ESP Start-up and operation Preliminary operations for start-up

7308-start_up_.ppt

- Количество слайдов: 46

ESP Start-up and operation

ESP Start-up and operation

Preliminary operations for start-up Start-up team includes the following: - production operator; - 2 electricians from Novomet-Service LLC; - maintenance & operation electrician; - drilling team manager. ESP Start-up

Preliminary operations for start-up Start-up team includes the following: - production operator; - 2 electricians from Novomet-Service LLC; - maintenance & operation electrician; - drilling team manager. ESP Start-up

Before start-up proceed as follows: - make visual inspection of ESP surface equipment, check switchboard (VSD) and step-up transformer grounding; - make sure downhole cable armor is grounded to the christmas tree; - check the switchboard, step-up transformer, junction box; check tightness of the bolts on electrical components; check connection to the zero point between step-up transformer and switchboard (VSD); - check phasing in the junction box with a high-voltage phase indicator.

Before start-up proceed as follows: - make visual inspection of ESP surface equipment, check switchboard (VSD) and step-up transformer grounding; - make sure downhole cable armor is grounded to the christmas tree; - check the switchboard, step-up transformer, junction box; check tightness of the bolts on electrical components; check connection to the zero point between step-up transformer and switchboard (VSD); - check phasing in the junction box with a high-voltage phase indicator.

Attention! Idle start-up is prohibited for VSD for PMM when the step-up transformer is connected. In this case during the startup the VSD determines the position of the rotor, and the frequency at the output terminals will be 6 Hertz, while the peak value will gradually rise to the nominal value of the power grid, i.e. to 380 V. It will lead to oversaturation of the magnetic system of step-up transformer and to high current value close to the short-circuit current. Attention! When using VSD for PMM, it is prohibited to check the phasing with a high-voltage phase indicator. Phasing should be checked with an ohmmeter. Attention! When running VSD for PMM do not use output filter between the VSD and transformer, because it will cause pulse distortion of the VSD output voltage, and it will be impossible to determine the rotor position.

Attention! Idle start-up is prohibited for VSD for PMM when the step-up transformer is connected. In this case during the startup the VSD determines the position of the rotor, and the frequency at the output terminals will be 6 Hertz, while the peak value will gradually rise to the nominal value of the power grid, i.e. to 380 V. It will lead to oversaturation of the magnetic system of step-up transformer and to high current value close to the short-circuit current. Attention! When using VSD for PMM, it is prohibited to check the phasing with a high-voltage phase indicator. Phasing should be checked with an ohmmeter. Attention! When running VSD for PMM do not use output filter between the VSD and transformer, because it will cause pulse distortion of the VSD output voltage, and it will be impossible to determine the rotor position.

Person in charge of start-up and commissioning should know the following: - capacity, head, operating range and completion of the unit; - production casing ID, tubing OD to determine annulus volume; - setting depth; - horsepower and type of the motor (kW) and required inflow; - rated current of the motor, idle current; - rated voltage of the motor; required voltage at the tap of the step-up transformer; - rated frequency of the electric motor; - type and density of kill fluid. If all the issues with the workover team are cleared, accept the completed operations note of ESP from the workover team.

Person in charge of start-up and commissioning should know the following: - capacity, head, operating range and completion of the unit; - production casing ID, tubing OD to determine annulus volume; - setting depth; - horsepower and type of the motor (kW) and required inflow; - rated current of the motor, idle current; - rated voltage of the motor; required voltage at the tap of the step-up transformer; - rated frequency of the electric motor; - type and density of kill fluid. If all the issues with the workover team are cleared, accept the completed operations note of ESP from the workover team.

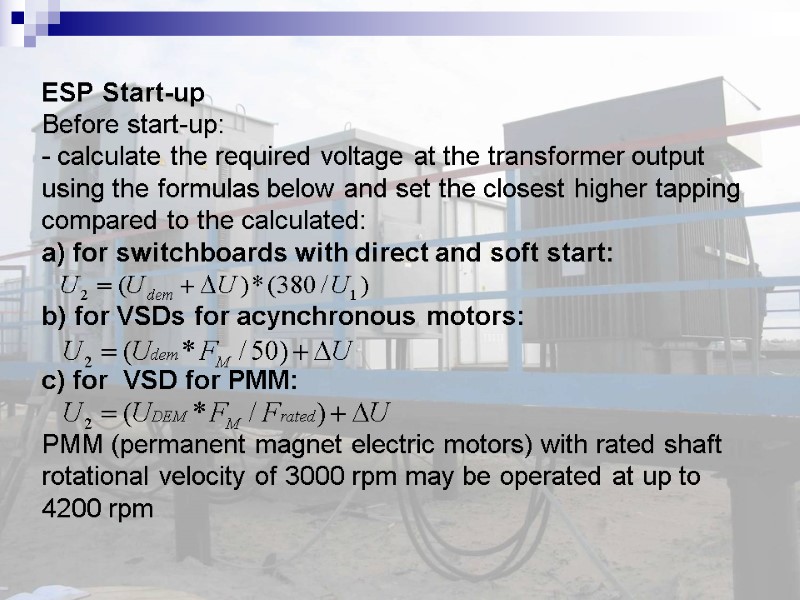

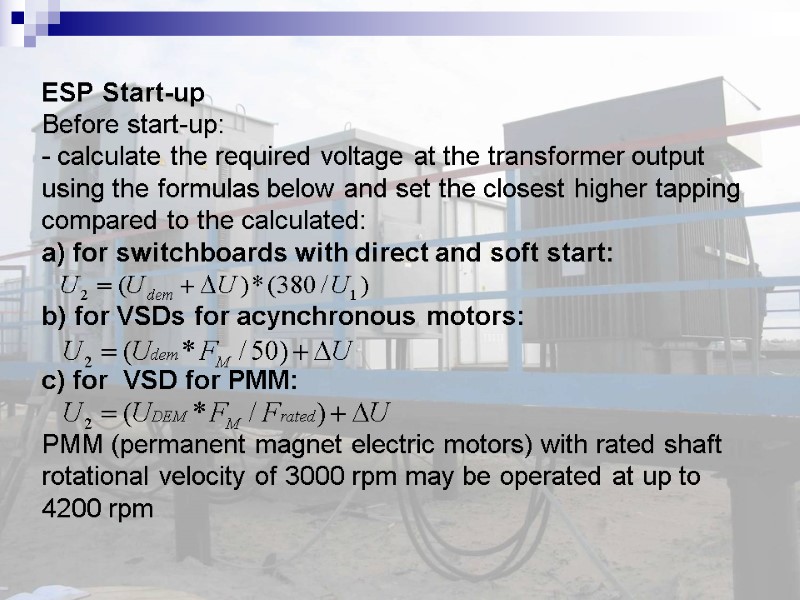

ESP Start-up Before start-up: - calculate the required voltage at the transformer output using the formulas below and set the closest higher tapping compared to the calculated: a) for switchboards with direct and soft start: b) for VSDs for acynchronous motors: c) for VSD for PMM: PMM (permanent magnet electric motors) with rated shaft rotational velocity of 3000 rpm may be operated at up to 4200 rpm

ESP Start-up Before start-up: - calculate the required voltage at the transformer output using the formulas below and set the closest higher tapping compared to the calculated: a) for switchboards with direct and soft start: b) for VSDs for acynchronous motors: c) for VSD for PMM: PMM (permanent magnet electric motors) with rated shaft rotational velocity of 3000 rpm may be operated at up to 4200 rpm

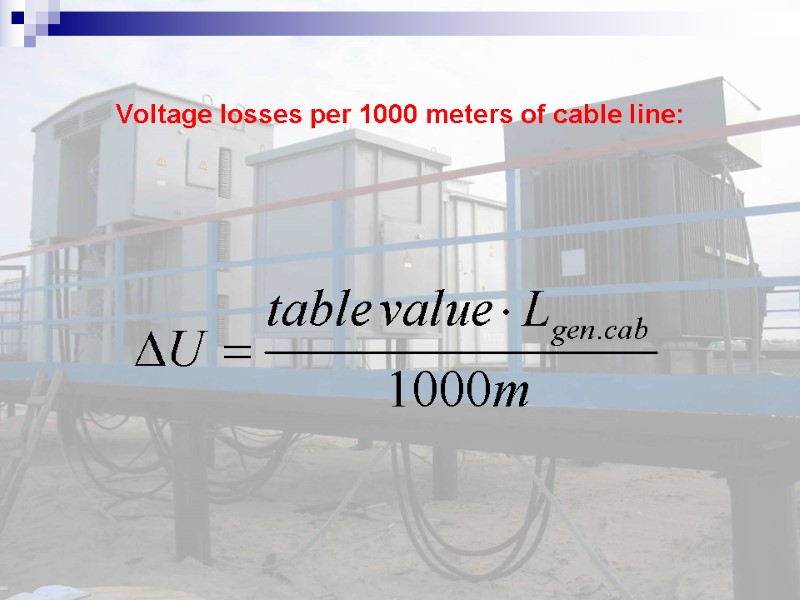

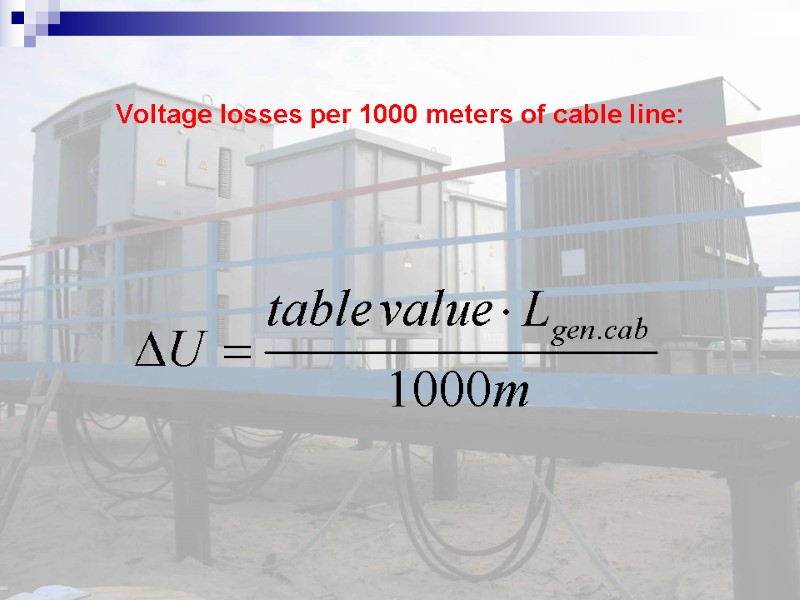

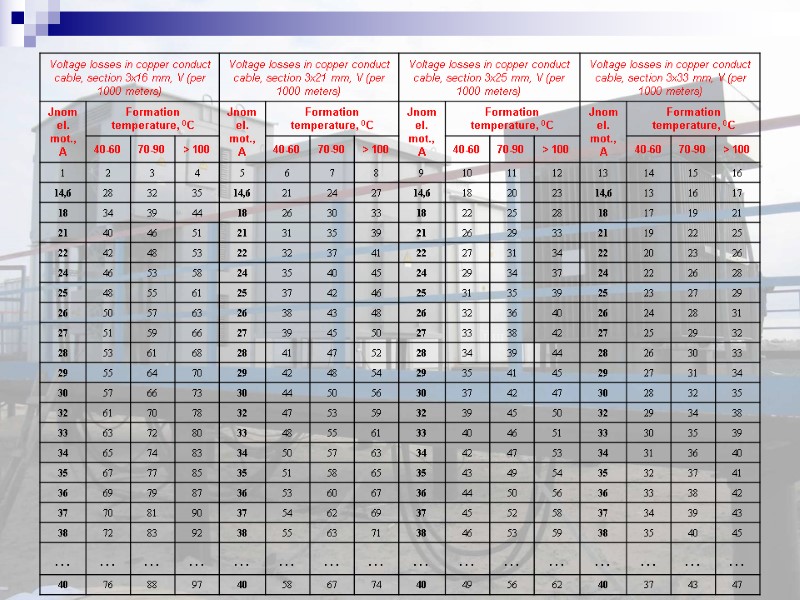

Voltage losses per 1000 meters of cable line:

Voltage losses per 1000 meters of cable line:

Switchboard/VSD settings and protection

Switchboard/VSD settings and protection

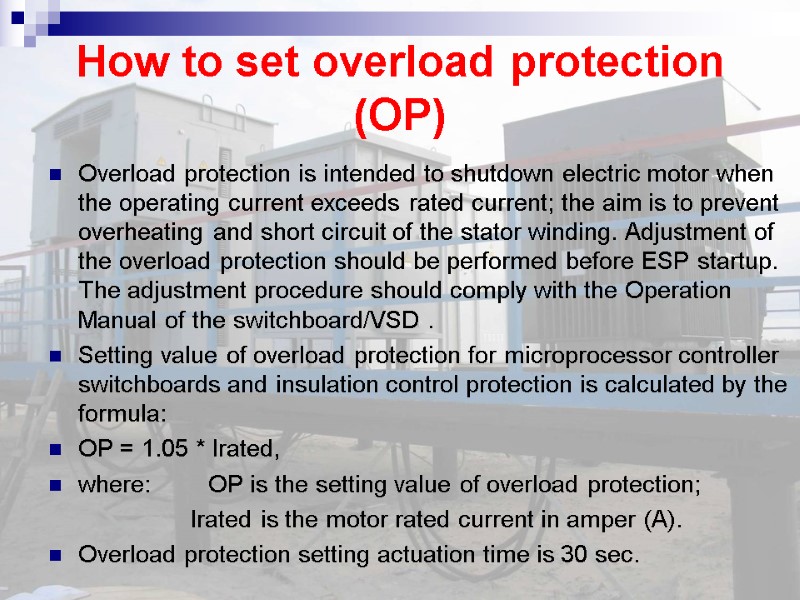

How to set overload protection (OP) Overload protection is intended to shutdown electric motor when the operating current exceeds rated current; the aim is to prevent overheating and short circuit of the stator winding. Adjustment of the overload protection should be performed before ESP startup. The adjustment procedure should comply with the Operation Manual of the switchboard/VSD . Setting value of overload protection for microprocessor controller switchboards and insulation control protection is calculated by the formula: OP = 1.05 * Irated, where: OP is the setting value of overload protection; Irated is the motor rated current in amper (А). Overload protection setting actuation time is 30 sec.

How to set overload protection (OP) Overload protection is intended to shutdown electric motor when the operating current exceeds rated current; the aim is to prevent overheating and short circuit of the stator winding. Adjustment of the overload protection should be performed before ESP startup. The adjustment procedure should comply with the Operation Manual of the switchboard/VSD . Setting value of overload protection for microprocessor controller switchboards and insulation control protection is calculated by the formula: OP = 1.05 * Irated, where: OP is the setting value of overload protection; Irated is the motor rated current in amper (А). Overload protection setting actuation time is 30 sec.

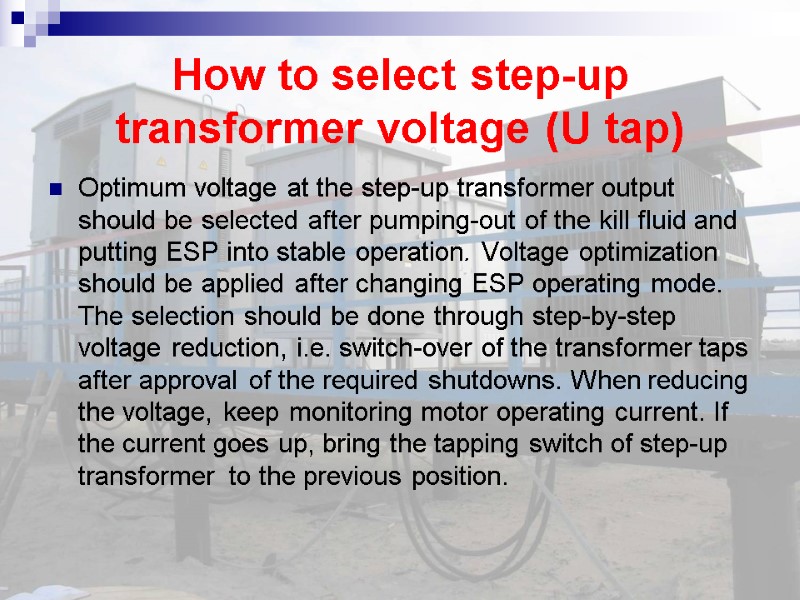

How to select step-up transformer voltage (U tap) Optimum voltage at the step-up transformer output should be selected after pumping-out of the kill fluid and putting ESP into stable operation. Voltage optimization should be applied after changing ESP operating mode. The selection should be done through step-by-step voltage reduction, i.е. switch-over of the transformer taps after approval of the required shutdowns. When reducing the voltage, keep monitoring motor operating current. If the current goes up, bring the tapping switch of step-up transformer to the previous position.

How to select step-up transformer voltage (U tap) Optimum voltage at the step-up transformer output should be selected after pumping-out of the kill fluid and putting ESP into stable operation. Voltage optimization should be applied after changing ESP operating mode. The selection should be done through step-by-step voltage reduction, i.е. switch-over of the transformer taps after approval of the required shutdowns. When reducing the voltage, keep monitoring motor operating current. If the current goes up, bring the tapping switch of step-up transformer to the previous position.

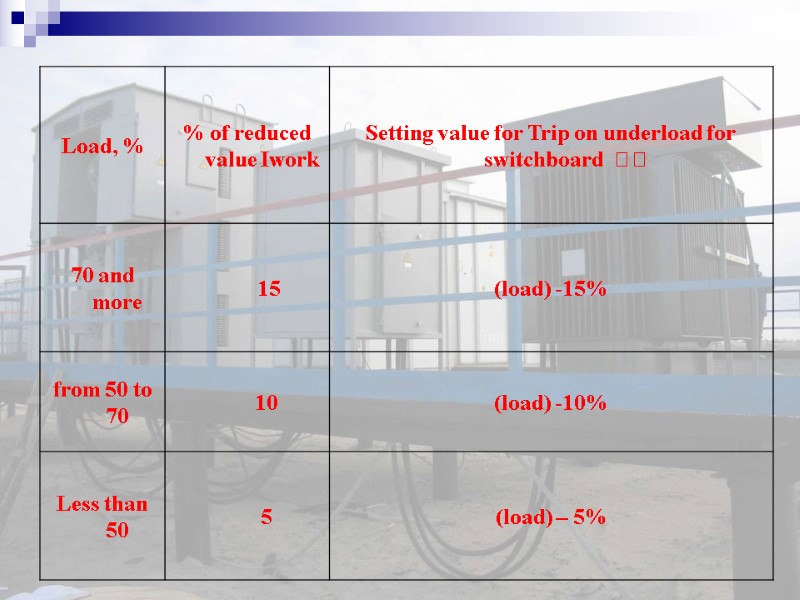

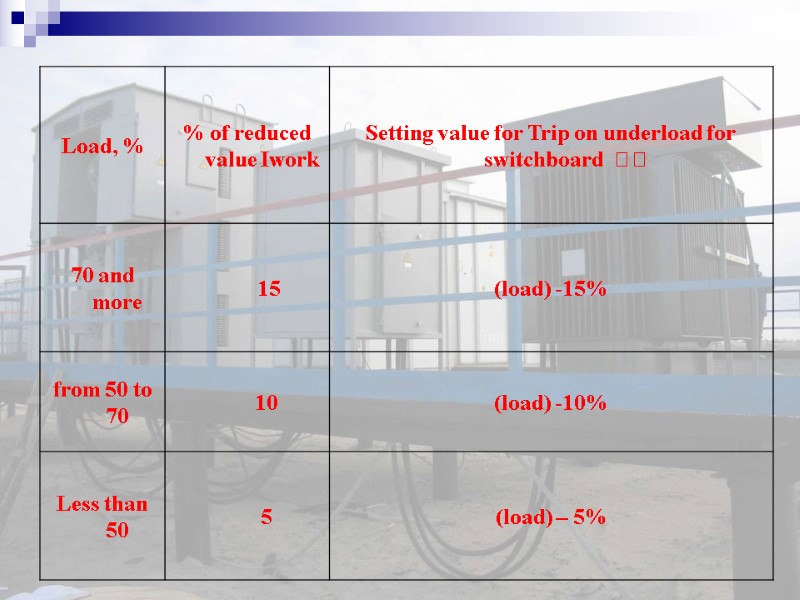

How to set motor underload protection - Underload setting during start-up should be 15% less than motor operating current. - Underload setting during commissioning of the well should be set according to Table B.1 after the optimal voltage is selected.

How to set motor underload protection - Underload setting during start-up should be 15% less than motor operating current. - Underload setting during commissioning of the well should be set according to Table B.1 after the optimal voltage is selected.

Protection against voltage spikes Voltage spikes protection is necessary for stable ESP operation. High-voltage protection setting: Umax = 420 V (110%). Actuation time delay should be set to 5 seconds. Low-voltage protection setting: Umin = 340 V (90%). Actuation time delay should be set to 5 seconds.

Protection against voltage spikes Voltage spikes protection is necessary for stable ESP operation. High-voltage protection setting: Umax = 420 V (110%). Actuation time delay should be set to 5 seconds. Low-voltage protection setting: Umin = 340 V (90%). Actuation time delay should be set to 5 seconds.

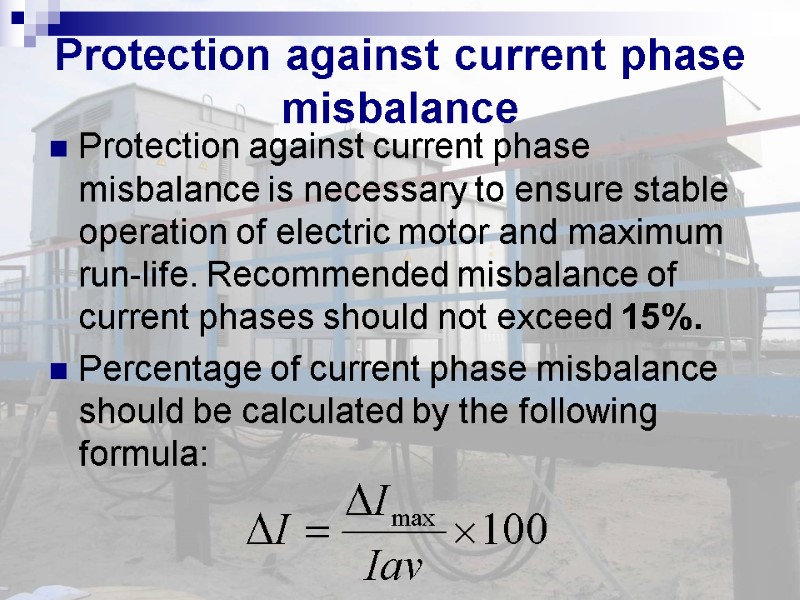

Protection against current phase misbalance Protection against current phase misbalance is necessary to ensure stable operation of electric motor and maximum run-life. Recommended misbalance of current phases should not exceed 15%. Percentage of current phase misbalance should be calculated by the following formula:

Protection against current phase misbalance Protection against current phase misbalance is necessary to ensure stable operation of electric motor and maximum run-life. Recommended misbalance of current phases should not exceed 15%. Percentage of current phase misbalance should be calculated by the following formula:

Protection against voltage phase misbalance Protection against voltage phase misbalance is necessary to ensure stable operation of electric motor. Misbalance of voltage phases should not exceed 5%.

Protection against voltage phase misbalance Protection against voltage phase misbalance is necessary to ensure stable operation of electric motor. Misbalance of voltage phases should not exceed 5%.

Insulation resistance protection of the ‘step-up transformer – cable – electric motor’ assembly Insulation resistance protection of the ‘step-up transformer – cable – electric motor’ assembly is intended to prevent short circuit of electrical components. Protection setting should not be less than 30 kohm. During conversion from standard mode to operation without control of insulation resistance): Switch off insulation control device or function; Actuation time of overload protection should be reduced to 5 sec.; Automatic restart should be switched to ‘Lock’ position for overload protection; When necessary, disconnect zero point.

Insulation resistance protection of the ‘step-up transformer – cable – electric motor’ assembly Insulation resistance protection of the ‘step-up transformer – cable – electric motor’ assembly is intended to prevent short circuit of electrical components. Protection setting should not be less than 30 kohm. During conversion from standard mode to operation without control of insulation resistance): Switch off insulation control device or function; Actuation time of overload protection should be reduced to 5 sec.; Automatic restart should be switched to ‘Lock’ position for overload protection; When necessary, disconnect zero point.

Backspin protection Backspin protection is intended to prevent ESP starting during fluid discharge from the tubing. The setting should be 5 Hertz. If switchboard includes this protection, automatic restart period for this switchboard should be set from 1 to 5 minutes.

Backspin protection Backspin protection is intended to prevent ESP starting during fluid discharge from the tubing. The setting should be 5 Hertz. If switchboard includes this protection, automatic restart period for this switchboard should be set from 1 to 5 minutes.

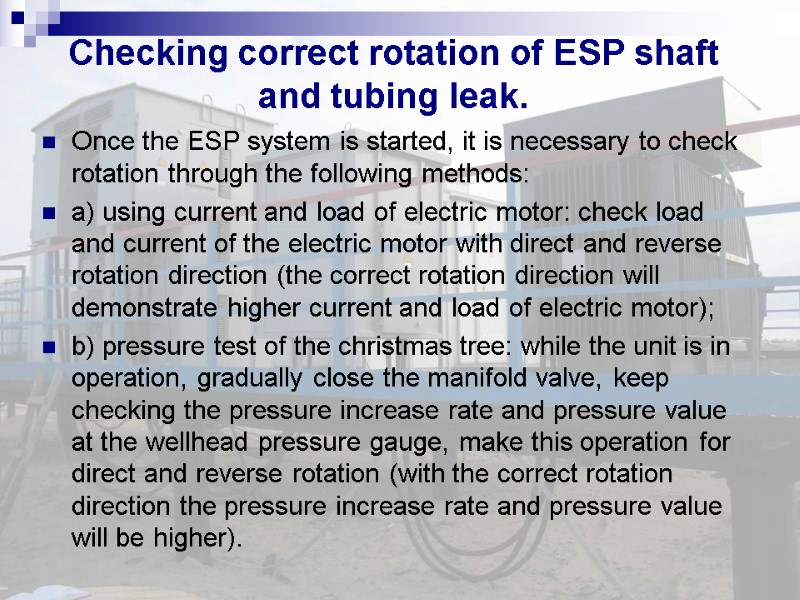

Checking correct rotation of ESP shaft and tubing leak. Once the ESP system is started, it is necessary to check rotation through the following methods: а) using current and load of electric motor: check load and current of the electric motor with direct and reverse rotation direction (the correct rotation direction will demonstrate higher current and load of electric motor); b) pressure test of the christmas tree: while the unit is in operation, gradually close the manifold valve, keep checking the pressure increase rate and pressure value at the wellhead pressure gauge, make this operation for direct and reverse rotation (with the correct rotation direction the pressure increase rate and pressure value will be higher).

Checking correct rotation of ESP shaft and tubing leak. Once the ESP system is started, it is necessary to check rotation through the following methods: а) using current and load of electric motor: check load and current of the electric motor with direct and reverse rotation direction (the correct rotation direction will demonstrate higher current and load of electric motor); b) pressure test of the christmas tree: while the unit is in operation, gradually close the manifold valve, keep checking the pressure increase rate and pressure value at the wellhead pressure gauge, make this operation for direct and reverse rotation (with the correct rotation direction the pressure increase rate and pressure value will be higher).

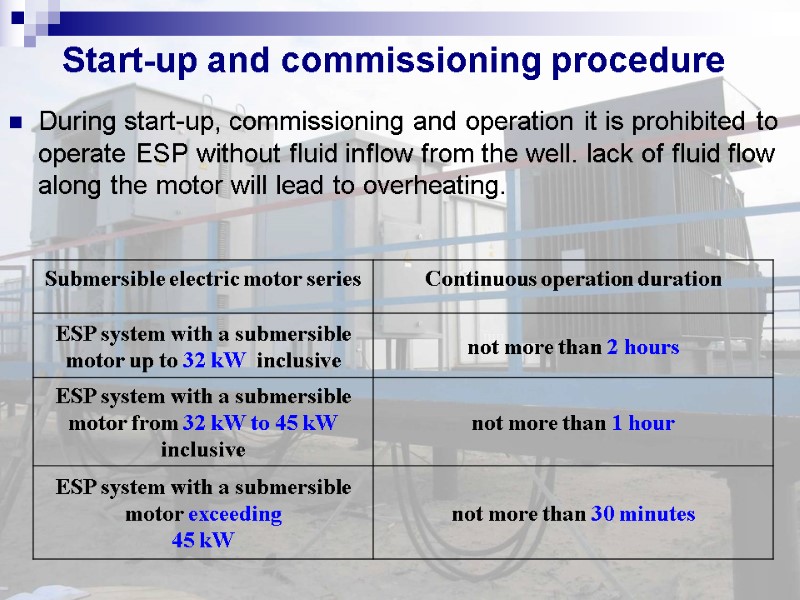

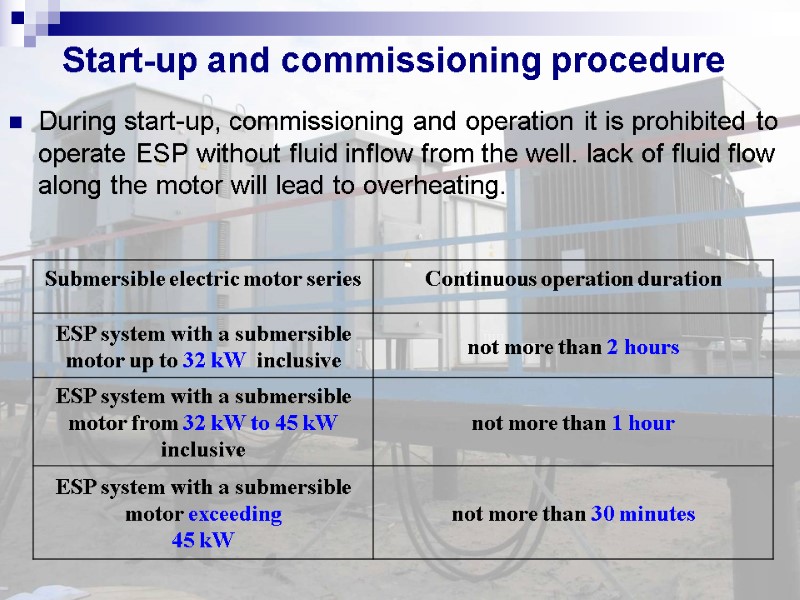

Start-up and commissioning procedure During start-up, commissioning and operation it is prohibited to operate ESP without fluid inflow from the well. lack of fluid flow along the motor will lead to overheating.

Start-up and commissioning procedure During start-up, commissioning and operation it is prohibited to operate ESP without fluid inflow from the well. lack of fluid flow along the motor will lead to overheating.

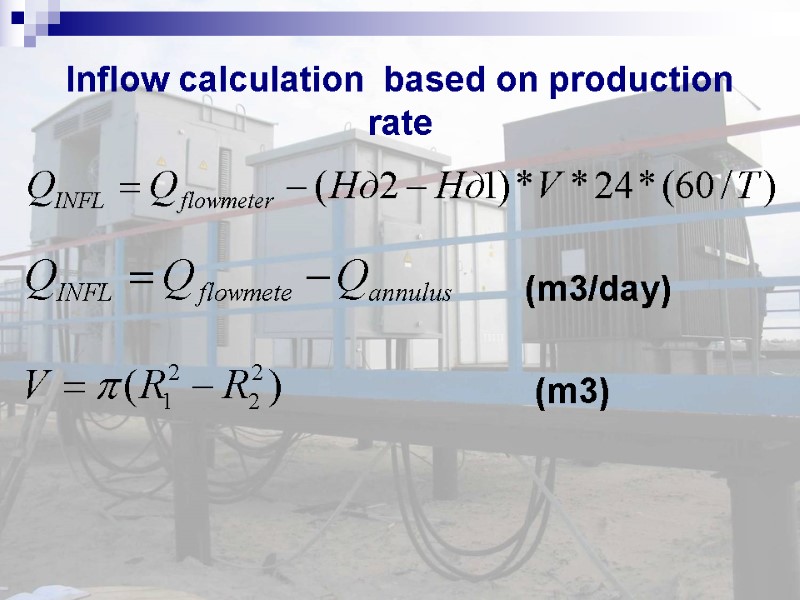

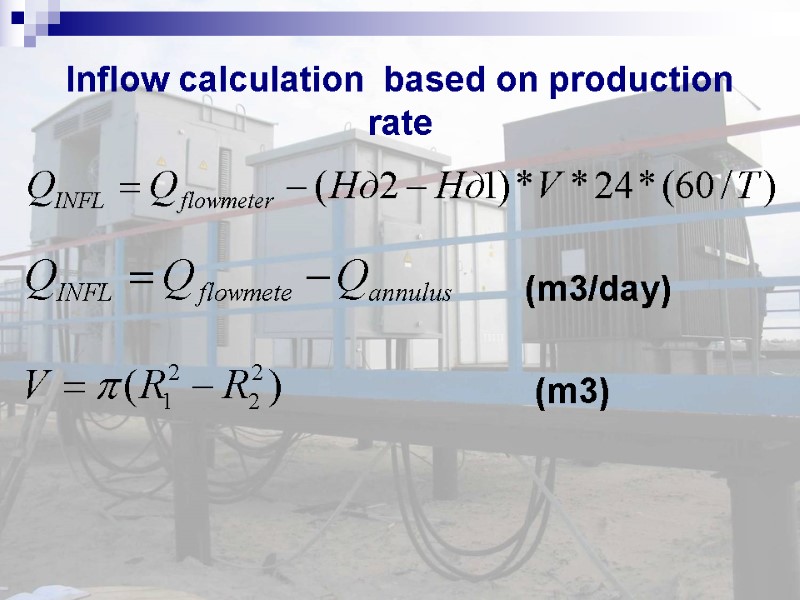

Inflow calculation based on production rate (m3/day) (m3)

Inflow calculation based on production rate (m3/day) (m3)

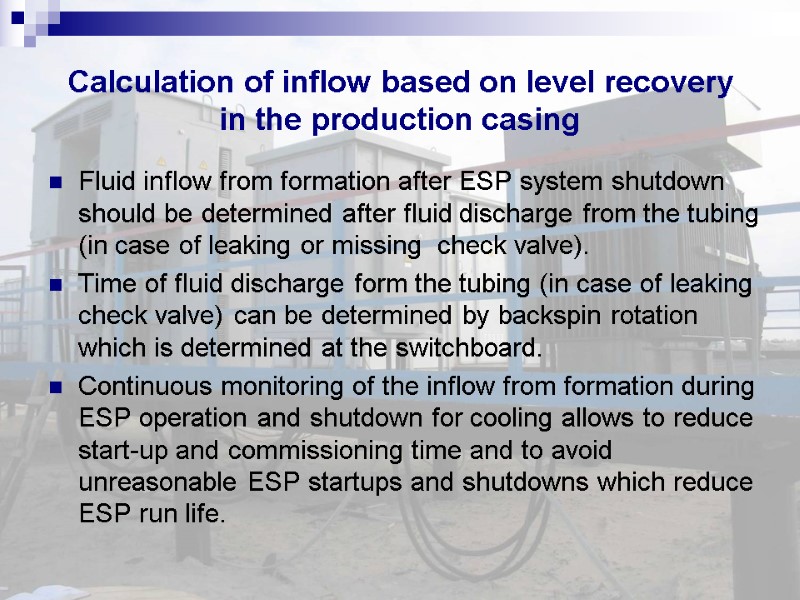

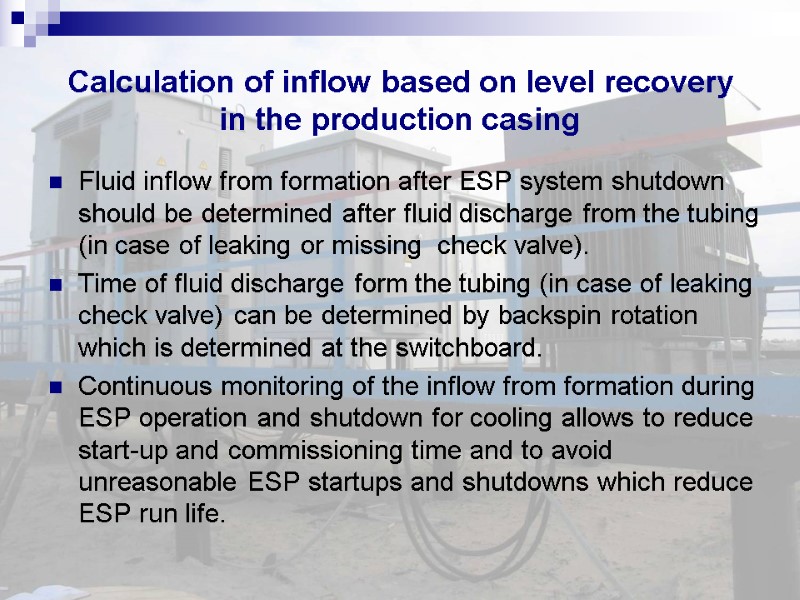

Calculation of inflow based on level recovery in the production casing Fluid inflow from formation after ESP system shutdown should be determined after fluid discharge from the tubing (in case of leaking or missing check valve). Time of fluid discharge form the tubing (in case of leaking check valve) can be determined by backspin rotation which is determined at the switchboard. Continuous monitoring of the inflow from formation during ESP operation and shutdown for cooling allows to reduce start-up and commissioning time and to avoid unreasonable ESP startups and shutdowns which reduce ESP run life.

Calculation of inflow based on level recovery in the production casing Fluid inflow from formation after ESP system shutdown should be determined after fluid discharge from the tubing (in case of leaking or missing check valve). Time of fluid discharge form the tubing (in case of leaking check valve) can be determined by backspin rotation which is determined at the switchboard. Continuous monitoring of the inflow from formation during ESP operation and shutdown for cooling allows to reduce start-up and commissioning time and to avoid unreasonable ESP startups and shutdowns which reduce ESP run life.

Final stage of the procedure The well is considered commissioned when flow rate and dynamic level have been stable for 6 hours, this time period may vary depending on well conditions, ESP size and completion, problemds during start-up, etc. Another criterion to commission the well is equal casing pressure and manifold pressure (Рcasing = Рmanifold), which is applicable for most of the wells.

Final stage of the procedure The well is considered commissioned when flow rate and dynamic level have been stable for 6 hours, this time period may vary depending on well conditions, ESP size and completion, problemds during start-up, etc. Another criterion to commission the well is equal casing pressure and manifold pressure (Рcasing = Рmanifold), which is applicable for most of the wells.

Specific features for commissioning procedure using a VSD

Specific features for commissioning procedure using a VSD

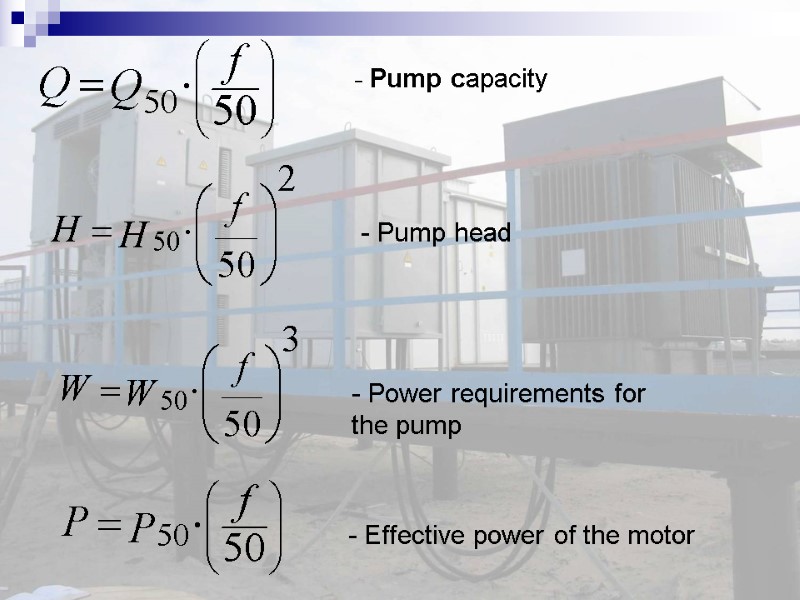

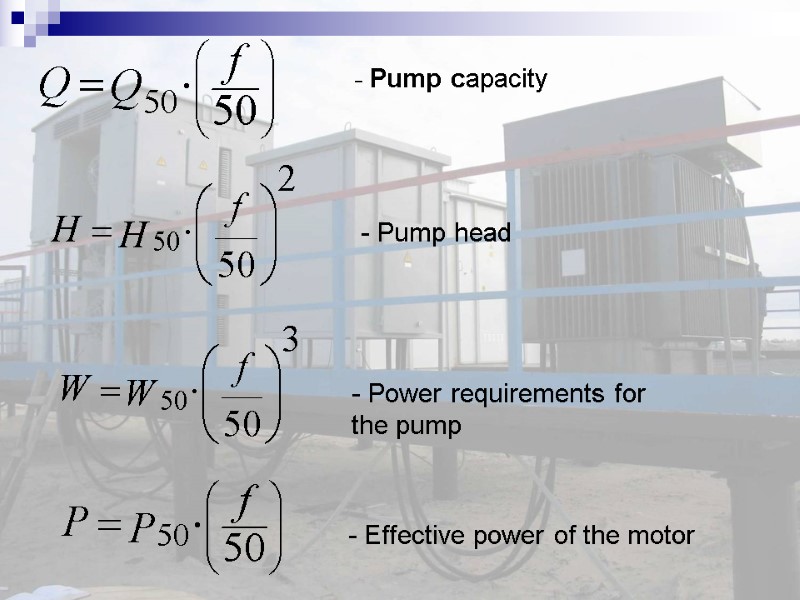

- Pump capacity - Pump head - Power requirements for the pump - Effective power of the motor

- Pump capacity - Pump head - Power requirements for the pump - Effective power of the motor

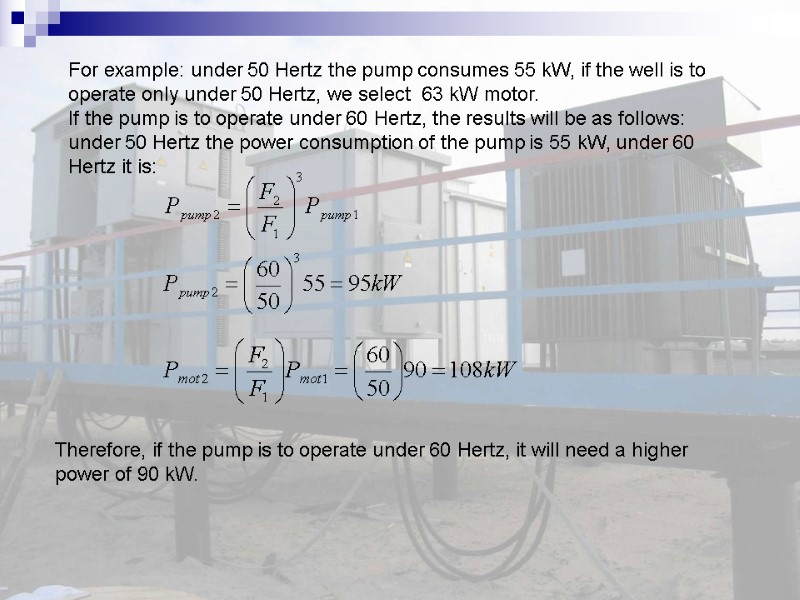

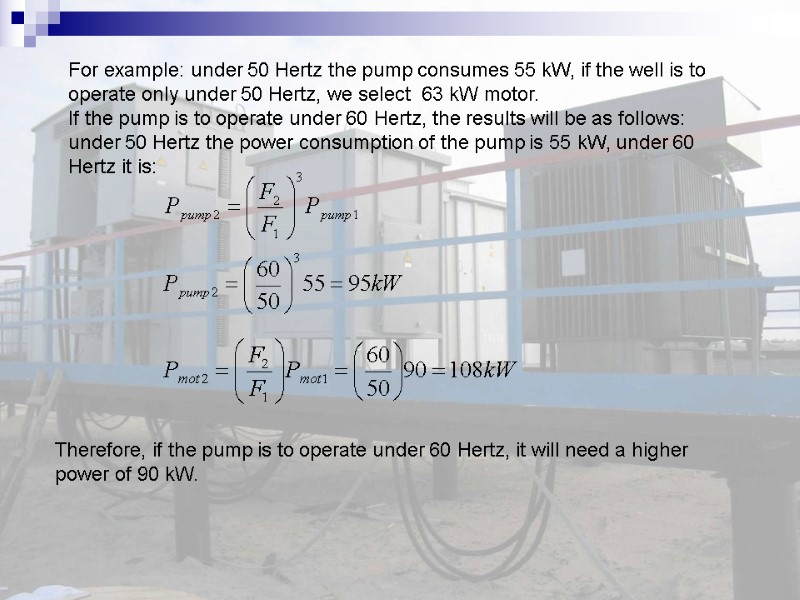

For example: under 50 Hertz the pump consumes 55 kW, if the well is to operate only under 50 Hertz, we select 63 kW motor. If the pump is to operate under 60 Hertz, the results will be as follows: under 50 Hertz the power consumption of the pump is 55 kW, under 60 Hertz it is: Therefore, if the pump is to operate under 60 Hertz, it will need a higher power of 90 kW.

For example: under 50 Hertz the pump consumes 55 kW, if the well is to operate only under 50 Hertz, we select 63 kW motor. If the pump is to operate under 60 Hertz, the results will be as follows: under 50 Hertz the power consumption of the pump is 55 kW, under 60 Hertz it is: Therefore, if the pump is to operate under 60 Hertz, it will need a higher power of 90 kW.

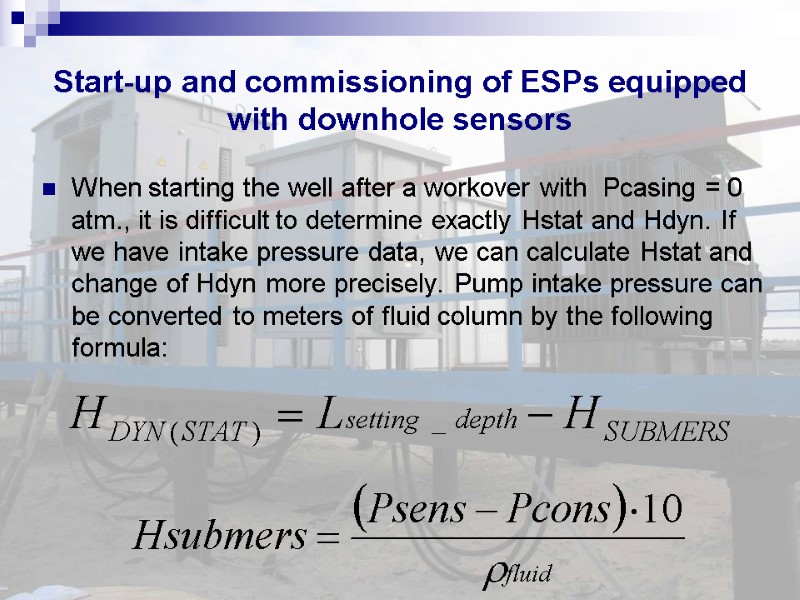

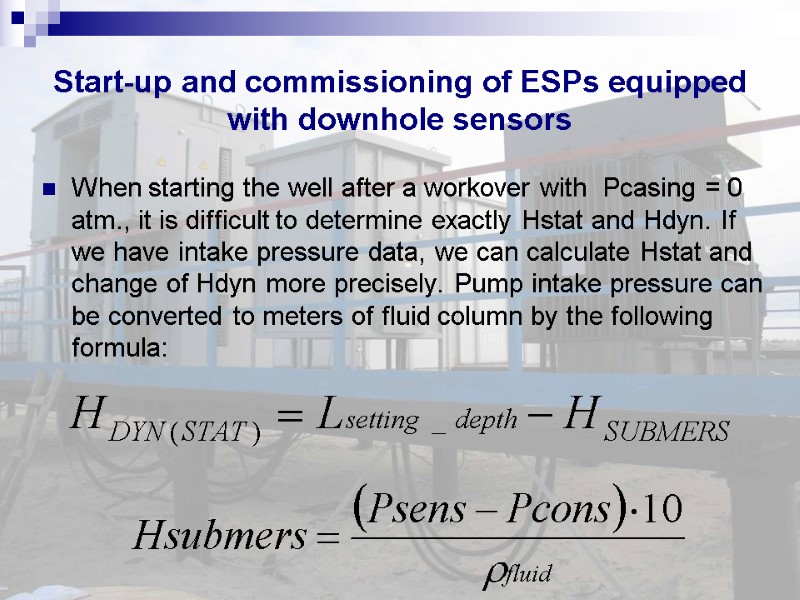

Start-up and commissioning of ESPs equipped with downhole sensors When starting the well after a workover with Рcasing = 0 atm., it is difficult to determine exactly Нstat and Нdyn. If we have intake pressure data, we can calculate Нstat and change of Нdyn more precisely. Pump intake pressure can be converted to meters of fluid column by the following formula:

Start-up and commissioning of ESPs equipped with downhole sensors When starting the well after a workover with Рcasing = 0 atm., it is difficult to determine exactly Нstat and Нdyn. If we have intake pressure data, we can calculate Нstat and change of Нdyn more precisely. Pump intake pressure can be converted to meters of fluid column by the following formula:

Advantages of VSD compared to switchboard during seizure troubleshooting During ESP operation, VSD has a number of considerable advantages compared to switchboard. These advantages can be clearly demonstrated during ESP startup and during wedging of seizure. The main advantage of VSD over switchboard both in normal ESP operation and during wedging of seizure is that VSD allows soft start of the unit. With the switchboard the motor during startup receives the voltage preset at the transformer.

Advantages of VSD compared to switchboard during seizure troubleshooting During ESP operation, VSD has a number of considerable advantages compared to switchboard. These advantages can be clearly demonstrated during ESP startup and during wedging of seizure. The main advantage of VSD over switchboard both in normal ESP operation and during wedging of seizure is that VSD allows soft start of the unit. With the switchboard the motor during startup receives the voltage preset at the transformer.

Firstly, in this case, there is a high probability of motor, seal or pump shaft fracture, especially if during wedging the voltage at the transformer is increased additionally. The result failure due to lack of fluid flow. Secondly, if motor shaft doesn’t move during start-up, all of the power supplied from the surface intended to generate torque goes to heating the motor winding and submersible cable. After a number of trials within a short period, this becomes the key reason for reduced insulation of ‘cable-motor’ assemble and hence, ‘R-0’ failure during seizure wedging. VSD allows to perform starting from 0-10 Hertz, therefore, the voltage supplied to the motor is also lower. As a result , the motor and the cable experience less heating. During startup of the unit the maximum torque is generated in the first 0.1-1 second. If the seizure is not wedging at this moment, the supplied power is used for heating during the remaining time till overload protection actuation.

Firstly, in this case, there is a high probability of motor, seal or pump shaft fracture, especially if during wedging the voltage at the transformer is increased additionally. The result failure due to lack of fluid flow. Secondly, if motor shaft doesn’t move during start-up, all of the power supplied from the surface intended to generate torque goes to heating the motor winding and submersible cable. After a number of trials within a short period, this becomes the key reason for reduced insulation of ‘cable-motor’ assemble and hence, ‘R-0’ failure during seizure wedging. VSD allows to perform starting from 0-10 Hertz, therefore, the voltage supplied to the motor is also lower. As a result , the motor and the cable experience less heating. During startup of the unit the maximum torque is generated in the first 0.1-1 second. If the seizure is not wedging at this moment, the supplied power is used for heating during the remaining time till overload protection actuation.

Another advantage of VSD over switchboard is opportunity to change rotation gradually without ESP shutdown (to avoid shaft fracture and slips of seal shafts) and application of various ejective methods of seizure troubleshooting. Rational application of these VSD functions combined with methods of wedging seizure described above considerably increases possibility of wedging ESP seizure. A competent approach to seizure troubleshooting using a VSD allows to avoid shaft fracture, motor and cable overheating and increases possibility of wedging compared to ESPs wth switchboard. Often, to wedging seizure we can use flushing (direct/(squeeze treatment) and reverse) by crude oil with solids or by formation water with scale. This causes deterioration of reservoir performance and killing of the well. Preparation for flushing takes 1 to 5 hours. Application of VSD allows to restart the unit without special tools, machines and no waste of time. Wedging ESP seizure using a VSD should be performed by competent personnel with enough knowledge, skills and experience to use a VSD.

Another advantage of VSD over switchboard is opportunity to change rotation gradually without ESP shutdown (to avoid shaft fracture and slips of seal shafts) and application of various ejective methods of seizure troubleshooting. Rational application of these VSD functions combined with methods of wedging seizure described above considerably increases possibility of wedging ESP seizure. A competent approach to seizure troubleshooting using a VSD allows to avoid shaft fracture, motor and cable overheating and increases possibility of wedging compared to ESPs wth switchboard. Often, to wedging seizure we can use flushing (direct/(squeeze treatment) and reverse) by crude oil with solids or by formation water with scale. This causes deterioration of reservoir performance and killing of the well. Preparation for flushing takes 1 to 5 hours. Application of VSD allows to restart the unit without special tools, machines and no waste of time. Wedging ESP seizure using a VSD should be performed by competent personnel with enough knowledge, skills and experience to use a VSD.

Checking ESP operation mode 3 days after ESP commissioning (not later than 7 days), an electrician and a Customer’s representative check the operation mode of the ESP by checking flow rate measurements, dynamic level, manifold, wellhead and annulus pressure; when setting the automatic restart time take into account the time required to discharge the fluid from the tubing (in case of the leaking or missing check valve); The electrician and a Customer’s representative perform adjustment of the switchboard protections based on Нd, flow rate and operating current. The electrician selects the optimum motor voltage by adjusting transformer taps or changing the base frequency or base frequency voltage, and checks the ESP insulation resistance. After that, based on achieved operating current he adjusts the switchboard protections. Minimum current is selected in order to ensure optimum load of the motor and to reduce heat losses. Settings and protections made are subject to approval by the Customer.

Checking ESP operation mode 3 days after ESP commissioning (not later than 7 days), an electrician and a Customer’s representative check the operation mode of the ESP by checking flow rate measurements, dynamic level, manifold, wellhead and annulus pressure; when setting the automatic restart time take into account the time required to discharge the fluid from the tubing (in case of the leaking or missing check valve); The electrician and a Customer’s representative perform adjustment of the switchboard protections based on Нd, flow rate and operating current. The electrician selects the optimum motor voltage by adjusting transformer taps or changing the base frequency or base frequency voltage, and checks the ESP insulation resistance. After that, based on achieved operating current he adjusts the switchboard protections. Minimum current is selected in order to ensure optimum load of the motor and to reduce heat losses. Settings and protections made are subject to approval by the Customer.

ESP shutdowns during operation

ESP shutdowns during operation

Reasons for shutdown ESP shutdown due to overload (OP) protection ESP shutdown due to underload ESP shutdown due to insulation control protection Reduced (no) flow Electric power cut (scheduled and emergency cases)

Reasons for shutdown ESP shutdown due to overload (OP) protection ESP shutdown due to underload ESP shutdown due to insulation control protection Reduced (no) flow Electric power cut (scheduled and emergency cases)

ESP shutdown by overload protection The reasons for overload shutdown may be as follows: - Seizure of pump due to plugging. - Incorrect selection of voltage tapping. - Penetration of formation fluid into the motor. - Low supply voltage - Improper adjustment of the switchboard

ESP shutdown by overload protection The reasons for overload shutdown may be as follows: - Seizure of pump due to plugging. - Incorrect selection of voltage tapping. - Penetration of formation fluid into the motor. - Low supply voltage - Improper adjustment of the switchboard

Make sure the following is serviceable and functioning: insulation control protection, overload protection, insulation resistance and a ‘star’ monitoring, serviceability of switchboard controller; Disconnect submersible cable form the junction box, wipe the wires dry and strip the surface of conducts of the submersible cable, measure the insulation resistance of ‘cable-motor’ system and ‘switchboard –vent box’ system using an ohmmeter and determine if there a ‘star’ at ‘cable-motor’, visually check condition of the cable from the junction box to the christmas tree (insulation melting, mechanical damage); Check supply voltage at the phases at the low and high voltage sides of the step-up transformer. Make a test run of the switchboard with the ESP cable disconnected. Check the supply voltage at the phases of the switchboard. If the insulation resistance exceeds 1 MOhm, proceed with the startup of the unit. Measure the current at the phases by clamp meter at the high and low sides of the transformer. Phase misbalance in terms of voltage and current should not exceed 3 and 15% respectively. Compare the readings of the ammeter and of the switchboard controller, if necessary adjust the readings of the controller; Monitor the operation mode until desired operational parameters are achieved (flow rate, dynamic level, watercut).

Make sure the following is serviceable and functioning: insulation control protection, overload protection, insulation resistance and a ‘star’ monitoring, serviceability of switchboard controller; Disconnect submersible cable form the junction box, wipe the wires dry and strip the surface of conducts of the submersible cable, measure the insulation resistance of ‘cable-motor’ system and ‘switchboard –vent box’ system using an ohmmeter and determine if there a ‘star’ at ‘cable-motor’, visually check condition of the cable from the junction box to the christmas tree (insulation melting, mechanical damage); Check supply voltage at the phases at the low and high voltage sides of the step-up transformer. Make a test run of the switchboard with the ESP cable disconnected. Check the supply voltage at the phases of the switchboard. If the insulation resistance exceeds 1 MOhm, proceed with the startup of the unit. Measure the current at the phases by clamp meter at the high and low sides of the transformer. Phase misbalance in terms of voltage and current should not exceed 3 and 15% respectively. Compare the readings of the ammeter and of the switchboard controller, if necessary adjust the readings of the controller; Monitor the operation mode until desired operational parameters are achieved (flow rate, dynamic level, watercut).

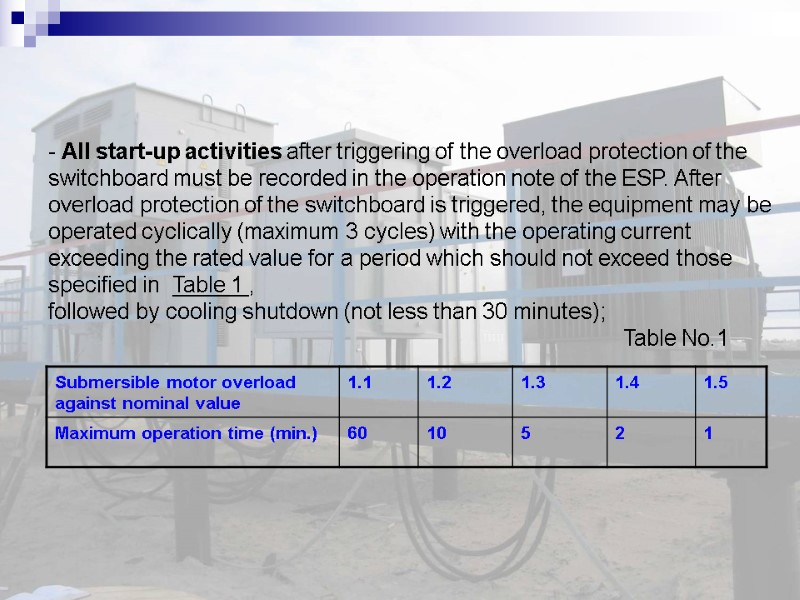

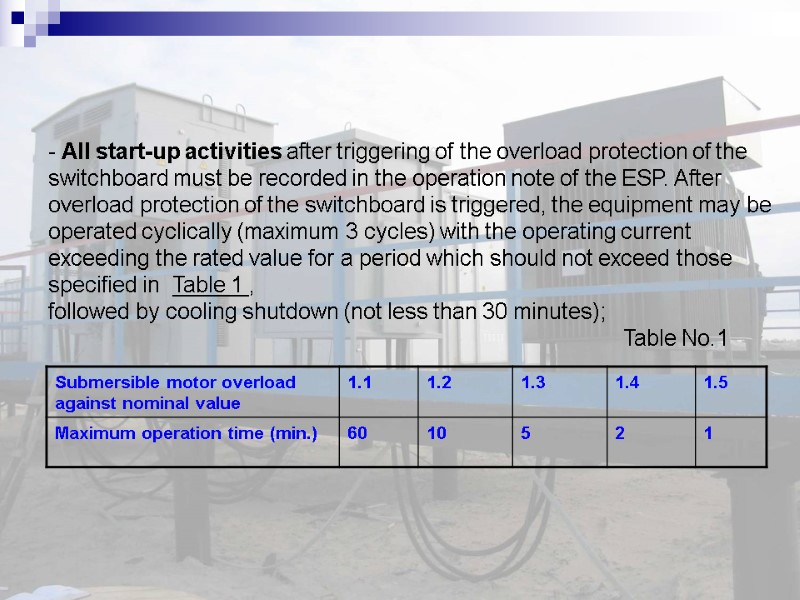

- All start-up activities after triggering of the overload protection of the switchboard must be recorded in the operation note of the ESP. After overload protection of the switchboard is triggered, the equipment may be operated cyclically (maximum 3 cycles) with the operating current exceeding the rated value for a period which should not exceed those specified in Table 1 , followed by cooling shutdown (not less than 30 minutes); Table No.1

- All start-up activities after triggering of the overload protection of the switchboard must be recorded in the operation note of the ESP. After overload protection of the switchboard is triggered, the equipment may be operated cyclically (maximum 3 cycles) with the operating current exceeding the rated value for a period which should not exceed those specified in Table 1 , followed by cooling shutdown (not less than 30 minutes); Table No.1

If the load current is not reduced to the rated value, a artificial lift engineer makes a decision about additional activites (flushing, seizure unlock with a VSD, etc.) or ESP pulling; After the load current reaches the rated value or becomes lower, make optimization of the transformer voltage and re-adjust the overload and under-load protections; If a decision is made to pull the ESP, shut down the unit. An electrician will scan the data of the controller and disconnect the cable from the junction box according to the safety requirements.

If the load current is not reduced to the rated value, a artificial lift engineer makes a decision about additional activites (flushing, seizure unlock with a VSD, etc.) or ESP pulling; After the load current reaches the rated value or becomes lower, make optimization of the transformer voltage and re-adjust the overload and under-load protections; If a decision is made to pull the ESP, shut down the unit. An electrician will scan the data of the controller and disconnect the cable from the junction box according to the safety requirements.

ESP shutdown due to underload, low production The following may lead to Underload / low production shutdown: Gas lock. Tubing plugging with paraffin. Tubing leak. Plugging of the choke at the christmas tree. Low dynamic level. Pump wear Shaft fracture

ESP shutdown due to underload, low production The following may lead to Underload / low production shutdown: Gas lock. Tubing plugging with paraffin. Tubing leak. Plugging of the choke at the christmas tree. Low dynamic level. Pump wear Shaft fracture

Disconnect the submersible cable from the junction box. Check correctness and functioning of underload protection without downhole equipment; Check the supply voltage at the phases at the low and high sides of the transformer; Check the current at the phases by clamp meter at the low and high sides of the transformer; Connect the unit, proceed with the startup; Compare the readings of the ammeter with switchboard controller, if necessary adjust the readings of the controller; Check serviceability of the current and voltage meter when reaching the working value of the dynamic level; Check pressure generated by the pump with the closed manifold valve. Not more than 60 atm.;

Disconnect the submersible cable from the junction box. Check correctness and functioning of underload protection without downhole equipment; Check the supply voltage at the phases at the low and high sides of the transformer; Check the current at the phases by clamp meter at the low and high sides of the transformer; Connect the unit, proceed with the startup; Compare the readings of the ammeter with switchboard controller, if necessary adjust the readings of the controller; Check serviceability of the current and voltage meter when reaching the working value of the dynamic level; Check pressure generated by the pump with the closed manifold valve. Not more than 60 atm.;

Check the measurement results for compliance with head capacity curve of the particular ESP series; Check the tubing for paraffin; In case of low or zero production, make reverse flushing through the pump with the simultaneous startup of the ESP (by water or inhibitor solution to remove the paraffin, if the equipment permits), in case of parrafins in the tubing, use hot oil (temperature not more than 80 С); Once the reason of underload is determined, the electrician should read out the database from the controller. Electrician and production engineer make a decision about further ESP operation (with adjusted switchboard/VSD settings), or ESP pulling.

Check the measurement results for compliance with head capacity curve of the particular ESP series; Check the tubing for paraffin; In case of low or zero production, make reverse flushing through the pump with the simultaneous startup of the ESP (by water or inhibitor solution to remove the paraffin, if the equipment permits), in case of parrafins in the tubing, use hot oil (temperature not more than 80 С); Once the reason of underload is determined, the electrician should read out the database from the controller. Electrician and production engineer make a decision about further ESP operation (with adjusted switchboard/VSD settings), or ESP pulling.

ESP shutdown due to insulation control protection Poor insulation may be caused by: Penetration of formation fluid into the motor. Submersible cable crush. Surface cable crush. Faulty insulation control unit. Insulation deterioration in the input at the tubing adaptor.

ESP shutdown due to insulation control protection Poor insulation may be caused by: Penetration of formation fluid into the motor. Submersible cable crush. Surface cable crush. Faulty insulation control unit. Insulation deterioration in the input at the tubing adaptor.

Check serviceability and functioning of the insulation control, overload protection, underload protection; Disconnect submersible cable form the junction box, wipe the wires dry and strip the surface of conducts of the submersible cable, measure the insulation resistance of ‘cable-motor’ system and ‘switchboard –vent box’ assembly using an ohmmeter and determine if there a ‘star’ at ‘cable-motor’, visually check condition of the cable from the junction box to the switchboard (melting, mechanical damage, burn); When there are no problems (‘star’ available at ‘cable-motor’, insulation of ‘cable-motor’ and ‘switchboard-junction box’ is more than 1 MOhm, no melting, mechanical damage of the cable on the surface), repeat ESP startup; When there are problems revealed (‘star’ is not available at ‘cable-motor’, insulation of ‘cable-motor’ and ‘switchboard-vent box’ is 1 MOhm or less, melting, mechanical damage of the cable on the surface) inform the production department. Further operation should be controlled by the production department; Decision to start-up ESP with the switched off insulation control system may be taken only upon approval from the artificial lift engineer and requires re-adjustment of the fast-response overload protection from the operating current; Record in detail the results of the works performed in the operations note and operations log.

Check serviceability and functioning of the insulation control, overload protection, underload protection; Disconnect submersible cable form the junction box, wipe the wires dry and strip the surface of conducts of the submersible cable, measure the insulation resistance of ‘cable-motor’ system and ‘switchboard –vent box’ assembly using an ohmmeter and determine if there a ‘star’ at ‘cable-motor’, visually check condition of the cable from the junction box to the switchboard (melting, mechanical damage, burn); When there are no problems (‘star’ available at ‘cable-motor’, insulation of ‘cable-motor’ and ‘switchboard-junction box’ is more than 1 MOhm, no melting, mechanical damage of the cable on the surface), repeat ESP startup; When there are problems revealed (‘star’ is not available at ‘cable-motor’, insulation of ‘cable-motor’ and ‘switchboard-vent box’ is 1 MOhm or less, melting, mechanical damage of the cable on the surface) inform the production department. Further operation should be controlled by the production department; Decision to start-up ESP with the switched off insulation control system may be taken only upon approval from the artificial lift engineer and requires re-adjustment of the fast-response overload protection from the operating current; Record in detail the results of the works performed in the operations note and operations log.

Electric power cut (scheduled and emergency) Startup the ESP system at the minimum frequency (depending on the fluid level in the annulus) with the compulsory adjustment of under-load protection; Based on startup results, make a decision to increase ESP frequency to the previous operating level (before the shutdown); After the ESP reaches the frequency used before the shutdown, make the decision on further frequency increase based on the operating parameters with the voltage optimization through changed basic frequency and adjusted under-load protection.

Electric power cut (scheduled and emergency) Startup the ESP system at the minimum frequency (depending on the fluid level in the annulus) with the compulsory adjustment of under-load protection; Based on startup results, make a decision to increase ESP frequency to the previous operating level (before the shutdown); After the ESP reaches the frequency used before the shutdown, make the decision on further frequency increase based on the operating parameters with the voltage optimization through changed basic frequency and adjusted under-load protection.

Unlocking ESP seizure by special machines The idea is to flush the ESP system by a fluid involving special machines. The flushing may be direct (through tubing) and reverse (through annulus). If the tubing is not equipped with a check valve (as a rule, in case of high performance ESPs) or the check valve is leaking, make direct ESP flushing through tubing. In other cases make a reverse flushing through the annulus. In ESP –produced wells the annulus fluid level is normally low. To create circulation through the unit in case of reverse flushing, we need fluid volume comparable to the kill fluid volume (~15m3). Reverse flushing is not feasible in wells where formation consumes fluid during reverse flushing, because it is impossible to create circulation in this case.

Unlocking ESP seizure by special machines The idea is to flush the ESP system by a fluid involving special machines. The flushing may be direct (through tubing) and reverse (through annulus). If the tubing is not equipped with a check valve (as a rule, in case of high performance ESPs) or the check valve is leaking, make direct ESP flushing through tubing. In other cases make a reverse flushing through the annulus. In ESP –produced wells the annulus fluid level is normally low. To create circulation through the unit in case of reverse flushing, we need fluid volume comparable to the kill fluid volume (~15m3). Reverse flushing is not feasible in wells where formation consumes fluid during reverse flushing, because it is impossible to create circulation in this case.

Procedure: Electrician increases voltage at the transformer (switch over tappings by three to five taps to increase the voltage). If necessary, replace surface electric equipment. Operator closes the annulus valve; Prepare the injection line depending on the type of flushing (direct, reverse), connect the line to wellhead or annulus; Direct flushing: - inject at least 10-15 m3 of fluid into the tubing, stop flushing, close wellhead valve, startup the unit in reverse (for ESPs with a motor of up to 63 kW inclusive), if the ESP motor is more than 63 kW, the decision about startup in reverse should be made by the production department; - if the unit is successfully started, leave it running for 10-15minutes, after that change to direct rotation. - if the unit is successfully started in direct rotation, leave it running, keep monitoring the well operation till the flow is stabilized to ensure proper cooling of the motor. - if the operating current did not reduce during reverse rotation (Iw>Inom), even after voltage increase, or the unit could not be started in direct rotation after reverse rotation, shutdown the unit to cool it down for at least 1 hour, then repeat the cycle of the operations (not more than 3 cycles).

Procedure: Electrician increases voltage at the transformer (switch over tappings by three to five taps to increase the voltage). If necessary, replace surface electric equipment. Operator closes the annulus valve; Prepare the injection line depending on the type of flushing (direct, reverse), connect the line to wellhead or annulus; Direct flushing: - inject at least 10-15 m3 of fluid into the tubing, stop flushing, close wellhead valve, startup the unit in reverse (for ESPs with a motor of up to 63 kW inclusive), if the ESP motor is more than 63 kW, the decision about startup in reverse should be made by the production department; - if the unit is successfully started, leave it running for 10-15minutes, after that change to direct rotation. - if the unit is successfully started in direct rotation, leave it running, keep monitoring the well operation till the flow is stabilized to ensure proper cooling of the motor. - if the operating current did not reduce during reverse rotation (Iw>Inom), even after voltage increase, or the unit could not be started in direct rotation after reverse rotation, shutdown the unit to cool it down for at least 1 hour, then repeat the cycle of the operations (not more than 3 cycles).

Thank you for your attention Questions are welcome

Thank you for your attention Questions are welcome