63ad378fab4ec3bdea19467038de5d9d.ppt

- Количество слайдов: 31

ENVR 430 -1 Microbial Control Measures by Wastewater Processes Suggested Reading: Brock Chapter 28 - Wastewater Treatment, Water Purification, and Waterborne Microbial Diseases pp. 934 -942 (posted as. PDF file on website) 1

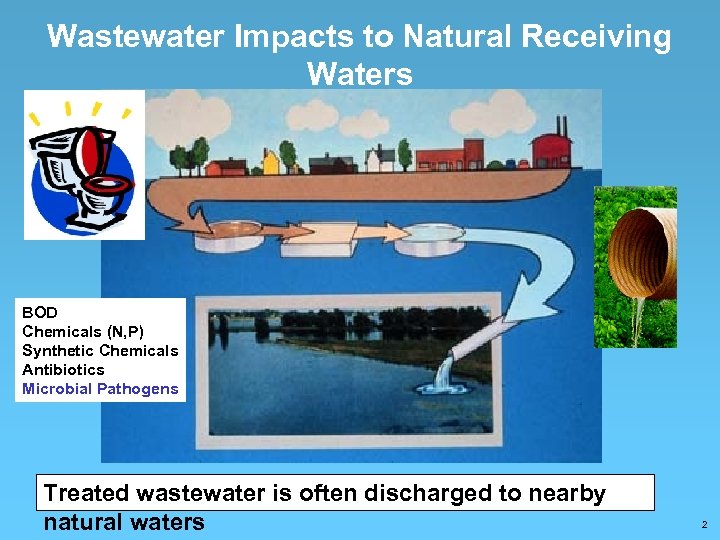

Wastewater Impacts to Natural Receiving Waters BOD Chemicals (N, P) Synthetic Chemicals Antibiotics Microbial Pathogens Treated wastewater is often discharged to nearby natural waters 2

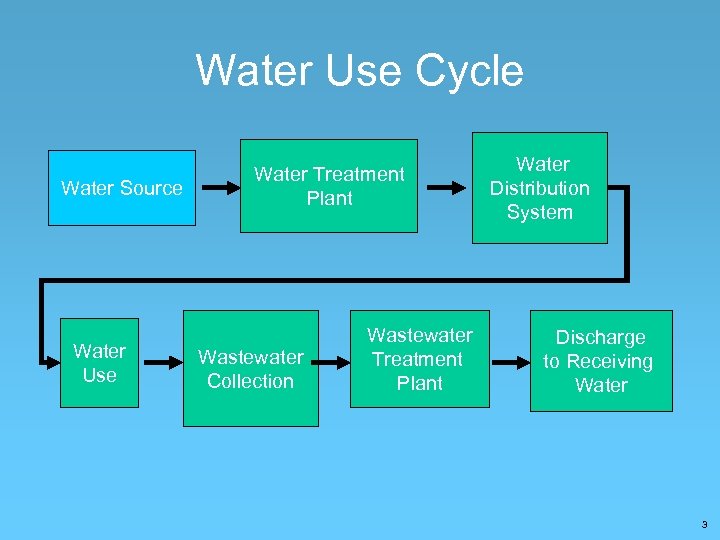

Water Use Cycle Water Source Water Use Water Treatment Plant Wastewater Collection Wastewater Treatment Plant Water Distribution System Discharge to Receiving Water 3

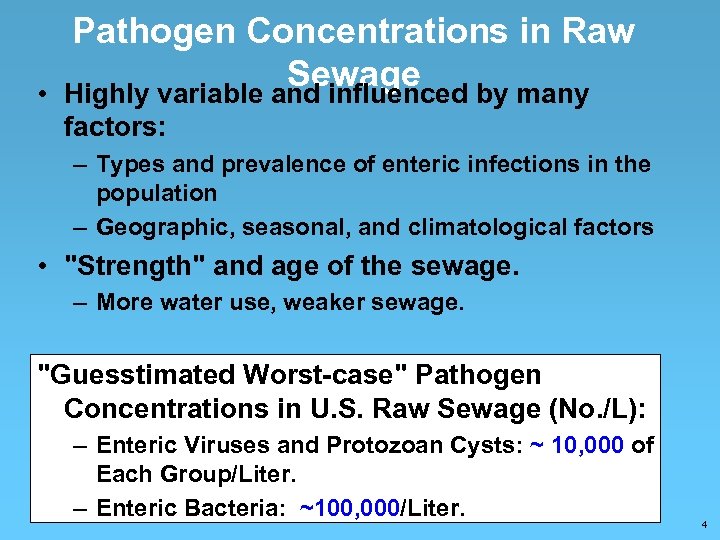

• Pathogen Concentrations in Raw Sewage Highly variable and influenced by many factors: – Types and prevalence of enteric infections in the population – Geographic, seasonal, and climatological factors • "Strength" and age of the sewage. – More water use, weaker sewage. "Guesstimated Worst-case" Pathogen Concentrations in U. S. Raw Sewage (No. /L): – Enteric Viruses and Protozoan Cysts: ~ 10, 000 of Each Group/Liter. – Enteric Bacteria: ~100, 000/Liter. 4

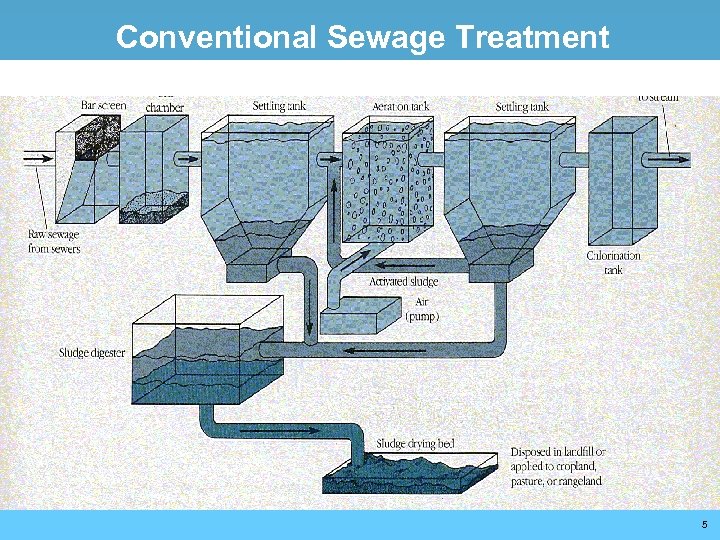

Conventional Sewage Treatment 5

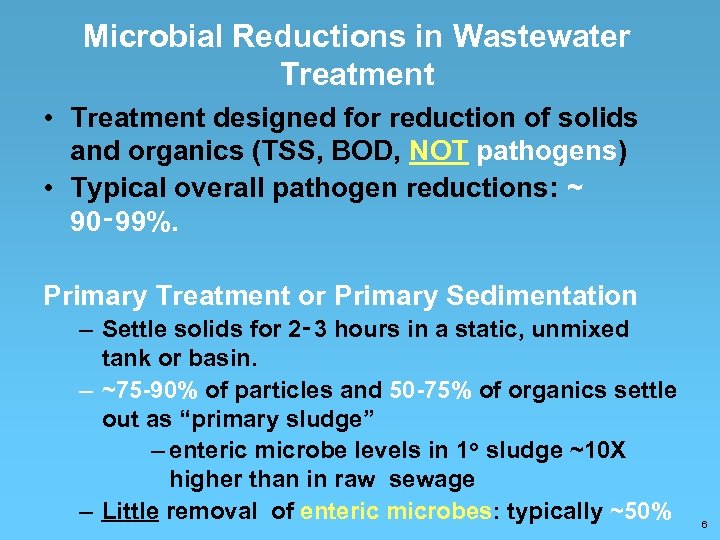

Microbial Reductions in Wastewater Treatment • Treatment designed for reduction of solids and organics (TSS, BOD, NOT pathogens) • Typical overall pathogen reductions: ~ 90‑ 99%. Primary Treatment or Primary Sedimentation – Settle solids for 2‑ 3 hours in a static, unmixed tank or basin. – ~75 -90% of particles and 50 -75% of organics settle out as “primary sludge” – enteric microbe levels in 1 o sludge ~10 X higher than in raw sewage – Little removal of enteric microbes: typically ~50% 6

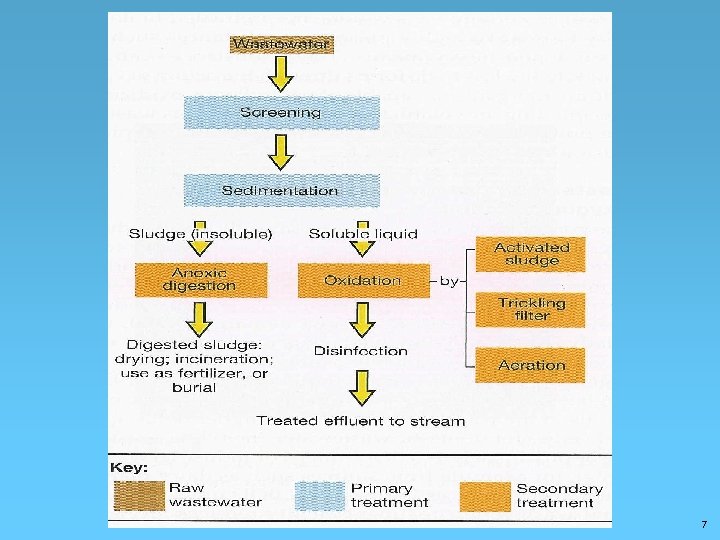

7

Trickling Filter and Aeration Basin for Wastewater Treatment 8

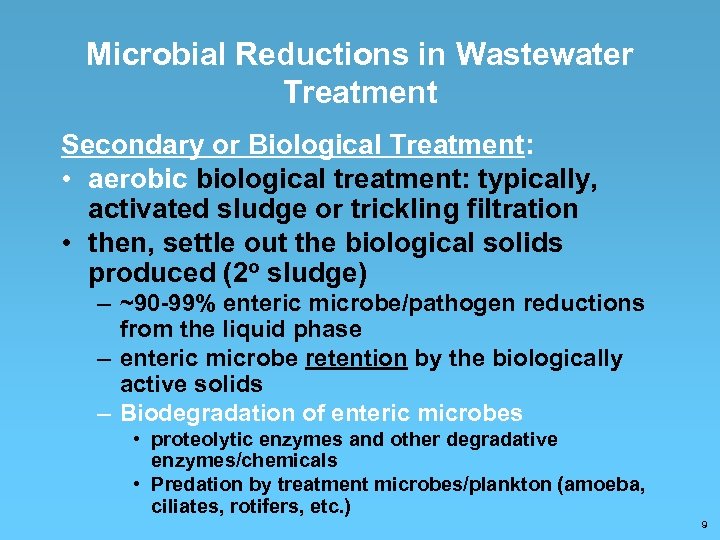

Microbial Reductions in Wastewater Treatment Secondary or Biological Treatment: • aerobic biological treatment: typically, activated sludge or trickling filtration • then, settle out the biological solids produced (2 o sludge) – ~90 -99% enteric microbe/pathogen reductions from the liquid phase – enteric microbe retention by the biologically active solids – Biodegradation of enteric microbes • proteolytic enzymes and other degradative enzymes/chemicals • Predation by treatment microbes/plankton (amoeba, ciliates, rotifers, etc. ) 9

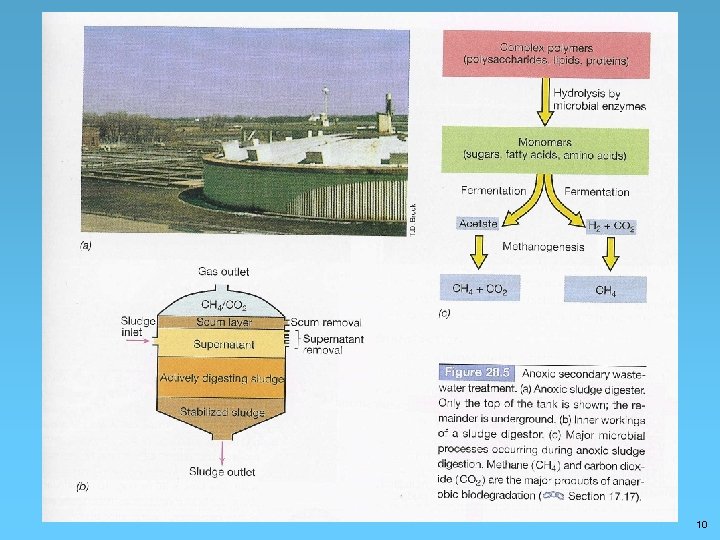

10

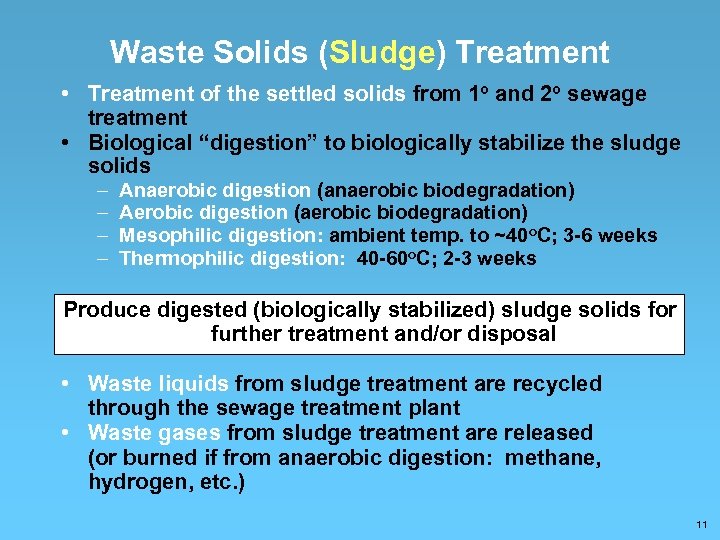

Waste Solids (Sludge) Treatment • Treatment of the settled solids from 1 o and 2 o sewage treatment • Biological “digestion” to biologically stabilize the sludge solids – – Anaerobic digestion (anaerobic biodegradation) Aerobic digestion (aerobic biodegradation) Mesophilic digestion: ambient temp. to ~40 o. C; 3 -6 weeks Thermophilic digestion: 40 -60 o. C; 2 -3 weeks Produce digested (biologically stabilized) sludge solids for further treatment and/or disposal • Waste liquids from sludge treatment are recycled through the sewage treatment plant • Waste gases from sludge treatment are released (or burned if from anaerobic digestion: methane, hydrogen, etc. ) 11

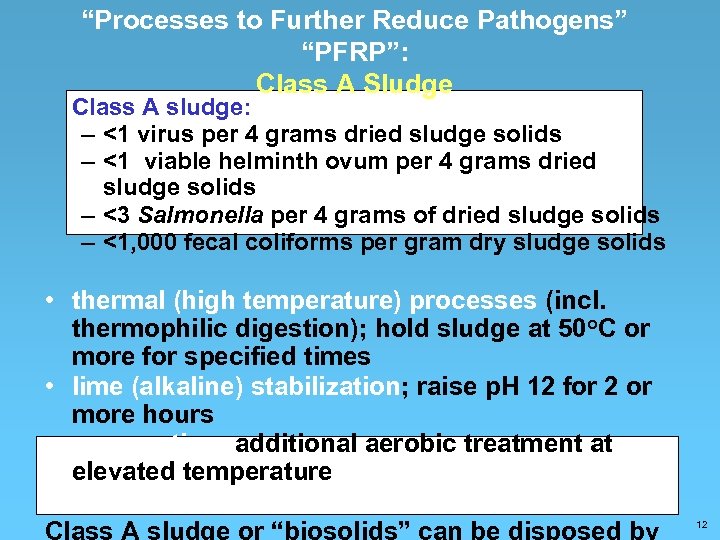

“Processes to Further Reduce Pathogens” “PFRP”: Class A Sludge Class A sludge: – <1 virus per 4 grams dried sludge solids – <1 viable helminth ovum per 4 grams dried sludge solids – <3 Salmonella per 4 grams of dried sludge solids – <1, 000 fecal coliforms per gram dry sludge solids • thermal (high temperature) processes (incl. thermophilic digestion); hold sludge at 50 o. C or more for specified times • lime (alkaline) stabilization; raise p. H 12 for 2 or more hours • composting: additional aerobic treatment at elevated temperature Class A sludge or “biosolids” can be disposed by 12

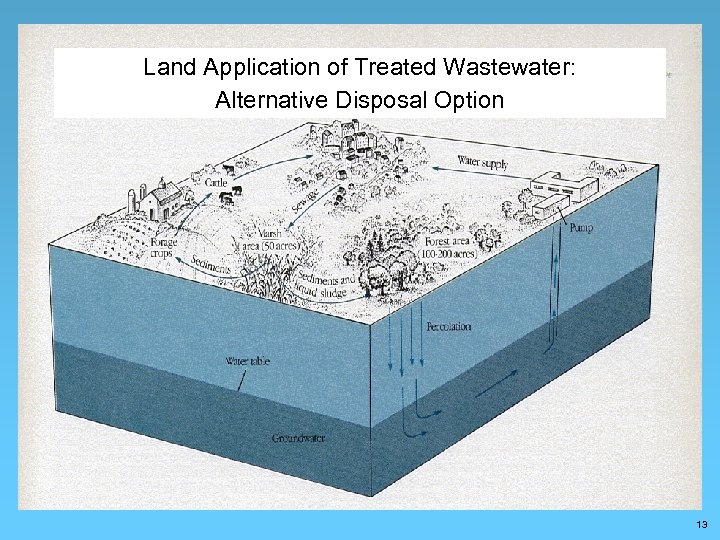

Land Application of Treated Wastewater: Alternative Disposal Option 13

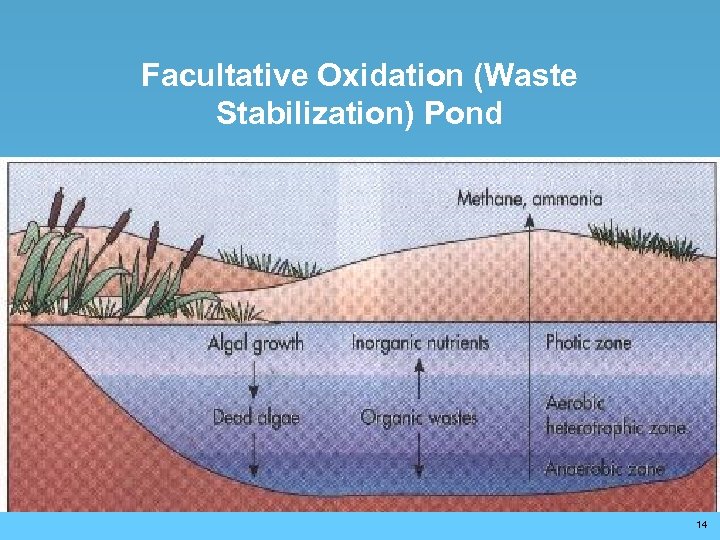

Facultative Oxidation (Waste Stabilization) Pond 14

15

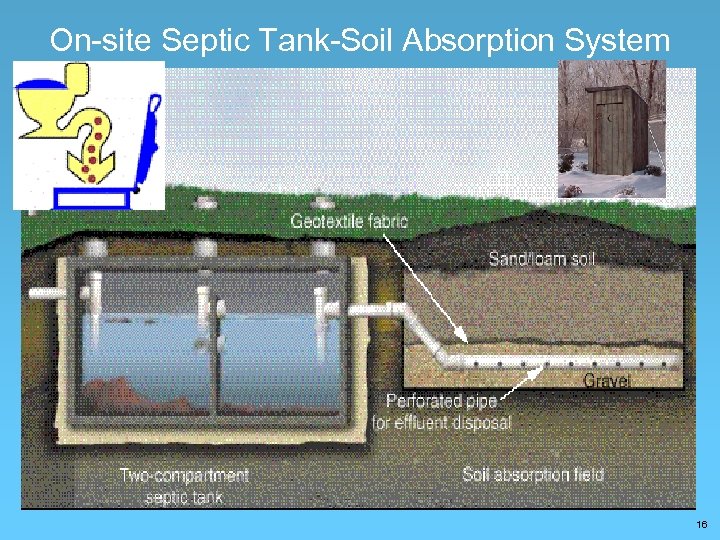

On-site Septic Tank-Soil Absorption System 16

20 th Annual On-Site Wastewater Treatment Conference Planning, Implementing and Managing Decentralized Wastewater October 11 -13, 2004 Mc. Kimmon Center, North Carolina State University To register or see complete conference details: www. soil. ncsu. edu/swetc/onsiteconf/2004/main 04. htm Our conference objectives are to give you: • A better understanding of how various planning, permitting and management processes can affect your job, community and environment. • Essential information regarding the use of GPS/GIS in your job. • An in-depth look at how failures can be avoided through proper planning and post permit inspections. • Methods to work with homeowners to improve system understanding. • Greater knowledge about the applicability and legal issues of Time-of-Sale inspections. • Up-to-date information on how local, state and national certifications are obtained. • A chance to interact with colleagues and manufacturers within the on-site community and understand how each member of the community can help with your job. 17

Modular Wastewater Treatment Systems electrochemical metals removal process, p. H adjustment, coagulation, clarification, multi-media filtration, air stripping, activated carbon adsorption, final p. H adjustment, sludge dewatering 18

Re. Cip: Reciprocating Wastewater Technology 19

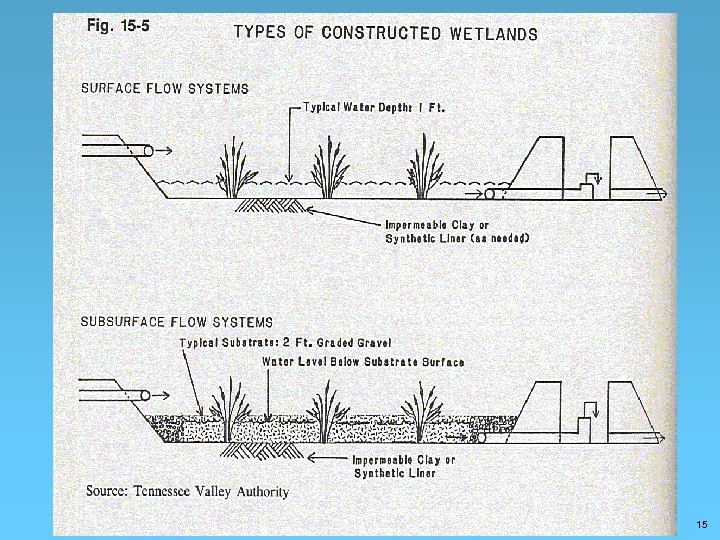

Wastewater Reuse Wastewater is sometimes reused for beneficial, non -potable purposes in arid and other water-short regions Often use advanced or additional treatment processes, sometimes referred to as “reclamation” 1. Biological treatment in “polishing” ponds and constructed wetlands 2. Physical-chemical treatment processes as used for drinking water: – Coagulation-flocculation and sedimentation – Filtration: granular medium filters; membrane filters 20

Microbiological water quality in a large in-building, water recycling facility R. Birks*, J. Colbourne**, S. Hills* and R. Hobson* * Thames Water Innovation and Development, Manor Farm Road, Reading, RG 2 0 JN, UK ** UK Drinking Water Inspectorate, Floor 2/D 1, Ashdown House, 123 Victoria Street, London, SW 1 E 6 DE, UK Abstract The Thames Water recycling plant at the Millennium Dome, London, reclaimed three sources of water: greywater from the washbasins, rainwater from the Dome roof and groundwater from a borehole onsite. These were pre-treated separately, and the mixed stream filtered using ultrafiltration and reverse osmosis membranes. Monitoring for indicator microorganisms was undertaken throughout the plant and in the reclaimed water distribution system, as well as ad-hoc monitoring for the presence of pathogens in the raw waters. Treatment to the level of ultrafiltration was more than adequate to produce a water quality meeting existing worldwide reclaimed water guidelines for toilet flushing. Owing to the excellent quality of the water leaving the plant, no significant microbiological growth was observed in the reclaimed water distribution system during the year. The raw greywater exhibited a higher faecal bacterial load than the rainwater and groundwater, as predicted from more human contact (i. e. hand washing). Environmental strains of Legionella were observed in the three raw greywater samples analysed for pathogens, as was Cryptosporidium, Giardia and faecal enterococci. The rainwater had relatively high levels of faecal bacteria, probably of avian origin. Giardia was detected in one rainwater sample confirming the potential for this water source to contain pathogens. From 2004 Water Science and Technology Vol 50 No 2 pp 165– 172 21

Disinfection • Disinfection is any process to destroy or prevent the growth of microbes • Many disinfection processes are intended to inactivate (destroy the infectivity of) the microbes by physical, chemical or biological processes • Inactivation is achieved by altering or destroying essential structures or functions within the microbe Inactivation processes include denaturation of: – proteins (structural proteins, enzymes, transport proteins) – nucleic acids (genomic DNA or RNA, m. RNA, t. RNA, etc) 22

When Wastewater Disinfection is Recommended or Required • Discharge to surface waters: – – – near water supply intakes used for primary contact recreation used for shellfish harvesting used for irrigation of crops and greenspace other direct and indirect reuse and reclamation purposes • Discharge to ground waters: – used as a water supply source – used for irrigation of crops and greenspace – other direct and indirect reuse and reclamation purposes 23

Disinfection of Wastewater • Intended to reduce microbes in 1 o or 2 o treated effluent – Typically chlorination – Alternatives: UV radiation, ozone, and chlorine dioxide • Good enteric bacterial reductions: typically, 99. 99+% – Meet fecal coliform limits for effluent discharge • Often 200 -1, 000 per 100 ml geometric mean as permitted discharge limit • Less effective for viruses and parasites: typically, 90% reduction Toxicity of chlorine and its by‑products to aquatic life now limits wastewater chlorination - may need to: – Dechlorinate – Use an alternative, less toxic chemical disinfectant – Use an alternative treatment process to reduce enteric microbes • granular medium filtration or membrane filtration 24

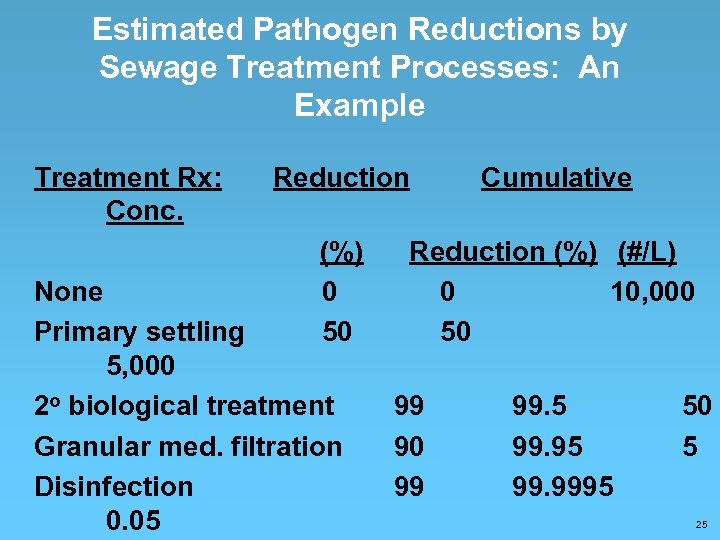

Estimated Pathogen Reductions by Sewage Treatment Processes: An Example Treatment Rx: Conc. Reduction (%) 0 50 None Primary settling 5, 000 2 o biological treatment Granular med. filtration Disinfection 0. 05 Cumulative Reduction (%) (#/L) 0 10, 000 50 99 99. 5 99. 9995 50 5 25

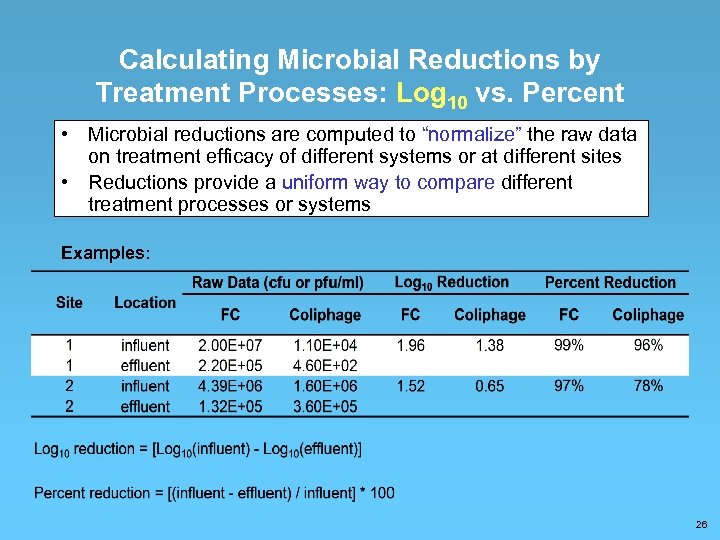

Calculating Microbial Reductions by Treatment Processes: Log 10 vs. Percent • Microbial reductions are computed to “normalize” the raw data on treatment efficacy of different systems or at different sites • Reductions provide a uniform way to compare different treatment processes or systems Examples: 26

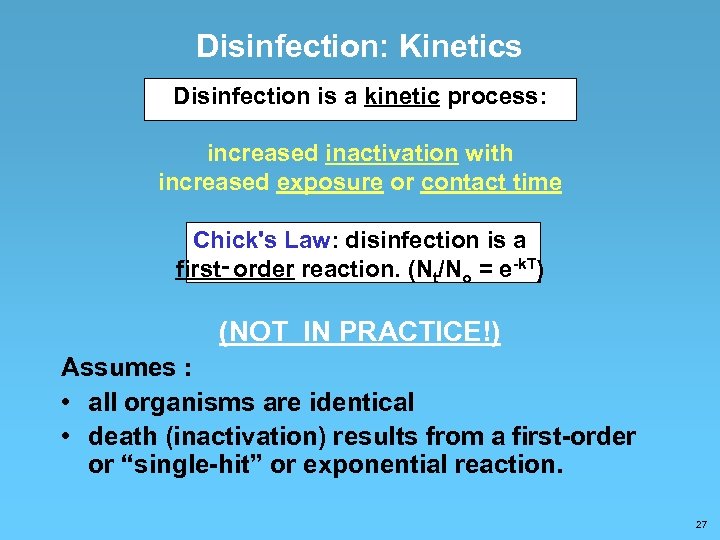

Disinfection: Kinetics Disinfection is a kinetic process: increased inactivation with increased exposure or contact time Chick's Law: disinfection is a first‑order reaction. (Nt/No = e-k. T) (NOT IN PRACTICE!) Assumes : • all organisms are identical • death (inactivation) results from a first-order or “single-hit” or exponential reaction. 27

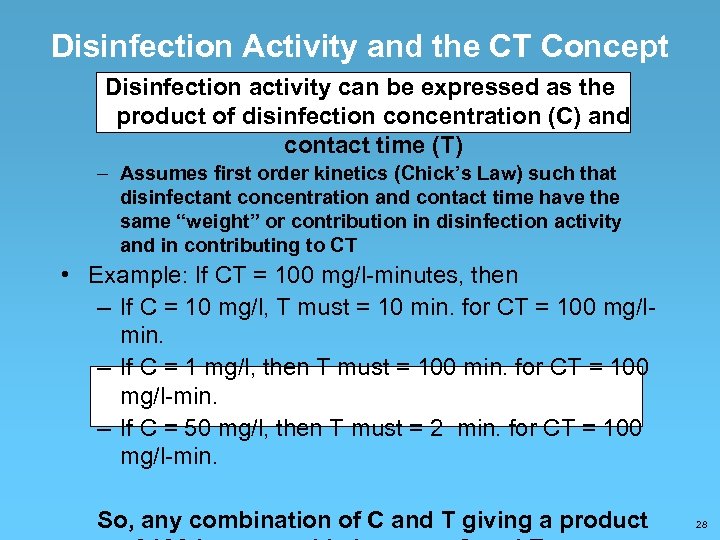

Disinfection Activity and the CT Concept Disinfection activity can be expressed as the product of disinfection concentration (C) and contact time (T) – Assumes first order kinetics (Chick’s Law) such that disinfectant concentration and contact time have the same “weight” or contribution in disinfection activity and in contributing to CT • Example: If CT = 100 mg/l-minutes, then – If C = 10 mg/l, T must = 10 min. for CT = 100 mg/lmin. – If C = 1 mg/l, then T must = 100 min. for CT = 100 mg/l-min. – If C = 50 mg/l, then T must = 2 min. for CT = 100 mg/l-min. So, any combination of C and T giving a product 28

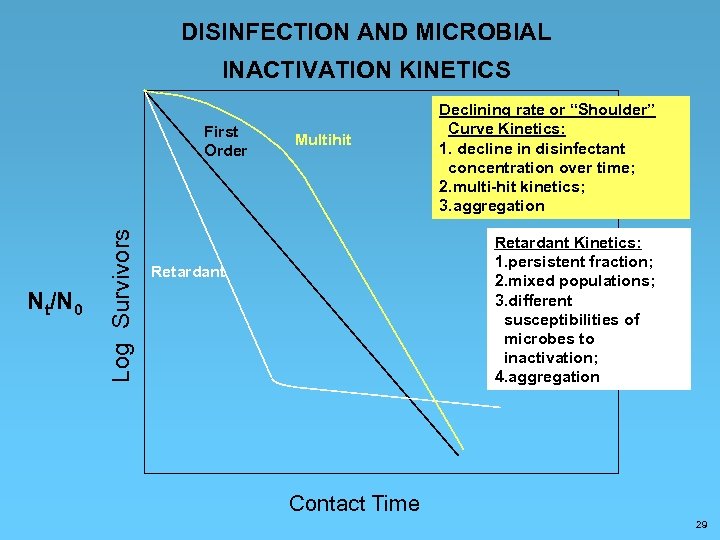

DISINFECTION AND MICROBIAL INACTIVATION KINETICS Nt/N 0 Log Survivors First Order Multihit Declining rate or “Shoulder” Curve Kinetics: 1. decline in disinfectant concentration over time; 2. multi-hit kinetics; 3. aggregation Retardant Kinetics: 1. persistent fraction; 2. mixed populations; 3. different susceptibilities of microbes to inactivation; 4. aggregation Retardant Contact Time 29

Properties of an Ideal Disinfectant 1. Broad spectrum: active against all microbes 2. Fast acting: produces rapid inactivation 3. Effective in the presence of organic matter, suspended solids and other matrix or sample constituents 4. Nontoxic; soluble; non-flammable; nonexplosive 5. Compatible with various materials/surfaces 6. Stable or persistent for the intended exposure period 7. Provides a residual (sometimes this is undesirable) 30

Common Disinfectants in Water and Wastewater Treatment • • • Free Chlorine Monochloramine Ozone Chlorine Dioxide UV Light • Low pressure mercury lamp (monochromatic) • Medium pressure mercury lamp (polychromatic) • Pulsed broadband radiation 31

63ad378fab4ec3bdea19467038de5d9d.ppt