0e97e326c96d3025df4d1fc71d6ac0d1.ppt

- Количество слайдов: 37

Enhanced Rate Chemical Processing Using Non-equilibrium Reactions Controlled with High Speed Gas Analysis IFPAC 2004 Presentation January 14, 2004 Ronald R. Rich, President Atmosphere Recovery, Inc. 15800 32 nd Avenue North, Suite 110 Plymouth, MN 55447 Ph: (763) 557 -8675 Fax: (763) 557 -8668 Web: www. atmrcv. com E-mail: rrr@atmrcv. com 1

Company Background ® Founded 1994 - Dana Corporation & DOE R&D ® Heat Treating Furnace Processes ® Grant & Contract Funding ® 1995 -1998 - Process Gas Recycling System Development ® 1997 -2000 - Laser Raman Gas Analyzer & Gas Processing Development ® 2000 -2001 – Analyzer/Controller Field Trials ® 2002 - – Furnace Analyzer Offerings ® 2003 - – Bio-Pharma Analyzer Offerings 2

Manufacturing Process Goals – General ® Lower Production Costs ® Higher Productivity and Yields ® Improved Quality ® Capital Avoidance ® Reduced Feedstock & Energy Use ® Other Factors ® New Processes & Materials ® Lower Analyzer Cost of Operation ® Reduced Process Air Emissions ® 12 Month Payback (Max. )

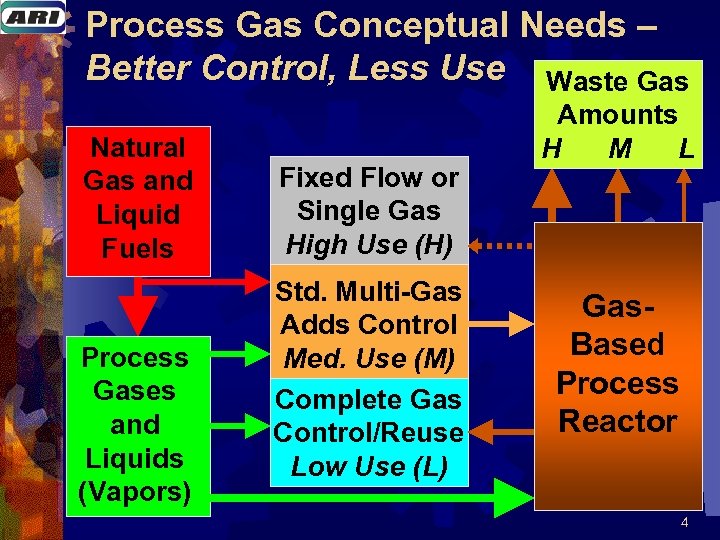

Process Gas Conceptual Needs – Better Control, Less Use Waste Gas Natural Gas and Liquid Fuels Process Gases and Liquids (Vapors) Fixed Flow or Single Gas High Use (H) Std. Multi-Gas Adds Control Med. Use (M) Complete Gas Control/Reuse Low Use (L) Amounts H M L Gas. Based Process Reactor 4

Metal Processing Atmospheres – Similar Constituents ® Carburizing, Carbonitriding, FNC & Nitriding ® N 2, CO, H 2, CO 2, H 2 O, CH 4, O 2, NH 3, CH 3 OH ® Atmosphere Tempering and Annealing ® N 2, H 2, CO 2, H 2 O, CH 4, O 2, NH 3, Ar ® Steel, Copper and Aluminum Brazing ® N 2, H 2, CO 2, H 2 O, CH 4, O 2, NH 3, Ar ® Powdered Metal Sintering and Annealing ® H 2, N 2, CO 2, H 2 O, CH 4, O 2, NH 3, H 2 S 5

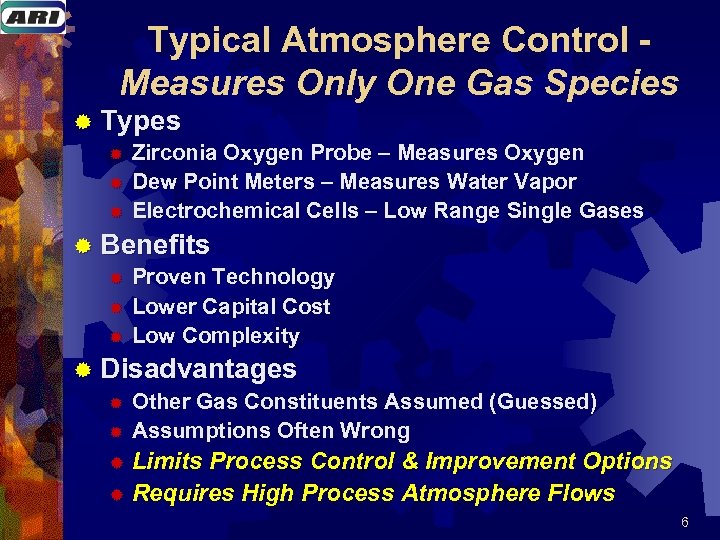

Typical Atmosphere Control - Measures Only One Gas Species ® Types ® Zirconia Oxygen Probe – Measures Oxygen ® Dew Point Meters – Measures Water Vapor ® Electrochemical Cells – Low Range Single Gases ® Benefits ® Proven Technology ® Lower Capital Cost ® Low Complexity ® Disadvantages ® Other Gas Constituents Assumed (Guessed) ® Assumptions Often Wrong ® Limits Process Control & Improvement Options ® Requires High Process Atmosphere Flows 6

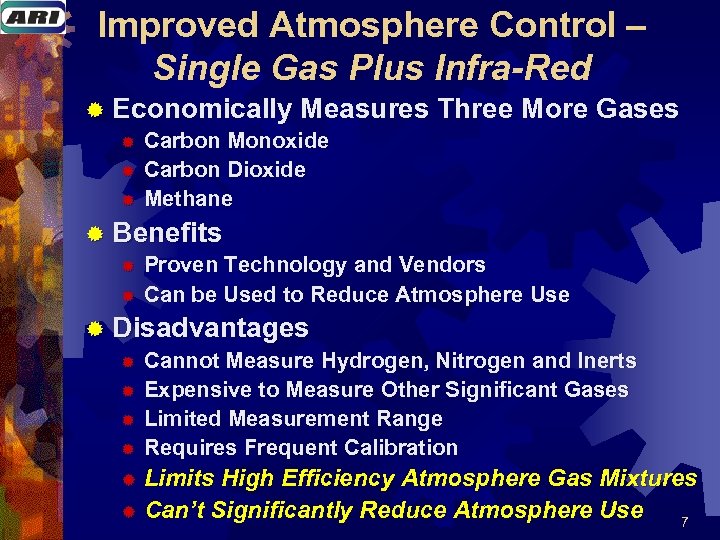

Improved Atmosphere Control – Single Gas Plus Infra-Red ® Economically Measures Three More Gases ® Carbon Monoxide ® Carbon Dioxide ® Methane ® Benefits ® Proven Technology and Vendors ® Can be Used to Reduce Atmosphere Use ® Disadvantages ® Cannot Measure Hydrogen, Nitrogen and Inerts ® Expensive to Measure Other Significant Gases ® Limited Measurement Range ® Requires Frequent Calibration ® Limits High Efficiency Atmosphere Gas Mixtures ® Can’t Significantly Reduce Atmosphere Use 7

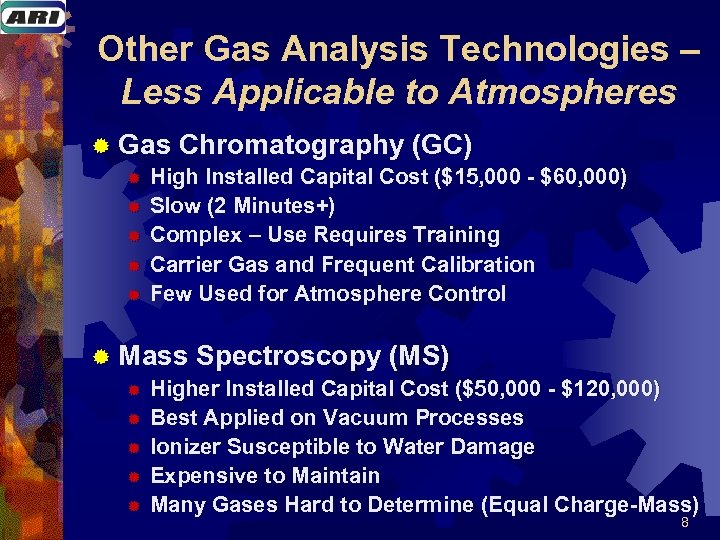

Other Gas Analysis Technologies – Less Applicable to Atmospheres ® Gas Chromatography (GC) ® High Installed Capital Cost ($15, 000 - $60, 000) ® Slow (2 Minutes+) ® Complex – Use Requires Training ® Carrier Gas and Frequent Calibration ® Few Used for Atmosphere Control ® Mass Spectroscopy (MS) ® Higher Installed Capital Cost ($50, 000 - $120, 000) ® Best Applied on Vacuum Processes ® Ionizer Susceptible to Water Damage ® Expensive to Maintain ® Many Gases Hard to Determine (Equal Charge-Mass) 8

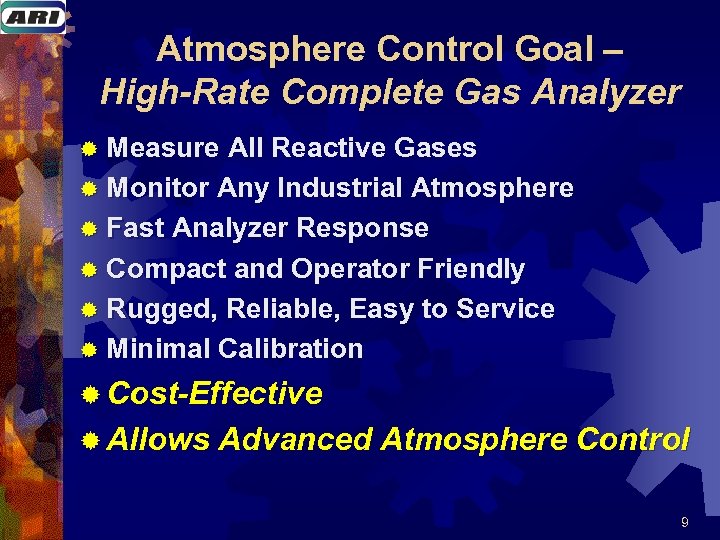

Atmosphere Control Goal – High-Rate Complete Gas Analyzer ® Measure All Reactive Gases ® Monitor Any Industrial Atmosphere ® Fast Analyzer Response ® Compact and Operator Friendly ® Rugged, Reliable, Easy to Service ® Minimal Calibration ® Cost-Effective ® Allows Advanced Atmosphere Control 9

Laser Raman Gas Spectroscopy - Features ® ® ® ® Unique Frequency “Shift” for Each Chemical Bond Little Interference Between Most Gases Measures Gases of All Types (Except Inerts) Rapid “Real Time” Response Rates Possible Signal Directly Proportional to Number of Gas Atoms PPM-100% Gas Concentrations with One Detector Resolution and Accuracy Depends On: ® ® ® Laser Power and Optics Variation Gas Concentration and Pressure Molecular Bond Type Background and Scattered Radiation Optical and Electronic Detector Circuitry 10

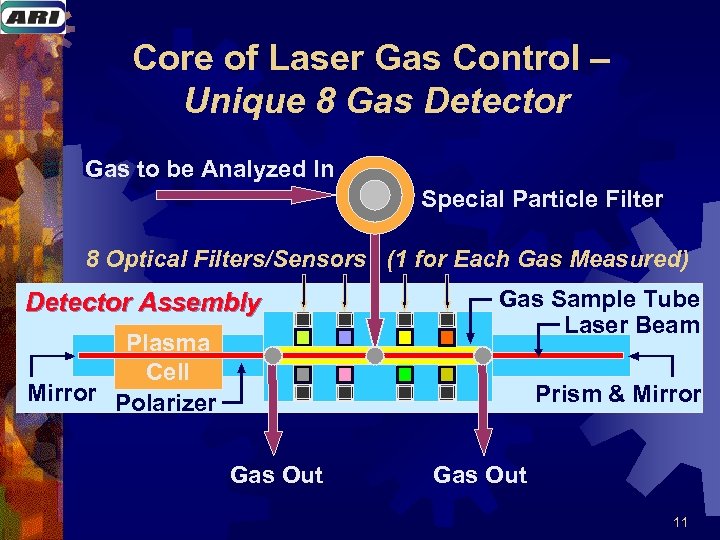

Core of Laser Gas Control – Unique 8 Gas Detector Gas to be Analyzed In Special Particle Filter 8 Optical Filters/Sensors (1 for Each Gas Measured) Detector Assembly Plasma Cell Mirror Polarizer Gas Sample Tube Laser Beam Prism & Mirror Gas Out 11

Laser Gas Detector Module – Features Low Power Laser Insures Safety ® Sample Gas Flows Analyzed Inside Instrument for Higher Inherent Accuracy ® ® Discrete Optical Filtering and Quantifying ® 8 Gases Detected – Can be Process Specific ® Simultaneous Detection of Each Gas Species ® Fast Detector Response (50 milliseconds) ® Array Based Interference Computations ® Most Cost-Effective Approach 12

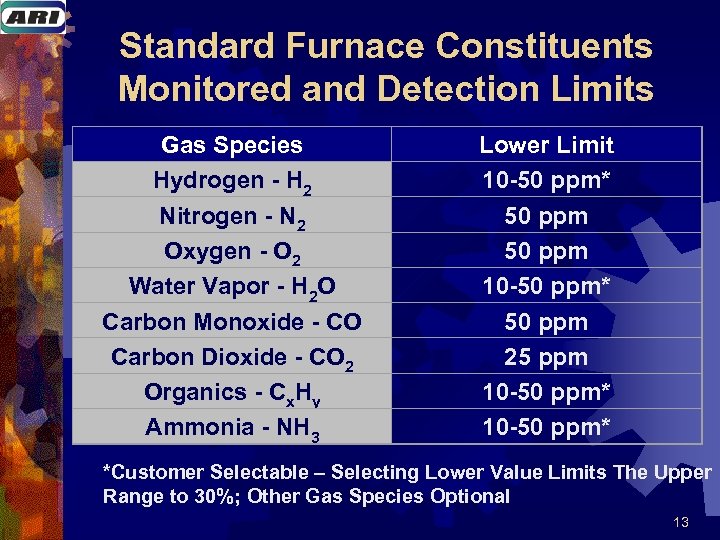

Standard Furnace Constituents Monitored and Detection Limits Gas Species Hydrogen - H 2 Nitrogen - N 2 Oxygen - O 2 Water Vapor - H 2 O Carbon Monoxide - CO Carbon Dioxide - CO 2 Organics - Cx. Hy Ammonia - NH 3 Lower Limit 10 -50 ppm* 50 ppm 25 ppm 10 -50 ppm* *Customer Selectable – Selecting Lower Value Limits The Upper Range to 30%; Other Gas Species Optional 13

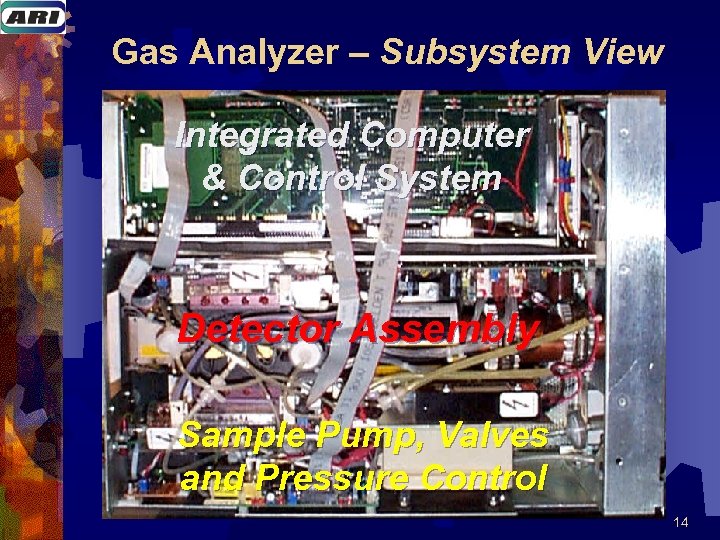

Gas Analyzer – Subsystem View Integrated Computer & Control System Detector Assembly Sample Pump, Valves and Pressure Control 14

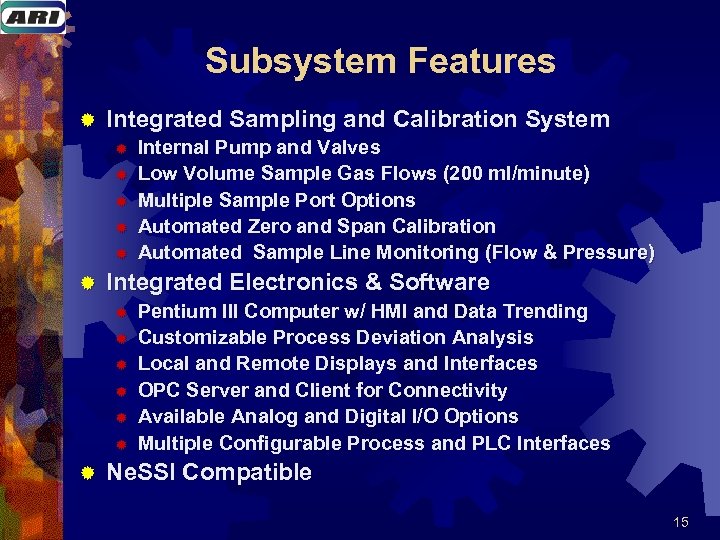

Subsystem Features ® Integrated Sampling and Calibration System ® ® ® Integrated Electronics & Software ® ® ® ® Internal Pump and Valves Low Volume Sample Gas Flows (200 ml/minute) Multiple Sample Port Options Automated Zero and Span Calibration Automated Sample Line Monitoring (Flow & Pressure) Pentium III Computer w/ HMI and Data Trending Customizable Process Deviation Analysis Local and Remote Displays and Interfaces OPC Server and Client for Connectivity Available Analog and Digital I/O Options Multiple Configurable Process and PLC Interfaces Ne. SSI Compatible 15

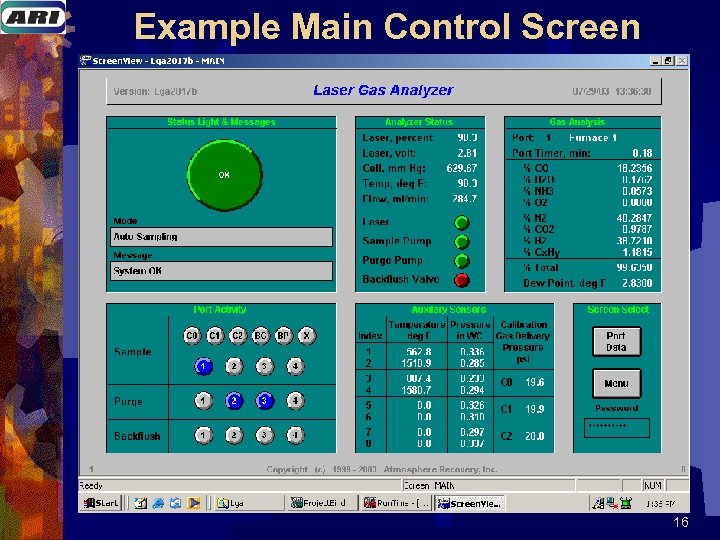

Example Main Control Screen 16

Mobile Furnace Process Control – 4 Samples, 8 Pressures, 8 Temperatures ® Furnace Tuning & Commissioning ® Furnace Performance Problem Resolution ® Advanced Atmosphere Demonstration and Testing ® ARI/APCI Consulting Service 17

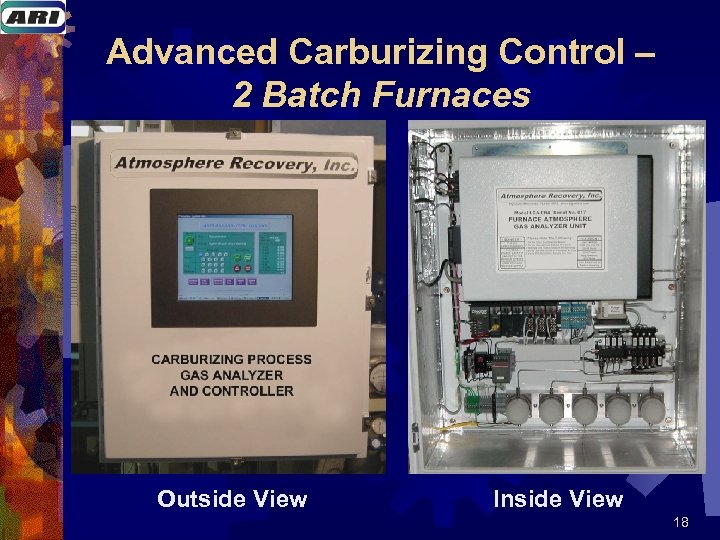

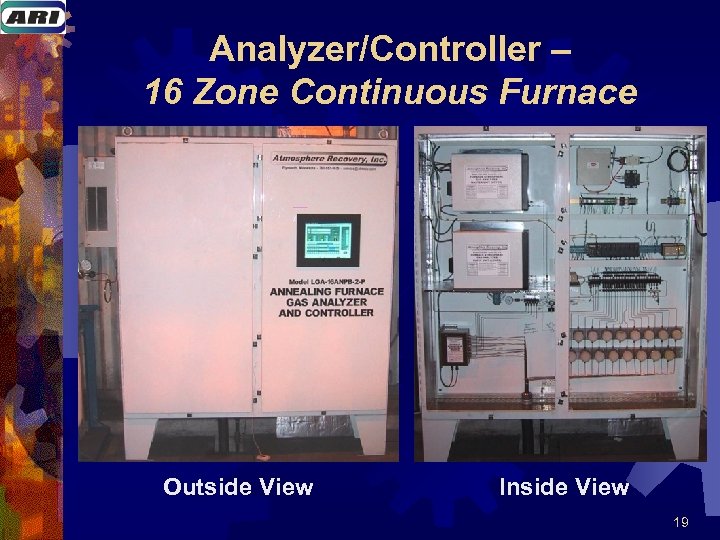

Advanced Carburizing Control – 2 Batch Furnaces Outside View Inside View 18

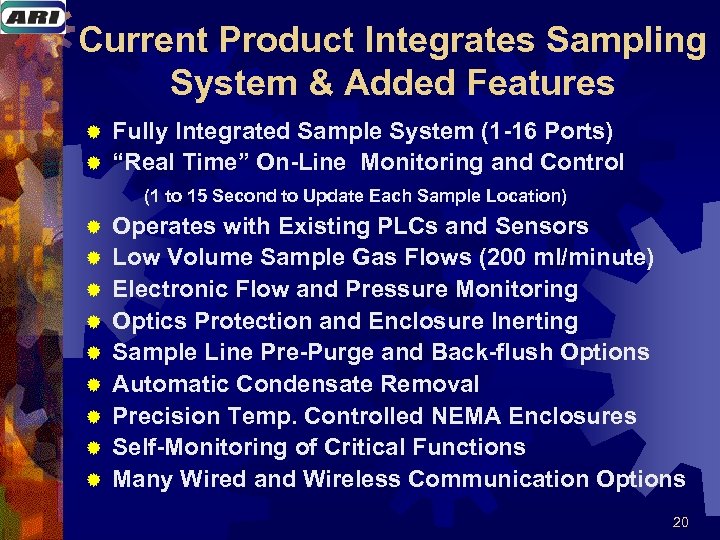

Analyzer/Controller – 16 Zone Continuous Furnace Outside View Inside View 19

Current Product Integrates Sampling System & Added Features Fully Integrated Sample System (1 -16 Ports) ® “Real Time” On-Line Monitoring and Control ® (1 to 15 Second to Update Each Sample Location) ® ® ® ® ® Operates with Existing PLCs and Sensors Low Volume Sample Gas Flows (200 ml/minute) Electronic Flow and Pressure Monitoring Optics Protection and Enclosure Inerting Sample Line Pre-Purge and Back-flush Options Automatic Condensate Removal Precision Temp. Controlled NEMA Enclosures Self-Monitoring of Critical Functions Many Wired and Wireless Communication Options 20

Economic Benefits of Laser Gas Atmosphere Analysis and Control ® Multiple Gas Analysis Capability = System Versatility ® Economic Paybacks in Many Ways ® Reduce Energy Costs ® Increase Production Capacity Depends ® Improve Component Quality on System ® Improve Component Consistency ® Reduce Destructive Analysis Costs Functions ® Reduce Re-Work Costs Used ® Better Process Documentation ® Maintenance Early Warnings ® Enhanced Furnace Safety 21

Rapid Carburizing and Atmosphere Recovery Demonstrated at Dana 22

System Location in Plant “Explosion Resistant” Test Area 23

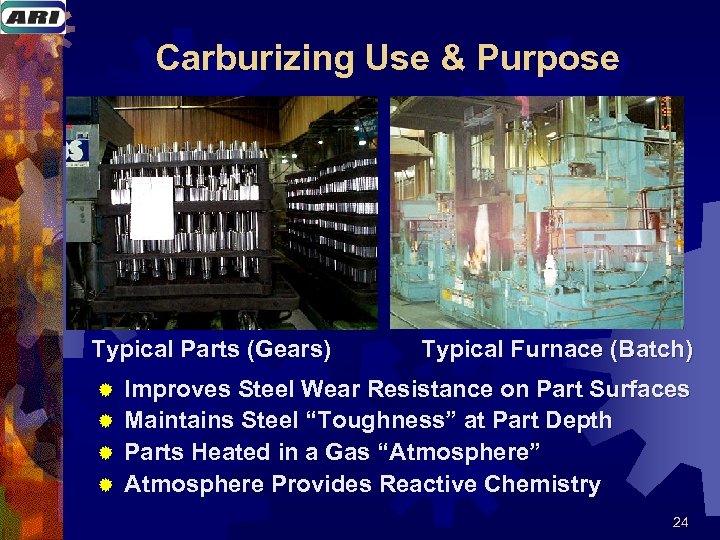

Carburizing Use & Purpose Typical Parts (Gears) ® ® Typical Furnace (Batch) Improves Steel Wear Resistance on Part Surfaces Maintains Steel “Toughness” at Part Depth Parts Heated in a Gas “Atmosphere” Atmosphere Provides Reactive Chemistry 24

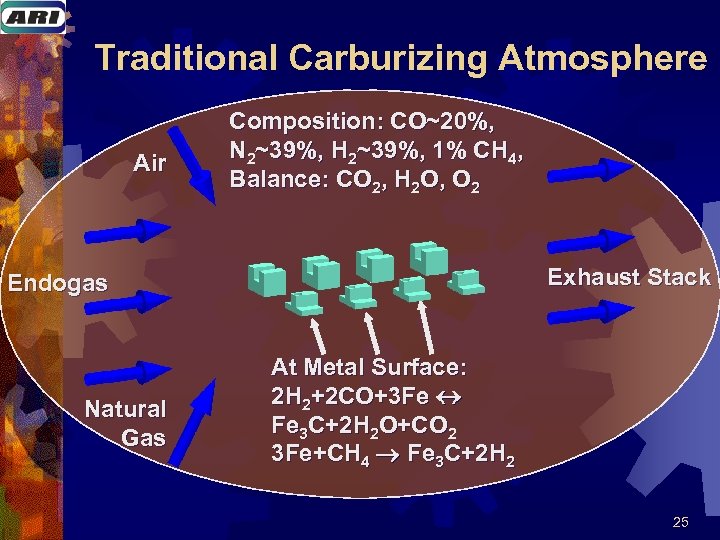

Traditional Carburizing Atmosphere Air Composition: CO~20%, N 2~39%, H 2~39%, 1% CH 4, Balance: CO 2, H 2 O, O 2 Exhaust Stack Endogas Natural Gas At Metal Surface: 2 H 2+2 CO+3 Fe Fe 3 C+2 H 2 O+CO 2 3 Fe+CH 4 Fe 3 C+2 H 2 25

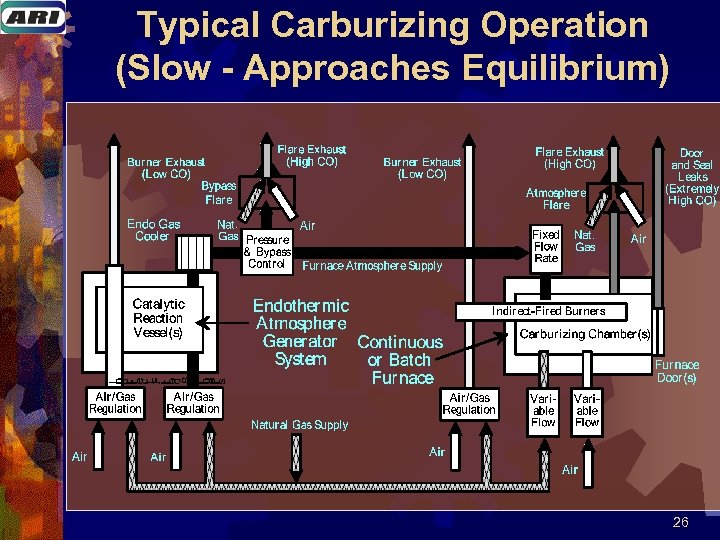

Typical Carburizing Operation (Slow - Approaches Equilibrium) 26

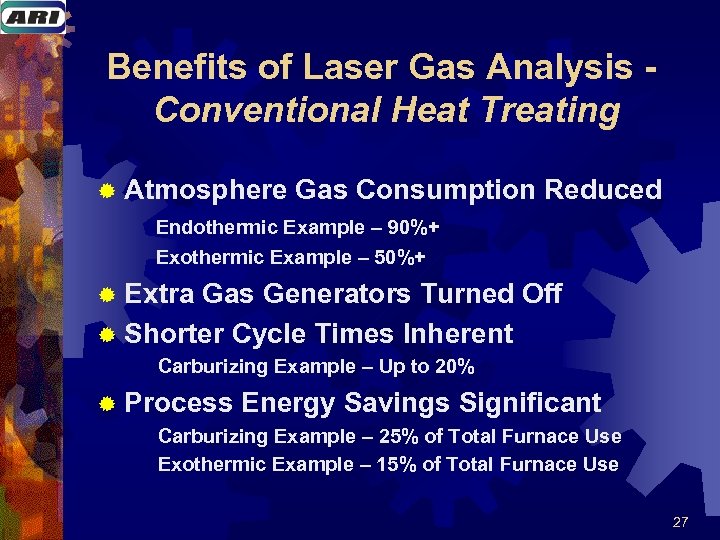

Benefits of Laser Gas Analysis Conventional Heat Treating ® Atmosphere Gas Consumption Reduced Endothermic Example – 90%+ Exothermic Example – 50%+ ® Extra Gas Generators Turned Off ® Shorter Cycle Times Inherent Carburizing Example – Up to 20% ® Process Energy Savings Significant Carburizing Example – 25% of Total Furnace Use Exothermic Example – 15% of Total Furnace Use 27

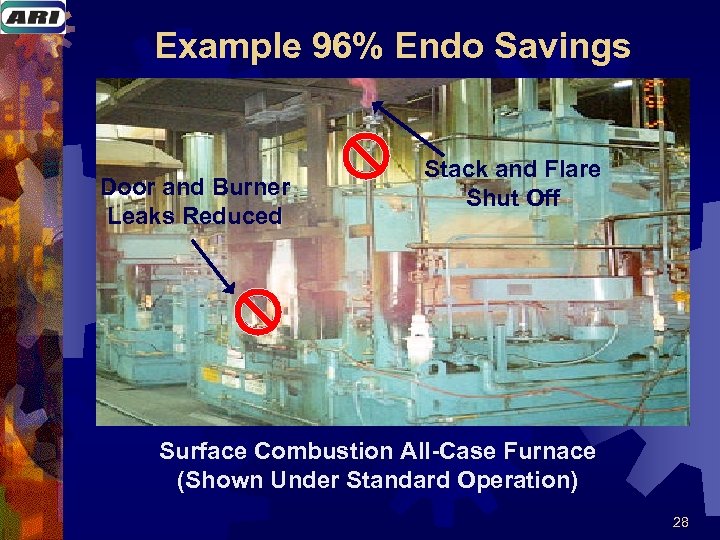

Example 96% Endo Savings Door and Burner Leaks Reduced Stack and Flare Shut Off Surface Combustion All-Case Furnace (Shown Under Standard Operation) 28

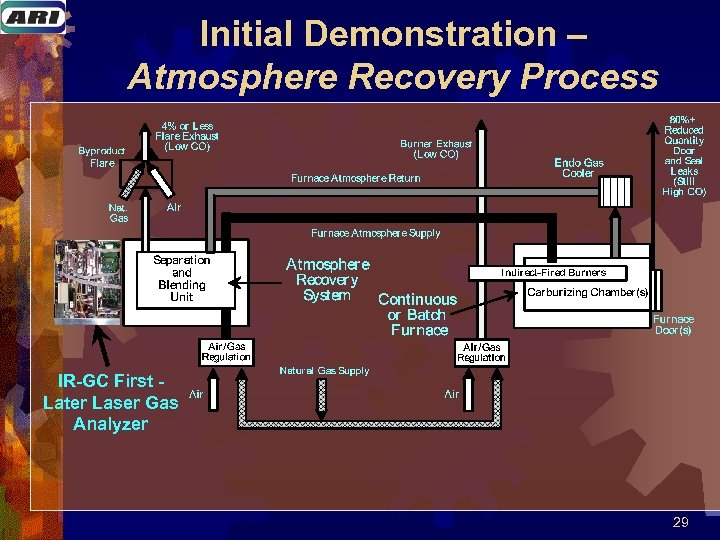

Initial Demonstration – Atmosphere Recovery Process IR-GC First Later Laser Gas Analyzer 29

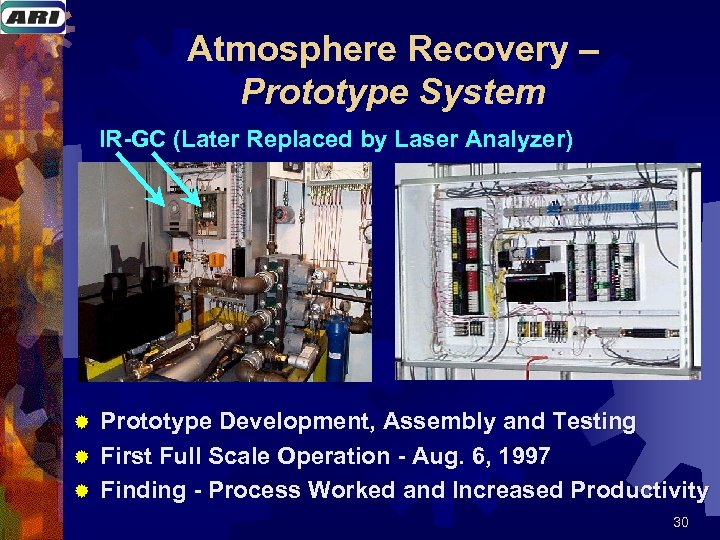

Atmosphere Recovery – Prototype System IR-GC (Later Replaced by Laser Analyzer) Prototype Development, Assembly and Testing ® First Full Scale Operation - Aug. 6, 1997 ® Finding - Process Worked and Increased Productivity ® 30

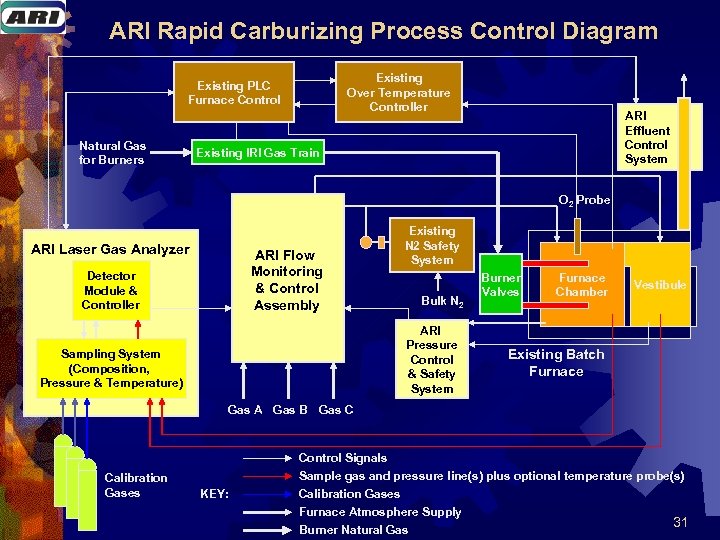

ARI Rapid Carburizing Process Control Diagram Existing Over Temperature Controller Existing PLC Furnace Control Natural Gas for Burners ARI Effluent Control System Existing IRI Gas Train O 2 Probe ARI Laser Gas Analyzer ARI Flow Monitoring & Control Assembly Detector Module & Controller Existing N 2 Safety System Bulk N 2 ARI Pressure Control & Safety System Sampling System (Composition, Pressure & Temperature) Burner Valves Furnace Chamber Vestibule Existing Batch Furnace Gas A Gas B Gas C Calibration Gases KEY: Control Signals Sample gas and pressure line(s) plus optional temperature probe(s) Calibration Gases Furnace Atmosphere Supply 31 Burner Natural Gas

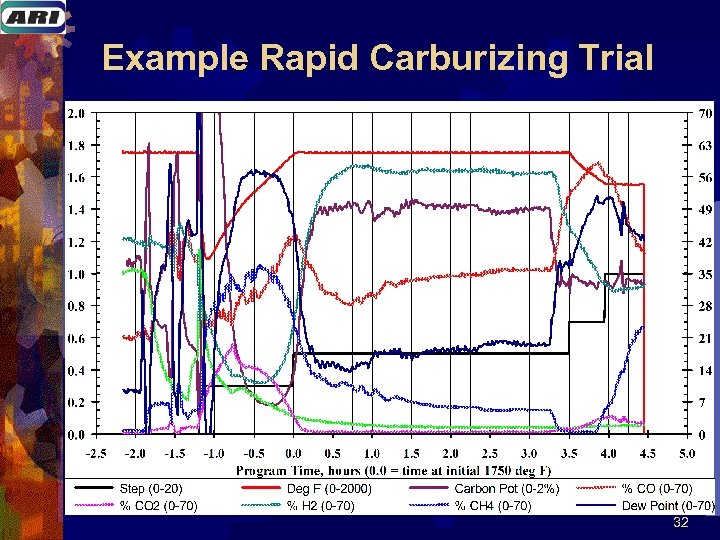

Example Rapid Carburizing Trial 32

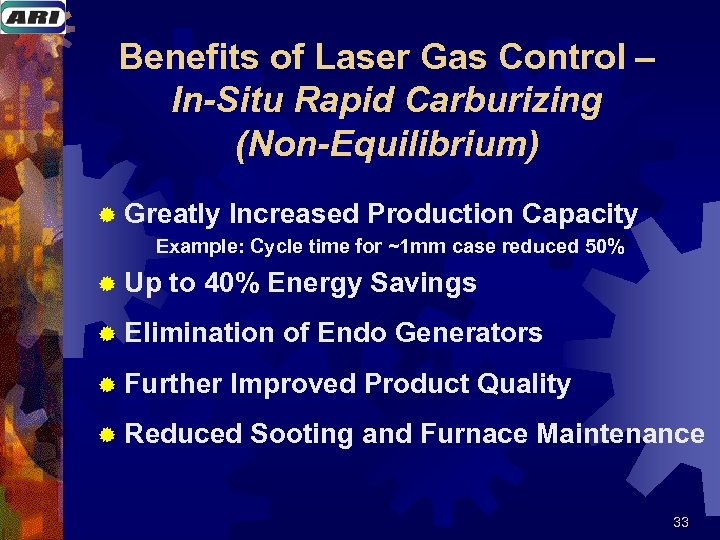

Benefits of Laser Gas Control – In-Situ Rapid Carburizing (Non-Equilibrium) ® Greatly Increased Production Capacity Example: Cycle time for ~1 mm case reduced 50% ® Up to 40% Energy Savings ® Elimination of Endo Generators ® Further Improved Product Quality ® Reduced Sooting and Furnace Maintenance 33

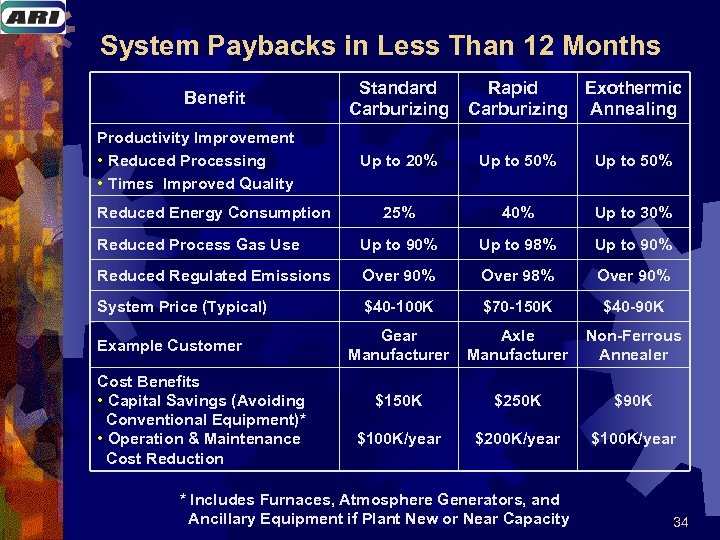

System Paybacks in Less Than 12 Months Benefit Productivity Improvement • Reduced Processing • Times Improved Quality Standard Carburizing Rapid Exothermic Carburizing Annealing Up to 20% Up to 50% 25% 40% Up to 30% Reduced Process Gas Use Up to 90% Up to 98% Up to 90% Reduced Regulated Emissions Over 90% Over 98% Over 90% System Price (Typical) $40 -100 K $70 -150 K $40 -90 K Gear Manufacturer Axle Manufacturer Non-Ferrous Annealer $150 K $250 K $90 K $100 K/year $200 K/year $100 K/year Reduced Energy Consumption Example Customer Cost Benefits • Capital Savings (Avoiding Conventional Equipment)* • Operation & Maintenance Cost Reduction * Includes Furnaces, Atmosphere Generators, and Ancillary Equipment if Plant New or Near Capacity 34

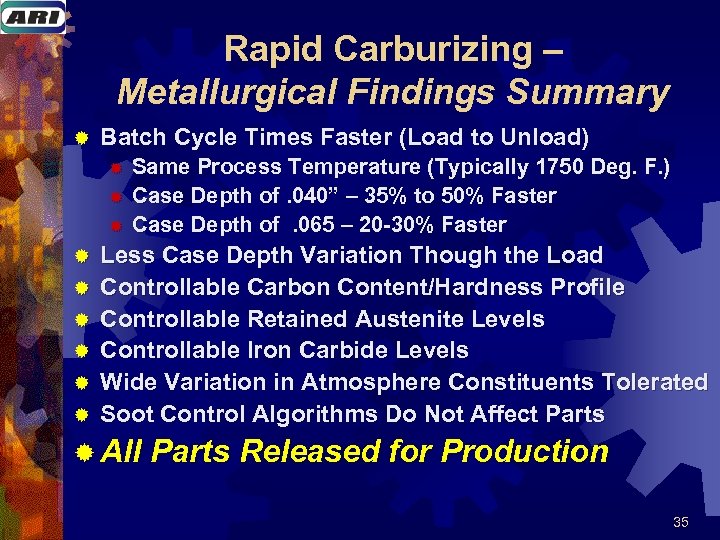

Rapid Carburizing – Metallurgical Findings Summary ® Batch Cycle Times Faster (Load to Unload) ® ® ® ® ® Same Process Temperature (Typically 1750 Deg. F. ) Case Depth of. 040” – 35% to 50% Faster Case Depth of . 065 – 20 -30% Faster Less Case Depth Variation Though the Load Controllable Carbon Content/Hardness Profile Controllable Retained Austenite Levels Controllable Iron Carbide Levels Wide Variation in Atmosphere Constituents Tolerated Soot Control Algorithms Do Not Affect Parts ® All Parts Released for Production 35

Significant Process Industries - Gas Based ® Metal Processing – Initial Success ® Automotive & Aerospace Heat Treating ® Metal Refining & Powdered Metal ® Many Others – Ready for Trials ® Bio-Pharma ® Petrochemical ® Semiconductor ® Energy Utilities ® Glass & Ceramic ® Continuous Emission Monitoring

Thank You For Listening ® Looking for Demonstration Sites ® Looking for Technology, Marketing & Financial Partners ® Brochures if Interested ® Questions? 37

0e97e326c96d3025df4d1fc71d6ac0d1.ppt