4c750b868a2ff03804eb2633ec52e155.ppt

- Количество слайдов: 16

Enhancement of Single Stretched Wire Measurements of LHC Short Straight Sections Guy Deferne, Nikolay Smirnov, CERN Joe Di. Marco, FNAL 14 th International Magnetic Measurement Workshop 26 -29 September 2005, Geneva, Switzerland 28. 09. 2005 IMMW 14

Enhancement of Single Stretched Wire Measurements of LHC Short Straight Sections Guy Deferne, Nikolay Smirnov, CERN Joe Di. Marco, FNAL 14 th International Magnetic Measurement Workshop 26 -29 September 2005, Geneva, Switzerland 28. 09. 2005 IMMW 14

Content q q q Introduction – The Single Stretched Wire (SSW) at CERN Part I - Roll Angle Offset Calibration § Introduction § Case of a centered magnet § Case of a non-centered magnet § Example of calibration Part II - Integrated Strength (Gdl) Measurements For more details, please see the presentation of N. Smirnov et al, « Focusing strength measurements of the main quadrupoles for the LHC » , submitted at the MT 19 Conference, 2005) § § § q Introduction Shape of the wire Gdl Measurement procedure Magnetic properties of the wire System performance Conclusion 28. 09. 2005 IMMW 14 2

Content q q q Introduction – The Single Stretched Wire (SSW) at CERN Part I - Roll Angle Offset Calibration § Introduction § Case of a centered magnet § Case of a non-centered magnet § Example of calibration Part II - Integrated Strength (Gdl) Measurements For more details, please see the presentation of N. Smirnov et al, « Focusing strength measurements of the main quadrupoles for the LHC » , submitted at the MT 19 Conference, 2005) § § § q Introduction Shape of the wire Gdl Measurement procedure Magnetic properties of the wire System performance Conclusion 28. 09. 2005 IMMW 14 2

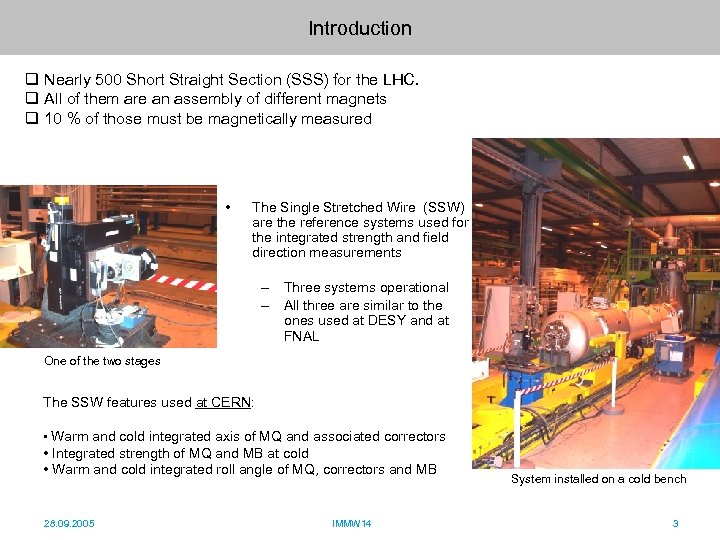

Introduction q Nearly 500 Short Straight Section (SSS) for the LHC. q All of them are an assembly of different magnets q 10 % of those must be magnetically measured • The Single Stretched Wire (SSW) are the reference systems used for the integrated strength and field direction measurements – Three systems operational – All three are similar to the ones used at DESY and at FNAL One of the two stages The SSW features used at CERN: • Warm and cold integrated axis of MQ and associated correctors • Integrated strength of MQ and MB at cold • Warm and cold integrated roll angle of MQ, correctors and MB 28. 09. 2005 IMMW 14 System installed on a cold bench 3

Introduction q Nearly 500 Short Straight Section (SSS) for the LHC. q All of them are an assembly of different magnets q 10 % of those must be magnetically measured • The Single Stretched Wire (SSW) are the reference systems used for the integrated strength and field direction measurements – Three systems operational – All three are similar to the ones used at DESY and at FNAL One of the two stages The SSW features used at CERN: • Warm and cold integrated axis of MQ and associated correctors • Integrated strength of MQ and MB at cold • Warm and cold integrated roll angle of MQ, correctors and MB 28. 09. 2005 IMMW 14 System installed on a cold bench 3

Roll angle offset calibration (1) Introduction Part I – Roll angle offset calibration q The field direction is one of the essential parameters of the measurement campaign q The SSW systems must be periodically calibrated in sense of roll angle in order to perform fast measurements that fulfill the requirements Two different type of calibration can be used, depending if the measured magnet is centered or not in between the stages 28. 09. 2005 IMMW 14 4

Roll angle offset calibration (1) Introduction Part I – Roll angle offset calibration q The field direction is one of the essential parameters of the measurement campaign q The SSW systems must be periodically calibrated in sense of roll angle in order to perform fast measurements that fulfill the requirements Two different type of calibration can be used, depending if the measured magnet is centered or not in between the stages 28. 09. 2005 IMMW 14 4

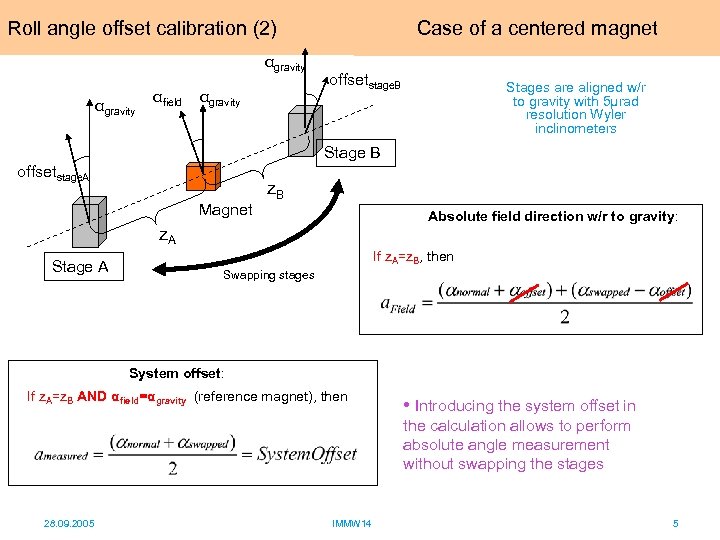

Roll angle offset calibration (2) αgravity αfield αgravity Case of a centered magnet offsetstage. B Stages are aligned w/r to gravity with 5µrad resolution Wyler inclinometers Stage B offsetstage. A Magnet z. B Absolute field direction w/r to gravity: z. A Stage A If z. A=z. B, then Swapping stages System offset: If z. A=z. B AND αfield=αgravity (reference magnet), then • Introducing the system offset in the calculation allows to perform absolute angle measurement without swapping the stages 28. 09. 2005 IMMW 14 5

Roll angle offset calibration (2) αgravity αfield αgravity Case of a centered magnet offsetstage. B Stages are aligned w/r to gravity with 5µrad resolution Wyler inclinometers Stage B offsetstage. A Magnet z. B Absolute field direction w/r to gravity: z. A Stage A If z. A=z. B, then Swapping stages System offset: If z. A=z. B AND αfield=αgravity (reference magnet), then • Introducing the system offset in the calculation allows to perform absolute angle measurement without swapping the stages 28. 09. 2005 IMMW 14 5

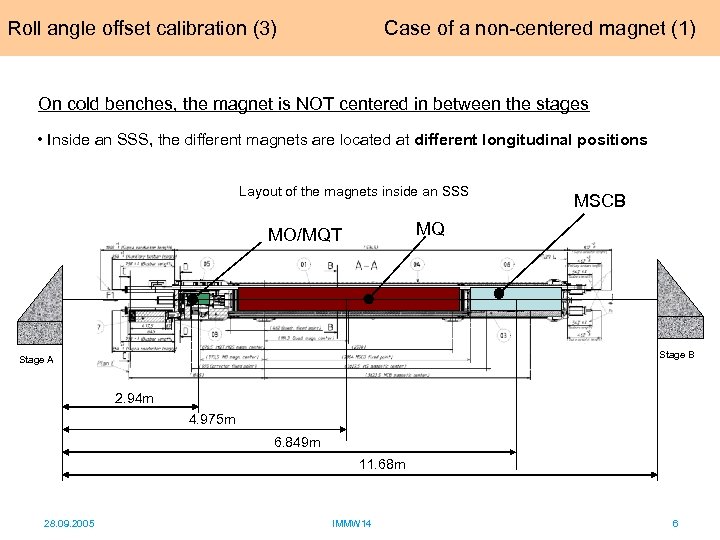

Roll angle offset calibration (3) Case of a non-centered magnet (1) On cold benches, the magnet is NOT centered in between the stages • Inside an SSS, the different magnets are located at different longitudinal positions Layout of the magnets inside an SSS MSCB MQ MO/MQT Stage B Stage A 2. 94 m 4. 975 m 6. 849 m 11. 68 m 28. 09. 2005 IMMW 14 6

Roll angle offset calibration (3) Case of a non-centered magnet (1) On cold benches, the magnet is NOT centered in between the stages • Inside an SSS, the different magnets are located at different longitudinal positions Layout of the magnets inside an SSS MSCB MQ MO/MQT Stage B Stage A 2. 94 m 4. 975 m 6. 849 m 11. 68 m 28. 09. 2005 IMMW 14 6

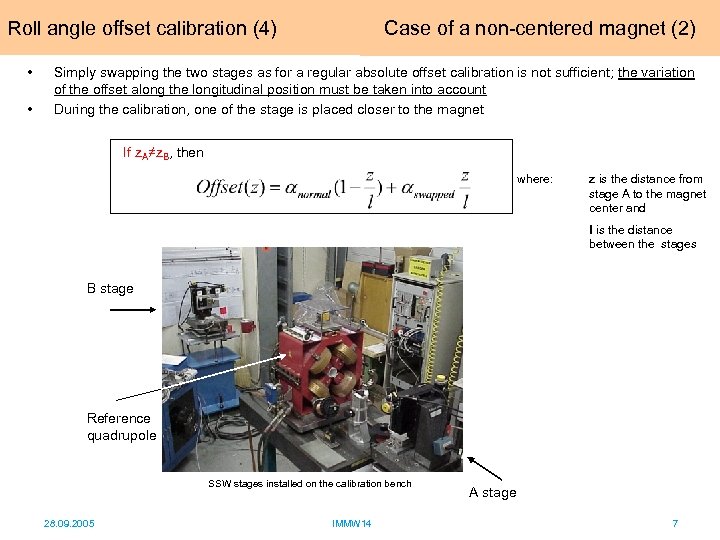

Roll angle offset calibration (4) • • Case of a non-centered magnet (2) Simply swapping the two stages as for a regular absolute offset calibration is not sufficient; the variation of the offset along the longitudinal position must be taken into account During the calibration, one of the stage is placed closer to the magnet If z. A≠z. B, then where: z is the distance from stage A to the magnet center and l is the distance between the stages B stage Reference quadrupole SSW stages installed on the calibration bench 28. 09. 2005 IMMW 14 A stage 7

Roll angle offset calibration (4) • • Case of a non-centered magnet (2) Simply swapping the two stages as for a regular absolute offset calibration is not sufficient; the variation of the offset along the longitudinal position must be taken into account During the calibration, one of the stage is placed closer to the magnet If z. A≠z. B, then where: z is the distance from stage A to the magnet center and l is the distance between the stages B stage Reference quadrupole SSW stages installed on the calibration bench 28. 09. 2005 IMMW 14 A stage 7

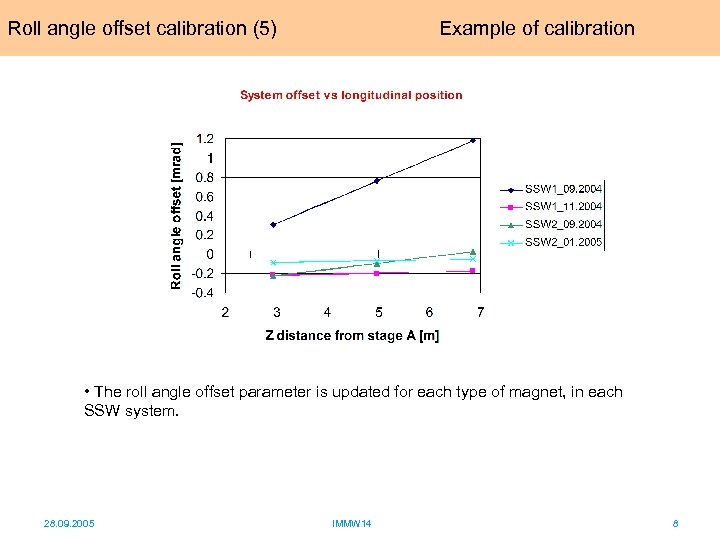

Roll angle offset calibration (5) Example of calibration • The roll angle offset parameter is updated for each type of magnet, in each SSW system. 28. 09. 2005 IMMW 14 8

Roll angle offset calibration (5) Example of calibration • The roll angle offset parameter is updated for each type of magnet, in each SSW system. 28. 09. 2005 IMMW 14 8

Integrated Strength (Gdl) (1) Introduction Part II – Integrated Strength (Gdl) measurement • • A second essential parameter of the measurement campaign is the integrated gradient (Gdl) of quadrupoles This is one of the most challenging magnetic parameters of the LHC magnets – Required absolute error (Magnetic measurement): – Required repeatability (Magnetic measurement): • 5 <5 [units] For the Stretched Wire Systems, this means an error on the wire positioning less than 2. 5µm over 12 m! Only a proper method and good properties of the wire can give results inside specifications 28. 09. 2005 IMMW 14 9

Integrated Strength (Gdl) (1) Introduction Part II – Integrated Strength (Gdl) measurement • • A second essential parameter of the measurement campaign is the integrated gradient (Gdl) of quadrupoles This is one of the most challenging magnetic parameters of the LHC magnets – Required absolute error (Magnetic measurement): – Required repeatability (Magnetic measurement): • 5 <5 [units] For the Stretched Wire Systems, this means an error on the wire positioning less than 2. 5µm over 12 m! Only a proper method and good properties of the wire can give results inside specifications 28. 09. 2005 IMMW 14 9

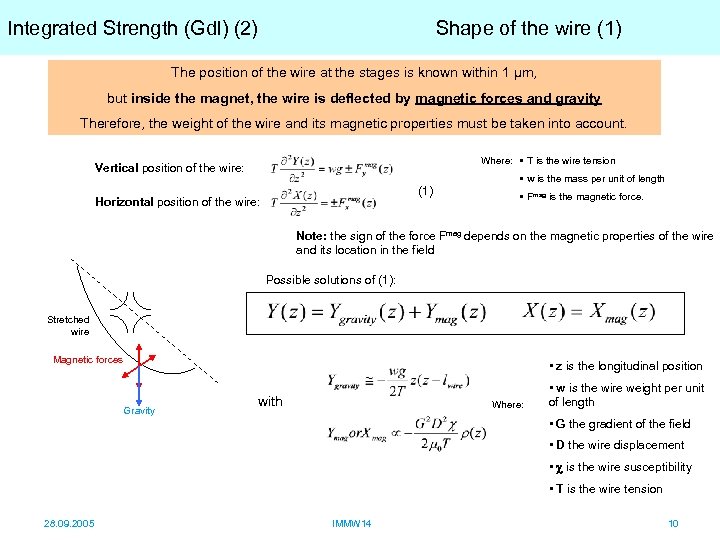

Integrated Strength (Gdl) (2) Shape of the wire (1) The position of the wire at the stages is known within 1 µm, but inside the magnet, the wire is deflected by magnetic forces and gravity Therefore, the weight of the wire and its magnetic properties must be taken into account. Where: • T is the wire tension Vertical position of the wire: (1) Horizontal position of the wire: • w is the mass per unit of length • Fmag is the magnetic force. Note: the sign of the force Fmag depends on the magnetic properties of the wire and its location in the field Possible solutions of (1): Stretched wire Magnetic forces • z is the longitudinal position Gravity with Where: • w is the wire weight per unit of length • G the gradient of the field • D the wire displacement • is the wire susceptibility • T is the wire tension 28. 09. 2005 IMMW 14 10

Integrated Strength (Gdl) (2) Shape of the wire (1) The position of the wire at the stages is known within 1 µm, but inside the magnet, the wire is deflected by magnetic forces and gravity Therefore, the weight of the wire and its magnetic properties must be taken into account. Where: • T is the wire tension Vertical position of the wire: (1) Horizontal position of the wire: • w is the mass per unit of length • Fmag is the magnetic force. Note: the sign of the force Fmag depends on the magnetic properties of the wire and its location in the field Possible solutions of (1): Stretched wire Magnetic forces • z is the longitudinal position Gravity with Where: • w is the wire weight per unit of length • G the gradient of the field • D the wire displacement • is the wire susceptibility • T is the wire tension 28. 09. 2005 IMMW 14 10

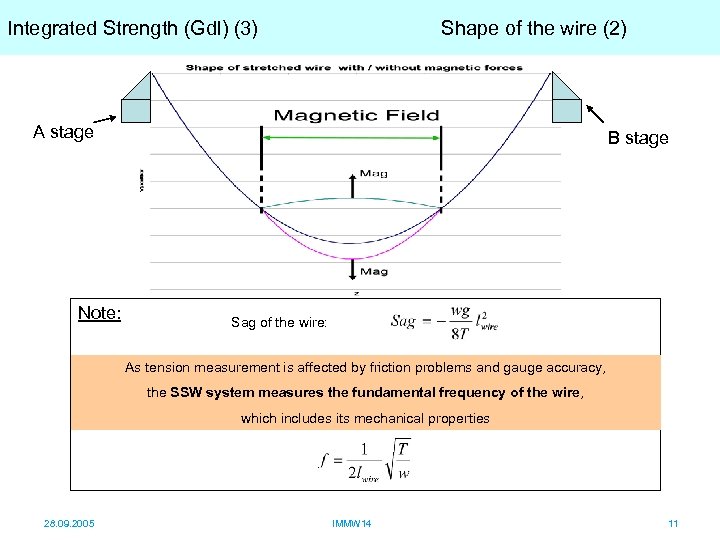

Integrated Strength (Gdl) (3) Shape of the wire (2) A stage Note: B stage Sag of the wire: As tension measurement is affected by friction problems and gauge accuracy, the SSW system measures the fundamental frequency of the wire, which includes its mechanical properties 28. 09. 2005 IMMW 14 11

Integrated Strength (Gdl) (3) Shape of the wire (2) A stage Note: B stage Sag of the wire: As tension measurement is affected by friction problems and gauge accuracy, the SSW system measures the fundamental frequency of the wire, which includes its mechanical properties 28. 09. 2005 IMMW 14 11

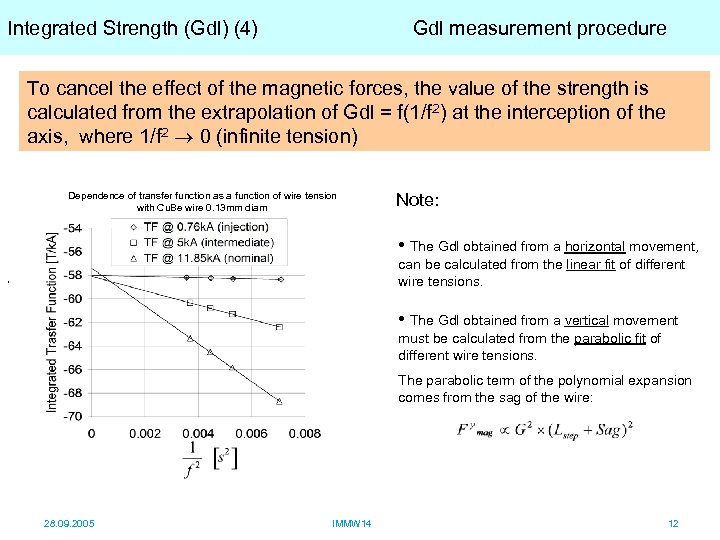

Integrated Strength (Gdl) (4) Gdl measurement procedure To cancel the effect of the magnetic forces, the value of the strength is calculated from the extrapolation of Gdl = f(1/f 2) at the interception of the axis, where 1/f 2 0 (infinite tension) Dependence of transfer function as a function of wire tension with Cu. Be wire 0. 13 mm diam Note: • The Gdl obtained from a horizontal movement, can be calculated from the linear fit of different wire tensions. , • The Gdl obtained from a vertical movement must be calculated from the parabolic fit of different wire tensions. The parabolic term of the polynomial expansion comes from the sag of the wire: 28. 09. 2005 IMMW 14 12

Integrated Strength (Gdl) (4) Gdl measurement procedure To cancel the effect of the magnetic forces, the value of the strength is calculated from the extrapolation of Gdl = f(1/f 2) at the interception of the axis, where 1/f 2 0 (infinite tension) Dependence of transfer function as a function of wire tension with Cu. Be wire 0. 13 mm diam Note: • The Gdl obtained from a horizontal movement, can be calculated from the linear fit of different wire tensions. , • The Gdl obtained from a vertical movement must be calculated from the parabolic fit of different wire tensions. The parabolic term of the polynomial expansion comes from the sag of the wire: 28. 09. 2005 IMMW 14 12

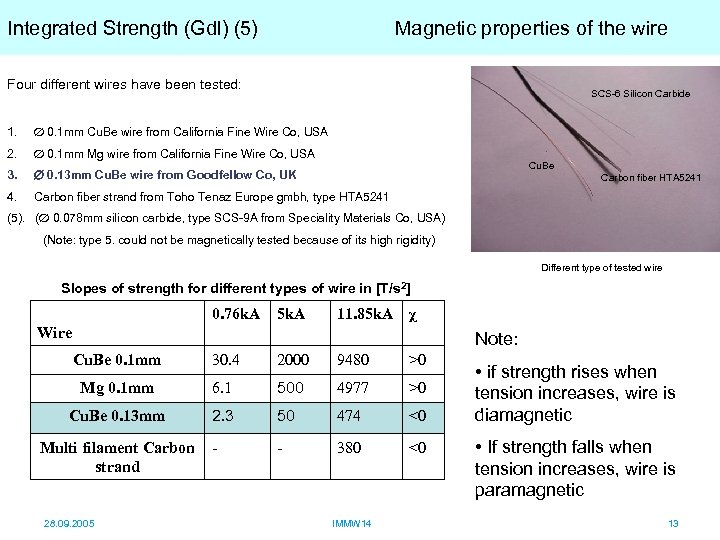

Integrated Strength (Gdl) (5) Magnetic properties of the wire Four different wires have been tested: SCS-6 Silicon Carbide 1. 0. 1 mm Cu. Be wire from California Fine Wire Co, USA 2. 0. 1 mm Mg wire from California Fine Wire Co, USA 3. 0. 13 mm Cu. Be wire from Goodfellow Co, UK 4. Carbon fiber strand from Toho Tenaz Europe gmbh, type HTA 5241 Cu. Be Carbon fiber HTA 5241 (5). ( 0. 078 mm silicon carbide, type SCS-9 A from Speciality Materials Co, USA) (Note: type 5. could not be magnetically tested because of its high rigidity) Different type of tested wire Slopes of strength for different types of wire in [T/s 2] 0. 76 k. A 5 k. A 11. 85 k. A χ Wire Note: Cu. Be 0. 1 mm 30. 4 2000 9480 >0 Mg 0. 1 mm 6. 1 500 4977 >0 Cu. Be 0. 13 mm 2. 3 50 474 <0 - - 380 <0 Multi filament Carbon strand 28. 09. 2005 IMMW 14 • if strength rises when tension increases, wire is diamagnetic • If strength falls when tension increases, wire is paramagnetic 13

Integrated Strength (Gdl) (5) Magnetic properties of the wire Four different wires have been tested: SCS-6 Silicon Carbide 1. 0. 1 mm Cu. Be wire from California Fine Wire Co, USA 2. 0. 1 mm Mg wire from California Fine Wire Co, USA 3. 0. 13 mm Cu. Be wire from Goodfellow Co, UK 4. Carbon fiber strand from Toho Tenaz Europe gmbh, type HTA 5241 Cu. Be Carbon fiber HTA 5241 (5). ( 0. 078 mm silicon carbide, type SCS-9 A from Speciality Materials Co, USA) (Note: type 5. could not be magnetically tested because of its high rigidity) Different type of tested wire Slopes of strength for different types of wire in [T/s 2] 0. 76 k. A 5 k. A 11. 85 k. A χ Wire Note: Cu. Be 0. 1 mm 30. 4 2000 9480 >0 Mg 0. 1 mm 6. 1 500 4977 >0 Cu. Be 0. 13 mm 2. 3 50 474 <0 - - 380 <0 Multi filament Carbon strand 28. 09. 2005 IMMW 14 • if strength rises when tension increases, wire is diamagnetic • If strength falls when tension increases, wire is paramagnetic 13

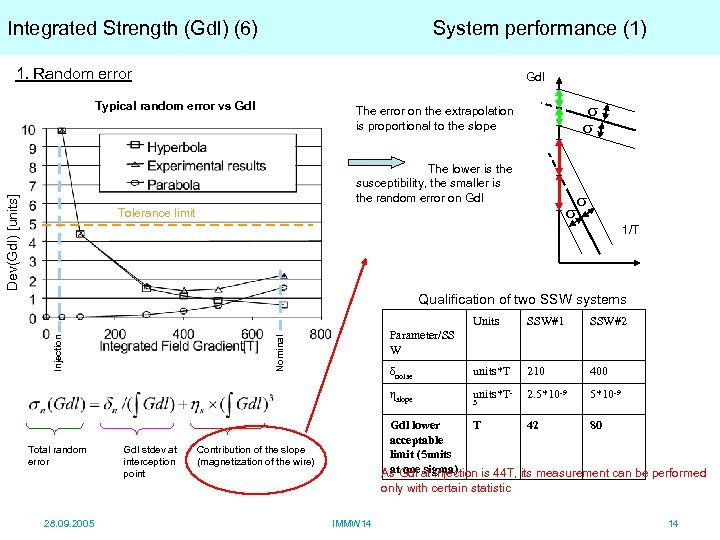

Integrated Strength (Gdl) (6) System performance (1) 1. Random error Gdl Typical random error vs Gdl The error on the extrapolation is proportional to the slope Dev(Gdl) [units] The lower is the susceptibility, the smaller is the random error on Gdl Tolerance limit 1/T Qualification of two SSW systems Total random error SSW#2 δnoise Nominal Gdl stdev at interception point SSW#1 units*T 210 400 ηslope Injection Units units*T- 2. 5*10 -9 Parameter/SS W 3 Gdl lower T 42 80 acceptable limit (5 units at one sigma) As Gdl at injection is 44 T, its measurement can be performed Contribution of the slope (magnetization of the wire) only with certain statistic 28. 09. 2005 IMMW 14 14

Integrated Strength (Gdl) (6) System performance (1) 1. Random error Gdl Typical random error vs Gdl The error on the extrapolation is proportional to the slope Dev(Gdl) [units] The lower is the susceptibility, the smaller is the random error on Gdl Tolerance limit 1/T Qualification of two SSW systems Total random error SSW#2 δnoise Nominal Gdl stdev at interception point SSW#1 units*T 210 400 ηslope Injection Units units*T- 2. 5*10 -9 Parameter/SS W 3 Gdl lower T 42 80 acceptable limit (5 units at one sigma) As Gdl at injection is 44 T, its measurement can be performed Contribution of the slope (magnetization of the wire) only with certain statistic 28. 09. 2005 IMMW 14 14

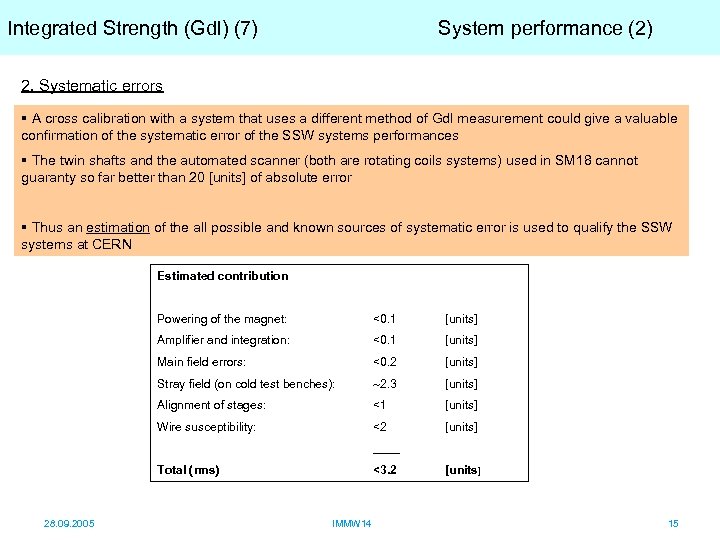

Integrated Strength (Gdl) (7) System performance (2) 2. Systematic errors § A cross calibration with a system that uses a different method of Gdl measurement could give a valuable confirmation of the systematic error of the SSW systems performances § The twin shafts and the automated scanner (both are rotating coils systems) used in SM 18 cannot guaranty so far better than 20 [units] of absolute error § Thus an estimation of the all possible and known sources of systematic error is used to qualify the SSW systems at CERN Estimated contribution Powering of the magnet: <0. 1 [units] Amplifier and integration: <0. 1 [units] Main field errors: <0. 2 [units] Stray field (on cold test benches): 2. 3 [units] Alignment of stages: <1 [units] Wire susceptibility: <2 [units] ____ Total (rms) 28. 09. 2005 <3. 2 IMMW 14 [units] 15

Integrated Strength (Gdl) (7) System performance (2) 2. Systematic errors § A cross calibration with a system that uses a different method of Gdl measurement could give a valuable confirmation of the systematic error of the SSW systems performances § The twin shafts and the automated scanner (both are rotating coils systems) used in SM 18 cannot guaranty so far better than 20 [units] of absolute error § Thus an estimation of the all possible and known sources of systematic error is used to qualify the SSW systems at CERN Estimated contribution Powering of the magnet: <0. 1 [units] Amplifier and integration: <0. 1 [units] Main field errors: <0. 2 [units] Stray field (on cold test benches): 2. 3 [units] Alignment of stages: <1 [units] Wire susceptibility: <2 [units] ____ Total (rms) 28. 09. 2005 <3. 2 IMMW 14 [units] 15

Conclusion Roll Angle Calibration • A procedure has been developed to calibrate the roll angle offset of the Single Stretched Wire systems as a function of the magnet longitudinal position. • This allows to measure the field angle w/r to gravity of the main quadrupoles and correctors magnets installed in an Short Straight Section without any swapping of the system stages. Integrated Strength • A special method has been developed to measure the integrated strength (Gdl) of the LHC MQ with an accuracy within the specification (even though a statistical study is required at injection field) • Gdl measurements: Absolute 5 est. <3. 2 Error specifications: Error obtained: [units] Random 5 <5 [units] • Different wires have been tested for their magnetic and mechanical properties and one type, the 0. 13 mm diam. Cu. Be from Goodfellow Ltd, has been chosen for the LHC measurements • As we have shown that not any wire can be used for Gdl measurements, the search for wires with a lower susceptibility will continue 28. 09. 2005 IMMW 14 16

Conclusion Roll Angle Calibration • A procedure has been developed to calibrate the roll angle offset of the Single Stretched Wire systems as a function of the magnet longitudinal position. • This allows to measure the field angle w/r to gravity of the main quadrupoles and correctors magnets installed in an Short Straight Section without any swapping of the system stages. Integrated Strength • A special method has been developed to measure the integrated strength (Gdl) of the LHC MQ with an accuracy within the specification (even though a statistical study is required at injection field) • Gdl measurements: Absolute 5 est. <3. 2 Error specifications: Error obtained: [units] Random 5 <5 [units] • Different wires have been tested for their magnetic and mechanical properties and one type, the 0. 13 mm diam. Cu. Be from Goodfellow Ltd, has been chosen for the LHC measurements • As we have shown that not any wire can be used for Gdl measurements, the search for wires with a lower susceptibility will continue 28. 09. 2005 IMMW 14 16