d745137733a12ebb1d1668c30184f2b6.ppt

- Количество слайдов: 75

Engineering High Performance Building HVAC and Associated Energy Systems Washington DC, December 2008 Grahame E. Maisey, P. E. & Beverly Milestone, LEED A. P.

High Performance: Min. Energy, Maintenance, Max. Comfort, Productivity With Long Life, Loose Fit; Least First & Operating Cost

Extra Cost High Performance Mechanical Systems Using Current Designs & Methods: 5% to 20% (3 Years Results) Using Experts, LCP, BIM, Proj Coll & Doc Man. -10% to +0. 5%

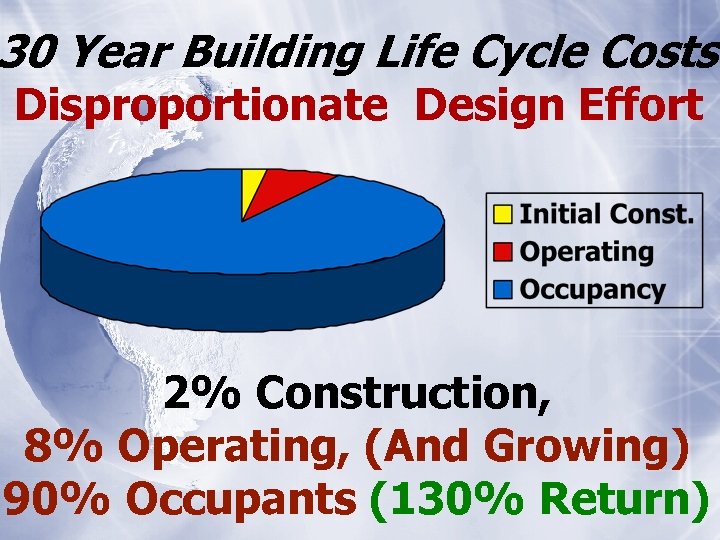

30 Year Building Life Cycle Costs Disproportionate Design Effort 2% Construction, 8% Operating, (And Growing) 90% Occupants (130% Return)

Why Concentrate On Mechanical Systems? 70% Electrical Demand 70% Building Energy Use 70% Occupant Complaints 70% of MEP Construction Cost

The Solution Energy Master Plans (EMPs) & Total Quality Commissioning (TQC)

“The greatest opportunities for saving costs over the life of a building occur at the beginning of the design process. ” AIA Energy Design Handbook

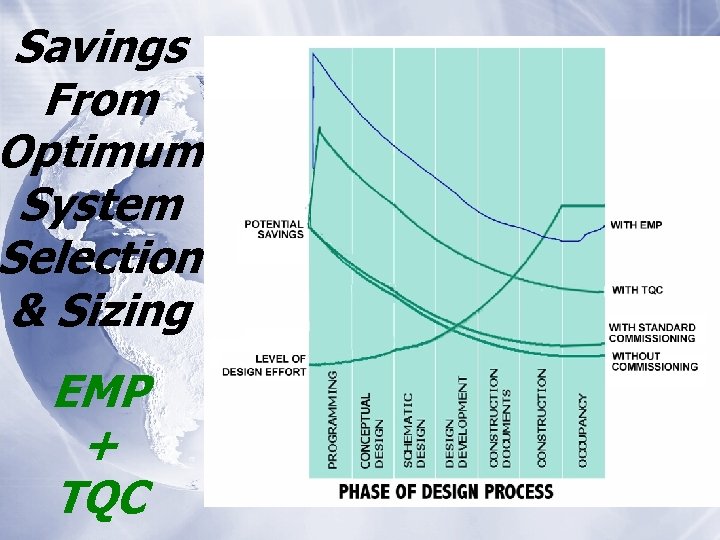

Savings From Optimum System Selection & Sizing EMP + TQC

Mechanical System Performance Characteristics System Maintainability Occupant Comfort Energy Demand Energy Use

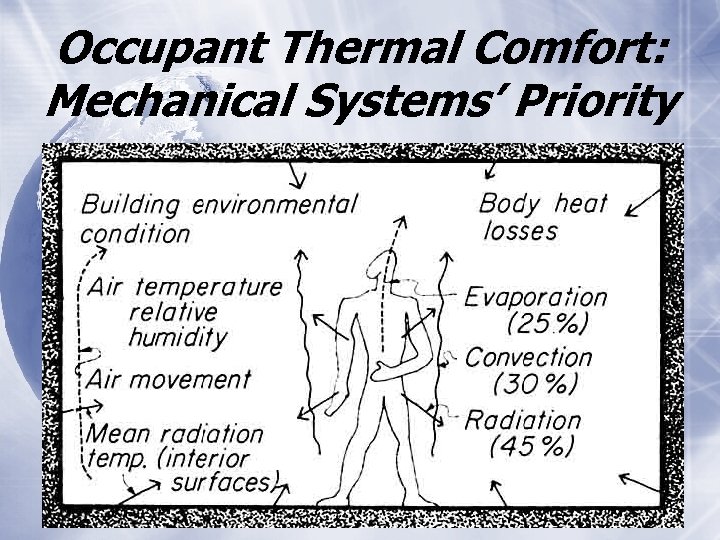

Let’s Talk About Thermal Comfort, The Reason Why Mechanical Systems Are Installed In Buildings

Occupant Thermal Comfort: Mechanical Systems’ Priority

ASHRAE’s Effective Temp 50% Mean Radiant Temp, 50% Ambient (Air) Temp Been Around for 30 Years Not Promoted or Advanced

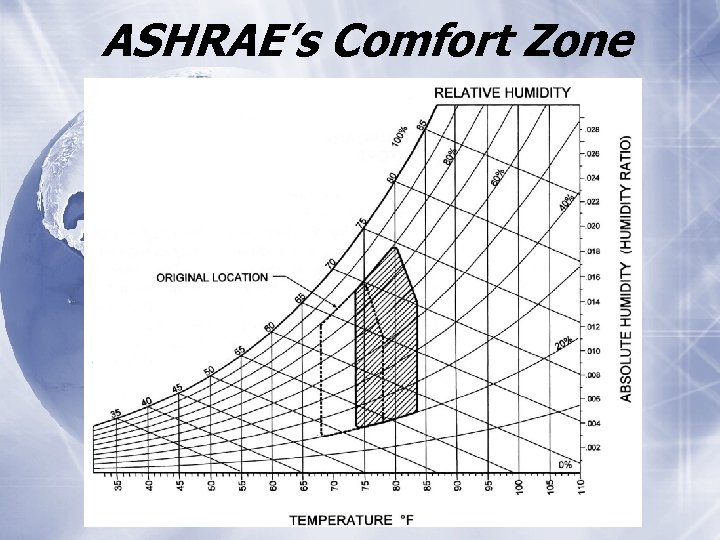

ASHRAE’s Comfort Zone

ASHRAE Comfort 20% Occupants Dissatisfied! 50% Not Comfortable? ASHRAE to Expand Comfort Envelope Increase Humidity

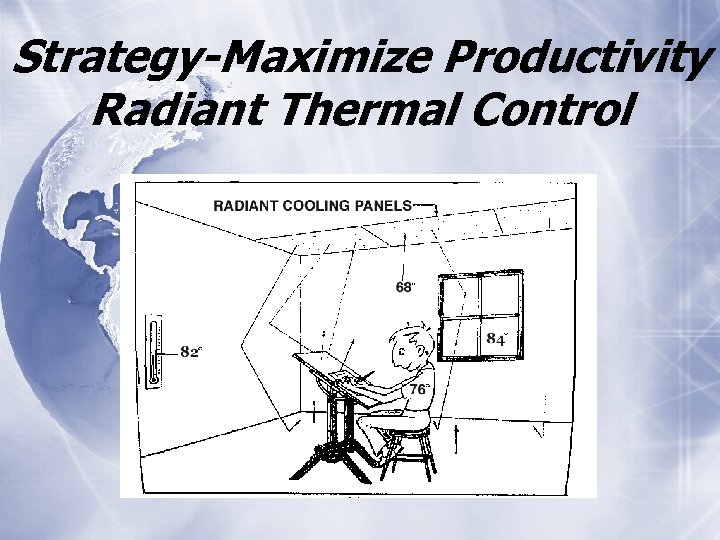

Strategy-Maximize Productivity Radiant Thermal Control

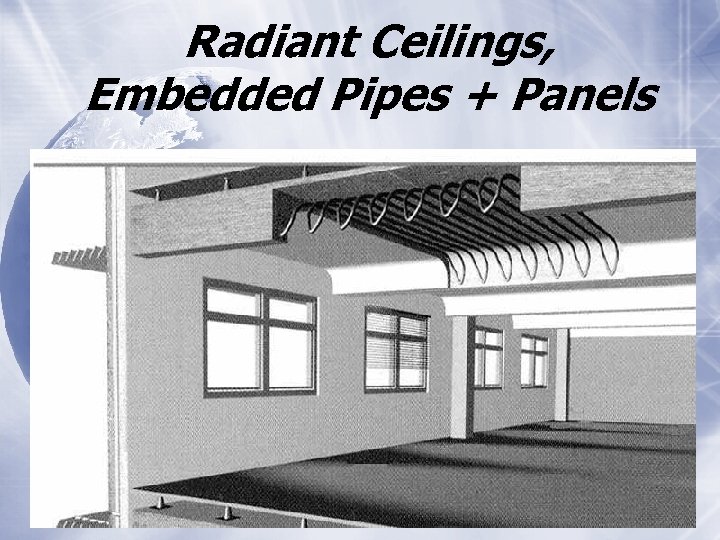

Radiant Ceilings, Embedded Pipes + Panels

Most Overlooked Strategy: Maximize Productivity With Year Round Humidity Control Usual Performance: 50%(80%) Summer, 15% Winter Productive Performance: 40% Summer, 35% Winter Not Just Comfort, For Health

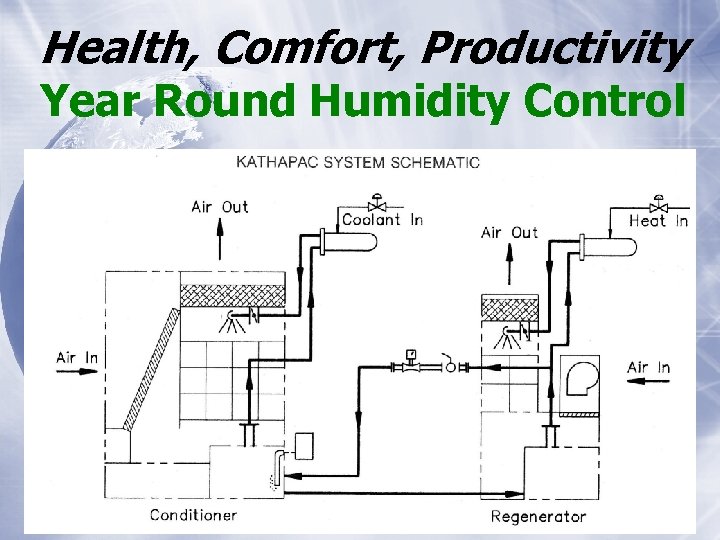

Health, Comfort, Productivity Year Round Humidity Control

Calculate Occupant Comfort Energy. Plus Simulation Program Calculates Thermal Comfort Calculate Building Energy Performance Use Sketchup From Minute One

Air Never Recirculate Air!!! Minimize Circulated Ammount: Fan Power, Conditioning (Humidity & Ventilation)

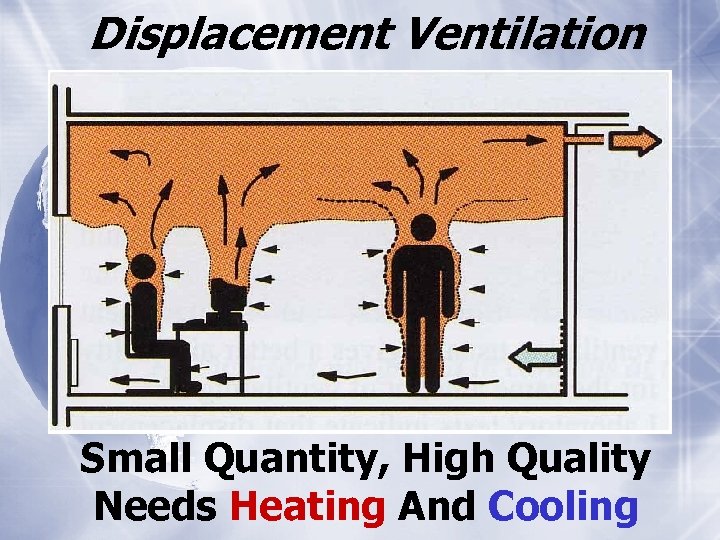

Displacement Ventilation Small Quantity, High Quality Needs Heating And Cooling

The Shameful Recent History of Mechanical Systems

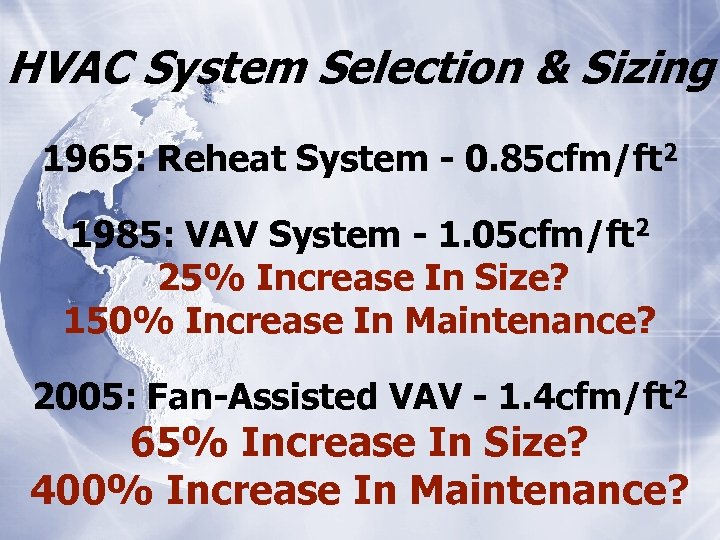

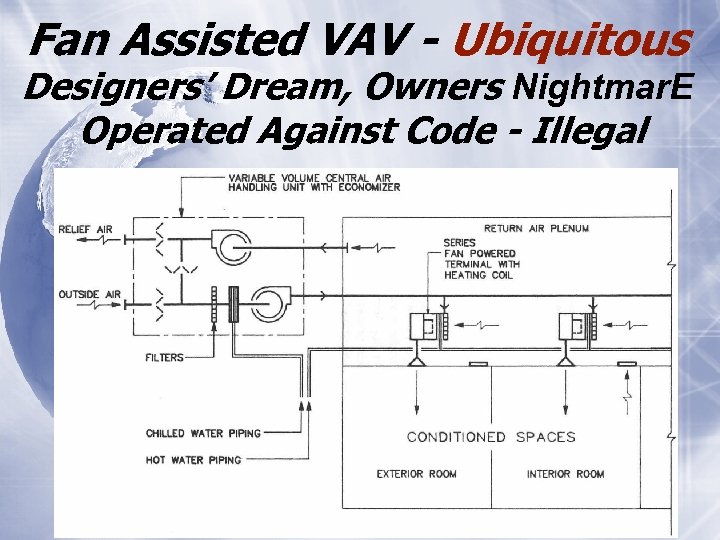

HVAC System Selection & Sizing 1965: Reheat System - 0. 85 cfm/ft 2 1985: VAV System - 1. 05 cfm/ft 2 25% Increase In Size? 150% Increase In Maintenance? 2005: Fan-Assisted VAV - 1. 4 cfm/ft 2 65% Increase In Size? 400% Increase In Maintenance?

Huge Opportunity Lost! Lovins 1988 HVAC Report Newer HVAC Systems Cost More to Install & Maintain, Use More Energy And Are Less Comfortable Report Buried By ASHRAE, AIA

Lovins’ Huge Mistakes 1. Asked Fox To Guard Hen House Solutions From Designers, Manufacturers 2. Didn’t Realize ‘ 73 & ‘ 79 Oil Crises Caused Poorer Design

Fan Assisted VAV - Ubiquitous Designers’ Dream, Owners Nightmar. E Operated Against Code - Illegal

LEED & ASHRAE Even High Performance Mechanical Systems & LEED Gold Buildings Lose 30% Efficiency Within 3 Years

Put Aside Legacy Look To The Future Whole Life Cycle High Performance

Challenge 2030, 2010 Initiative Climate Neutral Bldg Standard ACUPCC Many More to Come Working Toward Zero Carbon Footprints

Energy Master Plans Moving A Building, Facility or Community Toward A Sustainable Zero Carbon Footprint

End-Goal Performance Net Zero Energy Systems, Redundant Energy Sources Reduce O & M Costs by 75%, Preventive Maintenance Optimize Comfort/Productivity, Increase Productivity by 25% (Potential Highest Monetary Reward)

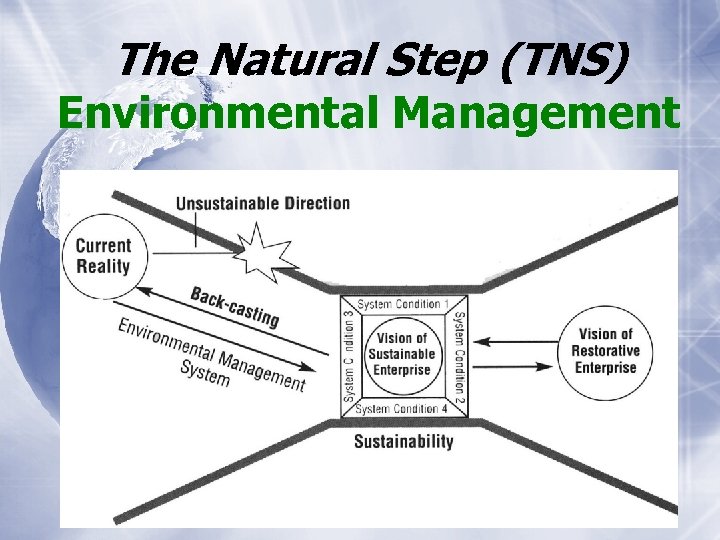

The Natural Step (TNS) Environmental Management

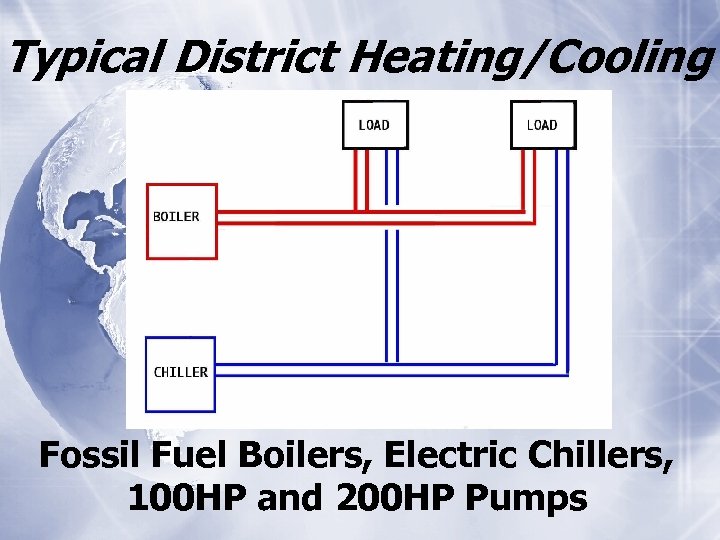

Typical District Heating/Cooling Fossil Fuel Boilers, Electric Chillers, 100 HP and 200 HP Pumps

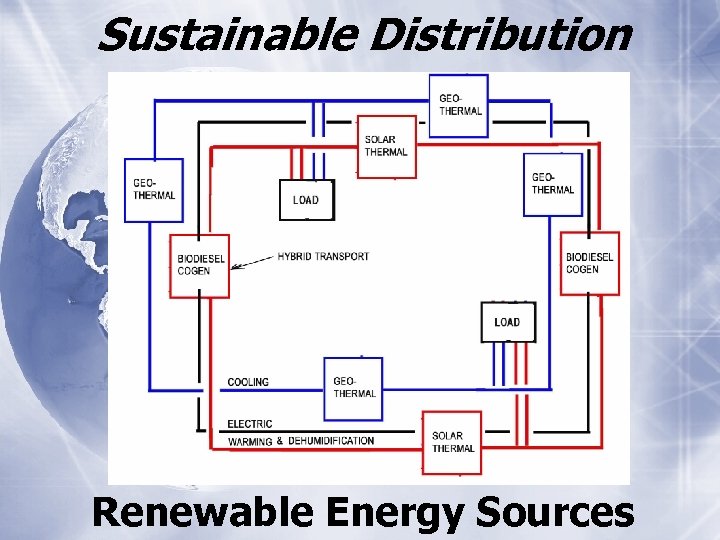

Sustainable Distribution Renewable Energy Sources

Design Integration EMP = Pre-Design Plan, Essential For Successful Charrette Designers, Commissioning Agents: Not Experts Need Experts in LCP

Total Quality Commissioning

How Can We Persuade Owners To Make Major Changes? Remove Risk Provide a Total QA/QC program that assures an Owner different smaller systems will work as required AND predicted

Assuring Building Performance Analysis, Evaluation, . . Documentation Expert Knowledge, Methods and Procedures . .

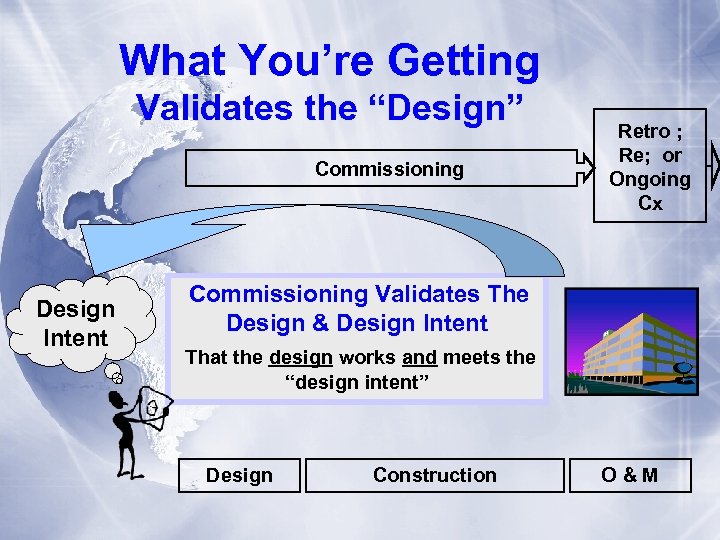

What You’re Getting Validates the “Design” Commissioning Design Intent Retro ; Re; or Ongoing Cx Commissioning Validates The Design & Design Intent That the design works and meets the “design intent” Design Construction O&M

DOE Commissioning “Commissioning is the process of insuring that the systems are designed, installed, functionally tested, and capable of being operated and maintained according to the Design Intent AND the Owner’s operational needs”

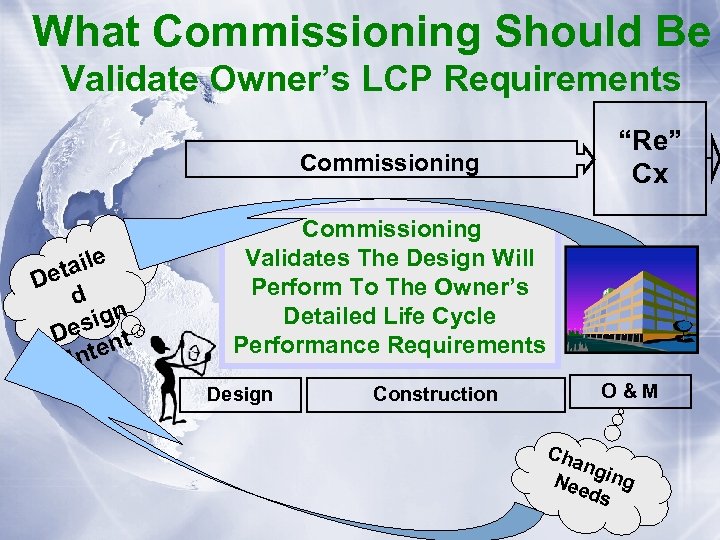

What Commissioning Should Be Validate Owner’s LCP Requirements “Re” Cx Commissioning e tail De d ign Des nt Inte Commissioning Validates The Design Will Perform To The Owner’s Detailed Life Cycle Performance Requirements Design Construction O&M Cha ngi Nee ng ds

Detailed Design Intent Detailed CB + DI + BOD Details of How & Why System Selected & Sized for LCP Design Decisions Transparency Removes “Grey” Areas

First Three Questions How Long Do You Want The System To Work For, And At What Level Of Efficiency And Effectiveness? What Level Of Maintenance Will You Have? Do You Have An Energy Master Plan?

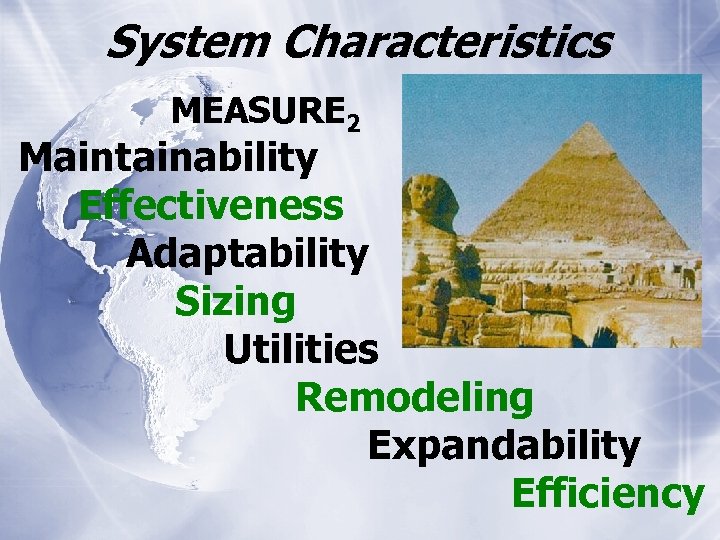

System Characteristics MEASURE 2 Maintainability Effectiveness Adaptability Sizing Utilities Remodeling Expandability Efficiency

What Owners Want CUT 1 Comfort Utility Thrift High Performance, Long Life, Loose Fit, Least First & Operating Cost

Strategies: __________ Maintainability Preventive Maintenance Optimize Longevity

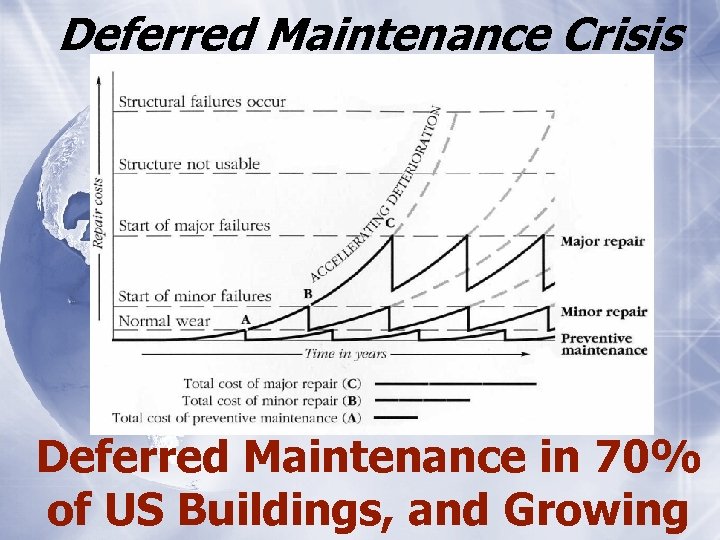

Deferred Maintenance Crisis Deferred Maintenance in 70% of US Buildings, and Growing

Sustainable Maintenance Laws All Moving Parts Must Be In Plantrooms or Equipment Rooms If It’s Not Easy To Maintain, It Won’t Be Designers: Not Our Problem

Operation & Maintenance 35% Reduction Design for Life Cycle Maintainability Adaptable, Expandable Systems and Equipment, Minimize Operation and Remodeling

Strategies: __________ Effectiveness Maximize Comfort Maximize Productivity

90% of Building Money: Occupant Productivity ASHRAE Comfort: 20% Occupants Dissatisfied 10% Slightly Dissatisfied: Every Factor is Considered

Maximize Productivity - Ventilation Control Air Tight Building Envelope Re-circulating Air in Schools? Re-circulating Air in Hospitals? Plenty Of Ventilation Air Maximize Ventilation Efficiency

Strategies __________ Adaptability, Remodeling, Expandability, Efficiency Minimum Energy Use, Long Life Cycle, Low Remodeling Costs

Energy Use Characteristics No Increase in Electrical Use at Highest Loads Can Easily Develop to Use Renewable Energy Sources

Strategies for Low Energy Mechanical Systems Reduce Fan, Pump Energy 90% Eliminate Electric Refrigeration Minimize Heat/Cool From Fossil Fuels

Ambient Systems High Cooling Temps - 60˚F Low Heating Temps - 90˚F Efficient Generating Plant Renewables More Efficient With Ambient Systems

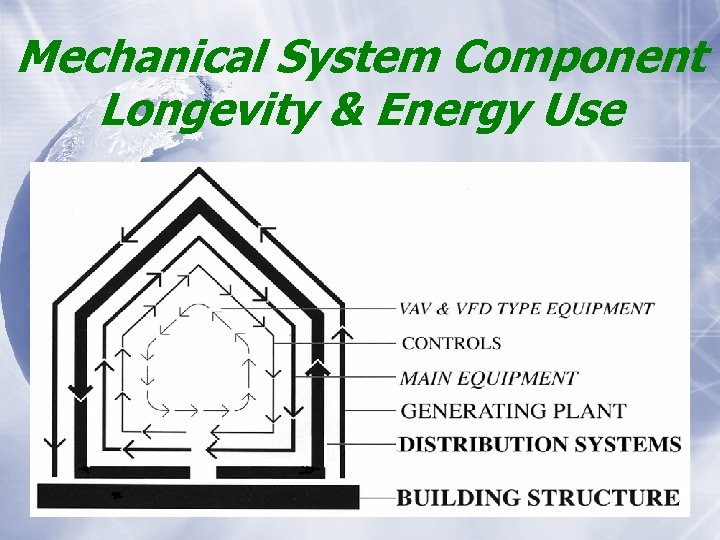

Mechanical System Component Longevity & Energy Use

Piping & Ducting Systems (Infrastructure) Lasts 30 to 100 years Uses 50% System Energy Costs 50% Installation Costs 75% Remodeling Costs Arbitrary Selection Process

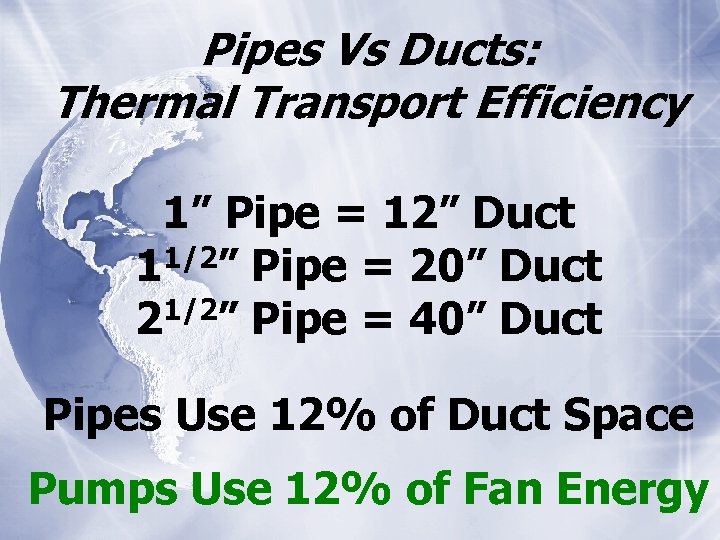

Pipes Vs Ducts: Thermal Transport Efficiency 1” Pipe = 12” Duct 1/2” Pipe = 20” Duct 1 21/2” Pipe = 40” Duct Pipes Use 12% of Duct Space Pumps Use 12% of Fan Energy

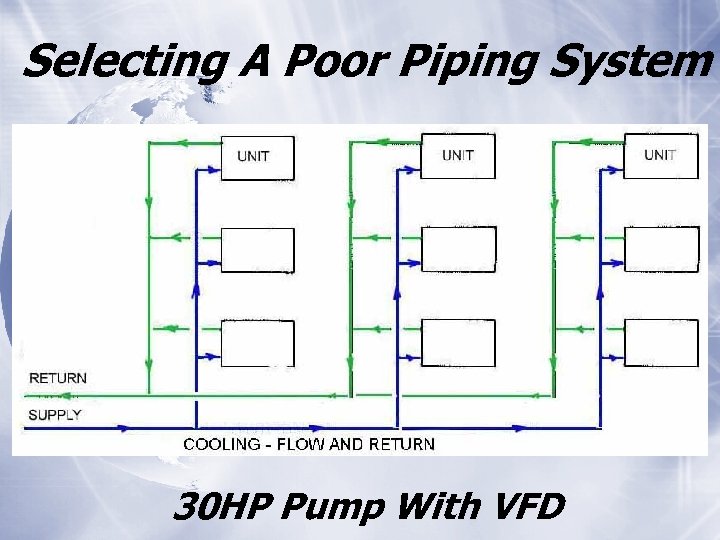

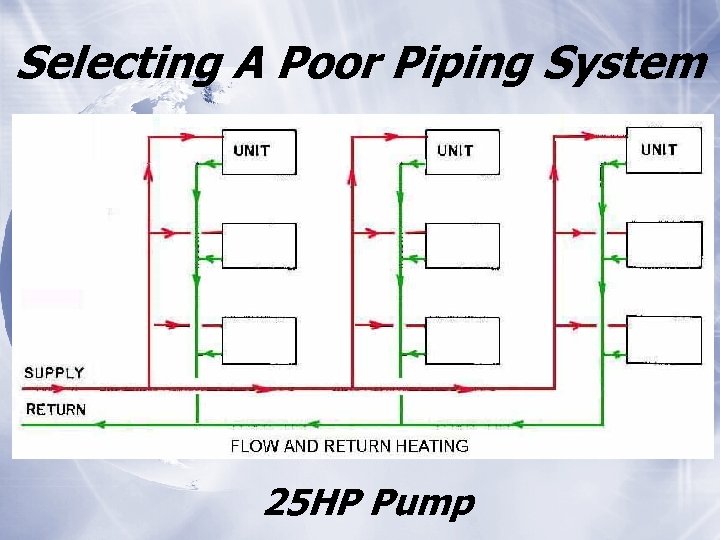

Selecting A Poor Piping System 30 HP Pump With VFD

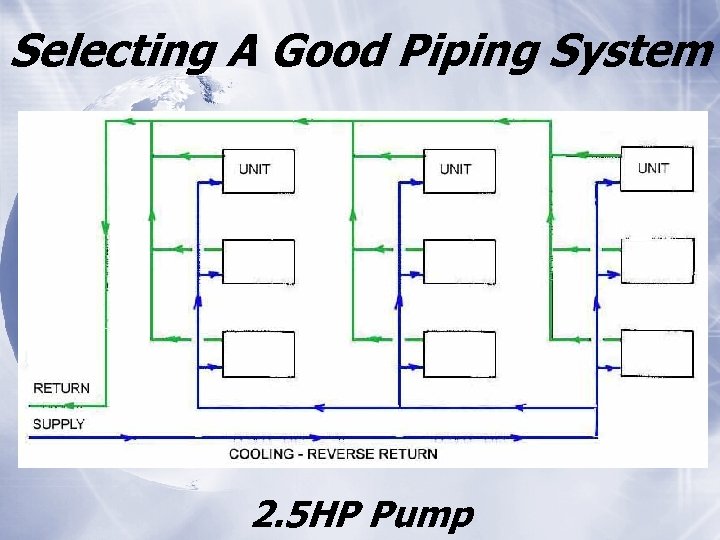

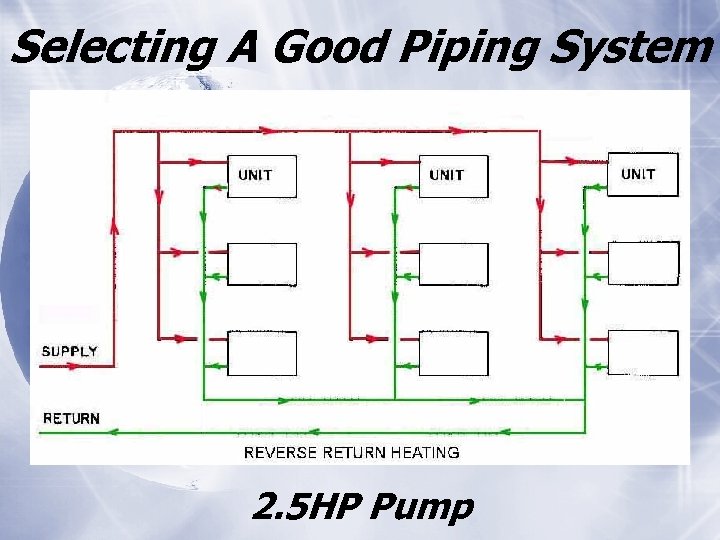

Selecting A Good Piping System 2. 5 HP Pump

Selecting A Poor Piping System 25 HP Pump

Selecting A Good Piping System 2. 5 HP Pump

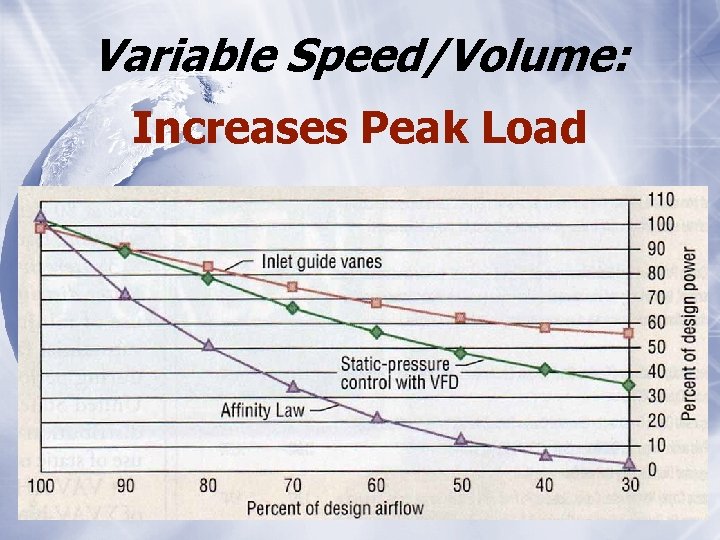

Variable Speed/Volume: Increases Peak Load

Controls - Digital Controls Only Advance in 100 Years Remote Control & Supervision Control Strategies: Reduce System Size by 15% Individual Control

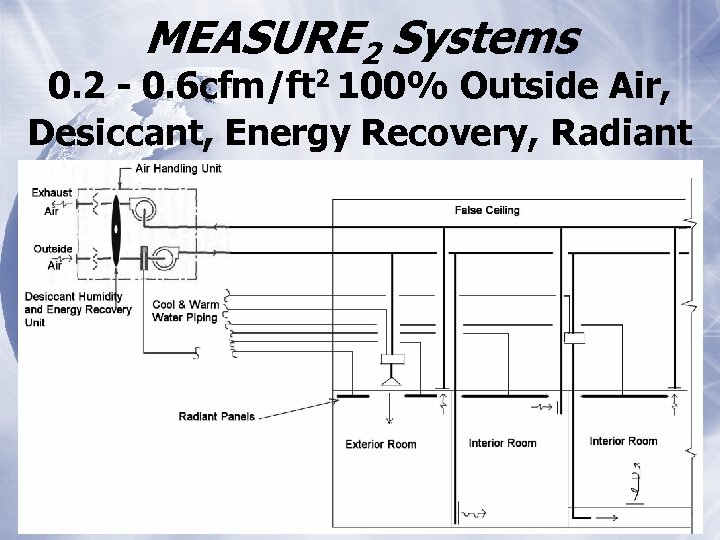

MEASURE 2 Systems 0. 2 - 0. 6 cfm/ft 2 100% Outside Air, Desiccant, Energy Recovery, Radiant

Strategies __________ Sizing, Utilities Optimum System & Equipment Sizing, Optimize Generating Plant

Design Challenge - Sizing Negotiate Sizing With Owner Simulation Vs Design Calcs Reduce Plant Size 60% Reduce System Size 40% 50% Operation @ Low Load 94% Operation @ Partial Load

Design Challenge Generating Plant Flexible, Adaptable, Expandable, Maintainable Min. Output: 10% Full Load (4% of Oversized Plant) Minimize Size, Modular Plant Negotiate With Owner

Low Load Control 15 Days/Year of Cooling and Heating Design Loads 150 Days/Year at Low Loads and Change-Over Loads

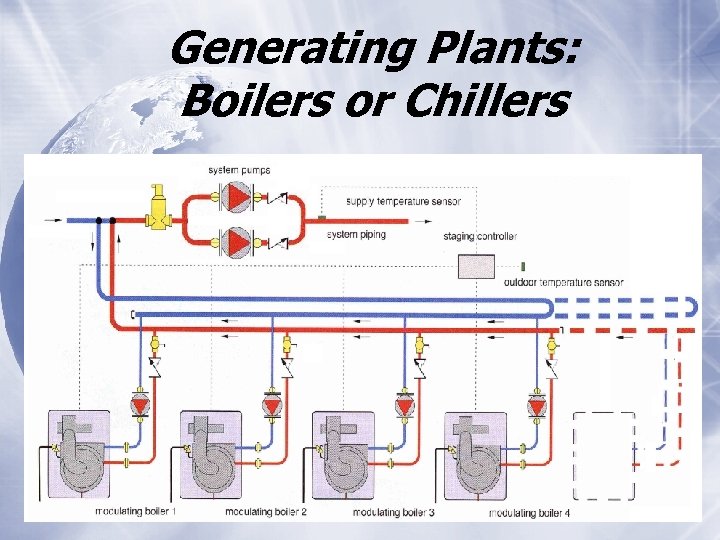

Generating Plants: Boilers or Chillers

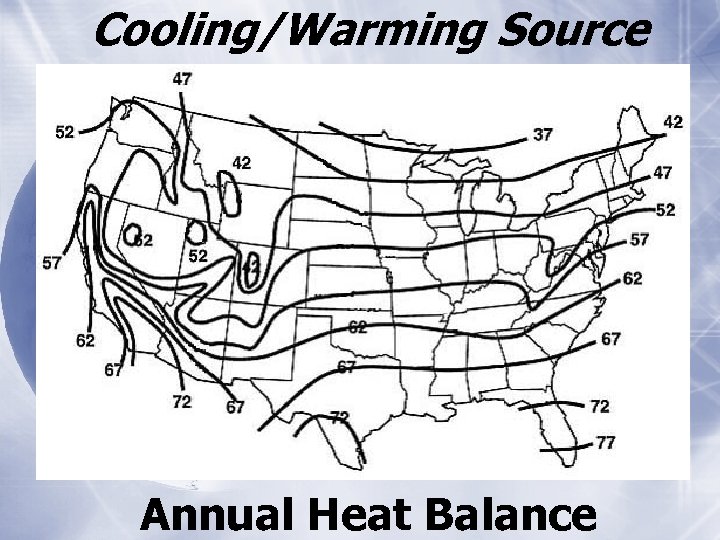

Cooling/Warming Source Annual Heat Balance

Steam to Water Heat Exchangers 1, 000’s in Universities and Hospitals: 1/3 & 2/3 Valves Exchangers 250% Oversized, 1/3 Valve Is Almost Full Load Need 2 - 1/20 Valves

Single Centrifugal Chiller 1, 000’s are 200% Oversized in Universities and Hospitals False Loading To Operate At Low Loads 30% Reciprocating Chiller

www. wbdg. org - Grahame Maisey HVAC System Selection & Sizing Energy Master Planning Dynamic Integration of HVAC Systems Recent Publications Emergency Climate Neutral Building Standard COAA Spring 2007 Magazine White Papers Sustainable Building Logbook Energy Master Planning grahame@bsc-worldwide. com 215. 886. 6464

d745137733a12ebb1d1668c30184f2b6.ppt