3d5bee50935d050f228396e18578d81e.ppt

- Количество слайдов: 61

ERP System and Current Practices References n n n Vernadat, Enterprise modeling and integration 王立志 , 系統化運籌與供應鏈管理 Keller, SAP R/3 process-oriented implementation Oracle ERP training handouts Shtub, Enterprise Resource Planning

ERP System and Current Practices References n n n Vernadat, Enterprise modeling and integration 王立志 , 系統化運籌與供應鏈管理 Keller, SAP R/3 process-oriented implementation Oracle ERP training handouts Shtub, Enterprise Resource Planning

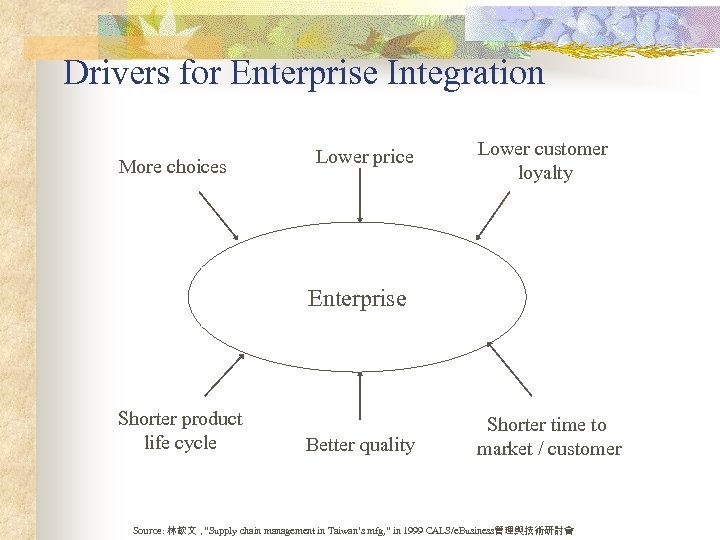

Drivers for Enterprise Integration More choices Lower price Lower customer loyalty Enterprise Shorter product life cycle Better quality Shorter time to market / customer Source: 林欽文 , “Supply chain management in Taiwan’s mfg, ” in 1999 CALS/e. Business管理與技術研討會

Drivers for Enterprise Integration More choices Lower price Lower customer loyalty Enterprise Shorter product life cycle Better quality Shorter time to market / customer Source: 林欽文 , “Supply chain management in Taiwan’s mfg, ” in 1999 CALS/e. Business管理與技術研討會

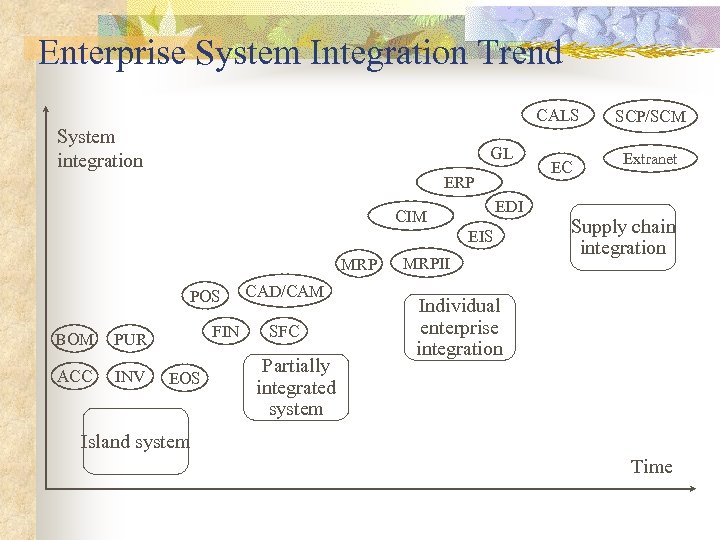

Enterprise System Integration Trend CALS System integration GL ERP EDI CIM EIS MRP POS BOM ACC INV FIN PUR EOS CAD/CAM SFC Partially integrated system MRPⅡ SCP/SCM EC Extranet Supply chain integration Individual enterprise integration Island system Time

Enterprise System Integration Trend CALS System integration GL ERP EDI CIM EIS MRP POS BOM ACC INV FIN PUR EOS CAD/CAM SFC Partially integrated system MRPⅡ SCP/SCM EC Extranet Supply chain integration Individual enterprise integration Island system Time

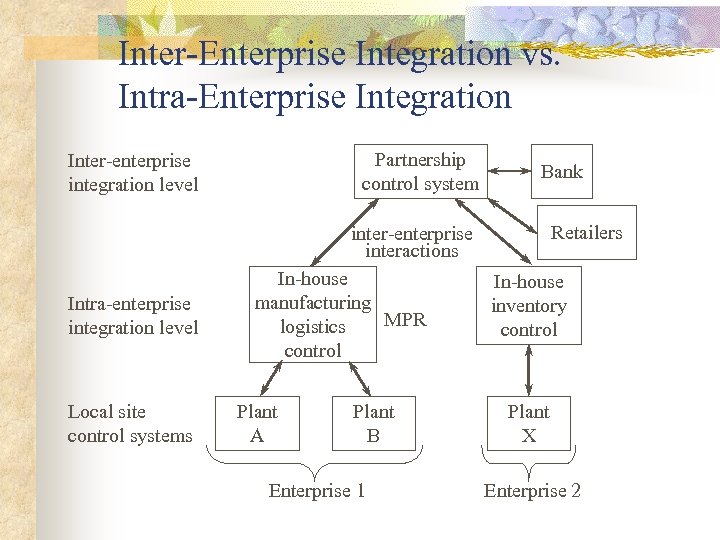

Inter-Enterprise Integration vs. Intra-Enterprise Integration Partnership control system Inter-enterprise integration level Bank Retailers inter-enterprise interactions Intra-enterprise integration level Local site control systems In-house manufacturing MPR logistics control Plant A Plant B Enterprise 1 In-house inventory control Plant X Enterprise 2

Inter-Enterprise Integration vs. Intra-Enterprise Integration Partnership control system Inter-enterprise integration level Bank Retailers inter-enterprise interactions Intra-enterprise integration level Local site control systems In-house manufacturing MPR logistics control Plant A Plant B Enterprise 1 In-house inventory control Plant X Enterprise 2

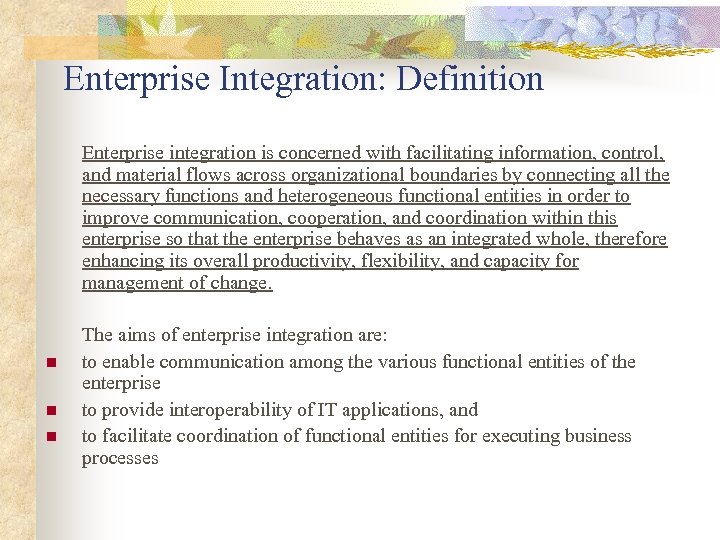

Enterprise Integration: Definition Enterprise integration is concerned with facilitating information, control, and material flows across organizational boundaries by connecting all the necessary functions and heterogeneous functional entities in order to improve communication, cooperation, and coordination within this enterprise so that the enterprise behaves as an integrated whole, therefore enhancing its overall productivity, flexibility, and capacity for management of change. n n n The aims of enterprise integration are: to enable communication among the various functional entities of the enterprise to provide interoperability of IT applications, and to facilitate coordination of functional entities for executing business processes

Enterprise Integration: Definition Enterprise integration is concerned with facilitating information, control, and material flows across organizational boundaries by connecting all the necessary functions and heterogeneous functional entities in order to improve communication, cooperation, and coordination within this enterprise so that the enterprise behaves as an integrated whole, therefore enhancing its overall productivity, flexibility, and capacity for management of change. n n n The aims of enterprise integration are: to enable communication among the various functional entities of the enterprise to provide interoperability of IT applications, and to facilitate coordination of functional entities for executing business processes

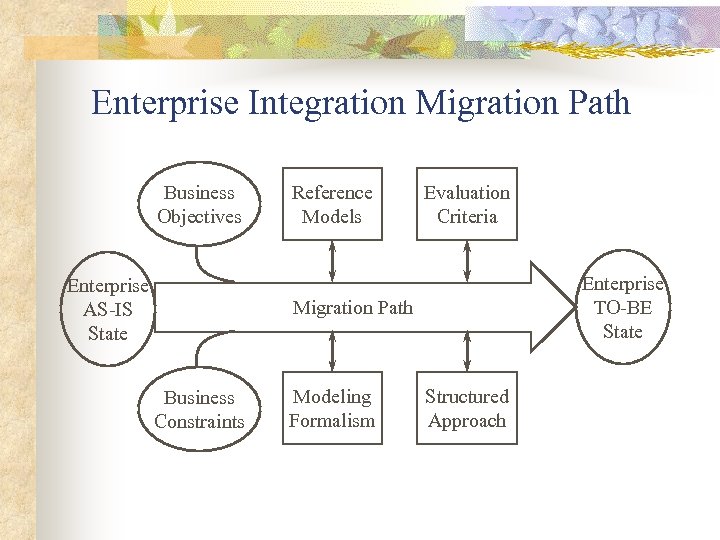

Enterprise Integration Migration Path Business Objectives Enterprise AS-IS State Reference Models Evaluation Criteria Enterprise TO-BE State Migration Path Business Constraints Modeling Formalism Structured Approach

Enterprise Integration Migration Path Business Objectives Enterprise AS-IS State Reference Models Evaluation Criteria Enterprise TO-BE State Migration Path Business Constraints Modeling Formalism Structured Approach

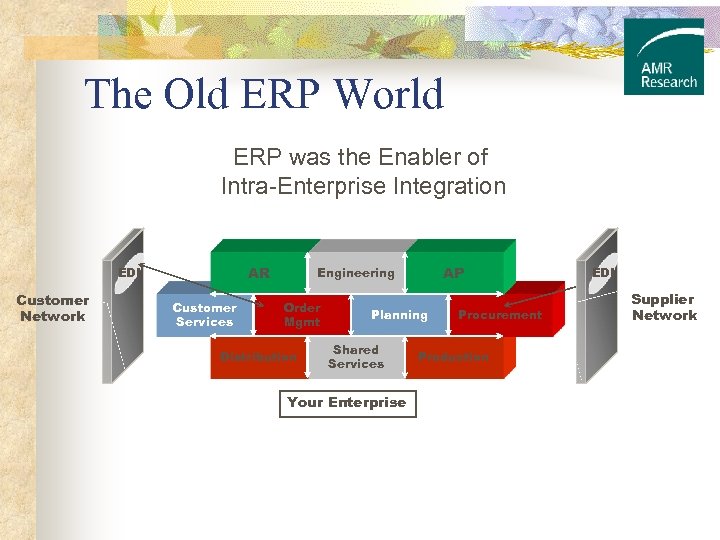

The Old ERP World ERP was the Enabler of Intra-Enterprise Integration AR EDI Customer Network Customer Services AP Engineering Order Mgmt Distribution Planning Shared Services Your Enterprise Procurement Production EDI Supplier Network

The Old ERP World ERP was the Enabler of Intra-Enterprise Integration AR EDI Customer Network Customer Services AP Engineering Order Mgmt Distribution Planning Shared Services Your Enterprise Procurement Production EDI Supplier Network

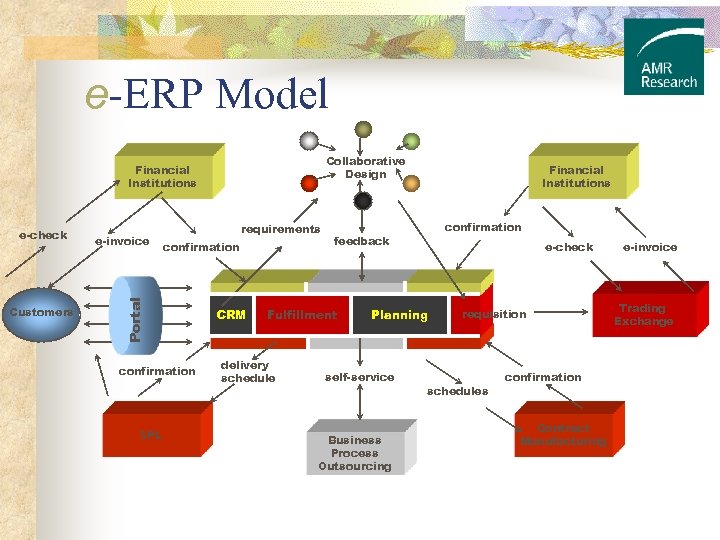

e-ERP Model Collaborative Design Financial Institutions Customers e-invoice requirements confirmation Portal e-check confirmation 3 PL CRM confirmation feedback Fulfillment delivery schedule Financial Institutions e-check Planning self-service Business Process Outsourcing requisition schedules confirmation Contract Manufacturing e-invoice Trading Exchange

e-ERP Model Collaborative Design Financial Institutions Customers e-invoice requirements confirmation Portal e-check confirmation 3 PL CRM confirmation feedback Fulfillment delivery schedule Financial Institutions e-check Planning self-service Business Process Outsourcing requisition schedules confirmation Contract Manufacturing e-invoice Trading Exchange

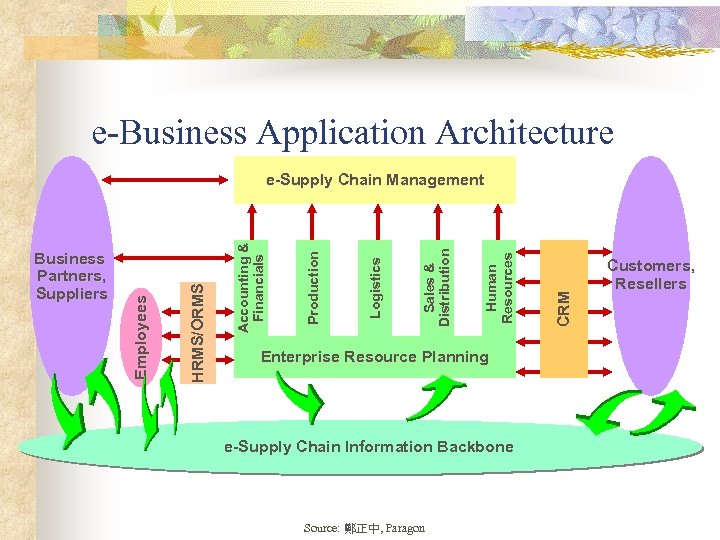

e-Business Application Architecture Enterprise Resource Planning e-Supply Chain Information Backbone Source: 鄭正中, Paragon CRM Human Resources Sales & Distribution Logistics Production Accounting & Financials HRMS/ORMS Business Partners, Suppliers Employees e-Supply Chain Management Customers, Resellers

e-Business Application Architecture Enterprise Resource Planning e-Supply Chain Information Backbone Source: 鄭正中, Paragon CRM Human Resources Sales & Distribution Logistics Production Accounting & Financials HRMS/ORMS Business Partners, Suppliers Employees e-Supply Chain Management Customers, Resellers

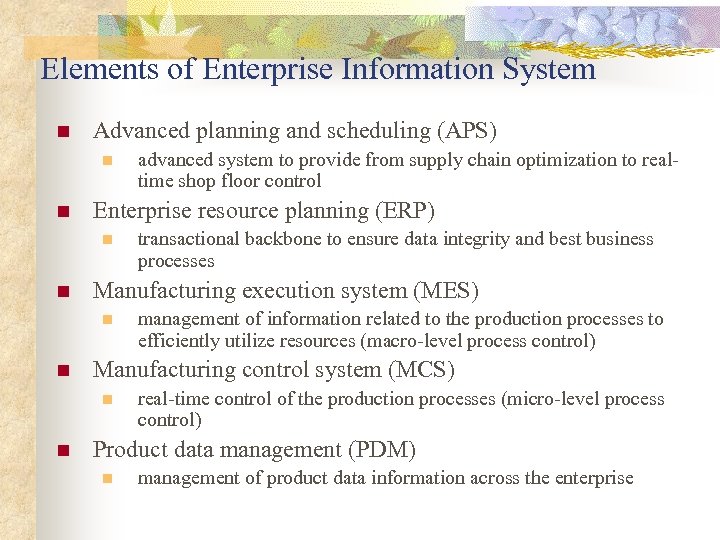

Elements of Enterprise Information System n Advanced planning and scheduling (APS) n n Enterprise resource planning (ERP) n n management of information related to the production processes to efficiently utilize resources (macro-level process control) Manufacturing control system (MCS) n n transactional backbone to ensure data integrity and best business processes Manufacturing execution system (MES) n n advanced system to provide from supply chain optimization to realtime shop floor control real-time control of the production processes (micro-level process control) Product data management (PDM) n management of product data information across the enterprise

Elements of Enterprise Information System n Advanced planning and scheduling (APS) n n Enterprise resource planning (ERP) n n management of information related to the production processes to efficiently utilize resources (macro-level process control) Manufacturing control system (MCS) n n transactional backbone to ensure data integrity and best business processes Manufacturing execution system (MES) n n advanced system to provide from supply chain optimization to realtime shop floor control real-time control of the production processes (micro-level process control) Product data management (PDM) n management of product data information across the enterprise

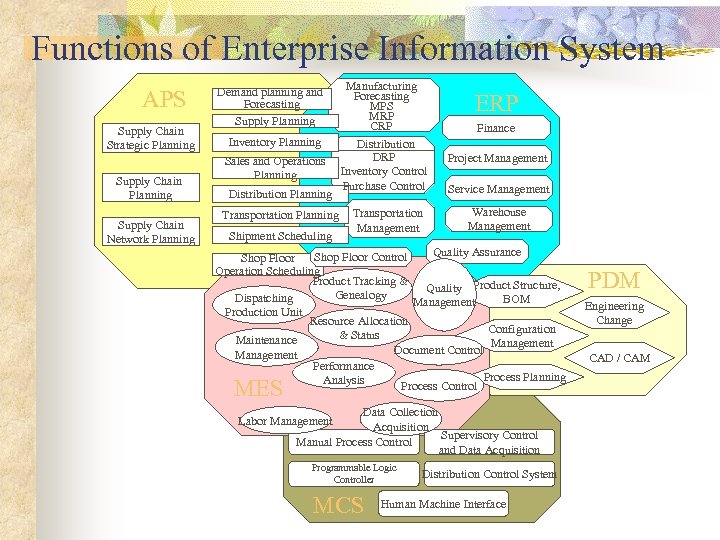

Functions of Enterprise Information System APS Supply Chain Strategic Planning Supply Chain Network Planning Demand planning and Forecasting Supply Planning Inventory Planning Sales and Operations Planning Distribution Planning Transportation Planning Shipment Scheduling Manufacturing Forecasting MPS MRP CRP Distribution DRP Inventory Control Purchase Control Transportation Management ERP Finance Project Management Service Management Warehouse Management Quality Assurance Shop Floor Control Shop Floor Operation Scheduling Product Tracking & Quality Product Structure, Genealogy Dispatching BOM Management Production Unit Resource Allocation Configuration & Status Maintenance Management Document Control Management Performance Process Planning Analysis Process Control MES Data Collection Acquisition Supervisory Control Manual Process Control and Data Acquisition Labor Management Programmable Logic Controller MCS Distribution Control System Human Machine Interface PDM Engineering Change CAD / CAM

Functions of Enterprise Information System APS Supply Chain Strategic Planning Supply Chain Network Planning Demand planning and Forecasting Supply Planning Inventory Planning Sales and Operations Planning Distribution Planning Transportation Planning Shipment Scheduling Manufacturing Forecasting MPS MRP CRP Distribution DRP Inventory Control Purchase Control Transportation Management ERP Finance Project Management Service Management Warehouse Management Quality Assurance Shop Floor Control Shop Floor Operation Scheduling Product Tracking & Quality Product Structure, Genealogy Dispatching BOM Management Production Unit Resource Allocation Configuration & Status Maintenance Management Document Control Management Performance Process Planning Analysis Process Control MES Data Collection Acquisition Supervisory Control Manual Process Control and Data Acquisition Labor Management Programmable Logic Controller MCS Distribution Control System Human Machine Interface PDM Engineering Change CAD / CAM

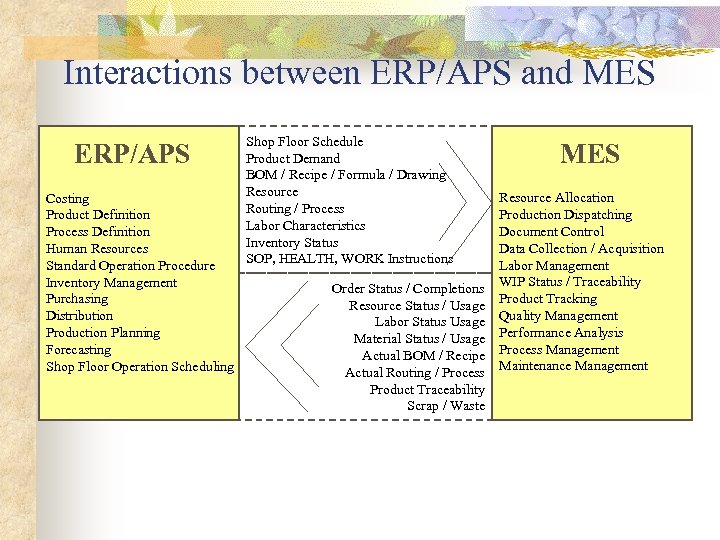

Interactions between ERP/APS and MES ERP/APS Costing Product Definition Process Definition Human Resources Standard Operation Procedure Inventory Management Purchasing Distribution Production Planning Forecasting Shop Floor Operation Scheduling Shop Floor Schedule Product Demand BOM / Recipe / Formula / Drawing Resource Routing / Process Labor Characteristics Inventory Status SOP, HEALTH, WORK Instructions Order Status / Completions Resource Status / Usage Labor Status Usage Material Status / Usage Actual BOM / Recipe Actual Routing / Process Product Traceability Scrap / Waste MES Resource Allocation Production Dispatching Document Control Data Collection / Acquisition Labor Management WIP Status / Traceability Product Tracking Quality Management Performance Analysis Process Management Maintenance Management

Interactions between ERP/APS and MES ERP/APS Costing Product Definition Process Definition Human Resources Standard Operation Procedure Inventory Management Purchasing Distribution Production Planning Forecasting Shop Floor Operation Scheduling Shop Floor Schedule Product Demand BOM / Recipe / Formula / Drawing Resource Routing / Process Labor Characteristics Inventory Status SOP, HEALTH, WORK Instructions Order Status / Completions Resource Status / Usage Labor Status Usage Material Status / Usage Actual BOM / Recipe Actual Routing / Process Product Traceability Scrap / Waste MES Resource Allocation Production Dispatching Document Control Data Collection / Acquisition Labor Management WIP Status / Traceability Product Tracking Quality Management Performance Analysis Process Management Maintenance Management

Enterprise Resource Planning n Enterprise transactional backbone to ensure data integrity and best business processes n Using a single database streamlines the flow of information through a business n Four main (M) functions: n n Money (financial) Man (human resources) Manufacturing (production and logistics) Marketing (sales and distribution)

Enterprise Resource Planning n Enterprise transactional backbone to ensure data integrity and best business processes n Using a single database streamlines the flow of information through a business n Four main (M) functions: n n Money (financial) Man (human resources) Manufacturing (production and logistics) Marketing (sales and distribution)

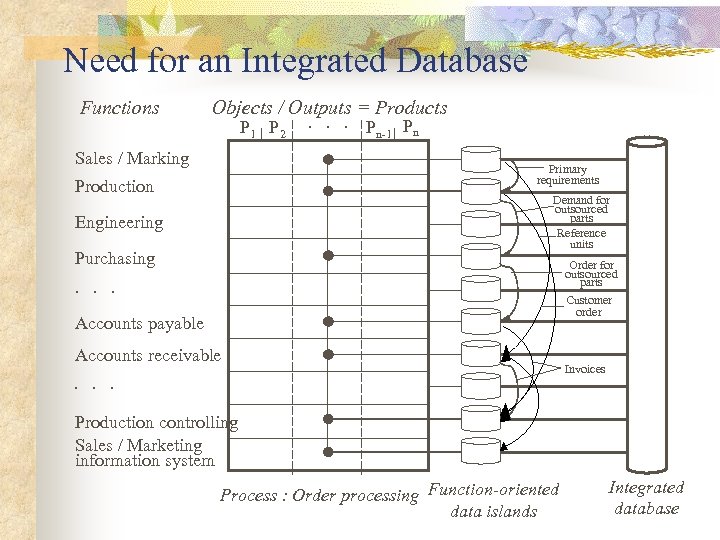

Need for an Integrated Database Functions Objects / Outputs = Products P 1 P 2 ... Pn-1 Pn Sales / Marking Primary requirements Production Demand for outsourced parts Reference units Engineering Purchasing Order for outsourced parts ... Customer order Accounts payable Accounts receivable Invoices ... Production controlling Sales / Marketing information system Process : Order processing Function-oriented data islands Integrated database

Need for an Integrated Database Functions Objects / Outputs = Products P 1 P 2 ... Pn-1 Pn Sales / Marking Primary requirements Production Demand for outsourced parts Reference units Engineering Purchasing Order for outsourced parts ... Customer order Accounts payable Accounts receivable Invoices ... Production controlling Sales / Marketing information system Process : Order processing Function-oriented data islands Integrated database

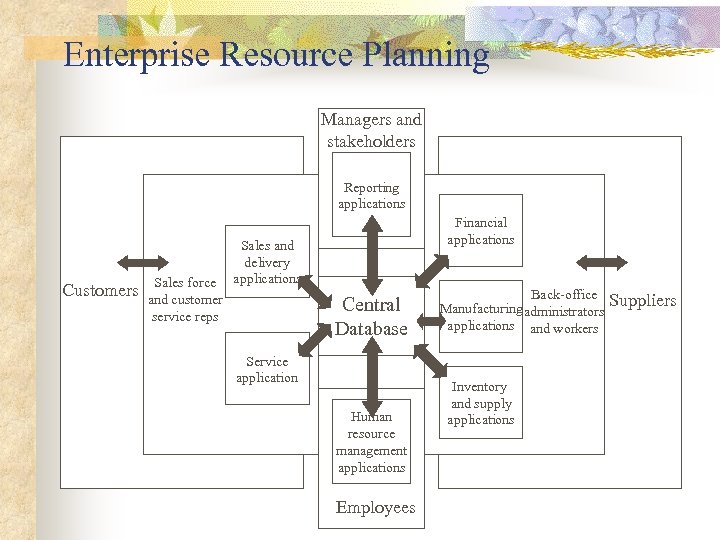

Enterprise Resource Planning Managers and stakeholders Reporting applications Customers Sales force and customer service reps Financial applications Sales and delivery applications Central Database Service application Human resource management applications Employees Back-office Manufacturing administrators applications and workers Inventory and supply applications Suppliers

Enterprise Resource Planning Managers and stakeholders Reporting applications Customers Sales force and customer service reps Financial applications Sales and delivery applications Central Database Service application Human resource management applications Employees Back-office Manufacturing administrators applications and workers Inventory and supply applications Suppliers

Features of ERP Compared to MRPII n n n n n Focus on external supply chain Client/server architecture (3 levels) Relationship database and SQL Graphic user interface Multiple database support Front-end systems for decision support Automated EDI Interoperability with multiple platforms Standard application programming interfaces

Features of ERP Compared to MRPII n n n n n Focus on external supply chain Client/server architecture (3 levels) Relationship database and SQL Graphic user interface Multiple database support Front-end systems for decision support Automated EDI Interoperability with multiple platforms Standard application programming interfaces

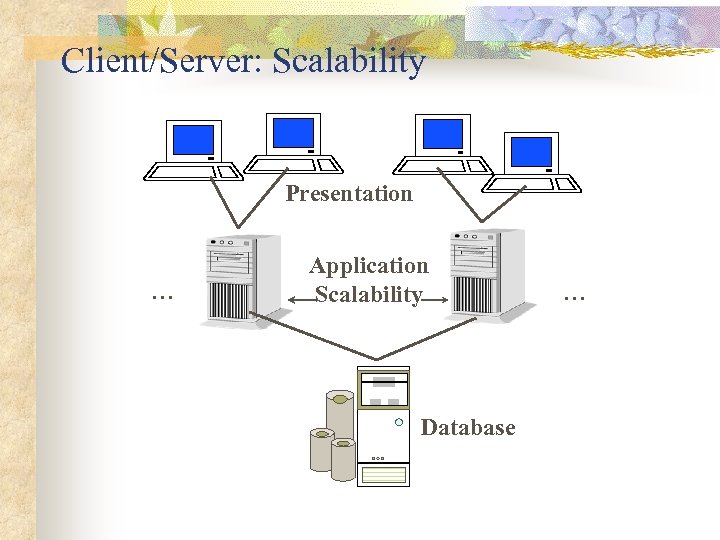

Client/Server: Scalability Presentation . . . Application Scalability Database . . .

Client/Server: Scalability Presentation . . . Application Scalability Database . . .

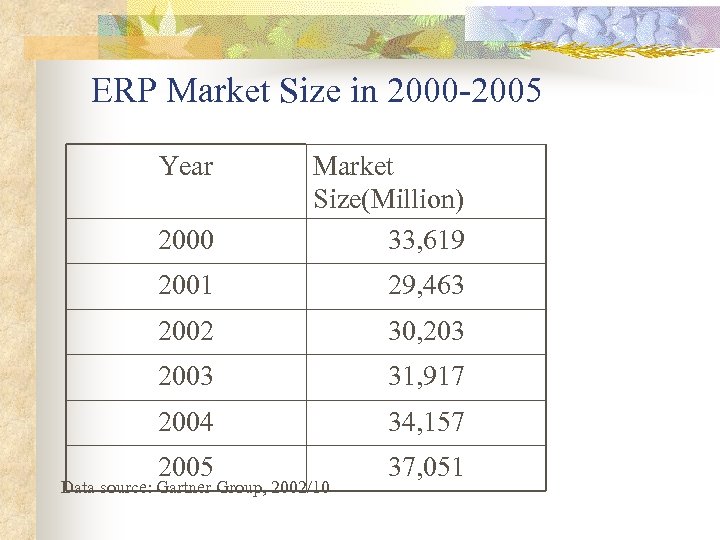

ERP Market Size in 2000 -2005 Year 2000 Market Size(Million) 33, 619 2001 29, 463 2002 30, 203 2003 31, 917 2004 34, 157 2005 37, 051 Data source: Gartner Group, 2002/10

ERP Market Size in 2000 -2005 Year 2000 Market Size(Million) 33, 619 2001 29, 463 2002 30, 203 2003 31, 917 2004 34, 157 2005 37, 051 Data source: Gartner Group, 2002/10

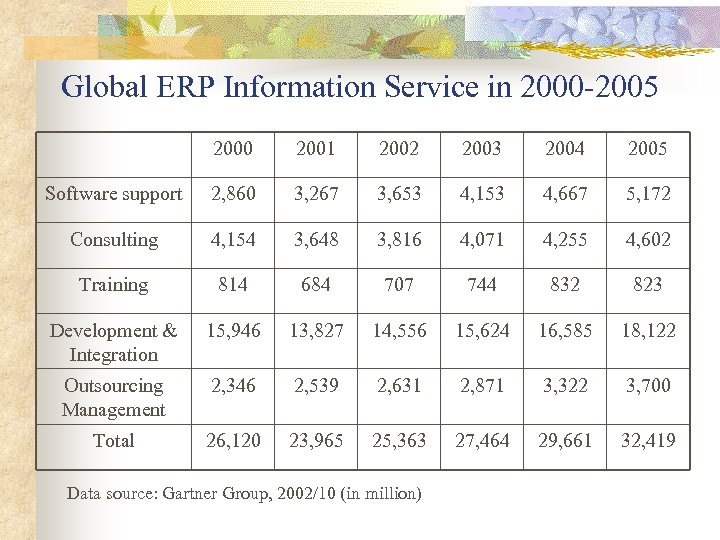

Global ERP Information Service in 2000 -2005 2000 2001 2002 2003 2004 2005 Software support 2, 860 3, 267 3, 653 4, 153 4, 667 5, 172 Consulting 4, 154 3, 648 3, 816 4, 071 4, 255 4, 602 Training 814 684 707 744 832 823 Development & Integration 15, 946 13, 827 14, 556 15, 624 16, 585 18, 122 Outsourcing Management 2, 346 2, 539 2, 631 2, 871 3, 322 3, 700 Total 26, 120 23, 965 25, 363 27, 464 29, 661 32, 419 Data source: Gartner Group, 2002/10 (in million)

Global ERP Information Service in 2000 -2005 2000 2001 2002 2003 2004 2005 Software support 2, 860 3, 267 3, 653 4, 153 4, 667 5, 172 Consulting 4, 154 3, 648 3, 816 4, 071 4, 255 4, 602 Training 814 684 707 744 832 823 Development & Integration 15, 946 13, 827 14, 556 15, 624 16, 585 18, 122 Outsourcing Management 2, 346 2, 539 2, 631 2, 871 3, 322 3, 700 Total 26, 120 23, 965 25, 363 27, 464 29, 661 32, 419 Data source: Gartner Group, 2002/10 (in million)

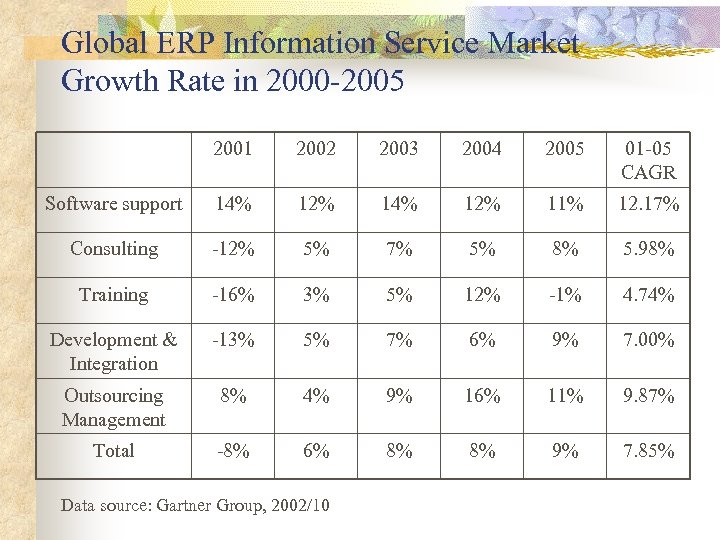

Global ERP Information Service Market Growth Rate in 2000 -2005 2001 2002 2003 2004 2005 01 -05 CAGR Software support 14% 12% 11% 12. 17% Consulting -12% 5% 7% 5% 8% 5. 98% Training -16% 3% 5% 12% -1% 4. 74% Development & Integration -13% 5% 7% 6% 9% 7. 00% Outsourcing Management 8% 4% 9% 16% 11% 9. 87% Total -8% 6% 8% 8% 9% 7. 85% Data source: Gartner Group, 2002/10

Global ERP Information Service Market Growth Rate in 2000 -2005 2001 2002 2003 2004 2005 01 -05 CAGR Software support 14% 12% 11% 12. 17% Consulting -12% 5% 7% 5% 8% 5. 98% Training -16% 3% 5% 12% -1% 4. 74% Development & Integration -13% 5% 7% 6% 9% 7. 00% Outsourcing Management 8% 4% 9% 16% 11% 9. 87% Total -8% 6% 8% 8% 9% 7. 85% Data source: Gartner Group, 2002/10

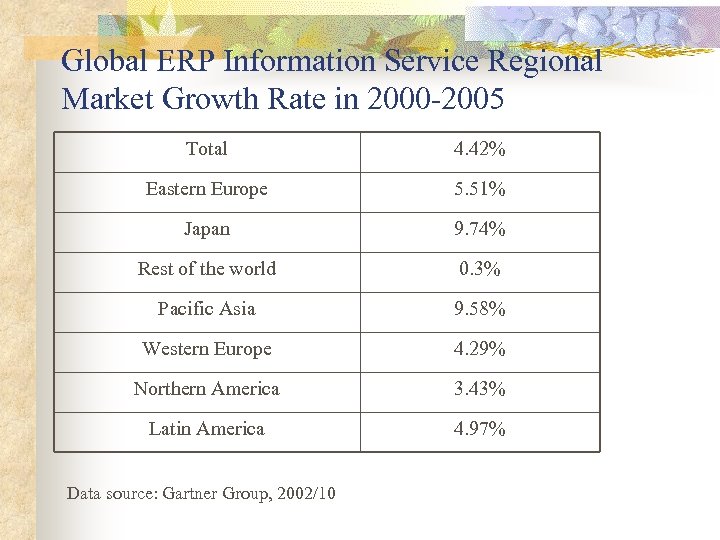

Global ERP Information Service Regional Market Growth Rate in 2000 -2005 Total 4. 42% Eastern Europe 5. 51% Japan 9. 74% Rest of the world 0. 3% Pacific Asia 9. 58% Western Europe 4. 29% Northern America 3. 43% Latin America 4. 97% Data source: Gartner Group, 2002/10

Global ERP Information Service Regional Market Growth Rate in 2000 -2005 Total 4. 42% Eastern Europe 5. 51% Japan 9. 74% Rest of the world 0. 3% Pacific Asia 9. 58% Western Europe 4. 29% Northern America 3. 43% Latin America 4. 97% Data source: Gartner Group, 2002/10

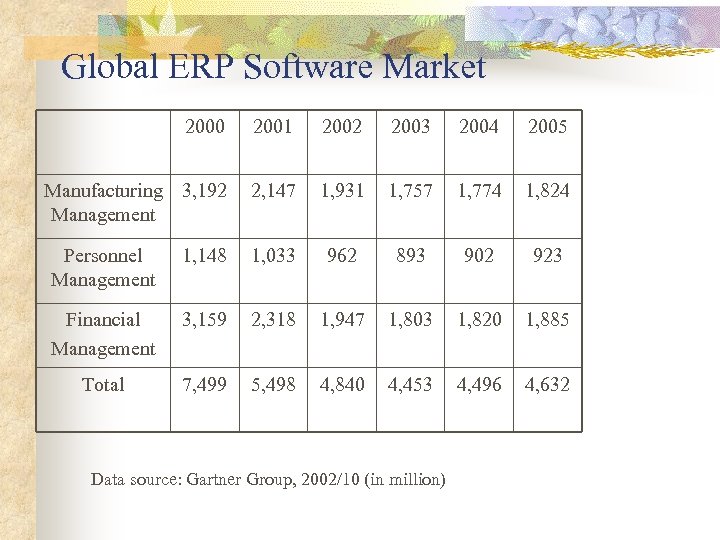

Global ERP Software Market 2000 2001 2002 2003 2004 2005 Manufacturing 3, 192 Management 2, 147 1, 931 1, 757 1, 774 1, 824 Personnel Management 1, 148 1, 033 962 893 902 923 Financial Management 3, 159 2, 318 1, 947 1, 803 1, 820 1, 885 Total 7, 499 5, 498 4, 840 4, 453 4, 496 4, 632 Data source: Gartner Group, 2002/10 (in million)

Global ERP Software Market 2000 2001 2002 2003 2004 2005 Manufacturing 3, 192 Management 2, 147 1, 931 1, 757 1, 774 1, 824 Personnel Management 1, 148 1, 033 962 893 902 923 Financial Management 3, 159 2, 318 1, 947 1, 803 1, 820 1, 885 Total 7, 499 5, 498 4, 840 4, 453 4, 496 4, 632 Data source: Gartner Group, 2002/10 (in million)

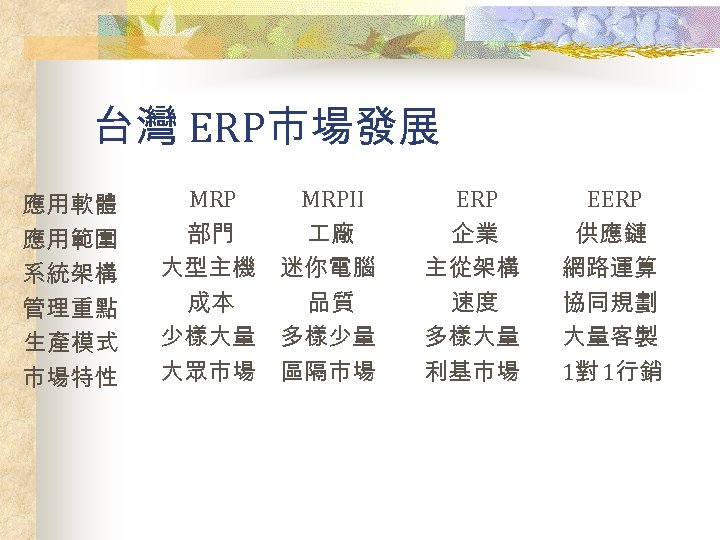

台灣 ERP市場發展 應用軟體 應用範圍 系統架構 管理重點 生產模式 市場特性 MRP 部門 大型主機 成本 少樣大量 大眾市場 MRPII 廠 迷你電腦 品質 多樣少量 區隔市場 ERP 企業 主從架構 速度 多樣大量 利基市場 EERP 供應鏈 網路運算 協同規劃 大量客製 1對 1行銷

台灣 ERP市場發展 應用軟體 應用範圍 系統架構 管理重點 生產模式 市場特性 MRP 部門 大型主機 成本 少樣大量 大眾市場 MRPII 廠 迷你電腦 品質 多樣少量 區隔市場 ERP 企業 主從架構 速度 多樣大量 利基市場 EERP 供應鏈 網路運算 協同規劃 大量客製 1對 1行銷

2000 -2003年台灣 ERP市場規模分析 單位:新台幣十億元 1997 2. 13 1998 4. 68 1999 6. 13 2000 7. 72 2001 9. 88 2002 12. 65 2003 16. 19

2000 -2003年台灣 ERP市場規模分析 單位:新台幣十億元 1997 2. 13 1998 4. 68 1999 6. 13 2000 7. 72 2001 9. 88 2002 12. 65 2003 16. 19

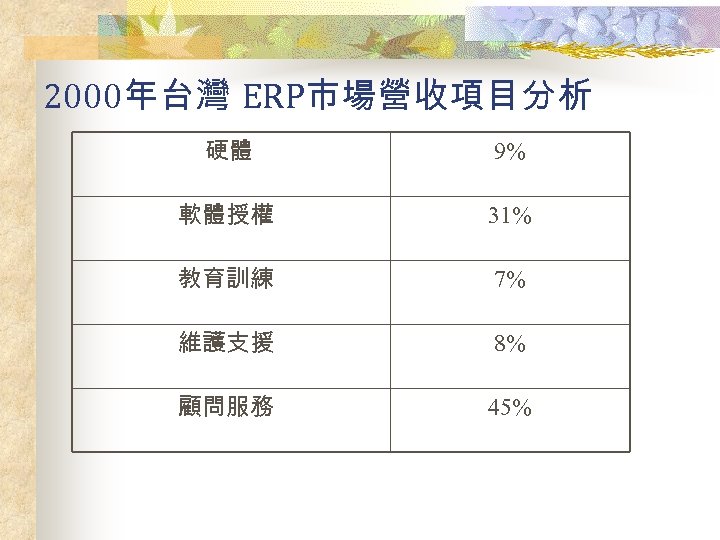

2000年台灣 ERP市場營收項目分析 硬體 9% 軟體授權 31% 教育訓練 7% 維護支援 8% 顧問服務 45%

2000年台灣 ERP市場營收項目分析 硬體 9% 軟體授權 31% 教育訓練 7% 維護支援 8% 顧問服務 45%

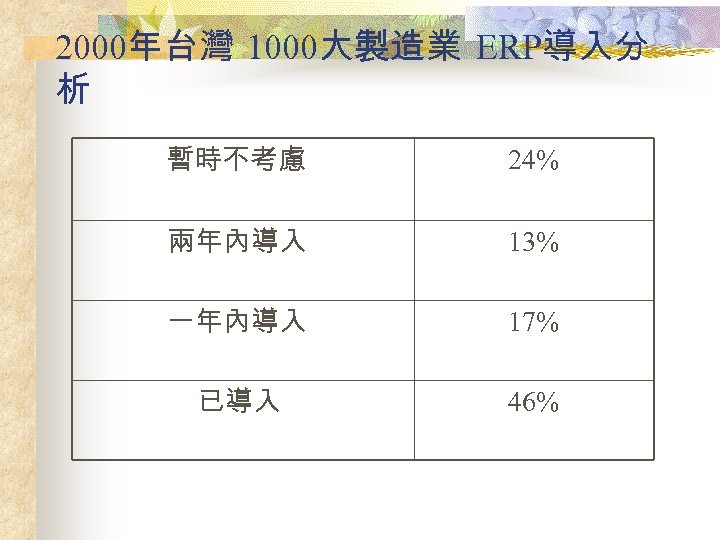

2000年台灣 1000大製造業 ERP導入分 析 暫時不考慮 24% 兩年內導入 13% 一年內導入 17% 已導入 46%

2000年台灣 1000大製造業 ERP導入分 析 暫時不考慮 24% 兩年內導入 13% 一年內導入 17% 已導入 46%

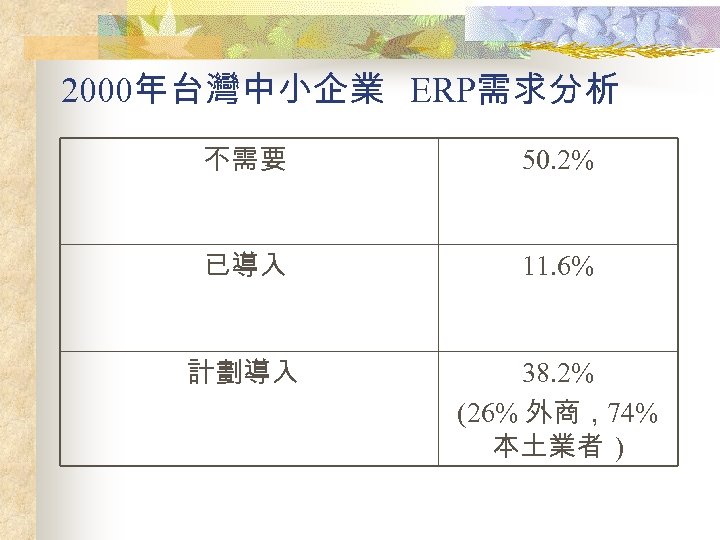

2000年台灣中小企業 ERP需求分析 不需要 50. 2% 已導入 11. 6% 計劃導入 38. 2% (26% 外商,74% 本土業者 )

2000年台灣中小企業 ERP需求分析 不需要 50. 2% 已導入 11. 6% 計劃導入 38. 2% (26% 外商,74% 本土業者 )

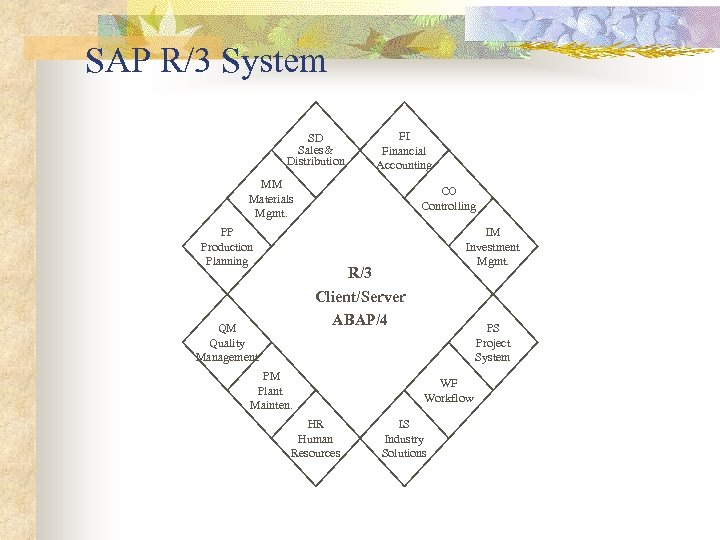

SAP R/3 System SD Sales& Distribution FI Financial Accounting MM Materials Mgmt. PP Production Planning CO Controlling IM Investment Mgmt. R/3 Client/Server ABAP/4 QM Quality Management PM Plant Mainten. HR Human Resources PS Project System WF Workflow IS Industry Solutions

SAP R/3 System SD Sales& Distribution FI Financial Accounting MM Materials Mgmt. PP Production Planning CO Controlling IM Investment Mgmt. R/3 Client/Server ABAP/4 QM Quality Management PM Plant Mainten. HR Human Resources PS Project System WF Workflow IS Industry Solutions

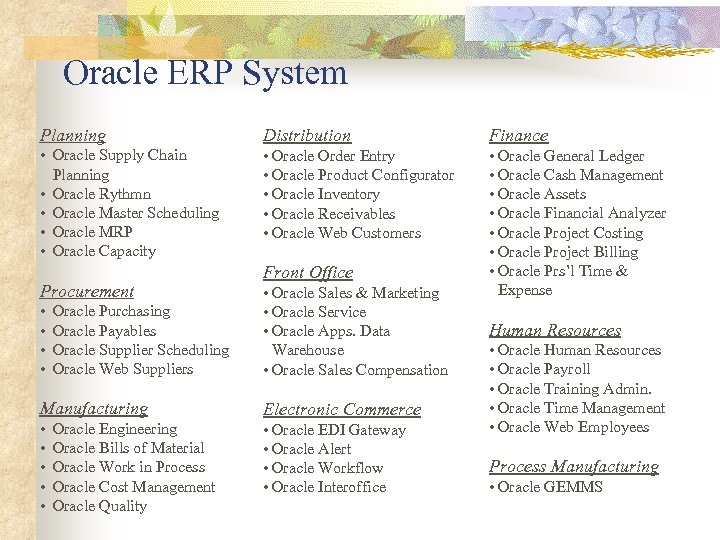

Oracle ERP System Planning Distribution Finance • Oracle Supply Chain Planning • Oracle Rythmn • Oracle Master Scheduling • Oracle MRP • Oracle Capacity • Oracle Order Entry • Oracle Product Configurator • Oracle Inventory • Oracle Receivables • Oracle Web Customers • Oracle General Ledger • Oracle Cash Management • Oracle Assets • Oracle Financial Analyzer • Oracle Project Costing • Oracle Project Billing • Oracle Prs’l Time & Expense Procurement • • Oracle Purchasing Oracle Payables Oracle Supplier Scheduling Oracle Web Suppliers Front Office • Oracle Sales & Marketing • Oracle Service • Oracle Apps. Data Warehouse • Oracle Sales Compensation Manufacturing Electronic Commerce • • • Oracle EDI Gateway • Oracle Alert • Oracle Workflow • Oracle Interoffice Oracle Engineering Oracle Bills of Material Oracle Work in Process Oracle Cost Management Oracle Quality Human Resources • Oracle Payroll • Oracle Training Admin. • Oracle Time Management • Oracle Web Employees Process Manufacturing • Oracle GEMMS

Oracle ERP System Planning Distribution Finance • Oracle Supply Chain Planning • Oracle Rythmn • Oracle Master Scheduling • Oracle MRP • Oracle Capacity • Oracle Order Entry • Oracle Product Configurator • Oracle Inventory • Oracle Receivables • Oracle Web Customers • Oracle General Ledger • Oracle Cash Management • Oracle Assets • Oracle Financial Analyzer • Oracle Project Costing • Oracle Project Billing • Oracle Prs’l Time & Expense Procurement • • Oracle Purchasing Oracle Payables Oracle Supplier Scheduling Oracle Web Suppliers Front Office • Oracle Sales & Marketing • Oracle Service • Oracle Apps. Data Warehouse • Oracle Sales Compensation Manufacturing Electronic Commerce • • • Oracle EDI Gateway • Oracle Alert • Oracle Workflow • Oracle Interoffice Oracle Engineering Oracle Bills of Material Oracle Work in Process Oracle Cost Management Oracle Quality Human Resources • Oracle Payroll • Oracle Training Admin. • Oracle Time Management • Oracle Web Employees Process Manufacturing • Oracle GEMMS

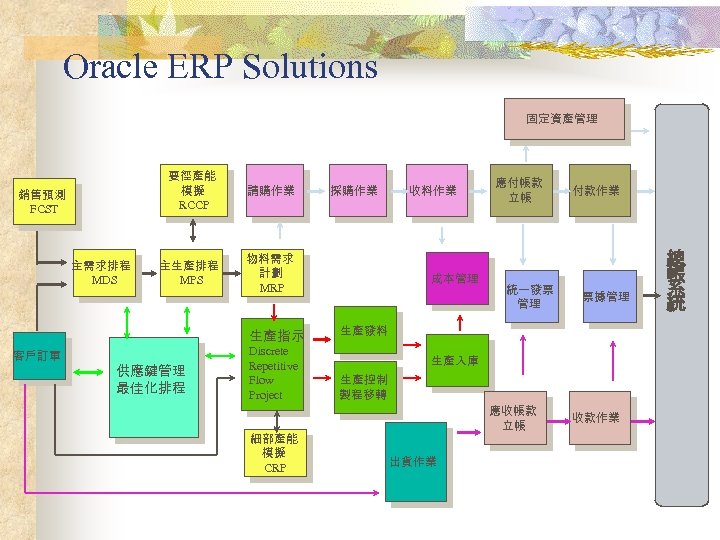

Oracle ERP Solutions 固定資產管理 要徑產能 模擬 RCCP 銷售預測 FCST 主需求排程 MDS 請購作業 主生產排程 MPS 物料需求 計劃 MRP 生產指示 客戶訂單 供應鍵管理 最佳化排程 Discrete Repetitive Flow Project 細部產能 模擬 CRP 採購作業 收料作業 成本管理 應付帳款 立帳 統一發票 管理 付款作業 票據管理 生產發料 生產入庫 生產控制 製程移轉 應收帳款 立帳 出貨作業 收款作業 總 帳 系 統

Oracle ERP Solutions 固定資產管理 要徑產能 模擬 RCCP 銷售預測 FCST 主需求排程 MDS 請購作業 主生產排程 MPS 物料需求 計劃 MRP 生產指示 客戶訂單 供應鍵管理 最佳化排程 Discrete Repetitive Flow Project 細部產能 模擬 CRP 採購作業 收料作業 成本管理 應付帳款 立帳 統一發票 管理 付款作業 票據管理 生產發料 生產入庫 生產控制 製程移轉 應收帳款 立帳 出貨作業 收款作業 總 帳 系 統

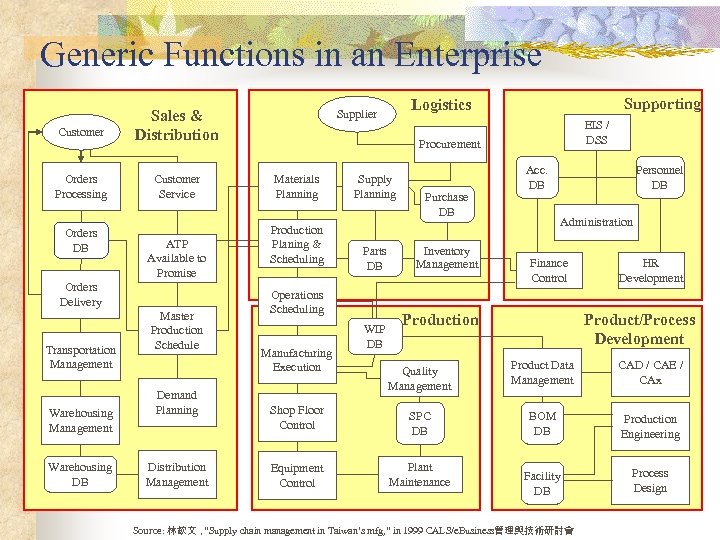

Generic Functions in an Enterprise Customer Sales & Distribution Orders Processing Customer Service Orders DB ATP Available to Promise Orders Delivery Transportation Management Warehousing DB Master Production Schedule Demand Planning Distribution Management Supporting Logistics Supplier EIS / DSS Procurement Materials Planning Production Planing & Scheduling Supply Planning Parts DB Operations Scheduling Manufacturing Execution WIP DB Purchase DB Inventory Management Acc. DB Personnel DB Administration Finance Control Production HR Development Product/Process Development Quality Management Product Data Management CAD / CAE / CAx Shop Floor Control SPC DB BOM DB Production Engineering Equipment Control Plant Maintenance Facility DB Process Design Source: 林欽文 , “Supply chain management in Taiwan’s mfg, ” in 1999 CALS/e. Business管理與技術研討會

Generic Functions in an Enterprise Customer Sales & Distribution Orders Processing Customer Service Orders DB ATP Available to Promise Orders Delivery Transportation Management Warehousing DB Master Production Schedule Demand Planning Distribution Management Supporting Logistics Supplier EIS / DSS Procurement Materials Planning Production Planing & Scheduling Supply Planning Parts DB Operations Scheduling Manufacturing Execution WIP DB Purchase DB Inventory Management Acc. DB Personnel DB Administration Finance Control Production HR Development Product/Process Development Quality Management Product Data Management CAD / CAE / CAx Shop Floor Control SPC DB BOM DB Production Engineering Equipment Control Plant Maintenance Facility DB Process Design Source: 林欽文 , “Supply chain management in Taiwan’s mfg, ” in 1999 CALS/e. Business管理與技術研討會

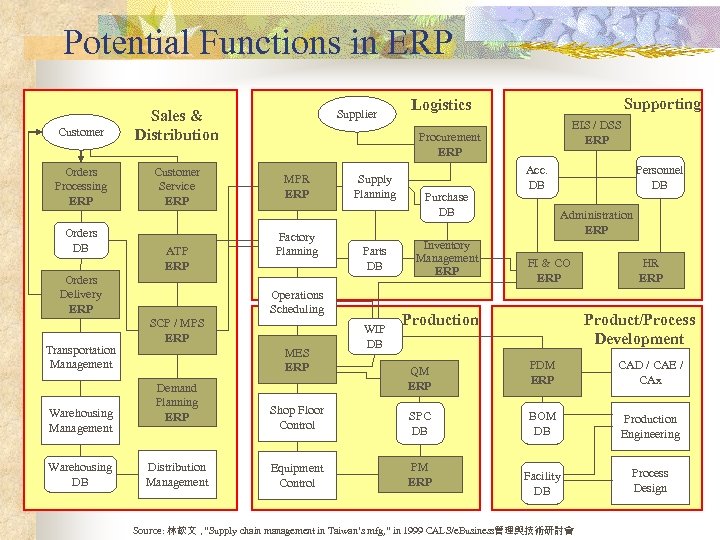

Potential Functions in ERP Customer Sales & Distribution Orders Processing ERP Customer Service ERP Orders DB ATP ERP Orders Delivery ERP Transportation Management Warehousing DB Supplier MPR ERP Factory Planning SCP / MPS ERP MES ERP Distribution Management EIS / DSS ERP Procurement ERP Supply Planning Parts DB Operations Scheduling Demand Planning ERP Supporting Logistics WIP DB Purchase DB Inventory Management ERP Acc. DB Personnel DB Administration ERP FI & CO ERP Production HR ERP Product/Process Development QM ERP PDM ERP CAD / CAE / CAx Shop Floor Control SPC DB BOM DB Production Engineering Equipment Control PM ERP Facility DB Process Design Source: 林欽文 , “Supply chain management in Taiwan’s mfg, ” in 1999 CALS/e. Business管理與技術研討會

Potential Functions in ERP Customer Sales & Distribution Orders Processing ERP Customer Service ERP Orders DB ATP ERP Orders Delivery ERP Transportation Management Warehousing DB Supplier MPR ERP Factory Planning SCP / MPS ERP MES ERP Distribution Management EIS / DSS ERP Procurement ERP Supply Planning Parts DB Operations Scheduling Demand Planning ERP Supporting Logistics WIP DB Purchase DB Inventory Management ERP Acc. DB Personnel DB Administration ERP FI & CO ERP Production HR ERP Product/Process Development QM ERP PDM ERP CAD / CAE / CAx Shop Floor Control SPC DB BOM DB Production Engineering Equipment Control PM ERP Facility DB Process Design Source: 林欽文 , “Supply chain management in Taiwan’s mfg, ” in 1999 CALS/e. Business管理與技術研討會

Order Fulfillment Process n The process is triggered by customer’s order. n The process is aimed at fulfilling customer’s order to ensure the long-term success of the organization.

Order Fulfillment Process n The process is triggered by customer’s order. n The process is aimed at fulfilling customer’s order to ensure the long-term success of the organization.

Design of Order Fulfillment Process n Focus on Time, Cost, Flexibility, and Quality. n The key design factor is the way production and purchasing orders are initiated.

Design of Order Fulfillment Process n Focus on Time, Cost, Flexibility, and Quality. n The key design factor is the way production and purchasing orders are initiated.

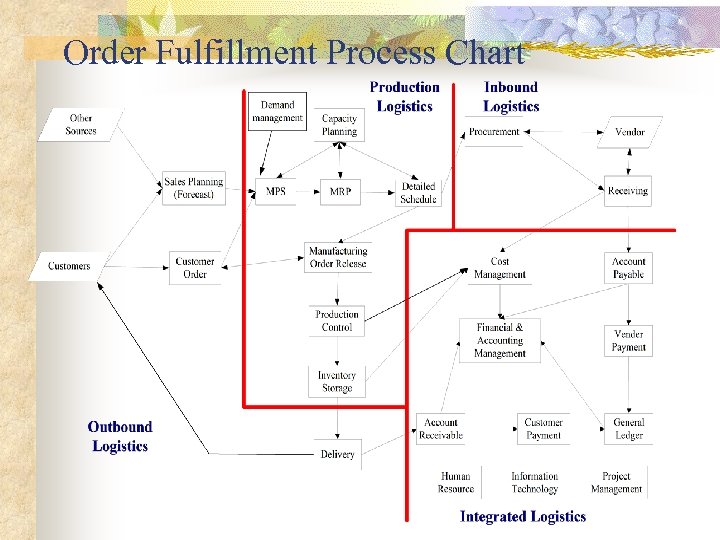

Order Fulfillment Process Chart

Order Fulfillment Process Chart

Part I: Outbound Logistics n Order Management n n Customer Service n n Order entry, order processing, order fulfillment Customer management, sales support (post-sales service), sales returns Sales & Marketing n Sales planning, forecast, sales & distribution system information, sales compensation, pricing & discount management.

Part I: Outbound Logistics n Order Management n n Customer Service n n Order entry, order processing, order fulfillment Customer management, sales support (post-sales service), sales returns Sales & Marketing n Sales planning, forecast, sales & distribution system information, sales compensation, pricing & discount management.

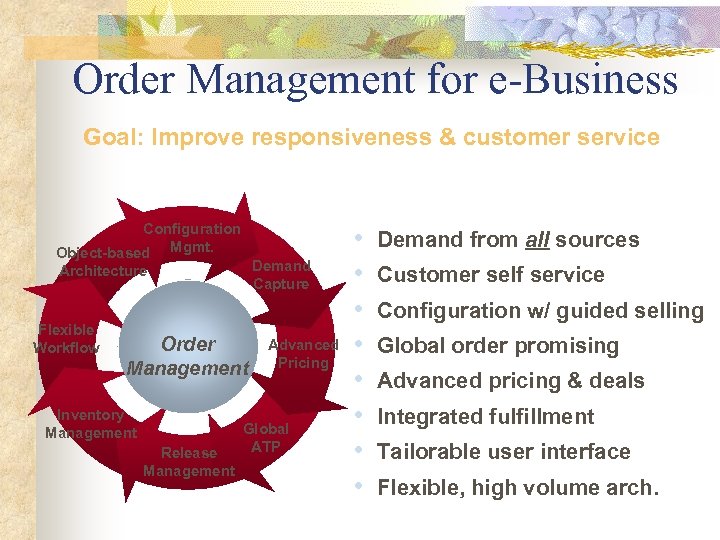

Order Management for e-Business Goal: Improve responsiveness & customer service Configuration Object-based Mgmt. Demand Capture Architecture Flexible Workflow Order Management Inventory Management Release Management Advanced Pricing Global ATP • • Demand from all sources Customer self service Configuration w/ guided selling Global order promising Advanced pricing & deals Integrated fulfillment Tailorable user interface Flexible, high volume arch.

Order Management for e-Business Goal: Improve responsiveness & customer service Configuration Object-based Mgmt. Demand Capture Architecture Flexible Workflow Order Management Inventory Management Release Management Advanced Pricing Global ATP • • Demand from all sources Customer self service Configuration w/ guided selling Global order promising Advanced pricing & deals Integrated fulfillment Tailorable user interface Flexible, high volume arch.

Customer Service n Customer Management n n Define customers, sites and contacts Maintain customer information Define credit limits and limits per order Define customer agreement and payment

Customer Service n Customer Management n n Define customers, sites and contacts Maintain customer information Define credit limits and limits per order Define customer agreement and payment

Customer Service n Sales Support n n Identify service requirement Create sale and service employee plan Schedule service Sales Return n Determine return materials process Receive and inspect returns Credit to customers

Customer Service n Sales Support n n Identify service requirement Create sale and service employee plan Schedule service Sales Return n Determine return materials process Receive and inspect returns Credit to customers

Sales and Marketing n Sale Planning n n Forecast n n Plan sales quantity for groups of products Evaluate planned sales quantities with data (sales revenue, rebates, discount) Plan profitability Predict future price and demand Sales and Distribution Information System n Gather, condense and evaluate data from sales

Sales and Marketing n Sale Planning n n Forecast n n Plan sales quantity for groups of products Evaluate planned sales quantities with data (sales revenue, rebates, discount) Plan profitability Predict future price and demand Sales and Distribution Information System n Gather, condense and evaluate data from sales

Sales & Marketing n Sales Compensation n Pricing and Discount Management n n Create pricing list Define currency Change price structure Define discount program

Sales & Marketing n Sales Compensation n Pricing and Discount Management n n Create pricing list Define currency Change price structure Define discount program

Part II: Production Logistics n Production Planning n n Inventory Control n n n Engineering, BOM, routing, materials forecast Quality n n Inventory, WIP, logistics information system, warehouse management Shop Floor Control Product & Process Development n n Sales and operations planning, demand management, master planning (MPS), MRP, capacity planning, scheduling Planning, inspection, control, certification, notification. Plant Maintenance n Preventive maintenance, maintenance order management, service management

Part II: Production Logistics n Production Planning n n Inventory Control n n n Engineering, BOM, routing, materials forecast Quality n n Inventory, WIP, logistics information system, warehouse management Shop Floor Control Product & Process Development n n Sales and operations planning, demand management, master planning (MPS), MRP, capacity planning, scheduling Planning, inspection, control, certification, notification. Plant Maintenance n Preventive maintenance, maintenance order management, service management

Part III: Inbound Logistics n Procurement n n n Purchasing Supplier Scheduling Receiving Invoice Certification Vender Management

Part III: Inbound Logistics n Procurement n n n Purchasing Supplier Scheduling Receiving Invoice Certification Vender Management

Part IV: Integrated Logistics n n n Human Resources n Organizational Management, Workforce Planning, Training & Event Management, Recruitment, Time Management, Incentive Wages, Payroll, Travel, Personal Development. Financial Management n Investment Management, Cash Management, Depreciation Simulation, Capital Measures. Accounting Management n General Ledger, A/P, A/R, Legal Consolidation, Asset Management.

Part IV: Integrated Logistics n n n Human Resources n Organizational Management, Workforce Planning, Training & Event Management, Recruitment, Time Management, Incentive Wages, Payroll, Travel, Personal Development. Financial Management n Investment Management, Cash Management, Depreciation Simulation, Capital Measures. Accounting Management n General Ledger, A/P, A/R, Legal Consolidation, Asset Management.

Part IV: Integrated Logistics n n n Cost Management n Overhead Cost Controlling, Product Cost Controlling, Profitability analysis. IT Related Management n E-commerce (Web employee, Suppliers, Customers), EDI, Workflow, Business Intelligence System (BIS), Exception System (alert). Project Management n Planning, Budgeting, Execution, Costing, Information System.

Part IV: Integrated Logistics n n n Cost Management n Overhead Cost Controlling, Product Cost Controlling, Profitability analysis. IT Related Management n E-commerce (Web employee, Suppliers, Customers), EDI, Workflow, Business Intelligence System (BIS), Exception System (alert). Project Management n Planning, Budgeting, Execution, Costing, Information System.

ERP Implementation

ERP Implementation

Six Phases n n n Definition Operations Analysis Solution Design Build Transition Production

Six Phases n n n Definition Operations Analysis Solution Design Build Transition Production

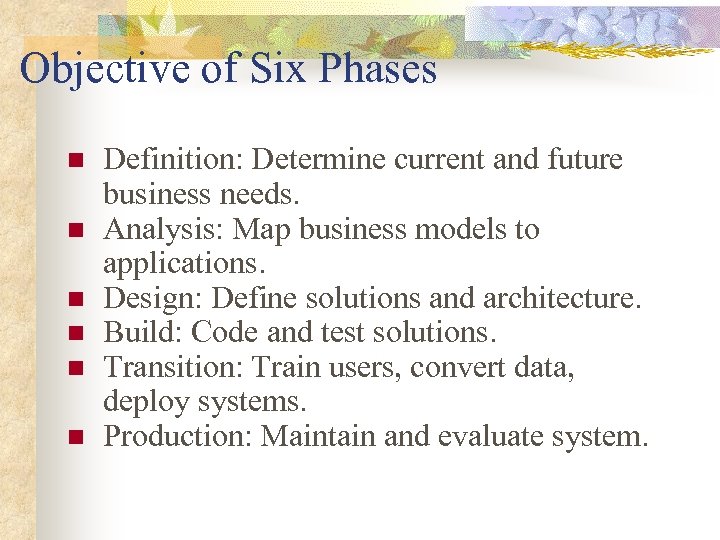

Objective of Six Phases n n n Definition: Determine current and future business needs. Analysis: Map business models to applications. Design: Define solutions and architecture. Build: Code and test solutions. Transition: Train users, convert data, deploy systems. Production: Maintain and evaluate system.

Objective of Six Phases n n n Definition: Determine current and future business needs. Analysis: Map business models to applications. Design: Define solutions and architecture. Build: Code and test solutions. Transition: Train users, convert data, deploy systems. Production: Maintain and evaluate system.

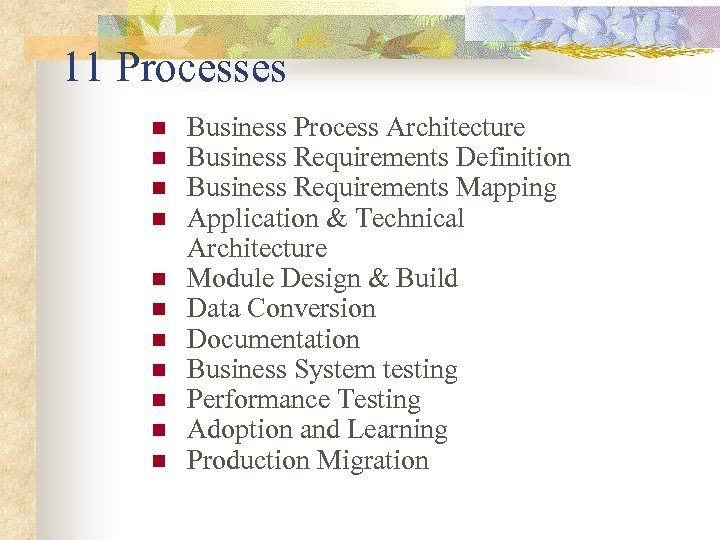

11 Processes n n n Business Process Architecture Business Requirements Definition Business Requirements Mapping Application & Technical Architecture Module Design & Build Data Conversion Documentation Business System testing Performance Testing Adoption and Learning Production Migration

11 Processes n n n Business Process Architecture Business Requirements Definition Business Requirements Mapping Application & Technical Architecture Module Design & Build Data Conversion Documentation Business System testing Performance Testing Adoption and Learning Production Migration

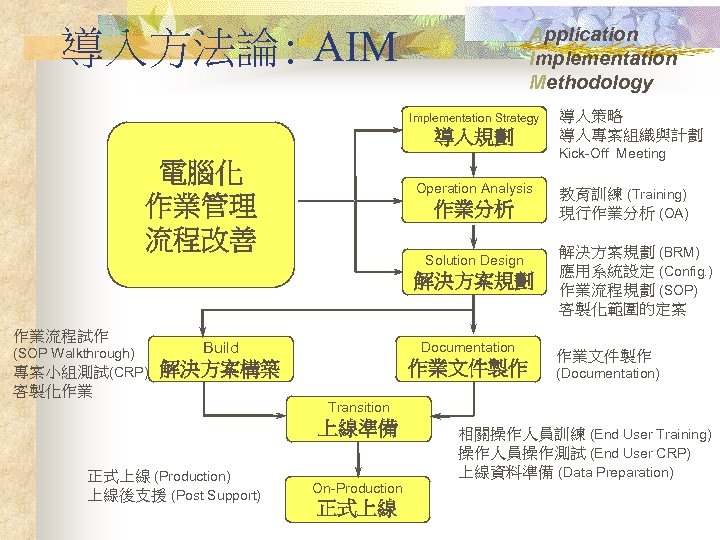

導入方法論: AIM Application Implementation Methodology Implementation Strategy 導入規劃 電腦化 作業管理 流程改善 Operation Analysis 作業分析 Solution Design 解決方案規劃 作業流程試作 (SOP Walkthrough) 專案小組測試(CRP) Build Documentation 解決方案構築 作業文件製作 導入策略 導入專案組織與計劃 Kick-Off Meeting 教育訓練 (Training) 現行作業分析 (OA) 解決方案規劃 (BRM) 應用系統設定 (Config. ) 作業流程規劃 (SOP) 客製化範圍的定案 作業文件製作 (Documentation) 客製化作業 Transition 上線準備 正式上線 (Production) 上線後支援 (Post Support) On-Production 正式上線 相關操作人員訓練 (End User Training) 操作人員操作測試 (End User CRP) 上線資料準備 (Data Preparation)

導入方法論: AIM Application Implementation Methodology Implementation Strategy 導入規劃 電腦化 作業管理 流程改善 Operation Analysis 作業分析 Solution Design 解決方案規劃 作業流程試作 (SOP Walkthrough) 專案小組測試(CRP) Build Documentation 解決方案構築 作業文件製作 導入策略 導入專案組織與計劃 Kick-Off Meeting 教育訓練 (Training) 現行作業分析 (OA) 解決方案規劃 (BRM) 應用系統設定 (Config. ) 作業流程規劃 (SOP) 客製化範圍的定案 作業文件製作 (Documentation) 客製化作業 Transition 上線準備 正式上線 (Production) 上線後支援 (Post Support) On-Production 正式上線 相關操作人員訓練 (End User Training) 操作人員操作測試 (End User CRP) 上線資料準備 (Data Preparation)

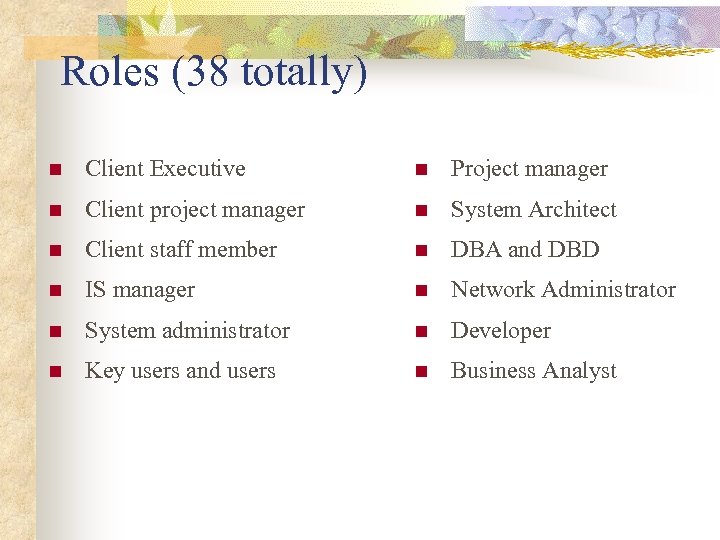

Roles (38 totally) n Client Executive n Project manager n Client project manager n System Architect n Client staff member n DBA and DBD n IS manager n Network Administrator n System administrator n Developer n Key users and users n Business Analyst

Roles (38 totally) n Client Executive n Project manager n Client project manager n System Architect n Client staff member n DBA and DBD n IS manager n Network Administrator n System administrator n Developer n Key users and users n Business Analyst

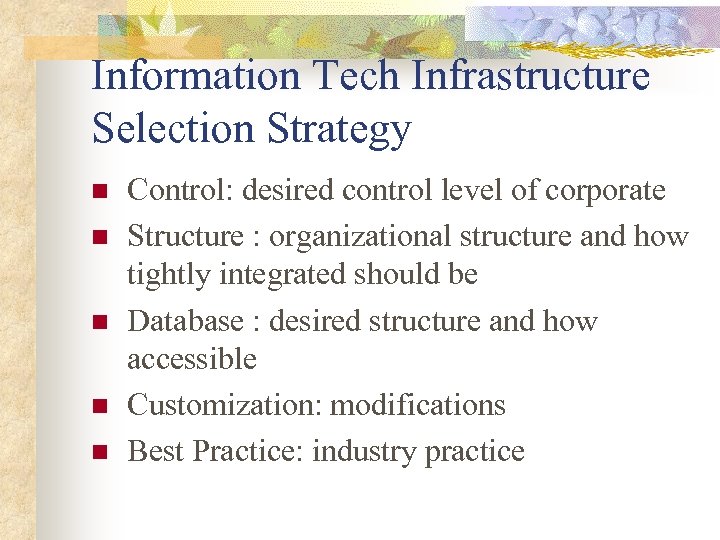

Information Tech Infrastructure Selection Strategy n n n Control: desired control level of corporate Structure : organizational structure and how tightly integrated should be Database : desired structure and how accessible Customization: modifications Best Practice: industry practice

Information Tech Infrastructure Selection Strategy n n n Control: desired control level of corporate Structure : organizational structure and how tightly integrated should be Database : desired structure and how accessible Customization: modifications Best Practice: industry practice

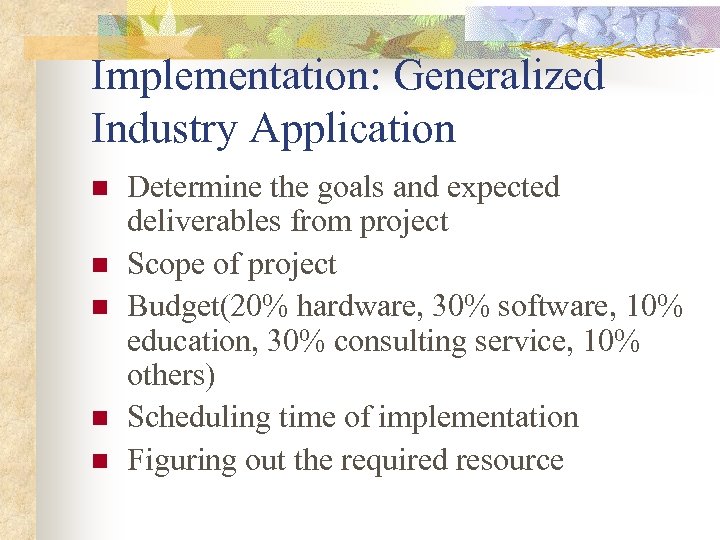

Implementation: Generalized Industry Application n n Determine the goals and expected deliverables from project Scope of project Budget(20% hardware, 30% software, 10% education, 30% consulting service, 10% others) Scheduling time of implementation Figuring out the required resource

Implementation: Generalized Industry Application n n Determine the goals and expected deliverables from project Scope of project Budget(20% hardware, 30% software, 10% education, 30% consulting service, 10% others) Scheduling time of implementation Figuring out the required resource

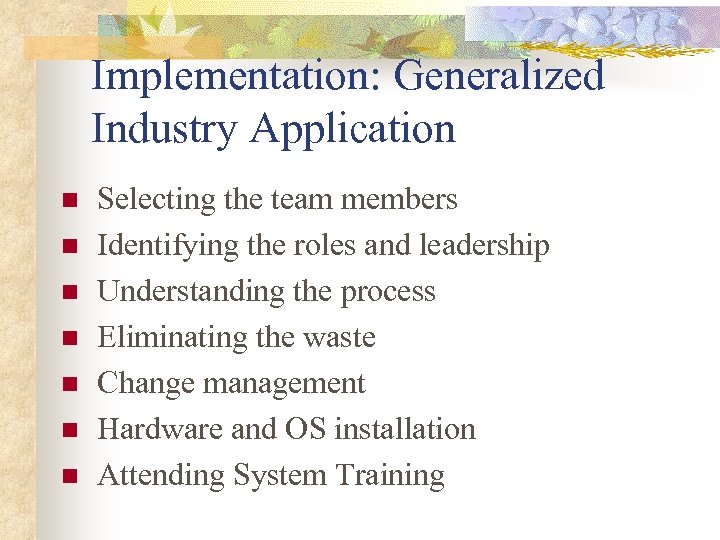

Implementation: Generalized Industry Application n n n Selecting the team members Identifying the roles and leadership Understanding the process Eliminating the waste Change management Hardware and OS installation Attending System Training

Implementation: Generalized Industry Application n n n Selecting the team members Identifying the roles and leadership Understanding the process Eliminating the waste Change management Hardware and OS installation Attending System Training

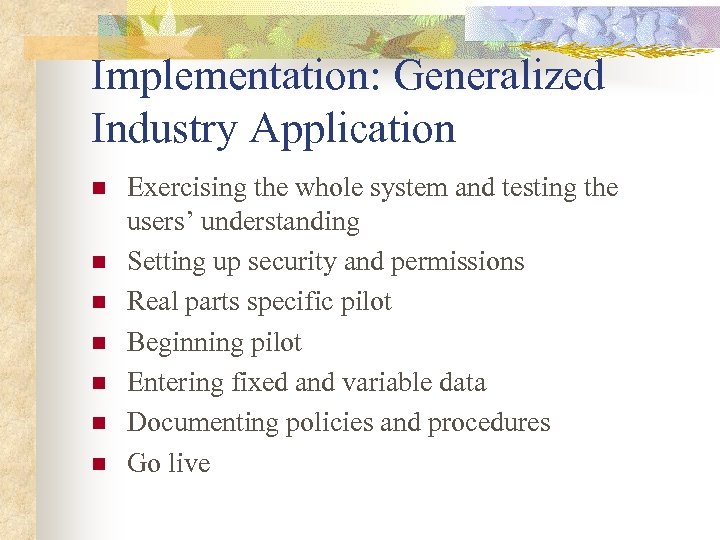

Implementation: Generalized Industry Application n n n Exercising the whole system and testing the users’ understanding Setting up security and permissions Real parts specific pilot Beginning pilot Entering fixed and variable data Documenting policies and procedures Go live

Implementation: Generalized Industry Application n n n Exercising the whole system and testing the users’ understanding Setting up security and permissions Real parts specific pilot Beginning pilot Entering fixed and variable data Documenting policies and procedures Go live

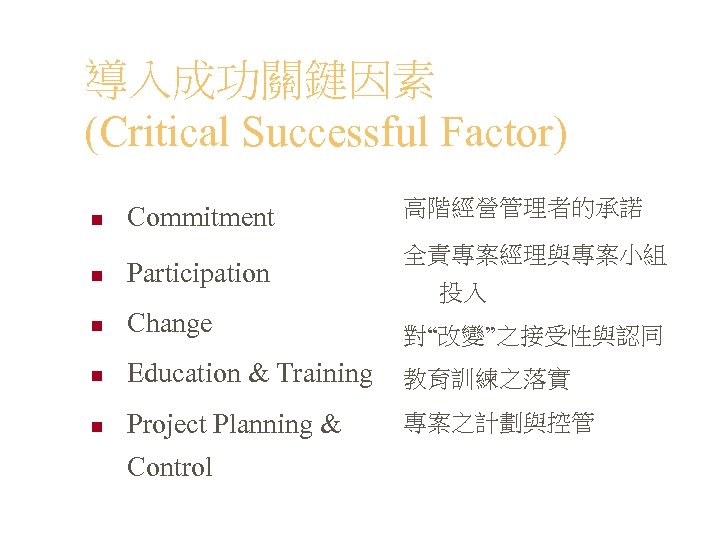

導入成功關鍵因素 (Critical Successful Factor) n Commitment 高階經營管理者的承諾 全責專案經理與專案小組 n Participation n Change 對“改變”之接受性與認同 n Education & Training 教育訓練之落實 n Project Planning & 專案之計劃與控管 Control 投入

導入成功關鍵因素 (Critical Successful Factor) n Commitment 高階經營管理者的承諾 全責專案經理與專案小組 n Participation n Change 對“改變”之接受性與認同 n Education & Training 教育訓練之落實 n Project Planning & 專案之計劃與控管 Control 投入

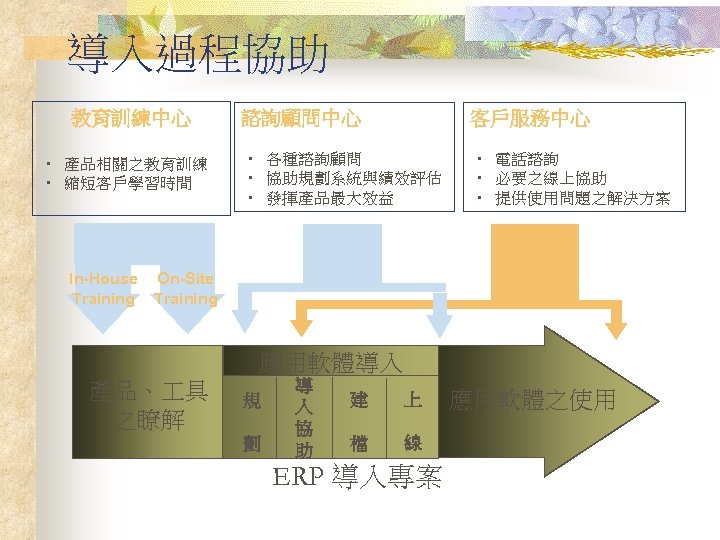

導入過程協助 教育訓練中心 • 產品相關之教育訓練 • 縮短客戶學習時間 In-House Training 諮詢顧問中心 客戶服務中心 • 各種諮詢顧問 • 協助規劃系統與績效評估 • 發揮產品最大效益 • 電話諮詢 • 必要之線上協助 • 提供使用問題之解決方案 On-Site Training 應用軟體導入 產品、 具 之瞭解 規 劃 導 入 協 助 建 上 檔 線 ERP 導入專案 應用軟體之使用

導入過程協助 教育訓練中心 • 產品相關之教育訓練 • 縮短客戶學習時間 In-House Training 諮詢顧問中心 客戶服務中心 • 各種諮詢顧問 • 協助規劃系統與績效評估 • 發揮產品最大效益 • 電話諮詢 • 必要之線上協助 • 提供使用問題之解決方案 On-Site Training 應用軟體導入 產品、 具 之瞭解 規 劃 導 入 協 助 建 上 檔 線 ERP 導入專案 應用軟體之使用

選擇合適之軟體與導入顧問 Your Company Consulting Firm Project Software Vendor

選擇合適之軟體與導入顧問 Your Company Consulting Firm Project Software Vendor

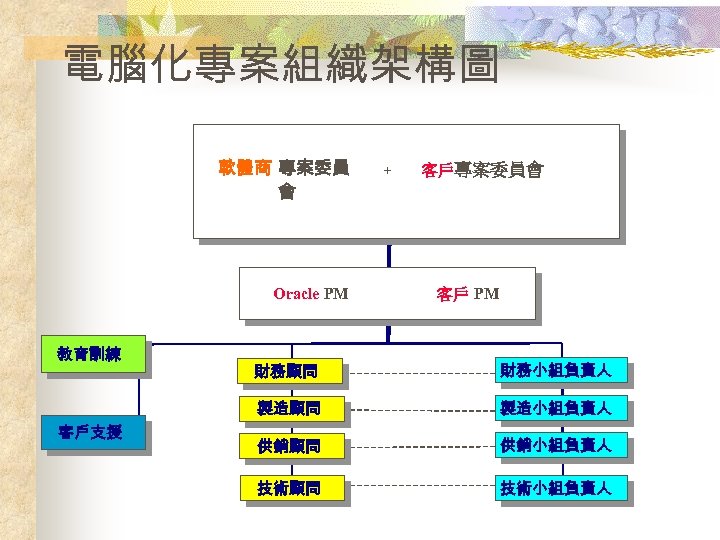

電腦化專案組織架構圖 軟體商 專案委員 會 Oracle PM 教育訓練 + 客戶專案委員會 客戶 PM 財務小組負責人 製造顧問 客戶支援 財務顧問 製造小組負責人 供銷顧問 供銷小組負責人 技術顧問 技術小組負責人

電腦化專案組織架構圖 軟體商 專案委員 會 Oracle PM 教育訓練 + 客戶專案委員會 客戶 PM 財務小組負責人 製造顧問 客戶支援 財務顧問 製造小組負責人 供銷顧問 供銷小組負責人 技術顧問 技術小組負責人

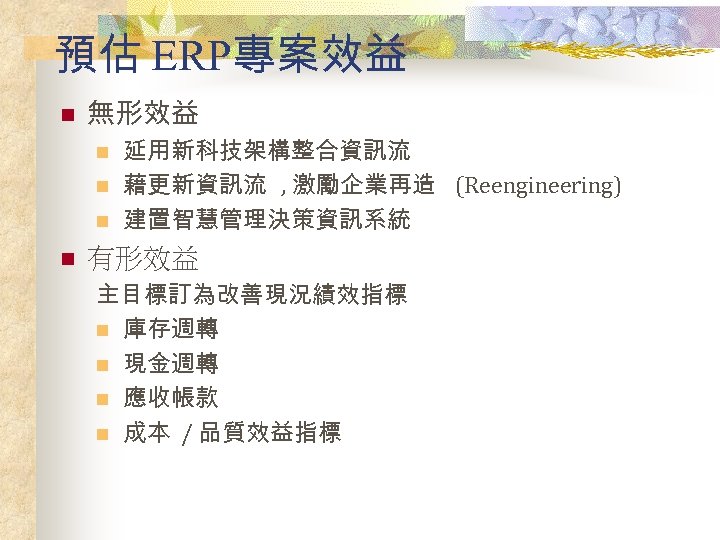

預估 ERP專案效益 n 無形效益 n n 延用新科技架構整合資訊流 藉更新資訊流 , 激勵企業再造 (Reengineering) 建置智慧管理決策資訊系統 有形效益 主目標訂為改善現況績效指標 n 庫存週轉 n 現金週轉 n 應收帳款 n 成本 / 品質效益指標

預估 ERP專案效益 n 無形效益 n n 延用新科技架構整合資訊流 藉更新資訊流 , 激勵企業再造 (Reengineering) 建置智慧管理決策資訊系統 有形效益 主目標訂為改善現況績效指標 n 庫存週轉 n 現金週轉 n 應收帳款 n 成本 / 品質效益指標