0cbc1bf7890e4f58a1086fe2a8a24004.ppt

- Количество слайдов: 75

ENGINEERING ASPECTS OF BIODIESEL PRODUCTION PROCESS Nurhan Turgut Dunford Oklahoma State University Department of Biosystems and Agricultural Engineering

Outline Ø Introduction Ø Transesterification Ø Esterification Ø Homogeneous catalysis Ø Heterogeneous catalysis Ø Enzymatic conversion Ø Conversion without a catalyst Ø Lipid hydrotreating Ø Planning for production Ø Site selection

Petroleum Ø A naturally occurring oil that contains mainly Ø Ø Ø hydrocarbons with some other elements such as sulphur, oxygen and nitrogen Gasoline: A mixture of hydrocarbons containing 5 -8 carbon atoms, boiling point 40 -180 o. C Kerosine (paraffin oil): A mixture of hydrocarbons containing 11 -12 carbon atoms, boiling point 160250 o. C Diesel oil: A mixture of hydrocarbons containing 1325 carbon atoms, boiling point 220 -350 o. C

Petroleum Diesel Ø A fuel derived from the distillation of crude oil Ø It is heavier than gasoline but lighter than engine oil and heavy oils. Ø Diesel fuel is generally separated into two fuels: diesel number 1 and diesel number 2. Diesel number 1 is similar to kerosene and is lighter than diesel number 2. While diesel number 2 is sold most of the time, diesel number 1 is sold during winter in very cold climates because it doesn’t cloud or gel as easily as diesel number 2. Ø Diesel fuel is ignited in an internal combustion engine cylinder by the heat of air under high compression in contrast to motor gasoline, which is ignited by electrical spark.

Definition of Biodiesel “A fuel comprised of mono-alkyl-ester of long chain fatty acids derived from vegetable oils or animal fat designated B 100” Biodiesel safety: http: //www. biodieselcommunity. org/safety/ http: //www. biodiesel. org/pdf_files/fuelfactsheets/M SDS. pdf

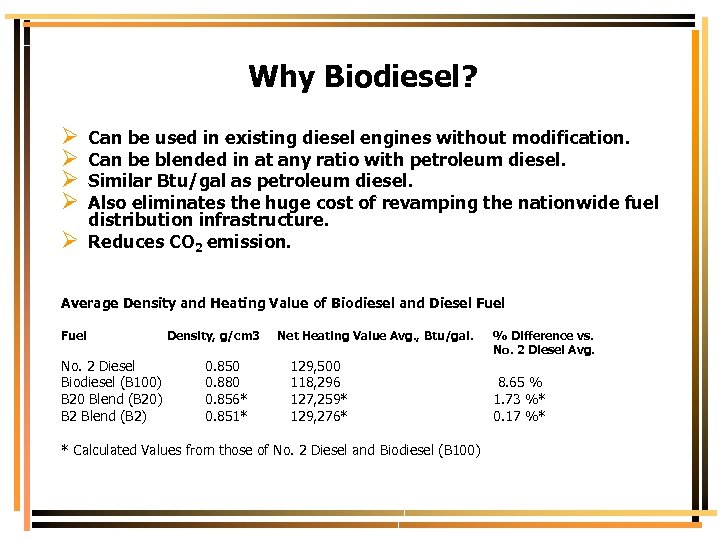

Why Biodiesel? Ø Ø Ø Can be used in existing diesel engines without modification. Can be blended in at any ratio with petroleum diesel. Similar Btu/gal as petroleum diesel. Also eliminates the huge cost of revamping the nationwide fuel distribution infrastructure. Reduces CO 2 emission. Average Density and Heating Value of Biodiesel and Diesel Fuel No. 2 Diesel Biodiesel (B 100) B 20 Blend (B 20) B 2 Blend (B 2) Density, g/cm 3 0. 850 0. 880 0. 856* 0. 851* Net Heating Value Avg. , Btu/gal. 129, 500 118, 296 127, 259* 129, 276* * Calculated Values from those of No. 2 Diesel and Biodiesel (B 100) % Difference vs. No. 2 Diesel Avg. 8. 65 % 1. 73 %* 0. 17 %*

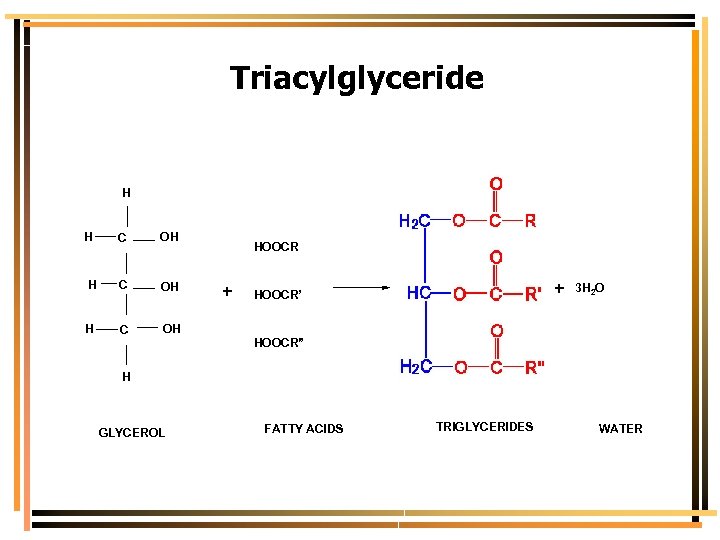

Triacylglyceride H H C OH H HOOCR + + HOOCR’ 3 H 2 O HOOCR” H GLYCEROL FATTY ACIDS TRIGLYCERIDES WATER

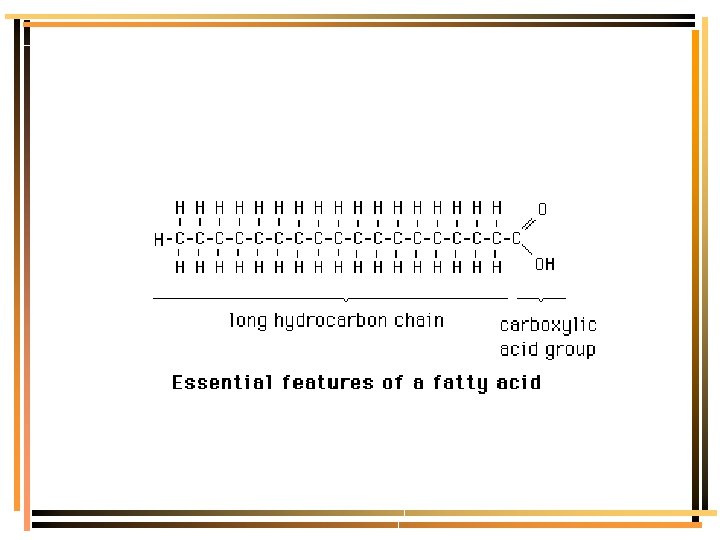

Fatty Acid Molecular Structure

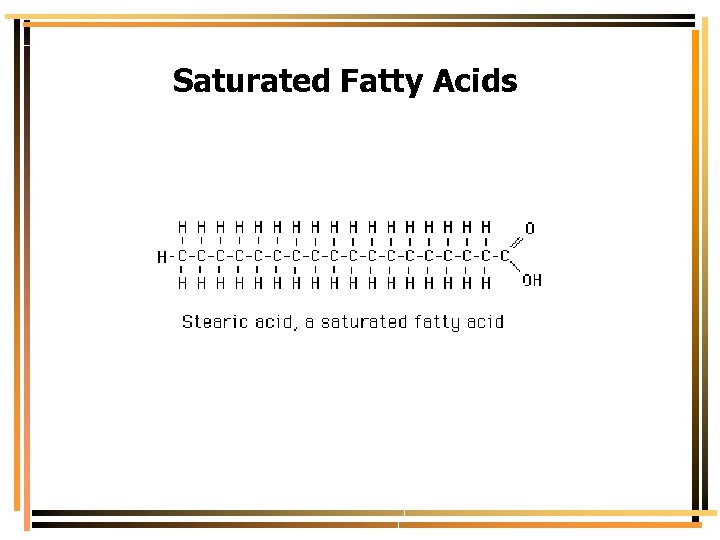

Saturated Fatty Acids

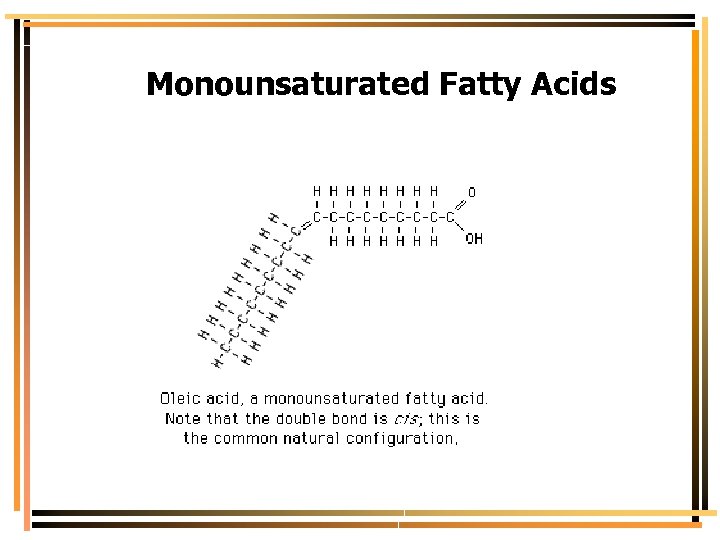

Monounsaturated Fatty Acids

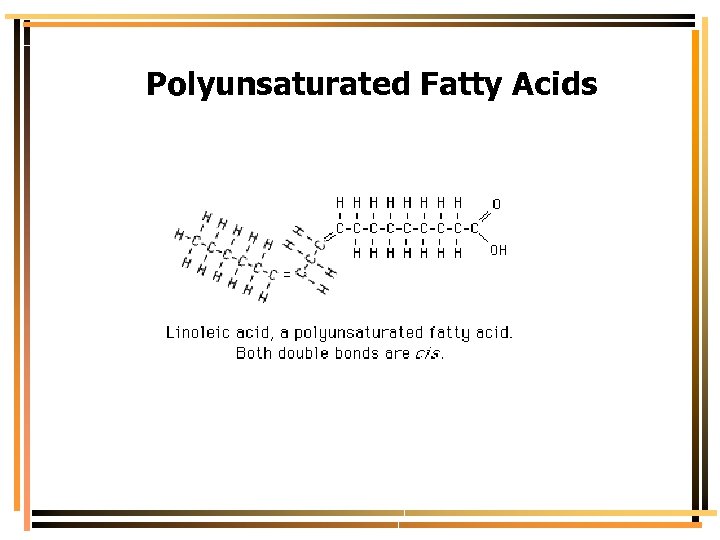

Polyunsaturated Fatty Acids

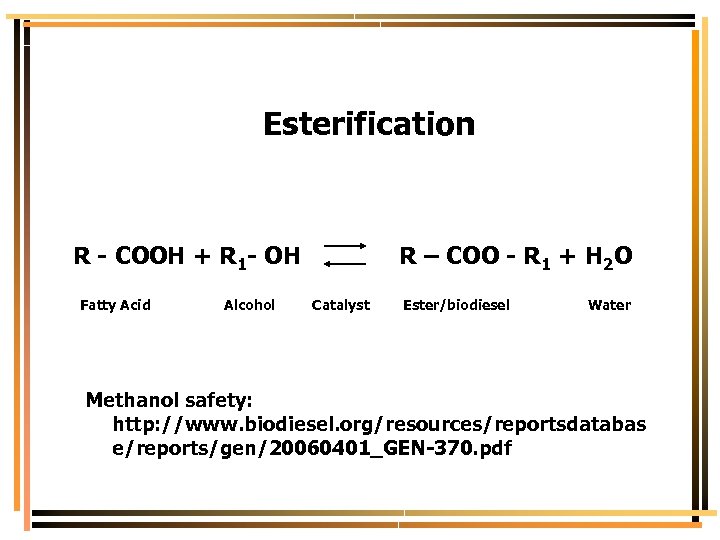

Esterification R - COOH + R 1 - OH R – COO - R 1 + H 2 O Fatty Acid Alcohol Catalyst Ester/biodiesel Water Methanol safety: http: //www. biodiesel. org/resources/reportsdatabas e/reports/gen/20060401_GEN-370. pdf

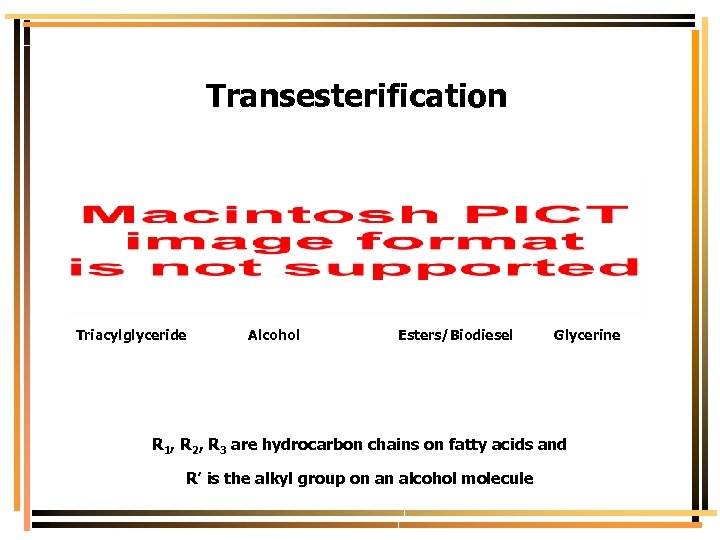

Transesterification Triacylglyceride Alcohol Esters/Biodiesel Glycerine R 1, R 2, R 3 are hydrocarbon chains on fatty acids and R’ is the alkyl group on an alcohol molecule

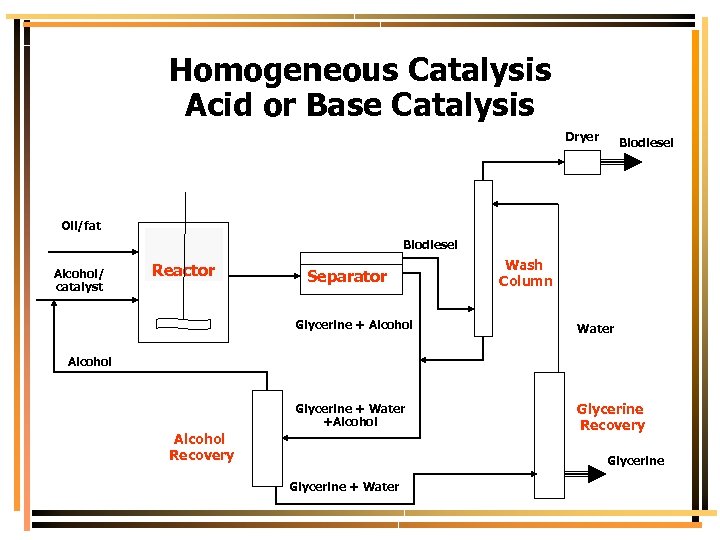

Homogeneous Catalysis Acid or Base Catalysis Dryer Biodiesel Oil/fat Biodiesel Alcohol/ catalyst Reactor Separator Wash Column Glycerine + Alcohol Water Glycerine + Water +Alcohol Glycerine Recovery Alcohol Recovery Glycerine + Water

Homogeneous Catalyst Options Ø Base Catalysts: Na. OH, KOH, Na/K-Methoxide Ø Acid Catalysts: H 2 SO 4, H 3 PO 4, Ca. CO 3 Ø Lipase Enzymes

Base Catalyzed Conversions ØBase catalyzed processes dominate current commercial production ØSensitive to water and free fatty acids ØTypical alcohol to oil ratio varies between 6: 1 and 10: 1 (mole ratio) ØTypical catalyst concentrations (w/w, %) ØNa. OH/KOH 0. 3 -1. 4% ØNa-Methoxide 0. 5% or less

Acid Catalyzed Conversions Ø Direct esterification, oils with high free fatty acid Ø Ø Ø content or for making esters from soap stock Requires water removal Requires high alcohol: free fatty acid ratio, i. e. 40: 1 Requires large amount of catalyst (5 -25%)

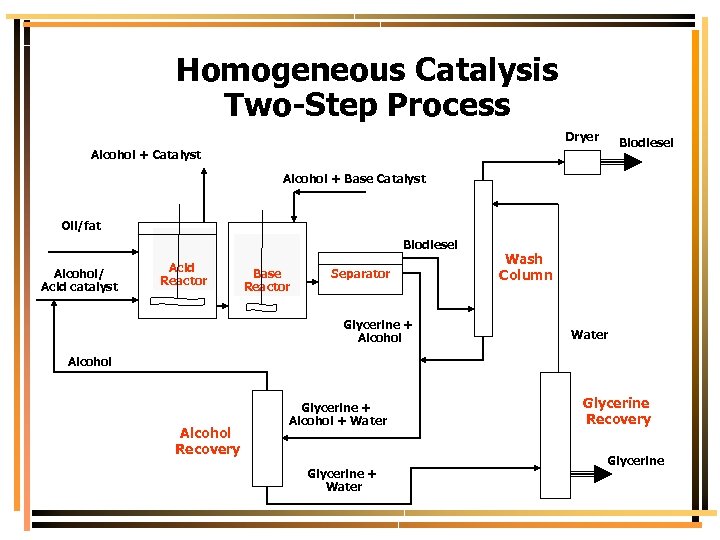

Homogeneous Catalysis Two-Step Process Dryer Biodiesel Alcohol + Catalyst Alcohol + Base Catalyst Oil/fat Biodiesel Alcohol/ Acid catalyst Acid Reactor Base Reactor Separator Glycerine + Alcohol Wash Column Water Alcohol Recovery Glycerine + Alcohol + Water Glycerine Recovery Glycerine

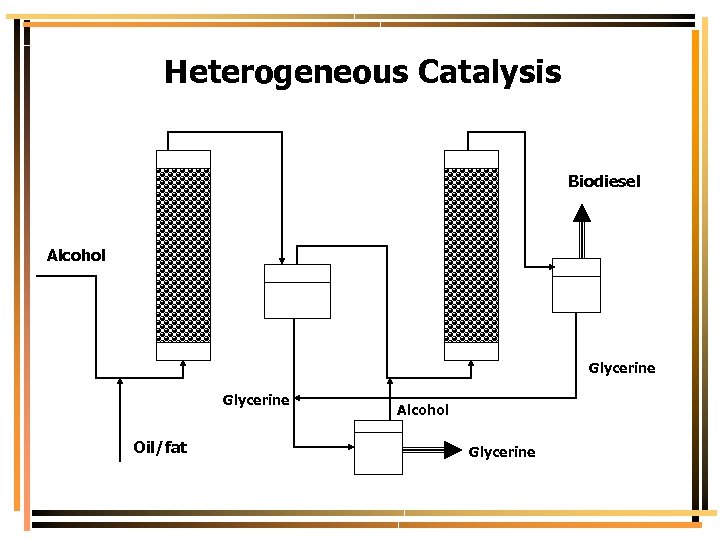

Heterogeneous Catalysis Biodiesel Alcohol Glycerine Oil/fat Alcohol Glycerine

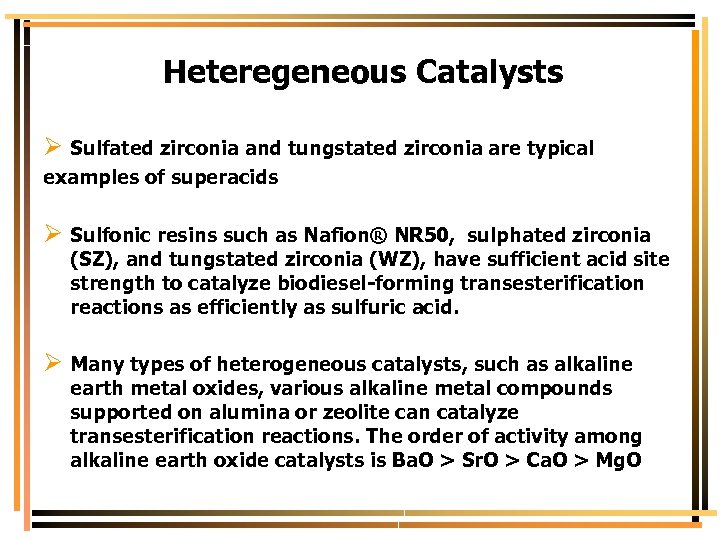

Heteregeneous Catalysts Ø Sulfated zirconia and tungstated zirconia are typical examples of superacids Ø Sulfonic resins such as Nafion® NR 50, sulphated zirconia (SZ), and tungstated zirconia (WZ), have sufficient acid site strength to catalyze biodiesel-forming transesterification reactions as efficiently as sulfuric acid. Ø Many types of heterogeneous catalysts, such as alkaline earth metal oxides, various alkaline metal compounds supported on alumina or zeolite can catalyze transesterification reactions. The order of activity among alkaline earth oxide catalysts is Ba. O > Sr. O > Ca. O > Mg. O

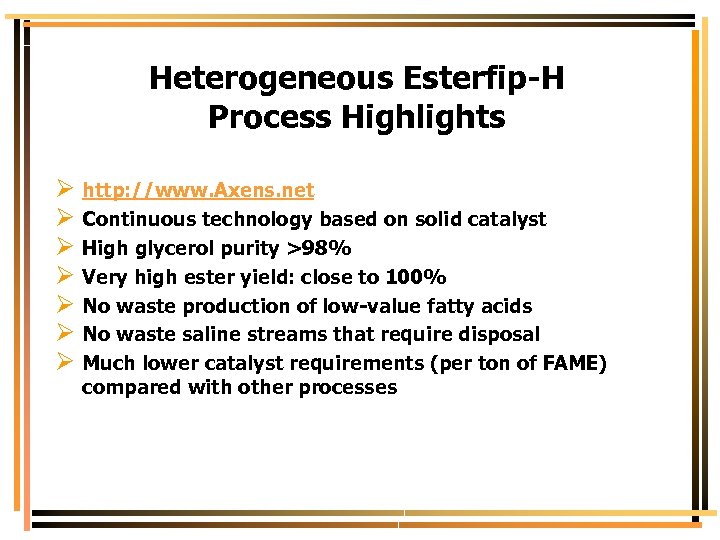

Heterogeneous Esterfip-H Process Highlights Ø http: //www. Axens. net Ø Continuous technology based on solid catalyst Ø High glycerol purity >98% Ø Very high ester yield: close to 100% Ø No waste production of low-value fatty acids Ø No waste saline streams that require disposal Ø Much lower catalyst requirements (per ton of FAME) compared with other processes

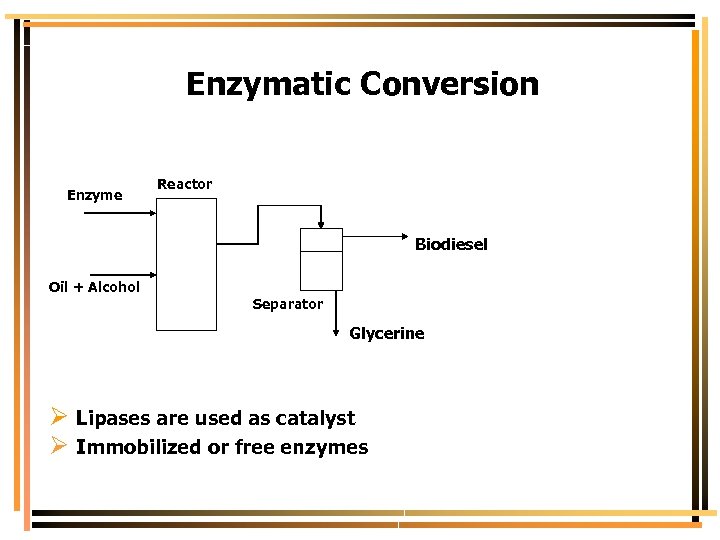

Enzymatic Conversion Enzyme Reactor Biodiesel Oil + Alcohol Separator Glycerine Ø Lipases are used as catalyst Ø Immobilized or free enzymes

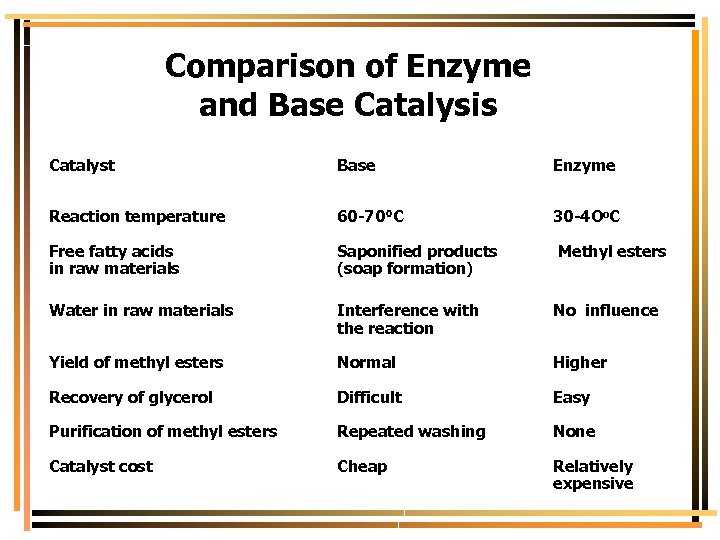

Comparison of Enzyme and Base Catalysis Catalyst Base Enzyme Reaction temperature 60 -70°C 30 -4 Oo. C Free fatty acids in raw materials Saponified products (soap formation) Methyl esters Water in raw materials Interference with the reaction No influence Yield of methyl esters Normal Higher Recovery of glycerol Difficult Easy Purification of methyl esters Repeated washing None Catalyst cost Cheap Relatively expensive

Batch vs Continuous System Ø Batch process is better suited to smaller plants (<1 million gallons/year) Ø Batch process provides operation flexibility Ø Continuous process allows use of high volume separation systems hence increases throughput

Transesterification Time Ø At ambient temperature (70 F and 21 o. C) reaction takes Ø Ø 4 -8 h to reach completion Higher temperature will decrease reaction times but this requires pressure vessel because boiling point of methanol is 148 F (65 o. C) High shear mixing and co-solvent use accelerates reaction rates

Non-Catalytic Conversions Ø Supercritical fluids Ø Co-solvent systems

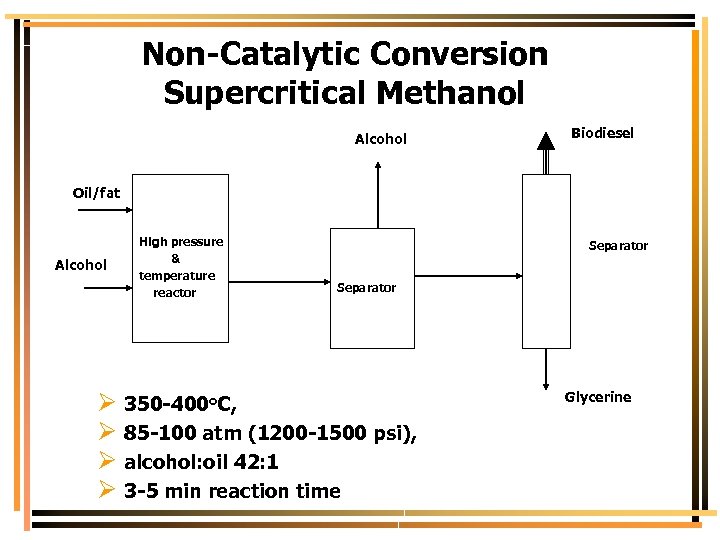

Non-Catalytic Conversion Supercritical Methanol Alcohol Biodiesel Oil/fat Alcohol High pressure & temperature reactor Separator Ø 350 -400 o. C, Ø 85 -100 atm (1200 -1500 psi), Ø alcohol: oil 42: 1 Ø 3 -5 min reaction time Glycerine

Non-Catalytic Conversion Co-Solvent Process Biox Process Ø Uses an inert co-solvents (tetrahydrofuran, MTBE-methyl tert-butyl ether, ) that generate an oil-rich one-phase system. Ø This reaction is 95% complete in ten minutes at ambient temperatures. Ø No catalyst is required. Alcohol Oil

Phase Separation Required density difference for phase separation 0. 1 Specific Gravity Methanol Biodiesel Soybean oil Catalyst Glycerine 0. 79 0. 88 0. 92 0. 97 1. 28 “Good reaction” “Good phase separation” as much methanol as possible min. methanol

Super. Cetane Ø Several reactions occur in the process, including: hydrocracking (breaking apart of large triglyceride molecules), hydrotreating (removal of oxygen), and hydrogenation (saturation of double bonds). A conventional commercial refinery hydrotreating catalyst is used in the process and hydrogen is the only other input. Ø Feedstocks: canola oil, soya oil, yellow grease, animal tallow and tall oil (a by-product of the kraft pulping process). Ø Cetane number (a measure of ignition quality) of around 100 – which is comparable to commercial cetane additives. The specific gravity of Super. Cetane is similar to regular diesel while its viscosity is similar to biodiesel. It is 97% biodegradable as compared to 45% for regular diesel. Ø http: //www. nrcan. gc. ca/es/etb/cetc 01/htmldocs/pdfs/sup ercetane_e. pdf

AVRO Diesel TM Process Ø(http: //www. nrcan. gc. ca/es/etb/cetc 01/htmldocs/ pdfs/avro_diesel_e. pdf) combines mild thermal cracking with esterification. This process is being patented by the CANMET Energy Technology Centre – Ottawa. ØFeedstock: waste animal fats, cooking greases, and trap grease that are 'too contaminated' for a conventional trans -esterification process, and produces clean diesel fuel. ØThe process yields 65 to 75 wt% hydrocarbons/methyl-esters mixtures suitable for diesel fuel blending.

Conoco. Phillips/Tyson Renewable Diesel Ø The production technology for renewable diesel uses a Ø thermal depolymerization process to co-process animal fat with hydrocarbon feedstock. The fuel is chemically equivalent to the diesel produced from hydrocarbon feedstocks and can be transported directly through existing pipelines to distribution terminals.

Biodiesel Dry. Wash. TM Ø Adsorbent purification Ø Magnesium Silicate (Magnesol D-Sol) Ø Removes both particles and soluble impurities Ø Excess methanol flash evaporated http: //www. dallasgrp. com/biodiesel. pdf

Ion Exchange Dry Wash Ø Ion exchange resin is used for biodiesel cleaning. Ø Greenline & Rohm-Haas Corporation collaboration: IonØ Ø Ø exchange resin known as Amberlite looks very much like coffee grounds and functions much like coffee grounds in a percolator. The biodiesel fuel enters the top of the percolator and trickles down through the cylinder of Amberlite. The final product is pure and dry. The resin needs replacing at the rate of about 1 metric ton for every 250, 000 gallons of biodiesel processed. http: //www. greenlineindustries. com/Process. Desc_1. htm

Technology Providers Ø Desmet Ballestra North America Ø Westfalia Separator, Inc. Ø Crown Irons Works Ø Lurgi PSI

Reading Material http: //www. southeastdiesel. org/Photos/Library/Ag/Eng_ Aspects. Ch 1. pdf http: //www. fapc. okstate. edu/factsheets/fapc 149. pdf http: //www. fapc. okstate. edu/factsheets/fapc 150. pdf http: //www. uidaho. edu/bioenergy/biodiesel. ED/publicati on/01. pdf University of Idaho-Questions http: //www. uidaho. edu/bioenergy/top 10 q_s. htm

Questions Ø Define biodiesel Ø What are three components that are required for Ø Ø Ø making biodiesel? What are the advantages and disadvantages of using ethanol instead of methanol for biodiesel production? What are the most common catalysts (acid and base) used for biodiesel production? Name two reactions that are used for biodiesel production and highlight differences Compare energy contents of biodisel and petroleum diesel Name two biodiesel production techniques which do not require a catalyst

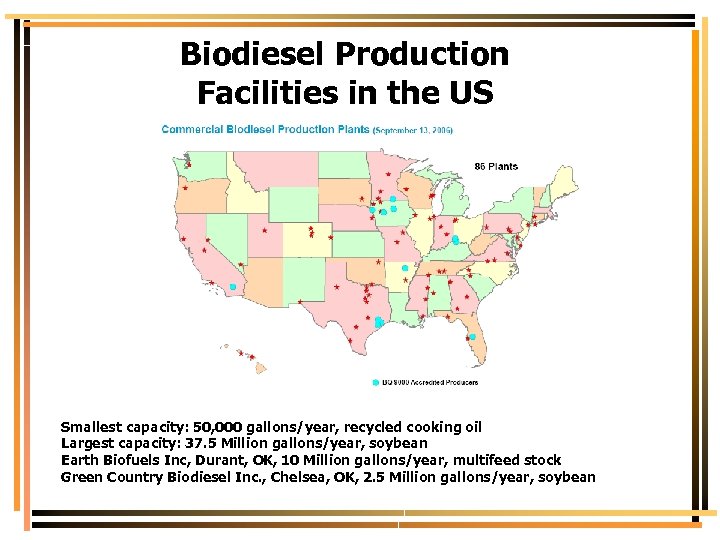

Biodiesel Production Facilities in the US Smallest capacity: 50, 000 gallons/year, recycled cooking oil Largest capacity: 37. 5 Million gallons/year, soybean Earth Biofuels Inc, Durant, OK, 10 Million gallons/year, multifeed stock Green Country Biodiesel Inc. , Chelsea, OK, 2. 5 Million gallons/year, soybean

Biodiesel Industry Expansion Largest Capacity: 100 Million gallons/year Smallest Capacity: 250, 000 gallons/year ADM, 85 Million gallons/year, canola oil Best Energy Solutions LLC, Tulsa, OK, 1 Million gallons/year

Planning* Ø Location Ø Biodiesel Marketing Ø Feedstock Sourcing Ø Glycerine Outlet Ø Process Plant Size * Chris Mitchell – Biodiesel Product Manager Desmet Ballestra North America

Location* ØMinimizing the freight cost for feedstock and biodiesel will be critical to survive. ØHow much biodiesel can be sold in a 200 mile radius? ØHow much competition or potential competition exists in a 200 mile radius? * Chris Mitchell – Biodiesel Product Manager Desmet Ballestra North America

Feedstock Sourcing* ØDo you have control of your own feedstock supply (as an oilseed crusher or animal fats renderer)? ØIf you are dependent on an external supply, how many potential suppliers are within a 200 mile radius? ØCan you sign a long-term contract with one of these suppliers to insure adequate feedstock? ØWill the feedstock suppliers in the area deliver by truck or rail, and at what frequency? * Chris Mitchell – Biodiesel Product Manager Desmet Ballestra North America

Glycerin Outlet* ØWhere are the closest potential buyers of glycerin? ØWhat quality of crude glycerin (H 2 O, Me. OH, soap, FFA, salt etc) will they purchase, and at what price relative to USP grade refined glycerin? ØWill the glycerin refiners in the area want delivery by truck or rail, and at what frequency? ØDo you need to install your own glycerin refinery? * Chris Mitchell – Biodiesel Product Manager Desmet Ballestra North America

Process Plant Size* ØWhat plant size will meet the short and long term needs of the local biodiesel market? ØHow does local feedstock availability limit plant size? ØWhat minimum plant size is required to provide a competitive conversion cost in the long-term? ØHow much equity and debt financing is available to build the plant, and how much capacity can that buy? * Chris Mitchell – Biodiesel Product Manager Desmet Ballestra North America

Plant Site Selection* ØTransportation Proximity Ø Utility Connections Ø Specific Parcel of Land Ø Shared Infrastructure * Chris Mitchell – Biodiesel Product Manager Desmet Ballestra North America

Transportation Proximity* ØIs the site adjacent to an active freight rail system? ØDoes the site, or can the site, have a rail siding installed with sufficient length of track? ØAt what frequency are rail switches possible, and how will the rail cars be moved for loading/unloading? ØIs the site in close proximity to a highway? * Chris Mitchell – Biodiesel Product Manager Desmet Ballestra North America

Utility Connections* ØDoes the site have sufficient power supply available? ØDoes the site have sufficient water supply available (to meet fire protection demand)? ØDoes the site have a sewer connection that can take the plant waste water? ØDoes the plant have natural gas supply available? * Chris Mitchell – Biodiesel Product Manager Desmet Ballestra North America

Land* ØDoes the site have sufficient space for the process plant (with surrounding safe area), tank farm, utility building, office building, rail siding and truck route? ØDoes the site have sufficient extra space for a future biodiesel plant expansion or glycerine refinery? ØIs the site long enough for the rail siding to hold a sufficient number of cars? ØAny environmental & construction permitting issues? * Chris Mitchell – Biodiesel Product Manager Desmet Ballestra North America

Infrastructure* ØDoes the site already have a process plant staff (management, marketing, purchasing, maintenance and quality control) that can be shared to offset conversion costs? ØDoes the site already feedstock tanks to reduce feedstock (freight) costs? ØDoes the site already have utilities that can be shared? * Chris Mitchell – Biodiesel Product Manager Desmet Ballestra North America

Critical Parameters* Ø Safety Ø Quality Ø Downtime/Uptime Ø Operating Costs Ø Capital Costs * Chris Mitchell – Biodiesel Product Manager Desmet Ballestra North America

Safety* ØBiodiesel plants use a considerable quantity of highly flammable liquid (methanol) & corrosive material (sodium methoxide). ØThe process plant must be designed as a hazardous area environment with the hazardous areas within and adjacent to the process building defined by NFPA-497 (NFPANational Fire Protection Association). ØThe methanol and sodium methoxide storage tanks must be designed in accordance with NFPA 30. * Chris Mitchell – Biodiesel Product Manager, Desmet Ballestra North America

Safety* ØSpecial Class 1, Division 1, Group D and Class 1, Division 2, Group D explosion proof electrical design is required as per NFPA-70 to minimize a source of ignition. * Chris Mitchell – Biodiesel Product Manager, Desmet Ballestra North America

Quality* ØAll biodiesel leaving the facility must meet ASTM (American Society of Testing and Materials) specs at a minimum. ØBiodiesel leaving the facility should meet specs as agreed to with the buyer. ØBiodiesel should also be transported in clean vessels. * Chris Mitchell – Biodiesel Product Manager, Desmet Ballestra North America

Quality* ØBiodiesel should be analyzed before being sent to storage. ØA biodiesel plant should have a fully equipped lab with a qualified chemist that understands the chemistry and unit processes in the plant well enough to trouble-shoot feedstock & process issues and give the operations staff feedback. * Chris Mitchell – Biodiesel Product Manager, Desmet Ballestra North America

Downtime* ØPlants are often stopped for lack of feedstock, biodiesel and crude glycerine sales, sufficient storage or loading & unloading logistics. ØPlants also suffer from quality problems which require significant rework, and resultant loss of production time. * Chris Mitchell – Biodiesel Product Manager, Desmet Ballestra North America

Uptime* ØA biodiesel plant should operate a minimum of 8, 000 hours per year at its design rate (>90% uptime). ØThe fixed costs of capital and semi-fixed costs of manpower need to be spread out upon a full production schedule to minimize conversion costs. * Chris Mitchell – Biodiesel Product Manager, Desmet Ballestra North America

Operating Costs* ØApproximately 85% of operating cost of a biodiesel plant is for feedstock. ØProducing your own feedstock to insure supply at a fair price, and minimizing the freight to deliver the feedstock to the biodiesel plant, are both critical factors in controlling profitability. ØAn alternative to controlling supply is to have a flexible process to handle multiple feedstock sources (such as soybean oil, poultry fat or yellow grease). * Chris Mitchell – Biodiesel Product Manager, Desmet Ballestra North America

Operating Costs* ØTotal conversion costs range from $0. 30 to $0. 50 per gallon depending on technology and plant size. ØChemical consumptions, utility consumptions and maintenance costs (50 -75% of the conversion cost) are more a function of the technology than plant size. ØSelecting automated, continuous or semi-continuous process technology is a critical factor in controlling plant profitability. * Chris Mitchell – Biodiesel Product Manager, Desmet Ballestra North America

Operating Costs* ØTotal conversion costs range from $0. 30 to $0. 50 per gallon depending on technology and plant size. ØManpower, taxes, insurance and depreciation (25 -50% of conversion cost) are more a function of plant size than technology. ØSelecting a plant large enough to take advantage of economy of scale (capital & manpower) is a critical factor in controlling plant profitability. * Chris Mitchell – Biodiesel Product Manager, Desmet Ballestra North America

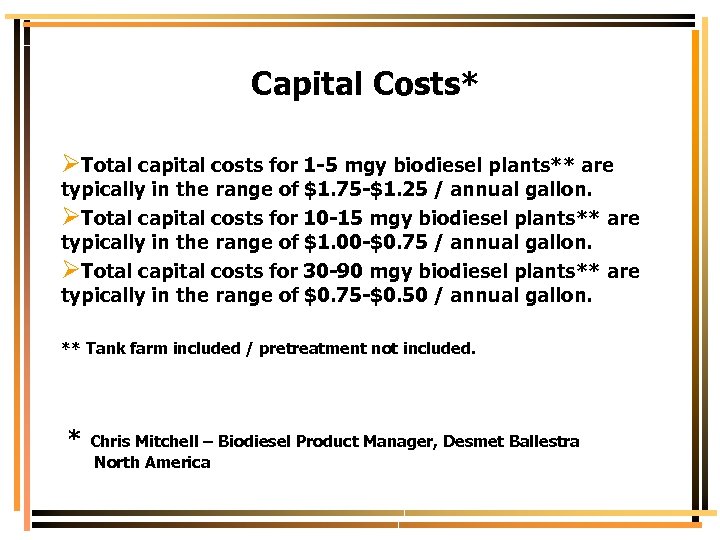

Capital Costs* ØProcess equipment only accounts for 25 -35% of total capital cost in a typical biodiesel plant. * Chris Mitchell – Biodiesel Product Manager, Desmet Ballestra North America

Capital Costs* ØTotal capital costs for 1 -5 mgy biodiesel plants** are typically in the range of $1. 75 -$1. 25 / annual gallon. ØTotal capital costs for 10 -15 mgy biodiesel plants** are typically in the range of $1. 00 -$0. 75 / annual gallon. ØTotal capital costs for 30 -90 mgy biodiesel plants** are typically in the range of $0. 75 -$0. 50 / annual gallon. ** Tank farm included / pretreatment not included. * Chris Mitchell – Biodiesel Product Manager, Desmet Ballestra North America

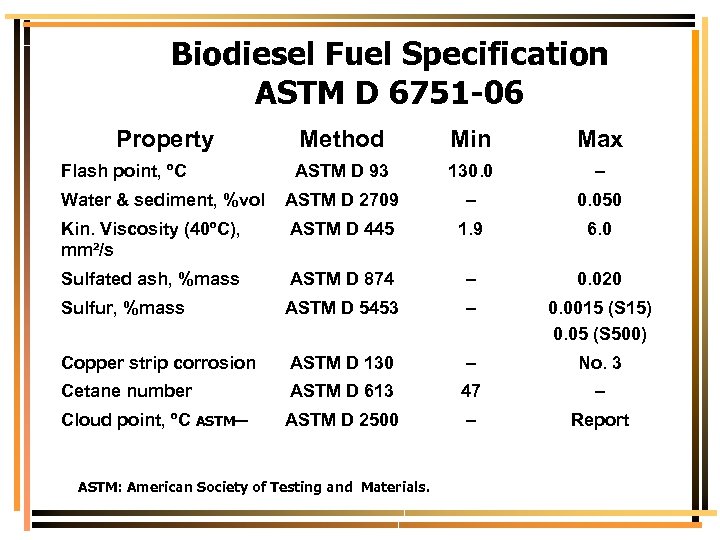

Biodiesel Fuel Specification ASTM D 6751 -06 Property Method Min Max ASTM D 93 130. 0 – Water & sediment, %vol ASTM D 2709 – 0. 050 Kin. Viscosity (40ºC), mm²/s ASTM D 445 1. 9 6. 0 Sulfated ash, %mass ASTM D 874 – 0. 020 Sulfur, %mass ASTM D 5453 – 0. 0015 (S 15) 0. 05 (S 500) Copper strip corrosion ASTM D 130 – No. 3 Cetane number ASTM D 613 47 – Cloud point, ºC ASTM— ASTM D 2500 – Report Flash point, ºC ASTM: American Society of Testing and Materials.

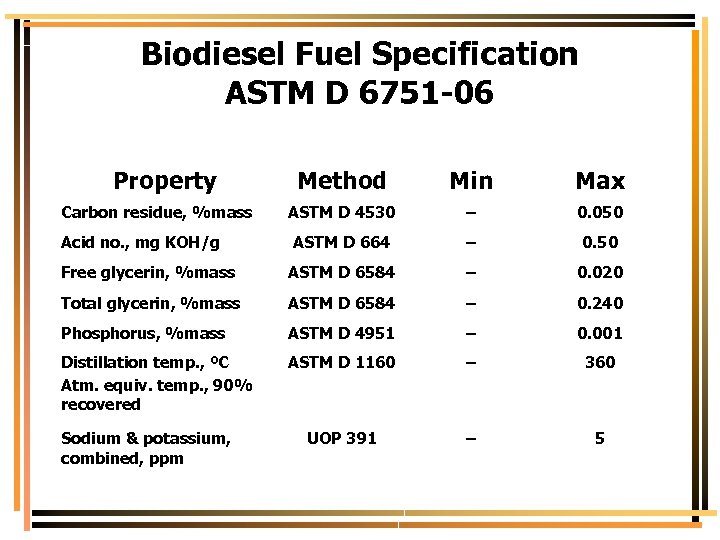

Biodiesel Fuel Specification ASTM D 6751 -06 Property Method Min Max ASTM D 4530 – 0. 050 ASTM D 664 – 0. 50 Free glycerin, %mass ASTM D 6584 – 0. 020 Total glycerin, %mass ASTM D 6584 – 0. 240 Phosphorus, %mass ASTM D 4951 – 0. 001 Distillation temp. , ºC Atm. equiv. temp. , 90% recovered ASTM D 1160 – 360 UOP 391 – 5 Carbon residue, %mass Acid no. , mg KOH/g Sodium & potassium, combined, ppm

Biodiesel Quality Assurance ØTesting in accordance with fuel specifications is time consuming and expensive ØIn North America, the “BQ-9000” program helps assure quality in biodiesel fuel

Biodiesel Quality Assurance BQ-9000 Program National Biodiesel Accreditation Program ØEndorsed by NBB & Canadian Renewable Fuels Association ØCooperative & voluntary program for accreditation of biodiesel producers & marketers ØOpen to manufacturers, marketers & distributors of biodiesel & blends in the U. S. & Canada ØCombines ASTM D 6751 standard with quality systems program including practices for storage, sampling, testing, blending, shipping, distribution & fuel management

Biodiesel Quality Assurance BQ-9000 Program National Biodiesel Accreditation Committee (NABC) is a fully autonomous committee of NBB Designed & implemented BQ-9000 program Responsible for developing improvements Program objectives: Promote commercial success & acceptance of biodiesel Help assure biodiesel is produced to & maintained at industry standard, ASTM D 6751 Avoid redundant testing during production & distribution Provide mechanism to track biodiesel in distribution chain Reduce probability of “out of spec” fuel reaching the market

Biodiesel Quality Assurance BQ-9000 Program Accreditation ØOpen to companies actively or planning to produce, distribute or market biodiesel in “neat” or blended formulations ØRequires formal review & audit of capacity of applicant to produce or market biodiesel that meets ASTM D 6751 standards ØOnce it is awarded, it is held for two years ØFollowing two-year period, company undergoes recertification audit to extend accreditation

Biodiesel Quality Assurance BQ-9000 Program Accredited Producer ØEntity engaged in production and/or distribution & sale of biodiesel and/or biodiesel blends of B 2 or greater ØSuccessfully met accreditation requirements Accredited Producers: AGP, Cargill, Eastman Chemical (AR Ops), Griffin Industries, Huish Detergents, Imperial Western Products, Johann Haltermann, Organic Fuels, Peter Cremer NA, Soy. Mor Biodiesel, West Central, World Energy Alternatives

Biodiesel Quality Assurance BQ-9000 Program Certified Marketer ØEntity undertaking to sell or resell biodiesel or biodiesel blends ØSuccessfully met accreditation requirements Certified Marketers: Peter Cremer NA, Sprague Energy

0cbc1bf7890e4f58a1086fe2a8a24004.ppt