447bccc04f9d07898574c6964673bdae.ppt

- Количество слайдов: 12

ESRF VACUUM SYSTEM R. Kersevan, Vacuum Group, Tech. Serv. Division, ESRF, Grenoble ALBA-Max. Lab Workshop on Vacuum Systems for Synchrotron Radiation Light Sources, Barcelona, 12 -13 Sept 2005 1

ESRF VACUUM SYSTEM R. Kersevan, Vacuum Group, Tech. Serv. Division, ESRF, Grenoble ALBA-Max. Lab Workshop on Vacuum Systems for Synchrotron Radiation Light Sources, Barcelona, 12 -13 Sept 2005 1

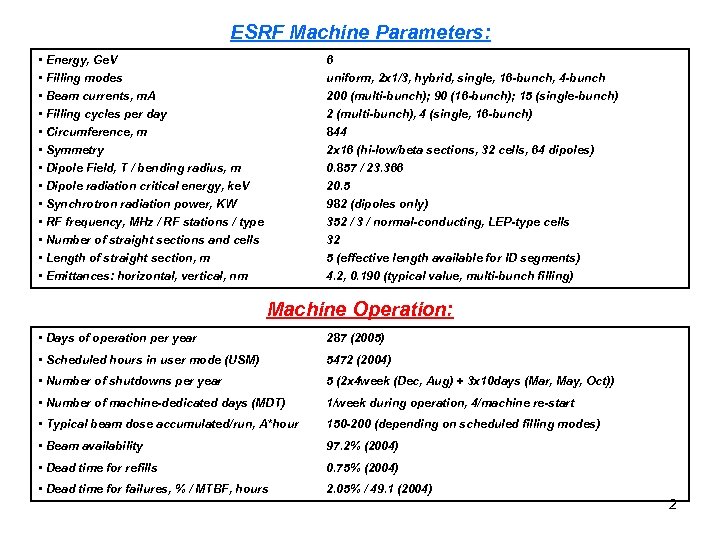

ESRF Machine Parameters: • Energy, Ge. V • Filling modes • Beam currents, m. A • Filling cycles per day • Circumference, m • Symmetry • Dipole Field, T / bending radius, m • Dipole radiation critical energy, ke. V • Synchrotron radiation power, KW • RF frequency, MHz / RF stations / type • Number of straight sections and cells • Length of straight section, m • Emittances: horizontal, vertical, nm 6 uniform, 2 x 1/3, hybrid, single, 16 -bunch, 4 -bunch 200 (multi-bunch); 90 (16 -bunch); 15 (single-bunch) 2 (multi-bunch), 4 (single, 16 -bunch) 844 2 x 16 (hi-low/beta sections, 32 cells, 64 dipoles) 0. 857 / 23. 366 20. 5 982 (dipoles only) 352 / 3 / normal-conducting, LEP-type cells 32 5 (effective length available for ID segments) 4. 2, 0. 190 (typical value, multi-bunch filling) Machine Operation: • Days of operation per year 287 (2005) • Scheduled hours in user mode (USM) 5472 (2004) • Number of shutdowns per year 5 (2 x 4 week (Dec, Aug) + 3 x 10 days (Mar, May, Oct)) • Number of machine-dedicated days (MDT) 1/week during operation, 4/machine re-start • Typical beam dose accumulated/run, A*hour 150 -200 (depending on scheduled filling modes) • Beam availability 97. 2% (2004) • Dead time for refills 0. 75% (2004) • Dead time for failures, % / MTBF, hours 2. 05% / 49. 1 (2004) 2

ESRF Machine Parameters: • Energy, Ge. V • Filling modes • Beam currents, m. A • Filling cycles per day • Circumference, m • Symmetry • Dipole Field, T / bending radius, m • Dipole radiation critical energy, ke. V • Synchrotron radiation power, KW • RF frequency, MHz / RF stations / type • Number of straight sections and cells • Length of straight section, m • Emittances: horizontal, vertical, nm 6 uniform, 2 x 1/3, hybrid, single, 16 -bunch, 4 -bunch 200 (multi-bunch); 90 (16 -bunch); 15 (single-bunch) 2 (multi-bunch), 4 (single, 16 -bunch) 844 2 x 16 (hi-low/beta sections, 32 cells, 64 dipoles) 0. 857 / 23. 366 20. 5 982 (dipoles only) 352 / 3 / normal-conducting, LEP-type cells 32 5 (effective length available for ID segments) 4. 2, 0. 190 (typical value, multi-bunch filling) Machine Operation: • Days of operation per year 287 (2005) • Scheduled hours in user mode (USM) 5472 (2004) • Number of shutdowns per year 5 (2 x 4 week (Dec, Aug) + 3 x 10 days (Mar, May, Oct)) • Number of machine-dedicated days (MDT) 1/week during operation, 4/machine re-start • Typical beam dose accumulated/run, A*hour 150 -200 (depending on scheduled filling modes) • Beam availability 97. 2% (2004) • Dead time for refills 0. 75% (2004) • Dead time for failures, % / MTBF, hours 2. 05% / 49. 1 (2004) 2

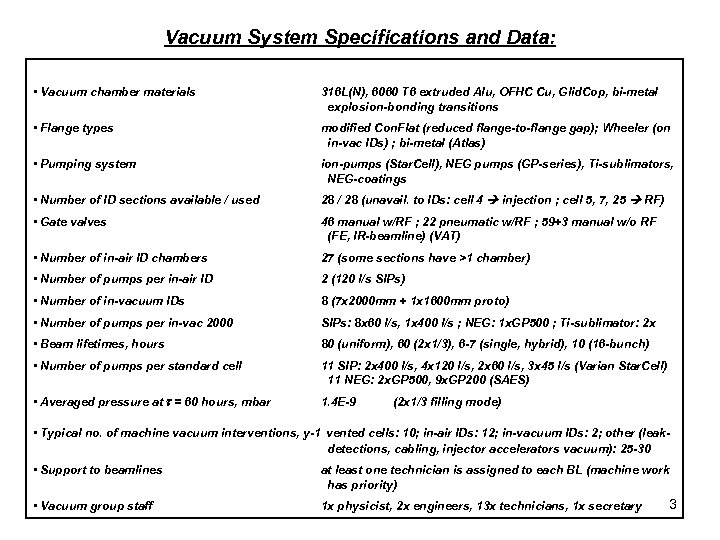

Vacuum System Specifications and Data: • Vacuum chamber materials 316 L(N), 6060 T 6 extruded Alu, OFHC Cu, Glid. Cop, bi-metal explosion-bonding transitions • Flange types modified Con. Flat (reduced flange-to-flange gap); Wheeler (on in-vac IDs) ; bi-metal (Atlas) • Pumping system ion-pumps (Star. Cell), NEG pumps (GP-series), Ti-sublimators, NEG-coatings • Number of ID sections available / used 28 / 28 (unavail. to IDs: cell 4 injection ; cell 5, 7, 25 RF) • Gate valves 46 manual w/RF ; 22 pneumatic w/RF ; 59+3 manual w/o RF (FE, IR-beamline) (VAT) • Number of in-air ID chambers 27 (some sections have >1 chamber) • Number of pumps per in-air ID 2 (120 l/s SIPs) • Number of in-vacuum IDs 8 (7 x 2000 mm + 1 x 1600 mm proto) • Number of pumps per in-vac 2000 SIPs: 8 x 60 l/s, 1 x 400 l/s ; NEG: 1 x. GP 500 ; Ti-sublimator: 2 x • Beam lifetimes, hours 80 (uniform), 60 (2 x 1/3), 6 -7 (single, hybrid), 10 (16 -bunch) • Number of pumps per standard cell 11 SIP: 2 x 400 l/s, 4 x 120 l/s, 2 x 60 l/s, 3 x 45 l/s (Varian Star. Cell) 11 NEG: 2 x. GP 500, 9 x. GP 200 (SAES) • Averaged pressure at t = 60 hours, mbar 1. 4 E-9 (2 x 1/3 filling mode) • Typical no. of machine vacuum interventions, y-1 vented cells: 10; in-air IDs: 12; in-vacuum IDs: 2; other (leakdetections, cabling, injector accelerators vacuum): 25 -30 • Support to beamlines at least one technician is assigned to each BL (machine work has priority) • Vacuum group staff 1 x physicist, 2 x engineers, 13 x technicians, 1 x secretary 3

Vacuum System Specifications and Data: • Vacuum chamber materials 316 L(N), 6060 T 6 extruded Alu, OFHC Cu, Glid. Cop, bi-metal explosion-bonding transitions • Flange types modified Con. Flat (reduced flange-to-flange gap); Wheeler (on in-vac IDs) ; bi-metal (Atlas) • Pumping system ion-pumps (Star. Cell), NEG pumps (GP-series), Ti-sublimators, NEG-coatings • Number of ID sections available / used 28 / 28 (unavail. to IDs: cell 4 injection ; cell 5, 7, 25 RF) • Gate valves 46 manual w/RF ; 22 pneumatic w/RF ; 59+3 manual w/o RF (FE, IR-beamline) (VAT) • Number of in-air ID chambers 27 (some sections have >1 chamber) • Number of pumps per in-air ID 2 (120 l/s SIPs) • Number of in-vacuum IDs 8 (7 x 2000 mm + 1 x 1600 mm proto) • Number of pumps per in-vac 2000 SIPs: 8 x 60 l/s, 1 x 400 l/s ; NEG: 1 x. GP 500 ; Ti-sublimator: 2 x • Beam lifetimes, hours 80 (uniform), 60 (2 x 1/3), 6 -7 (single, hybrid), 10 (16 -bunch) • Number of pumps per standard cell 11 SIP: 2 x 400 l/s, 4 x 120 l/s, 2 x 60 l/s, 3 x 45 l/s (Varian Star. Cell) 11 NEG: 2 x. GP 500, 9 x. GP 200 (SAES) • Averaged pressure at t = 60 hours, mbar 1. 4 E-9 (2 x 1/3 filling mode) • Typical no. of machine vacuum interventions, y-1 vented cells: 10; in-air IDs: 12; in-vacuum IDs: 2; other (leakdetections, cabling, injector accelerators vacuum): 25 -30 • Support to beamlines at least one technician is assigned to each BL (machine work has priority) • Vacuum group staff 1 x physicist, 2 x engineers, 13 x technicians, 1 x secretary 3

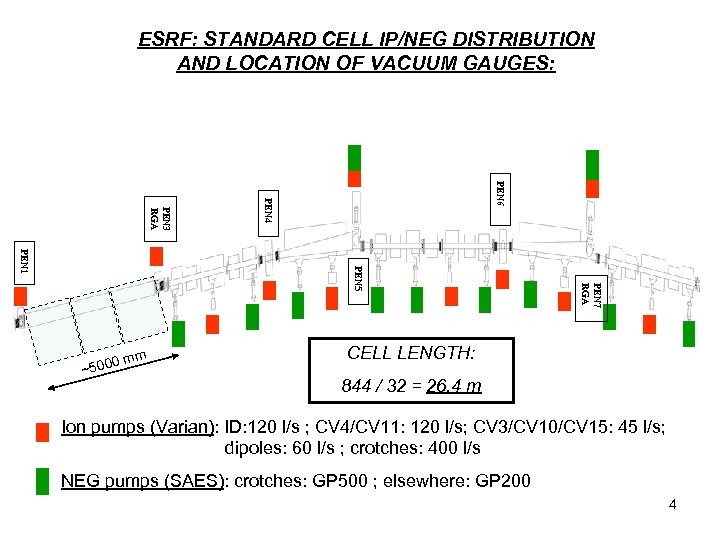

ESRF: STANDARD CELL IP/NEG DISTRIBUTION AND LOCATION OF VACUUM GAUGES: PEN 6 PEN 4 PEN 3 RGA PEN 7 RGA PEN 5 PEN 1 m 0 m ~500 CELL LENGTH: 844 / 32 = 26. 4 m Ion pumps (Varian): ID: 120 l/s ; CV 4/CV 11: 120 l/s; CV 3/CV 10/CV 15: 45 l/s; dipoles: 60 l/s ; crotches: 400 l/s NEG pumps (SAES): crotches: GP 500 ; elsewhere: GP 200 4

ESRF: STANDARD CELL IP/NEG DISTRIBUTION AND LOCATION OF VACUUM GAUGES: PEN 6 PEN 4 PEN 3 RGA PEN 7 RGA PEN 5 PEN 1 m 0 m ~500 CELL LENGTH: 844 / 32 = 26. 4 m Ion pumps (Varian): ID: 120 l/s ; CV 4/CV 11: 120 l/s; CV 3/CV 10/CV 15: 45 l/s; dipoles: 60 l/s ; crotches: 400 l/s NEG pumps (SAES): crotches: GP 500 ; elsewhere: GP 200 4

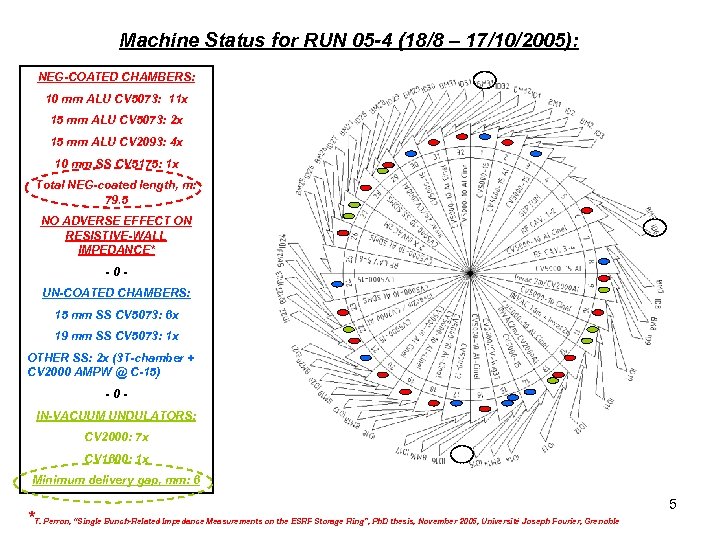

Machine Status for RUN 05 -4 (18/8 – 17/10/2005): NEG-COATED CHAMBERS: 10 mm ALU CV 5073: 11 x 15 mm ALU CV 5073: 2 x 15 mm ALU CV 2093: 4 x 10 mm SS CV 5175: 1 x Total NEG-coated length, m: 79. 5 NO ADVERSE EFFECT ON RESISTIVE-WALL IMPEDANCE* -0 UN-COATED CHAMBERS: 15 mm SS CV 5073: 6 x 19 mm SS CV 5073: 1 x OTHER SS: 2 x (3 T-chamber + CV 2000 AMPW @ C-15) -0 IN-VACUUM UNDULATORS: CV 2000: 7 x CV 1600: 1 x Minimum delivery gap, mm: 6 *T. Perron, “Single Bunch-Related Impedance Measurements on the ESRF Storage Ring", Ph. D thesis, November 2005, Université Joseph Fourier, Grenoble 5

Machine Status for RUN 05 -4 (18/8 – 17/10/2005): NEG-COATED CHAMBERS: 10 mm ALU CV 5073: 11 x 15 mm ALU CV 5073: 2 x 15 mm ALU CV 2093: 4 x 10 mm SS CV 5175: 1 x Total NEG-coated length, m: 79. 5 NO ADVERSE EFFECT ON RESISTIVE-WALL IMPEDANCE* -0 UN-COATED CHAMBERS: 15 mm SS CV 5073: 6 x 19 mm SS CV 5073: 1 x OTHER SS: 2 x (3 T-chamber + CV 2000 AMPW @ C-15) -0 IN-VACUUM UNDULATORS: CV 2000: 7 x CV 1600: 1 x Minimum delivery gap, mm: 6 *T. Perron, “Single Bunch-Related Impedance Measurements on the ESRF Storage Ring", Ph. D thesis, November 2005, Université Joseph Fourier, Grenoble 5

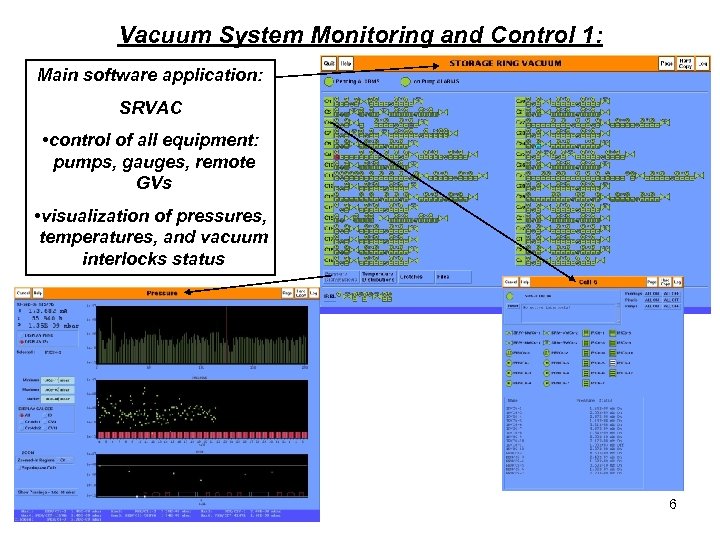

Vacuum System Monitoring and Control 1: Main software application: SRVAC • control of all equipment: pumps, gauges, remote GVs • visualization of pressures, temperatures, and vacuum interlocks status 6

Vacuum System Monitoring and Control 1: Main software application: SRVAC • control of all equipment: pumps, gauges, remote GVs • visualization of pressures, temperatures, and vacuum interlocks status 6

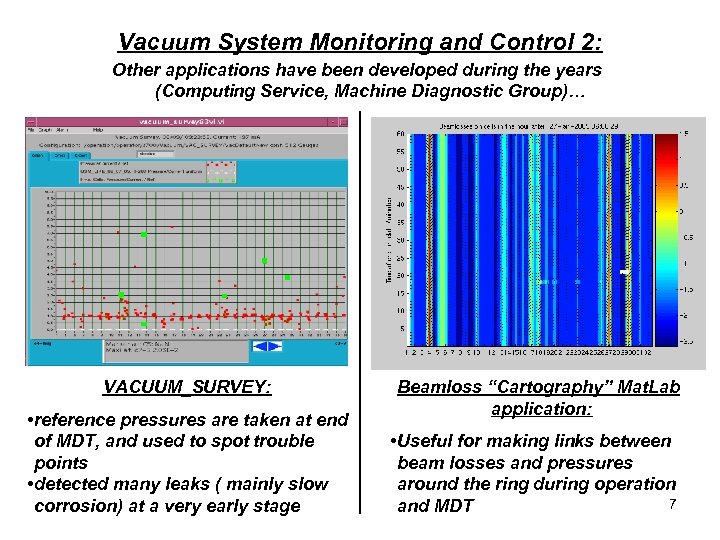

Vacuum System Monitoring and Control 2: Other applications have been developed during the years (Computing Service, Machine Diagnostic Group)… VACUUM_SURVEY: • reference pressures are taken at end of MDT, and used to spot trouble points • detected many leaks ( mainly slow corrosion) at a very early stage Beamloss “Cartography” Mat. Lab application: • Useful for making links between beam losses and pressures around the ring during operation 7 and MDT

Vacuum System Monitoring and Control 2: Other applications have been developed during the years (Computing Service, Machine Diagnostic Group)… VACUUM_SURVEY: • reference pressures are taken at end of MDT, and used to spot trouble points • detected many leaks ( mainly slow corrosion) at a very early stage Beamloss “Cartography” Mat. Lab application: • Useful for making links between beam losses and pressures around the ring during operation 7 and MDT

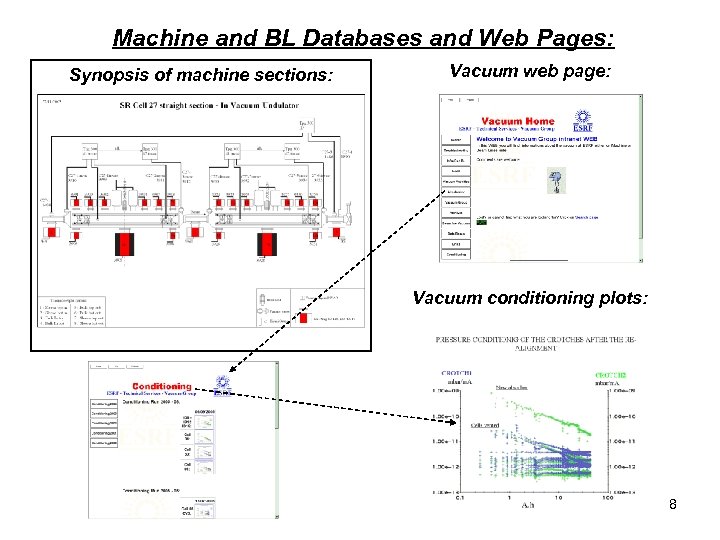

Machine and BL Databases and Web Pages: Synopsis of machine sections: Vacuum web page: Vacuum conditioning plots: 8

Machine and BL Databases and Web Pages: Synopsis of machine sections: Vacuum web page: Vacuum conditioning plots: 8

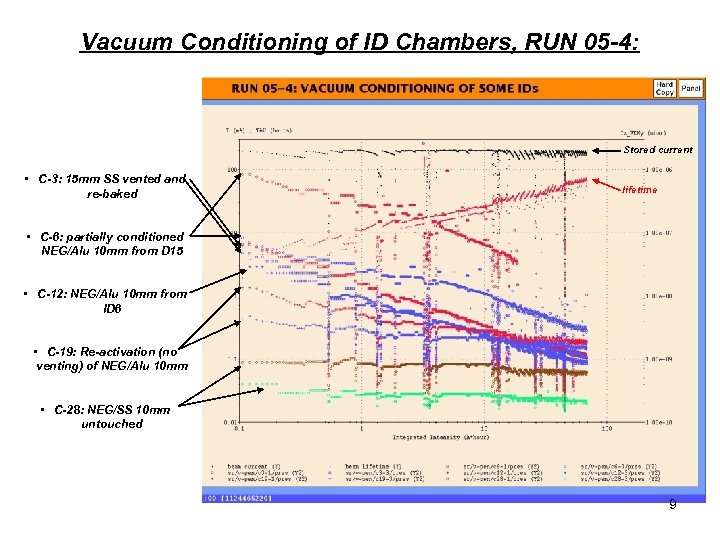

Vacuum Conditioning of ID Chambers, RUN 05 -4: Stored current • C-3: 15 mm SS vented and re-baked lifetime • C-6: partially conditioned NEG/Alu 10 mm from D 15 • C-12: NEG/Alu 10 mm from ID 6 • C-19: Re-activation (no venting) of NEG/Alu 10 mm • C-28: NEG/SS 10 mm untouched 9

Vacuum Conditioning of ID Chambers, RUN 05 -4: Stored current • C-3: 15 mm SS vented and re-baked lifetime • C-6: partially conditioned NEG/Alu 10 mm from D 15 • C-12: NEG/Alu 10 mm from ID 6 • C-19: Re-activation (no venting) of NEG/Alu 10 mm • C-28: NEG/SS 10 mm untouched 9

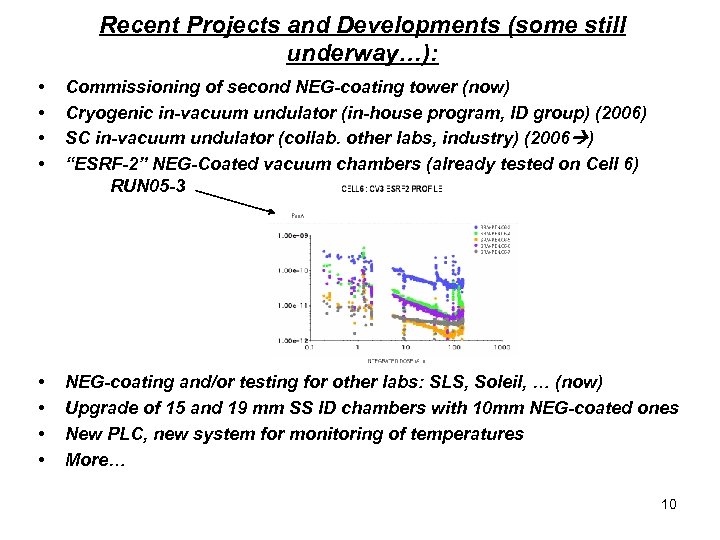

Recent Projects and Developments (some still underway…): • • Commissioning of second NEG-coating tower (now) Cryogenic in-vacuum undulator (in-house program, ID group) (2006) SC in-vacuum undulator (collab. other labs, industry) (2006 ) “ESRF-2” NEG-Coated vacuum chambers (already tested on Cell 6) RUN 05 -3 • • NEG-coating and/or testing for other labs: SLS, Soleil, … (now) Upgrade of 15 and 19 mm SS ID chambers with 10 mm NEG-coated ones New PLC, new system for monitoring of temperatures More… 10

Recent Projects and Developments (some still underway…): • • Commissioning of second NEG-coating tower (now) Cryogenic in-vacuum undulator (in-house program, ID group) (2006) SC in-vacuum undulator (collab. other labs, industry) (2006 ) “ESRF-2” NEG-Coated vacuum chambers (already tested on Cell 6) RUN 05 -3 • • NEG-coating and/or testing for other labs: SLS, Soleil, … (now) Upgrade of 15 and 19 mm SS ID chambers with 10 mm NEG-coated ones New PLC, new system for monitoring of temperatures More… 10

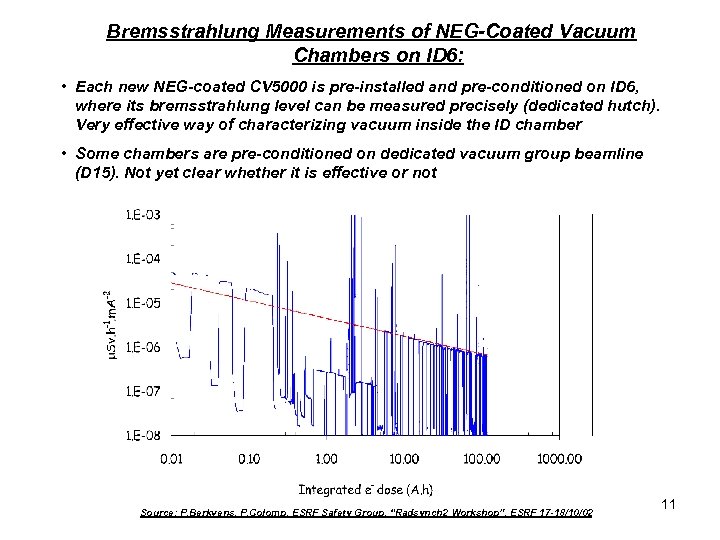

Bremsstrahlung Measurements of NEG-Coated Vacuum Chambers on ID 6: • Each new NEG-coated CV 5000 is pre-installed and pre-conditioned on ID 6, where its bremsstrahlung level can be measured precisely (dedicated hutch). Very effective way of characterizing vacuum inside the ID chamber • Some chambers are pre-conditioned on dedicated vacuum group beamline (D 15). Not yet clear whether it is effective or not Source: P. Berkvens, P. Colomp, ESRF Safety Group, “Radsynch 2 Workshop”, ESRF 17 -18/10/02 11

Bremsstrahlung Measurements of NEG-Coated Vacuum Chambers on ID 6: • Each new NEG-coated CV 5000 is pre-installed and pre-conditioned on ID 6, where its bremsstrahlung level can be measured precisely (dedicated hutch). Very effective way of characterizing vacuum inside the ID chamber • Some chambers are pre-conditioned on dedicated vacuum group beamline (D 15). Not yet clear whether it is effective or not Source: P. Berkvens, P. Colomp, ESRF Safety Group, “Radsynch 2 Workshop”, ESRF 17 -18/10/02 11

Presentation made thanks to contributions and work from all members of the vacuum group, machine and operation groups, safety group, mechanical engineering group. THANK YOU FOR YOUR ATTENTION! 12

Presentation made thanks to contributions and work from all members of the vacuum group, machine and operation groups, safety group, mechanical engineering group. THANK YOU FOR YOUR ATTENTION! 12