ffea93be943770e23e32b232cc96713a.ppt

- Количество слайдов: 52

Environmental Impacts of an Ethanol Plant in the Missouri Ozarks for 2007 NACAA AM/PIC Grand Rapids, MI July 17, 2007 by Bob Schultheis Natural Resource Engineering Specialist

Environmental Impacts of an Ethanol Plant in the Missouri Ozarks for 2007 NACAA AM/PIC Grand Rapids, MI July 17, 2007 by Bob Schultheis Natural Resource Engineering Specialist

Why the Rush for Ethanol? Ø $3 per gallon gasoline Ø Demand for greater energy security Ø Concern over relying on oil imports from politically volatile regions – Those opposing ethanol are branded as “unpatriotic” or “supporting terrorism” Ø Growing worries about CO 2 contributing to “global warming” – Methane & nitrogen oxides (NOx) are much bigger contributors Ø Income for grain farmers & petroleum companies 2

Why the Rush for Ethanol? Ø $3 per gallon gasoline Ø Demand for greater energy security Ø Concern over relying on oil imports from politically volatile regions – Those opposing ethanol are branded as “unpatriotic” or “supporting terrorism” Ø Growing worries about CO 2 contributing to “global warming” – Methane & nitrogen oxides (NOx) are much bigger contributors Ø Income for grain farmers & petroleum companies 2

Basics of Ethanol Production Ø Ethanol is an alcohol made by fermenting grain and other carbohydrates Ø This is an old process which traditionally has been used to produce ethanol for use as a beverage Ø 97% of U. S. ethanol is made from corn 3

Basics of Ethanol Production Ø Ethanol is an alcohol made by fermenting grain and other carbohydrates Ø This is an old process which traditionally has been used to produce ethanol for use as a beverage Ø 97% of U. S. ethanol is made from corn 3

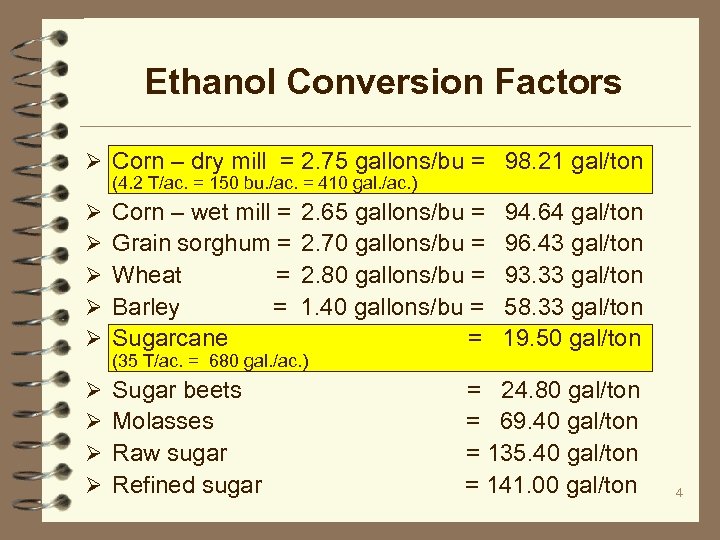

Ethanol Conversion Factors Ø Corn – dry mill = 2. 75 gallons/bu = 98. 21 gal/ton (4. 2 T/ac. = 150 bu. /ac. = 410 gal. /ac. ) Ø Ø Ø Corn – wet mill = Grain sorghum = Wheat = Barley = Sugarcane Ø Ø Sugar beets Molasses Raw sugar Refined sugar 2. 65 gallons/bu = 2. 70 gallons/bu = 2. 80 gallons/bu = 1. 40 gallons/bu = = (35 T/ac. = 680 gal. /ac. ) 94. 64 gal/ton 96. 43 gal/ton 93. 33 gal/ton 58. 33 gal/ton 19. 50 gal/ton = 24. 80 gal/ton = 69. 40 gal/ton = 135. 40 gal/ton = 141. 00 gal/ton 4

Ethanol Conversion Factors Ø Corn – dry mill = 2. 75 gallons/bu = 98. 21 gal/ton (4. 2 T/ac. = 150 bu. /ac. = 410 gal. /ac. ) Ø Ø Ø Corn – wet mill = Grain sorghum = Wheat = Barley = Sugarcane Ø Ø Sugar beets Molasses Raw sugar Refined sugar 2. 65 gallons/bu = 2. 70 gallons/bu = 2. 80 gallons/bu = 1. 40 gallons/bu = = (35 T/ac. = 680 gal. /ac. ) 94. 64 gal/ton 96. 43 gal/ton 93. 33 gal/ton 58. 33 gal/ton 19. 50 gal/ton = 24. 80 gal/ton = 69. 40 gal/ton = 135. 40 gal/ton = 141. 00 gal/ton 4

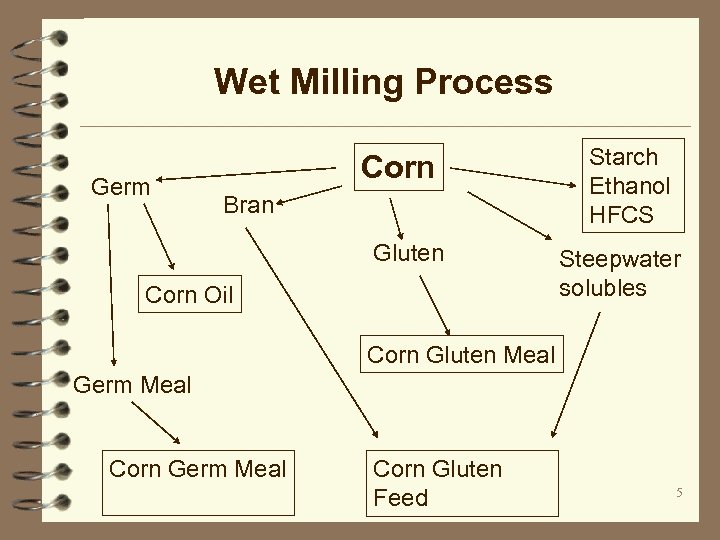

Wet Milling Process Germ Corn Bran Gluten Corn Oil Starch Ethanol HFCS Steepwater solubles Corn Gluten Meal Germ Meal Corn Gluten Feed 5

Wet Milling Process Germ Corn Bran Gluten Corn Oil Starch Ethanol HFCS Steepwater solubles Corn Gluten Meal Germ Meal Corn Gluten Feed 5

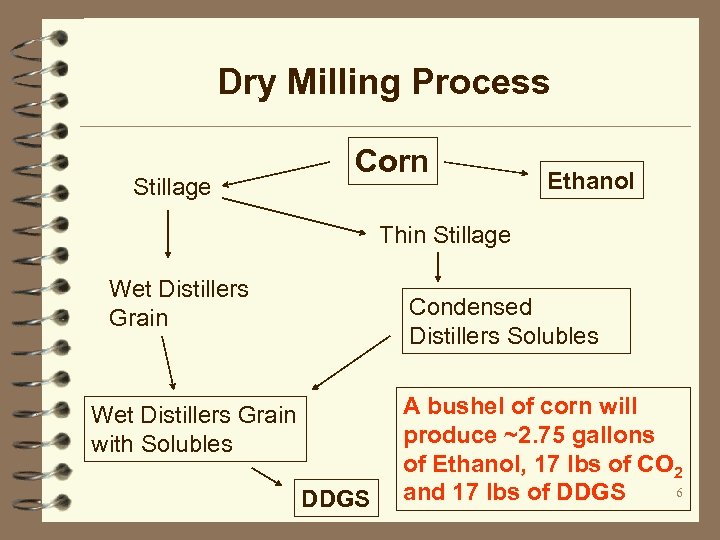

Dry Milling Process Stillage Corn Ethanol Thin Stillage Wet Distillers Grain Condensed Distillers Solubles Wet Distillers Grain with Solubles DDGS A bushel of corn will produce ~2. 75 gallons of Ethanol, 17 lbs of CO 2 6 and 17 lbs of DDGS

Dry Milling Process Stillage Corn Ethanol Thin Stillage Wet Distillers Grain Condensed Distillers Solubles Wet Distillers Grain with Solubles DDGS A bushel of corn will produce ~2. 75 gallons of Ethanol, 17 lbs of CO 2 6 and 17 lbs of DDGS

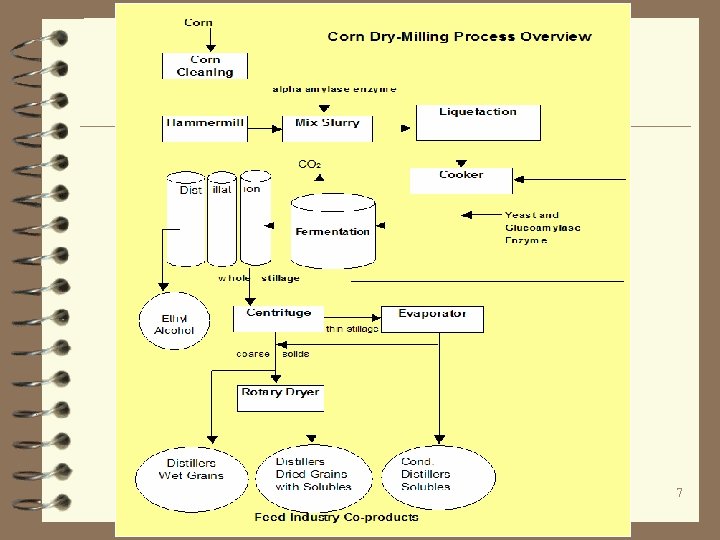

7

7

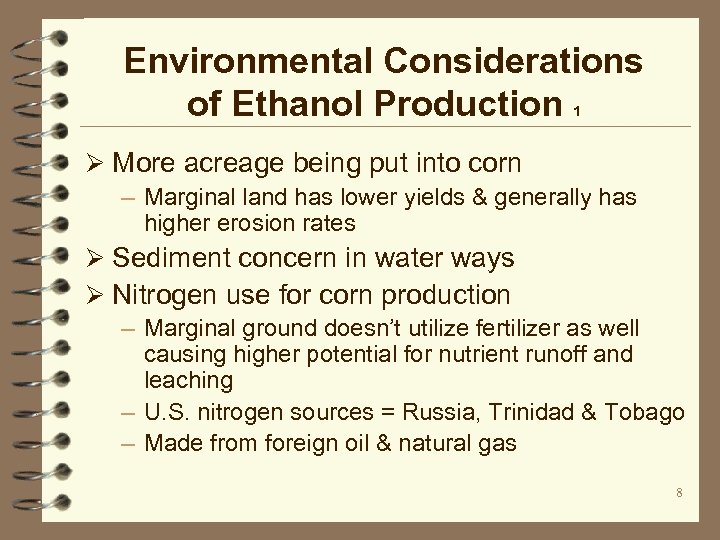

Environmental Considerations of Ethanol Production 1 Ø More acreage being put into corn – Marginal land has lower yields & generally has higher erosion rates Ø Sediment concern in water ways Ø Nitrogen use for corn production – Marginal ground doesn’t utilize fertilizer as well causing higher potential for nutrient runoff and leaching – U. S. nitrogen sources = Russia, Trinidad & Tobago – Made from foreign oil & natural gas 8

Environmental Considerations of Ethanol Production 1 Ø More acreage being put into corn – Marginal land has lower yields & generally has higher erosion rates Ø Sediment concern in water ways Ø Nitrogen use for corn production – Marginal ground doesn’t utilize fertilizer as well causing higher potential for nutrient runoff and leaching – U. S. nitrogen sources = Russia, Trinidad & Tobago – Made from foreign oil & natural gas 8

Environmental Considerations of Ethanol Production 2 Ø Atrazine runoff concerns – Whether in water or attached to soil, atrazine use for weed control has higher potential to runoff into water bodies – If not wisely managed in targeted watersheds, it may be banned in all watersheds Ø Water demand – Growing the corn = 1450 gallons per 1 gal. ethanol (600, 000 gal. /ac. /season ÷ 150 bu. /ac. ÷ 2. 75 gal. /bu. ) – Making ethanol = 3 -5 gallons per 1 gal. ethanol Ø Air emissions of the ethanol plants 9

Environmental Considerations of Ethanol Production 2 Ø Atrazine runoff concerns – Whether in water or attached to soil, atrazine use for weed control has higher potential to runoff into water bodies – If not wisely managed in targeted watersheds, it may be banned in all watersheds Ø Water demand – Growing the corn = 1450 gallons per 1 gal. ethanol (600, 000 gal. /ac. /season ÷ 150 bu. /ac. ÷ 2. 75 gal. /bu. ) – Making ethanol = 3 -5 gallons per 1 gal. ethanol Ø Air emissions of the ethanol plants 9

Environmental Considerations of Ethanol Production 3 Ø High P, K and S content of DDGs as feed Ø Ethanol cannot be transported by pipeline – Truck fuel use & air emissions to transport it Ø Underwriters Laboratories (UL) has not issued safety approval for E 85 pumps Ø Is U. S. ethanol replacing foreign oil or domestic oil? 10

Environmental Considerations of Ethanol Production 3 Ø High P, K and S content of DDGs as feed Ø Ethanol cannot be transported by pipeline – Truck fuel use & air emissions to transport it Ø Underwriters Laboratories (UL) has not issued safety approval for E 85 pumps Ø Is U. S. ethanol replacing foreign oil or domestic oil? 10

Economic Considerations of Ethanol Production Ø $. 51/gallon federal excise tax credit – 5. 1 cents/gallon for 10% blend – Government tax incentives used since 1978 to make ethanol competitive with gasoline Ø $. 54/gallon federal tariff on imported ethanol Ø States may also offer incentives – Missouri = $. 20/gallon producer tax credit on first 12. 5 million gallons 11

Economic Considerations of Ethanol Production Ø $. 51/gallon federal excise tax credit – 5. 1 cents/gallon for 10% blend – Government tax incentives used since 1978 to make ethanol competitive with gasoline Ø $. 54/gallon federal tariff on imported ethanol Ø States may also offer incentives – Missouri = $. 20/gallon producer tax credit on first 12. 5 million gallons 11

Economic Considerations of Ethanol Use Ø E 10 = negligible MPG loss – 3% less energy per gallon than gasoline + 2. 5 points higher octane rating Ø E 85 = 15 -20% MPG loss, depending on driving habits and terrain – 27% less energy per gallon than gasoline + 13 points higher octane rating Ø Only select vehicles can burn E 85 – Flex-Fuel Vehicles or FFVs built mostly after 1999 – Corrosion-resistant stainless steel gas tanks and Teflon-lined fuel lines 12

Economic Considerations of Ethanol Use Ø E 10 = negligible MPG loss – 3% less energy per gallon than gasoline + 2. 5 points higher octane rating Ø E 85 = 15 -20% MPG loss, depending on driving habits and terrain – 27% less energy per gallon than gasoline + 13 points higher octane rating Ø Only select vehicles can burn E 85 – Flex-Fuel Vehicles or FFVs built mostly after 1999 – Corrosion-resistant stainless steel gas tanks and Teflon-lined fuel lines 12

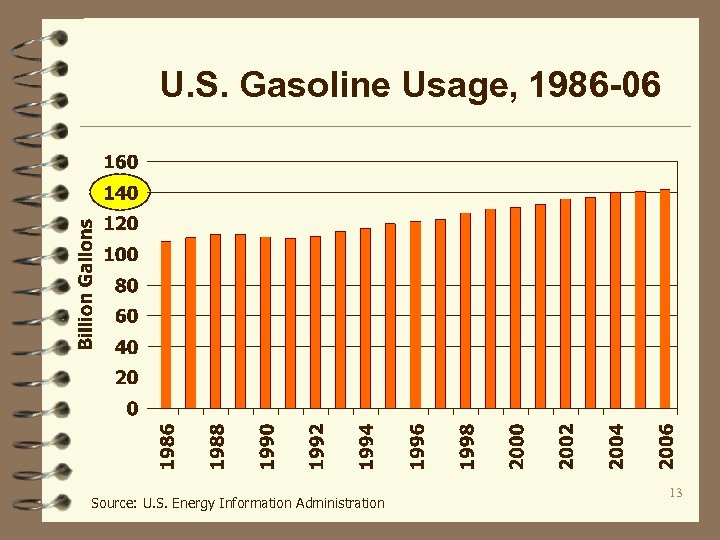

U. S. Gasoline Usage, 1986 -06 Source: U. S. Energy Information Administration 13

U. S. Gasoline Usage, 1986 -06 Source: U. S. Energy Information Administration 13

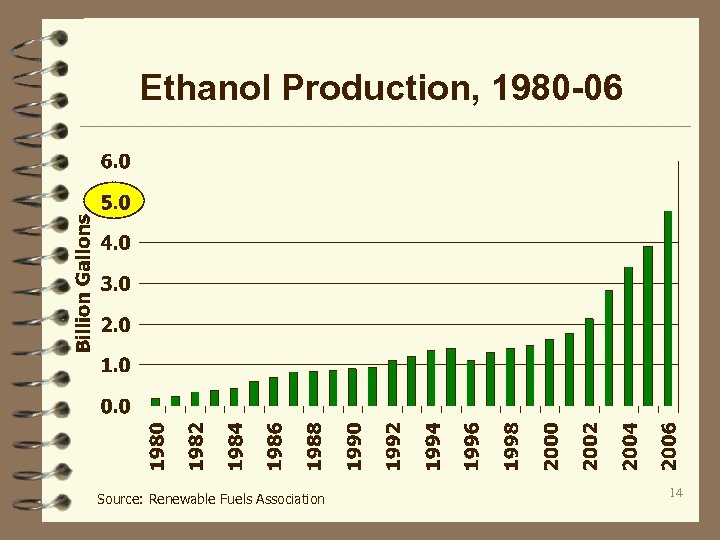

Ethanol Production, 1980 -06 Source: Renewable Fuels Association 14

Ethanol Production, 1980 -06 Source: Renewable Fuels Association 14

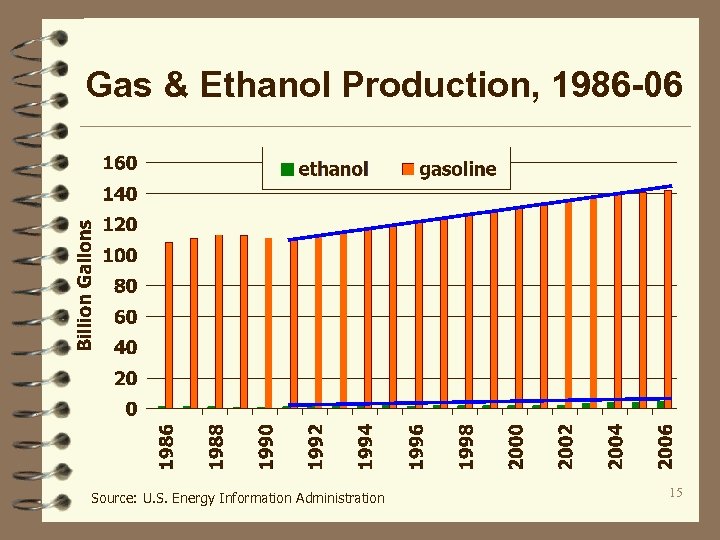

Gas & Ethanol Production, 1986 -06 Source: U. S. Energy Information Administration 15

Gas & Ethanol Production, 1986 -06 Source: U. S. Energy Information Administration 15

U. S. Gasoline Usage Ø Mandating 10% ethanol in all gasoline would require that nearly half of the U. S. corn crop be processed into ethanol Ø If all U. S. corn were made into ethanol, it would produce 31 billion gallons per year Ø To replace all U. S. gasoline would require 78. 6 billion bushels of corn annually Source: FAPRI 2006 16

U. S. Gasoline Usage Ø Mandating 10% ethanol in all gasoline would require that nearly half of the U. S. corn crop be processed into ethanol Ø If all U. S. corn were made into ethanol, it would produce 31 billion gallons per year Ø To replace all U. S. gasoline would require 78. 6 billion bushels of corn annually Source: FAPRI 2006 16

Webster County Groundwater Impact Committee (Appointed 8/23/06 by County Commission, dissolved 11/18/06) Bob Schultheis - Natural resource engineering specialist Marshfield, MO (Committee Chair) Larry Alberty - Fordland area businessman Fordland, MO Karen Asher - Seymour area farmer Seymour, MO Joe Blaine - Soil scientist Seymour, MO Joyce Noland - District technician, Webster County SWCD Marshfield, MO 17

Webster County Groundwater Impact Committee (Appointed 8/23/06 by County Commission, dissolved 11/18/06) Bob Schultheis - Natural resource engineering specialist Marshfield, MO (Committee Chair) Larry Alberty - Fordland area businessman Fordland, MO Karen Asher - Seymour area farmer Seymour, MO Joe Blaine - Soil scientist Seymour, MO Joyce Noland - District technician, Webster County SWCD Marshfield, MO 17

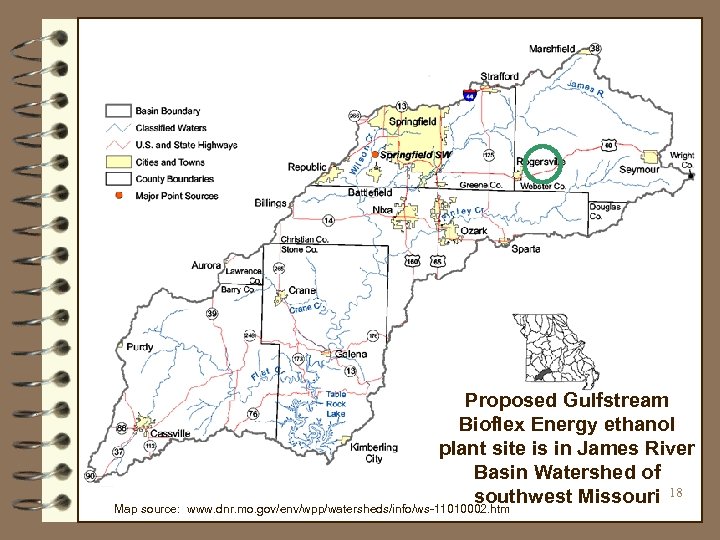

Proposed Gulfstream Bioflex Energy ethanol plant site is in James River Basin Watershed of southwest Missouri 18 Map source: www. dnr. mo. gov/env/wpp/watersheds/info/ws-11010002. htm

Proposed Gulfstream Bioflex Energy ethanol plant site is in James River Basin Watershed of southwest Missouri 18 Map source: www. dnr. mo. gov/env/wpp/watersheds/info/ws-11010002. htm

Equivalent Residential Demand 880 GPM water = 21, 000 persons @ 60 GPD 10, 000 Kw. H = 5, 100 houses @ 1400 Kw. H per month 19

Equivalent Residential Demand 880 GPM water = 21, 000 persons @ 60 GPD 10, 000 Kw. H = 5, 100 houses @ 1400 Kw. H per month 19

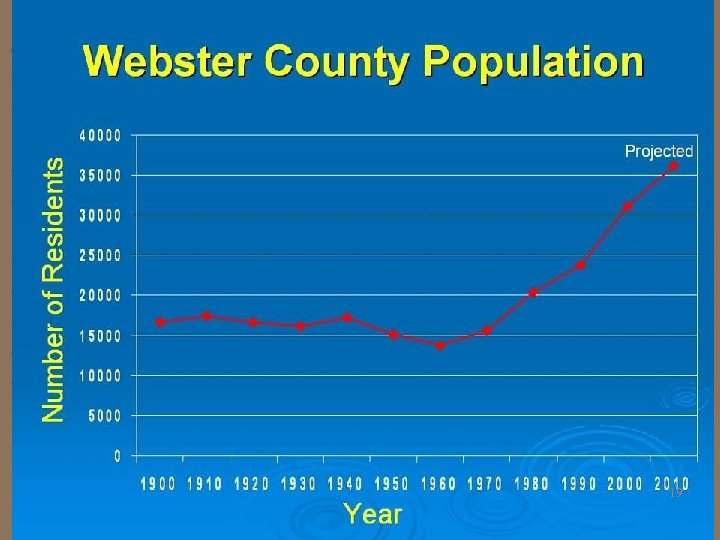

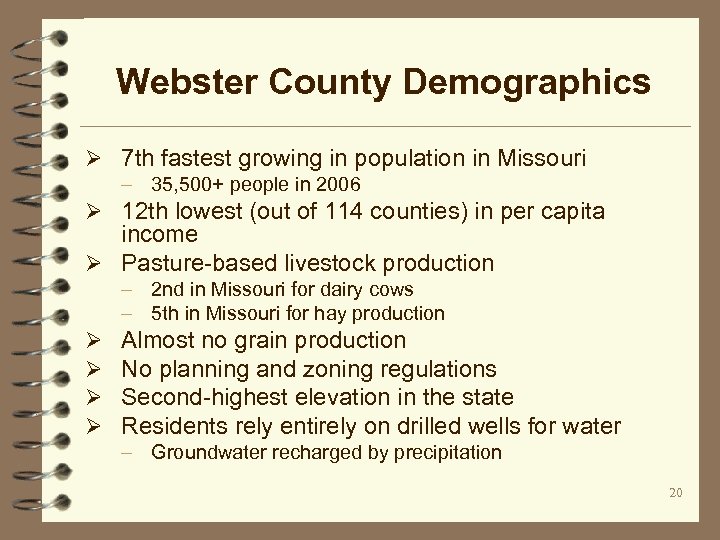

Webster County Demographics Ø 7 th fastest growing in population in Missouri – 35, 500+ people in 2006 Ø 12 th lowest (out of 114 counties) in per capita income Ø Pasture-based livestock production – 2 nd in Missouri for dairy cows – 5 th in Missouri for hay production Ø Ø Almost no grain production No planning and zoning regulations Second-highest elevation in the state Residents rely entirely on drilled wells for water – Groundwater recharged by precipitation 20

Webster County Demographics Ø 7 th fastest growing in population in Missouri – 35, 500+ people in 2006 Ø 12 th lowest (out of 114 counties) in per capita income Ø Pasture-based livestock production – 2 nd in Missouri for dairy cows – 5 th in Missouri for hay production Ø Ø Almost no grain production No planning and zoning regulations Second-highest elevation in the state Residents rely entirely on drilled wells for water – Groundwater recharged by precipitation 20

Geology of Missouri 21

Geology of Missouri 21

Geology of SW Missouri 22

Geology of SW Missouri 22

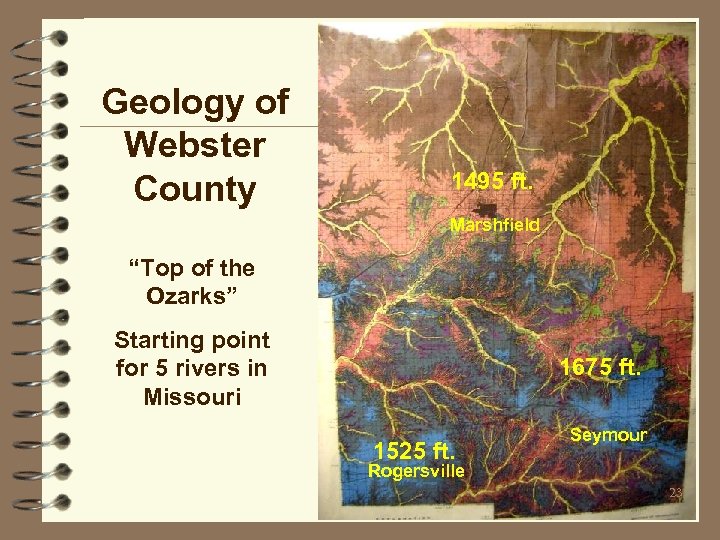

Geology of Webster County 1495 ft. Marshfield “Top of the Ozarks” Starting point for 5 rivers in Missouri 1675 ft. 1525 ft. Seymour Rogersville 23

Geology of Webster County 1495 ft. Marshfield “Top of the Ozarks” Starting point for 5 rivers in Missouri 1675 ft. 1525 ft. Seymour Rogersville 23

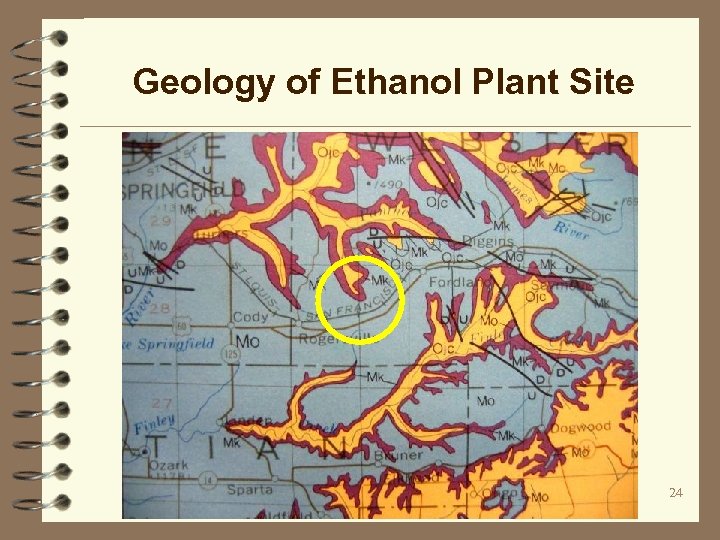

Geology of Ethanol Plant Site 24

Geology of Ethanol Plant Site 24

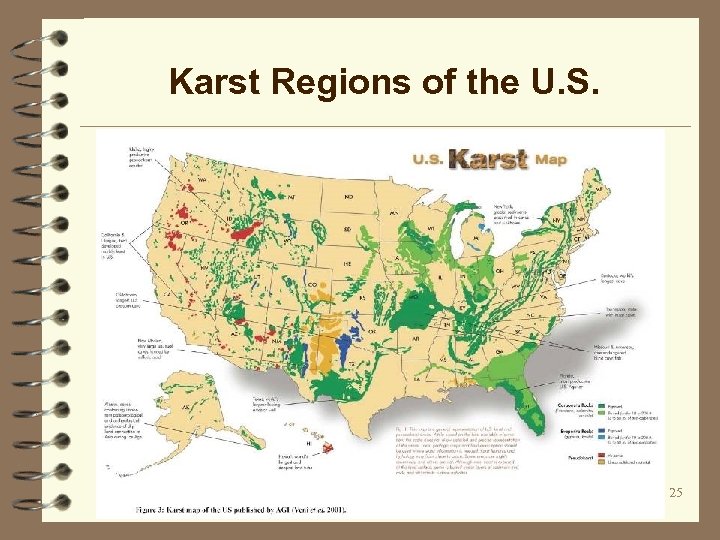

Karst Regions of the U. S. 25

Karst Regions of the U. S. 25

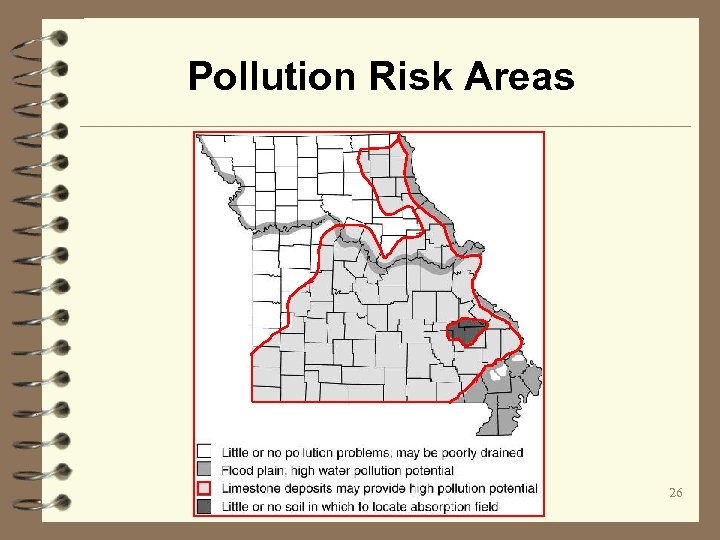

Pollution Risk Areas 26

Pollution Risk Areas 26

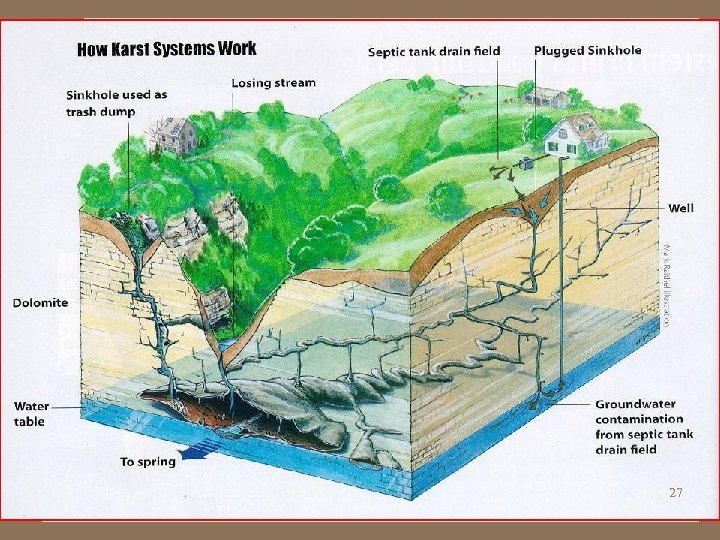

27

27

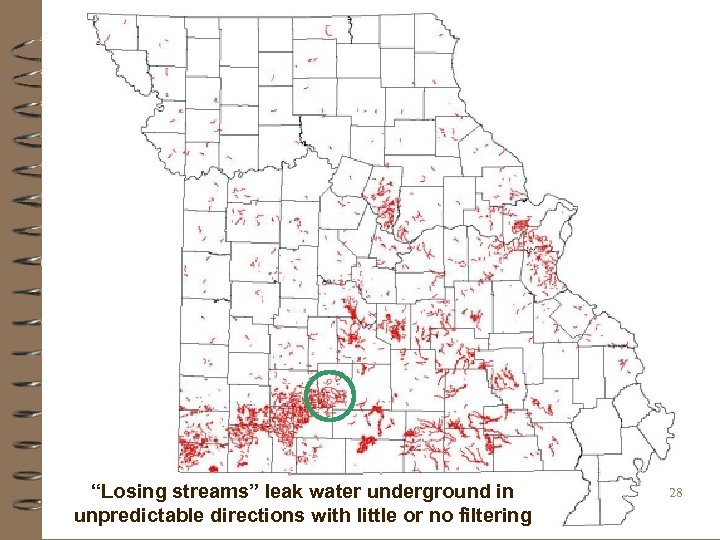

“Losing streams” leak water underground in unpredictable directions with little or no filtering 28

“Losing streams” leak water underground in unpredictable directions with little or no filtering 28

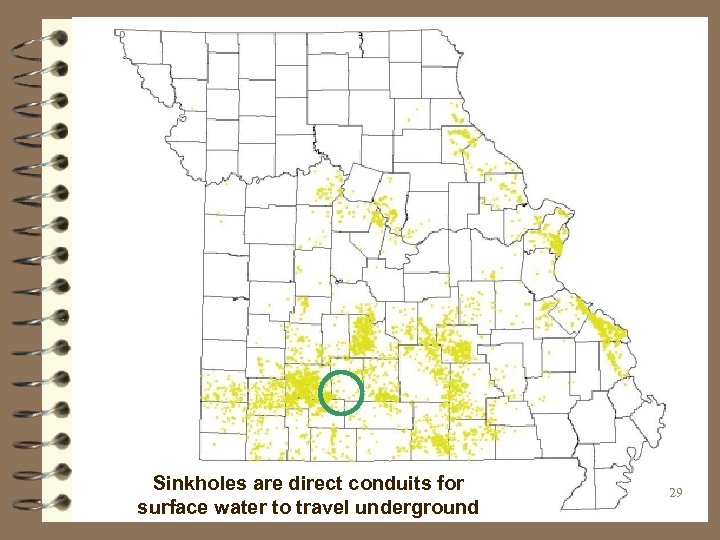

Sinkholes are direct conduits for surface water to travel underground 29

Sinkholes are direct conduits for surface water to travel underground 29

Solution Channel 30

Solution Channel 30

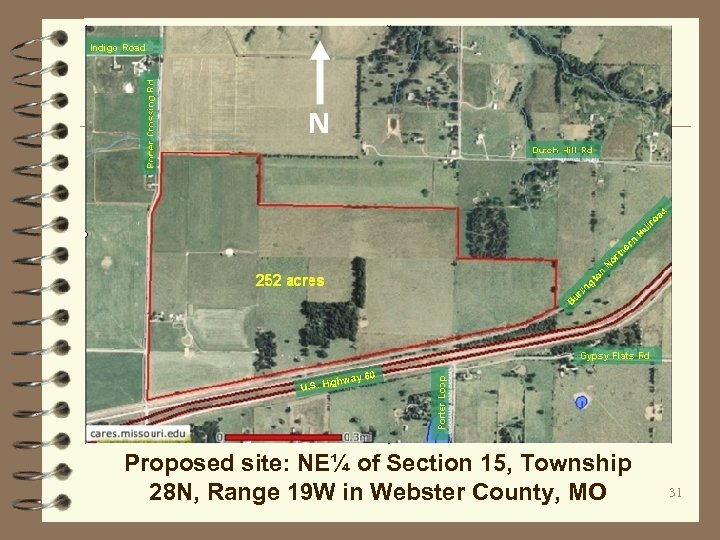

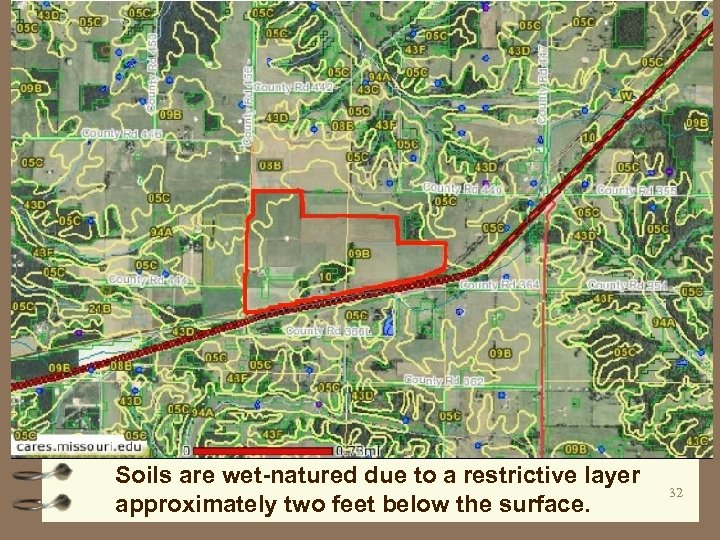

Proposed site: NE¼ of Section 15, Township 28 N, Range 19 W in Webster County, MO 31

Proposed site: NE¼ of Section 15, Township 28 N, Range 19 W in Webster County, MO 31

Soils are wet-natured due to a restrictive layer approximately two feet below the surface. 32

Soils are wet-natured due to a restrictive layer approximately two feet below the surface. 32

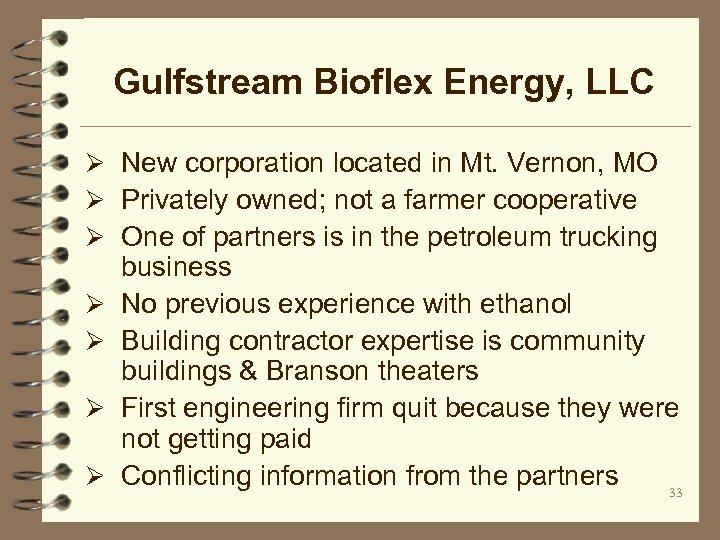

Gulfstream Bioflex Energy, LLC Ø New corporation located in Mt. Vernon, MO Ø Privately owned; not a farmer cooperative Ø One of partners is in the petroleum trucking Ø Ø business No previous experience with ethanol Building contractor expertise is community buildings & Branson theaters First engineering firm quit because they were not getting paid Conflicting information from the partners 33

Gulfstream Bioflex Energy, LLC Ø New corporation located in Mt. Vernon, MO Ø Privately owned; not a farmer cooperative Ø One of partners is in the petroleum trucking Ø Ø business No previous experience with ethanol Building contractor expertise is community buildings & Branson theaters First engineering firm quit because they were not getting paid Conflicting information from the partners 33

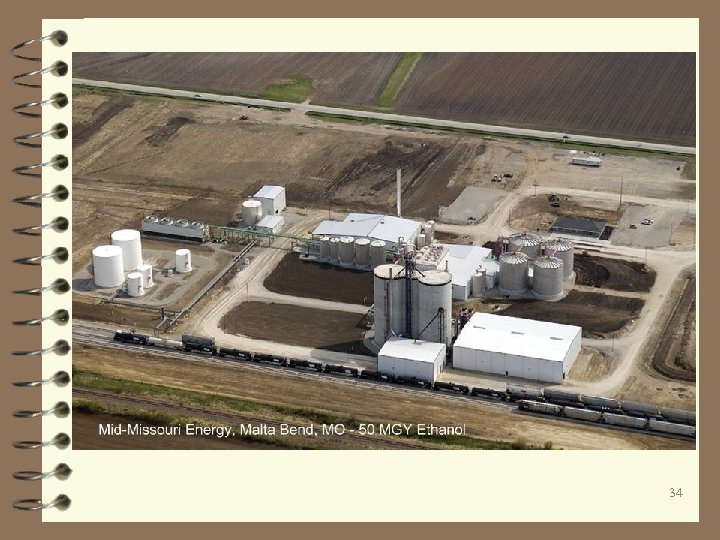

34

34

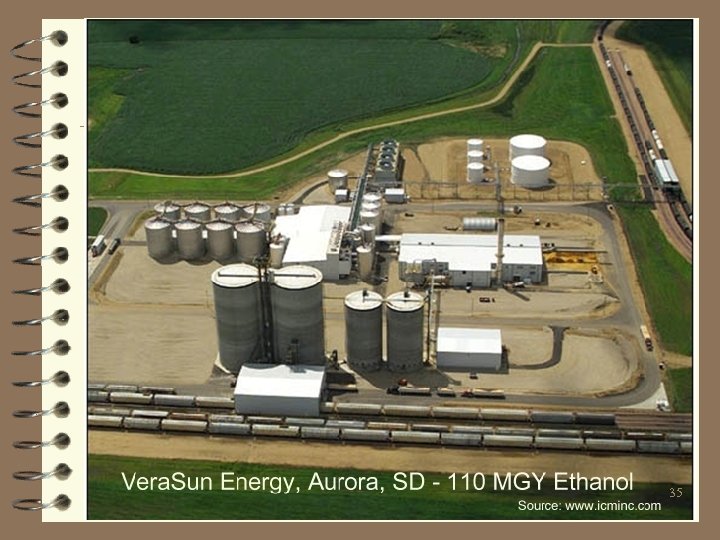

35

35

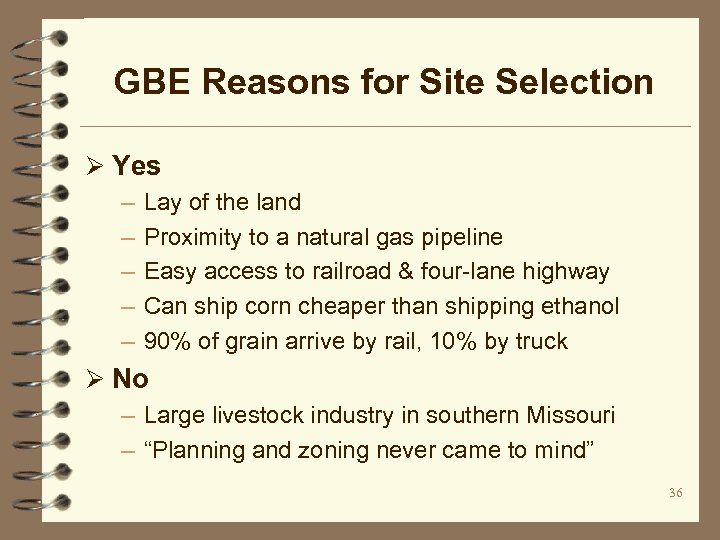

GBE Reasons for Site Selection Ø Yes – Lay of the land – Proximity to a natural gas pipeline – Easy access to railroad & four-lane highway – Can ship corn cheaper than shipping ethanol – 90% of grain arrive by rail, 10% by truck Ø No – Large livestock industry in southern Missouri – “Planning and zoning never came to mind” 36

GBE Reasons for Site Selection Ø Yes – Lay of the land – Proximity to a natural gas pipeline – Easy access to railroad & four-lane highway – Can ship corn cheaper than shipping ethanol – 90% of grain arrive by rail, 10% by truck Ø No – Large livestock industry in southern Missouri – “Planning and zoning never came to mind” 36

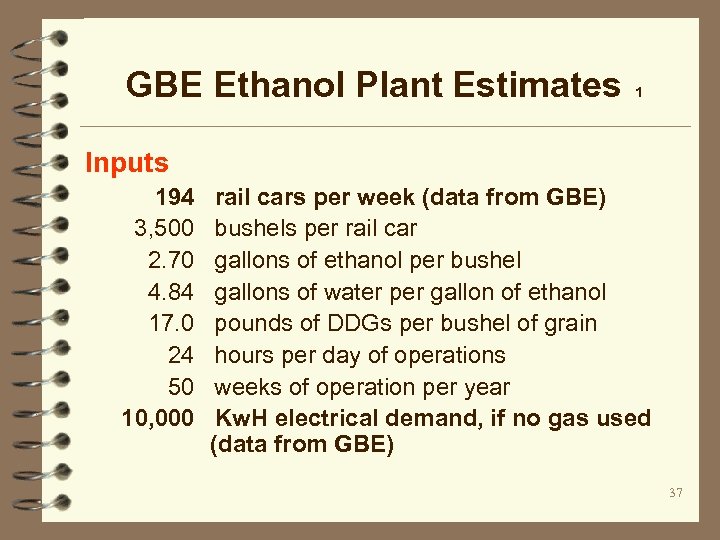

GBE Ethanol Plant Estimates 1 Inputs 194 3, 500 2. 70 4. 84 17. 0 24 50 10, 000 rail cars per week (data from GBE) bushels per rail car gallons of ethanol per bushel gallons of water per gallon of ethanol pounds of DDGs per bushel of grain hours per day of operations weeks of operation per year Kw. H electrical demand, if no gas used (data from GBE) 37

GBE Ethanol Plant Estimates 1 Inputs 194 3, 500 2. 70 4. 84 17. 0 24 50 10, 000 rail cars per week (data from GBE) bushels per rail car gallons of ethanol per bushel gallons of water per gallon of ethanol pounds of DDGs per bushel of grain hours per day of operations weeks of operation per year Kw. H electrical demand, if no gas used (data from GBE) 37

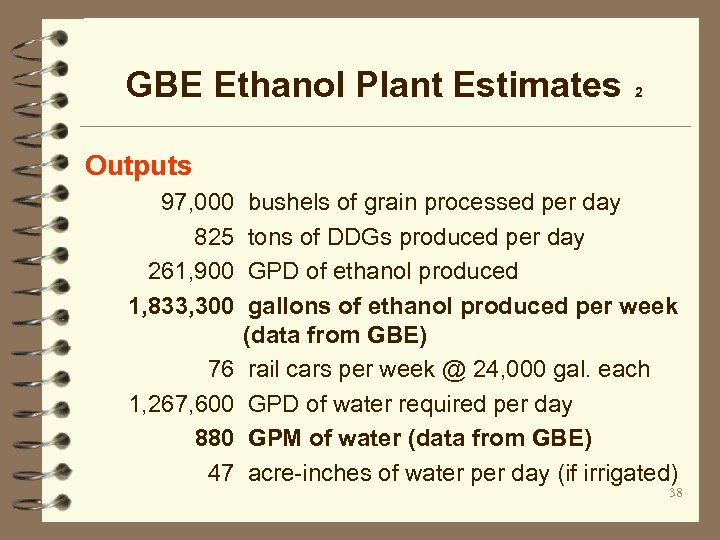

GBE Ethanol Plant Estimates 2 Outputs 97, 000 825 261, 900 1, 833, 300 76 1, 267, 600 880 47 bushels of grain processed per day tons of DDGs produced per day GPD of ethanol produced gallons of ethanol produced per week (data from GBE) rail cars per week @ 24, 000 gal. each GPD of water required per day GPM of water (data from GBE) acre-inches of water per day (if irrigated) 38

GBE Ethanol Plant Estimates 2 Outputs 97, 000 825 261, 900 1, 833, 300 76 1, 267, 600 880 47 bushels of grain processed per day tons of DDGs produced per day GPD of ethanol produced gallons of ethanol produced per week (data from GBE) rail cars per week @ 24, 000 gal. each GPD of water required per day GPM of water (data from GBE) acre-inches of water per day (if irrigated) 38

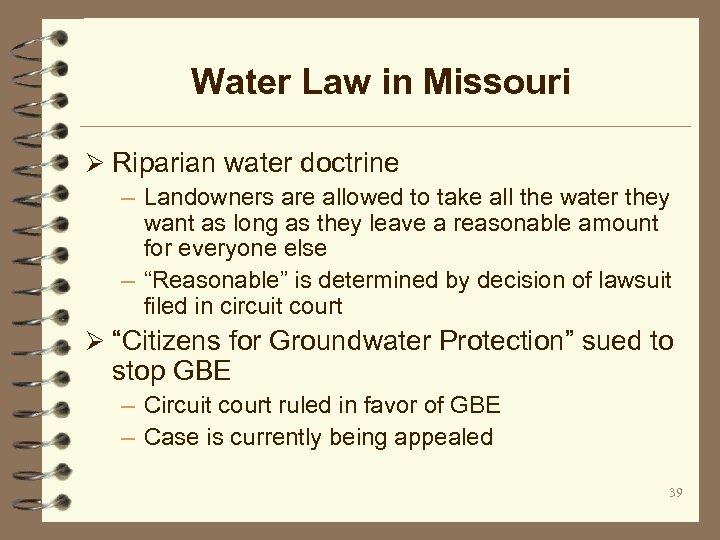

Water Law in Missouri Ø Riparian water doctrine – Landowners are allowed to take all the water they want as long as they leave a reasonable amount for everyone else – “Reasonable” is determined by decision of lawsuit filed in circuit court Ø “Citizens for Groundwater Protection” sued to stop GBE – Circuit court ruled in favor of GBE – Case is currently being appealed 39

Water Law in Missouri Ø Riparian water doctrine – Landowners are allowed to take all the water they want as long as they leave a reasonable amount for everyone else – “Reasonable” is determined by decision of lawsuit filed in circuit court Ø “Citizens for Groundwater Protection” sued to stop GBE – Circuit court ruled in favor of GBE – Case is currently being appealed 39

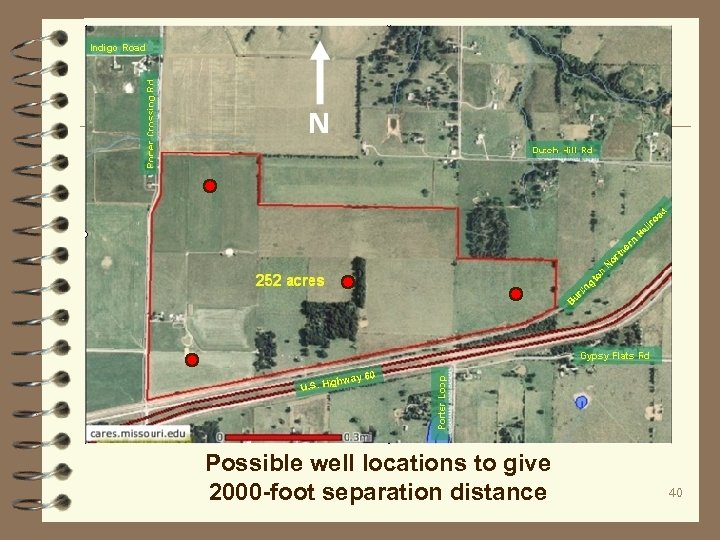

Possible well locations to give 2000 -foot separation distance 40

Possible well locations to give 2000 -foot separation distance 40

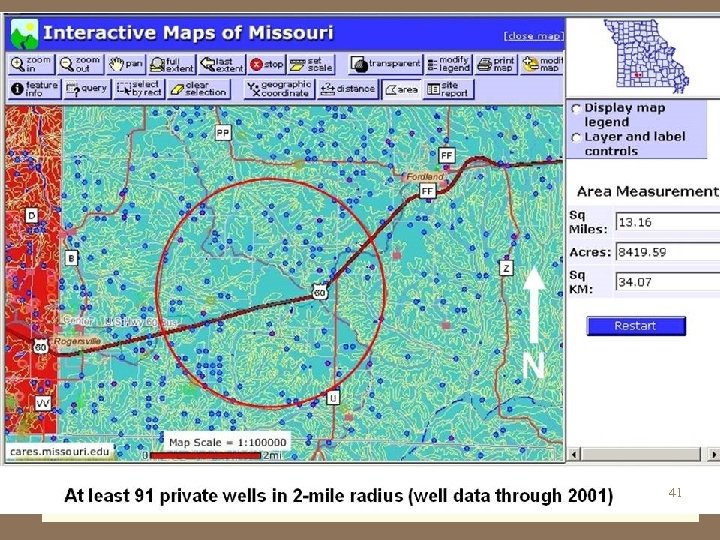

41

41

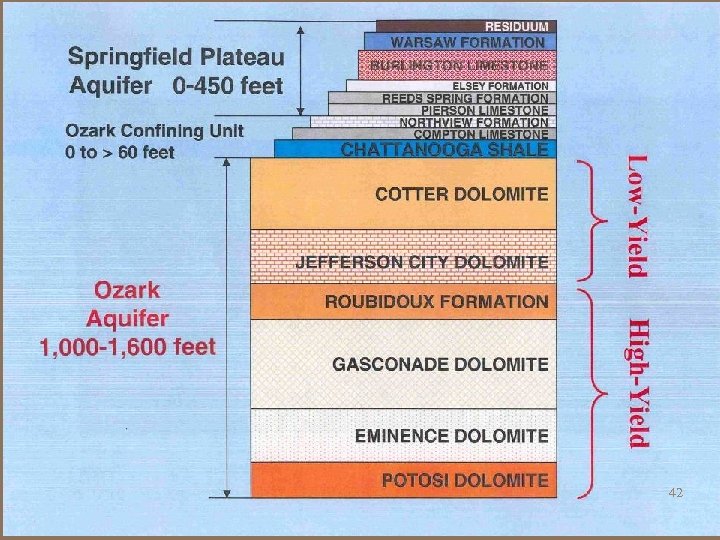

42

42

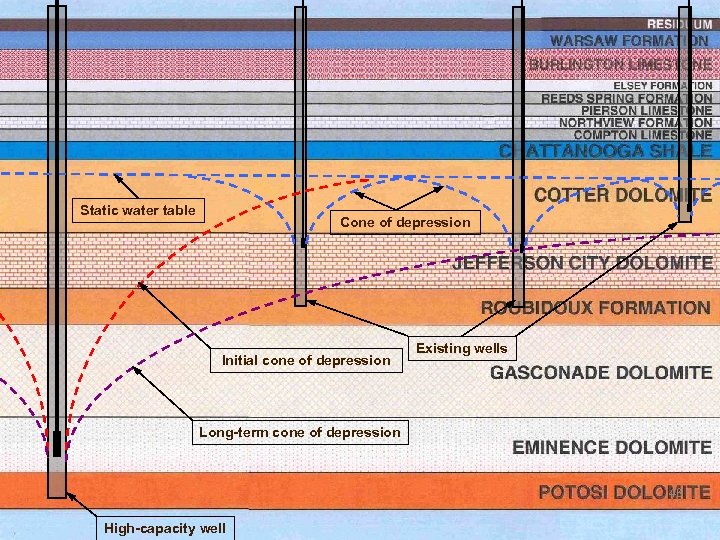

Static water table Cone of depression Initial cone of depression Existing wells Long-term cone of depression 43 High-capacity well

Static water table Cone of depression Initial cone of depression Existing wells Long-term cone of depression 43 High-capacity well

What Happens to Discharge Water? Ø Unclear from GBE how much water will be discharged Ø 880 GPM = 47 acre-inches per day Ø Soils will hold total of 3. 5 -5. 0 inches of water Ø Annual precipitation and evaporation are nearly equal Ø Rest must be discharged to drainage-ways or irrigated Ø How much will recycling concentrate the discharge water? What’s in it? 44

What Happens to Discharge Water? Ø Unclear from GBE how much water will be discharged Ø 880 GPM = 47 acre-inches per day Ø Soils will hold total of 3. 5 -5. 0 inches of water Ø Annual precipitation and evaporation are nearly equal Ø Rest must be discharged to drainage-ways or irrigated Ø How much will recycling concentrate the discharge water? What’s in it? 44

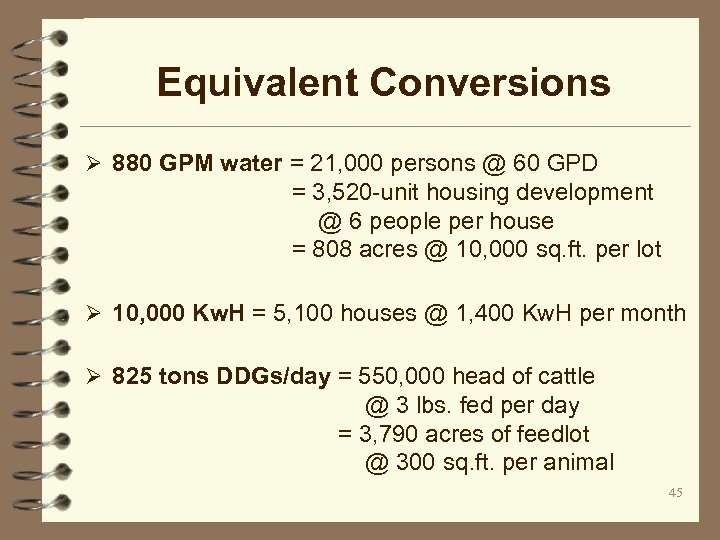

Equivalent Conversions Ø 880 GPM water = 21, 000 persons @ 60 GPD = 3, 520 -unit housing development @ 6 people per house = 808 acres @ 10, 000 sq. ft. per lot Ø 10, 000 Kw. H = 5, 100 houses @ 1, 400 Kw. H per month Ø 825 tons DDGs/day = 550, 000 head of cattle @ 3 lbs. fed per day = 3, 790 acres of feedlot @ 300 sq. ft. per animal 45

Equivalent Conversions Ø 880 GPM water = 21, 000 persons @ 60 GPD = 3, 520 -unit housing development @ 6 people per house = 808 acres @ 10, 000 sq. ft. per lot Ø 10, 000 Kw. H = 5, 100 houses @ 1, 400 Kw. H per month Ø 825 tons DDGs/day = 550, 000 head of cattle @ 3 lbs. fed per day = 3, 790 acres of feedlot @ 300 sq. ft. per animal 45

Other Considerations Ø Noise from hammermills & dryers Ø Light pollution Ø Odor Ø Air emissions – EPA rule change on 4/12/07 increased allowable levels from 100 tons/year to 250 tons/year) Ø Safety from explosion and fire Ø Traffic on Highway 60 and railroad 46

Other Considerations Ø Noise from hammermills & dryers Ø Light pollution Ø Odor Ø Air emissions – EPA rule change on 4/12/07 increased allowable levels from 100 tons/year to 250 tons/year) Ø Safety from explosion and fire Ø Traffic on Highway 60 and railroad 46

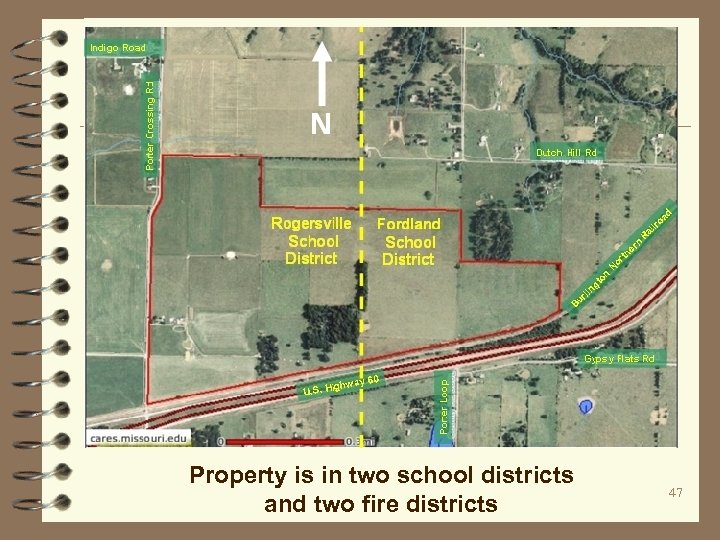

Property is in two school districts and two fire districts 47

Property is in two school districts and two fire districts 47

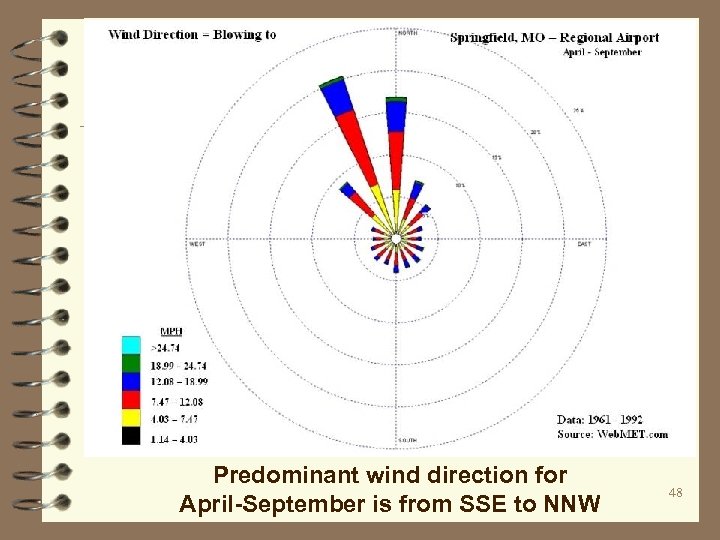

Predominant wind direction for April-September is from SSE to NNW 48

Predominant wind direction for April-September is from SSE to NNW 48

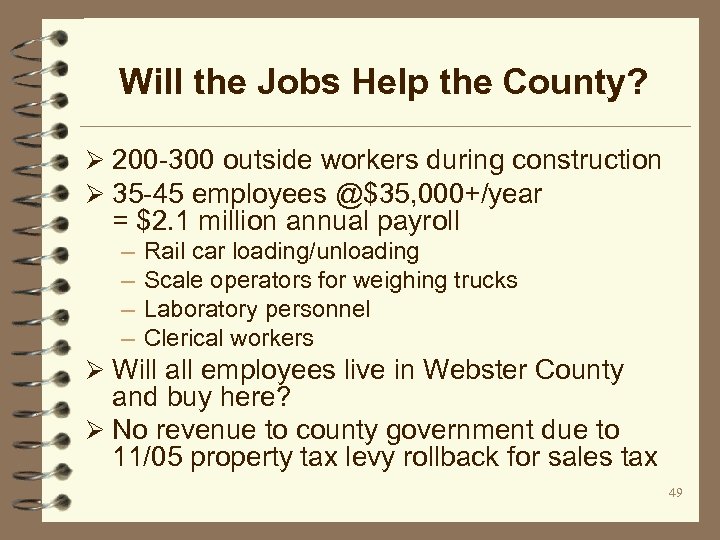

Will the Jobs Help the County? Ø 200 -300 outside workers during construction Ø 35 -45 employees @$35, 000+/year = $2. 1 million annual payroll – – Rail car loading/unloading Scale operators for weighing trucks Laboratory personnel Clerical workers Ø Will all employees live in Webster County and buy here? Ø No revenue to county government due to 11/05 property tax levy rollback for sales tax 49

Will the Jobs Help the County? Ø 200 -300 outside workers during construction Ø 35 -45 employees @$35, 000+/year = $2. 1 million annual payroll – – Rail car loading/unloading Scale operators for weighing trucks Laboratory personnel Clerical workers Ø Will all employees live in Webster County and buy here? Ø No revenue to county government due to 11/05 property tax levy rollback for sales tax 49

Summary – Big Picture Questions Ø Is ethanol from corn sustainable? Ø Does it reduce energy needs from foreign sources? Ø Would the site pass an environmental impact study? Ø Are natural resources available to support a plant without damaging others? Ø Can the plant be converted to cellulosic ethanol? 50

Summary – Big Picture Questions Ø Is ethanol from corn sustainable? Ø Does it reduce energy needs from foreign sources? Ø Would the site pass an environmental impact study? Ø Are natural resources available to support a plant without damaging others? Ø Can the plant be converted to cellulosic ethanol? 50

For More Information, Contact: Click on Ethanol Plant Development link at www. jrbp. missouristate. edu Paul Ipock Webster County Presiding Commissioner Courthouse, 1 st Floor Marshfield, MO 65706 417 -859 -4250 (Mondays or Tuesdays) 417 -859 -2223 (County Clerk) 51

For More Information, Contact: Click on Ethanol Plant Development link at www. jrbp. missouristate. edu Paul Ipock Webster County Presiding Commissioner Courthouse, 1 st Floor Marshfield, MO 65706 417 -859 -4250 (Mondays or Tuesdays) 417 -859 -2223 (County Clerk) 51

Questions? ? ? Robert A. (Bob) Schultheis Natural Resource Engineering Specialist Webster County Extension Center 800 S. Marshall St. Marshfield, MO 65706 Voice: 417 -859 -2044 Fax: 417 -468 -2086 E-mail: schultheisr@missouri. edu Web: extension. missouri. edu/webster 52

Questions? ? ? Robert A. (Bob) Schultheis Natural Resource Engineering Specialist Webster County Extension Center 800 S. Marshall St. Marshfield, MO 65706 Voice: 417 -859 -2044 Fax: 417 -468 -2086 E-mail: schultheisr@missouri. edu Web: extension. missouri. edu/webster 52