8ceb4be70df1d56e9a0525e2563c9895.ppt

- Количество слайдов: 47

• • • Eric Graves Richard Roh David Mapes Nick Bertrand Mark Adamak • • • BSEE, CS minor BSEE, BSBio. Chem BSEE, BSME

• • • Eric Graves Richard Roh David Mapes Nick Bertrand Mark Adamak • • • BSEE, CS minor BSEE, BSBio. Chem BSEE, BSME

Expertise and Experience • Eric Graves: Expertise: Digital: PLD/FPGA VHDL; Experience: 2 years intern Hayes Brake • Richard Roh: Expertise: Analog design, Microprocessor; Experience: 2 years co-op Re. GENco • David Mapes: Expertise: Digital: PLD/FPGA VHDL, IC’s • Nick Bertrand: Expertise: Amplifier design, Microprocessor • Mark Adamak: Expertise: Digital/Analog Circuit, AC Motors/Drives, VHDL, PLC/PLD, Experience: Co-op at Kohler Co. ; Internship at Interstate Drop Forge

Expertise and Experience • Eric Graves: Expertise: Digital: PLD/FPGA VHDL; Experience: 2 years intern Hayes Brake • Richard Roh: Expertise: Analog design, Microprocessor; Experience: 2 years co-op Re. GENco • David Mapes: Expertise: Digital: PLD/FPGA VHDL, IC’s • Nick Bertrand: Expertise: Amplifier design, Microprocessor • Mark Adamak: Expertise: Digital/Analog Circuit, AC Motors/Drives, VHDL, PLC/PLD, Experience: Co-op at Kohler Co. ; Internship at Interstate Drop Forge

Contact Information Eric Graves: Phone: (414) 232 -0792; Email: ejgraves@uwm. edu Richard Roh: Phone: (262) 853 -1475; Email: rcroh@wi. rr. com David Mapes: Phone: (414) 324 -5816 Email: dmapes@uwm. edu Nick Bertrand: Phone 1: (414) 727 -4912 Email: bertran 2@uwm. edu Mark Adamak: Phone 1: (262) 548 -0331 Email: madamak@uwm. edu

Contact Information Eric Graves: Phone: (414) 232 -0792; Email: ejgraves@uwm. edu Richard Roh: Phone: (262) 853 -1475; Email: rcroh@wi. rr. com David Mapes: Phone: (414) 324 -5816 Email: dmapes@uwm. edu Nick Bertrand: Phone 1: (414) 727 -4912 Email: bertran 2@uwm. edu Mark Adamak: Phone 1: (262) 548 -0331 Email: madamak@uwm. edu

Weekly Availability Information • Eric Graves: Tuesday after 5 pm; Friday after 5 pm; Monday until noon; Wednesday until noon • Richard Roh: Monday till noon; Monday after 5 pm; Thursday 8 am to 6 pm; Wednesday till 2 pm • David Mapes: Monday until 4 pm; Wednesday till 4 pm; Tuesday after 5 pm • Nick Bertrand: Tuesday after 5 pm; Friday after 4 pm; Sat/Sun after 4 pm • Mark Adamak: Mon/Wed Before 5 pm; Tues/Thus Before 1 pm Friday after noon; Weekends

Weekly Availability Information • Eric Graves: Tuesday after 5 pm; Friday after 5 pm; Monday until noon; Wednesday until noon • Richard Roh: Monday till noon; Monday after 5 pm; Thursday 8 am to 6 pm; Wednesday till 2 pm • David Mapes: Monday until 4 pm; Wednesday till 4 pm; Tuesday after 5 pm • Nick Bertrand: Tuesday after 5 pm; Friday after 4 pm; Sat/Sun after 4 pm • Mark Adamak: Mon/Wed Before 5 pm; Tues/Thus Before 1 pm Friday after noon; Weekends

Weekly Project Meeting Times Weekly Meeting 1: Electronics lab E 203 EMS Building , Wednesday 6: 30 pm - 10 pm Weekly Meeting 2: Monday and Wednesday, 8 am - 12 pm Other Weekly Meetings: AS NEEDED

Weekly Project Meeting Times Weekly Meeting 1: Electronics lab E 203 EMS Building , Wednesday 6: 30 pm - 10 pm Weekly Meeting 2: Monday and Wednesday, 8 am - 12 pm Other Weekly Meetings: AS NEEDED

Total Resources • A total of approximately 500 man-hours is what this group has committed to the project. • The group decided that a $250 ($50 per group member) budget was adequate for the project. This figure may be adjusted as the design project evolves.

Total Resources • A total of approximately 500 man-hours is what this group has committed to the project. • The group decided that a $250 ($50 per group member) budget was adequate for the project. This figure may be adjusted as the design project evolves.

Decision • The group will make all major decisions based on a majority vote. Consensus of three members. • Each individual assigned to a design block will have the discretion to make their own decisions. • If a conflict arises for any reason, a vote will be taken to resolve the situation.

Decision • The group will make all major decisions based on a majority vote. Consensus of three members. • Each individual assigned to a design block will have the discretion to make their own decisions. • If a conflict arises for any reason, a vote will be taken to resolve the situation.

Group Roles • Project Archiver: Nick - Owns weekly backup of all electronic material generated that week. • Presentation Mgr: Mark - Owns master MS Powerpoint slide set. • Report Mgr: Richard - Owns master MS Word document for team including revision control.

Group Roles • Project Archiver: Nick - Owns weekly backup of all electronic material generated that week. • Presentation Mgr: Mark - Owns master MS Powerpoint slide set. • Report Mgr: Richard - Owns master MS Word document for team including revision control.

Project Selection: • The ‘Mountain Bike ABS Control System’ was the project that we selected.

Project Selection: • The ‘Mountain Bike ABS Control System’ was the project that we selected.

We chose this project because of the following reasons… • Originality: No other similar product for a mountain bike application. • Donated Parts: Most of the hydraulic brake system provided by Hayes Brakes LLC. • Feasibility and Likeability: Adapting an already implemented idea to a new application that could possibly be marketable. Also, all of the group members liked the project.

We chose this project because of the following reasons… • Originality: No other similar product for a mountain bike application. • Donated Parts: Most of the hydraulic brake system provided by Hayes Brakes LLC. • Feasibility and Likeability: Adapting an already implemented idea to a new application that could possibly be marketable. Also, all of the group members liked the project.

Other projects were rejected because… • Difficulty Level: The other two projects were either to simple (Multiple Hazard Detector) or to difficult (Automated Robotic Lawnmower) for the scope of this class. • Expertise: Group lacked experience with topics needed for other selected projects. • Desire to do the Project: Disagreement in group on feasibility and likeability of other projects.

Other projects were rejected because… • Difficulty Level: The other two projects were either to simple (Multiple Hazard Detector) or to difficult (Automated Robotic Lawnmower) for the scope of this class. • Expertise: Group lacked experience with topics needed for other selected projects. • Desire to do the Project: Disagreement in group on feasibility and likeability of other projects.

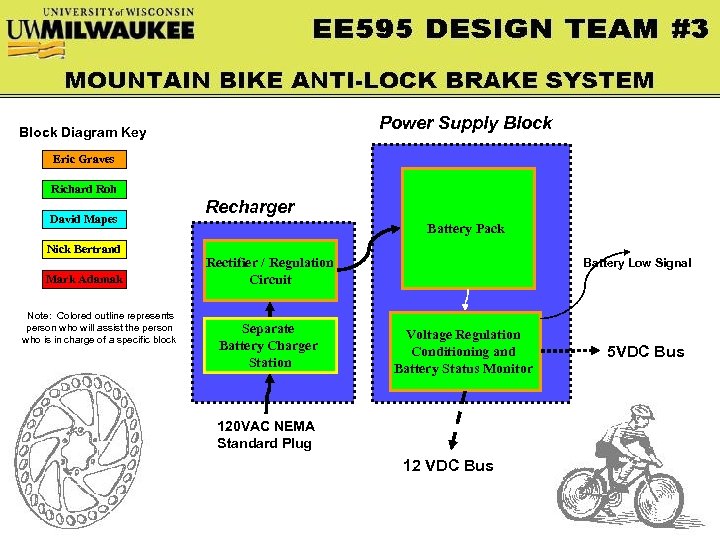

Power Supply Block Diagram Key Eric Graves Richard Roh David Mapes Nick Bertrand Mark Adamak Note: Colored outline represents person who will assist the person who is in charge of a specific block Recharger Battery Pack Rectifier / Regulation Circuit Separate Battery Charger Station Battery Low Signal Voltage Regulation Conditioning and Battery Status Monitor 120 VAC NEMA Standard Plug 12 VDC Bus 5 VDC Bus

Power Supply Block Diagram Key Eric Graves Richard Roh David Mapes Nick Bertrand Mark Adamak Note: Colored outline represents person who will assist the person who is in charge of a specific block Recharger Battery Pack Rectifier / Regulation Circuit Separate Battery Charger Station Battery Low Signal Voltage Regulation Conditioning and Battery Status Monitor 120 VAC NEMA Standard Plug 12 VDC Bus 5 VDC Bus

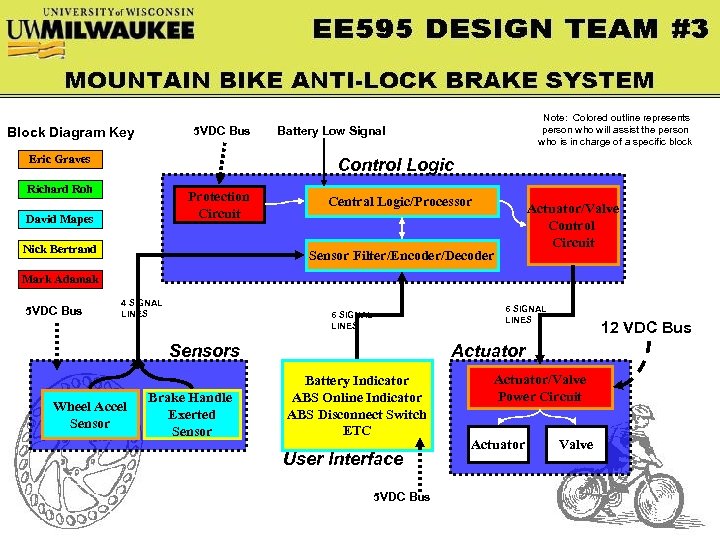

5 VDC Bus Block Diagram Key Eric Graves Note: Colored outline represents person who will assist the person who is in charge of a specific block Battery Low Signal Control Logic Richard Roh Protection Circuit David Mapes Nick Bertrand Central Logic/Processor Actuator/Valve Control Circuit Sensor Filter/Encoder/Decoder Mark Adamak 5 VDC Bus 4 SIGNAL LINES 6 SIGNAL LINES Sensors Wheel Accel Sensor Brake Handle Exerted Sensor 12 VDC Bus Actuator Battery Indicator ABS Online Indicator ABS Disconnect Switch ETC User Interface 5 VDC Bus Actuator/Valve Power Circuit Actuator Valve

5 VDC Bus Block Diagram Key Eric Graves Note: Colored outline represents person who will assist the person who is in charge of a specific block Battery Low Signal Control Logic Richard Roh Protection Circuit David Mapes Nick Bertrand Central Logic/Processor Actuator/Valve Control Circuit Sensor Filter/Encoder/Decoder Mark Adamak 5 VDC Bus 4 SIGNAL LINES 6 SIGNAL LINES Sensors Wheel Accel Sensor Brake Handle Exerted Sensor 12 VDC Bus Actuator Battery Indicator ABS Online Indicator ABS Disconnect Switch ETC User Interface 5 VDC Bus Actuator/Valve Power Circuit Actuator Valve

The Mountain Bike ABS Control System Description… • Aftermarket antilock brakes for a dual rotor, hydraulic disc brake system. • This will provide steering control in an aggressive braking situation while the rider is participating in extreme mountain bike riding. • Will prevent the locking of brakes during decel and low friction conditions. • The controller will also give the rider the ability to over-ride the ABS action. • A small display will inform the rider of the status of the system; when brakes are enabled, activated, and battery charge indicator.

The Mountain Bike ABS Control System Description… • Aftermarket antilock brakes for a dual rotor, hydraulic disc brake system. • This will provide steering control in an aggressive braking situation while the rider is participating in extreme mountain bike riding. • Will prevent the locking of brakes during decel and low friction conditions. • The controller will also give the rider the ability to over-ride the ABS action. • A small display will inform the rider of the status of the system; when brakes are enabled, activated, and battery charge indicator.

The Mountain Bike ABS Control System Specifics… • Cost of System not to exceed $250 • Must have standard NEMA plug (120 VAC) power input battery recharger • ABS Actuation system will be comprised of springs, solenoids and valves to remove and drive pressure into brake system. Must be constructed by the end of February, 2004 • A 6 VAC tire generator power input producing approximately 60 WH for recharging battery during operation of mountain bike • 1 AHr Nickel Metal Hydride battery pack • Maximum product mass of 10 lbs • 4 Printed circuit boards

The Mountain Bike ABS Control System Specifics… • Cost of System not to exceed $250 • Must have standard NEMA plug (120 VAC) power input battery recharger • ABS Actuation system will be comprised of springs, solenoids and valves to remove and drive pressure into brake system. Must be constructed by the end of February, 2004 • A 6 VAC tire generator power input producing approximately 60 WH for recharging battery during operation of mountain bike • 1 AHr Nickel Metal Hydride battery pack • Maximum product mass of 10 lbs • 4 Printed circuit boards

The Mountain Bike ABS Control System Specifics… • An inductive proximity sensor that operates on 5 VDC to measure change in wheel rotation • User Interface incorporating LED display to inform rider of low battery, ABS actuation, and when the ABS system is online • Momentary contact switch to turn ABS System on and off at riders discretion • Two maintained voltage busses: 5 VDC for control logic; 12 VDC for powering actuators and valves • Mounting and packaging consideration for all components must be chosen

The Mountain Bike ABS Control System Specifics… • An inductive proximity sensor that operates on 5 VDC to measure change in wheel rotation • User Interface incorporating LED display to inform rider of low battery, ABS actuation, and when the ABS system is online • Momentary contact switch to turn ABS System on and off at riders discretion • Two maintained voltage busses: 5 VDC for control logic; 12 VDC for powering actuators and valves • Mounting and packaging consideration for all components must be chosen

Design Block I: Richard Roh, Power Supply, Standard Requirements. • A total of five thousand power supply units will be produced • Production cost will be $105 per unit, and estimated prototype cost will be $120 per unit. • There are three energy sources: ~ Nickel Metal Hydride Battery, operating @ 10 VDC to 14 VDC, with energy consumption of 4100 m. AH, temporary 9 position male/female quick connects. ~120 VAC/60 Hz Charger, operating @ 102 VAC to 132 VAC, with energy consumption of 56 WH, with NEMA plug to wall outlet and 9 position male/female plug to battery pack. • Power supply block will occupy approximately 189 cubic centimeters. • Shipping volume will be about 274 cubic centimeters. • Approximate weight of power supply is 1. 6 Kg. • One PC board will be used to interface with voltage regulators and power buses, this board will occupy about 5 squared centimeters • Power supply will be able to sustain an impact of 5 G’s with a repetition of 100 times of impact. • Power supply will operate in the same environmental condition as the entire ABS unit.

Design Block I: Richard Roh, Power Supply, Standard Requirements. • A total of five thousand power supply units will be produced • Production cost will be $105 per unit, and estimated prototype cost will be $120 per unit. • There are three energy sources: ~ Nickel Metal Hydride Battery, operating @ 10 VDC to 14 VDC, with energy consumption of 4100 m. AH, temporary 9 position male/female quick connects. ~120 VAC/60 Hz Charger, operating @ 102 VAC to 132 VAC, with energy consumption of 56 WH, with NEMA plug to wall outlet and 9 position male/female plug to battery pack. • Power supply block will occupy approximately 189 cubic centimeters. • Shipping volume will be about 274 cubic centimeters. • Approximate weight of power supply is 1. 6 Kg. • One PC board will be used to interface with voltage regulators and power buses, this board will occupy about 5 squared centimeters • Power supply will be able to sustain an impact of 5 G’s with a repetition of 100 times of impact. • Power supply will operate in the same environmental condition as the entire ABS unit.

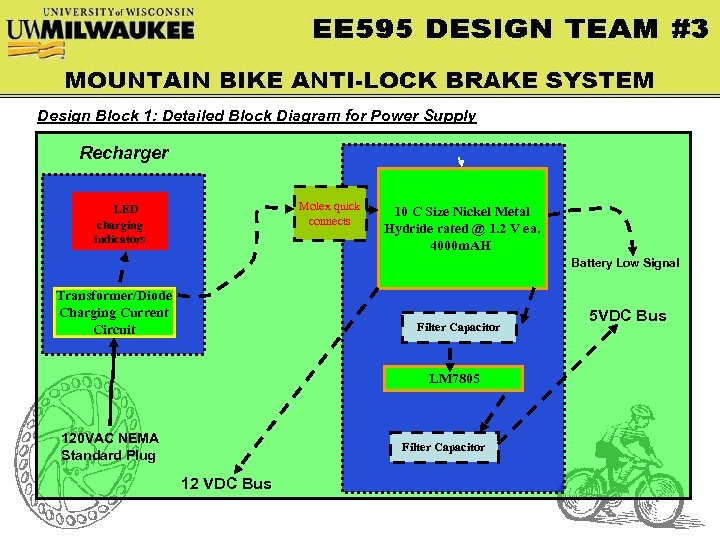

Design Block 1: Detailed Block Diagram for Power Supply Recharger CLED Molex quick connects charging indicators 10 C Size Nickel Metal Hydride rated @ 1. 2 V ea. 4000 m. AH Battery Low Signal Transformer/Diode Charging Current Circuit Filter Capacitor LM 7805 120 VAC NEMA Standard Plug Filter Capacitor 12 VDC Bus 5 VDC Bus

Design Block 1: Detailed Block Diagram for Power Supply Recharger CLED Molex quick connects charging indicators 10 C Size Nickel Metal Hydride rated @ 1. 2 V ea. 4000 m. AH Battery Low Signal Transformer/Diode Charging Current Circuit Filter Capacitor LM 7805 120 VAC NEMA Standard Plug Filter Capacitor 12 VDC Bus 5 VDC Bus

Design Block I: Richard Roh, Power Supply, Standard Requirements. Continued • A total of five thousand power supply units will be produced • Primary safety standards will be articulated by the articles IEC 950 and UL 2601. • Primary EMC standards will be set forth by EN 55011, IEC 60601 -1 -2, 61000 -4 -5, 61000 -4 -11, 61000 -4 -2, 61000 -3 -3, 61000 -4 -5 • The total parts count of power supply will be about 63 ; of these about 50 will unique. • Total material cost will be estimated to $100, and maximum assembly and test cost will be $12. • Maximum production lifetime is 5 years, and the average storage life of the battery pack is two years. • Battery pack is environmentally friendly and can be recycled. • Battery pack will be replaced for any defects within 90 days. • Nickel Metal Hydride battery pack will consist of 10 AA stacked in series spot welded by nickel foil strips. • Battery pack will be shrinked wrapped. • Charger consists of AC transformer, diode bridge rectifier, and Zener diode charge indicator circuit.

Design Block I: Richard Roh, Power Supply, Standard Requirements. Continued • A total of five thousand power supply units will be produced • Primary safety standards will be articulated by the articles IEC 950 and UL 2601. • Primary EMC standards will be set forth by EN 55011, IEC 60601 -1 -2, 61000 -4 -5, 61000 -4 -11, 61000 -4 -2, 61000 -3 -3, 61000 -4 -5 • The total parts count of power supply will be about 63 ; of these about 50 will unique. • Total material cost will be estimated to $100, and maximum assembly and test cost will be $12. • Maximum production lifetime is 5 years, and the average storage life of the battery pack is two years. • Battery pack is environmentally friendly and can be recycled. • Battery pack will be replaced for any defects within 90 days. • Nickel Metal Hydride battery pack will consist of 10 AA stacked in series spot welded by nickel foil strips. • Battery pack will be shrinked wrapped. • Charger consists of AC transformer, diode bridge rectifier, and Zener diode charge indicator circuit.

Design Block I: Richard Roh, Power Supply, Performance Requirements • Zener diode LED circuit is used to indicate charge status. • Amber LED wiil indicate a charge voltage of less than 14 VDC, while green LED will indicate a charge voltage of greater than 14 VDC (full charge). This display will be viewed at a maximum distance of 1 meter, in an indoor setting. • Charging Characteristics ~charger will be constructed with AC transformer of primary rating of 120 VAC/60 Hz, and secondary rating of 12 VAC at 0. 5 A. ~nominal charge voltage will be 1. 55 V ~standard charge rate method will be used, charge is for 16 hours, 10 % of rated capacity per hour (C/10). Discharge rate of C/3 will given an approximate continuous runtime of 5 hours. ~current charge range will be from 345 m. A to 375 m. A. ~discharge rate will be 3 C continuous, spikes @ 6 C, and minimum voltage cutoff 1. 0 V ~charging temperature 10 to 40 C, discharging -20 to 40 C, storage – 20 to 30 C • Battery Characteristics: ~500 recharging cycles. ~minimal memory effect, environmentally friendly ~nominal voltage 1. 2 V, fully charged voltage 1. 4 V, fully discharged voltage 1. 0 V. ~capacity range from 3900 m. AH to 4100 m. AH ~maximum internal resistance @ 1000 Hz is 19. 0 m. Ohm. ~battery pack will have a voltage range of 10 V to 14 V.

Design Block I: Richard Roh, Power Supply, Performance Requirements • Zener diode LED circuit is used to indicate charge status. • Amber LED wiil indicate a charge voltage of less than 14 VDC, while green LED will indicate a charge voltage of greater than 14 VDC (full charge). This display will be viewed at a maximum distance of 1 meter, in an indoor setting. • Charging Characteristics ~charger will be constructed with AC transformer of primary rating of 120 VAC/60 Hz, and secondary rating of 12 VAC at 0. 5 A. ~nominal charge voltage will be 1. 55 V ~standard charge rate method will be used, charge is for 16 hours, 10 % of rated capacity per hour (C/10). Discharge rate of C/3 will given an approximate continuous runtime of 5 hours. ~current charge range will be from 345 m. A to 375 m. A. ~discharge rate will be 3 C continuous, spikes @ 6 C, and minimum voltage cutoff 1. 0 V ~charging temperature 10 to 40 C, discharging -20 to 40 C, storage – 20 to 30 C • Battery Characteristics: ~500 recharging cycles. ~minimal memory effect, environmentally friendly ~nominal voltage 1. 2 V, fully charged voltage 1. 4 V, fully discharged voltage 1. 0 V. ~capacity range from 3900 m. AH to 4100 m. AH ~maximum internal resistance @ 1000 Hz is 19. 0 m. Ohm. ~battery pack will have a voltage range of 10 V to 14 V.

Design Block I: Richard Roh, Power Supply, Performance Requirements Continued • Electrical Interfaces: ~The voltage from the charged battery pack will interface with a 5 VDC and 12 VDC bus. ~LM 7805 will be used for the 5 VDC bus.

Design Block I: Richard Roh, Power Supply, Performance Requirements Continued • Electrical Interfaces: ~The voltage from the charged battery pack will interface with a 5 VDC and 12 VDC bus. ~LM 7805 will be used for the 5 VDC bus.

Design Block 2: Eric Graves, Control Logic, Standard Requirements • 30% of total prototype cost - $150 • 1% of total product volume – 5. 4 cm^3 • 3. 33% of total product mass – 0. 165 kg

Design Block 2: Eric Graves, Control Logic, Standard Requirements • 30% of total prototype cost - $150 • 1% of total product volume – 5. 4 cm^3 • 3. 33% of total product mass – 0. 165 kg

Design Block 2: Eric Graves, Control Logic, Performance Requirements • Nominal input power – 5 VDC • Must not consume a lot of power • Must have capacity to “decide” if the breaks are locked. • Must have ability to do fast floating-point calculations. • Must have TTL I/O • Must take input from rider and bike asynchronously

Design Block 2: Eric Graves, Control Logic, Performance Requirements • Nominal input power – 5 VDC • Must not consume a lot of power • Must have capacity to “decide” if the breaks are locked. • Must have ability to do fast floating-point calculations. • Must have TTL I/O • Must take input from rider and bike asynchronously

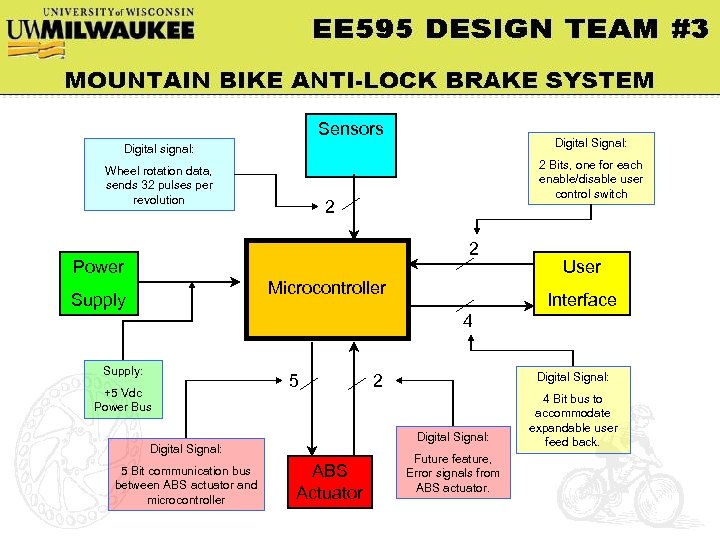

Sensors Digital signal: Digital Signal: Wheel rotation data, sends 32 pulses per revolution 2 Bits, one for each enable/disable user control switch 2 2 Power Microcontroller Supply User Interface 4 Supply: +5 Vdc Power Bus 5 Digital Signal: 5 Bit communication bus between ABS actuator and microcontroller Digital Signal: 2 ABS Actuator Future feature, Error signals from ABS actuator. 4 Bit bus to accommodate expandable user feed back.

Sensors Digital signal: Digital Signal: Wheel rotation data, sends 32 pulses per revolution 2 Bits, one for each enable/disable user control switch 2 2 Power Microcontroller Supply User Interface 4 Supply: +5 Vdc Power Bus 5 Digital Signal: 5 Bit communication bus between ABS actuator and microcontroller Digital Signal: 2 ABS Actuator Future feature, Error signals from ABS actuator. 4 Bit bus to accommodate expandable user feed back.

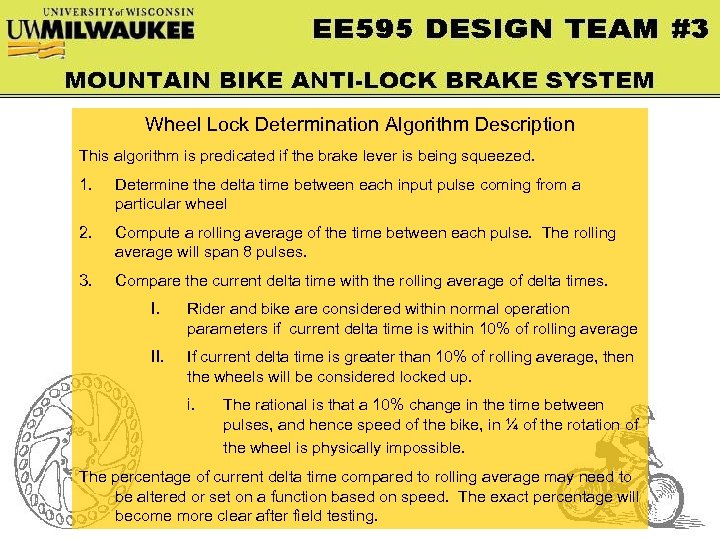

Wheel Lock Determination Algorithm Description This algorithm is predicated if the brake lever is being squeezed. 1. Determine the delta time between each input pulse coming from a particular wheel 2. Compute a rolling average of the time between each pulse. The rolling average will span 8 pulses. 3. Compare the current delta time with the rolling average of delta times. I. Rider and bike are considered within normal operation parameters if current delta time is within 10% of rolling average II. If current delta time is greater than 10% of rolling average, then the wheels will be considered locked up. i. The rational is that a 10% change in the time between pulses, and hence speed of the bike, in ¼ of the rotation of the wheel is physically impossible. The percentage of current delta time compared to rolling average may need to be altered or set on a function based on speed. The exact percentage will become more clear after field testing.

Wheel Lock Determination Algorithm Description This algorithm is predicated if the brake lever is being squeezed. 1. Determine the delta time between each input pulse coming from a particular wheel 2. Compute a rolling average of the time between each pulse. The rolling average will span 8 pulses. 3. Compare the current delta time with the rolling average of delta times. I. Rider and bike are considered within normal operation parameters if current delta time is within 10% of rolling average II. If current delta time is greater than 10% of rolling average, then the wheels will be considered locked up. i. The rational is that a 10% change in the time between pulses, and hence speed of the bike, in ¼ of the rotation of the wheel is physically impossible. The percentage of current delta time compared to rolling average may need to be altered or set on a function based on speed. The exact percentage will become more clear after field testing.

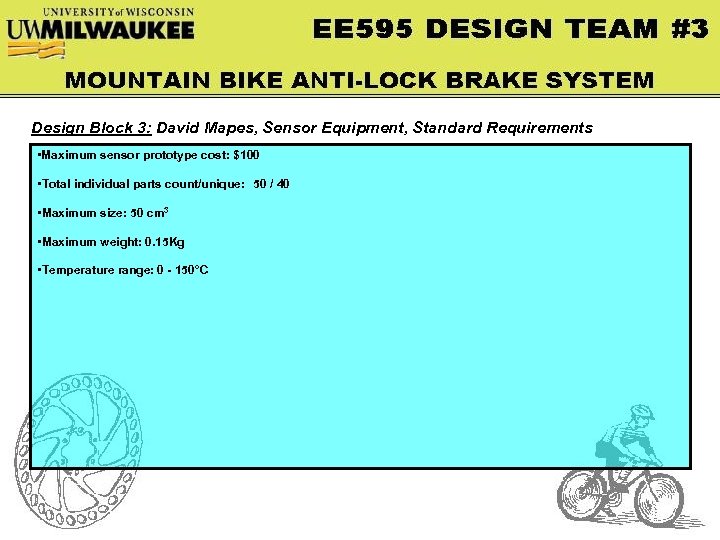

Design Block 3: David Mapes, Sensor Equipment, Standard Requirements • Maximum sensor prototype cost: $100 • Total individual parts count/unique: 50 / 40 • Maximum size: 50 cm 3 • Maximum weight: 0. 15 Kg • Temperature range: 0 - 150°C

Design Block 3: David Mapes, Sensor Equipment, Standard Requirements • Maximum sensor prototype cost: $100 • Total individual parts count/unique: 50 / 40 • Maximum size: 50 cm 3 • Maximum weight: 0. 15 Kg • Temperature range: 0 - 150°C

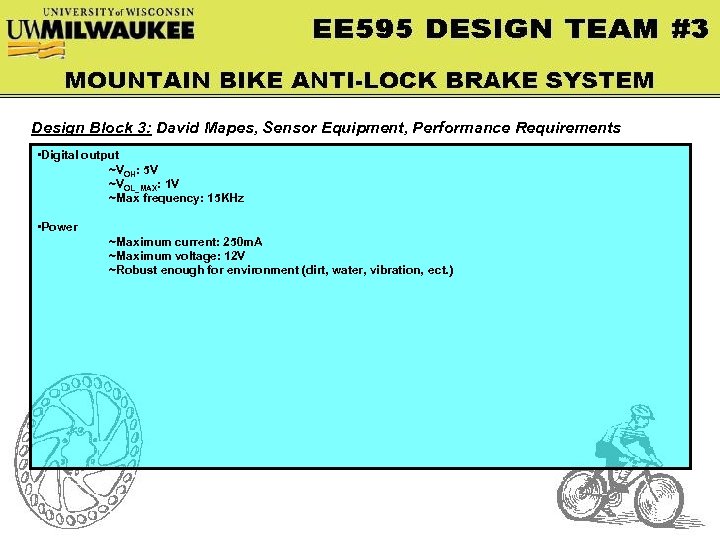

Design Block 3: David Mapes, Sensor Equipment, Performance Requirements • Digital output ~VOH: 5 V ~VOL_MAX: 1 V ~Max frequency: 15 KHz • Power ~Maximum current: 250 m. A ~Maximum voltage: 12 V ~Robust enough for environment (dirt, water, vibration, ect. )

Design Block 3: David Mapes, Sensor Equipment, Performance Requirements • Digital output ~VOH: 5 V ~VOL_MAX: 1 V ~Max frequency: 15 KHz • Power ~Maximum current: 250 m. A ~Maximum voltage: 12 V ~Robust enough for environment (dirt, water, vibration, ect. )

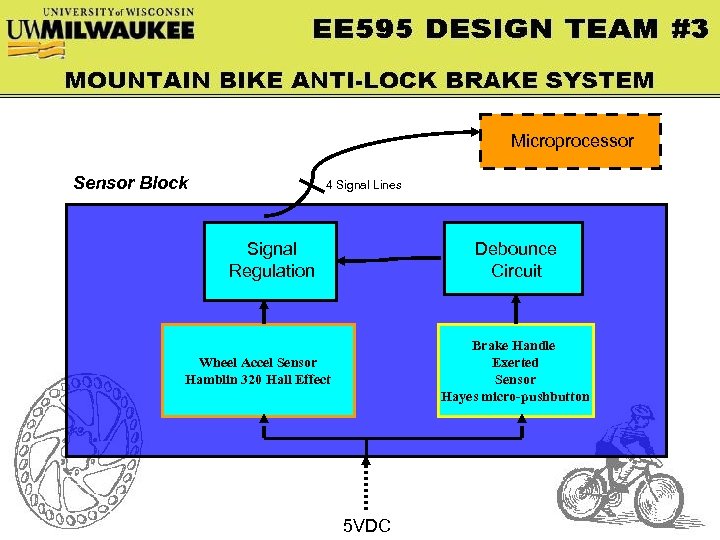

Microprocessor Sensor Block 4 Signal Lines Signal Regulation Debounce Circuit Brake Handle Exerted Sensor Hayes micro-pushbutton Wheel Accel Sensor Hamblin 320 Hall Effect 5 VDC

Microprocessor Sensor Block 4 Signal Lines Signal Regulation Debounce Circuit Brake Handle Exerted Sensor Hayes micro-pushbutton Wheel Accel Sensor Hamblin 320 Hall Effect 5 VDC

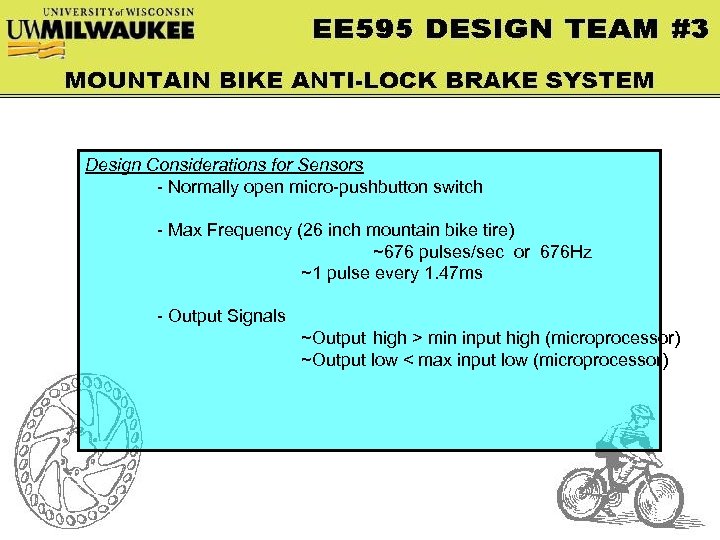

Design Considerations for Sensors - Normally open micro-pushbutton switch - Max Frequency (26 inch mountain bike tire) ~676 pulses/sec or 676 Hz ~1 pulse every 1. 47 ms - Output Signals ~Output high > min input high (microprocessor) ~Output low < max input low (microprocessor)

Design Considerations for Sensors - Normally open micro-pushbutton switch - Max Frequency (26 inch mountain bike tire) ~676 pulses/sec or 676 Hz ~1 pulse every 1. 47 ms - Output Signals ~Output high > min input high (microprocessor) ~Output low < max input low (microprocessor)

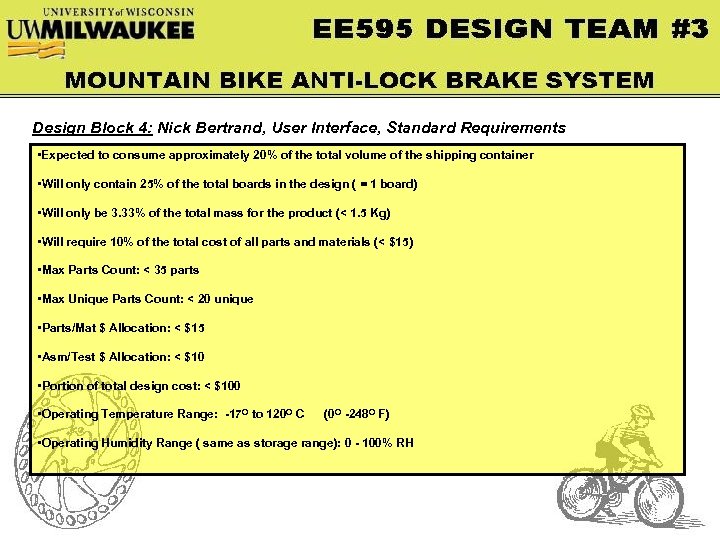

Design Block 4: Nick Bertrand, User Interface, Standard Requirements • Expected to consume approximately 20% of the total volume of the shipping container • Will only contain 25% of the total boards in the design ( = 1 board) • Will only be 3. 33% of the total mass for the product (< 1. 5 Kg) • Will require 10% of the total cost of all parts and materials (< $15) • Max Parts Count: < 35 parts • Max Unique Parts Count: < 20 unique • Parts/Mat $ Allocation: < $15 • Asm/Test $ Allocation: < $10 • Portion of total design cost: < $100 • Operating Temperature Range: -17 O to 120 O C (0 O -248 O F) • Operating Humidity Range ( same as storage range): 0 - 100% RH

Design Block 4: Nick Bertrand, User Interface, Standard Requirements • Expected to consume approximately 20% of the total volume of the shipping container • Will only contain 25% of the total boards in the design ( = 1 board) • Will only be 3. 33% of the total mass for the product (< 1. 5 Kg) • Will require 10% of the total cost of all parts and materials (< $15) • Max Parts Count: < 35 parts • Max Unique Parts Count: < 20 unique • Parts/Mat $ Allocation: < $15 • Asm/Test $ Allocation: < $10 • Portion of total design cost: < $100 • Operating Temperature Range: -17 O to 120 O C (0 O -248 O F) • Operating Humidity Range ( same as storage range): 0 - 100% RH

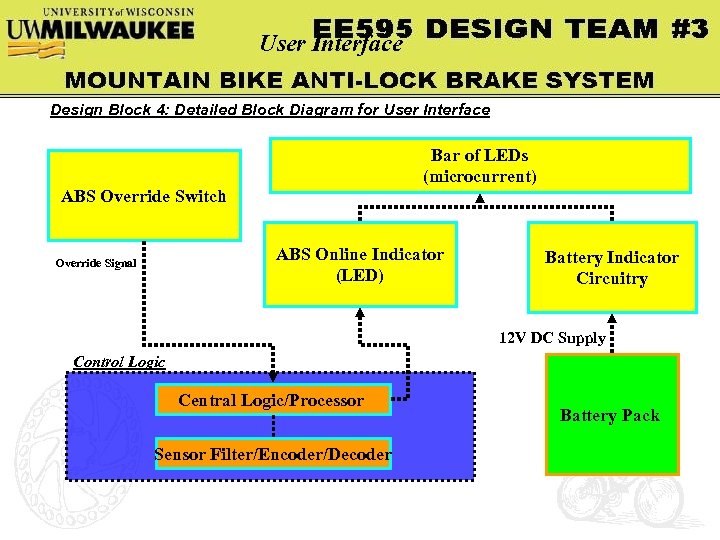

User Interface Design Block 4: Detailed Block Diagram for User Interface Bar of LEDs (microcurrent) ABS Override Switch ABS Online Indicator (LED) Override Signal Battery Indicator Circuitry 12 V DC Supply Control Logic Central Logic/Processor Sensor Filter/Encoder/Decoder Battery Pack

User Interface Design Block 4: Detailed Block Diagram for User Interface Bar of LEDs (microcurrent) ABS Override Switch ABS Online Indicator (LED) Override Signal Battery Indicator Circuitry 12 V DC Supply Control Logic Central Logic/Processor Sensor Filter/Encoder/Decoder Battery Pack

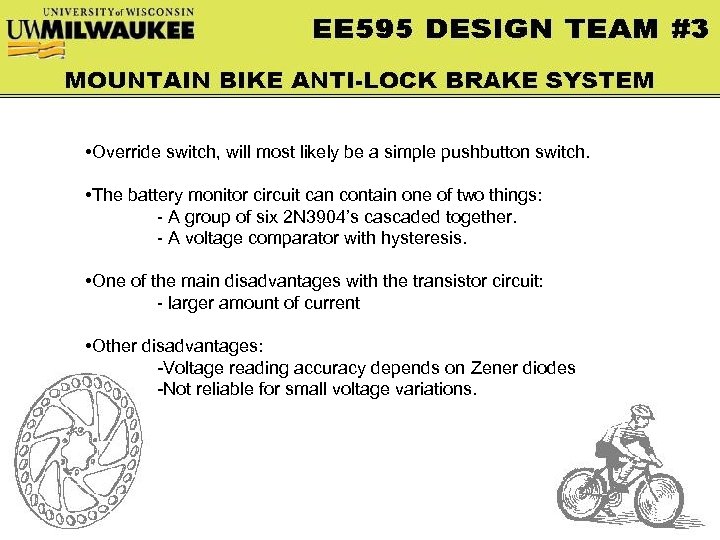

• Override switch, will most likely be a simple pushbutton switch. • The battery monitor circuit can contain one of two things: - A group of six 2 N 3904’s cascaded together. - A voltage comparator with hysteresis. • One of the main disadvantages with the transistor circuit: - larger amount of current • Other disadvantages: -Voltage reading accuracy depends on Zener diodes -Not reliable for small voltage variations.

• Override switch, will most likely be a simple pushbutton switch. • The battery monitor circuit can contain one of two things: - A group of six 2 N 3904’s cascaded together. - A voltage comparator with hysteresis. • One of the main disadvantages with the transistor circuit: - larger amount of current • Other disadvantages: -Voltage reading accuracy depends on Zener diodes -Not reliable for small voltage variations.

• A comparator will be used within the battery indicator circuitry (LM 239 or LM 138) - LM 138 a better temperature range of (-25 O to +125 O) - The leakage current in off position will be approximately 0. 5 n. A • Main disadvantage of IC comparator: - Needs a reliable reference voltage • Main advantage of IC comparator: - High accuracy of the voltage measurements. - Low power dissipation (approximately 1 m. W) - Outputting to an oscillator, then to LEDs could conserve power.

• A comparator will be used within the battery indicator circuitry (LM 239 or LM 138) - LM 138 a better temperature range of (-25 O to +125 O) - The leakage current in off position will be approximately 0. 5 n. A • Main disadvantage of IC comparator: - Needs a reliable reference voltage • Main advantage of IC comparator: - High accuracy of the voltage measurements. - Low power dissipation (approximately 1 m. W) - Outputting to an oscillator, then to LEDs could conserve power.

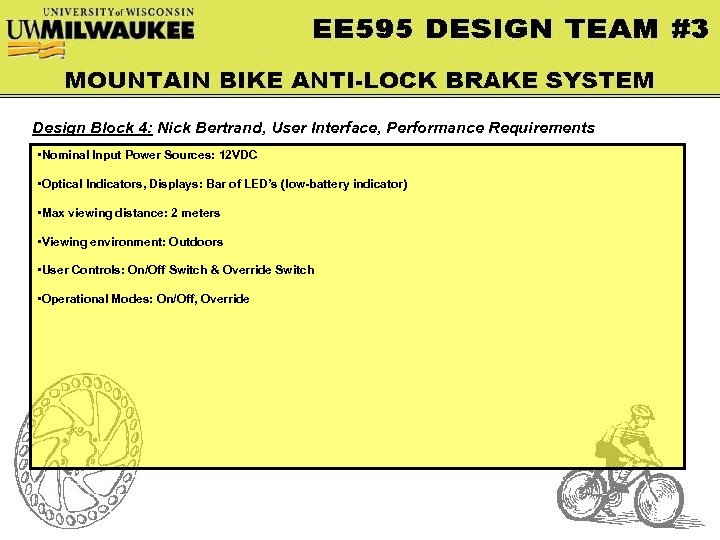

Design Block 4: Nick Bertrand, User Interface, Performance Requirements • Nominal Input Power Sources: 12 VDC • Optical Indicators, Displays: Bar of LED’s (low-battery indicator) • Max viewing distance: 2 meters • Viewing environment: Outdoors • User Controls: On/Off Switch & Override Switch • Operational Modes: On/Off, Override

Design Block 4: Nick Bertrand, User Interface, Performance Requirements • Nominal Input Power Sources: 12 VDC • Optical Indicators, Displays: Bar of LED’s (low-battery indicator) • Max viewing distance: 2 meters • Viewing environment: Outdoors • User Controls: On/Off Switch & Override Switch • Operational Modes: On/Off, Override

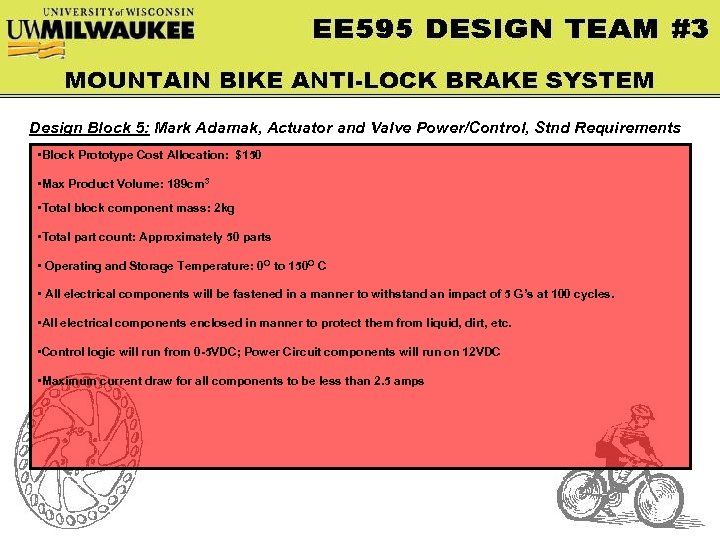

Design Block 5: Mark Adamak, Actuator and Valve Power/Control, Stnd Requirements • Block Prototype Cost Allocation: $150 • Max Product Volume: 189 cm 3 • Total block component mass: 2 kg • Total part count: Approximately 50 parts • Operating and Storage Temperature: 0 O to 150 O C • All electrical components will be fastened in a manner to withstand an impact of 5 G’s at 100 cycles. • All electrical components enclosed in manner to protect them from liquid, dirt, etc. • Control logic will run from 0 -5 VDC; Power Circuit components will run on 12 VDC • Maximum current draw for all components to be less than 2. 5 amps

Design Block 5: Mark Adamak, Actuator and Valve Power/Control, Stnd Requirements • Block Prototype Cost Allocation: $150 • Max Product Volume: 189 cm 3 • Total block component mass: 2 kg • Total part count: Approximately 50 parts • Operating and Storage Temperature: 0 O to 150 O C • All electrical components will be fastened in a manner to withstand an impact of 5 G’s at 100 cycles. • All electrical components enclosed in manner to protect them from liquid, dirt, etc. • Control logic will run from 0 -5 VDC; Power Circuit components will run on 12 VDC • Maximum current draw for all components to be less than 2. 5 amps

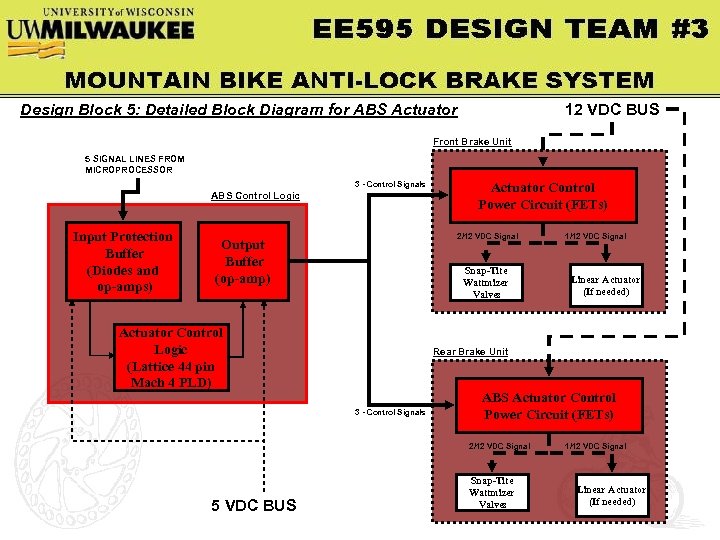

Design Block 5: Detailed Block Diagram for ABS Actuator 12 VDC BUS Front Brake Unit 5 SIGNAL LINES FROM MICROPROCESSOR 3 - Control Signals ABS Control Logic Input Protection Buffer (Diodes and op-amps) Actuator Control Power Circuit (FETs) 2/12 VDC Signal Output Buffer (op-amp) Snap-Tite Wattmizer Valves Actuator Control Logic (Lattice 44 pin Mach 4 PLD) Linear Actuator (If needed) Rear Brake Unit 3 - Control Signals ABS Actuator Control Power Circuit (FETs) 2/12 VDC Signal 5 VDC BUS 1/12 VDC Signal Snap-Tite Wattmizer Valves 1/12 VDC Signal Linear Actuator (If needed)

Design Block 5: Detailed Block Diagram for ABS Actuator 12 VDC BUS Front Brake Unit 5 SIGNAL LINES FROM MICROPROCESSOR 3 - Control Signals ABS Control Logic Input Protection Buffer (Diodes and op-amps) Actuator Control Power Circuit (FETs) 2/12 VDC Signal Output Buffer (op-amp) Snap-Tite Wattmizer Valves Actuator Control Logic (Lattice 44 pin Mach 4 PLD) Linear Actuator (If needed) Rear Brake Unit 3 - Control Signals ABS Actuator Control Power Circuit (FETs) 2/12 VDC Signal 5 VDC BUS 1/12 VDC Signal Snap-Tite Wattmizer Valves 1/12 VDC Signal Linear Actuator (If needed)

• Advantages of stage one design: - Low weight - Low power consumption - Minimal parts and construction • Disadvantages of stage one design: - Design based on idealized model - Relies on random oscillation - Timing problems - Possible bottoming out of ABS cylinder

• Advantages of stage one design: - Low weight - Low power consumption - Minimal parts and construction • Disadvantages of stage one design: - Design based on idealized model - Relies on random oscillation - Timing problems - Possible bottoming out of ABS cylinder

• Advantages of stage three design: - Guarantee of operation - More predictable timing • Disadvantages of stage three design: - Heavier and more volume - More costly - More power required

• Advantages of stage three design: - Guarantee of operation - More predictable timing • Disadvantages of stage three design: - Heavier and more volume - More costly - More power required

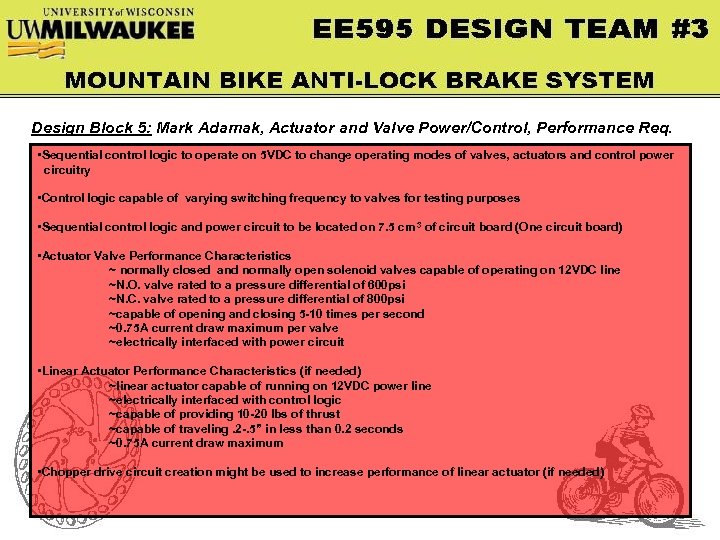

Design Block 5: Mark Adamak, Actuator and Valve Power/Control, Performance Req. • Sequential control logic to operate on 5 VDC to change operating modes of valves, actuators and control power circuitry • Control logic capable of varying switching frequency to valves for testing purposes • Sequential control logic and power circuit to be located on 7. 5 cm 3 of circuit board (One circuit board) • Actuator Valve Performance Characteristics ~ normally closed and normally open solenoid valves capable of operating on 12 VDC line ~N. O. valve rated to a pressure differential of 600 psi ~N. C. valve rated to a pressure differential of 800 psi ~capable of opening and closing 5 -10 times per second ~0. 75 A current draw maximum per valve ~electrically interfaced with power circuit • Linear Actuator Performance Characteristics (if needed) ~linear actuator capable of running on 12 VDC power line ~electrically interfaced with control logic ~capable of providing 10 -20 lbs of thrust ~capable of traveling. 2 -. 5” in less than 0. 2 seconds ~0. 75 A current draw maximum • Chopper drive circuit creation might be used to increase performance of linear actuator (if needed)

Design Block 5: Mark Adamak, Actuator and Valve Power/Control, Performance Req. • Sequential control logic to operate on 5 VDC to change operating modes of valves, actuators and control power circuitry • Control logic capable of varying switching frequency to valves for testing purposes • Sequential control logic and power circuit to be located on 7. 5 cm 3 of circuit board (One circuit board) • Actuator Valve Performance Characteristics ~ normally closed and normally open solenoid valves capable of operating on 12 VDC line ~N. O. valve rated to a pressure differential of 600 psi ~N. C. valve rated to a pressure differential of 800 psi ~capable of opening and closing 5 -10 times per second ~0. 75 A current draw maximum per valve ~electrically interfaced with power circuit • Linear Actuator Performance Characteristics (if needed) ~linear actuator capable of running on 12 VDC power line ~electrically interfaced with control logic ~capable of providing 10 -20 lbs of thrust ~capable of traveling. 2 -. 5” in less than 0. 2 seconds ~0. 75 A current draw maximum • Chopper drive circuit creation might be used to increase performance of linear actuator (if needed)

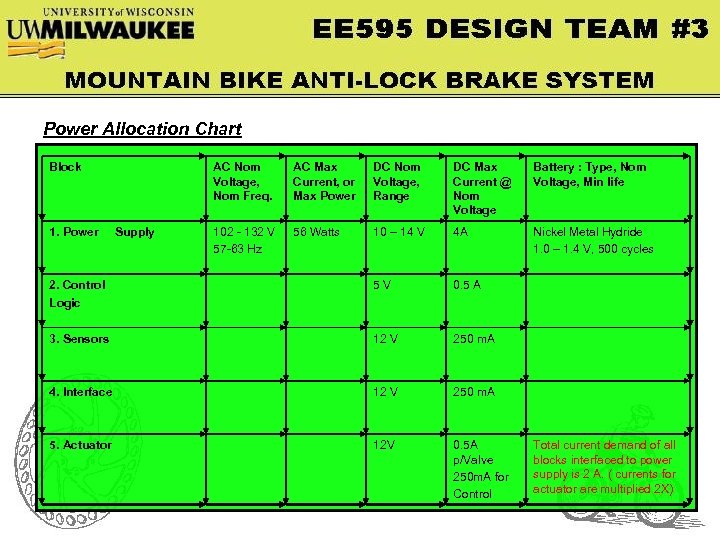

Power Allocation Chart Block AC Nom Voltage, Nom Freq. AC Max Current, or Max Power DC Nom Voltage, Range DC Max Current @ Nom Voltage Battery : Type, Nom Voltage, Min life 102 - 132 V 57 -63 Hz 56 Watts 10 – 14 V 4 A Nickel Metal Hydride 1. 0 – 1. 4 V, 500 cycles 2. Control Logic 5 V 0. 5 A 3. Sensors 12 V 250 m. A 4. Interface 12 V 250 m. A 5. Actuator 12 V 0. 5 A p/Valve 250 m. A for Control 1. Power Supply Total current demand of all blocks interfaced to power supply is 2 A. ( currents for actuator are multiplied 2 X)

Power Allocation Chart Block AC Nom Voltage, Nom Freq. AC Max Current, or Max Power DC Nom Voltage, Range DC Max Current @ Nom Voltage Battery : Type, Nom Voltage, Min life 102 - 132 V 57 -63 Hz 56 Watts 10 – 14 V 4 A Nickel Metal Hydride 1. 0 – 1. 4 V, 500 cycles 2. Control Logic 5 V 0. 5 A 3. Sensors 12 V 250 m. A 4. Interface 12 V 250 m. A 5. Actuator 12 V 0. 5 A p/Valve 250 m. A for Control 1. Power Supply Total current demand of all blocks interfaced to power supply is 2 A. ( currents for actuator are multiplied 2 X)

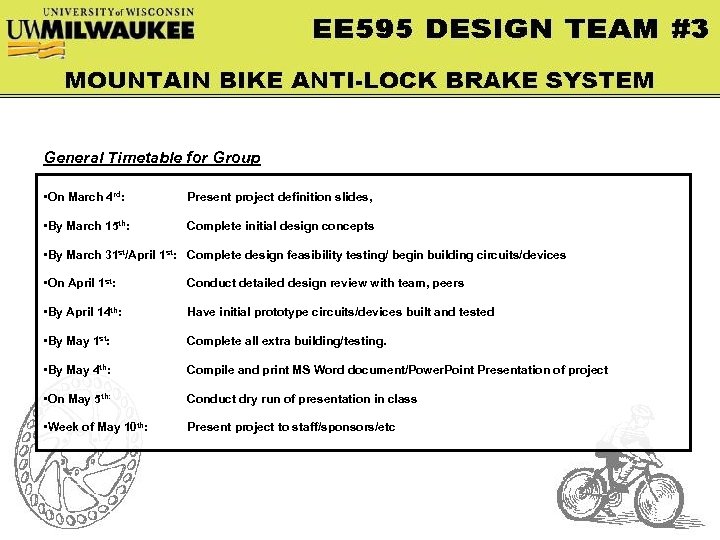

General Timetable for Group • On March 4 rd: Present project definition slides, • By March 15 th: Complete initial design concepts • By March 31 st/April 1 st: Complete design feasibility testing/ begin building circuits/devices • On April 1 st: Conduct detailed design review with team, peers • By April 14 th: Have initial prototype circuits/devices built and tested • By May 1 st: Complete all extra building/testing. • By May 4 th: Compile and print MS Word document/Power. Point Presentation of project • On May 5 th: Conduct dry run of presentation in class • Week of May 10 th: Present project to staff/sponsors/etc

General Timetable for Group • On March 4 rd: Present project definition slides, • By March 15 th: Complete initial design concepts • By March 31 st/April 1 st: Complete design feasibility testing/ begin building circuits/devices • On April 1 st: Conduct detailed design review with team, peers • By April 14 th: Have initial prototype circuits/devices built and tested • By May 1 st: Complete all extra building/testing. • By May 4 th: Compile and print MS Word document/Power. Point Presentation of project • On May 5 th: Conduct dry run of presentation in class • Week of May 10 th: Present project to staff/sponsors/etc