89c8166a060fb79e1a7182c4ffea8803.ppt

- Количество слайдов: 36

Environmentally Conscious Design & Manufacturing Class 21, 22: Energy Aspects Prof. S. M. Pandit Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 1

Environmentally Conscious Design & Manufacturing Class 21, 22: Energy Aspects Prof. S. M. Pandit Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 1

Agenda • • Environmental Burden: Energy and industry Energy and automobile General approach to minimizing energy use Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 2

Agenda • • Environmental Burden: Energy and industry Energy and automobile General approach to minimizing energy use Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 2

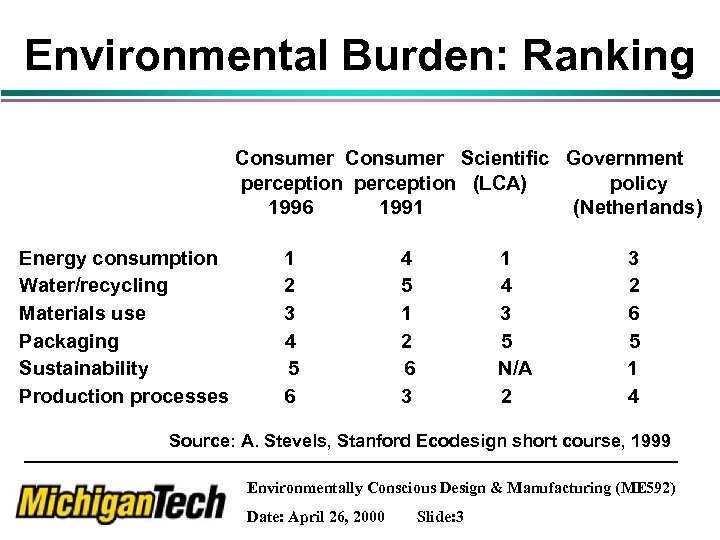

Environmental Burden: Ranking Consumer Scientific Government perception (LCA) policy 1996 1991 (Netherlands) Energy consumption Water/recycling Materials use Packaging Sustainability Production processes 1 2 3 4 5 6 4 5 1 2 6 3 1 4 3 5 N/A 2 3 2 6 5 1 4 Source: A. Stevels, Stanford Ecodesign short course, 1999 Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 3

Environmental Burden: Ranking Consumer Scientific Government perception (LCA) policy 1996 1991 (Netherlands) Energy consumption Water/recycling Materials use Packaging Sustainability Production processes 1 2 3 4 5 6 4 5 1 2 6 3 1 4 3 5 N/A 2 3 2 6 5 1 4 Source: A. Stevels, Stanford Ecodesign short course, 1999 Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 3

Incentives The three incentives to encourage efficiency and renewable energy are: • Avoided emissions • Conservation and renewable energy reserve • The reduced utilization provision Source: EPA Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 4

Incentives The three incentives to encourage efficiency and renewable energy are: • Avoided emissions • Conservation and renewable energy reserve • The reduced utilization provision Source: EPA Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 4

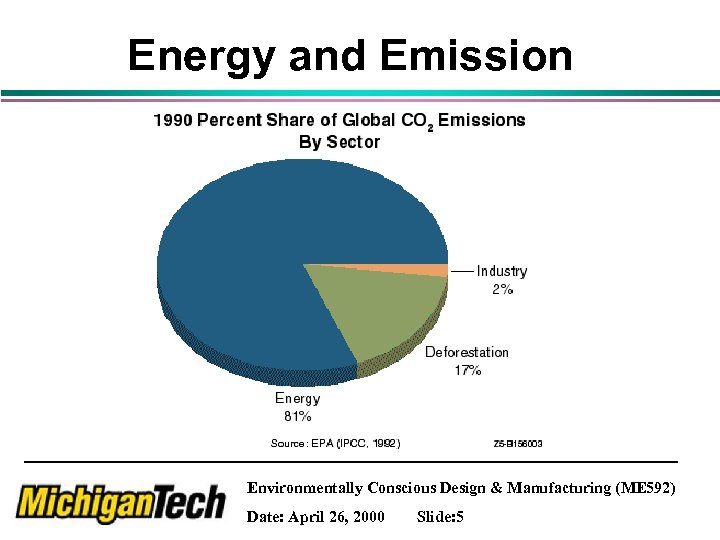

Energy and Emission Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 5

Energy and Emission Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 5

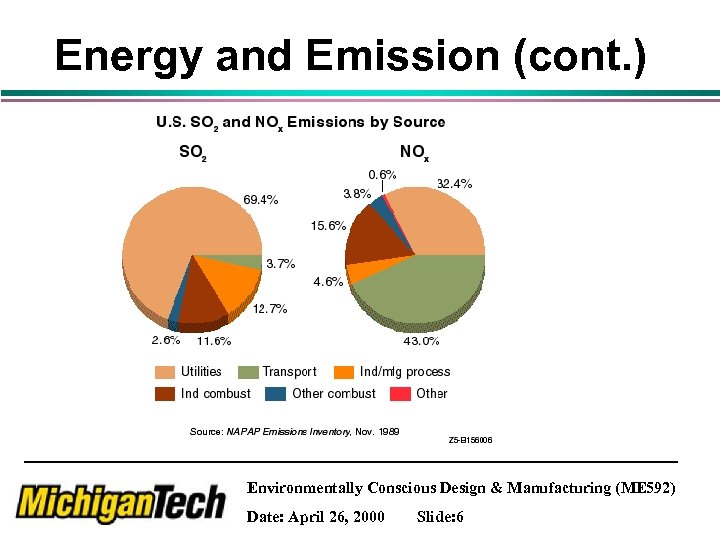

Energy and Emission (cont. ) Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 6

Energy and Emission (cont. ) Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 6

Energy and Industrial Ecology • Tracking energy flows and transformation is a fundamental approach of industrial ecology • Energy accounting is essential for identifying and assessing environmental consequences of industrial activities. Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 7

Energy and Industrial Ecology • Tracking energy flows and transformation is a fundamental approach of industrial ecology • Energy accounting is essential for identifying and assessing environmental consequences of industrial activities. Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 7

Environmental Performance: Energy • Quality of energy used per year or per unit of product • Quality of energy used per service or per customer • Quality of each type of energy used • Quality of energy units saved due to energy conservation Source: International Organization for standardization, Annexes Testing committee. (1996) Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 8

Environmental Performance: Energy • Quality of energy used per year or per unit of product • Quality of energy used per service or per customer • Quality of each type of energy used • Quality of energy units saved due to energy conservation Source: International Organization for standardization, Annexes Testing committee. (1996) Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 8

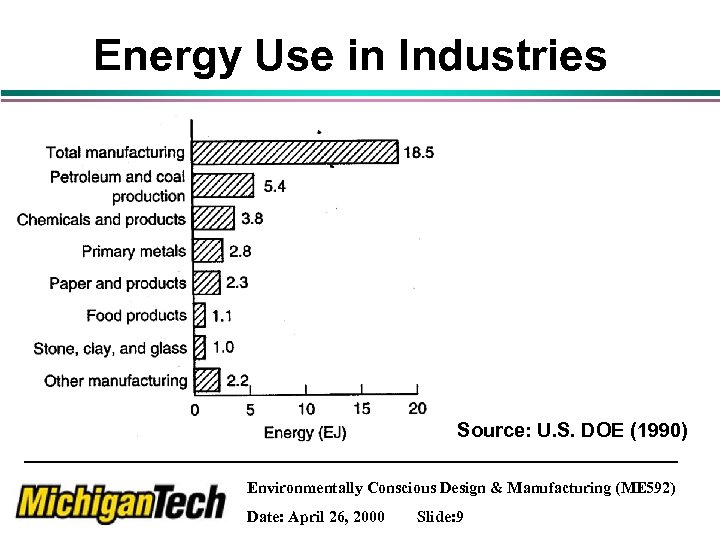

Energy Use in Industries Source: U. S. DOE (1990) Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 9

Energy Use in Industries Source: U. S. DOE (1990) Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 9

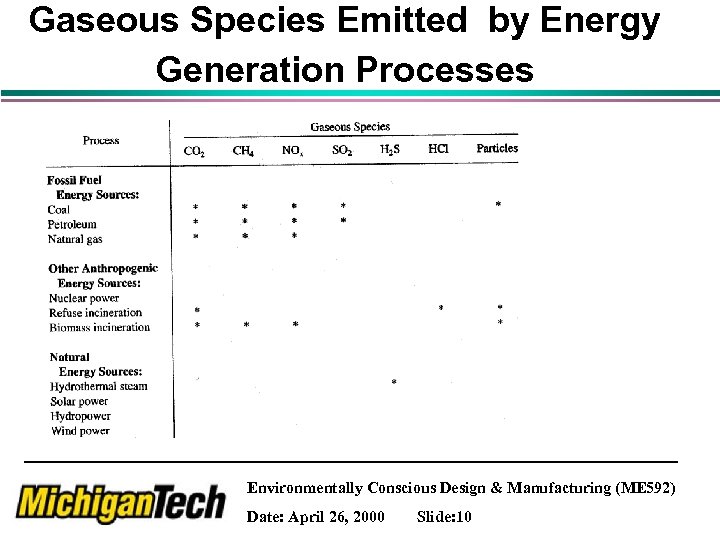

Gaseous Species Emitted by Energy Generation Processes Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 10

Gaseous Species Emitted by Energy Generation Processes Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 10

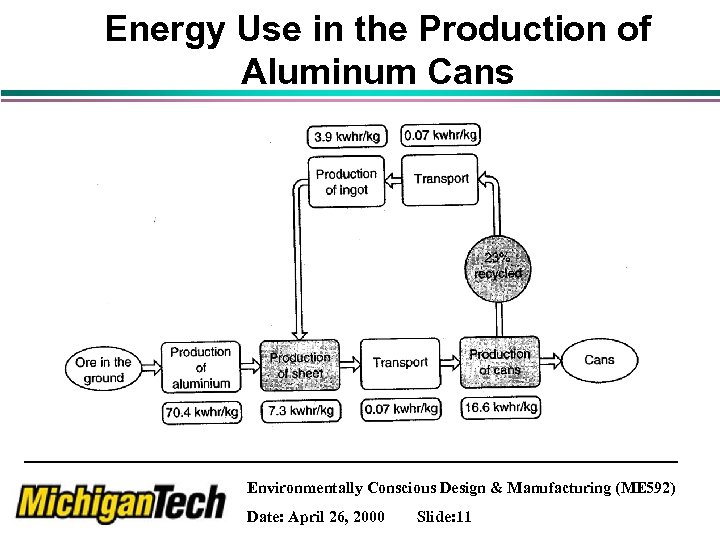

Energy Use in the Production of Aluminum Cans Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 11

Energy Use in the Production of Aluminum Cans Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 11

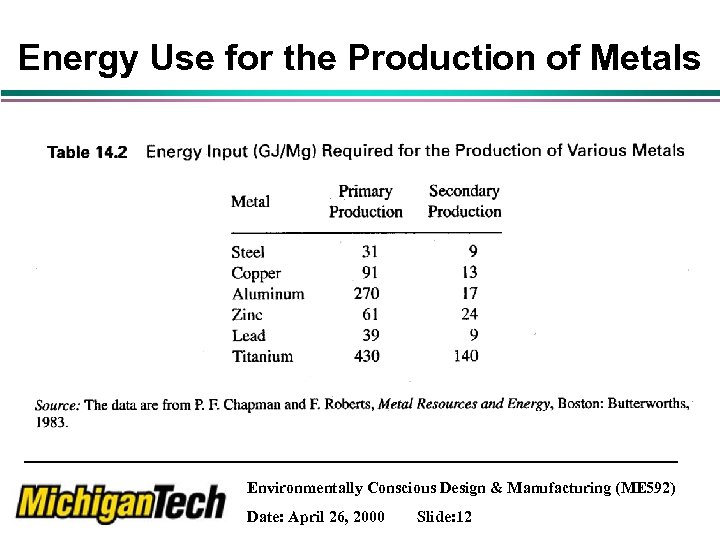

Energy Use for the Production of Metals Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 12

Energy Use for the Production of Metals Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 12

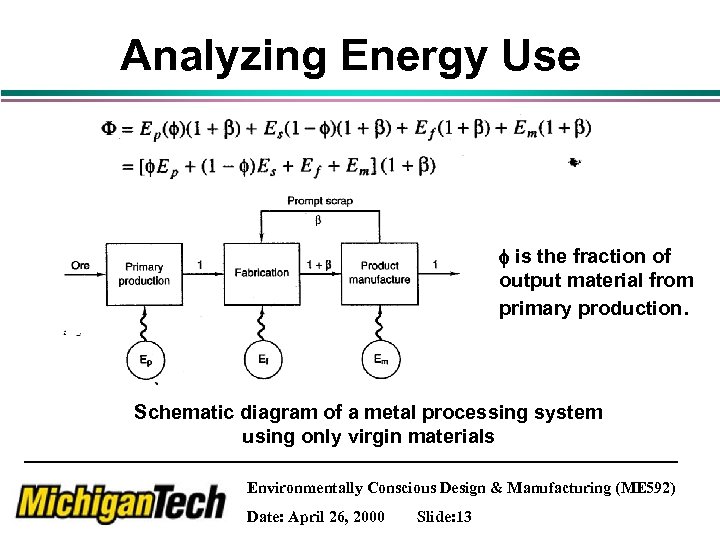

Analyzing Energy Use is the fraction of output material from primary production. Schematic diagram of a metal processing system using only virgin materials Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 13

Analyzing Energy Use is the fraction of output material from primary production. Schematic diagram of a metal processing system using only virgin materials Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 13

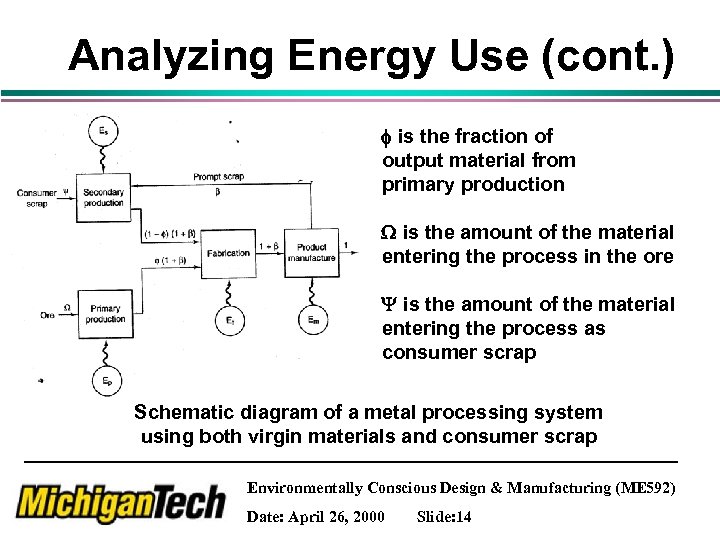

Analyzing Energy Use (cont. ) is the fraction of output material from primary production is the amount of the material entering the process in the ore is the amount of the material entering the process as consumer scrap Schematic diagram of a metal processing system using both virgin materials and consumer scrap Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 14

Analyzing Energy Use (cont. ) is the fraction of output material from primary production is the amount of the material entering the process in the ore is the amount of the material entering the process as consumer scrap Schematic diagram of a metal processing system using both virgin materials and consumer scrap Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 14

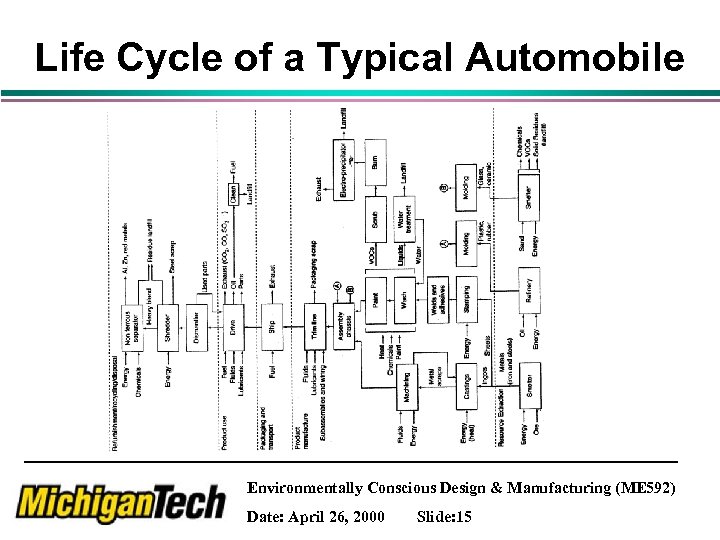

Life Cycle of a Typical Automobile Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 15

Life Cycle of a Typical Automobile Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 15

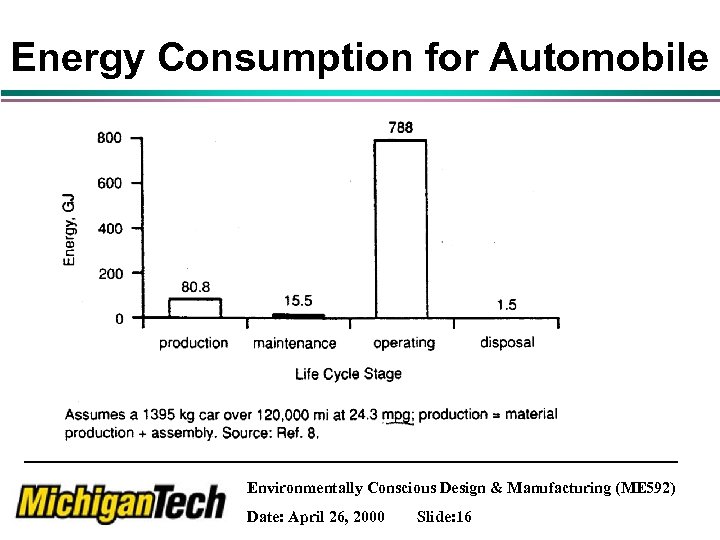

Energy Consumption for Automobile Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 16

Energy Consumption for Automobile Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 16

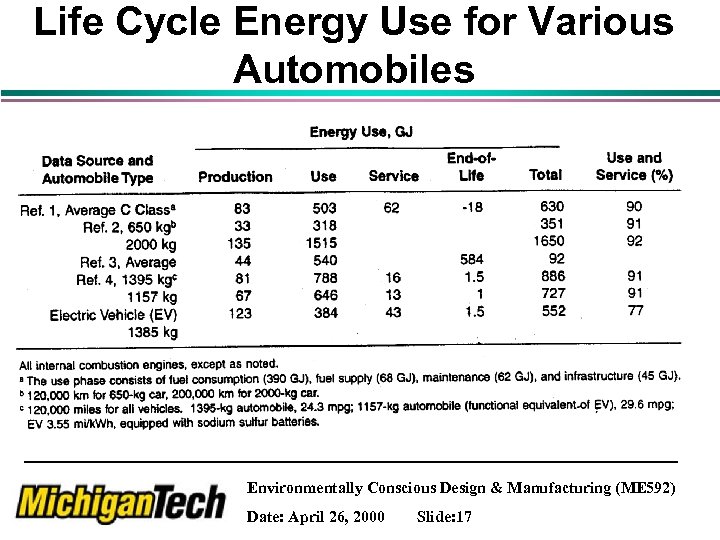

Life Cycle Energy Use for Various Automobiles Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 17

Life Cycle Energy Use for Various Automobiles Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 17

Checklist for Energy Analysis For facility engineers • • • Replace incandescent lighting with high-efficiency fluorescent lighting Install an automatic lighting control system Check boilers and furnaces for leaks Utilize cogenerated heat and electricity from within the facility or nearby Use waste heat Encourage good energy housekeeping Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 18

Checklist for Energy Analysis For facility engineers • • • Replace incandescent lighting with high-efficiency fluorescent lighting Install an automatic lighting control system Check boilers and furnaces for leaks Utilize cogenerated heat and electricity from within the facility or nearby Use waste heat Encourage good energy housekeeping Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 18

Checklist for Energy Analysis (Cont. ) For Process designer • • • Minimize the use of energy-intensive process steps Optimize the use of heat exchangers and similar devices to utilize otherwise wasted heat Use the maximum possible amount of recycled material Utilize energy management approaches and equipment Utilize energy variable speed motors and other automated load control Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 19

Checklist for Energy Analysis (Cont. ) For Process designer • • • Minimize the use of energy-intensive process steps Optimize the use of heat exchangers and similar devices to utilize otherwise wasted heat Use the maximum possible amount of recycled material Utilize energy management approaches and equipment Utilize energy variable speed motors and other automated load control Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 19

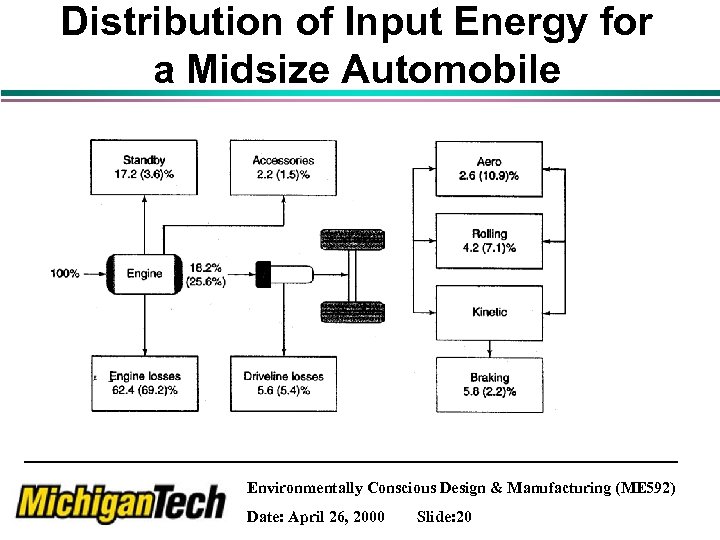

Distribution of Input Energy for a Midsize Automobile Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 20

Distribution of Input Energy for a Midsize Automobile Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 20

Automobiles Energy Options • • Alternative carbon-based fuels Electric vehicles Hybrid-powered vehicles Fuel cell-powered vehicles Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 21

Automobiles Energy Options • • Alternative carbon-based fuels Electric vehicles Hybrid-powered vehicles Fuel cell-powered vehicles Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 21

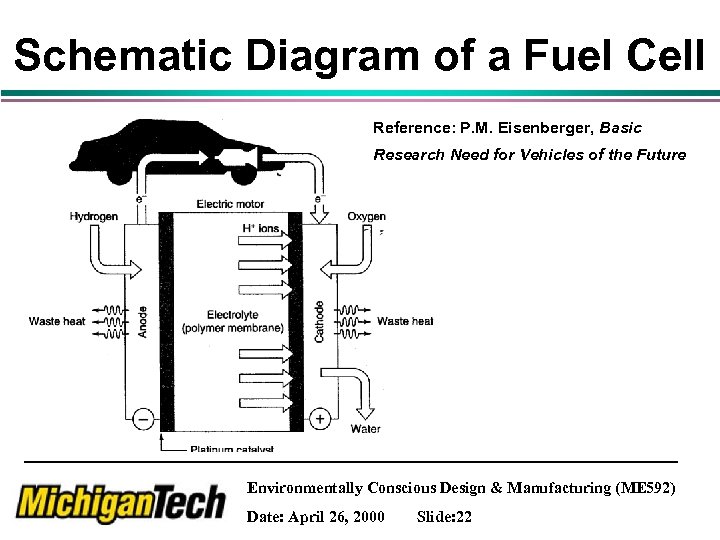

Schematic Diagram of a Fuel Cell Reference: P. M. Eisenberger, Basic Research Need for Vehicles of the Future Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 22

Schematic Diagram of a Fuel Cell Reference: P. M. Eisenberger, Basic Research Need for Vehicles of the Future Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 22

Fuel Cells - Why • • Direct conversion of chemical to electrical energy Environmental considerations: » Clean power source – Non toxic emissions – Efficient Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 23

Fuel Cells - Why • • Direct conversion of chemical to electrical energy Environmental considerations: » Clean power source – Non toxic emissions – Efficient Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 23

Types of Fuel Cells • Phosphoric acid • Most commercially developed type of fuel cell - Generate electricity at more than 40% efficiency - Nearly 85% of steam this fuel cell produces is used for cogeneration (compared to 30% for the most efficient internal combustion engine) Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 24

Types of Fuel Cells • Phosphoric acid • Most commercially developed type of fuel cell - Generate electricity at more than 40% efficiency - Nearly 85% of steam this fuel cell produces is used for cogeneration (compared to 30% for the most efficient internal combustion engine) Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 24

Types of Fuel Cells - Phosphoric Acid • • Operating temperatures are in the range of 400 degrees F. These fuel cells also can be used in larger vehicles, such as buses and locomotives. Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 25

Types of Fuel Cells - Phosphoric Acid • • Operating temperatures are in the range of 400 degrees F. These fuel cells also can be used in larger vehicles, such as buses and locomotives. Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 25

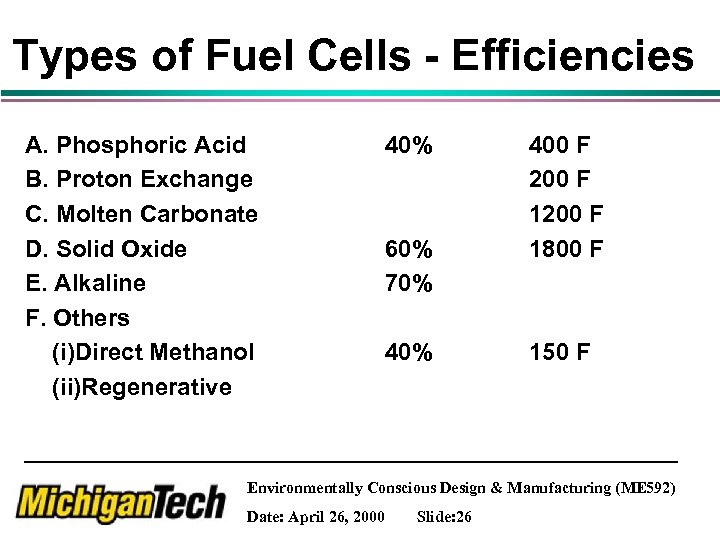

Types of Fuel Cells - Efficiencies A. Phosphoric Acid B. Proton Exchange C. Molten Carbonate D. Solid Oxide E. Alkaline F. Others (i)Direct Methanol (ii)Regenerative 40% 60% 70% 400 F 200 F 1800 F 150 F Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 26

Types of Fuel Cells - Efficiencies A. Phosphoric Acid B. Proton Exchange C. Molten Carbonate D. Solid Oxide E. Alkaline F. Others (i)Direct Methanol (ii)Regenerative 40% 60% 70% 400 F 200 F 1800 F 150 F Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 26

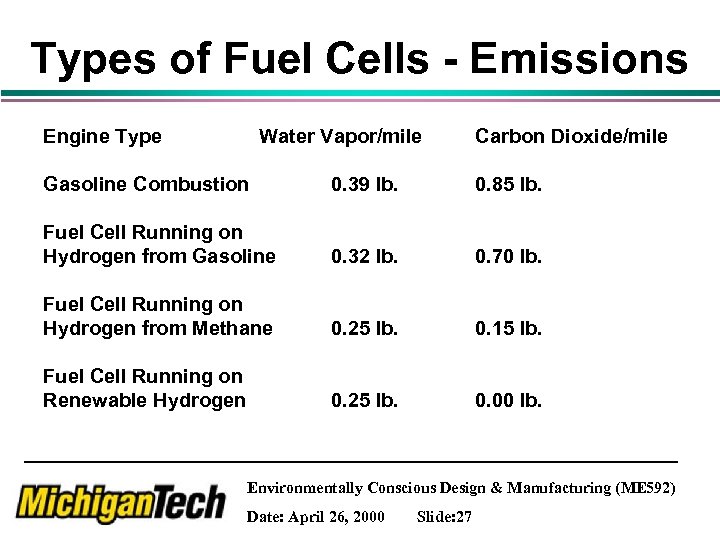

Types of Fuel Cells - Emissions Engine Type Water Vapor/mile Carbon Dioxide/mile Gasoline Combustion 0. 39 lb. 0. 85 lb. Fuel Cell Running on Hydrogen from Gasoline 0. 32 lb. 0. 70 lb. Fuel Cell Running on Hydrogen from Methane 0. 25 lb. 0. 15 lb. Fuel Cell Running on Renewable Hydrogen 0. 25 lb. 0. 00 lb. Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 27

Types of Fuel Cells - Emissions Engine Type Water Vapor/mile Carbon Dioxide/mile Gasoline Combustion 0. 39 lb. 0. 85 lb. Fuel Cell Running on Hydrogen from Gasoline 0. 32 lb. 0. 70 lb. Fuel Cell Running on Hydrogen from Methane 0. 25 lb. 0. 15 lb. Fuel Cell Running on Renewable Hydrogen 0. 25 lb. 0. 00 lb. Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 27

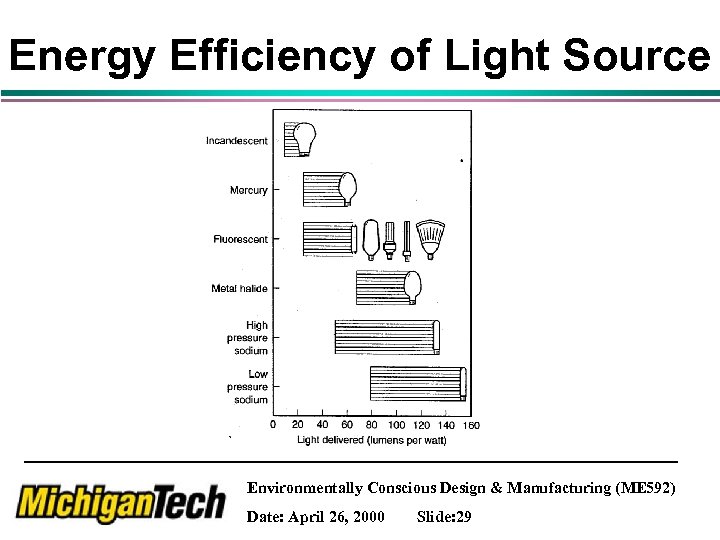

General Approaches to Minimizing Energy Use • • Heating, Ventilating, Air Conditioning (HVAC) Lighting On-site energy generation Energy housekeeping Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 28

General Approaches to Minimizing Energy Use • • Heating, Ventilating, Air Conditioning (HVAC) Lighting On-site energy generation Energy housekeeping Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 28

Energy Efficiency of Light Source Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 29

Energy Efficiency of Light Source Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 29

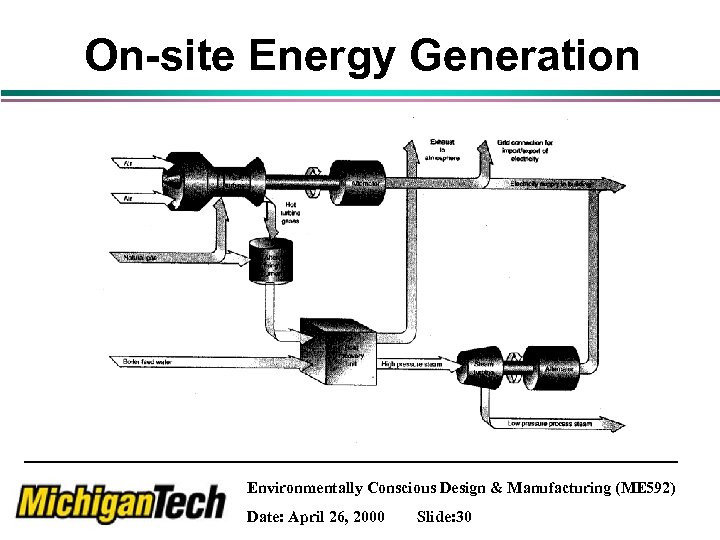

On-site Energy Generation Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 30

On-site Energy Generation Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 30

Energy Housekeeping Make the existing industrial situation more energyefficient e. g. • • • More efficiently design computer Improve heat-transfer efficiency Employ point-of-use fluid heaters Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 31

Energy Housekeeping Make the existing industrial situation more energyefficient e. g. • • • More efficiently design computer Improve heat-transfer efficiency Employ point-of-use fluid heaters Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 31

Energy Consumption in EU • Strong pressure by the EU on national authorities to bring energy consumption down • Planning difficulties to build new generating plants • Opposition to nuclear energy • Dependence on imports of fuel • Declaration of energy consumption on products for sale e. g. refrigerators • Reduction of stand-by energy, e. g. TVs, VCRs, computers Source: A. Stevels, Stanford Ecodesign short course, 1999 Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 32

Energy Consumption in EU • Strong pressure by the EU on national authorities to bring energy consumption down • Planning difficulties to build new generating plants • Opposition to nuclear energy • Dependence on imports of fuel • Declaration of energy consumption on products for sale e. g. refrigerators • Reduction of stand-by energy, e. g. TVs, VCRs, computers Source: A. Stevels, Stanford Ecodesign short course, 1999 Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 32

Energy Consumption in Japan Targets • Standard for standby power for all CE products=1 watt • Energy reduction in operational modes • 1/6 for TV, air conditioner • 1/3 for refrigerator • 1/2 for washing machine Source: A. Stevels, Stanford Ecodesign short course, 1999 Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 33

Energy Consumption in Japan Targets • Standard for standby power for all CE products=1 watt • Energy reduction in operational modes • 1/6 for TV, air conditioner • 1/3 for refrigerator • 1/2 for washing machine Source: A. Stevels, Stanford Ecodesign short course, 1999 Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 33

New Energy Technologies • Solar power, photovoltaics • Pulsed combustion • Waste pyrolysis systems • Waste to energy conversion • Gasification and wet thermal oxidation Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 34

New Energy Technologies • Solar power, photovoltaics • Pulsed combustion • Waste pyrolysis systems • Waste to energy conversion • Gasification and wet thermal oxidation Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 34

Homework #7 1. Give a chart showing the performance hierarchy of recycling options 2. Discuss the primary considerations in recycling economics. 3. Graphically illustrate the cost benefits of recycling against the competition. 4. Discuss an example of successful reuse effort. Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 35

Homework #7 1. Give a chart showing the performance hierarchy of recycling options 2. Discuss the primary considerations in recycling economics. 3. Graphically illustrate the cost benefits of recycling against the competition. 4. Discuss an example of successful reuse effort. Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 35

Homework #7 5 Compare the costs of new, reused and remanufactured product. What is needed to improve the status of reused product? How is it accomplished in your example given in #4. 6 Discuss an example of successful remanufacture effort. Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 36

Homework #7 5 Compare the costs of new, reused and remanufactured product. What is needed to improve the status of reused product? How is it accomplished in your example given in #4. 6 Discuss an example of successful remanufacture effort. Environmentally Conscious Design & Manufacturing (ME 592) Date: April 26, 2000 Slide: 36