in service using an in -line eductor. This objective is measured in Skill Sheet 16 -II-1. 16– 51

Learning Objective 9 Place a foam line in service using an in -line eductor. This objective is measured in Skill Sheet 16 -II-1. 16– 51

Learning Objective 10 Extinguish an ignitable liquid fire. This objective is measured in Skill Sheet 16 -II-2. 16– 52

Learning Objective 10 Extinguish an ignitable liquid fire. This objective is measured in Skill Sheet 16 -II-2. 16– 52