61fb57e0df72c2c13f5b4e2ac2448ede.ppt

- Количество слайдов: 21

ERP system applications on BSP’s Supply Chain Management THIRD AEGEAN INTERNATIONAL CONFERENCE on DESIGN AND ANALYSIS OF MANUFACTURING SYSTEMS MAY 19 -22, 2001 TINOS ISLAND, GREECE Th. Modestou May 2001

ERP system applications on BSP’s Supply Chain Management Who are we ? a traditional Greek household appliance manufacturer founded in 1865 and named PITSOS which was acquired in 1977 by B/S/H/ (Bosch und Siemens Hausgeraete Gmb. H) and has been renamed BSP which means: Th. Modestou May 2001

ERP system applications on BSP’s Supply Chain Management What are we producing? BSP has become a modern competence centre for the development and production of cookers and refrigerators for several brands, such as: Th. Modestou May 2001

ERP system applications on BSP’s Supply Chain Management Some inf. 's about us: • • • Our 62 K m 2 production facility is located in Piraeus we produce more than 500. 000 appliances per year we employ more than 1000 people we are holding more than 40% of the Greek market we export 60% of our production to nearly 20 countries in Europe and overseas • we were able to constantly increase our annual turnover and PBT • we deploy modern Quality Management systems such as: ISO 9001, ISO 14001, and Total Quality Management • and are committed to achieve outstanding performance thanks to the “diligence of the individual and excellent management”. Th. Modestou May 2001

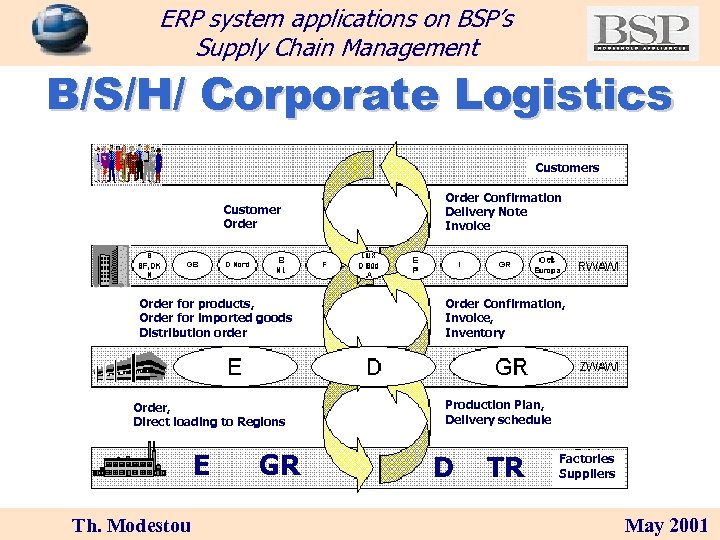

ERP system applications on BSP’s Supply Chain Management B/S/H/ Corporate Logistics Customer Order for products, Order for imported goods Distribution order Order, Direct loading to Regions E Th. Modestou GR Order Confirmation Delivery Note Invoice Order Confirmation, Invoice, Inventory Production Plan, Delivery schedule D TR Factories Suppliers May 2001

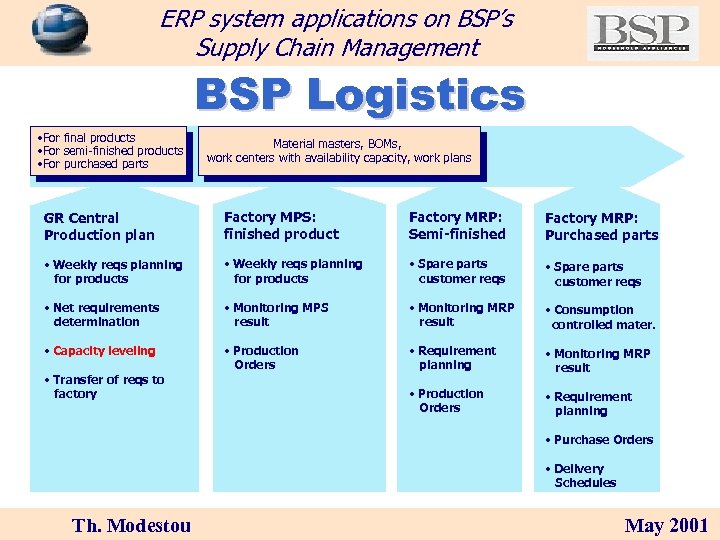

ERP system applications on BSP’s Supply Chain Management BSP Logistics • For final products • For semi-finished products • For purchased parts Material masters, BOMs, work centers with availability capacity, work plans GR Central Production plan Factory MPS: finished product Factory MRP: Semi-finished Factory MRP: Purchased parts • Weekly reqs planning for products • Spare parts customer reqs • Net requirements determination • Monitoring MPS result • Monitoring MRP result • Consumption controlled mater. • Capacity leveling • Production Orders • Requirement planning • Monitoring MRP result • Production Orders • Requirement planning • Transfer of reqs to factory • Purchase Orders • Delivery Schedules Th. Modestou May 2001

ERP system applications on BSP’s Supply Chain Management Competitive Criteria Production quality alone is no longer a decisive competitive advantage. Success is also based on the ability to meet customer requirements for: • time • volume • responsiveness • service level Customer requirements in the future will only be met by collaborate relationships among trading partners on joint planning and execution Th. Modestou May 2001

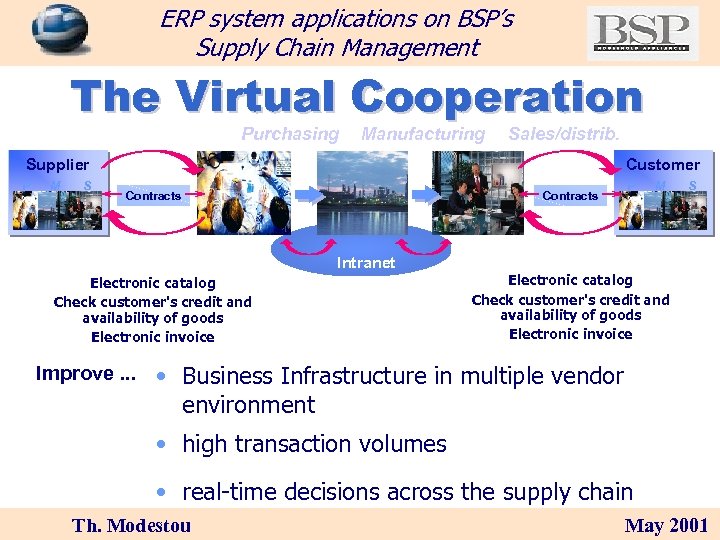

ERP system applications on BSP’s Supply Chain Management The Virtual Cooperation Purchasing Manufacturing Sales/distrib. Supplier P M S Customer Contracts Internet Contracts M S Intranet Electronic catalog Check customer's credit and availability of goods Electronic invoice Improve. . . P Electronic catalog Check customer's credit and availability of goods Electronic invoice • Business Infrastructure in multiple vendor environment • high transaction volumes • real-time decisions across the supply chain Th. Modestou May 2001

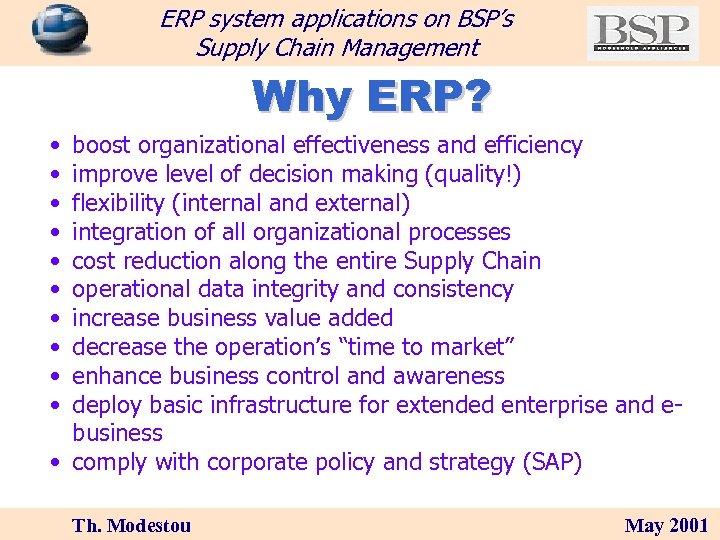

ERP system applications on BSP’s Supply Chain Management Why ERP? • • • boost organizational effectiveness and efficiency improve level of decision making (quality!) flexibility (internal and external) integration of all organizational processes cost reduction along the entire Supply Chain operational data integrity and consistency increase business value added decrease the operation’s “time to market” enhance business control and awareness deploy basic infrastructure for extended enterprise and ebusiness • comply with corporate policy and strategy (SAP) Th. Modestou May 2001

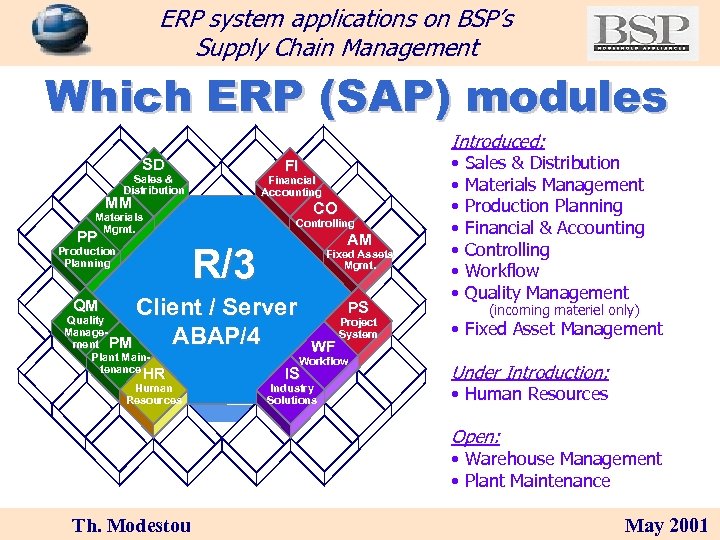

ERP system applications on BSP’s Supply Chain Management Which ERP (SAP) modules SD FI Sales & Distribution Financial Accounting MM CO Materials Mgmt. PP AM R/3 Production Planning QM Controlling Fixed Assets Mgmt. Client / Server ABAP/4 Quality Management PM Plant Maintenance HR Human Resources PS WF Project System Workflow IS Industry Solutions Introduced: • Sales & Distribution • Materials Management • Production Planning • Financial & Accounting • Controlling • Workflow • Quality Management (incoming materiel only) • Fixed Asset Management Under Introduction: • Human Resources Open: • Warehouse Management • Plant Maintenance Th. Modestou May 2001

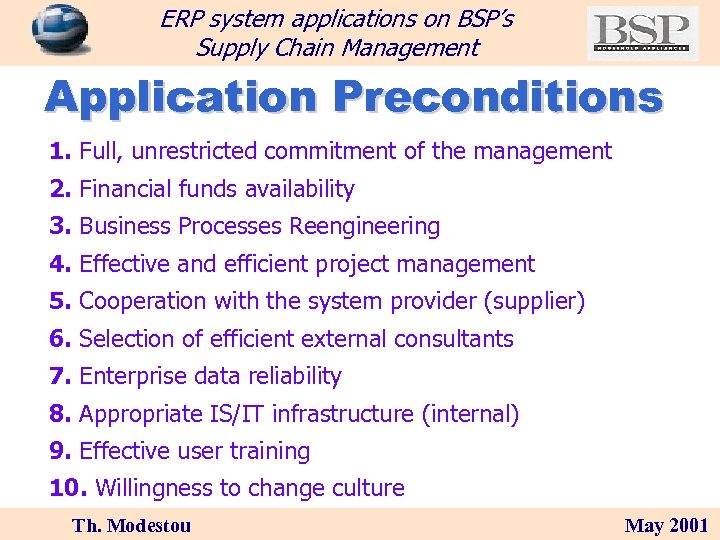

ERP system applications on BSP’s Supply Chain Management Application Preconditions 1. Full, unrestricted commitment of the management 2. Financial funds availability 3. Business Processes Reengineering 4. Effective and efficient project management 5. Cooperation with the system provider (supplier) 6. Selection of efficient external consultants 7. Enterprise data reliability 8. Appropriate IS/IT infrastructure (internal) 9. Effective user training 10. Willingness to change culture Th. Modestou May 2001

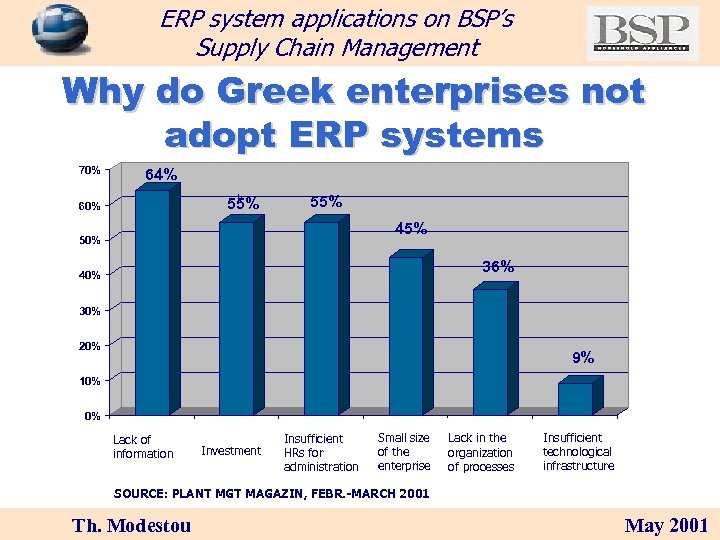

ERP system applications on BSP’s Supply Chain Management Why do Greek enterprises not adopt ERP systems 70% 64% k 55% 60% 55% 45% 50% 36% 40% 30% 20% 9% 10% 0% Lack of information Investment Insufficient HRs for administration Small size of the enterprise Lack in the organization of processes Insufficient technological infrastructure SOURCE: PLANT MGT MAGAZIN, FEBR. -MARCH 2001 Th. Modestou May 2001

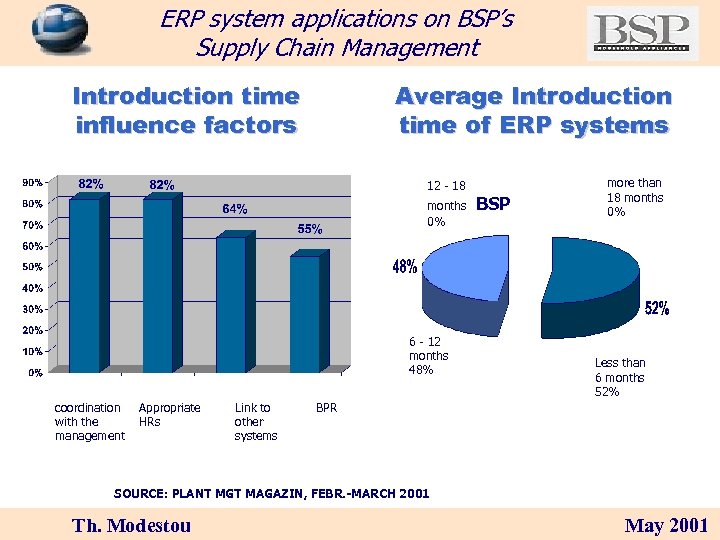

ERP system applications on BSP’s Supply Chain Management Introduction time influence factors Average Introduction time of ERP systems 12 - 18 months 0% 6 - 12 months 48% coordination with the management Appropriate HRs Link to other systems BSP more than 18 months 0% Less than 6 months 52% BPR SOURCE: PLANT MGT MAGAZIN, FEBR. -MARCH 2001 Th. Modestou May 2001

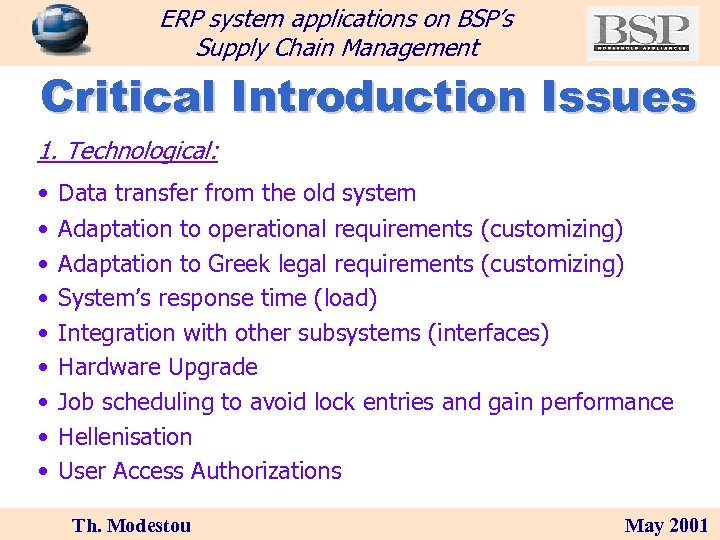

ERP system applications on BSP’s Supply Chain Management Critical Introduction Issues 1. Technological: • • • Data transfer from the old system Adaptation to operational requirements (customizing) Adaptation to Greek legal requirements (customizing) System’s response time (load) Integration with other subsystems (interfaces) Hardware Upgrade Job scheduling to avoid lock entries and gain performance Hellenisation User Access Authorizations Th. Modestou May 2001

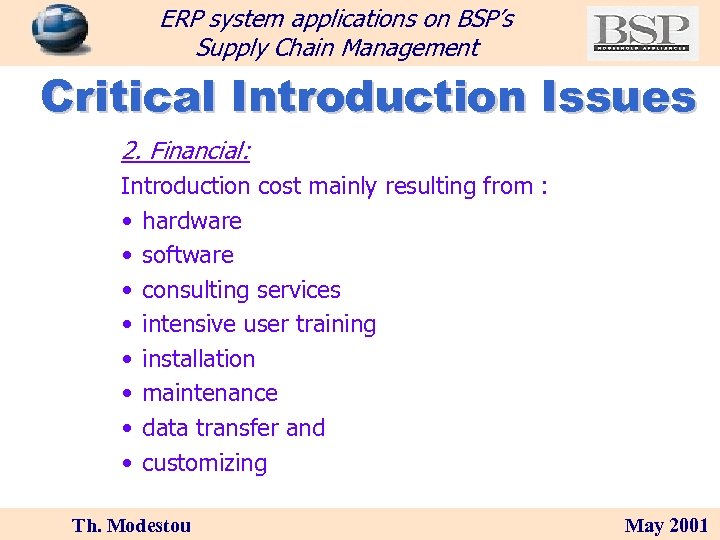

ERP system applications on BSP’s Supply Chain Management Critical Introduction Issues 2. Financial: Introduction cost mainly resulting from : • hardware • software • consulting services • intensive user training • installation • maintenance • data transfer and • customizing Th. Modestou May 2001

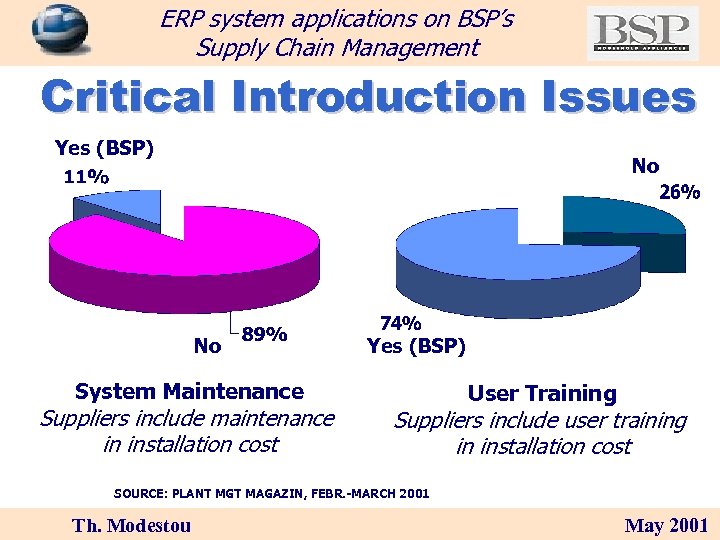

ERP system applications on BSP’s Supply Chain Management Critical Introduction Issues Yes (BSP) No No Yes (BSP) System Maintenance Suppliers include maintenance in installation cost User Training Suppliers include user training in installation cost SOURCE: PLANT MGT MAGAZIN, FEBR. -MARCH 2001 Th. Modestou May 2001

ERP system applications on BSP’s Supply Chain Management Critical Introduction Issues 3. Organizational: • Cultural shock • The organization was not prepared to deal with the high degree of interdepartmental process integration • Adaptation and redefinition of several operational processes (Business Process Reengineering) • Adaptation and redefinition of organizational schemes Th. Modestou May 2001

ERP system applications on BSP’s Supply Chain Management Critical Introduction Issues 4. Operational: • Error frequency in data entering/processing during the introduction period was extremely high • Continuous comparison between physical and system stocks was necessary • New material numbering was a source for confusion. • Definition & parameterization of master data cannot be taught, but only experienced. • No matter how good the level of training, it can not prepare someone for the productive start of the system Th. Modestou May 2001

ERP system applications on BSP’s Supply Chain Management Critical Introduction Issues 5. Human Resources: • It became extremely difficult and costly to find and hire personnel with (ERP/SAP) related professional experience and expertise. • Great percentage of the existing personnel didn’t have any IT system familiarization/competency. • Special care had to be taken for these people, to ensure their quick adaptation and utilization in the context of the new system • The competency profile of the personnel had to be drastically upgraded. Th. Modestou May 2001

ERP system applications on BSP’s Supply Chain Management The bottom line • organization • communication • Information • scheduling • forecasting • unification • soundness • transparency • control • online inf. s • direct access on data • integration Th. Modestou • excellent reporting • fun • motivation • personal improvement • order • discipline • know how • upgraded services • coordination • quality • speed May 2001

ERP system applications on BSP’s Supply Chain Management The bottom line After almost 2 1/2 years of operation with our ERP system, we do not doubt about the correctness of our decision. The successful introduction and ERP-based operation of the company became possible because of : • the management’s commitment to change culture • excellent project management, which was a corporate joint effort • the continuously improving user support by our IT department specialists (business analysts ) • and last but not least, because of the extraordinary personal efforts and dedication of the key users Th. Modestou May 2001

61fb57e0df72c2c13f5b4e2ac2448ede.ppt