2119dc9cdea390b42b35e9dd0e06540e.ppt

- Количество слайдов: 16

EPA Compliant Fuel Systems IBEX Oct 18, 2011 Sean Whelan P. E. 1

Agenda 1. I have chosen a Diurnal path, now what? 2. Validation and Testing 3. Common Pitfalls to Avoid 2

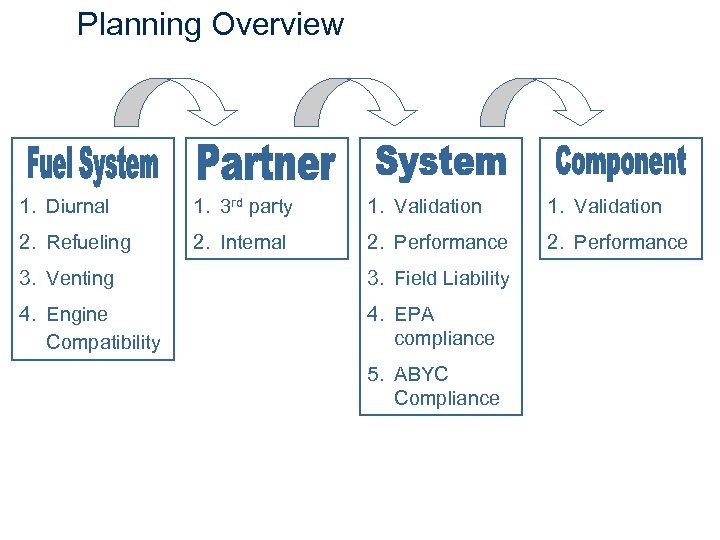

Planning Overview 1. Diurnal 1. 3 rd party 1. Validation 2. Refueling 2. Internal 2. Performance 3. Venting 3. Field Liability 4. Engine Compatibility 4. EPA compliance 5. ABYC Compliance 3

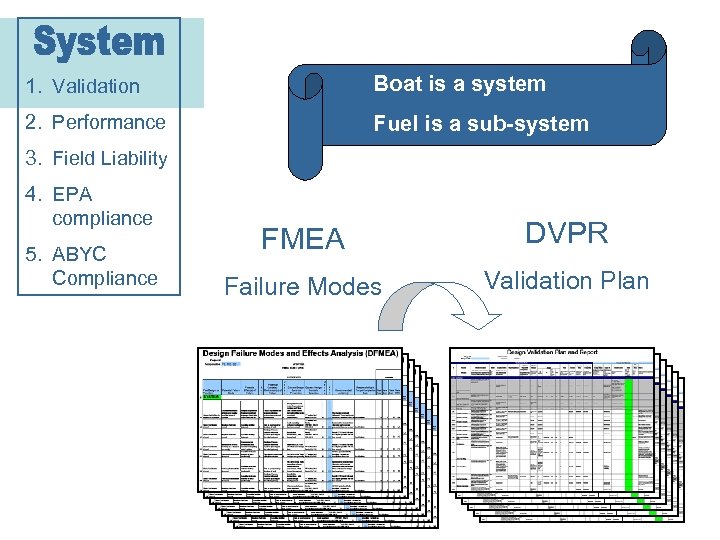

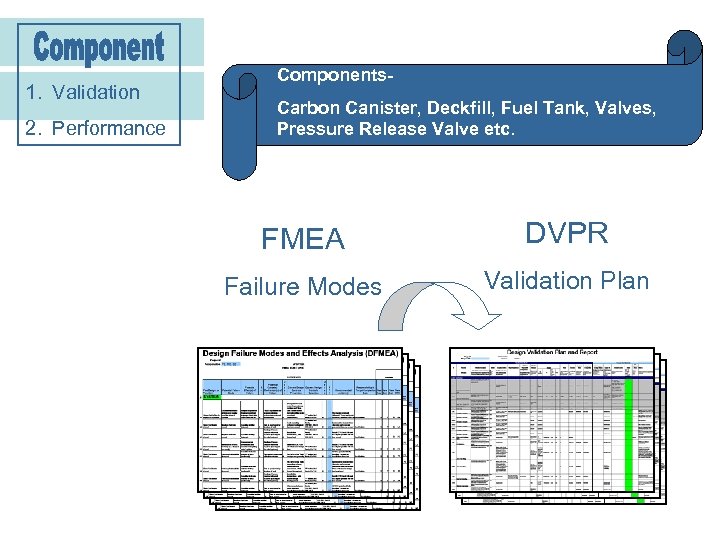

1. Validation Boat is a system 2. Performance Fuel is a sub-system 3. Field Liability 4. EPA compliance 5. ABYC Compliance FMEA DVPR Failure Modes Validation Plan 4

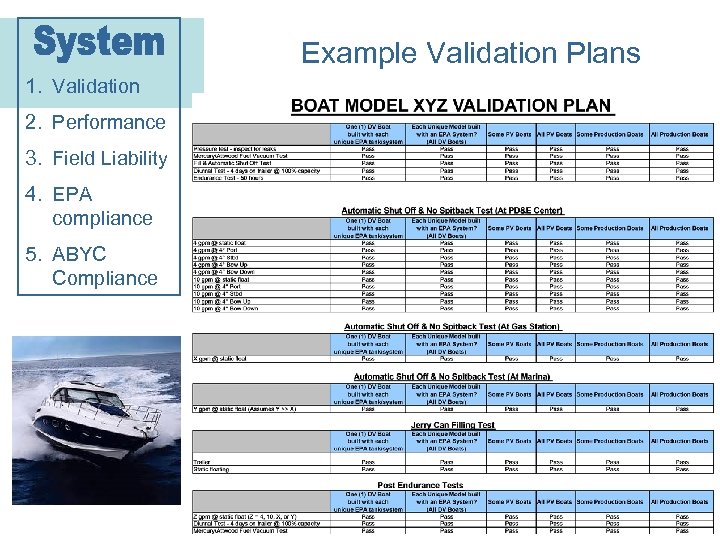

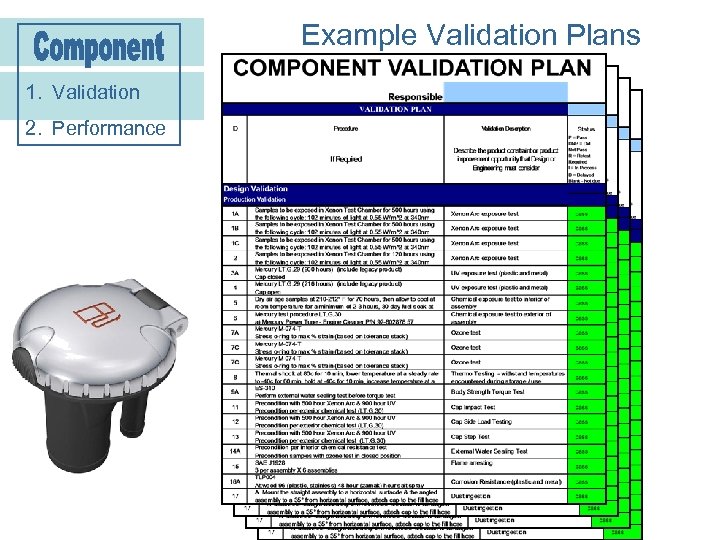

Example Validation Plans 1. Validation 2. Performance 3. Field Liability 4. EPA compliance 5. ABYC Compliance 5

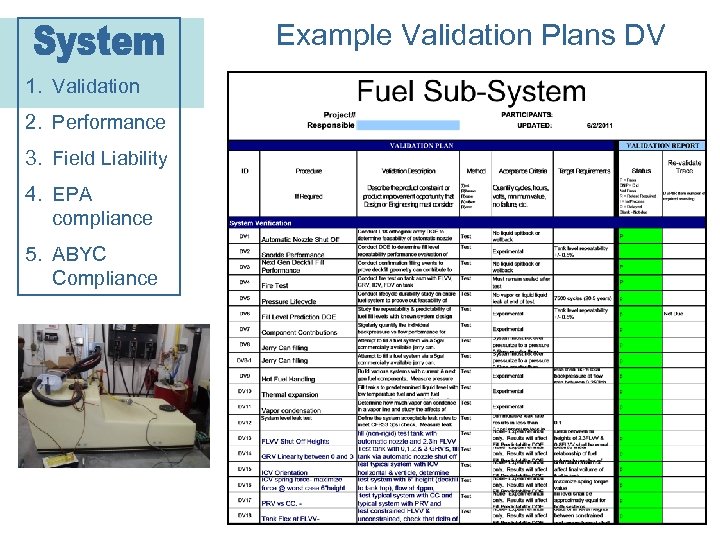

Example Validation Plans DV 1. Validation 2. Performance 3. Field Liability 4. EPA compliance 5. ABYC Compliance 6

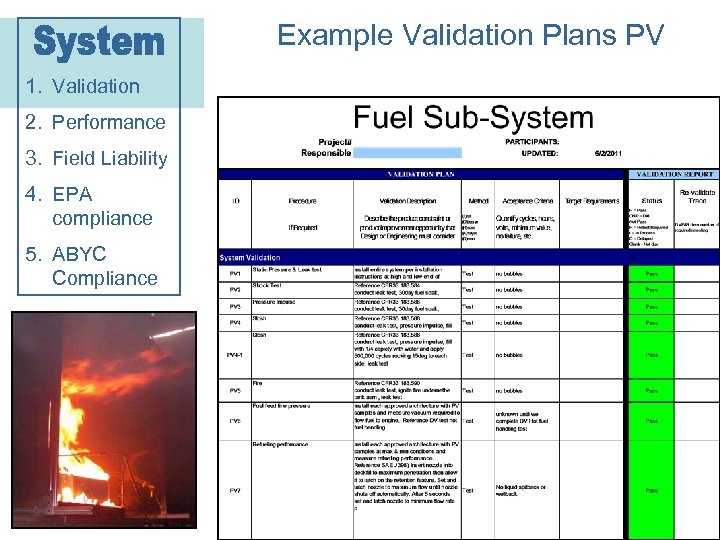

Example Validation Plans PV 1. Validation 2. Performance 3. Field Liability 4. EPA compliance 5. ABYC Compliance 7

How well does it perform? 1. Validation 2. Performance High RVP fuels? Hot Days? 3. Field Liability With Jerry Cans? At Marinas? 4. EPA compliance With engine? Etc… 5. ABYC Compliance 8

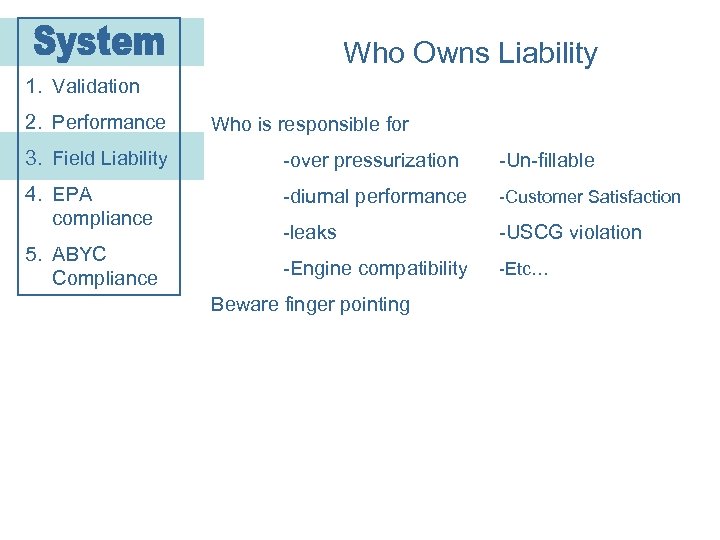

Who Owns Liability 1. Validation 2. Performance Who is responsible for 3. Field Liability -over pressurization -Un-fillable 4. EPA compliance -diurnal performance -Customer Satisfaction 5. ABYC Compliance -leaks -USCG violation -Engine compatibility -Etc… Beware finger pointing 9

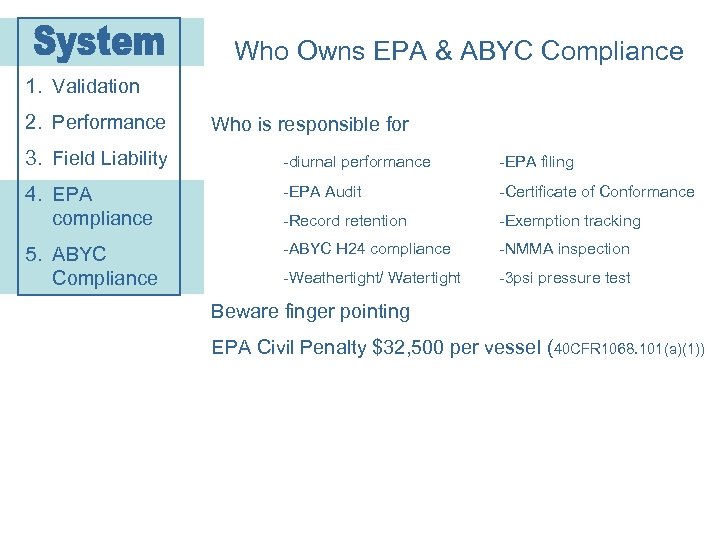

Who Owns EPA & ABYC Compliance 1. Validation 2. Performance Who is responsible for 3. Field Liability -diurnal performance -EPA filing 4. EPA compliance -EPA Audit -Certificate of Conformance -Record retention -Exemption tracking 5. ABYC Compliance -ABYC H 24 compliance -NMMA inspection -Weathertight/ Watertight -3 psi pressure test Beware finger pointing EPA Civil Penalty $32, 500 per vessel (40 CFR 1068. 101(a)(1)) 10

1. Validation 2. Performance Components. Carbon Canister, Deckfill, Fuel Tank, Valves, Pressure Release Valve etc. FMEA DVPR Failure Modes Validation Plan 11

Example Validation Plans 1. Validation 2. Performance

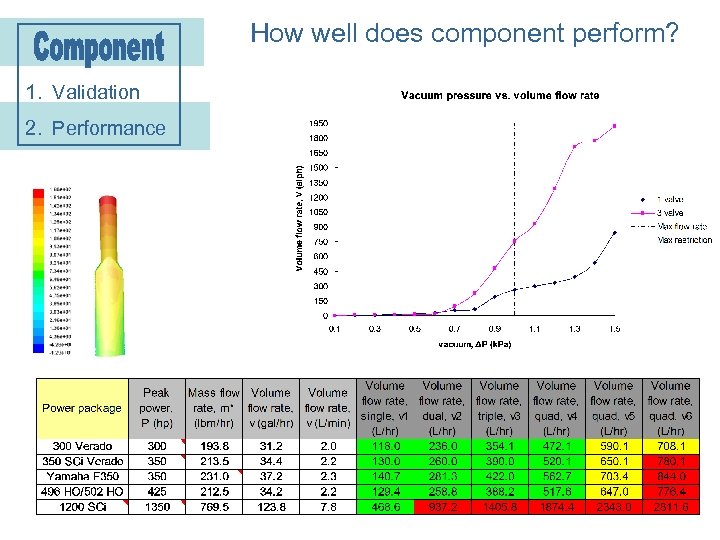

How well does component perform? 1. Validation 2. Performance

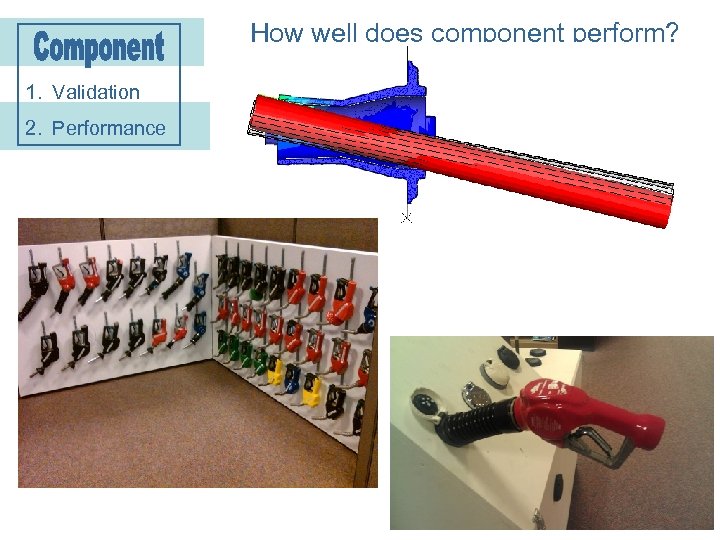

How well does component perform? 1. Validation 2. Performance

Common Pitfalls to Avoid 1. Do not assume water will act like gasoline. 2. Make sure all needs are met, not just one. 3. If boat refuels well at 70°F, do not assume it fills well at 90°F. 4. Don’t assume that an initial demonstration means that system will work after years on the water. 5. Verify plant installation early in process. 6. Consult with engine manufacturer and measure pressure drop at engine. 7. Plan for future CARB regulations now. 8. Do not underestimate the task of implementation.

Thank you Questions? 16

2119dc9cdea390b42b35e9dd0e06540e.ppt