6e89fd0ef05856aed32607e6662477dd.ppt

- Количество слайдов: 46

ERSA Hybrid Rework Technology: A Benchtop Revolution ERSA Gmb. H Wertheim, Germany © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 Page

ERSA Hybrid Rework Benchtop Rework Requirements Technical requirements for Bench Top Rework Systems Market Needs © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 2

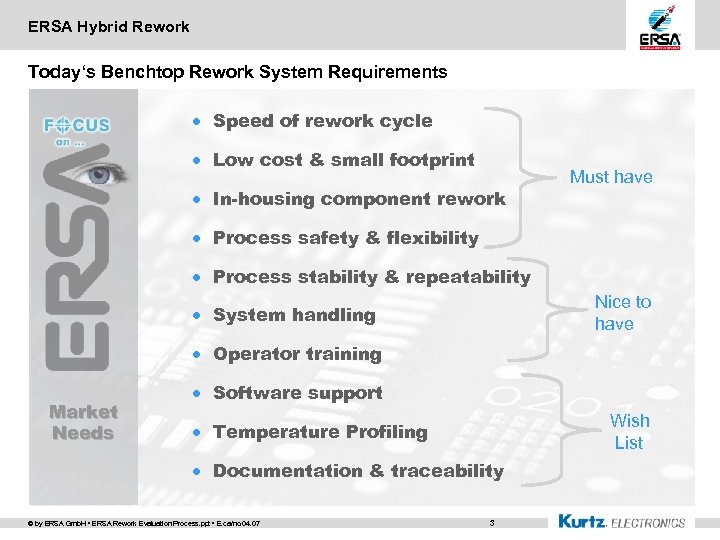

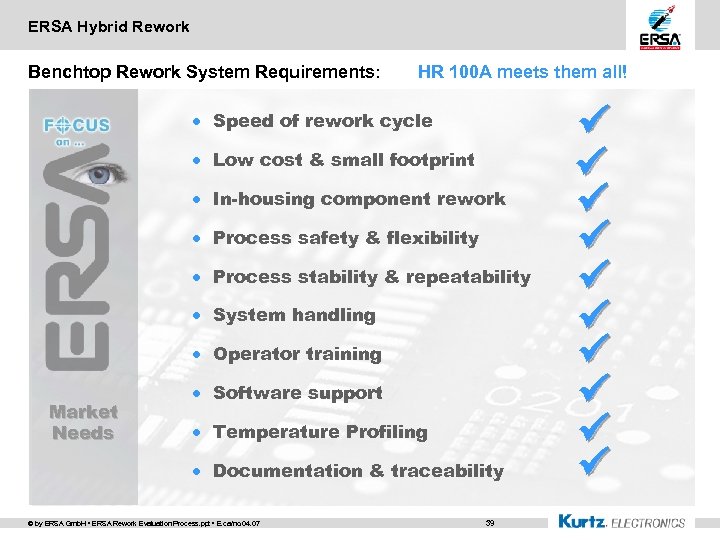

ERSA Hybrid Rework Today‘s Benchtop Rework System Requirements · Speed of rework cycle · Low cost & small footprint · In-housing component rework Must have · Process safety & flexibility · Process stability & repeatability Nice to have · System handling · Operator training Market Needs · Software support Wish List · Temperature Profiling · Documentation & traceability © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 3

ERSA Hybrid Rework The need for something new Lead Free Rework on small SMDs … ● Hot tweezers can shock the component ● Hot air blowers can blow adjacent components away ● Short wavelength IR tools can overheat component ● PCB still in its housing is difficult to rework ● Low budget, small workspace available Hybrid No More Need to Compromise! ERSA puts an end to these rework challenges! © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 4

ERSA Hybrid Rework A true innovation Hybrid Technology: The Benchtop Rework Revolution Hybrid © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 5

ERSA Hybrid Rework Combining the best of both worlds Combining the best of Safe IR & Hot Air Technology © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 6

ERSA Hybrid Rework A standard for the future Technology The best of both worlds! © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 7

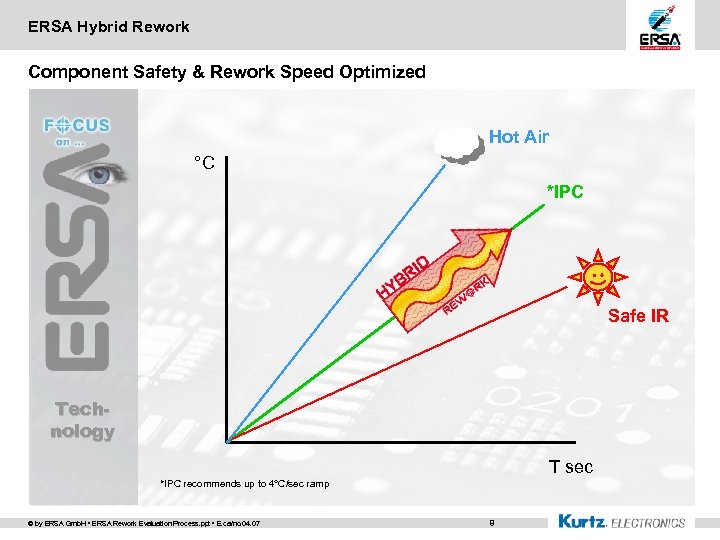

ERSA Hybrid Rework Component Safety & Rework Speed Optimized Hot Air °C *IPC Safe IR Technology T sec *IPC recommends up to 4°C/sec ramp © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 8

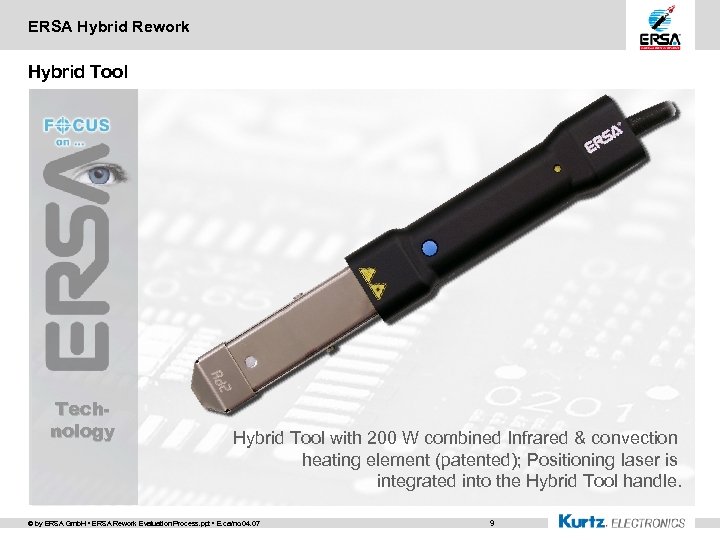

ERSA Hybrid Rework Hybrid Tool Technology Hybrid Tool with 200 W combined Infrared & convection heating element (patented); Positioning laser is integrated into the Hybrid Tool handle. © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 9

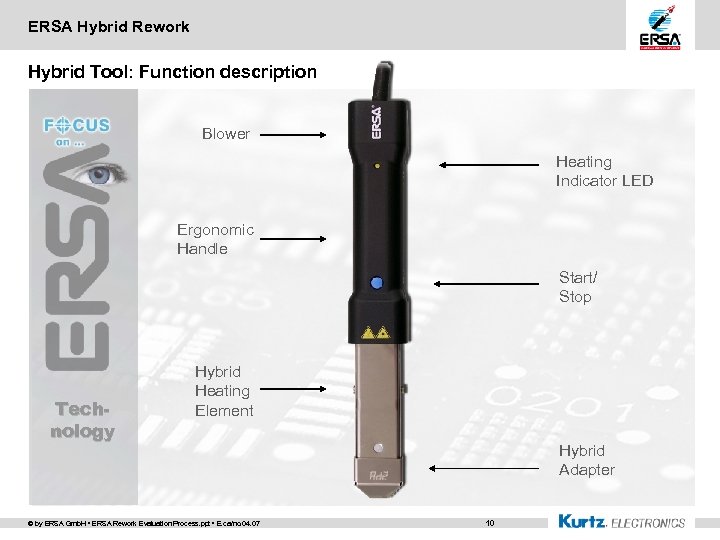

ERSA Hybrid Rework Hybrid Tool: Function description Blower Heating Indicator LED Ergonomic Handle Start/ Stop Technology Hybrid Heating Element © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 Hybrid Adapter 10

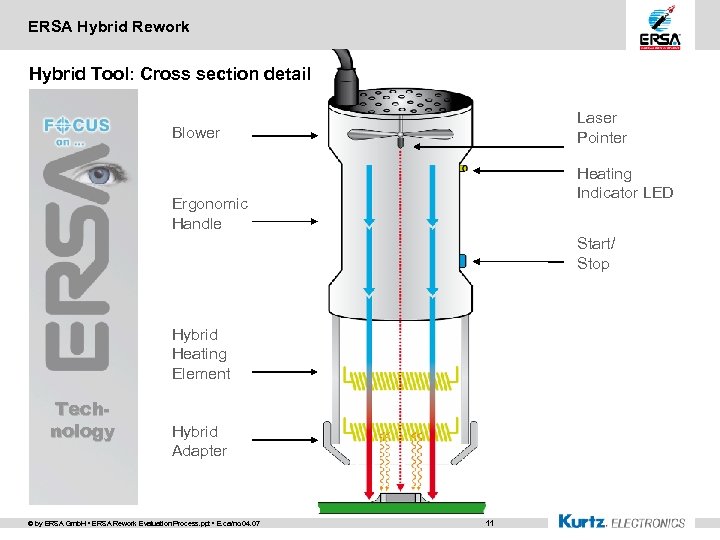

ERSA Hybrid Rework Hybrid Tool: Cross section detail Laser Pointer Blower Heating Indicator LED Ergonomic Handle Start/ Stop Hybrid Heating Element Technology Hybrid Adapter © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 11

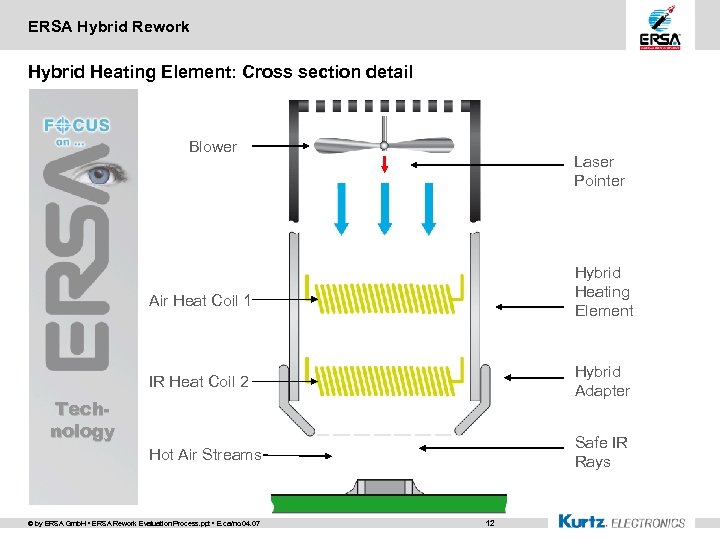

ERSA Hybrid Rework Hybrid Heating Element: Cross section detail Blower Laser Pointer Hybrid Heating Element Air Heat Coil 1 IR Heat Coil 2 Hybrid Adapter Hot Air Streams Safe IR Rays Technology © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 12

ERSA Hybrid Rework Hybrid Adapters: Ad 1, Ad 2 and Ad 3 Technology Ad 1: 20 x 20 mm Ad 2: 10 x 10 mm Ad 3 6 x 6 mm Three exchangeable Hybrid Adaptors included. © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 13

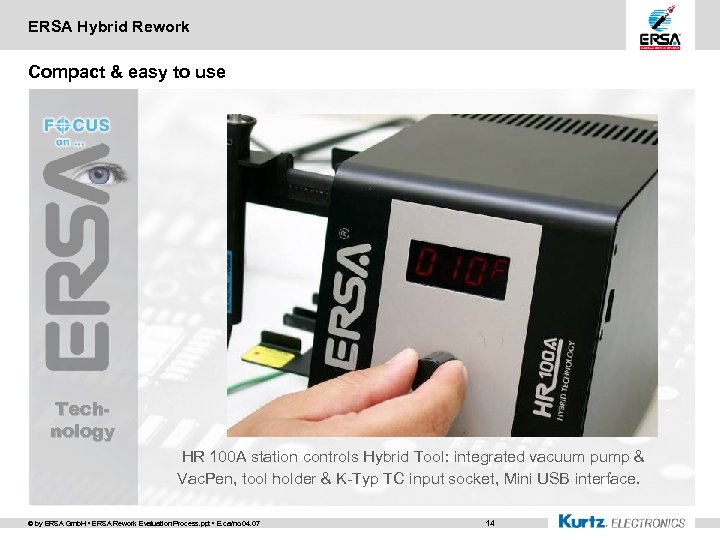

ERSA Hybrid Rework Compact & easy to use Technology HR 100 A station controls Hybrid Tool: integrated vacuum pump & Vac. Pen, tool holder & K-Typ TC input socket, Mini USB interface. © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 14

ERSA Hybrid Rework User Friendly Menu · Standard Rework Programs: Ad 1 to Ad 3 · IR Energy level & blower speed setting · Run time or temperature displayed · 7 -segment LED- display Technology · Single knob “Turn & Push” control © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 15

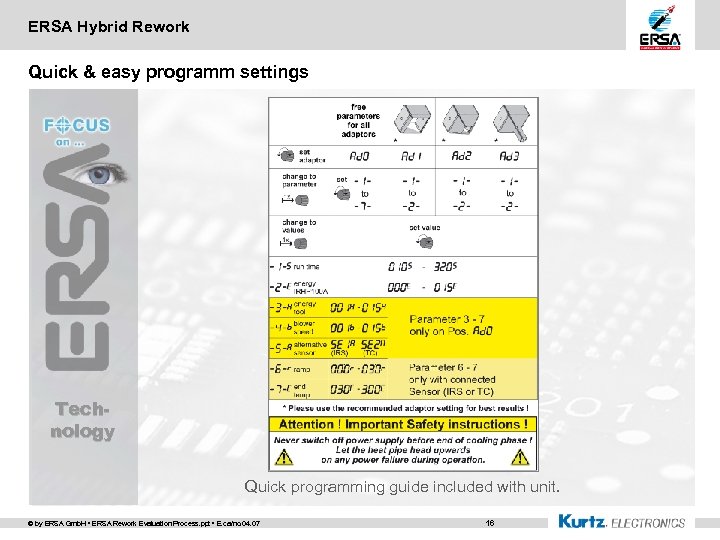

ERSA Hybrid Rework Quick & easy programm settings Technology Quick programming guide included with unit. © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 16

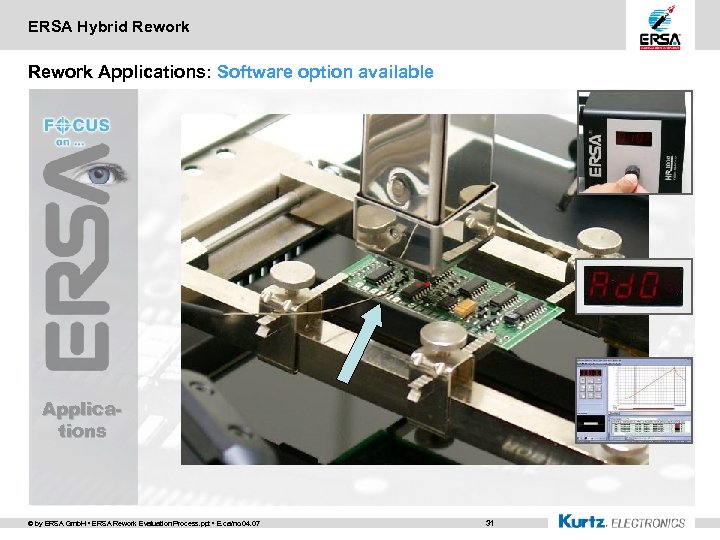

ERSA Hybrid Rework IRSoft Rework Software (optional) · Individual Parameter settings · Closed loop Ramp profiles · Process Profile recording & documentation · User Level Access · 2 Channel temp. recording option: TC & IRS Technology · Start/Stop & Vac. Pen software operated © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 17

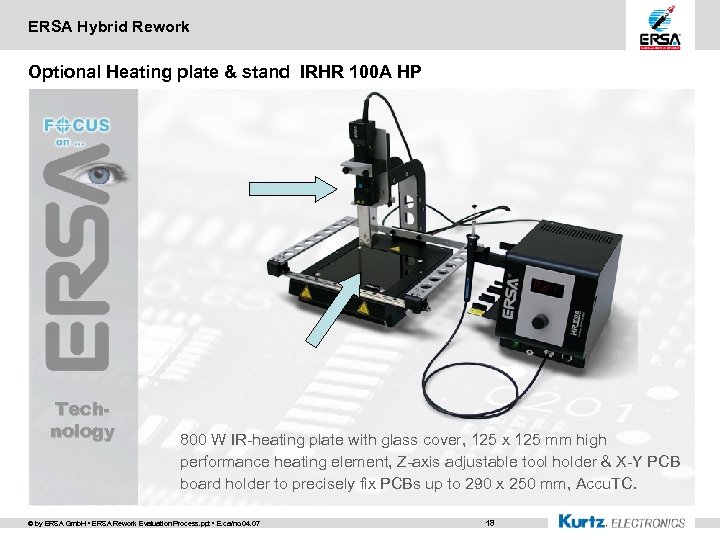

ERSA Hybrid Rework Optional Heating plate & stand IRHR 100 A HP Technology 800 W IR-heating plate with glass cover, 125 x 125 mm high performance heating element, Z-axis adjustable tool holder & X-Y PCB board holder to precisely fix PCBs up to 290 x 250 mm, Accu. TC. © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 18

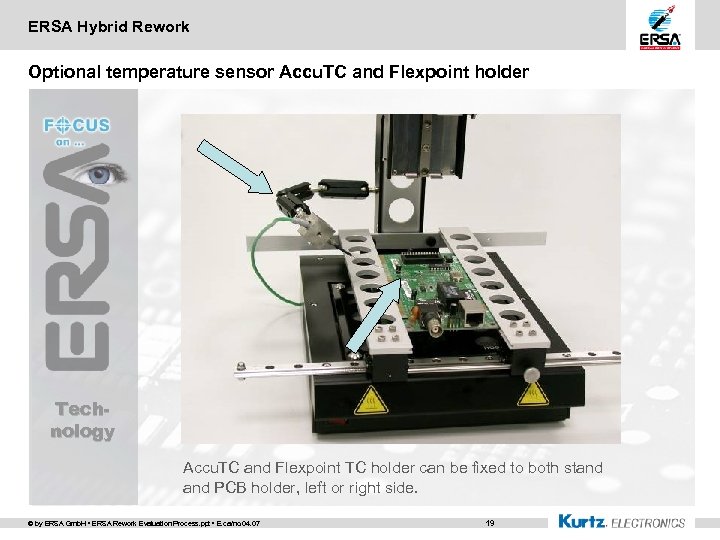

ERSA Hybrid Rework Optional temperature sensor Accu. TC and Flexpoint holder Technology Accu. TC and Flexpoint TC holder can be fixed to both stand PCB holder, left or right side. © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 19

ERSA Hybrid Rework Applications © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 20

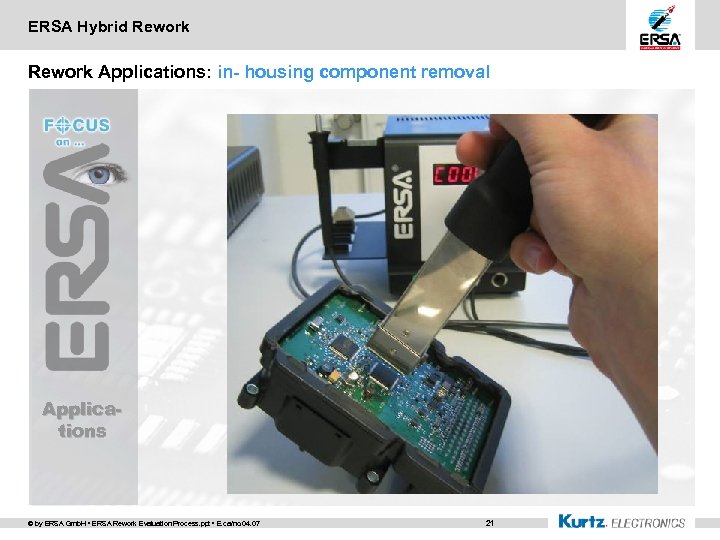

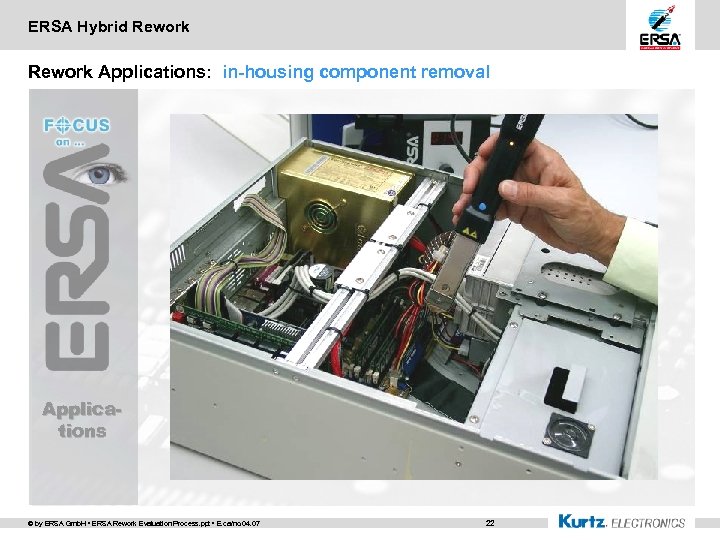

ERSA Hybrid Rework Applications: in- housing component removal Applications © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 21

ERSA Hybrid Rework Applications: in-housing component removal Applications © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 22

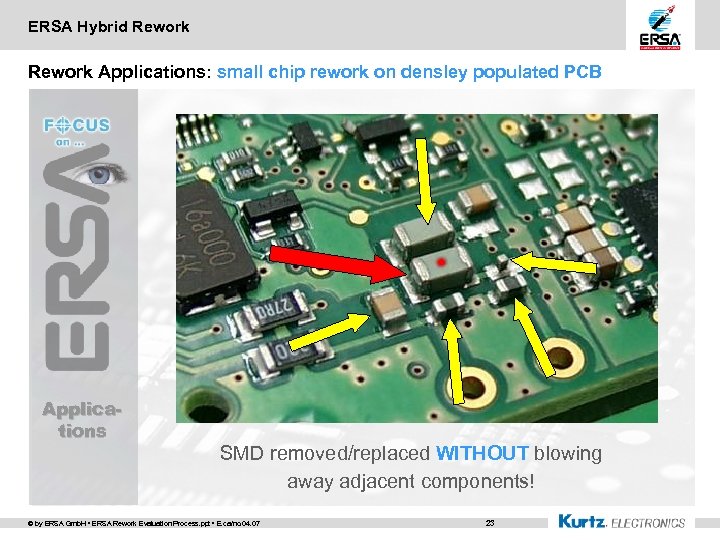

ERSA Hybrid Rework Applications: small chip rework on densley populated PCB Applications SMD removed/replaced WITHOUT blowing away adjacent components! © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 23

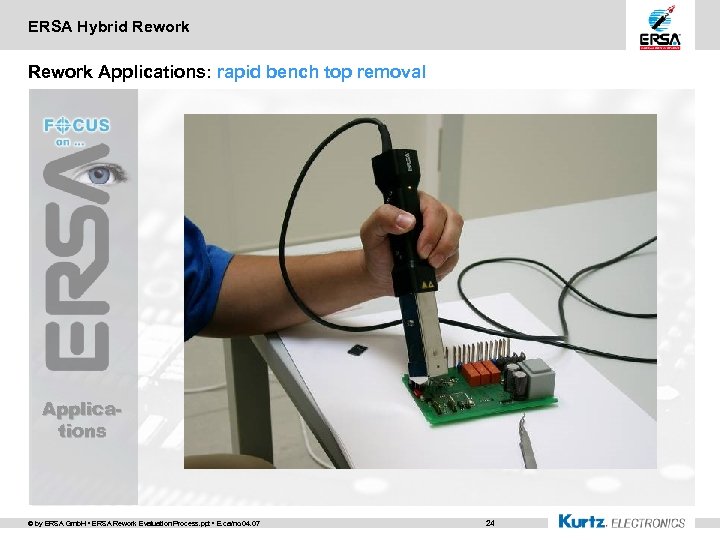

ERSA Hybrid Rework Applications: rapid bench top removal Applications © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 24

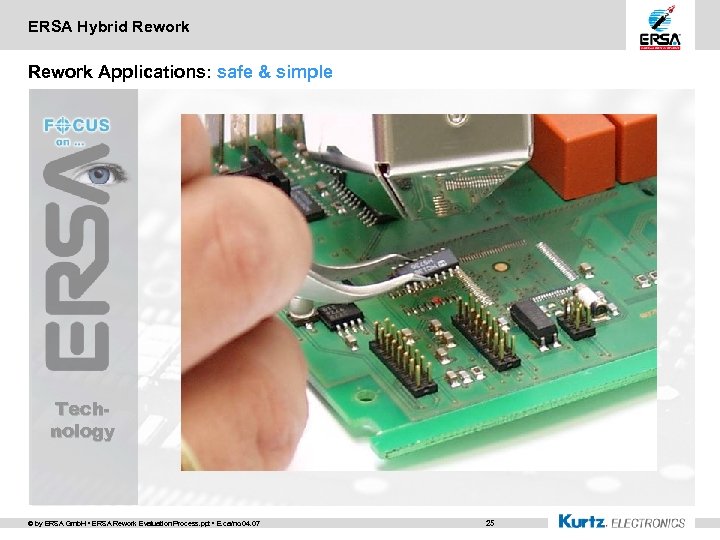

ERSA Hybrid Rework Applications: safe & simple Technology © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 25

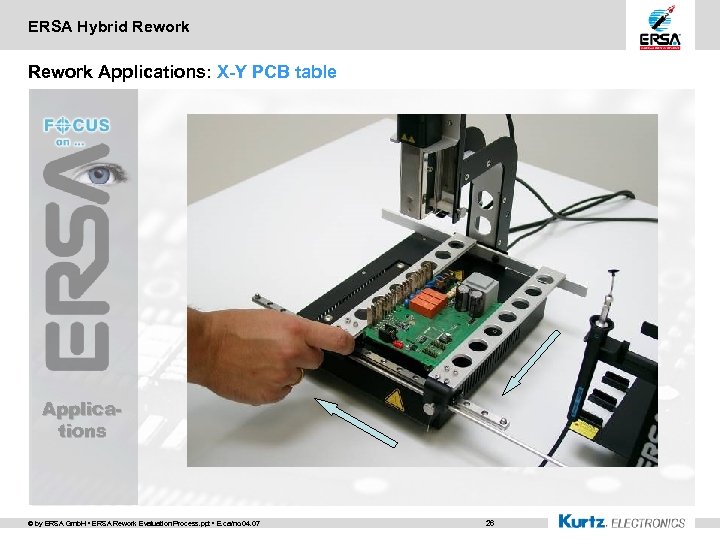

ERSA Hybrid Rework Applications: X-Y PCB table Applications © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 26

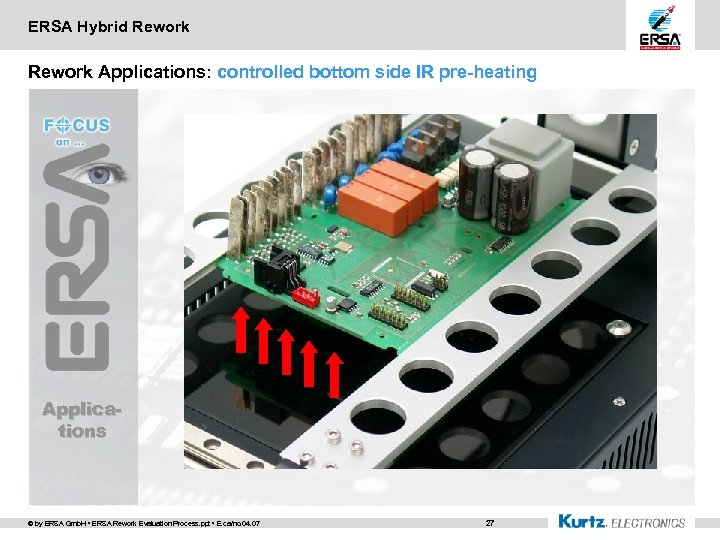

ERSA Hybrid Rework Applications: controlled bottom side IR pre-heating Applications © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 27

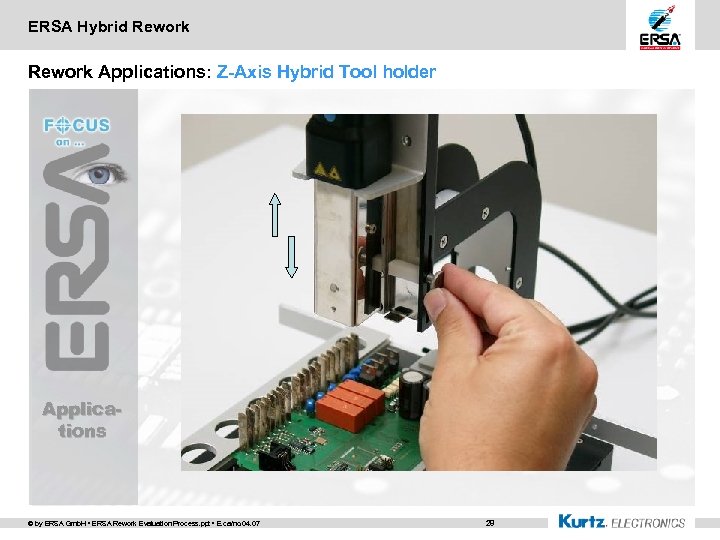

ERSA Hybrid Rework Applications: Z-Axis Hybrid Tool holder Applications © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 28

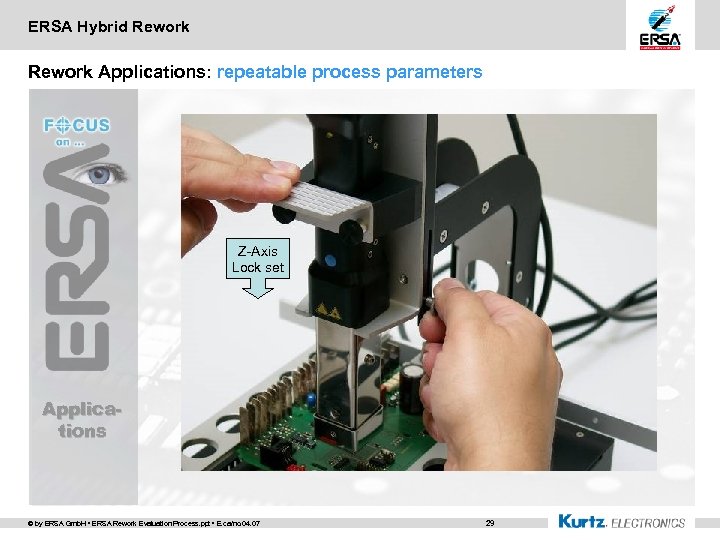

ERSA Hybrid Rework Applications: repeatable process parameters Z-Axis Lock set Applications © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 29

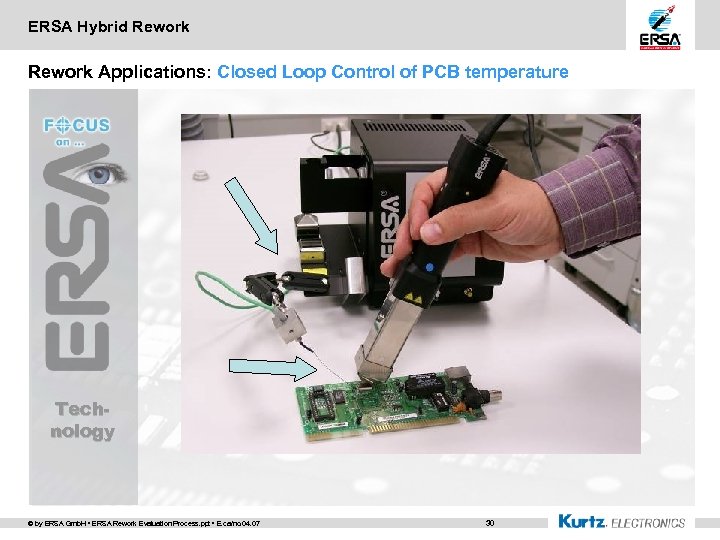

ERSA Hybrid Rework Applications: Closed Loop Control of PCB temperature Technology © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 30

ERSA Hybrid Rework Applications: Software option available Applications © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 31

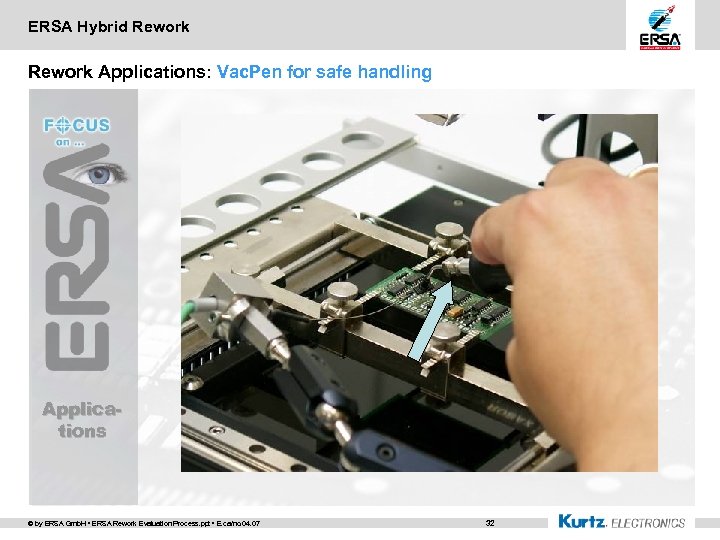

ERSA Hybrid Rework Applications: Vac. Pen for safe handling Applications © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 32

ERSA Hybrid Rework Applications: Optional cooling fan Technology Optional cooling fan for effective cooling after reflow. PCB can be handled easier after the repair process. © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 33

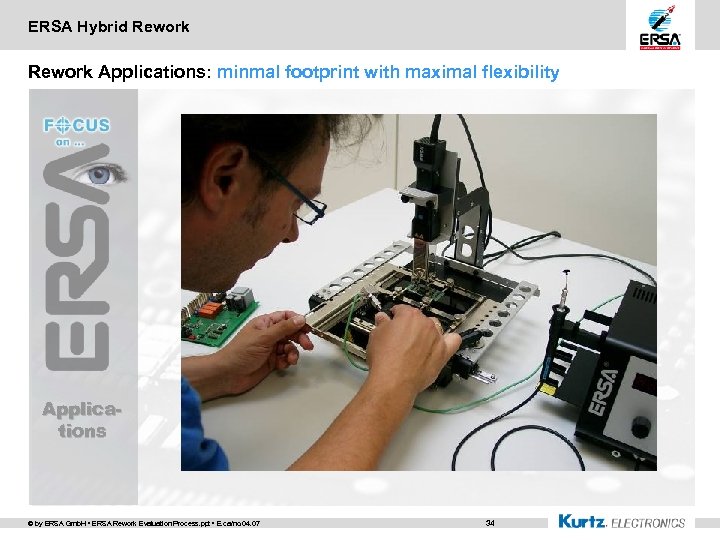

ERSA Hybrid Rework Applications: minmal footprint with maximal flexibility Applications © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 34

ERSA Hybrid Rework Product Line Process © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 35

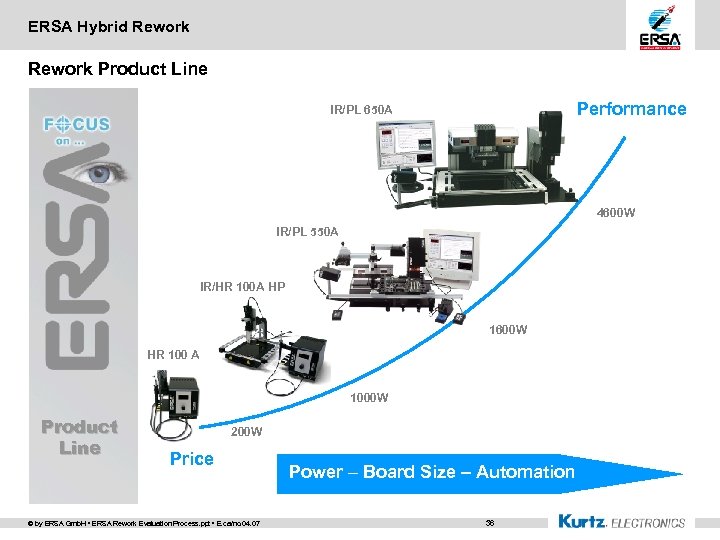

ERSA Hybrid Rework Product Line Performance IR/PL 650 A 4600 W IR/PL 550 A IR/HR 100 A HP 1600 W HR 100 A 1000 W Product Line 200 W Price © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 Power – Board Size – Automation 36

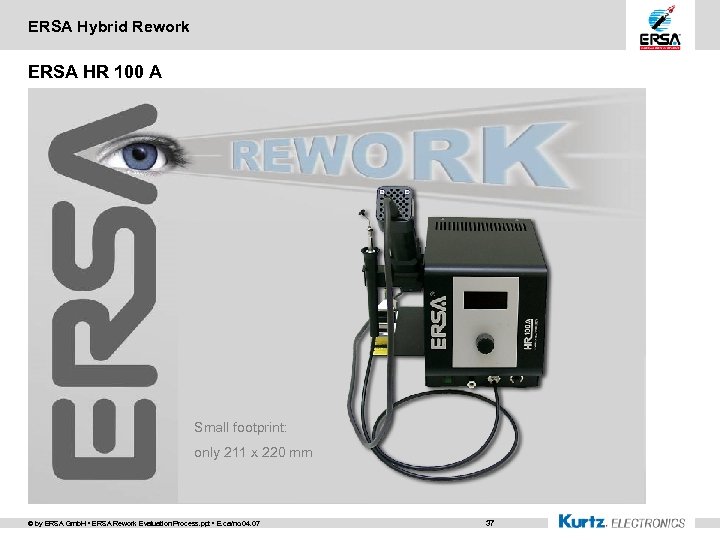

ERSA Hybrid Rework ERSA HR 100 A Small footprint: only 211 x 220 mm © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 37

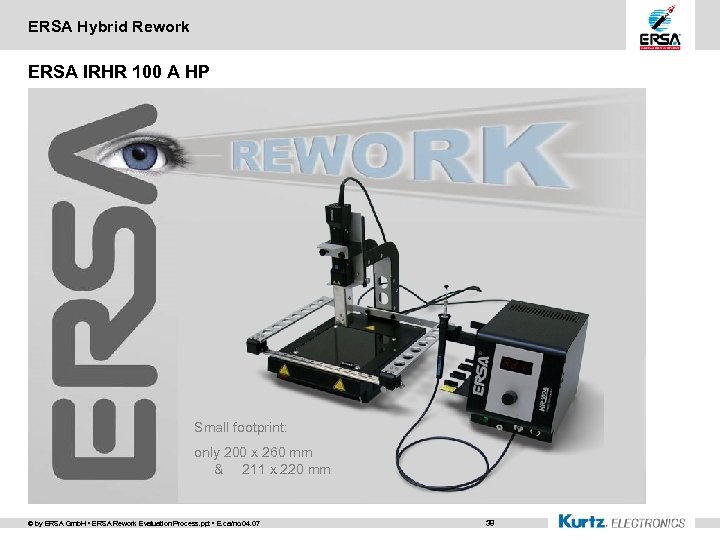

ERSA Hybrid Rework ERSA IRHR 100 A HP Small footprint: only 200 x 260 mm & 211 x 220 mm © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 38

ERSA Hybrid Rework Benchtop Rework System Requirements: HR 100 A meets them all! · Speed of rework cycle · Low cost & small footprint · In-housing component rework · Process safety & flexibility · Process stability & repeatability · System handling · Operator training Market Needs · Software support · Temperature Profiling · Documentation & traceability © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 39

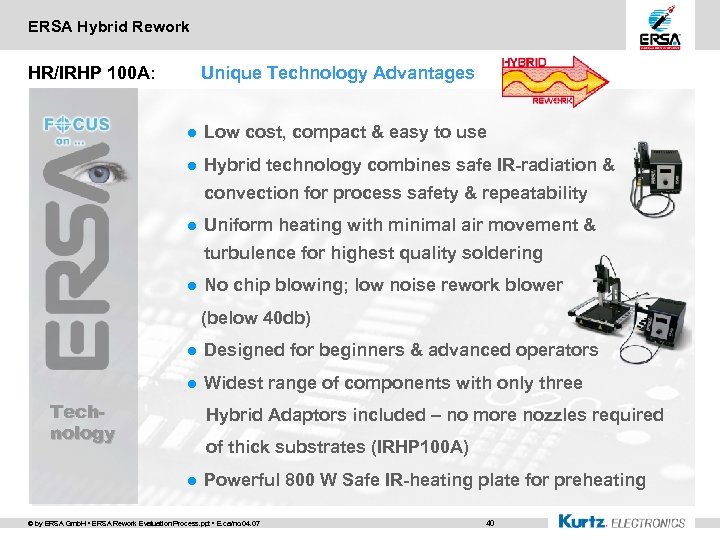

ERSA Hybrid Rework HR/IRHP 100 A: Unique Technology Advantages ● Low cost, compact & easy to use ● Hybrid technology combines safe IR-radiation & convection for process safety & repeatability ● Uniform heating with minimal air movement & turbulence for highest quality soldering ● No chip blowing; low noise rework blower (below 40 db) ● Designed for beginners & advanced operators ● Widest range of components with only three Technology Hybrid Adaptors included – no more nozzles required of thick substrates (IRHP 100 A) ● Powerful 800 W Safe IR-heating plate for preheating © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 40

ERSA Hybrid Rework Support Worldwide Support © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 41

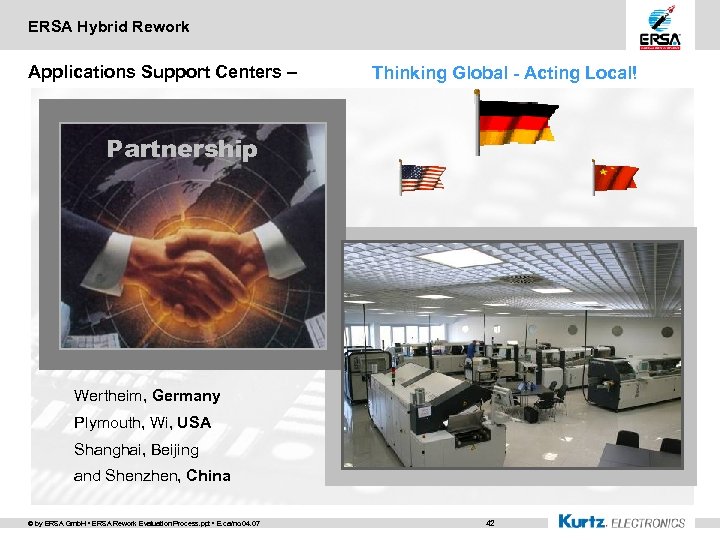

ERSA Hybrid Rework Applications Support Centers – Thinking Global - Acting Local! Partnership Wertheim, Germany Plymouth, Wi, USA Shanghai, Beijing and Shenzhen, China © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 42

ERSA Hybrid Rework In Depth Process Expertise in All Areas of Soldering · Reflow Soldering • Wave Soldering • Selective Soldering • Rework & Repair • Hand Soldering Expertise • BGA Inspection • Solderpaste Printing © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 43

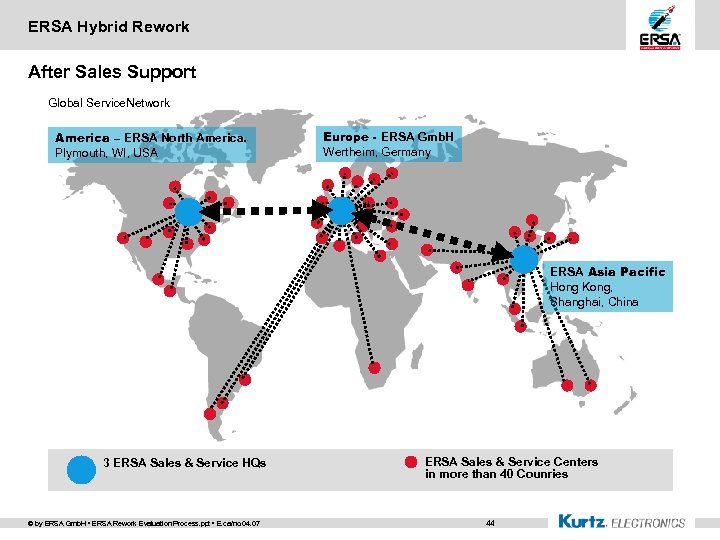

ERSA Hybrid Rework After Sales Support Global Service. Network America – ERSA North America. Plymouth, WI, USA Europe - ERSA Gmb. H Wertheim, Germany ERSA Asia Pacific Hong Kong, Shanghai, China 3 ERSA Sales & Service HQs © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 ERSA Sales & Service Centers in more than 40 Counries 44

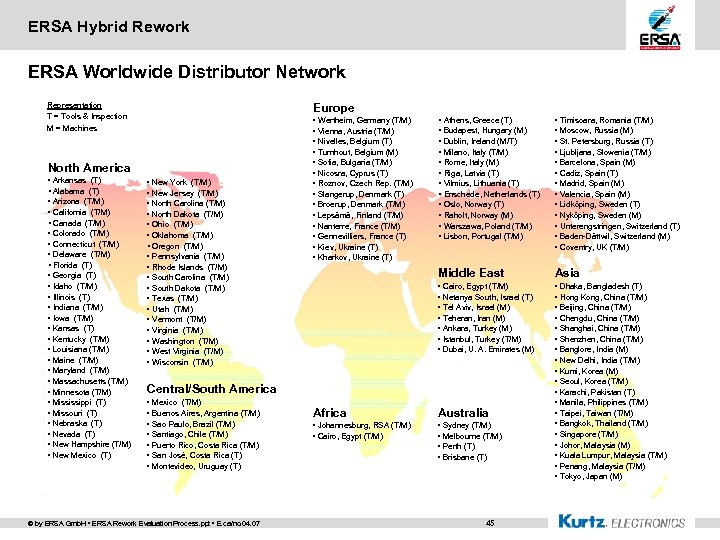

ERSA Hybrid Rework ERSA Worldwide Distributor Network Europe Representation T = Tools & Inspection M = Machines North America • Arkansas (T) • Alabama (T) • Arizona (T/M) • California (T/M) • Canada (T/M) • Colorado (T/M) • Connecticut (T/M) • Delaware (T/M) • Florida (T) • Georgia (T) • Idaho (T/M) • Illinois (T) • Indiana (T/M) • Iowa (T/M) • Kansas (T) • Kentucky (T/M) • Louisiana (T/M) • Maine (T/M) • Maryland (T/M) • Massachusetts (T/M) • Minnesota (T/M) • Mississippi (T) • Missouri (T) • Nebraska (T) • Nevada (T) • New Hampshire (T/M) • New Mexico (T) • New York (T/M) • New Jersey (T/M) • North Carolina (T/M) • North Dakota (T/M) • Ohio (T/M) • Oklahoma (T/M) • Oregon (T/M) • Pennsylvania (T/M) • Rhode Islands (T/M) • South Carolina (T/M) • South Dakota (T/M) • Texas (T/M) • Utah (T/M) • Vermont (T/M) • Virginia (T/M) • Washington (T/M) • West Virginia (T/M) • Wisconsin (T/M) • Athens, Greece (T) • Budapest, Hungary (M) • Dublin, Ireland (M/T) • Milano, Italy (T/M) • Rome, Italy (M) • Riga, Latvia (T) • Vilmius, Lithuania (T) • Enschede, Netherlands (T) • Oslo, Norway (T) • Raholt, Norway (M) • Warszawa, Poland (T/M) • Lisbon, Portugal (T/M) • Timisoara, Romania (T/M) • Moscow, Russia (M) • St. Petersburg, Russia (T) • Ljubljana, Slowenia (T/M) • Barcelona, Spain (M) • Cadiz, Spain (T) • Madrid, Spain (M) • Valencia, Spain (M) • Lidköping, Sweden (T) • Nyköping, Sweden (M) • Unterengstringen, Switzerland (T) • Baden-Dättwil, Switzerland (M) • Coventry, UK (T/M) Middle East Asia • Cairo, Egypt (T/M) • Netanya South, Israel (T) • Tel Aviv, Israel (M) • Teheran, Iran (M) • Ankara, Turkey (M) • Istanbul, Turkey (T/M) • Dubai, U. A. Emirates (M) • Wertheim, Germany (T/M) • Vienna, Austria (T/M) • Nivelles, Belgium (T) • Turnhout, Belgium (M) • Sofia, Bulgaria (T/M) • Nicosra, Cyprus (T) • Roznov, Czech Rep. (T/M) • Slangerup, Denmark (T) • Broerup, Denmark (T/M) • Lepsämä, Finland (T/M) • Nanterre, France (T/M) • Gennevilliers, France (T) • Kiev, Ukraine (T) • Kharkov, Ukraine (T) • Dhaka, Bangladesh (T) • Hong Kong, China (T/M) • Beijing, China (T/M) • Chengdu, China (T/M) • Shanghai, China (T/M) • Shenzhen, China (T/M) • Banglore, India (M) • New Delhi, India (T/M) • Kumi, Korea (M) • Seoul, Korea (T/M) • Karachi, Pakistan (T) • Manila, Philippines (T/M) • Taipei, Taiwan (T/M) • Bangkok, Thailand (T/M) • Singapore (T/M) • Johor, Malaysia (M) • Kuala Lumpur, Malaysia (T/M) • Penang, Malaysia (T/M) • Tokyo, Japan (M) Central/South America • Mexico (T/M) • Buenos Aires, Argentina (T/M) • Sao Paulo, Brazil (T/M) • Santiago, Chile (T/M) • Puerto Rico, Costa Rica (T/M) • San José, Costa Rica (T) • Montevideo, Uruguay (T) © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 Africa Australia • Johannesburg, RSA (T/M) • Cairo, Egypt (T/M) • Sydney (T/M) • Melbourne (T/M) • Perth (T) • Brisbane (T) 45

ERSA Hybrid Rework Thank you very much for your attention! © by ERSA Gmb. H • ERSA Rework Evaluation Process. ppt • E. ca/no. 04. 07 46

6e89fd0ef05856aed32607e6662477dd.ppt