8f0b8f20d27e7003cdd0feb3976db630.ppt

- Количество слайдов: 23

ERDMP 27. 09. 2012

ERDMP 27. 09. 2012

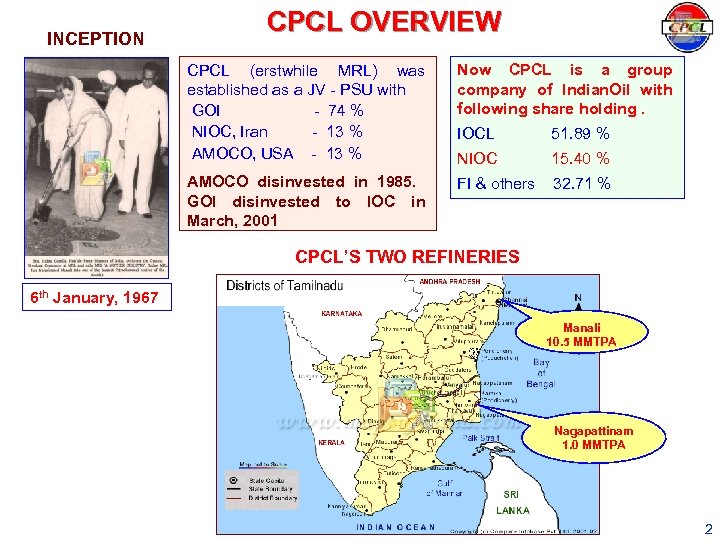

INCEPTION CPCL OVERVIEW CPCL (erstwhile MRL) was established as a JV - PSU with GOI - 74 % NIOC, Iran - 13 % AMOCO, USA - 13 % Now CPCL is a group company of Indian. Oil with following share holding. AMOCO disinvested in 1985. GOI disinvested to IOC in March, 2001 IOCL 51. 89 % NIOC 15. 40 % FI & others 32. 71 % CPCL’S TWO REFINERIES 6 th January, 1967 Manali 10. 5 MMTPA Nagapattinam 1. 0 MMTPA 2

INCEPTION CPCL OVERVIEW CPCL (erstwhile MRL) was established as a JV - PSU with GOI - 74 % NIOC, Iran - 13 % AMOCO, USA - 13 % Now CPCL is a group company of Indian. Oil with following share holding. AMOCO disinvested in 1985. GOI disinvested to IOC in March, 2001 IOCL 51. 89 % NIOC 15. 40 % FI & others 32. 71 % CPCL’S TWO REFINERIES 6 th January, 1967 Manali 10. 5 MMTPA Nagapattinam 1. 0 MMTPA 2

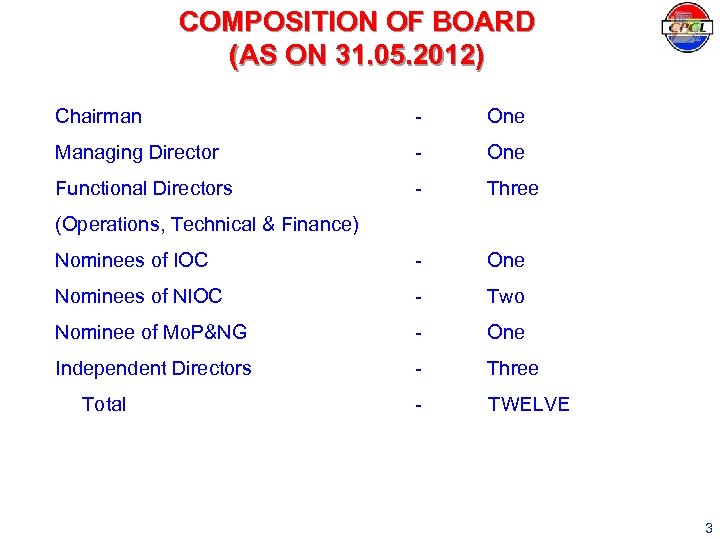

COMPOSITION OF BOARD (AS ON 31. 05. 2012) Chairman - One Managing Director - One Functional Directors - Three Nominees of IOC - One Nominees of NIOC - Two Nominee of Mo. P&NG - One Independent Directors - Three - TWELVE (Operations, Technical & Finance) Total 3

COMPOSITION OF BOARD (AS ON 31. 05. 2012) Chairman - One Managing Director - One Functional Directors - Three Nominees of IOC - One Nominees of NIOC - Two Nominee of Mo. P&NG - One Independent Directors - Three - TWELVE (Operations, Technical & Finance) Total 3

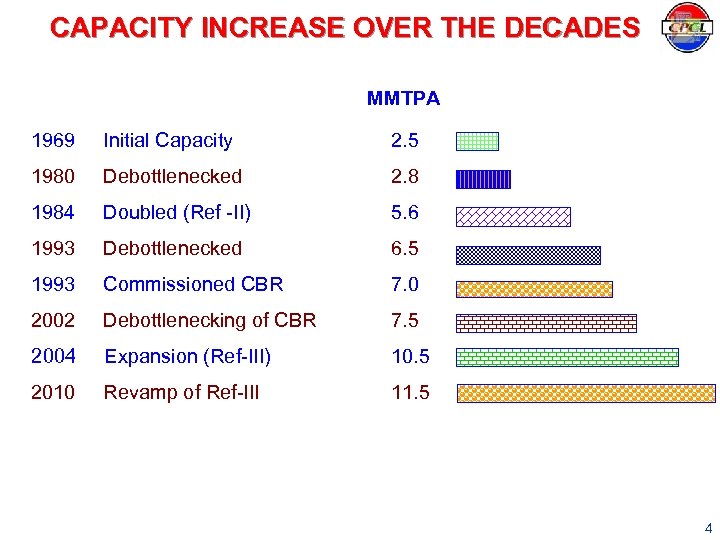

CAPACITY INCREASE OVER THE DECADES MMTPA 1969 Initial Capacity 2. 5 1980 Debottlenecked 2. 8 1984 Doubled (Ref -II) 5. 6 1993 Debottlenecked 6. 5 1993 Commissioned CBR 7. 0 2002 Debottlenecking of CBR 7. 5 2004 Expansion (Ref-III) 10. 5 2010 Revamp of Ref-III 11. 5 4

CAPACITY INCREASE OVER THE DECADES MMTPA 1969 Initial Capacity 2. 5 1980 Debottlenecked 2. 8 1984 Doubled (Ref -II) 5. 6 1993 Debottlenecked 6. 5 1993 Commissioned CBR 7. 0 2002 Debottlenecking of CBR 7. 5 2004 Expansion (Ref-III) 10. 5 2010 Revamp of Ref-III 11. 5 4

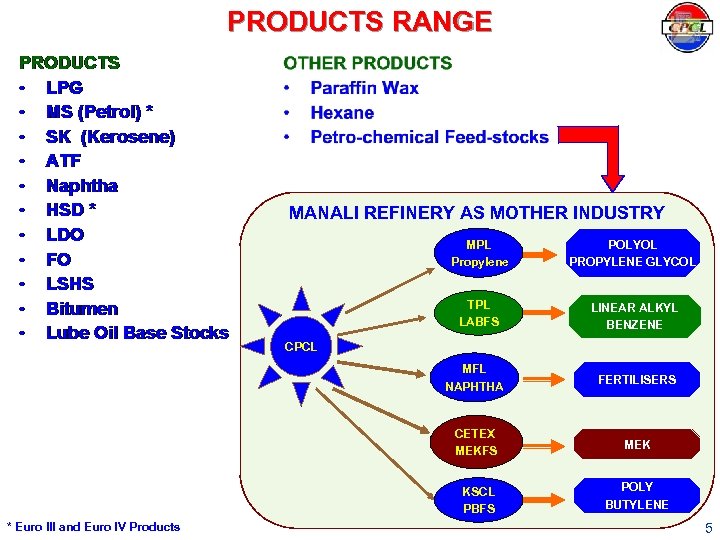

PRODUCTS RANGE MANALI REFINERY AS MOTHER INDUSTRY MPL Propylene POLYOL PROPYLENE GLYCOL TPL LABFS LINEAR ALKYL BENZENE CPCL MFL NAPHTHA CETEX MEKFS MEK KSCL PBFS * Euro III and Euro IV Products FERTILISERS POLY BUTYLENE 5

PRODUCTS RANGE MANALI REFINERY AS MOTHER INDUSTRY MPL Propylene POLYOL PROPYLENE GLYCOL TPL LABFS LINEAR ALKYL BENZENE CPCL MFL NAPHTHA CETEX MEKFS MEK KSCL PBFS * Euro III and Euro IV Products FERTILISERS POLY BUTYLENE 5

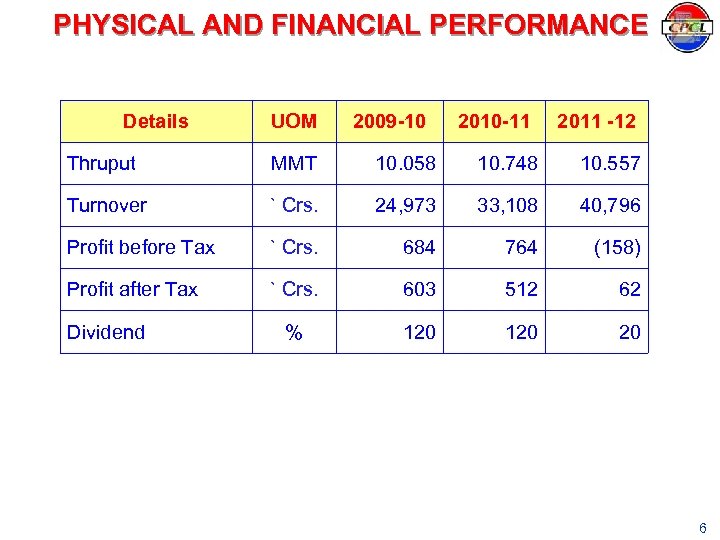

PHYSICAL AND FINANCIAL PERFORMANCE Details UOM 2009 -10 2010 -11 2011 -12 Thruput MMT 10. 058 10. 748 10. 557 Turnover ` Crs. 24, 973 33, 108 40, 796 Profit before Tax ` Crs. 684 764 (158) Profit after Tax ` Crs. 603 512 62 % 120 20 Dividend 6

PHYSICAL AND FINANCIAL PERFORMANCE Details UOM 2009 -10 2010 -11 2011 -12 Thruput MMT 10. 058 10. 748 10. 557 Turnover ` Crs. 24, 973 33, 108 40, 796 Profit before Tax ` Crs. 684 764 (158) Profit after Tax ` Crs. 603 512 62 % 120 20 Dividend 6

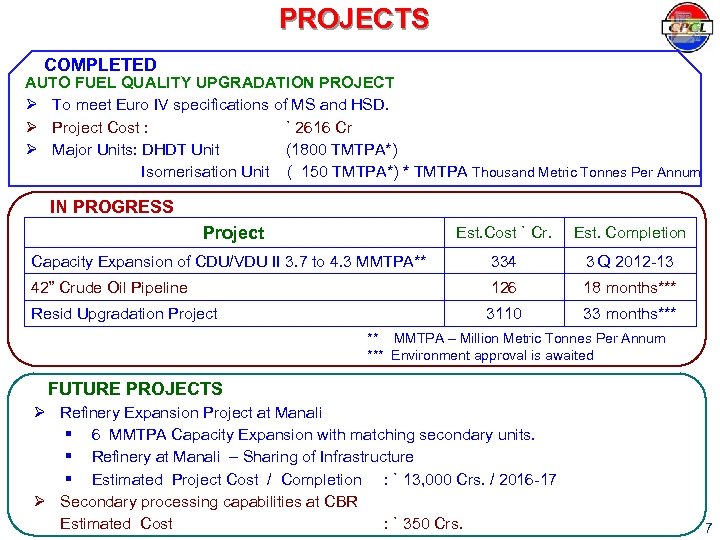

PROJECTS COMPLETED AUTO FUEL QUALITY UPGRADATION PROJECT Ø To meet Euro IV specifications of MS and HSD. Ø Project Cost : ` 2616 Cr Ø Major Units: DHDT Unit (1800 TMTPA*) Isomerisation Unit ( 150 TMTPA*) * TMTPA Thousand Metric Tonnes Per Annum IN PROGRESS Project Est. Cost ` Cr. Est. Completion Capacity Expansion of CDU/VDU II 3. 7 to 4. 3 MMTPA** 334 3 Q 2012 -13 42” Crude Oil Pipeline 126 18 months*** Resid Upgradation Project 3110 33 months*** ** MMTPA – Million Metric Tonnes Per Annum *** Environment approval is awaited FUTURE PROJECTS Ø Refinery Expansion Project at Manali § 6 MMTPA Capacity Expansion with matching secondary units. § Refinery at Manali – Sharing of Infrastructure § Estimated Project Cost / Completion : ` 13, 000 Crs. / 2016 -17 Ø Secondary processing capabilities at CBR Estimated Cost : ` 350 Crs. 7

PROJECTS COMPLETED AUTO FUEL QUALITY UPGRADATION PROJECT Ø To meet Euro IV specifications of MS and HSD. Ø Project Cost : ` 2616 Cr Ø Major Units: DHDT Unit (1800 TMTPA*) Isomerisation Unit ( 150 TMTPA*) * TMTPA Thousand Metric Tonnes Per Annum IN PROGRESS Project Est. Cost ` Cr. Est. Completion Capacity Expansion of CDU/VDU II 3. 7 to 4. 3 MMTPA** 334 3 Q 2012 -13 42” Crude Oil Pipeline 126 18 months*** Resid Upgradation Project 3110 33 months*** ** MMTPA – Million Metric Tonnes Per Annum *** Environment approval is awaited FUTURE PROJECTS Ø Refinery Expansion Project at Manali § 6 MMTPA Capacity Expansion with matching secondary units. § Refinery at Manali – Sharing of Infrastructure § Estimated Project Cost / Completion : ` 13, 000 Crs. / 2016 -17 Ø Secondary processing capabilities at CBR Estimated Cost : ` 350 Crs. 7

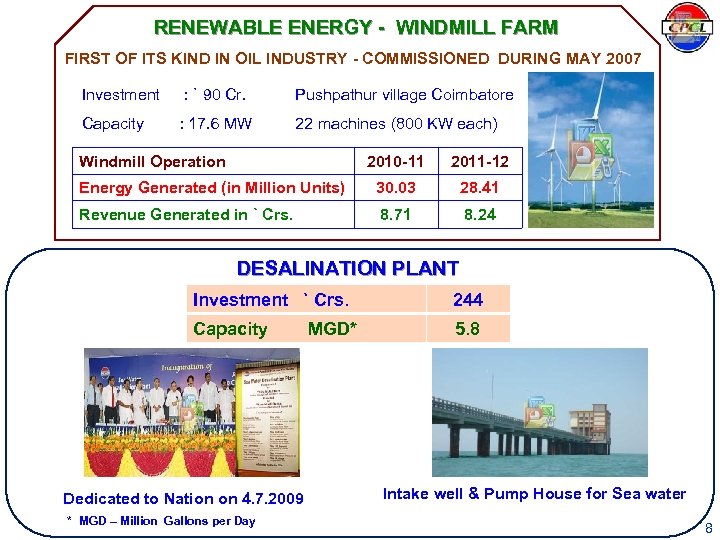

RENEWABLE ENERGY - WINDMILL FARM FIRST OF ITS KIND IN OIL INDUSTRY - COMMISSIONED DURING MAY 2007 Investment : ` 90 Cr. Pushpathur village Coimbatore Capacity : 17. 6 MW 22 machines (800 KW each) Windmill Operation 2010 -11 2011 -12 Energy Generated (in Million Units) 30. 03 28. 41 Revenue Generated in ` Crs. 8. 71 8. 24 DESALINATION PLANT Investment ` Crs. 244 Capacity 5. 8 Dedicated to Nation on 4. 7. 2009 * MGD – Million Gallons per Day MGD* Intake well & Pump House for Sea water 8

RENEWABLE ENERGY - WINDMILL FARM FIRST OF ITS KIND IN OIL INDUSTRY - COMMISSIONED DURING MAY 2007 Investment : ` 90 Cr. Pushpathur village Coimbatore Capacity : 17. 6 MW 22 machines (800 KW each) Windmill Operation 2010 -11 2011 -12 Energy Generated (in Million Units) 30. 03 28. 41 Revenue Generated in ` Crs. 8. 71 8. 24 DESALINATION PLANT Investment ` Crs. 244 Capacity 5. 8 Dedicated to Nation on 4. 7. 2009 * MGD – Million Gallons per Day MGD* Intake well & Pump House for Sea water 8

DISASTER MANAGEMENT PLAN TO HANDLE THE FOLLOWING EMERGENCIES: Ø Natural Calamities : Flood, Earthquake, Cyclone, Tsunami Ø Man made : Heavy leakage. Fire, Explosion. Ø Extraneous : Riots, Terrorism, Sabotage. Ø Incidents from neighboring Industries CONSEQUENCES: Ø Fire, Explosion, Boiling Liquid Evaporating Vapour Explosion (BLEVE), Blast waves etc. - Confined within premises – Onsite Emergencies. - Spill to off-site triggering cascade effects – Offsite Emergencies. 9

DISASTER MANAGEMENT PLAN TO HANDLE THE FOLLOWING EMERGENCIES: Ø Natural Calamities : Flood, Earthquake, Cyclone, Tsunami Ø Man made : Heavy leakage. Fire, Explosion. Ø Extraneous : Riots, Terrorism, Sabotage. Ø Incidents from neighboring Industries CONSEQUENCES: Ø Fire, Explosion, Boiling Liquid Evaporating Vapour Explosion (BLEVE), Blast waves etc. - Confined within premises – Onsite Emergencies. - Spill to off-site triggering cascade effects – Offsite Emergencies. 9

DISASTER MANAGEMENT PLAN INTERNAL SYSTEM & CONTROL NATURAL CALAMITIES – CRISIS MANAGEMENT ON-SITE EMERGENCY CONTROL OFF-SITE EMERGENCY CONTROL 10

DISASTER MANAGEMENT PLAN INTERNAL SYSTEM & CONTROL NATURAL CALAMITIES – CRISIS MANAGEMENT ON-SITE EMERGENCY CONTROL OFF-SITE EMERGENCY CONTROL 10

INTERNAL SYSTEM & CONTROL FIRE PREVENTION Ø Rules and regulations for prevention of fire in place for compliance by employees and outsiders entering Refinery. Ø Oil Industries Safety Directorate (OISD) Standards and Guidelines are followed and complied. Ø Safe design aspects incorporated based on Comprehensive Risk Assessment and HAZOP studies by Central Leather Research Institute (CLRI). 11

INTERNAL SYSTEM & CONTROL FIRE PREVENTION Ø Rules and regulations for prevention of fire in place for compliance by employees and outsiders entering Refinery. Ø Oil Industries Safety Directorate (OISD) Standards and Guidelines are followed and complied. Ø Safe design aspects incorporated based on Comprehensive Risk Assessment and HAZOP studies by Central Leather Research Institute (CLRI). 11

DETECTION & COMMUNICATION SYSTEMS DETECTION SYSTEMS: § HC, CO, NH 3 & H 2 S detectors (466 nos) § Smoke detectors (1931 nos) § CCTVs COMMUNICATION SYSTEMS: Manual Call Points (MCP) Fire Call thru’ Field Telephones Repeat multi-call by Fire Station UHF Radio Hand Sets Neumann Plant Communication Emergency Siren Hot Line with Mutual Aid Partners Madras Fertilisers Limited (MFL) & Tamilnadu Petro products Limited (TPL) 12

DETECTION & COMMUNICATION SYSTEMS DETECTION SYSTEMS: § HC, CO, NH 3 & H 2 S detectors (466 nos) § Smoke detectors (1931 nos) § CCTVs COMMUNICATION SYSTEMS: Manual Call Points (MCP) Fire Call thru’ Field Telephones Repeat multi-call by Fire Station UHF Radio Hand Sets Neumann Plant Communication Emergency Siren Hot Line with Mutual Aid Partners Madras Fertilisers Limited (MFL) & Tamilnadu Petro products Limited (TPL) 12

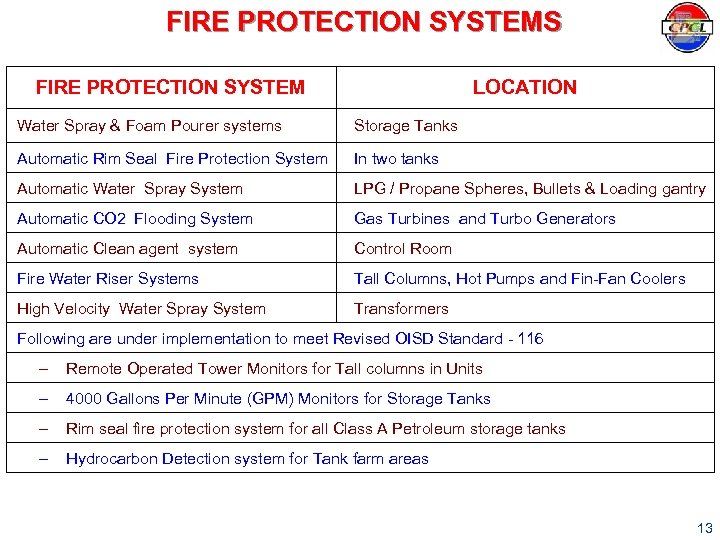

FIRE PROTECTION SYSTEMS FIRE PROTECTION SYSTEM LOCATION Water Spray & Foam Pourer systems Storage Tanks Automatic Rim Seal Fire Protection System In two tanks Automatic Water Spray System LPG / Propane Spheres, Bullets & Loading gantry Automatic CO 2 Flooding System Gas Turbines and Turbo Generators Automatic Clean agent system Control Room Fire Water Riser Systems Tall Columns, Hot Pumps and Fin-Fan Coolers High Velocity Water Spray System Transformers Following are under implementation to meet Revised OISD Standard - 116 - Remote Operated Tower Monitors for Tall columns in Units - 4000 Gallons Per Minute (GPM) Monitors for Storage Tanks - Rim seal fire protection system for all Class A Petroleum storage tanks - Hydrocarbon Detection system for Tank farm areas 13

FIRE PROTECTION SYSTEMS FIRE PROTECTION SYSTEM LOCATION Water Spray & Foam Pourer systems Storage Tanks Automatic Rim Seal Fire Protection System In two tanks Automatic Water Spray System LPG / Propane Spheres, Bullets & Loading gantry Automatic CO 2 Flooding System Gas Turbines and Turbo Generators Automatic Clean agent system Control Room Fire Water Riser Systems Tall Columns, Hot Pumps and Fin-Fan Coolers High Velocity Water Spray System Transformers Following are under implementation to meet Revised OISD Standard - 116 - Remote Operated Tower Monitors for Tall columns in Units - 4000 Gallons Per Minute (GPM) Monitors for Storage Tanks - Rim seal fire protection system for all Class A Petroleum storage tanks - Hydrocarbon Detection system for Tank farm areas 13

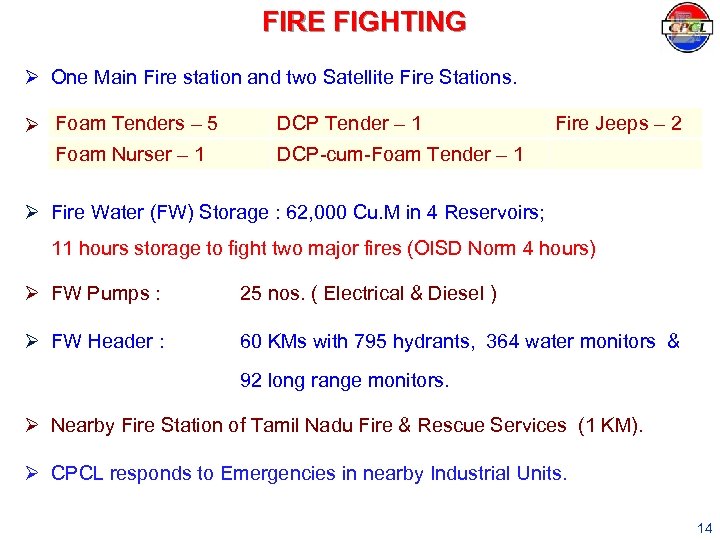

FIRE FIGHTING Ø One Main Fire station and two Satellite Fire Stations. Foam Tenders – 5 Ø Fire Fighting Vehicles: Foam Nurser – 1 DCP Tender – 1 Fire Jeeps – 2 DCP-cum-Foam Tender – 1 Ø Fire Water (FW) Storage : 62, 000 Cu. M in 4 Reservoirs; 11 hours storage to fight two major fires (OISD Norm 4 hours) Ø FW Pumps : 25 nos. ( Electrical & Diesel ) Ø FW Header : 60 KMs with 795 hydrants, 364 water monitors & 92 long range monitors. Ø Nearby Fire Station of Tamil Nadu Fire & Rescue Services (1 KM). Ø CPCL responds to Emergencies in nearby Industrial Units. 14

FIRE FIGHTING Ø One Main Fire station and two Satellite Fire Stations. Foam Tenders – 5 Ø Fire Fighting Vehicles: Foam Nurser – 1 DCP Tender – 1 Fire Jeeps – 2 DCP-cum-Foam Tender – 1 Ø Fire Water (FW) Storage : 62, 000 Cu. M in 4 Reservoirs; 11 hours storage to fight two major fires (OISD Norm 4 hours) Ø FW Pumps : 25 nos. ( Electrical & Diesel ) Ø FW Header : 60 KMs with 795 hydrants, 364 water monitors & 92 long range monitors. Ø Nearby Fire Station of Tamil Nadu Fire & Rescue Services (1 KM). Ø CPCL responds to Emergencies in nearby Industrial Units. 14

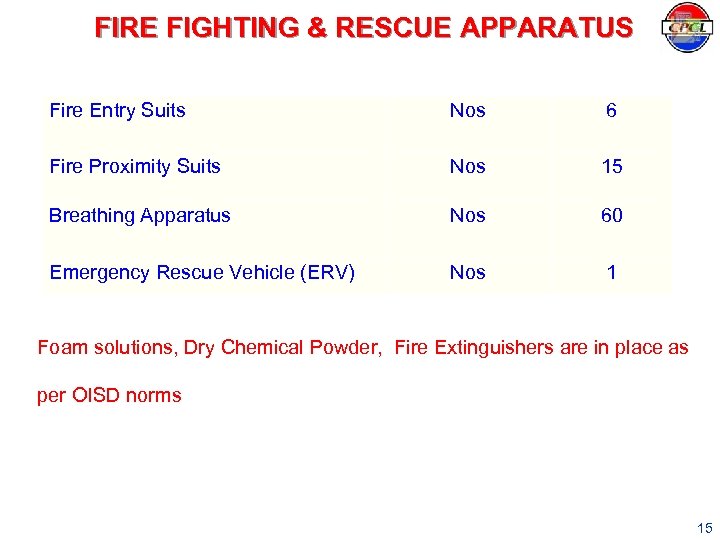

FIRE FIGHTING & RESCUE APPARATUS Fire Entry Suits Nos 6 Fire Proximity Suits Nos 15 Breathing Apparatus Nos 60 Emergency Rescue Vehicle (ERV) Nos 1 Foam solutions, Dry Chemical Powder, Fire Extinguishers are in place as per OISD norms 15

FIRE FIGHTING & RESCUE APPARATUS Fire Entry Suits Nos 6 Fire Proximity Suits Nos 15 Breathing Apparatus Nos 60 Emergency Rescue Vehicle (ERV) Nos 1 Foam solutions, Dry Chemical Powder, Fire Extinguishers are in place as per OISD norms 15

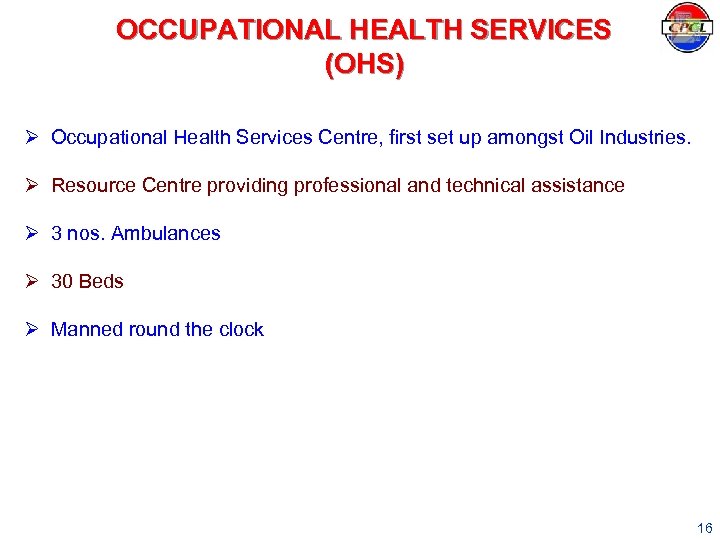

OCCUPATIONAL HEALTH SERVICES (OHS) Ø Occupational Health Services Centre, first set up amongst Oil Industries. Ø Resource Centre providing professional and technical assistance Ø 3 nos. Ambulances Ø 30 Beds Ø Manned round the clock 16

OCCUPATIONAL HEALTH SERVICES (OHS) Ø Occupational Health Services Centre, first set up amongst Oil Industries. Ø Resource Centre providing professional and technical assistance Ø 3 nos. Ambulances Ø 30 Beds Ø Manned round the clock 16

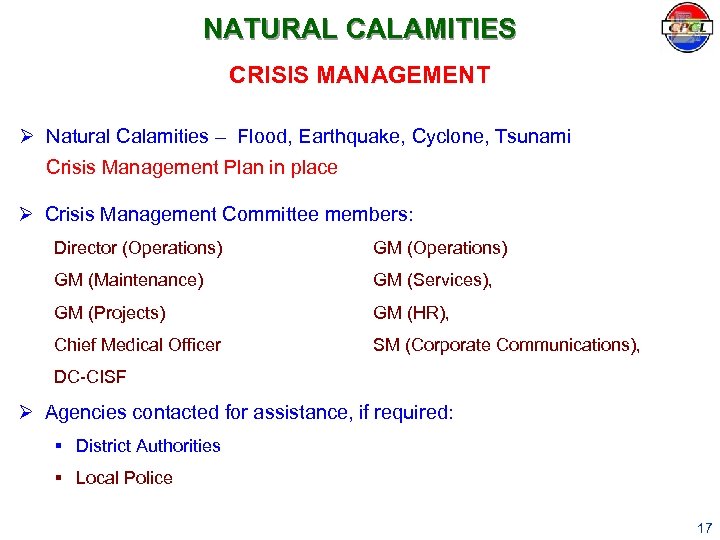

NATURAL CALAMITIES CRISIS MANAGEMENT Ø Natural Calamities – Flood, Earthquake, Cyclone, Tsunami Crisis Management Plan in place Ø Crisis Management Committee members: Director (Operations) GM (Maintenance) GM (Services), GM (Projects) GM (HR), Chief Medical Officer SM (Corporate Communications), DC-CISF Ø Agencies contacted for assistance, if required: § District Authorities § Local Police 17

NATURAL CALAMITIES CRISIS MANAGEMENT Ø Natural Calamities – Flood, Earthquake, Cyclone, Tsunami Crisis Management Plan in place Ø Crisis Management Committee members: Director (Operations) GM (Maintenance) GM (Services), GM (Projects) GM (HR), Chief Medical Officer SM (Corporate Communications), DC-CISF Ø Agencies contacted for assistance, if required: § District Authorities § Local Police 17

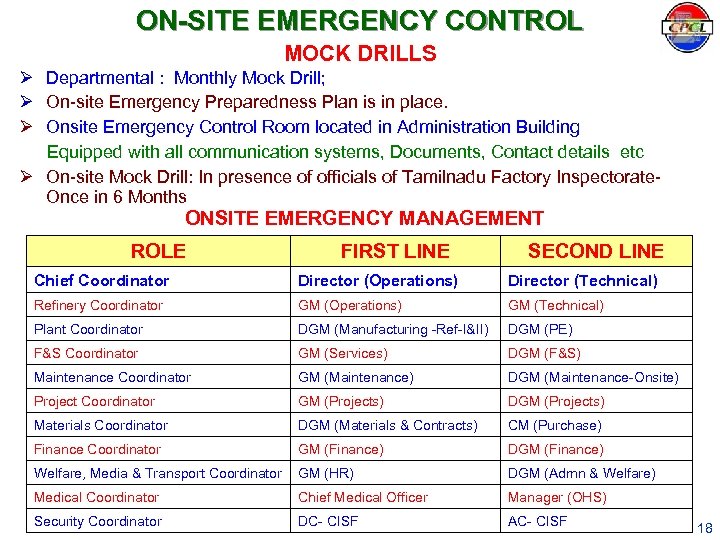

ON-SITE EMERGENCY CONTROL MOCK DRILLS Ø Departmental : Monthly Mock Drill; Ø On-site Emergency Preparedness Plan is in place. Ø Onsite Emergency Control Room located in Administration Building Equipped with all communication systems, Documents, Contact details etc Ø On-site Mock Drill: In presence of officials of Tamilnadu Factory Inspectorate. Once in 6 Months ONSITE EMERGENCY MANAGEMENT ROLE FIRST LINE SECOND LINE Chief Coordinator Director (Operations) Director (Technical) Refinery Coordinator GM (Operations) GM (Technical) Plant Coordinator DGM (Manufacturing -Ref-I&II) DGM (PE) F&S Coordinator GM (Services) DGM (F&S) Maintenance Coordinator GM (Maintenance) DGM (Maintenance-Onsite) Project Coordinator GM (Projects) DGM (Projects) Materials Coordinator DGM (Materials & Contracts) CM (Purchase) Finance Coordinator GM (Finance) DGM (Finance) Welfare, Media & Transport Coordinator GM (HR) DGM (Admn & Welfare) Medical Coordinator Chief Medical Officer Manager (OHS) Security Coordinator DC- CISF AC- CISF 18

ON-SITE EMERGENCY CONTROL MOCK DRILLS Ø Departmental : Monthly Mock Drill; Ø On-site Emergency Preparedness Plan is in place. Ø Onsite Emergency Control Room located in Administration Building Equipped with all communication systems, Documents, Contact details etc Ø On-site Mock Drill: In presence of officials of Tamilnadu Factory Inspectorate. Once in 6 Months ONSITE EMERGENCY MANAGEMENT ROLE FIRST LINE SECOND LINE Chief Coordinator Director (Operations) Director (Technical) Refinery Coordinator GM (Operations) GM (Technical) Plant Coordinator DGM (Manufacturing -Ref-I&II) DGM (PE) F&S Coordinator GM (Services) DGM (F&S) Maintenance Coordinator GM (Maintenance) DGM (Maintenance-Onsite) Project Coordinator GM (Projects) DGM (Projects) Materials Coordinator DGM (Materials & Contracts) CM (Purchase) Finance Coordinator GM (Finance) DGM (Finance) Welfare, Media & Transport Coordinator GM (HR) DGM (Admn & Welfare) Medical Coordinator Chief Medical Officer Manager (OHS) Security Coordinator DC- CISF AC- CISF 18

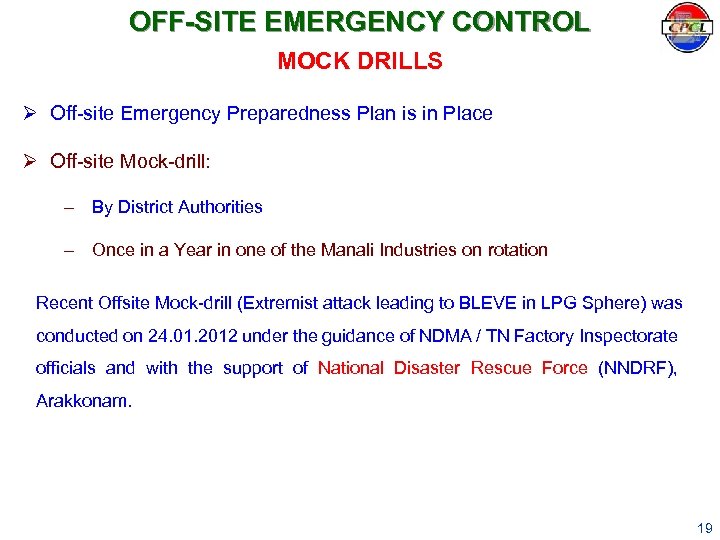

OFF-SITE EMERGENCY CONTROL MOCK DRILLS Ø Off-site Emergency Preparedness Plan is in Place Ø Off-site Mock-drill: - By District Authorities - Once in a Year in one of the Manali Industries on rotation Recent Offsite Mock-drill (Extremist attack leading to BLEVE in LPG Sphere) was conducted on 24. 01. 2012 under the guidance of NDMA / TN Factory Inspectorate officials and with the support of National Disaster Rescue Force (NNDRF), Arakkonam. 19

OFF-SITE EMERGENCY CONTROL MOCK DRILLS Ø Off-site Emergency Preparedness Plan is in Place Ø Off-site Mock-drill: - By District Authorities - Once in a Year in one of the Manali Industries on rotation Recent Offsite Mock-drill (Extremist attack leading to BLEVE in LPG Sphere) was conducted on 24. 01. 2012 under the guidance of NDMA / TN Factory Inspectorate officials and with the support of National Disaster Rescue Force (NNDRF), Arakkonam. 19

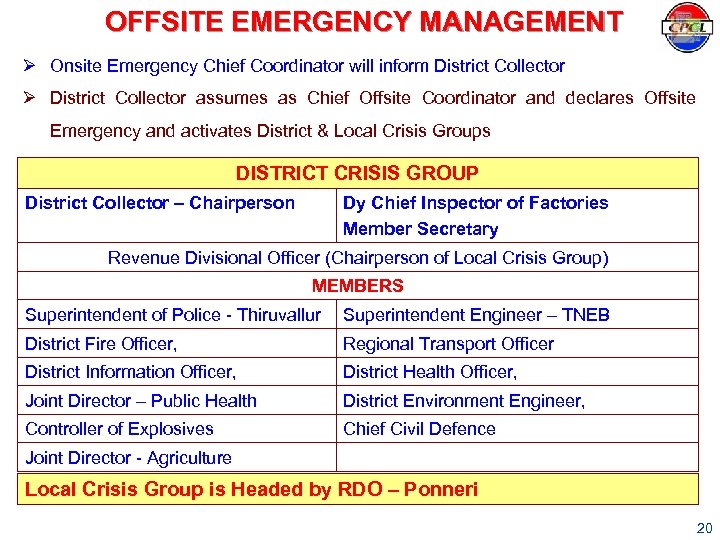

OFFSITE EMERGENCY MANAGEMENT Ø Onsite Emergency Chief Coordinator will inform District Collector Ø District Collector assumes as Chief Offsite Coordinator and declares Offsite Emergency and activates District & Local Crisis Groups DISTRICT CRISIS GROUP District Collector – Chairperson Dy Chief Inspector of Factories Member Secretary Revenue Divisional Officer (Chairperson of Local Crisis Group) MEMBERS Superintendent of Police - Thiruvallur Superintendent Engineer – TNEB District Fire Officer, Regional Transport Officer District Information Officer, District Health Officer, Joint Director – Public Health District Environment Engineer, Controller of Explosives Chief Civil Defence Joint Director - Agriculture Local Crisis Group is Headed by RDO – Ponneri 20

OFFSITE EMERGENCY MANAGEMENT Ø Onsite Emergency Chief Coordinator will inform District Collector Ø District Collector assumes as Chief Offsite Coordinator and declares Offsite Emergency and activates District & Local Crisis Groups DISTRICT CRISIS GROUP District Collector – Chairperson Dy Chief Inspector of Factories Member Secretary Revenue Divisional Officer (Chairperson of Local Crisis Group) MEMBERS Superintendent of Police - Thiruvallur Superintendent Engineer – TNEB District Fire Officer, Regional Transport Officer District Information Officer, District Health Officer, Joint Director – Public Health District Environment Engineer, Controller of Explosives Chief Civil Defence Joint Director - Agriculture Local Crisis Group is Headed by RDO – Ponneri 20

EMERGENCY MANAGEMENT REVIEW MECHANISM Ø Three Level Committees for review of Safety aspects ‒ Ten Zonal Safety Committees headed by officer at Chief Manager level ‒ Two Area Safety Committees headed by officer at Dy. General Manager level ‒ Central Safety Committee headed by Director (Operations) Ø Surprise Safety Check by OISD once in 2 years Ø External Safety Audit by OISD once in 4 years Ø Monitoring of SSC and ESA recommendations and other safety related matters by Board of CPCL on quarterly basis. 21

EMERGENCY MANAGEMENT REVIEW MECHANISM Ø Three Level Committees for review of Safety aspects ‒ Ten Zonal Safety Committees headed by officer at Chief Manager level ‒ Two Area Safety Committees headed by officer at Dy. General Manager level ‒ Central Safety Committee headed by Director (Operations) Ø Surprise Safety Check by OISD once in 2 years Ø External Safety Audit by OISD once in 4 years Ø Monitoring of SSC and ESA recommendations and other safety related matters by Board of CPCL on quarterly basis. 21

TRAINING & AWARENESS PROGRAMMES Ø Mandatory Fire & Safety training for all employees once in two years. Ø Disaster Management Workshops held at CPCL periodically for benefit of MIA industries. Ø New contract workers briefed on basic fire prevention requirements, communication facilities and their roles in the event of emergency. Ø Monthly meeting with Contractors Safety Officers – Good & wrong practices discussed, case studies videos screened. Ø Contractor Safety Steering Committee constituted to promote safe working practices, cross-auditing of work spots. Ø Contractors also encouraged to report Near Miss Incidents (NMIs) Ø Awareness programs, including live fire exercises, conducted in nearby schools periodically Ø Short Film in Tamil / Hindi (Acham Illai / Darna Mana Hai) made for educating the Public on Safety with specific reference to Petroleum Industries covering Do’s & Don’ts during emergency. It is screened in schools, seminars and Local TV channels. 22

TRAINING & AWARENESS PROGRAMMES Ø Mandatory Fire & Safety training for all employees once in two years. Ø Disaster Management Workshops held at CPCL periodically for benefit of MIA industries. Ø New contract workers briefed on basic fire prevention requirements, communication facilities and their roles in the event of emergency. Ø Monthly meeting with Contractors Safety Officers – Good & wrong practices discussed, case studies videos screened. Ø Contractor Safety Steering Committee constituted to promote safe working practices, cross-auditing of work spots. Ø Contractors also encouraged to report Near Miss Incidents (NMIs) Ø Awareness programs, including live fire exercises, conducted in nearby schools periodically Ø Short Film in Tamil / Hindi (Acham Illai / Darna Mana Hai) made for educating the Public on Safety with specific reference to Petroleum Industries covering Do’s & Don’ts during emergency. It is screened in schools, seminars and Local TV channels. 22

THANK YOU

THANK YOU