d23c7b4ab2041dfe0b2b1dcee0f10ee7.ppt

- Количество слайдов: 17

EPSON Service & Support – Sure. Color EEB & SEC WW S&S Meeting Epson Engineering Europe / ESC ‘s July 2013

9 TH – 10 TH PRE-SALES TRAINING AGENDA • Current available Countermeasure • New Countermeasure – Take-Up Improvements Paper Feed accuracy – Flange Attachments Slippery Media Core – New Pressure Rollers Roller marks on media – Setting Tape Ease of media installation – After heater Adjusters Media Skew – Firmware upgrade Print Quality improvements – Lubrication Tool Remove Abnormal CR Noises Page 2 EMD PRE-SALES TRAINING - Sept 2013 Epson Confidential

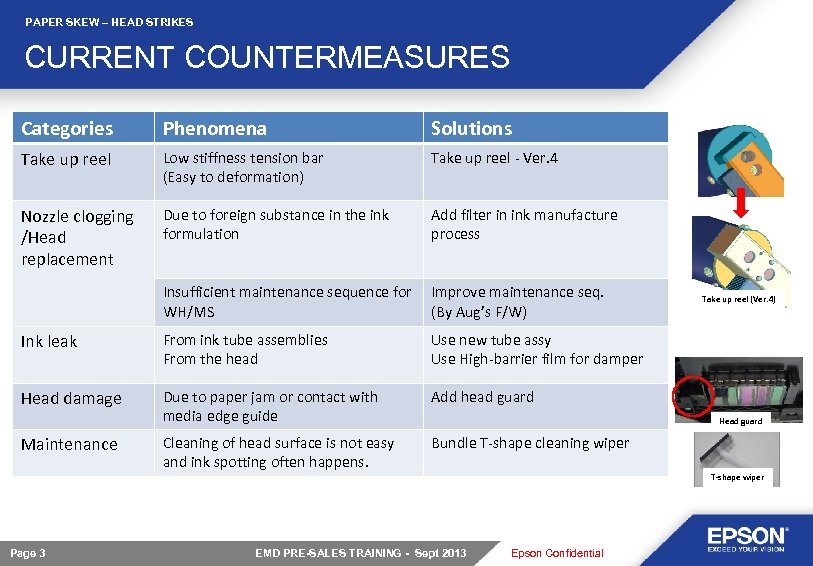

PAPER SKEW – HEAD STRIKES CURRENT COUNTERMEASURES Categories Phenomena Solutions Take up reel Low stiffness tension bar (Easy to deformation) Take up reel - Ver. 4 Nozzle clogging /Head replacement Due to foreign substance in the ink formulation Add filter in ink manufacture process Insufficient maintenance sequence for WH/MS Improve maintenance seq. (By Aug’s F/W) Ink leak From ink tube assemblies From the head Use new tube assy Use High-barrier film for damper Head damage Due to paper jam or contact with media edge guide Add head guard Cleaning of head surface is not easy and ink spotting often happens. Bundle T-shape cleaning wiper Maintenance Take up reel (Ver. 4) Head guard T-shape wiper Page 3 EMD PRE-SALES TRAINING - Sept 2013 Epson Confidential

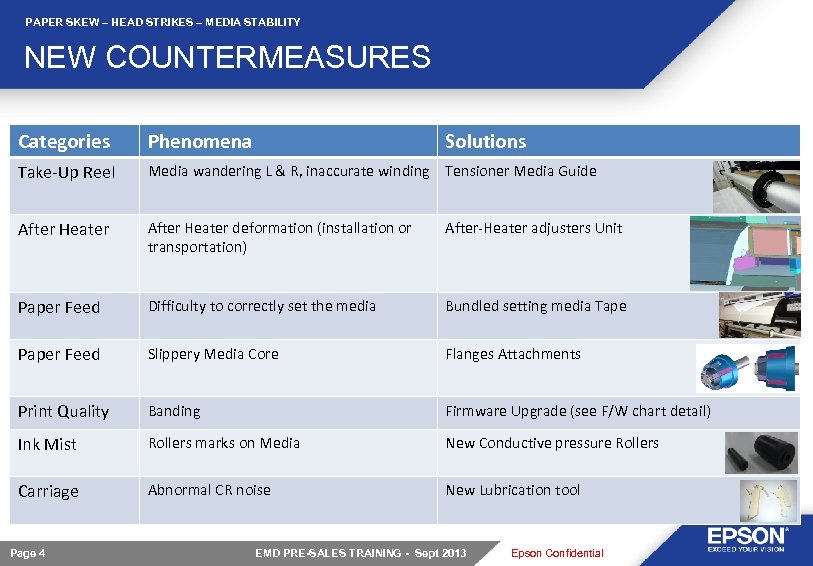

PAPER SKEW – HEAD STRIKES – MEDIA STABILITY NEW COUNTERMEASURES Categories Phenomena Take-Up Reel Media wandering L & R, inaccurate winding Tensioner Media Guide After Heater deformation (installation or transportation) After-Heater adjusters Unit Paper Feed Difficulty to correctly set the media Bundled setting media Tape Paper Feed Slippery Media Core Flanges Attachments Print Quality Banding Firmware Upgrade (see F/W chart detail) Ink Mist Rollers marks on Media New Conductive pressure Rollers Carriage Abnormal CR noise New Lubrication tool Page 4 Solutions EMD PRE-SALES TRAINING - Sept 2013 Epson Confidential

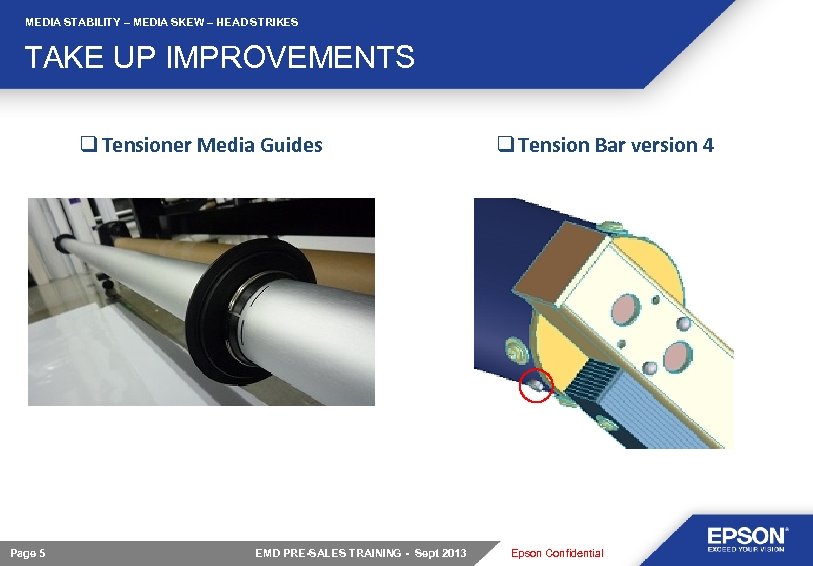

MEDIA STABILITY – MEDIA SKEW – HEAD STRIKES TAKE UP IMPROVEMENTS q Tensioner Media Guides Page 5 EMD PRE-SALES TRAINING - Sept 2013 q Tension Bar version 4 Epson Confidential

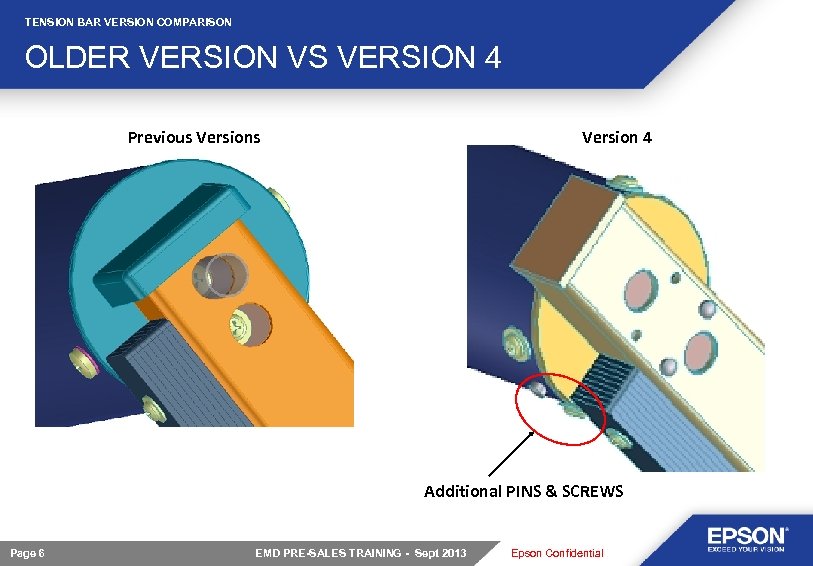

TENSION BAR VERSION COMPARISON OLDER VERSION VS VERSION 4 Previous Version 4 Additional PINS & SCREWS Page 6 EMD PRE-SALES TRAINING - Sept 2013 Epson Confidential

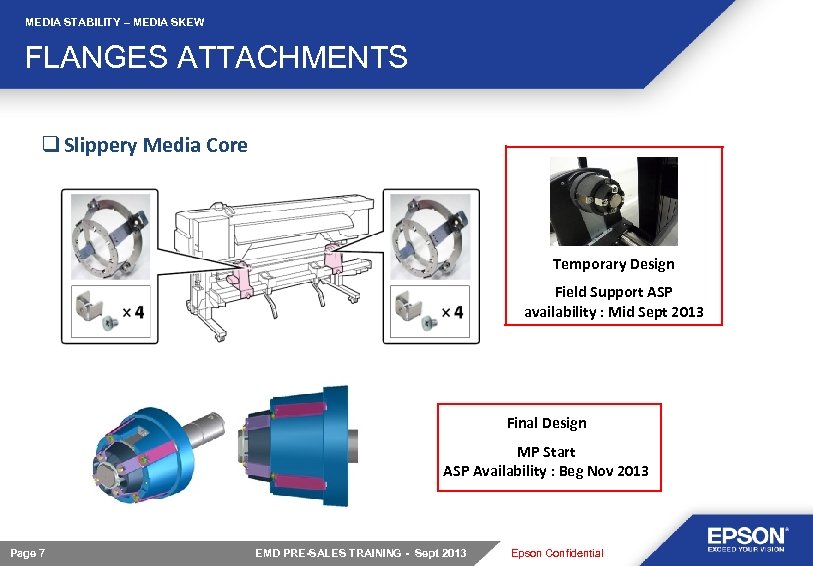

MEDIA STABILITY – MEDIA SKEW FLANGES ATTACHMENTS q Slippery Media Core Temporary Design Field Support ASP availability : Mid Sept 2013 Final Design MP Start ASP Availability : Beg Nov 2013 Page 7 EMD PRE-SALES TRAINING - Sept 2013 Epson Confidential

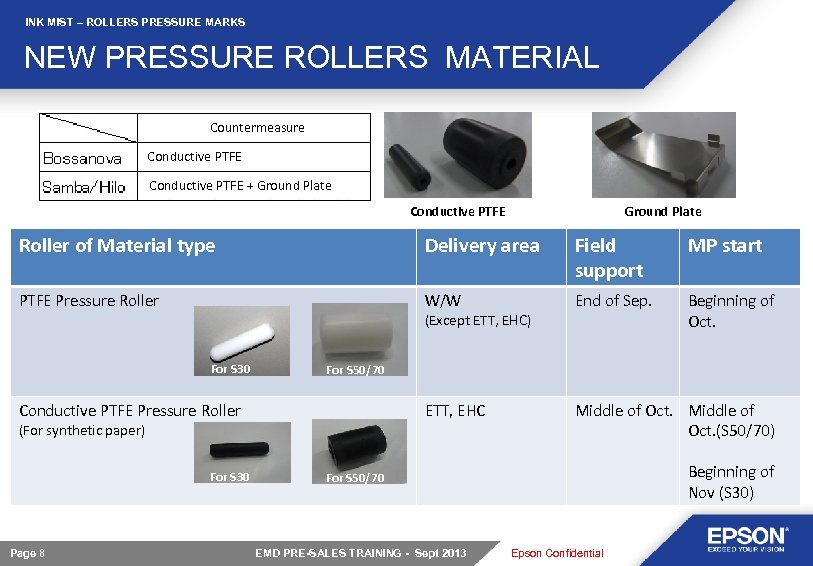

INK MIST – ROLLERS PRESSURE MARKS NEW PRESSURE ROLLERS MATERIAL Countermeasure Conductive PTFE + Ground Plate Conductive PTFE Ground Plate Roller of Material type Delivery area Field support MP start PTFE Pressure Roller W/W End of Sep. Beginning of Oct. ETT, EHC Middle of Oct. (S 50/70) (Except ETT, EHC) For S 30 For S 50/70 Conductive PTFE Pressure Roller (For synthetic paper) For S 30 Page 8 Beginning of Nov (S 30) For S 50/70 EMD PRE-SALES TRAINING - Sept 2013 Epson Confidential

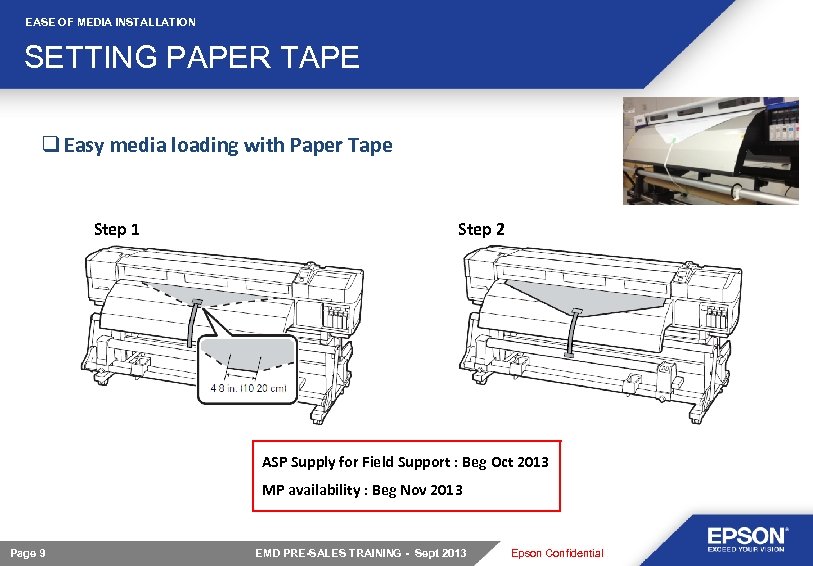

EASE OF MEDIA INSTALLATION SETTING PAPER TAPE q Easy media loading with Paper Tape Step 1 Step 2 ASP Supply for Field Support : Beg Oct 2013 MP availability : Beg Nov 2013 Page 9 EMD PRE-SALES TRAINING - Sept 2013 Epson Confidential

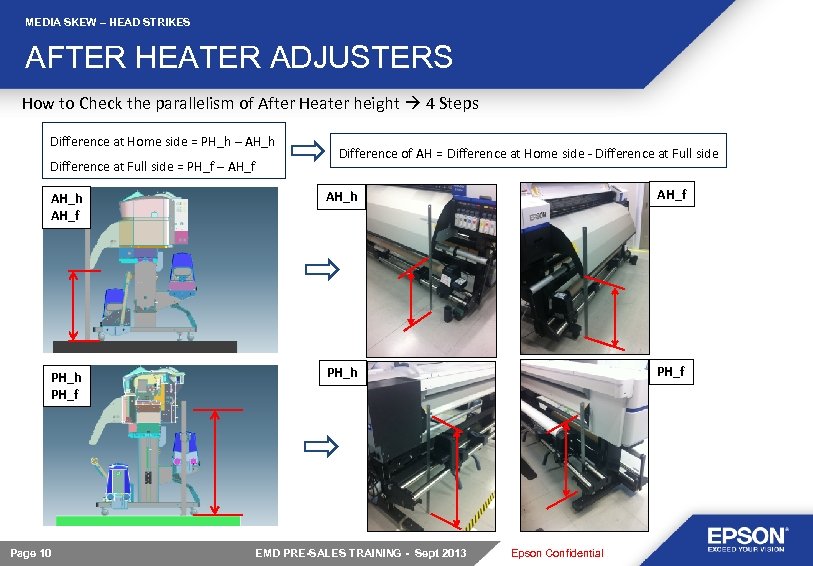

MEDIA SKEW – HEAD STRIKES AFTER HEATER ADJUSTERS How to Check the parallelism of After Heater height 4 Steps Difference at Home side = PH_h – AH_h Difference at Full side = PH_f – AH_f Difference of AH = Difference at Home side - Difference at Full side AH_h AH_f PH_h PH_f Page 10 EMD PRE-SALES TRAINING - Sept 2013 Epson Confidential

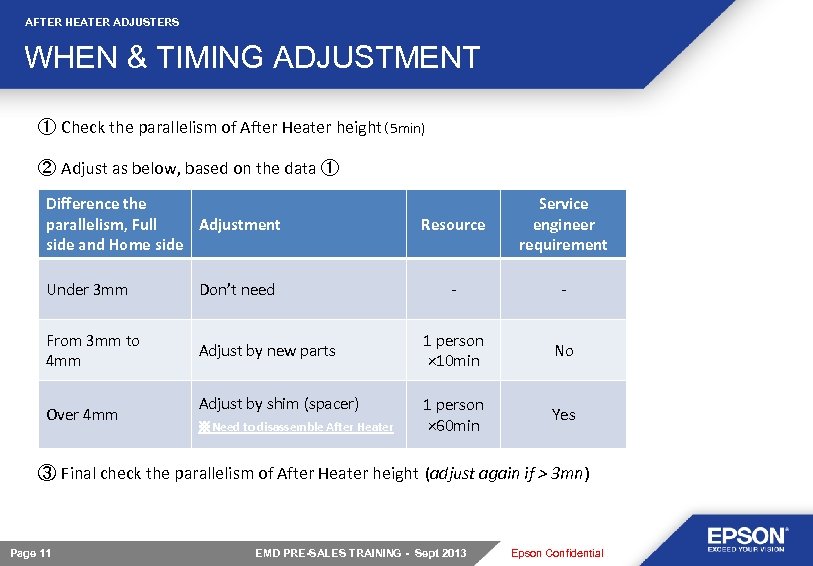

AFTER HEATER ADJUSTERS WHEN & TIMING ADJUSTMENT ① Check the parallelism of After Heater height(5 min) ② Adjust as below, based on the data ① Difference the Adjustment parallelism, Full side and Home side Under 3 mm Don’t need From 3 mm to 4 mm Adjust by new parts Over 4 mm Adjust by shim (spacer) ※Need to disassemble After Heater Resource Service engineer requirement - - 1 person × 10 min No 1 person × 60 min Yes ③ Final check the parallelism of After Heater height (adjust again if > 3 mn) Page 11 EMD PRE-SALES TRAINING - Sept 2013 Epson Confidential

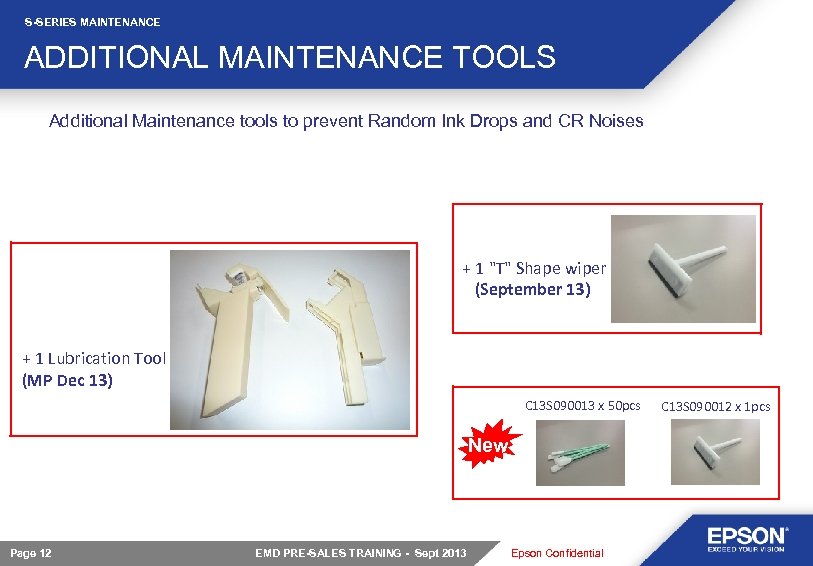

S-SERIES MAINTENANCE ADDITIONAL MAINTENANCE TOOLS Additional Maintenance tools to prevent Random Ink Drops and CR Noises + 1 "T" Shape wiper (September 13) + 1 Lubrication Tool (MP Dec 13) C 13 S 090013 x 50 pcs New Page 12 EMD PRE-SALES TRAINING - Sept 2013 Epson Confidential C 13 S 090012 x 1 pcs

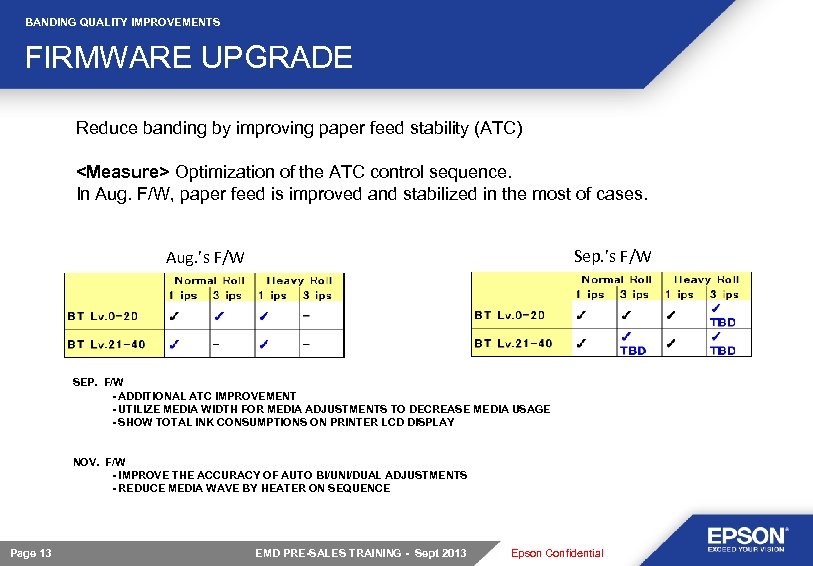

BANDING QUALITY IMPROVEMENTS FIRMWARE UPGRADE Reduce banding by improving paper feed stability (ATC) <Measure> Optimization of the ATC control sequence. In Aug. F/W, paper feed is improved and stabilized in the most of cases. Sep. ’s F/W Aug. ’s F/W SEP. F/W - ADDITIONAL ATC IMPROVEMENT - UTILIZE MEDIA WIDTH FOR MEDIA ADJUSTMENTS TO DECREASE MEDIA USAGE - SHOW TOTAL INK CONSUMPTIONS ON PRINTER LCD DISPLAY NOV. F/W - IMPROVE THE ACCURACY OF AUTO BI/UNI/DUAL ADJUSTMENTS - REDUCE MEDIA WAVE BY HEATER ON SEQUENCE Page 13 EMD PRE-SALES TRAINING - Sept 2013 Epson Confidential

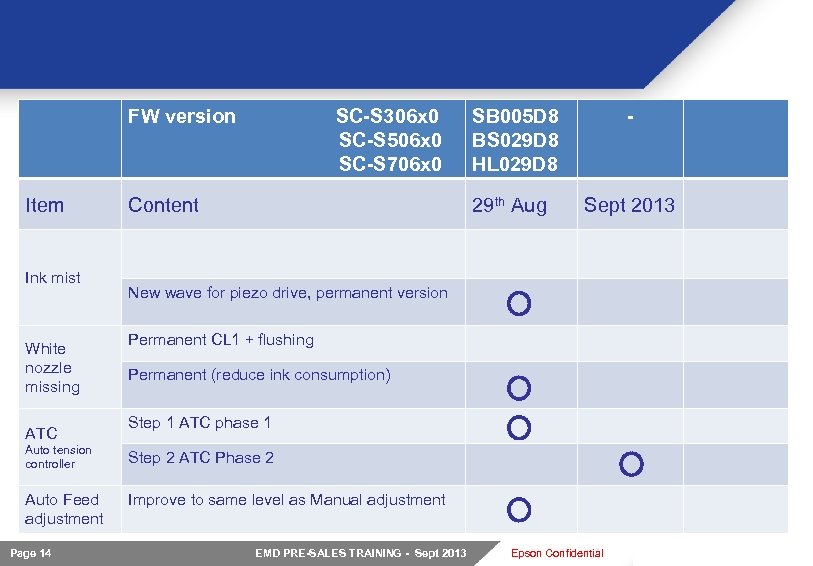

FW version Item Ink mist White nozzle missing ATC SC-S 306 x 0 SC-S 506 x 0 SC-S 706 x 0 Content SB 005 D 8 BS 029 D 8 HL 029 D 8 29 th Aug - Sept 2013 New wave for piezo drive, permanent version Permanent CL 1 + flushing Permanent (reduce ink consumption) Step 1 ATC phase 1 Auto tension controller Step 2 ATC Phase 2 Auto Feed adjustment Improve to same level as Manual adjustment Page 14 EMD PRE-SALES TRAINING - Sept 2013 Epson Confidential

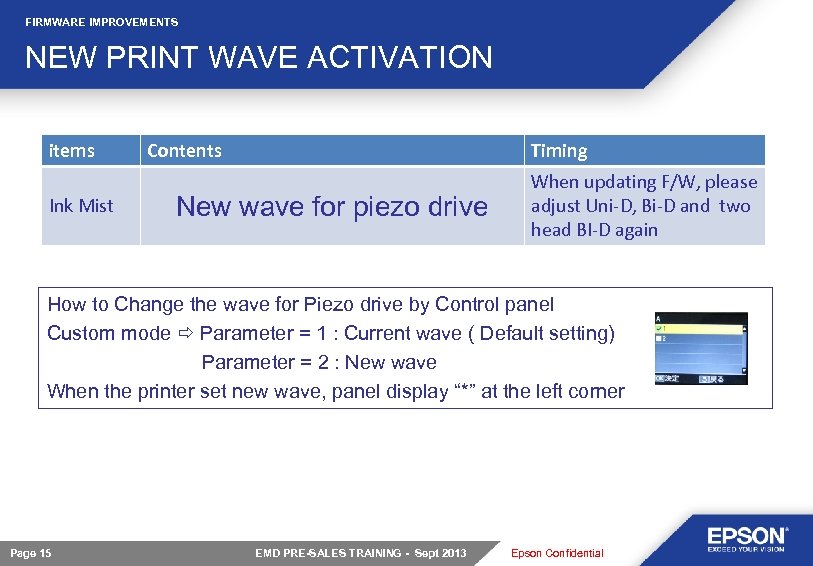

FIRMWARE IMPROVEMENTS NEW PRINT WAVE ACTIVATION items Ink Mist Contents Timing New wave for piezo drive When updating F/W, please adjust Uni-D, Bi-D and two head BI-D again How to Change the wave for Piezo drive by Control panel Custom mode Parameter = 1 : Current wave ( Default setting) Parameter = 2 : New wave When the printer set new wave, panel display “*” at the left corner Page 15 EMD PRE-SALES TRAINING - Sept 2013 Epson Confidential

Sure. Color S series Any Questions ? Page 16 EMD PRE-SALES TRAINING - Sept 2013 Epson Confidential

THANK YOU FOR YOUR ATTENTION EEEB Europe / July 2013

d23c7b4ab2041dfe0b2b1dcee0f10ee7.ppt