5666bb73da111cfcb3a7d51056deaee8.ppt

- Количество слайдов: 11

ERIP – the Swedish Experience Comparison between different SME programme philosophies Dr. Birgitta Öjmertz, Swerea IVF, Programme Director Produktionslyftet Mr. Björn Westling, Swerea IVF 12/6/07

About Swerea IVF We offer advanced research and consulting services. We put new technology and new methods into practice. We care about the world’s limited resources. 2018 -03 -17 2

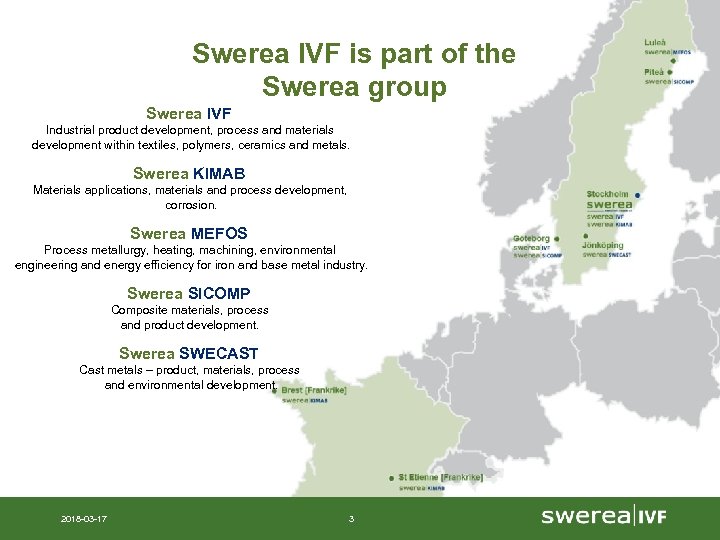

Swerea IVF is part of the Swerea group Swerea IVF Industrial product development, process and materials development within textiles, polymers, ceramics and metals. Swerea KIMAB Materials applications, materials and process development, corrosion. Swerea MEFOS Process metallurgy, heating, machining, environmental engineering and energy efficiency for iron and base metal industry. Swerea SICOMP Composite materials, process and product development. Swerea SWECAST Cast metals – product, materials, process and environmental development. 2018 -03 -17 3

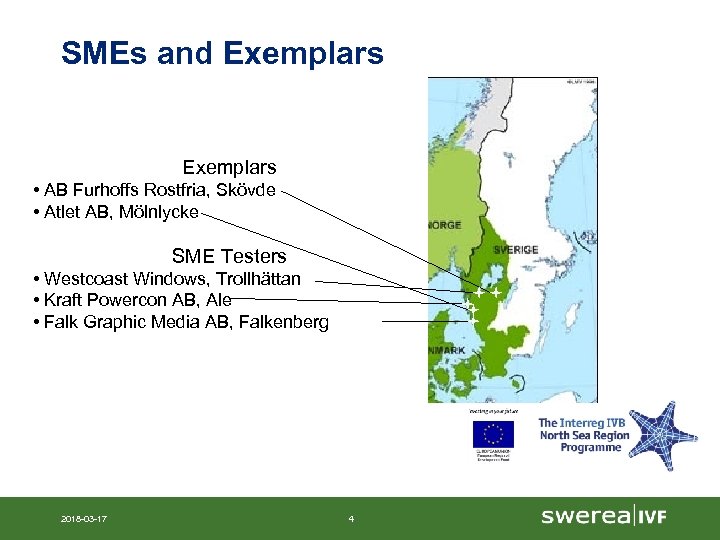

SMEs and Exemplars • AB Furhoffs Rostfria, Skövde • Atlet AB, Mölnlycke SME Testers • Westcoast Windows, Trollhättan • Kraft Powercon AB, Ale • Falk Graphic Media AB, Falkenberg 2018 -03 -17 4

Methodology § ”Standard ERIP” Methdology used – Inspired by NEPA/Barry Rogerson • • Pre-diagnostic, selection of pilot areas Diagnostic Improvement cycles/workshops Indicators chosen and tracked for each cycle § SME testers were also enrolled in ”Produktionslyftet” process 2018 -03 -17 5

Westcoast Windows – introduction § 62 employees § 10 M€ turnover § Manufacturer of wooden/aluminium windows for all kind of buildings 2018 -03 -17 6

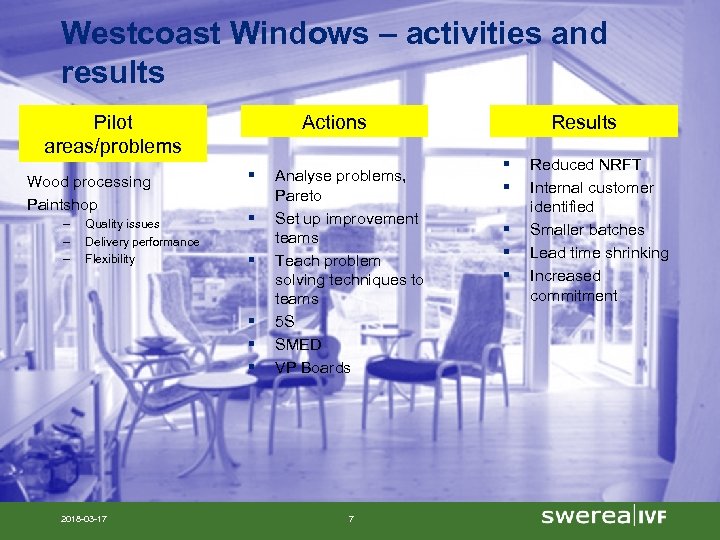

Westcoast Windows – activities and results Pilot areas/problems Wood processing Paintshop – – – Quality issues Delivery performance Flexibility Actions § § § 2018 -03 -17 Analyse problems, Pareto Set up improvement teams Teach problem solving techniques to teams 5 S SMED VP Boards 7 Results § § § Reduced NRFT Internal customer identified Smaller batches Lead time shrinking Increased commitment

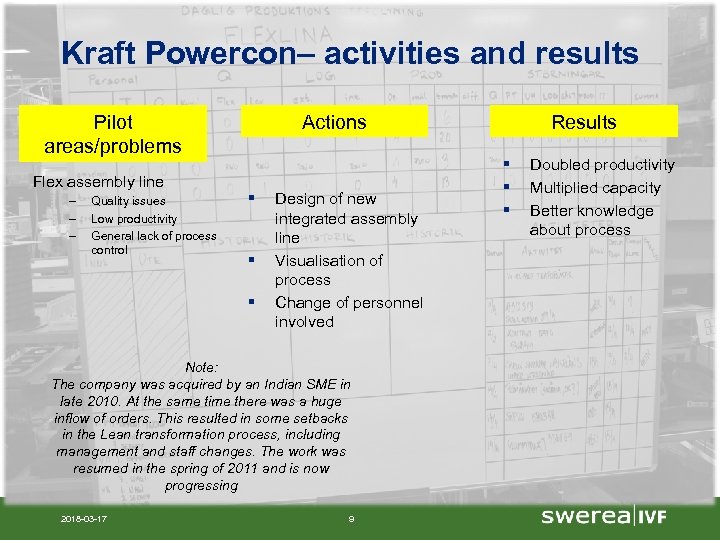

Kraft Powercon – introduction § 90 employees § 23 M€ turnover § Manufacturer of power supplies for industry – high current sources 2018 -03 -17 8

Kraft Powercon– activities and results Pilot areas/problems Flex assembly line – – – Quality issues Low productivity General lack of process control Actions § § § Design of new integrated assembly line Visualisation of process Change of personnel involved Note: The company was acquired by an Indian SME in late 2010. At the same time there was a huge inflow of orders. This resulted in some setbacks in the Lean transformation process, including management and staff changes. The work was resumed in the spring of 2011 and is now progressing 2018 -03 -17 9 Results § § § Doubled productivity Multiplied capacity Better knowledge about process

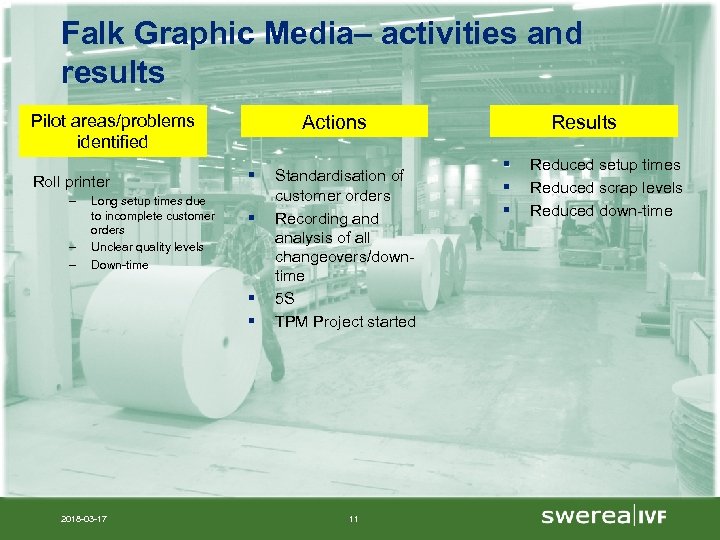

Falk Graphic Media – introduction § 51 employees § 12 M€ turnover § Printing and graphic production for Direct Mail Advertising 2018 -03 -17 10

Falk Graphic Media– activities and results Pilot areas/problems identified Roll printer – – – Long setup times due to incomplete customer orders Unclear quality levels Down-time Actions § § 2018 -03 -17 Standardisation of customer orders Recording and analysis of all changeovers/downtime 5 S TPM Project started 11 Results § § § Reduced setup times Reduced scrap levels Reduced down-time

5666bb73da111cfcb3a7d51056deaee8.ppt