bb027e2ff85bceb8b799263830759450.ppt

- Количество слайдов: 53

Equipment Automation 半導體設備及LCD機台自動化 陳建志

Agenda ● 晶圓製造流程 ● 電腦整合製造 Computer Integrated Manufacturing (CIM) ● 半導體機台通訊協定 (SECS) ● 機台自動化 (Equipment Automation) 2

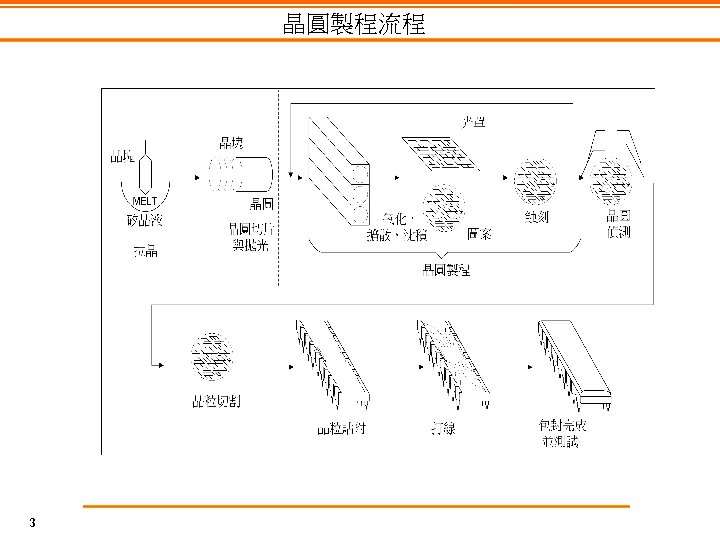

晶圓製程流程 3

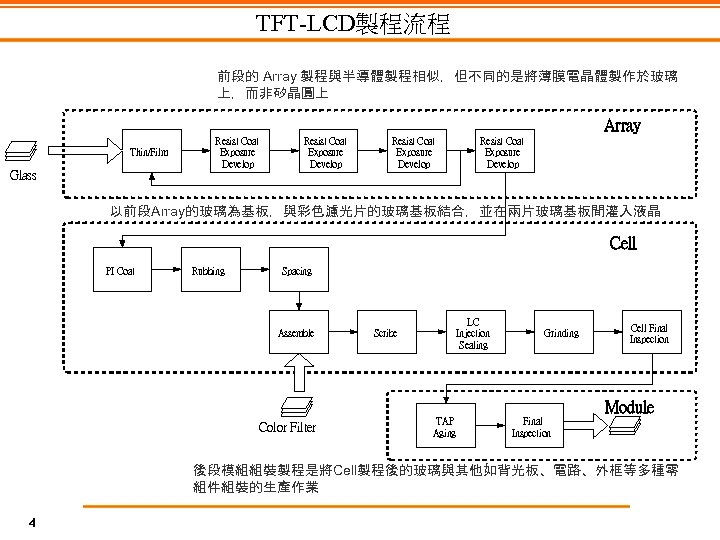

TFT-LCD製程流程 前段的 Array 製程與半導體製程相似,但不同的是將薄膜電晶體製作於玻璃 上,而非矽晶圓上 Array Thin/Film Glass Resist Coat Exposure Develop 以前段Array的玻璃為基板,與彩色濾光片的玻璃基板結合,並在兩片玻璃基板間灌入液晶 Cell PI Coat Rubbing Spacing Assemble LC Injection Sealing Scribe Grinding Cell Final Inspection Module Color Filter TAP Aging Final Inspection 後段模組組裝製程是將Cell製程後的玻璃與其他如背光板、電路、外框等多種零 組件組裝的生產作業 4

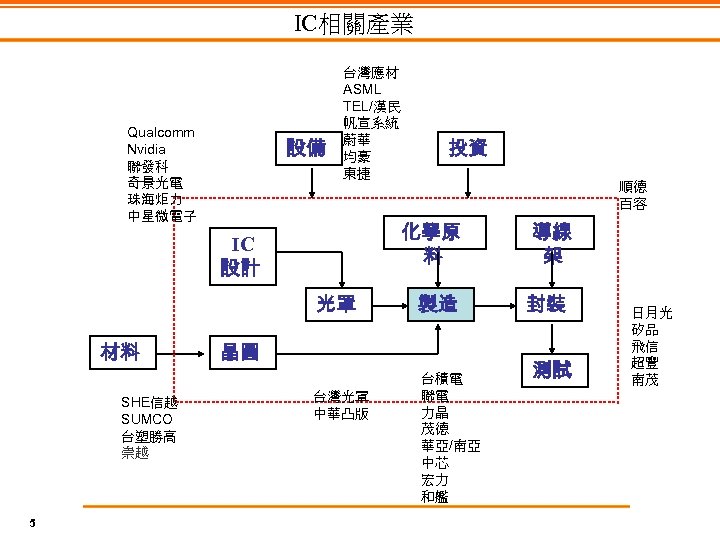

IC相關產業 Qualcomm Nvidia 聯發科 奇景光電 珠海炬力 中星微電子 設備 台灣應材 ASML TEL/漢民 帆宣系統 蔚華 均豪 東捷 光罩 SHE信越 SUMCO 台塑勝高 崇越 5 順德 百容 化學原 料 IC 設計 材料 投資 導線 架 製造 封裝 晶圓 台灣光罩 中華凸版 台積電 聯電 力晶 茂德 華亞/南亞 中芯 宏力 和艦 測試 日月光 矽品 飛信 超豐 南茂

機台設備 • 薄膜區 (Thin-Film) –氧化沉積製程 – 化學氣相沉積 • 擴散區 (Diff) - 擴散, 離子植入製程 – 離子植入機 – 爐管 • 黃光區 (Litho) -微影製程 – 微影機 • 蝕刻區 (Etch) • 量測機台 6

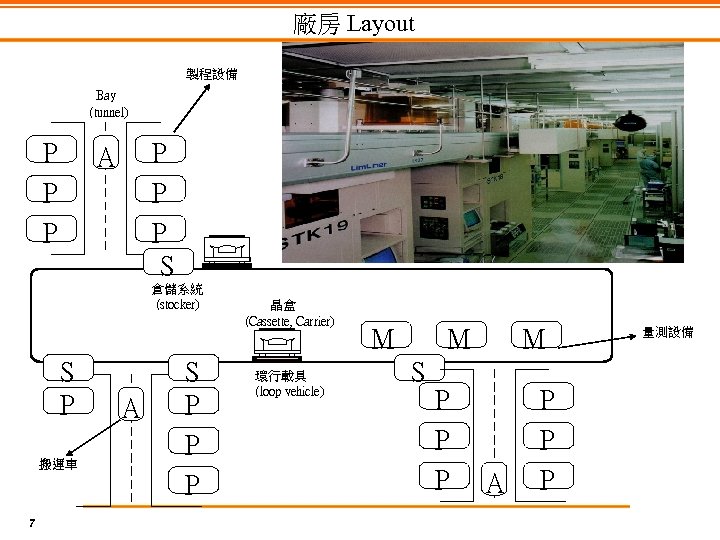

廠房 Layout 製程設備 Bay (tunnel) P P P S A 倉儲系統 (stocker) S P 搬運車 7 A S P P P 晶盒 (Cassette, Carrier) 環行載具 (loop vehicle) M M M S P P P A P P P 量測設備

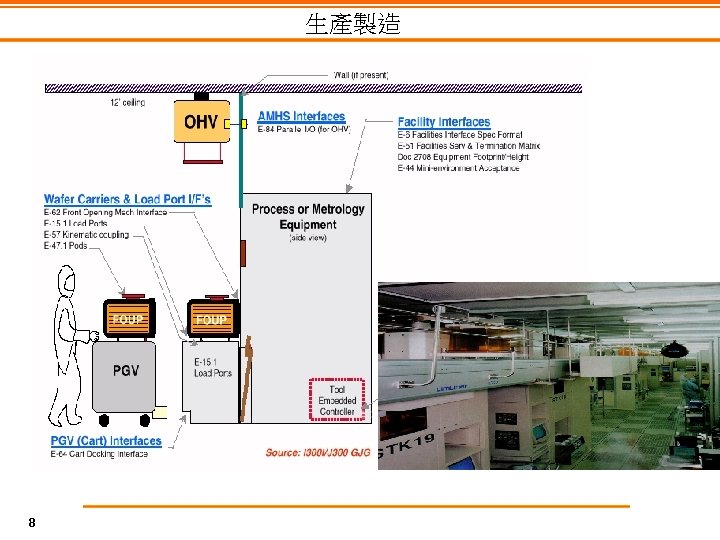

生產製造 8

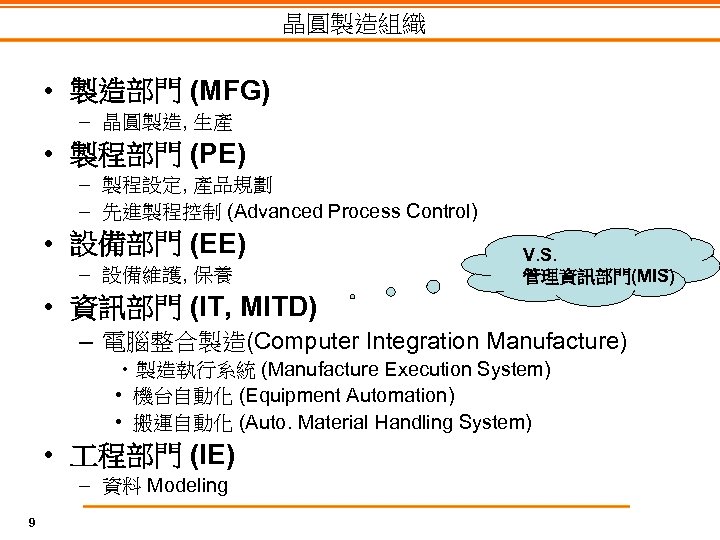

晶圓製造組織 • 製造部門 (MFG) – 晶圓製造, 生產 • 製程部門 (PE) – 製程設定, 產品規劃 – 先進製程控制 (Advanced Process Control) • 設備部門 (EE) – 設備維護, 保養 V. S. 管理資訊部門(MIS) • 資訊部門 (IT, MITD) – 電腦整合製造(Computer Integration Manufacture) • 製造執行系統 (Manufacture Execution System) • 機台自動化 (Equipment Automation) • 搬運自動化 (Auto. Material Handling System) • 程部門 (IE) – 資料 Modeling 9

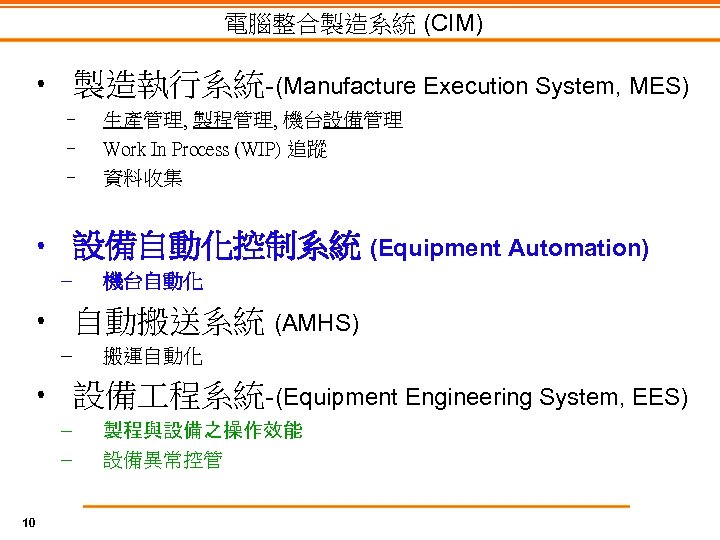

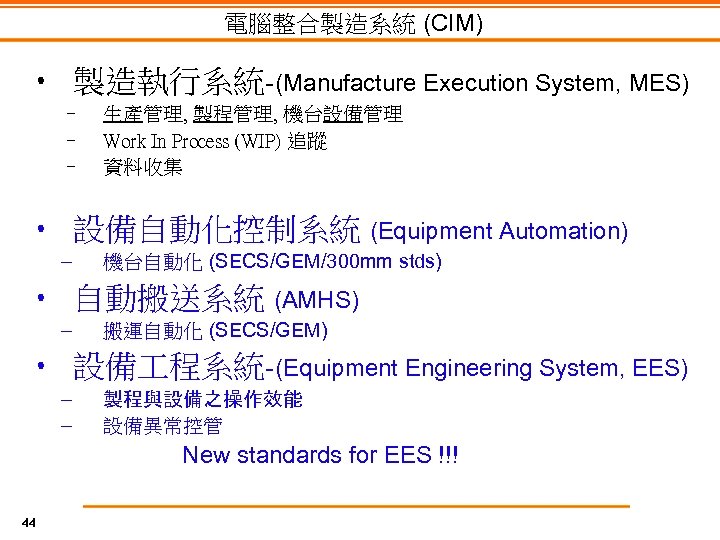

電腦整合製造系統 (CIM) • 製造執行系統-(Manufacture Execution System, MES) – – – 生產管理, 製程管理, 機台設備管理 Work In Process (WIP) 追蹤 資料收集 • 設備自動化控制系統 (Equipment Automation) – 機台自動化 • 自動搬送系統 (AMHS) – 搬運自動化 • 設備 程系統-(Equipment Engineering System, EES) – – 10 製程與設備之操作效能 設備異常控管

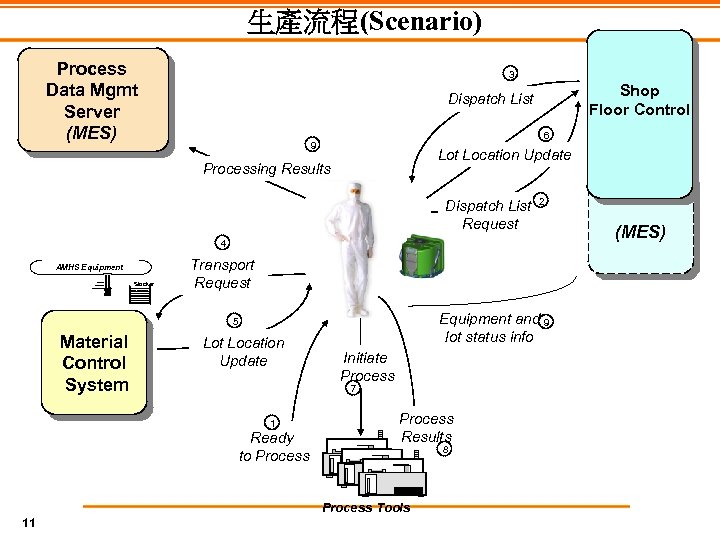

生產流程(Scenario) Process Data Mgmt Server (MES) 3 Shop Floor Control Dispatch List 6 9 Lot Location Update Processing Results Dispatch List Request 2 4 AMHS Equipment Stocker Transport Request Equipment and 9 lot status info 5 Material Control System Lot Location Update Initiate Process 7 1 Ready to Process Results 8 Process Tools 11 (MES)

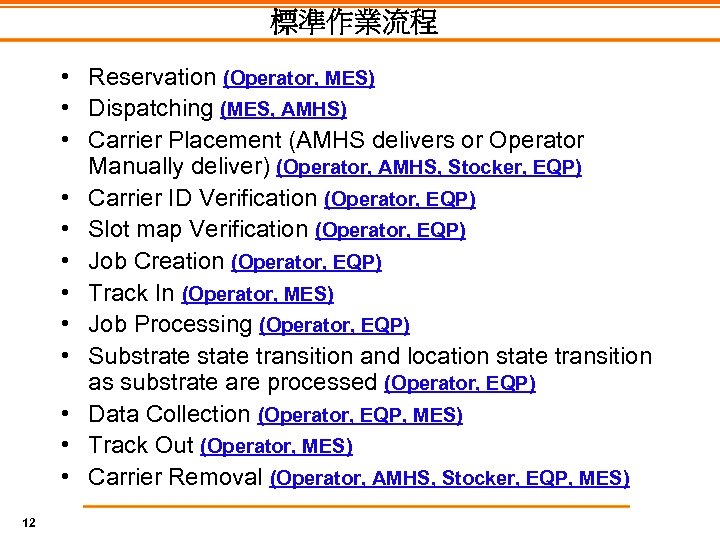

標準作業流程 • Reservation (Operator, MES) • Dispatching (MES, AMHS) • Carrier Placement (AMHS delivers or Operator Manually deliver) (Operator, AMHS, Stocker, EQP) • Carrier ID Verification (Operator, EQP) • Slot map Verification (Operator, EQP) • Job Creation (Operator, EQP) • Track In (Operator, MES) • Job Processing (Operator, EQP) • Substrate state transition and location state transition as substrate are processed (Operator, EQP) • Data Collection (Operator, EQP, MES) • Track Out (Operator, MES) • Carrier Removal (Operator, AMHS, Stocker, EQP, MES) 12

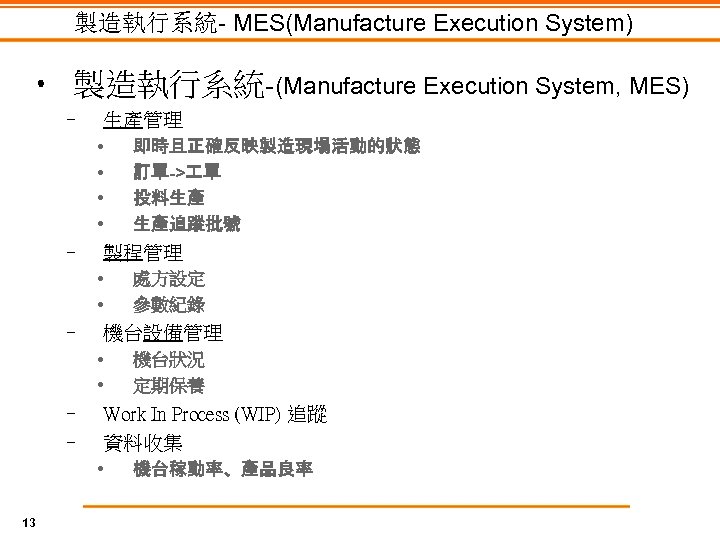

製造執行系統- MES(Manufacture Execution System) • 製造執行系統-(Manufacture Execution System, MES) – 生產管理 • • – 製程管理 • • – 機台狀況 定期保養 Work In Process (WIP) 追蹤 資料收集 • 13 處方設定 參數紀錄 機台設備管理 • • – – 即時且正確反映製造現場活動的狀態 訂單-> 單 投料生產 生產追蹤批號 機台稼動率、產品良率

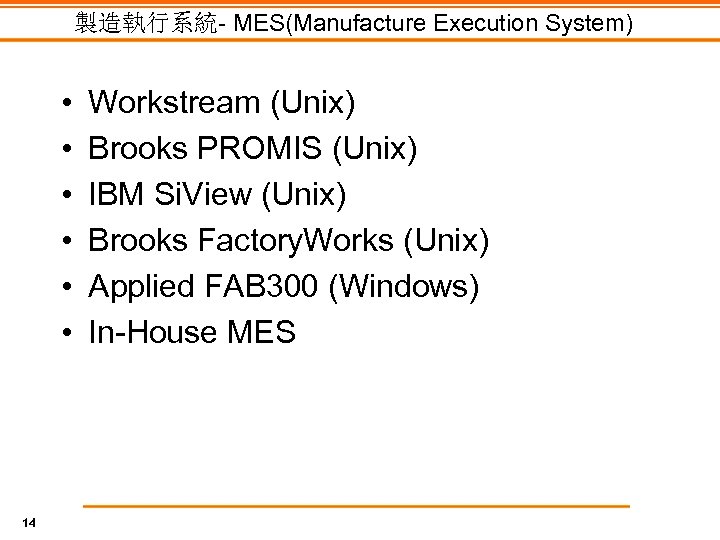

製造執行系統- MES(Manufacture Execution System) • • • 14 Workstream (Unix) Brooks PROMIS (Unix) IBM Si. View (Unix) Brooks Factory. Works (Unix) Applied FAB 300 (Windows) In-House MES

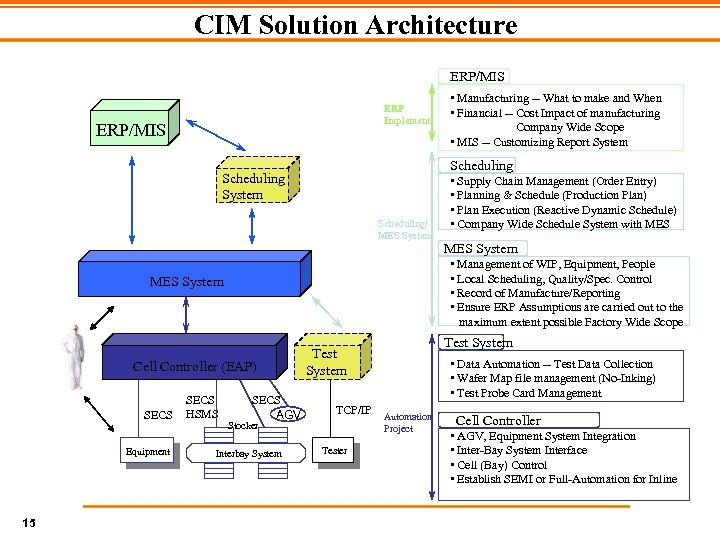

CIM Solution Architecture ERP/MIS ERP Implement ERP/MIS Scheduling System Scheduling/ MES System Cell Controller (EAP) SECS Equipment 15 • Supply Chain Management (Order Entry) • Planning & Schedule (Production Plan) • Plan Execution (Reactive Dynamic Schedule) • Company Wide Schedule System with MES MES System • Management of WIP, Equipment, People • Local Scheduling, Quality/Spec. Control • Record of Manufacture/Reporting • Ensure ERP Assumptions are carried out to the maximum extent possible Factory Wide Scope MES System SECS HSMS • Manufacturing -- What to make and When • Financial -- Cost Impact of manufacturing Company Wide Scope • MIS -- Customizing Report System SECS AGV TCP/IP Stocker Interbay System Tester Automation Project • Data Automation -- Test Data Collection • Wafer Map file management (No-Inking) • Test Probe Card Management Cell Controller • AGV, Equipment System Integration • Inter-Bay System Interface • Cell (Bay) Control • Establish SEMI or Full-Automation for Inline

為何要自動化 半導體廠的目標是生產而非自動化,但自動化卻可以使產品更 有競爭力(產能&良率)。 • 降低人員誤動作的風險 (MO: Miss – Operation) – – – 流程控制 (Flow Control) 晶圓放置 (Carrier Handling) 選擇配方 (Recipe Selection) 程式執行 (Job Creation) 資料收集 (Data Collection) • 降低污染 (Particle) • 晶圓, 玻璃尺寸越來越大 • 節省人力 – 生產自動化、無人化 16

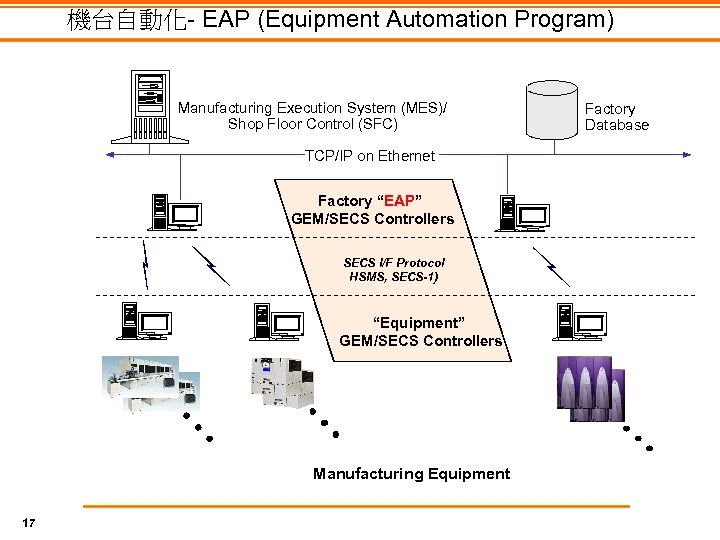

機台自動化- EAP (Equipment Automation Program) Manufacturing Execution System (MES)/ Shop Floor Control (SFC) TCP/IP on Ethernet Factory “EAP” GEM/SECS Controllers SECS I/F Protocol HSMS, SECS-1) “Equipment” GEM/SECS Controllers Manufacturing Equipment 17 Factory Database

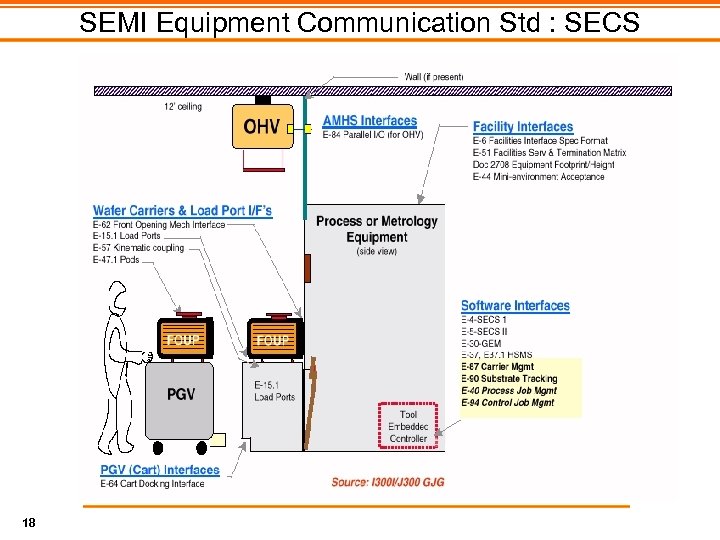

SEMI Equipment Communication Std : SECS 18

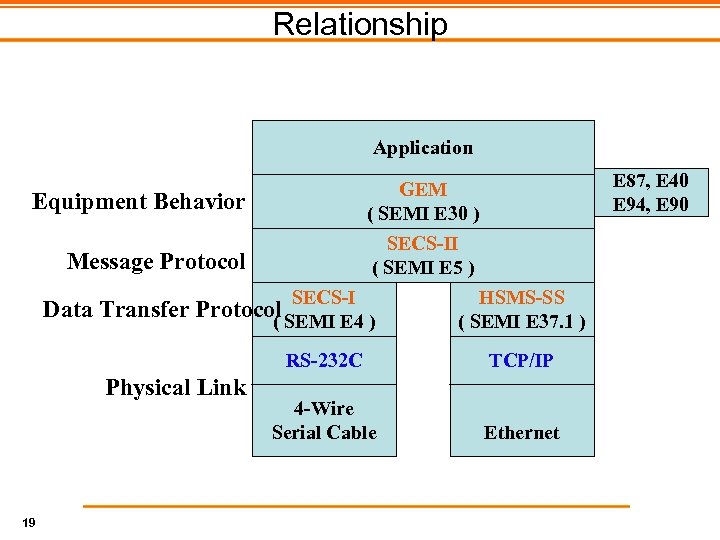

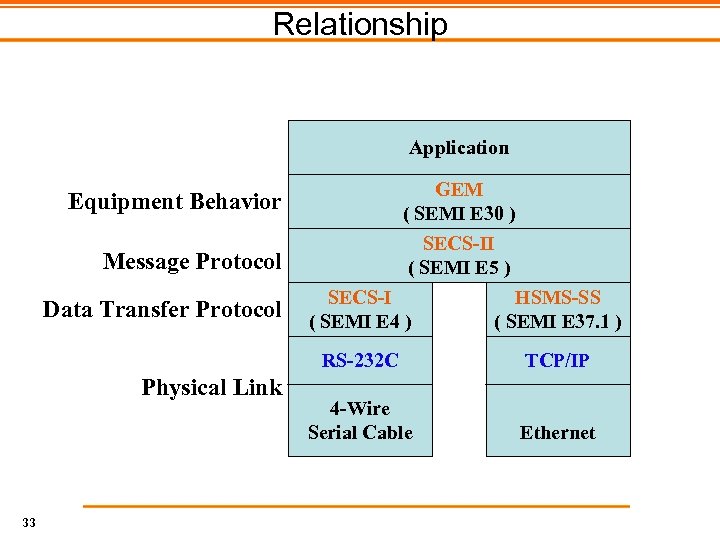

Relationship Application Equipment Behavior Message Protocol E 87, E 40 E 94, E 90 GEM ( SEMI E 30 ) SECS-II ( SEMI E 5 ) SECS-I HSMS-SS ( SEMI E 37. 1 ) RS-232 C TCP/IP 4 -Wire Serial Cable Ethernet Data Transfer Protocol SEMI E 4 ) ( Physical Link 19

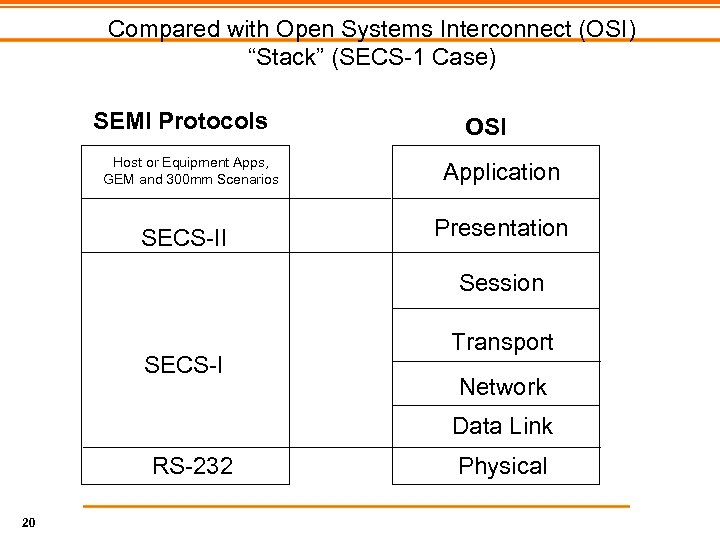

Compared with Open Systems Interconnect (OSI) “Stack” (SECS-1 Case) SEMI Protocols Host or Equipment Apps, GEM and 300 mm Scenarios SECS-II OSI Application Presentation Session SECS-I Transport Network Data Link RS-232 20 Physical

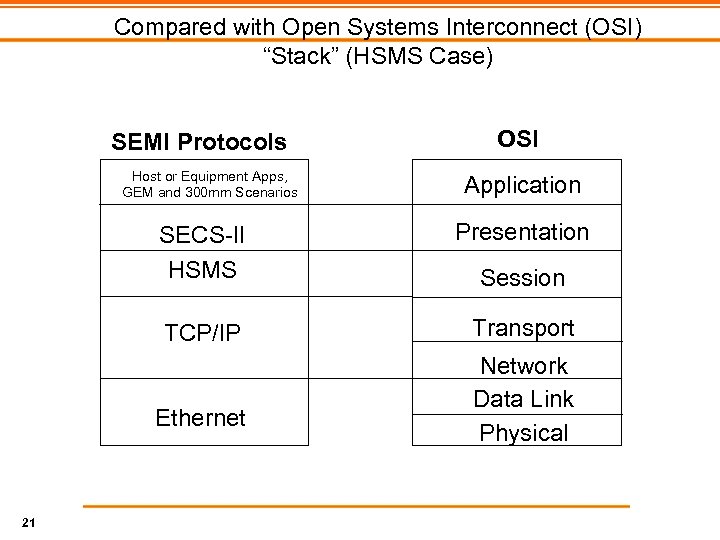

Compared with Open Systems Interconnect (OSI) “Stack” (HSMS Case) SEMI Protocols Host or Equipment Apps, GEM and 300 mm Scenarios OSI Application SECS-II HSMS Presentation TCP/IP Transport Ethernet 21 Session Network Data Link Physical

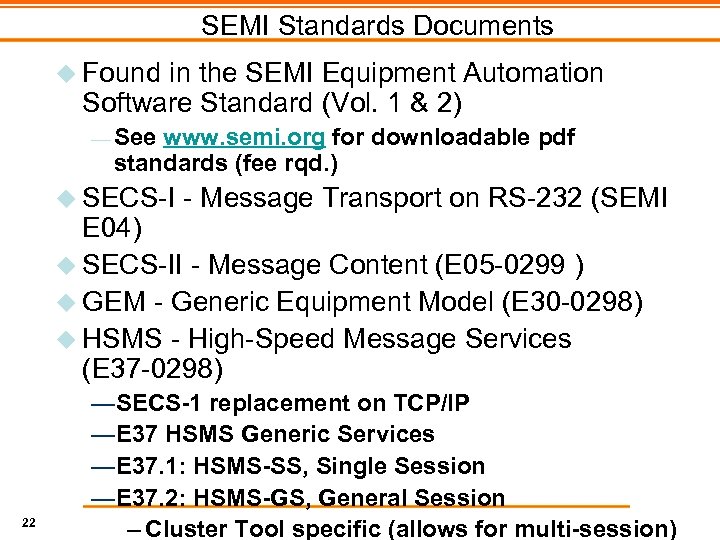

SEMI Standards Documents u Found in the SEMI Equipment Automation Software Standard (Vol. 1 & 2) — See www. semi. org for downloadable pdf standards (fee rqd. ) u SECS-I - Message Transport on RS-232 (SEMI E 04) u SECS-II - Message Content (E 05 -0299 ) u GEM - Generic Equipment Model (E 30 -0298) u HSMS - High-Speed Message Services (E 37 -0298) 22 —SECS-1 replacement on TCP/IP —E 37 HSMS Generic Services —E 37. 1: HSMS-SS, Single Session —E 37. 2: HSMS-GS, General Session – Cluster Tool specific (allows for multi-session)

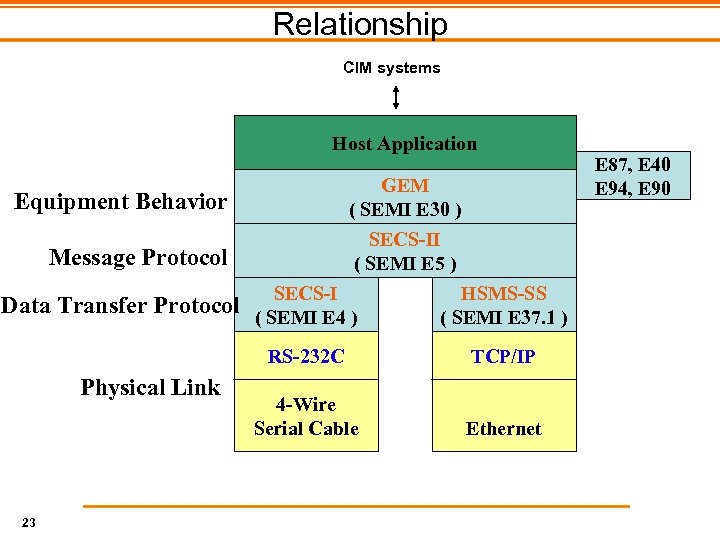

Relationship CIM systems Host Application Equipment Behavior GEM ( SEMI E 30 ) Message Protocol SECS-II ( SEMI E 5 ) Physical Link 23 HSMS-SS ( SEMI E 37. 1 ) RS-232 C Data Transfer Protocol SECS-I ( SEMI E 4 ) TCP/IP 4 -Wire Serial Cable Ethernet E 87, E 40 E 94, E 90

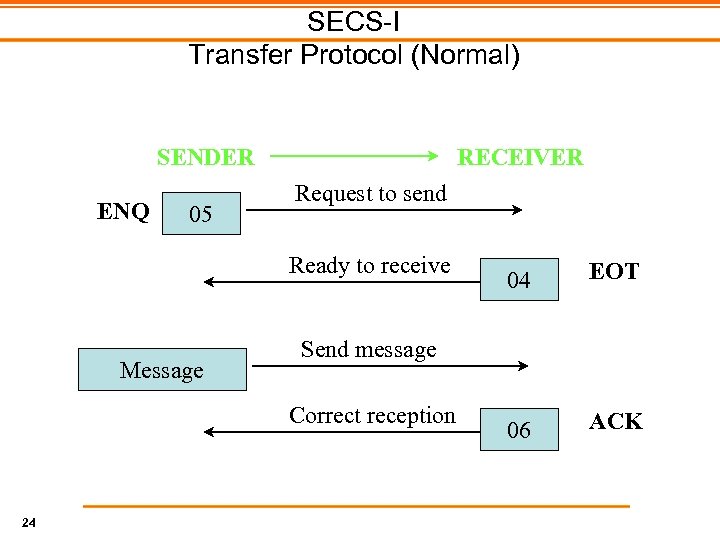

SECS-I Transfer Protocol (Normal) SENDER ENQ 05 RECEIVER Request to send Ready to receive Message EOT 06 ACK Send message Correct reception 24 04

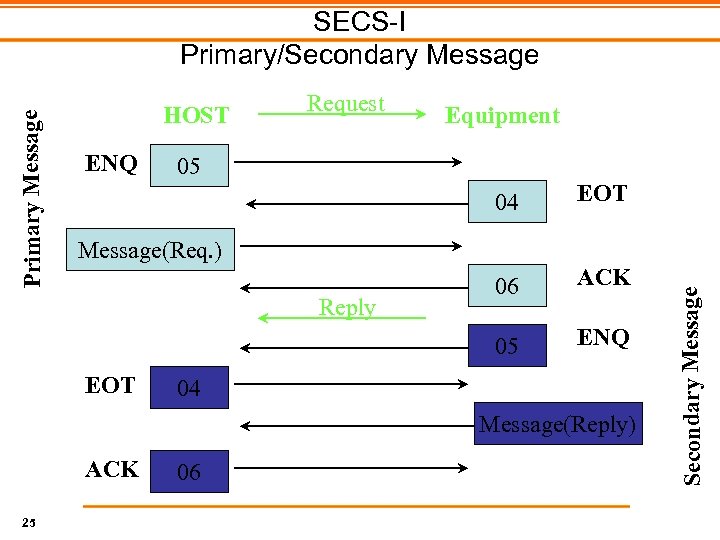

HOST ENQ Request Equipment 05 04 EOT 06 ACK 05 ENQ Message(Req. ) Reply EOT 04 Message(Reply) ACK 25 06 Secondary Message Primary Message SECS-I Primary/Secondary Message

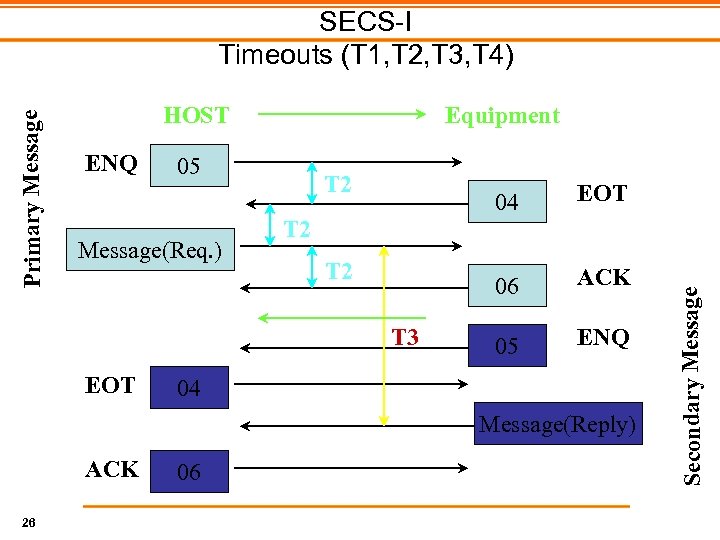

HOST ENQ Equipment 05 Message(Req. ) T 2 04 06 ACK 05 ENQ T 2 T 3 EOT 04 Message(Reply) ACK 26 06 Secondary Message Primary Message SECS-I Timeouts (T 1, T 2, T 3, T 4)

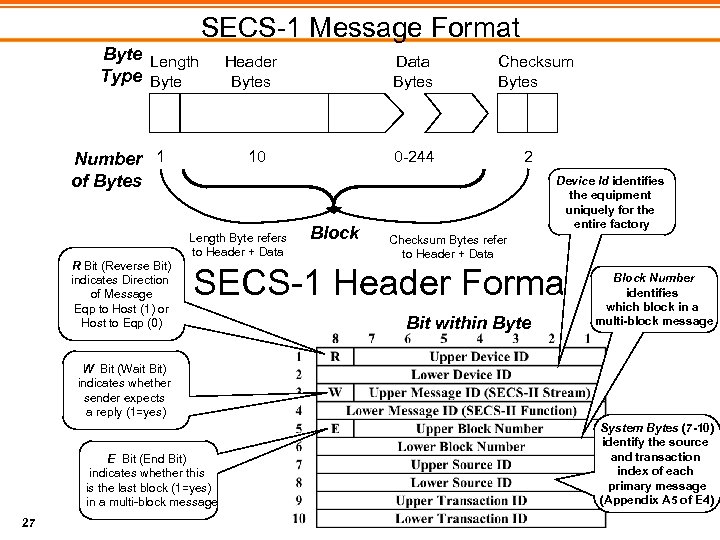

SECS-1 Message Format Byte Length Type Byte Number 1 of Bytes R Bit (Reverse Bit) indicates Direction of Message Eqp to Host (1) or Host to Eqp (0) Data Bytes 10 Length Byte refers to Header + Data Checksum Bytes 0 -244 Block 2 Device Id identifies the equipment uniquely for the entire factory Checksum Bytes refer to Header + Data SECS-1 Header Format W Bit (Wait Bit) indicates whether sender expects a reply (1=yes) E Bit (End Bit) indicates whether this is the last block (1=yes) in a multi-block message 27 Header Bytes Bit within Byte Number Block Number identifies which block in a multi-block message System Bytes (7 -10) identify the source and transaction index of each primary message (Appendix A 5 of E 4)

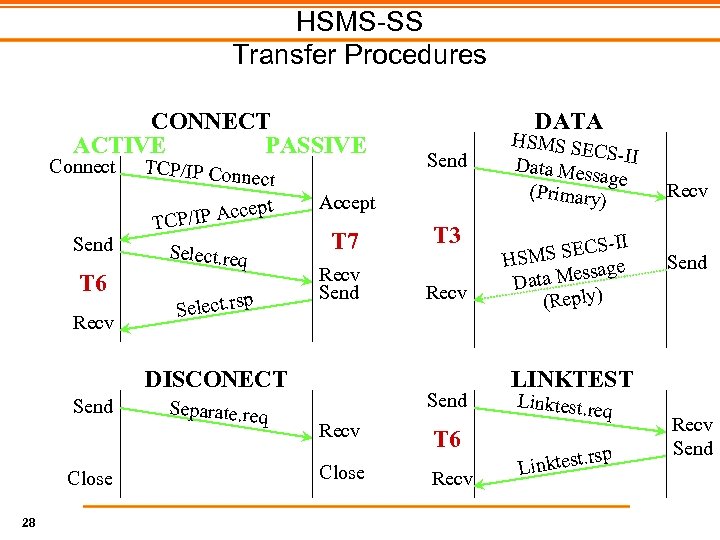

HSMS-SS Transfer Procedures CONNECT ACTIVE PASSIVE Connect Send T 6 Recv TCP/IP Con nect Accept TCP/IP Select. req p Select. rs Close 28 Separate. req Send Accept T 7 T 3 Recv Send Recv DISCONECT Send DATA Send Recv Close T 6 Recv HSMS SE CS Data Mes -II sage (Primary) S-II MS SEC HS age ata Mess D (Reply) Recv Send LINKTEST Linktest. re q t. rsp Linktes Recv Send

SECS-2 Introduction • • 29 SECS II Data Structure Data Item Formats Stream/Functions SECS-2 Message Conversations

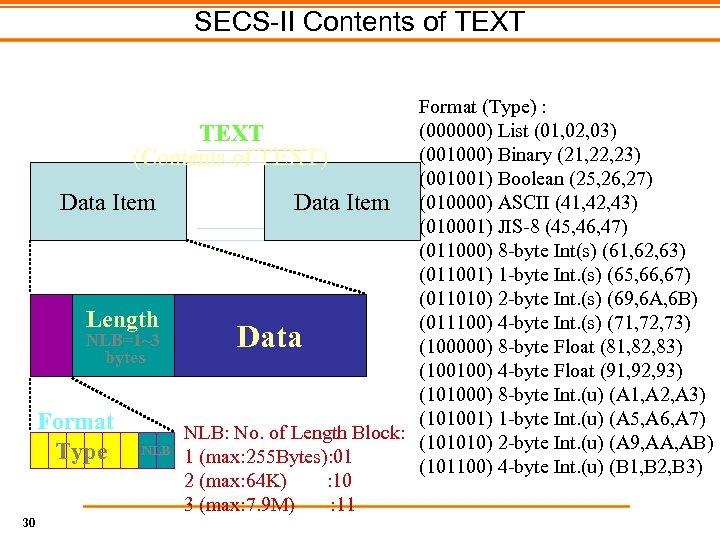

SECS-II Contents of TEXT Format (Type) : (000000) List (01, 02, 03) TEXT (001000) Binary (21, 22, 23) (Contents of TEXT) (001001) Boolean (25, 26, 27) Data Item (010000) ASCII (41, 42, 43) (010001) JIS-8 (45, 46, 47) (011000) 8 -byte Int(s) (61, 62, 63) (011001) 1 -byte Int. (s) (65, 66, 67) (011010) 2 -byte Int. (s) (69, 6 A, 6 B) Length (011100) 4 -byte Int. (s) (71, 72, 73) NLB=1~3 (100000) 8 -byte Float (81, 82, 83) bytes (100100) 4 -byte Float (91, 92, 93) (101000) 8 -byte Int. (u) (A 1, A 2, A 3) (101001) 1 -byte Int. (u) (A 5, A 6, A 7) Format NLB: No. of Length Block: (101010) 2 -byte Int. (u) (A 9, AA, AB) Type NLB 1 (max: 255 Bytes): 01 (101100) 4 -byte Int. (u) (B 1, B 2, B 3) 2 (max: 64 K) : 10 3 (max: 7. 9 M) : 11 Data 30

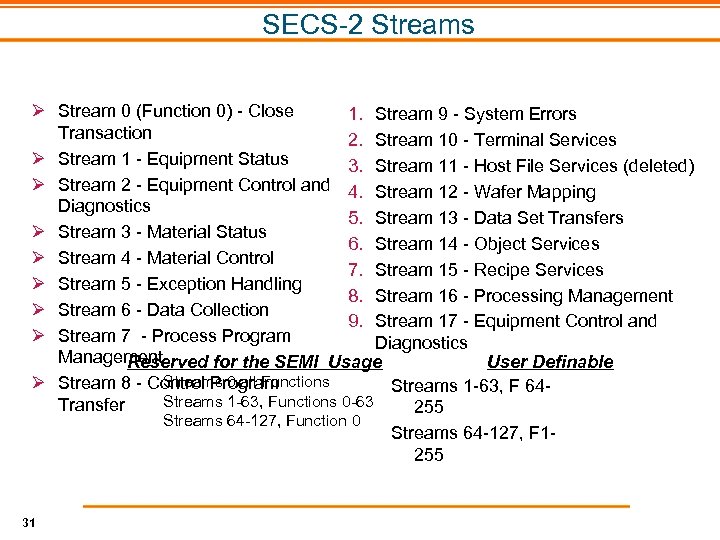

SECS-2 Streams Ø Stream 0 (Function 0) - Close 1. Stream 9 - System Errors Transaction 2. Stream 10 - Terminal Services Ø Stream 1 - Equipment Status 3. Stream 11 - Host File Services (deleted) Ø Stream 2 - Equipment Control and 4. Stream 12 - Wafer Mapping Diagnostics 5. Stream 13 - Data Set Transfers Ø Stream 3 - Material Status 6. Stream 14 - Object Services Ø Stream 4 - Material Control 7. Stream 15 - Recipe Services Ø Stream 5 - Exception Handling 8. Stream 16 - Processing Management Ø Stream 6 - Data Collection 9. Stream 17 - Equipment Control and Ø Stream 7 - Process Program Diagnostics Management Reserved for the SEMI Usage User Definable Streams 0 all Functions Ø Stream 8 - Control Program Streams 1 -63, F 64 Streams 1 -63, Functions 0 -63 Transfer 255 Streams 64 -127, Function 0 Streams 64 -127, F 1255 31

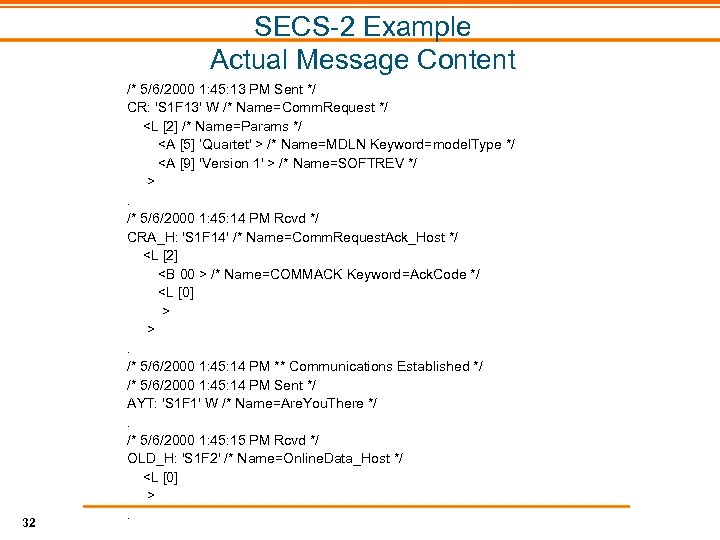

SECS-2 Example Actual Message Content 32 /* 5/6/2000 1: 45: 13 PM Sent */ CR: 'S 1 F 13' W /* Name=Comm. Request */ <L [2] /* Name=Params */ <A [5] ’Quartet' > /* Name=MDLN Keyword=model. Type */ <A [9] 'Version 1' > /* Name=SOFTREV */ >. /* 5/6/2000 1: 45: 14 PM Rcvd */ CRA_H: 'S 1 F 14' /* Name=Comm. Request. Ack_Host */ <L [2] <B 00 > /* Name=COMMACK Keyword=Ack. Code */ <L [0] > >. /* 5/6/2000 1: 45: 14 PM ** Communications Established */ /* 5/6/2000 1: 45: 14 PM Sent */ AYT: 'S 1 F 1' W /* Name=Are. You. There */. /* 5/6/2000 1: 45: 15 PM Rcvd */ OLD_H: 'S 1 F 2' /* Name=Online. Data_Host */ <L [0] >.

Relationship Application Equipment Behavior GEM ( SEMI E 30 ) Message Protocol SECS-II ( SEMI E 5 ) Physical Link 33 SECS-I ( SEMI E 4 ) HSMS-SS ( SEMI E 37. 1 ) RS-232 C Data Transfer Protocol TCP/IP 4 -Wire Serial Cable Ethernet

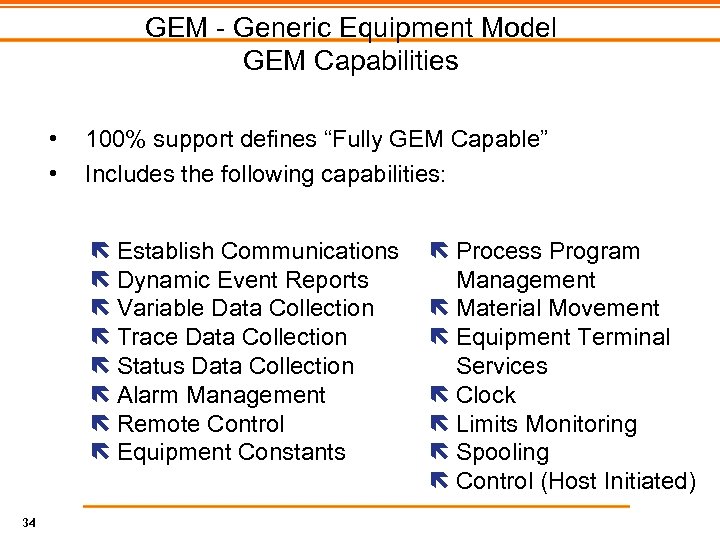

GEM - Generic Equipment Model GEM Capabilities • • 100% support defines “Fully GEM Capable” Includes the following capabilities: ë Establish Communications ë Dynamic Event Reports ë Variable Data Collection ë Trace Data Collection ë Status Data Collection ë Alarm Management ë Remote Control ë Equipment Constants 34 ë Process Program Management ë Material Movement ë Equipment Terminal Services ë Clock ë Limits Monitoring ë Spooling ë Control (Host Initiated)

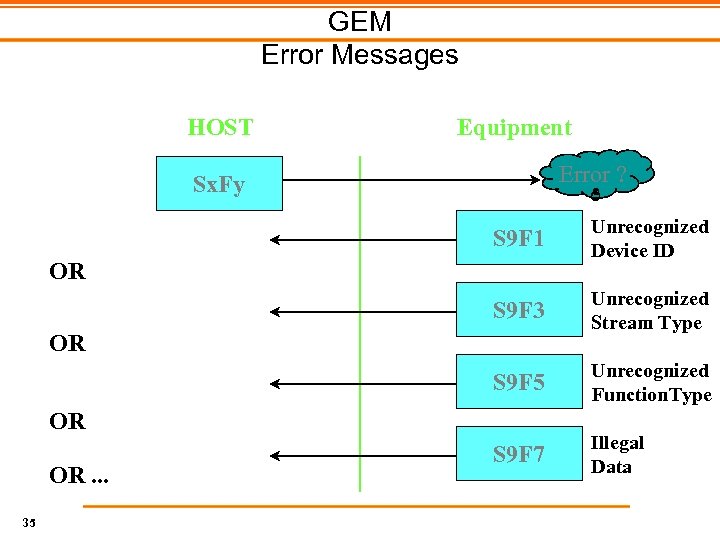

GEM Error Messages HOST Equipment Error ? Sx. Fy S 9 F 1 Unrecognized Device ID S 9 F 3 Unrecognized Stream Type S 9 F 5 Unrecognized Function. Type S 9 F 7 Illegal Data OR OR. . . 35

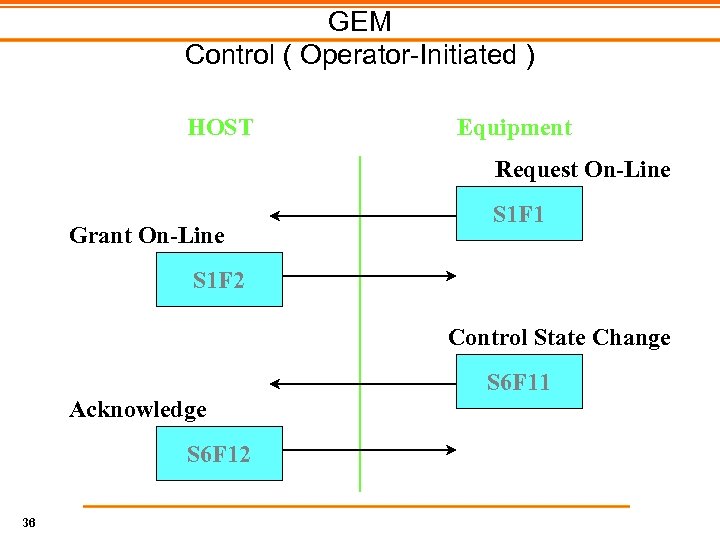

GEM Control ( Operator-Initiated ) HOST Equipment Request On-Line Grant On-Line S 1 F 1 S 1 F 2 Control State Change S 6 F 11 Acknowledge S 6 F 12 36

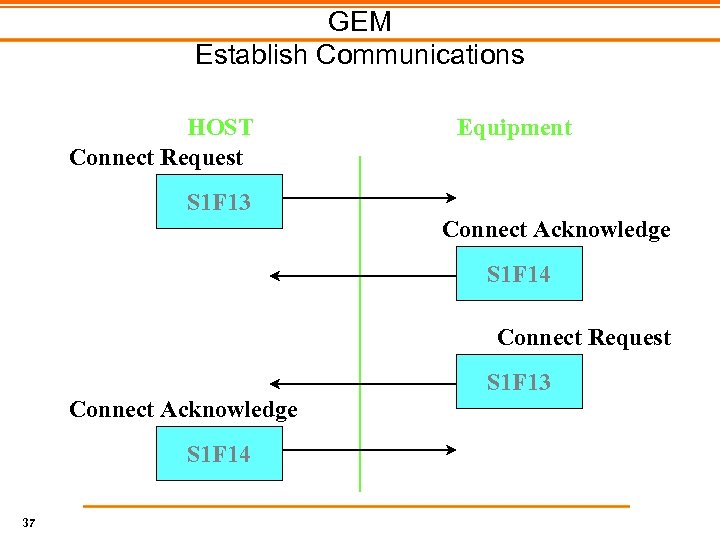

GEM Establish Communications HOST Connect Request Equipment S 1 F 13 Connect Acknowledge S 1 F 14 Connect Request S 1 F 13 Connect Acknowledge S 1 F 14 37

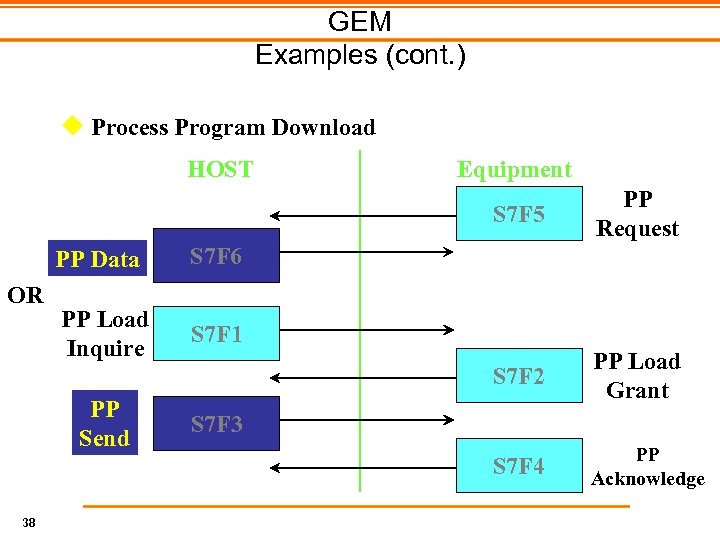

GEM Examples (cont. ) Process Program Download HOST Equipment S 7 F 5 S 7 F 2 OR S 7 F 1 PP Send 38 PP Acknowledge S 7 F 6 PP Load Inquire PP Load Grant S 7 F 4 PP Data PP Request S 7 F 3

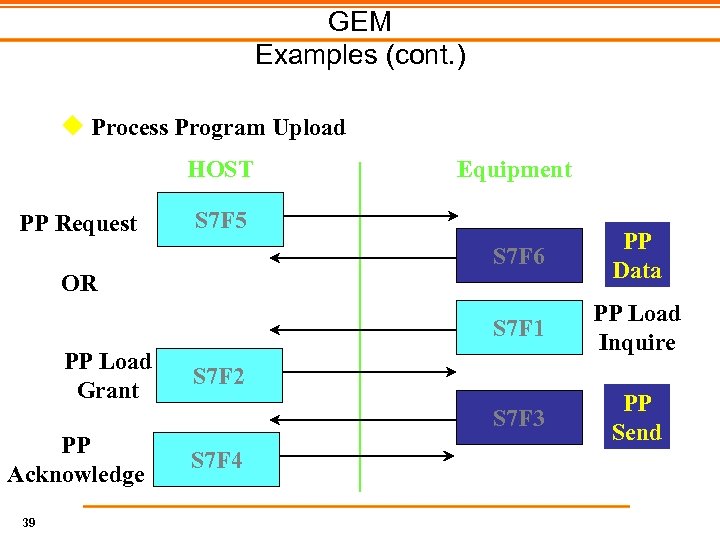

GEM Examples (cont. ) Process Program Upload HOST PP Request Equipment S 7 F 5 S 7 F 6 PP Data S 7 F 1 PP Load Inquire S 7 F 3 PP Send OR PP Load Grant PP Acknowledge 39 S 7 F 2 S 7 F 4

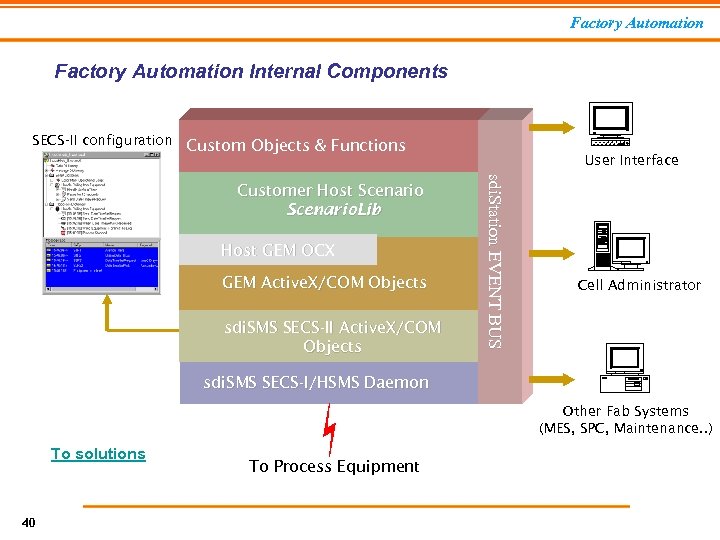

Factory Automation Internal Components SECS-II configuration Custom Objects & Functions Event Bus Host GEM OCX GEM Active. X/COM Objects sdi. SMS SECS-II Active. X/COM Objects sdi. Station EVENT BUS Customer Host Scenario. Lib User Interface Cell Administrator sdi. SMS SECS-I/HSMS Daemon Other Fab Systems (MES, SPC, Maintenance. . ) To solutions 40 To Process Equipment

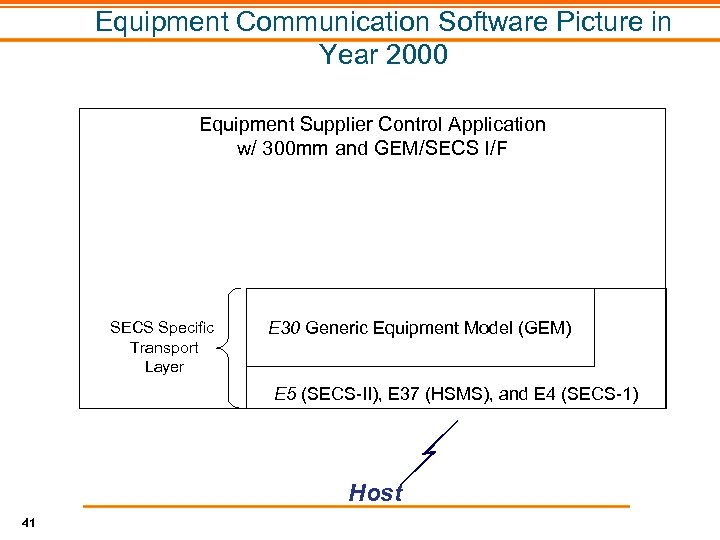

Equipment Communication Software Picture in Year 2000 Equipment Supplier Control Application w/ 300 mm and GEM/SECS I/F SECS Specific Transport Layer E 30 Generic Equipment Model (GEM) E 5 (SECS-II), E 37 (HSMS), and E 4 (SECS-1) Host 41

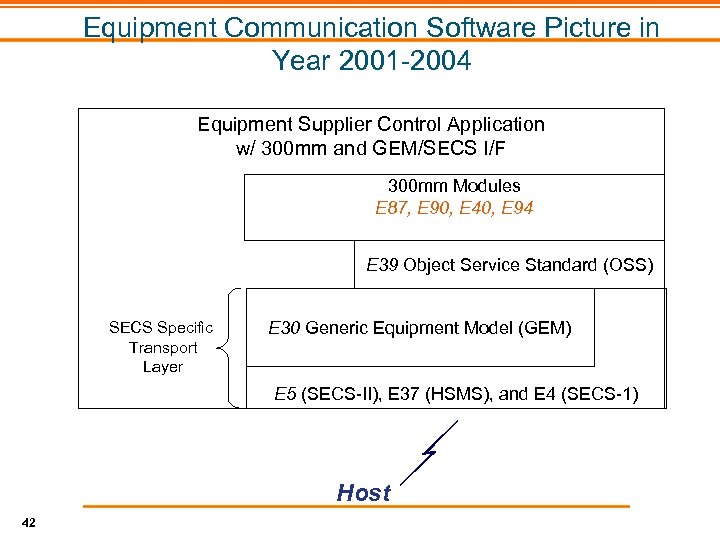

Equipment Communication Software Picture in Year 2001 -2004 Equipment Supplier Control Application w/ 300 mm and GEM/SECS I/F 300 mm Modules E 87, E 90, E 40, E 94 E 39 Object Service Standard (OSS) SECS Specific Transport Layer E 30 Generic Equipment Model (GEM) E 5 (SECS-II), E 37 (HSMS), and E 4 (SECS-1) Host 42

300 mm Standards • E 40 – Process Job Management • Recipe ID and Recipe Parameters • E 84 – AMHS Parallel I/O Handoff • Hardware PIO signal handshake for carrier handoff • E 87 – Carrier Management (Provisional) • Carrier control scenario for Fixed/Internal Buffer equipment • Proceed. With. Carrier, Carrier. In, Carrier. Out, and etc. • E 90 – Substrate Tracking • Wafer Level Tracking • E 94 – Control Job Management (Provisional) • Multiple lots/Recipes in one carrier and more … • E 99 – Carrier ID Read/Write • SECS message definitions for Carrier ID Read/Write • EPM and e-Diagnostics • GEM 300 – SECS/GEM for 300 -mm 43

電腦整合製造系統 (CIM) • 製造執行系統-(Manufacture Execution System, MES) – – – 生產管理, 製程管理, 機台設備管理 Work In Process (WIP) 追蹤 資料收集 • 設備自動化控制系統 (Equipment Automation) – 機台自動化 (SECS/GEM/300 mm stds) • 自動搬送系統 (AMHS) – 搬運自動化 (SECS/GEM) • 設備 程系統-(Equipment Engineering System, EES) – – 製程與設備之操作效能 設備異常控管 New standards for EES !!! 44

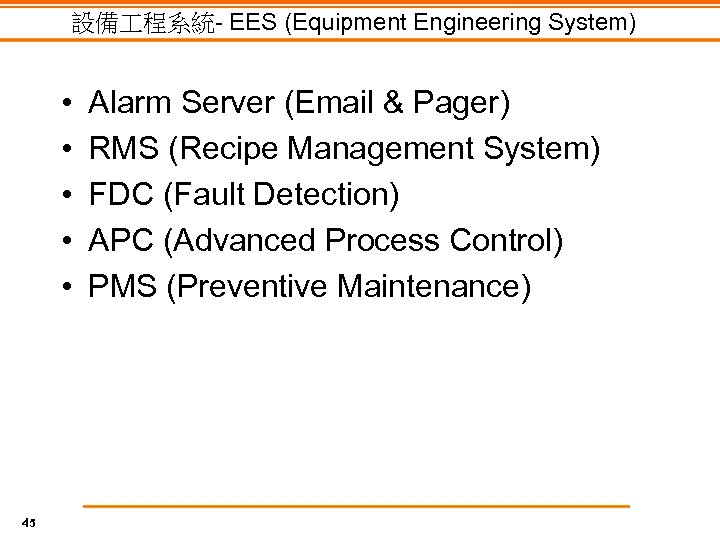

設備 程系統- EES (Equipment Engineering System) • • • 45 Alarm Server (Email & Pager) RMS (Recipe Management System) FDC (Fault Detection) APC (Advanced Process Control) PMS (Preventive Maintenance)

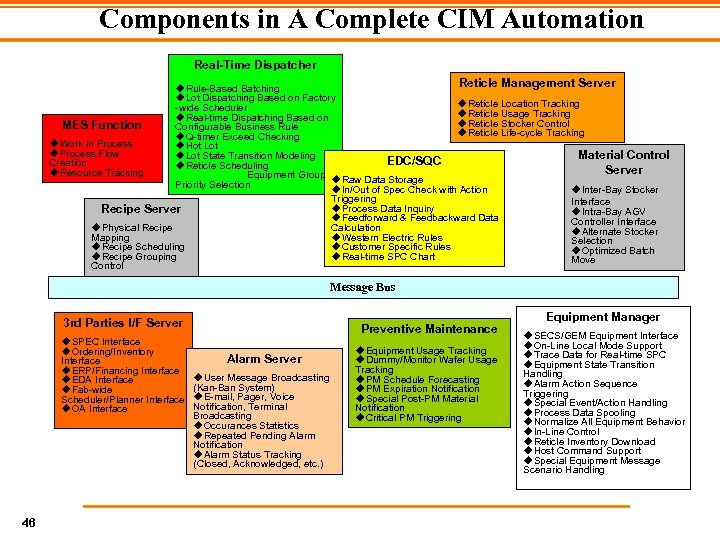

Components in A Complete CIM Automation Real-Time Dispatcher Reticle Management Server u. Rule-Based Batching u. Lot Dispatching Based on Factory u. Reticle Location Tracking -wide Scheduler u. Reticle Usage Tracking u. Real-time Dispatching Based on u. Reticle Stocker Control MES Function Configurable Business Rule u. Reticle Life-cycle Tracking u. Q-timer Exceed Checking u. Work In Process u. Hot Lot u. Process Flow u. Lot State Transition Modeling Material Control EDC/SQC Creation u. Reticle Scheduling Server u. Resource Tracking Equipment Group u. Raw Data Storage Priority Selection u. In/Out of Spec Check with Action u. Inter-Bay Stocker Triggering Interface u. Process Data Inquiry Recipe Server u. Intra-Bay AGV u. Feedforward & Feedbackward Data Controller Interface u. Physical Recipe Calculation u. Alternate Stocker Mapping u. Western Electric Rules Selection u. Customer Specific Rules u. Recipe Scheduling u. Optimized Batch u. Real-time SPC Chart u. Recipe Grouping Move Control Message Bus 3 rd Parties I/F Server u. SPEC Interface u. Ordering/Inventory Interface u. ERP/Financing Interface u. EDA Interface u. Fab-wide Scheduler/Planner Interface u. OA Interface 46 Preventive Maintenance Alarm Server u. User Message Broadcasting (Kan-Ban System) u. E-mail, Pager, Voice Notification, Terminal Broadcasting u. Occurances Statistics u. Repeated Pending Alarm Notification u. Alarm Status Tracking (Closed, Acknowledged, etc. ) u. Equipment Usage Tracking u. Dummy/Monitor Wafer Usage Tracking u. PM Schedule Forecasting u. PM Expiration Notification u. Special Post-PM Material Notification u. Critical PM Triggering Equipment Manager u. SECS/GEM Equipment Interface u. On-Line Local Mode Support u. Trace Data for Real-time SPC u. Equipment State Transition Handling u. Alarm Action Sequence Triggering u. Special Event/Action Handling u. Process Data Spooling u. Normalize All Equipment Behavior u. In-Line Control u. Reticle Inventory Download u. Host Command Support u. Special Equipment Message Scenario Handling

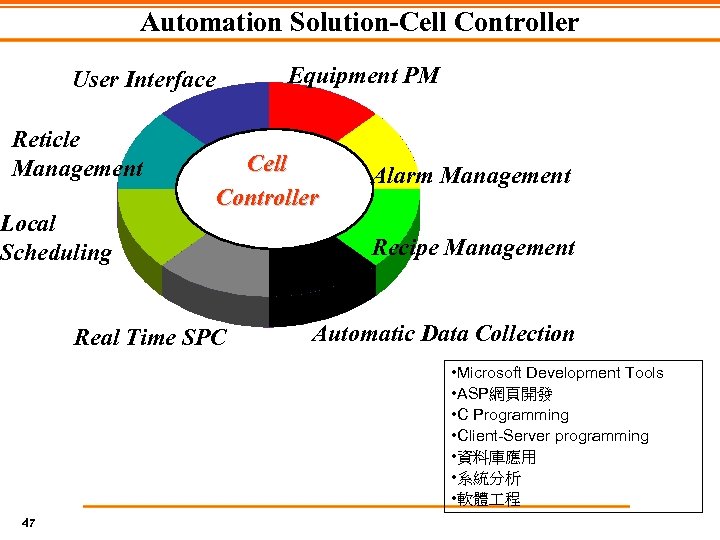

Automation Solution-Cell Controller Equipment PM User Interface Reticle Management Local Scheduling Cell Controller Real Time SPC Alarm Management Recipe Management Automatic Data Collection • Microsoft Development Tools • ASP網頁開發 • C Programming • Client-Server programming • 資料庫應用 • 系統分析 • 軟體 程 47

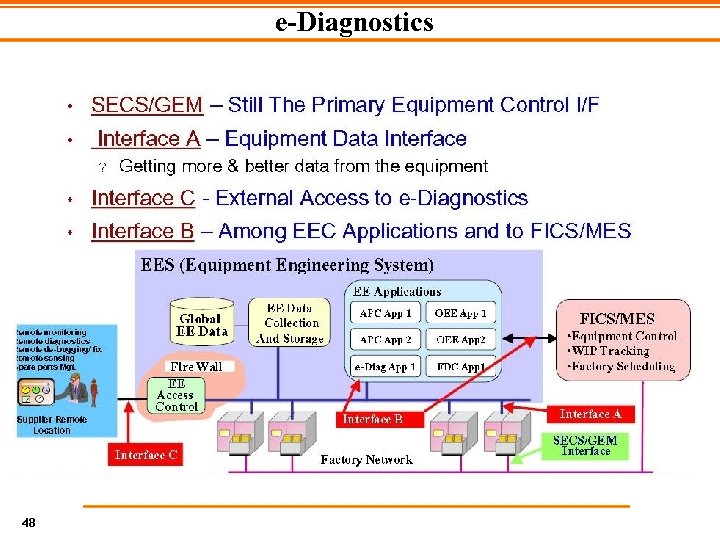

e-Diagnostics 48

EA Responsibility Boundary • Equipment Spec. Definition and Negotiation with EQP vendor – 200 mm/300 mm SEMI Standards – EQP Functional Requirements – EAP Scenarios • Coordination with FAB Users – Users Requirements – Interface with MES or CIM systems • Vendor Site Test – Vendor Site Test Plan – Perform Vendor Site Test 49

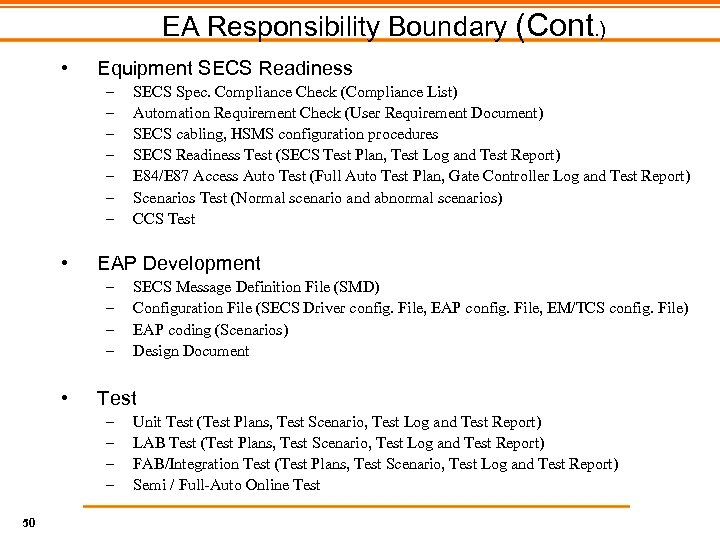

EA Responsibility Boundary (Cont. ) • Equipment SECS Readiness – – – – • EAP Development – – • SECS Message Definition File (SMD) Configuration File (SECS Driver config. File, EAP config. File, EM/TCS config. File) EAP coding (Scenarios) Design Document Test – – 50 SECS Spec. Compliance Check (Compliance List) Automation Requirement Check (User Requirement Document) SECS cabling, HSMS configuration procedures SECS Readiness Test (SECS Test Plan, Test Log and Test Report) E 84/E 87 Access Auto Test (Full Auto Test Plan, Gate Controller Log and Test Report) Scenarios Test (Normal scenario and abnormal scenarios) CCS Test Unit Test (Test Plans, Test Scenario, Test Log and Test Report) LAB Test (Test Plans, Test Scenario, Test Log and Test Report) FAB/Integration Test (Test Plans, Test Scenario, Test Log and Test Report) Semi / Full-Auto Online Test

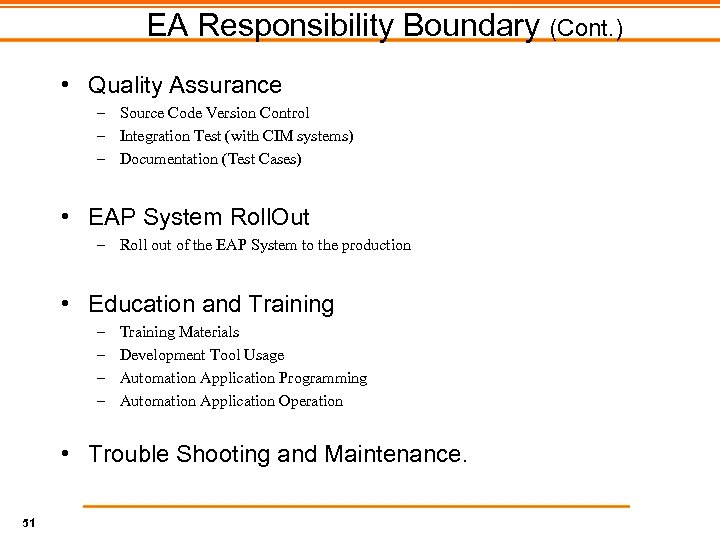

EA Responsibility Boundary (Cont. ) • Quality Assurance – Source Code Version Control – Integration Test (with CIM systems) – Documentation (Test Cases) • EAP System Roll. Out – Roll out of the EAP System to the production • Education and Training – – Training Materials Development Tool Usage Automation Application Programming Automation Application Operation • Trouble Shooting and Maintenance. 51

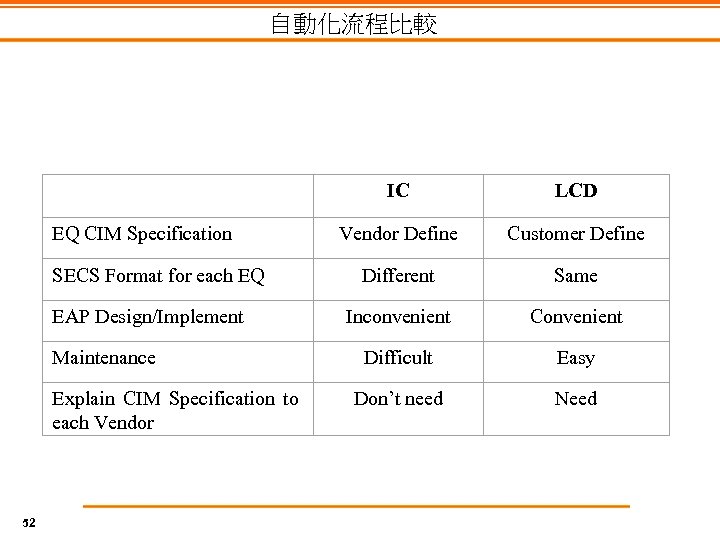

自動化流程比較 EQ CIM Specification SECS Format for each EQ EAP Design/Implement Maintenance Explain CIM Specification to each Vendor 52 IC LCD Vendor Define Customer Define Different Same Inconvenient Convenient Difficult Easy Don’t need Need

Q&A 經 驗 分 享 53 敬 請 指 教

bb027e2ff85bceb8b799263830759450.ppt