d804446a9ef8eee1063421d61ca1b2b3.ppt

- Количество слайдов: 56

Engineering 11 Formulate Design Prob Bruce Mayer, PE Licensed Electrical & Mechanical Engineer BMayer@Chabot. College. edu Engineering-11: Engineering Design 1 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

Example Improve Motor. Cycle § Other Useful Information • What is the target cost-to-manufacture? • Which is more preferred: low-end torque or high-end speed? • What is the anticipated production run quantity? • What types of instruments are preferred, digital and or analog? • What are the desired service intervals? Engineering-11: Engineering Design 2 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

Formulating Design Problems § § § § § Designing a high-performance motorcycle What is a “design problem? ” What is the “solution” to a design problem? How do we solve a design problem? Steps in formulating the Design Problem Customer & Company requirements Engineering Design Specifications Gaining Consensus Quality Products QFD/House of Quality Engineering-11: Engineering Design 3 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

What is a design problem? § An opportunity to make and sell a new product § Need to fix an existing product § Make and sell a variant of an older design [Customer or Company Requirements] ↓define↓ [”Function”] Engineering-11: Engineering Design 4 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

Example Improve Motor. Cycle § What info would help us understand this design problem? • How quickly should the Motor. Cycle accelerate to 60 mph? • What should the top speed be? • Is fuel consumption less important than acceleration? • What riding comforts are expected? • Is an electric starter desired? • Will the customer tolerate a liquid cooling system? • Will customer care about aesthetics? Engineering-11: Engineering Design 5 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

“Solution” to a Design Prob § § § Set of Drawings & Bills of Materials Predicted performance calculations Test reports on prototypes Manufacturing specifications Estimates of sales-revenue, costs, profit § [“design” ready for manufacture] →defines→ [“Form”] Engineering-11: Engineering Design 6 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

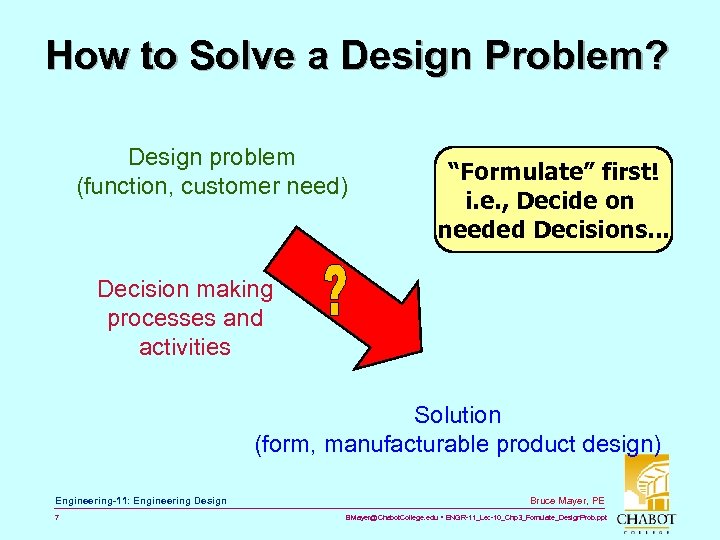

How to Solve a Design Problem? Design problem (function, customer need) “Formulate” first! i. e. , Decide on needed Decisions. . . Decision making processes and activities Solution (form, manufacturable product design) Engineering-11: Engineering Design 7 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

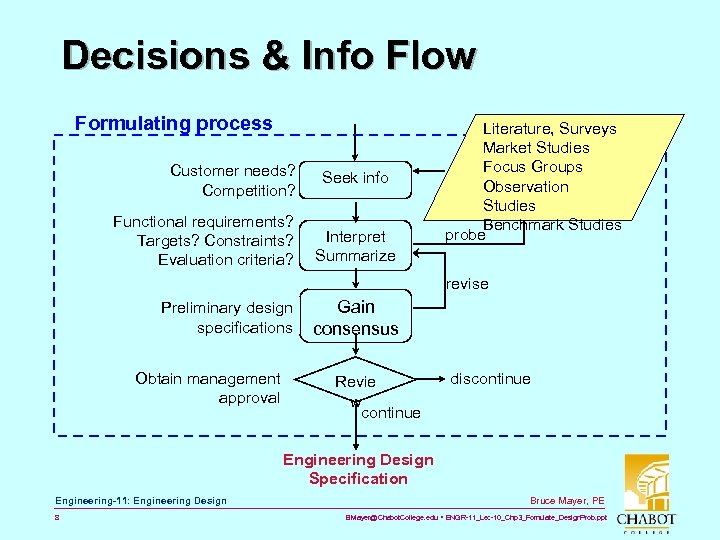

Decisions & Info Flow Formulating process Customer needs? Competition? Functional requirements? Targets? Constraints? Evaluation criteria? Seek info Interpret Summarize Literature, Surveys Market Studies Focus Groups Observation Studies Benchmark Studies probe revise Preliminary design specifications Obtain management approval Gain consensus Revie w continue discontinue Engineering Design Specification Engineering-11: Engineering Design 8 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

Steps In Formulating Design Prob 1. obtain a detailed understanding of the design problem; i. e. , the application 2. document our understanding in an Engineering Design Spec (EDS) 3. choose a solution strategy 4. develop a project plan (scope of work, budget and schedule) 5. establish a consensus among team members & management Engineering-11: Engineering Design 9 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

1. Obtain a Detailed Understanding § Need ACCURATE Information on • Company Requirements (easy) • CUSTOMER Requirements (hard) § The “Requirements” for a Design typically divide into two categories • PERFORMANCE Requirements • Constraint Requirements – e. g. , Meet N. E. C. Electrical Code • Business Impact Revenue, Profit, Ro. I Engineering-11: Engineering Design 10 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

Market Requirements State. Ment § The “MRS” is Also often called the Market Requirements Document (MRD) § MRS Most Often Prepared by the Technical Marketing Team With Extensive Consultation with • Upper Management • Senior Design Engineers Engineering-11: Engineering Design 11 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

MRS/MRD Purpose § Provide an outline of the prospective product for all interested parties • Investors, Sales Engineers, Finance, Upper Management, Engineering, others § Provide enough information for engineering to write a functional design specification for the product • The Design Spec if Often Called the Engineering Design Specification (EDS) Engineering-11: Engineering Design 12 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

MRS ↔ Design Engineering § Once the New Product Has been Approved (i. e. , Meets the Company Ro. I Requirement) The Design Engineering Focuses on These Portions of the MRS • Product Performance – Becomes the Heart of the Engineering Design Spec (EDS) • Code-Compliance Constraints • Product Cost Targets Engineering-11: Engineering Design 13 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

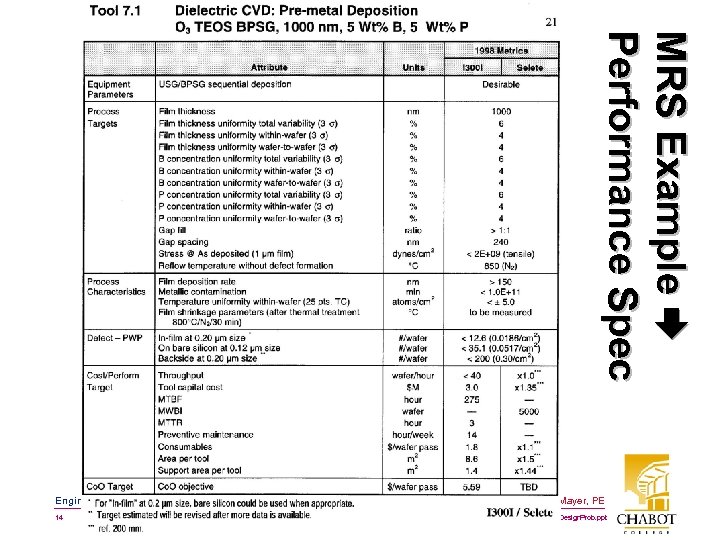

MR S E x a m p l e P e r fo r m a n c e S p e c Engineering-11: Engineering Design 14 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

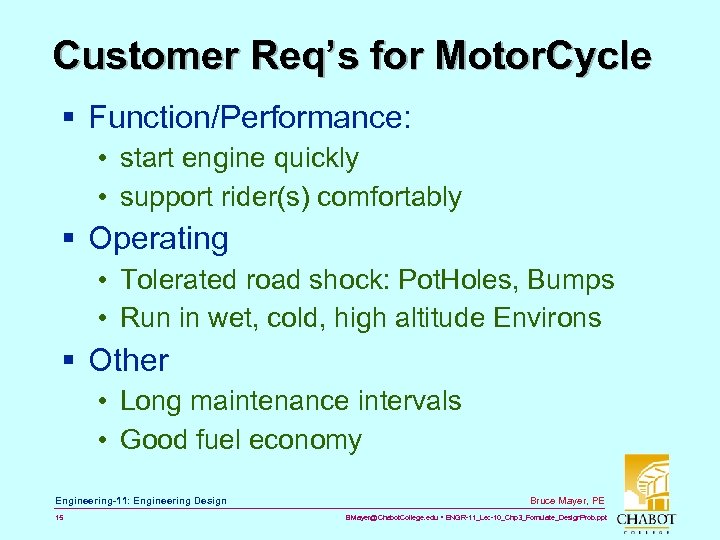

Customer Req’s for Motor. Cycle § Function/Performance: • start engine quickly • support rider(s) comfortably § Operating • Tolerated road shock: Pot. Holes, Bumps • Run in wet, cold, high altitude Environs § Other • Long maintenance intervals • Good fuel economy Engineering-11: Engineering Design 15 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

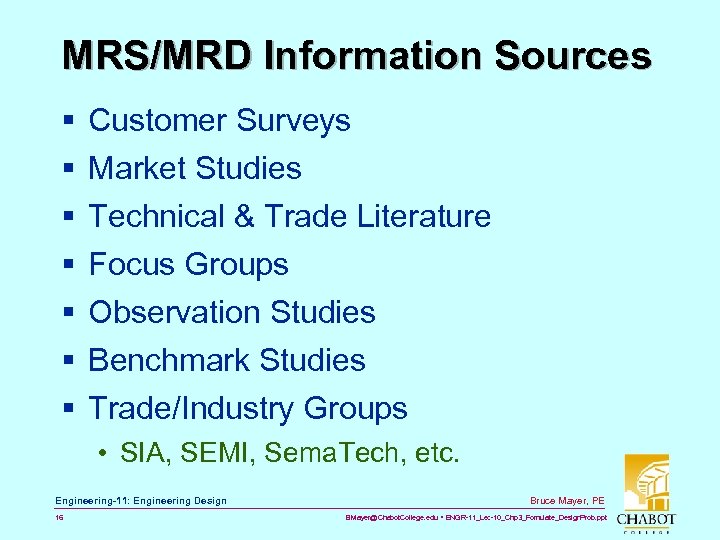

MRS/MRD Information Sources § § § § Customer Surveys Market Studies Technical & Trade Literature Focus Groups Observation Studies Benchmark Studies Trade/Industry Groups • SIA, SEMI, Sema. Tech, etc. Engineering-11: Engineering Design 16 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

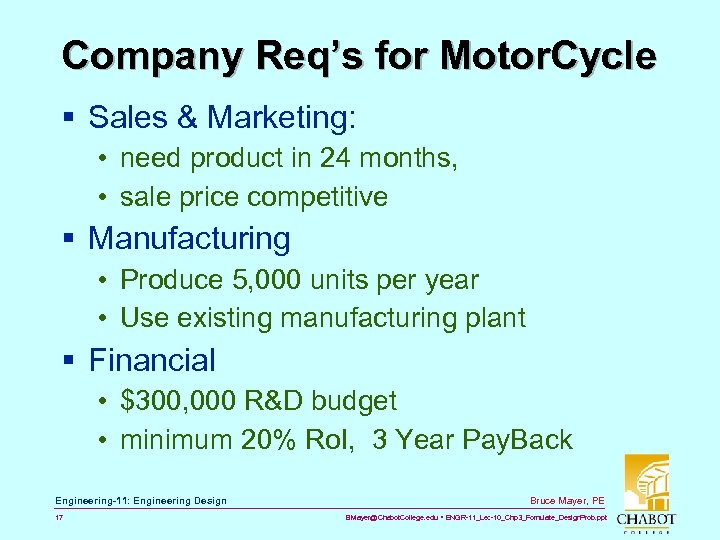

Company Req’s for Motor. Cycle § Sales & Marketing: • need product in 24 months, • sale price competitive § Manufacturing • Produce 5, 000 units per year • Use existing manufacturing plant § Financial • $300, 000 R&D budget • minimum 20% Ro. I, 3 Year Pay. Back Engineering-11: Engineering Design 17 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

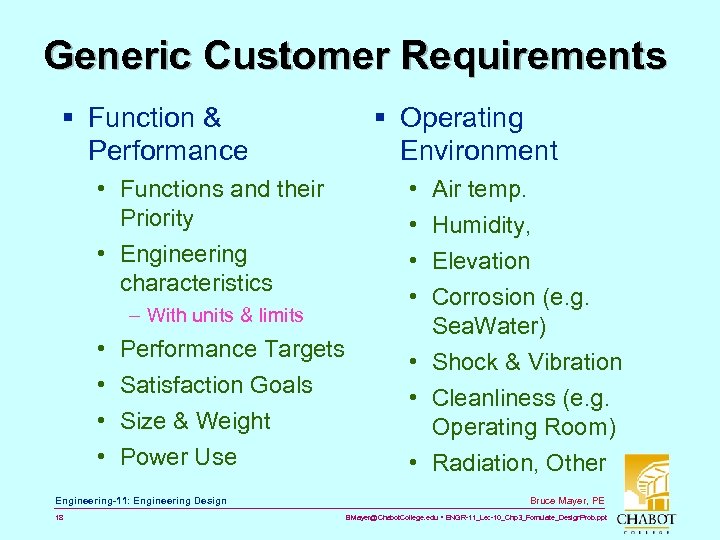

Generic Customer Requirements § Function & Performance • Functions and their Priority • Engineering characteristics – With units & limits • • Performance Targets Satisfaction Goals Size & Weight Power Use Engineering-11: Engineering Design 18 § Operating Environment • • Air temp. Humidity, Elevation Corrosion (e. g. Sea. Water) • Shock & Vibration • Cleanliness (e. g. Operating Room) • Radiation, Other Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

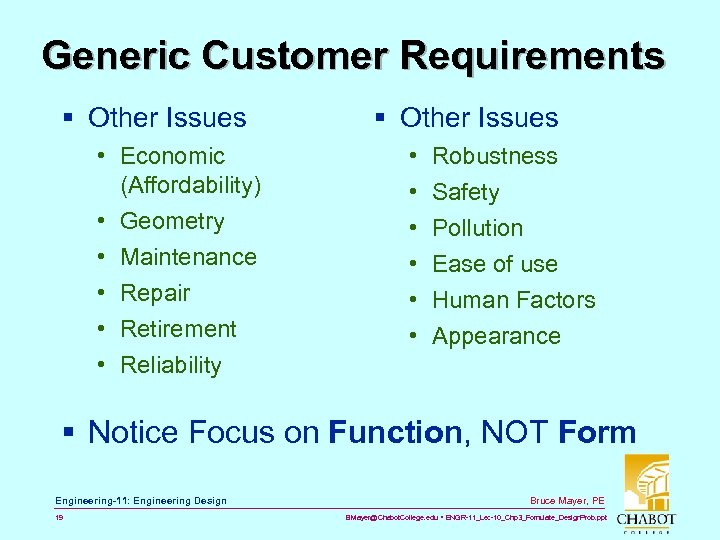

Generic Customer Requirements § Other Issues • Economic (Affordability) • Geometry • Maintenance • Repair • Retirement • Reliability § Other Issues • • • Robustness Safety Pollution Ease of use Human Factors Appearance § Notice Focus on Function, NOT Form Engineering-11: Engineering Design 19 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

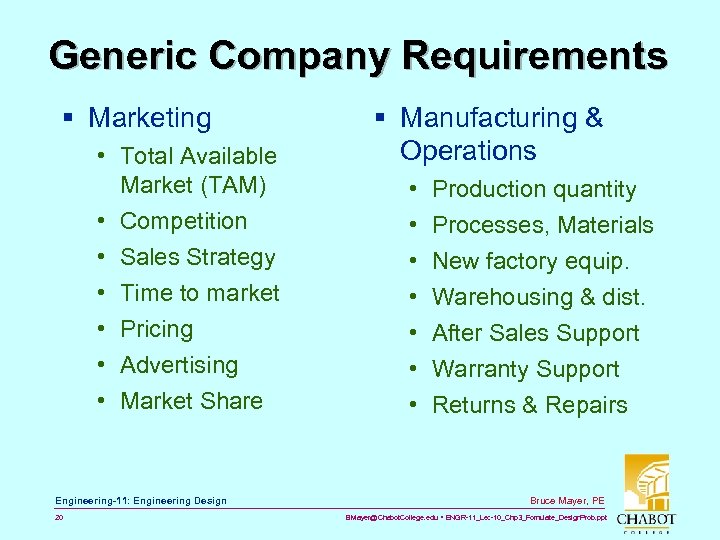

Generic Company Requirements § Marketing • Total Available Market (TAM) • Competition • Sales Strategy • Time to market • Pricing • Advertising • Market Share Engineering-11: Engineering Design 20 § Manufacturing & Operations • • Production quantity Processes, Materials New factory equip. Warehousing & dist. After Sales Support Warranty Support Returns & Repairs Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

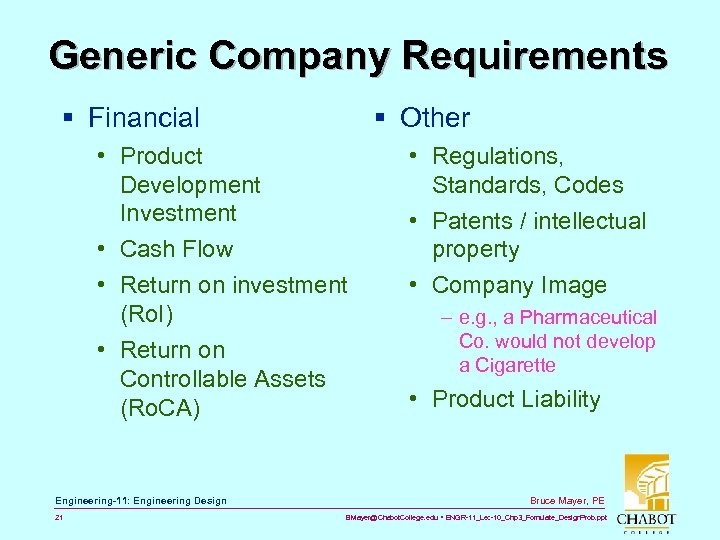

Generic Company Requirements § Financial § Other • Product Development Investment • Cash Flow • Return on investment (Ro. I) • Return on Controllable Assets (Ro. CA) Engineering-11: Engineering Design 21 • Regulations, Standards, Codes • Patents / intellectual property • Company Image – e. g. , a Pharmaceutical Co. would not develop a Cigarette • Product Liability Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

Must all requirements be satisfied? § Requirements can be separated into: • NEED-to-Have items – Product WILL FAIL in Market. Place w/o these – These “Must-Have” items Become “Constraints” on the Design • Nice-to-Have items – Produce will be MORE COMPETITIVE w/ these – These “Desirable” Features should be Weighted by “Importance-to-the-Market” Ø Weighting is Typically a Marketing Engineering Fcn Engineering-11: Engineering Design 22 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

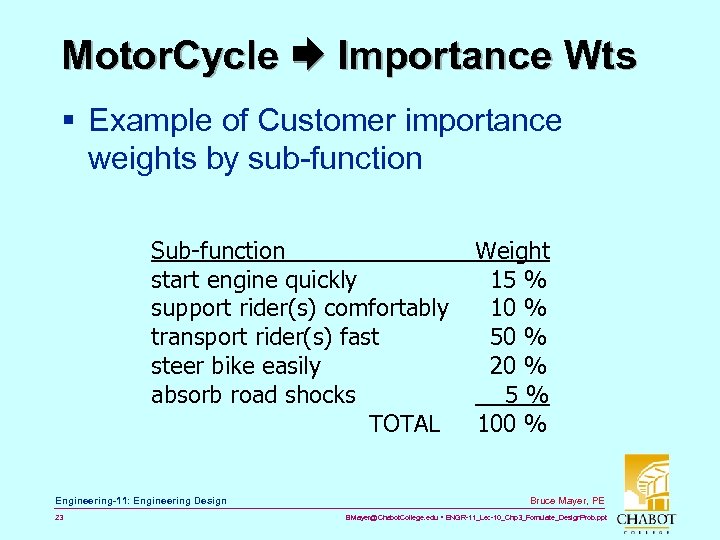

Motor. Cycle Importance Wts § Example of Customer importance weights by sub-function Sub-function start engine quickly support rider(s) comfortably transport rider(s) fast steer bike easily absorb road shocks TOTAL Engineering-11: Engineering Design 23 Weight 15 % 10 % 50 % 20 % 5% 100 % Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

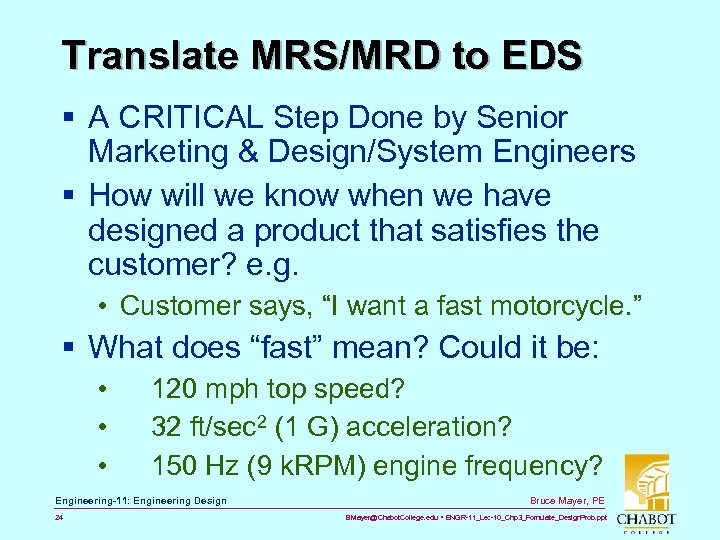

Translate MRS/MRD to EDS § A CRITICAL Step Done by Senior Marketing & Design/System Engineers § How will we know when we have designed a product that satisfies the customer? e. g. • Customer says, “I want a fast motorcycle. ” § What does “fast” mean? Could it be: • • • 120 mph top speed? 32 ft/sec 2 (1 G) acceleration? 150 Hz (9 k. RPM) engine frequency? Engineering-11: Engineering Design 24 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

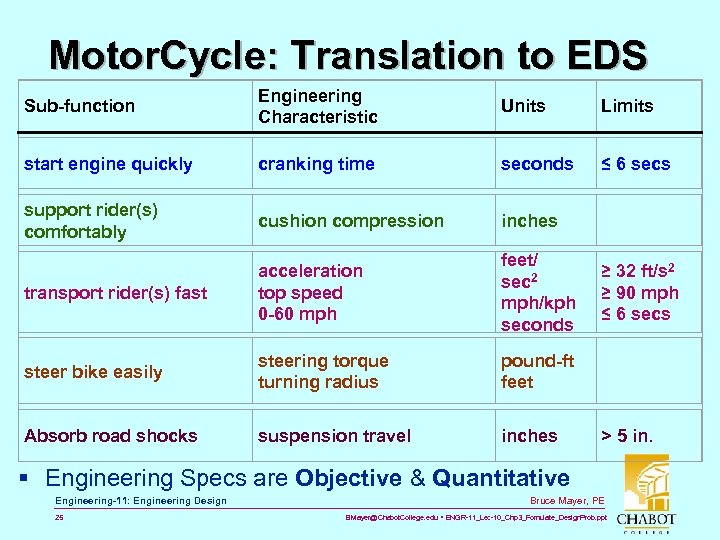

Motor. Cycle: Translation to EDS Sub-function Engineering Characteristic Units Limits start engine quickly cranking time seconds ≤ 6 secs support rider(s) comfortably cushion compression inches transport rider(s) fast acceleration top speed 0 -60 mph feet/ sec 2 mph/kph seconds steer bike easily steering torque turning radius pound-ft feet Absorb road shocks suspension travel inches > 5 in. ≥ 32 ft/s 2 ≥ 90 mph ≤ 6 secs § Engineering Specs are Objective & Quantitative Engineering-11: Engineering Design 25 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

Engineering Characteristics § Engineering Design Spec Elements are: quantities that measure the “performance” of a candidate design with respect to specific customer required functions Engineering-11: Engineering Design 26 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

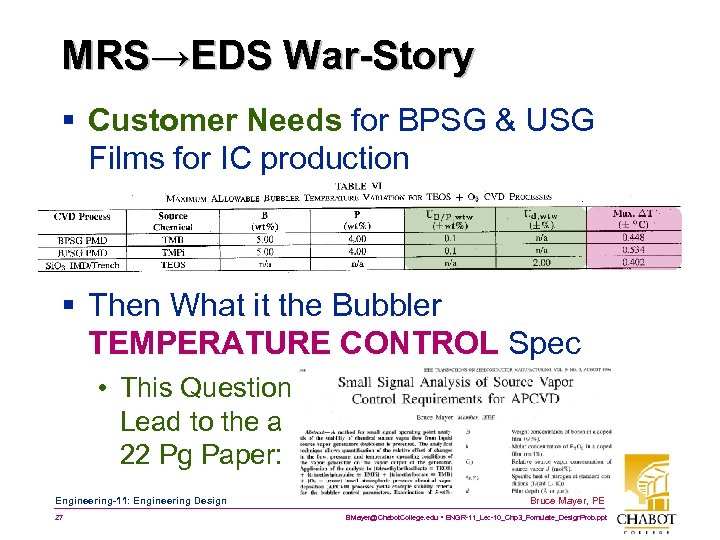

MRS→EDS War-Story § Customer Needs for BPSG & USG Films for IC production § Then What it the Bubbler TEMPERATURE CONTROL Spec • This Question Lead to the a 22 Pg Paper: Engineering-11: Engineering Design 27 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

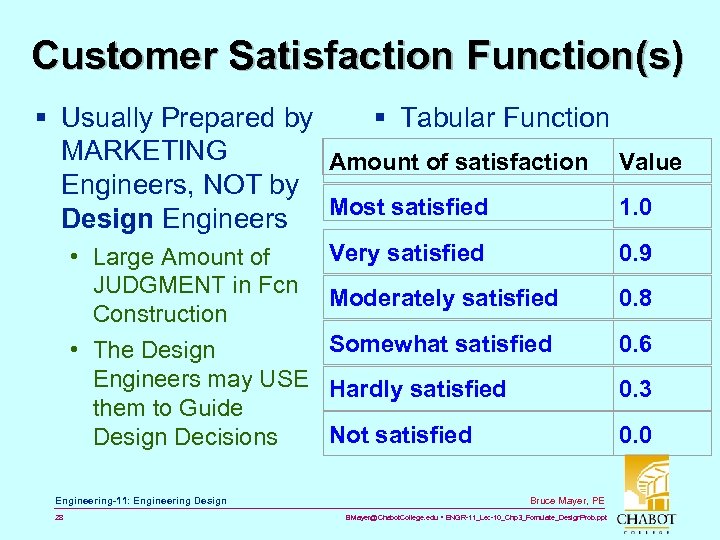

Customer Satisfaction Function(s) § Usually Prepared by § Tabular Function MARKETING Amount of satisfaction Value Engineers, NOT by 1. 0 Design Engineers Most satisfied • Large Amount of JUDGMENT in Fcn Construction • The Design Engineers may USE them to Guide Design Decisions Engineering-11: Engineering Design 28 Very satisfied 0. 9 Moderately satisfied 0. 8 Somewhat satisfied 0. 6 Hardly satisfied 0. 3 Not satisfied 0. 0 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

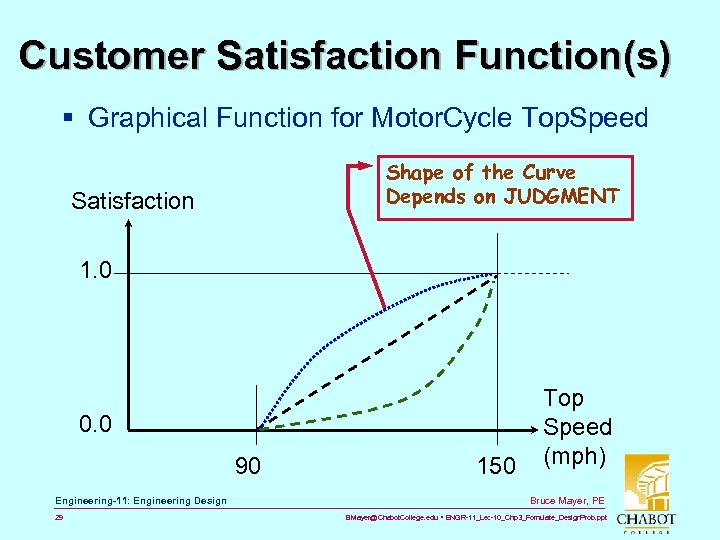

Customer Satisfaction Function(s) § Graphical Function for Motor. Cycle Top. Speed Shape of the Curve Depends on JUDGMENT Satisfaction 1. 0 0. 0 90 Engineering-11: Engineering Design 29 150 Top Speed (mph) Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

2. Document Under. Standing in EDS § The Engineering Design Specification is a Quantitative listing of the critical parameters, specifications, targets and requirements for the product you are designing. § It is a statement of what the product should BE and should DO. § Detail is added as the design grows. § The EDS is driven by customer needs. It is intended to show WHAT you are trying to ACHIEVE, NOT what you will end up with. Engineering-11: Engineering Design 30 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

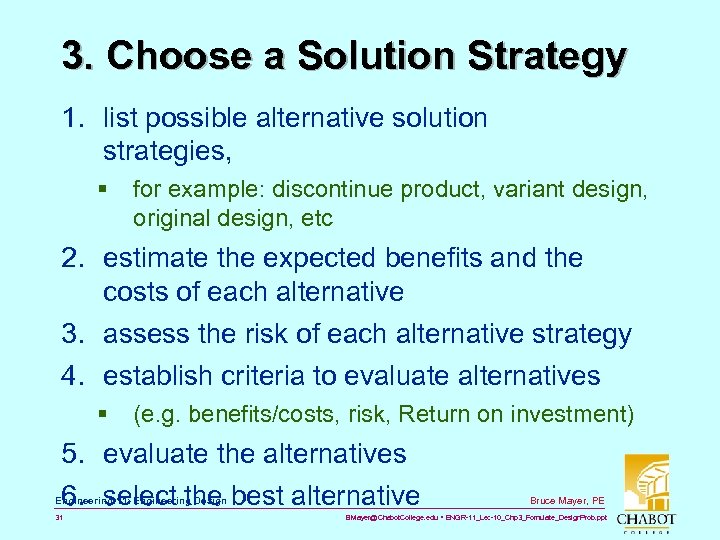

3. Choose a Solution Strategy 1. list possible alternative solution strategies, § for example: discontinue product, variant design, original design, etc 2. estimate the expected benefits and the costs of each alternative 3. assess the risk of each alternative strategy 4. establish criteria to evaluate alternatives § (e. g. benefits/costs, risk, Return on investment) 5. evaluate the alternatives 6. select the best alternative Engineering-11: Engineering Design 31 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

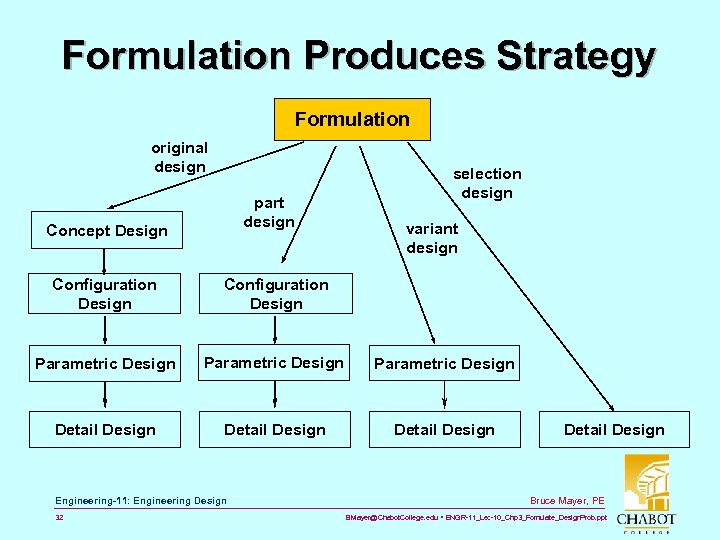

Formulation Produces Strategy Formulation original design part design Concept Design selection design variant design Configuration Design Parametric Design Detail Design Engineering-11: Engineering Design 32 Detail Design Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

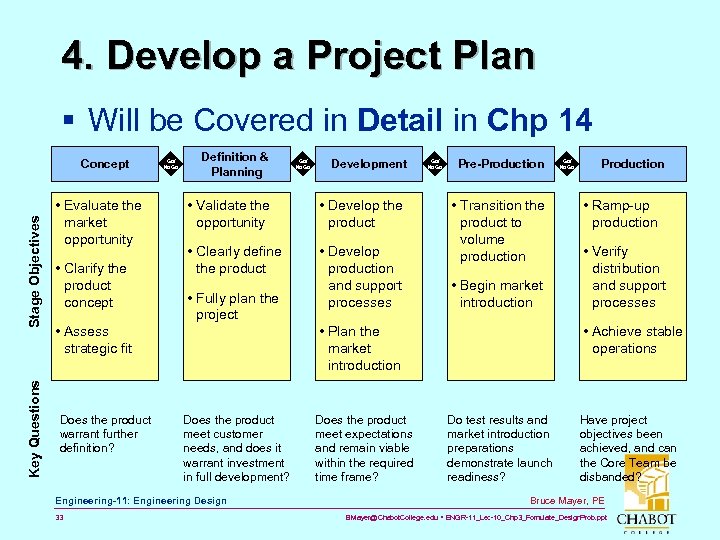

4. Develop a Project Plan § Will be Covered in Detail in Chp 14 Key Questions Stage Objectives Concept • Evaluate the market opportunity • Clarify the product concept Go/ No Go Definition & Planning • Develop the product • Clearly define the product • Develop production and support processes • Fully plan the project Go/ No Go Pre-Production • Transition the product to volume production • Begin market introduction • Plan the market introduction Does the product meet customer needs, and does it warrant investment in full development? Engineering-11: Engineering Design 33 Development • Validate the opportunity • Assess strategic fit Does the product warrant further definition? Go/ No Go Does the product meet expectations and remain viable within the required time frame? Go/ No Go Production • Ramp-up production • Verify distribution and support processes • Achieve stable operations Do test results and market introduction preparations demonstrate launch readiness? Have project objectives been achieved, and can the Core Team be disbanded? Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

5. Establish a Consensus § “Building In” the Consensus • Consensus is INTEGRAL To the Process § If all team members follow the previous five steps to a sound formulation, they will: • • Have a common understanding of the “problem, ” All Understand WHY, All Know WHAT has to be done and WHEN, and All Commit to WHO & HOW-MUCH Engineering-11: Engineering Design 34 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

Quality What is it? § TIME Magazine Survey responses • • • Works as it should Lasts a long time Is easy to maintain § Garvin, Commenting on Eight Dimensions of Quality, Harvard Business Review, Nov/Dec 1987 § § § Features § Durability Serviceability § Aesthetics Conformance to conventions/standards Perceived quality reputation of manufacturer Performance Reliability Engineering-11: Engineering Design 35 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

All Done for Today Motor. Cycle Engine Blue. Print Engineering-11: Engineering Design 36 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

Engineering 11 Appendix QFD & Ho. Q Bruce Mayer, PE Registered Electrical & Mechanical Engineer BMayer@Chabot. College. edu Engineering-11: Engineering Design 37 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

Quality Function Deployment, QFD § Quality Function Deployment (QFD) • Team based visual, connective process • Focuses on customer needs throughout entire product development process § QFD is a systematic process • Helps identify customer desires and to “deploy” them through all functions and activities of the organization § House of Quality (Ho. Q) • Use of large visual displays or diagrams to – Focus decision making interactions of multifunctional teams – Visually display relevant information for ready reference – Document decisions in a graphical Form Engineering-11: Engineering Design 38 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

Quality Function Deployment, QFD § Team discussions and research results summarized in House of Quality (Ho. Q) diagrams • • Product Part Process Production information § Representatives from all parts of company involved in creating and refining Ho. Q diagrams § Desire to achieve high level of consensus Engineering-11: Engineering Design 39 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

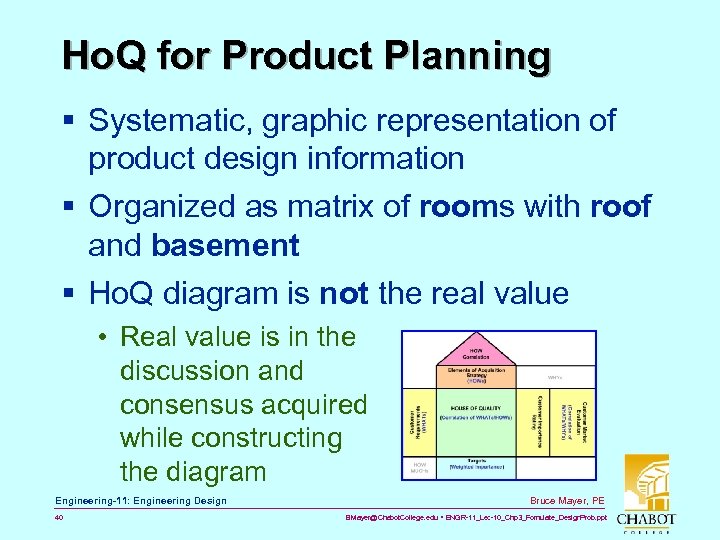

Ho. Q for Product Planning § Systematic, graphic representation of product design information § Organized as matrix of rooms with roof and basement § Ho. Q diagram is not the real value • Real value is in the discussion and consensus acquired while constructing the diagram Engineering-11: Engineering Design 40 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

Ho. Q for Product Planning § Team gathers information related to product design • • Customer requirements Customer importance weights Engineering characteristics (technical specifications) Correlation ratings of requirements & characteristics Benchmark satisfaction ratings Coupling between technical specifications Benchmark performance values New product design target values Engineering-11: Engineering Design 41 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

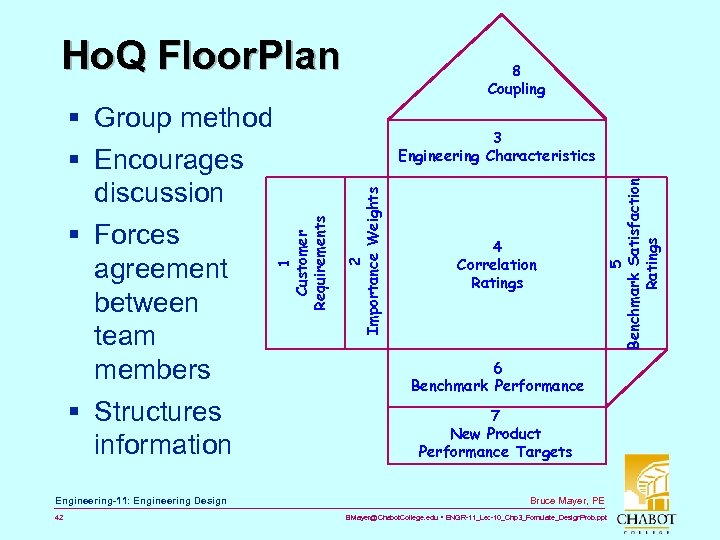

Ho. Q Floor. Plan Engineering-11: Engineering Design 42 4 Correlation Ratings 5 Benchmark Satisfaction Ratings 3 Engineering Characteristics 2 Importance Weights 1 Customer Requirements § Group method § Encourages discussion § Forces agreement between team members § Structures information 8 Coupling 6 Benchmark Performance 7 New Product Performance Targets Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

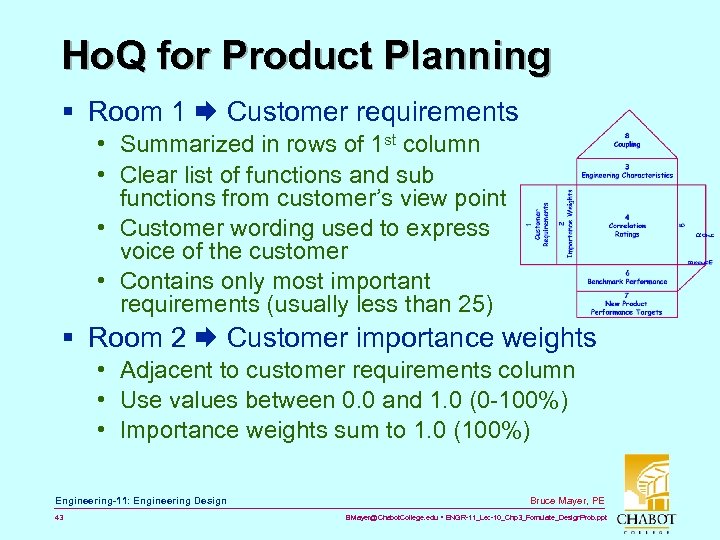

Ho. Q for Product Planning § Room 1 Customer requirements • Summarized in rows of 1 st column • Clear list of functions and sub functions from customer’s view point • Customer wording used to express voice of the customer • Contains only most important requirements (usually less than 25) § Room 2 Customer importance weights • Adjacent to customer requirements column • Use values between 0. 0 and 1. 0 (0 -100%) • Importance weights sum to 1. 0 (100%) Engineering-11: Engineering Design 43 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

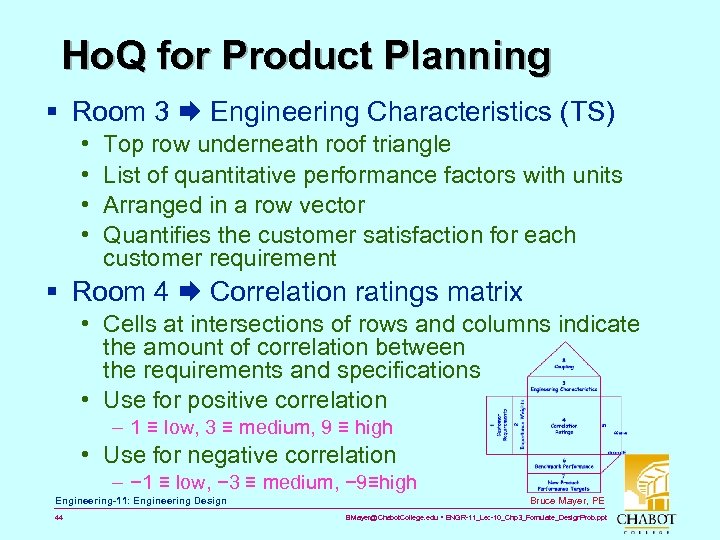

Ho. Q for Product Planning § Room 3 Engineering Characteristics (TS) • • Top row underneath roof triangle List of quantitative performance factors with units Arranged in a row vector Quantifies the customer satisfaction for each customer requirement § Room 4 Correlation ratings matrix • Cells at intersections of rows and columns indicate the amount of correlation between the requirements and specifications • Use for positive correlation – 1 ≡ low, 3 ≡ medium, 9 ≡ high • Use for negative correlation – − 1 ≡ low, − 3 ≡ medium, − 9≡high Engineering-11: Engineering Design 44 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

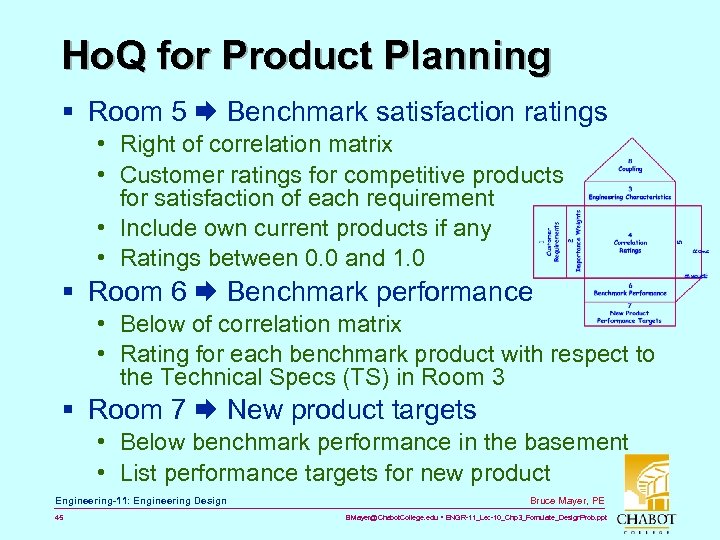

Ho. Q for Product Planning § Room 5 Benchmark satisfaction ratings • Right of correlation matrix • Customer ratings for competitive products for satisfaction of each requirement • Include own current products if any • Ratings between 0. 0 and 1. 0 § Room 6 Benchmark performance • Below of correlation matrix • Rating for each benchmark product with respect to the Technical Specs (TS) in Room 3 § Room 7 New product targets • Below benchmark performance in the basement • List performance targets for new product Engineering-11: Engineering Design 45 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

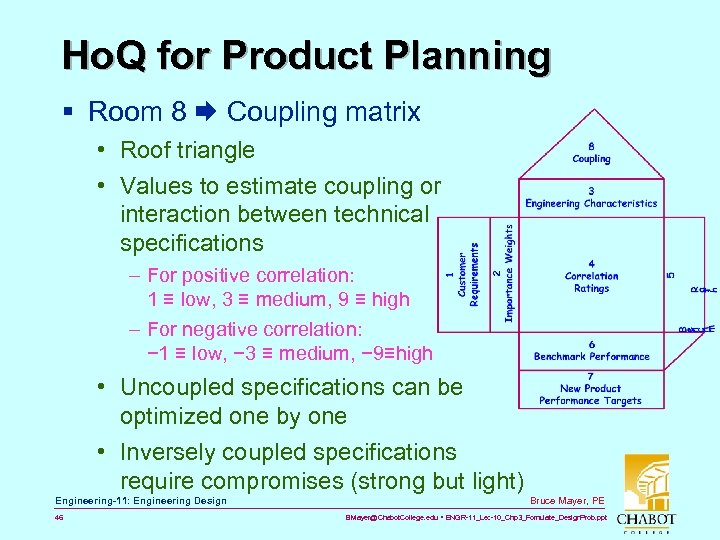

Ho. Q for Product Planning § Room 8 Coupling matrix • Roof triangle • Values to estimate coupling or interaction between technical specifications – For positive correlation: 1 ≡ low, 3 ≡ medium, 9 ≡ high – For negative correlation: − 1 ≡ low, − 3 ≡ medium, − 9≡high • Uncoupled specifications can be optimized one by one • Inversely coupled specifications require compromises (strong but light) Engineering-11: Engineering Design 46 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

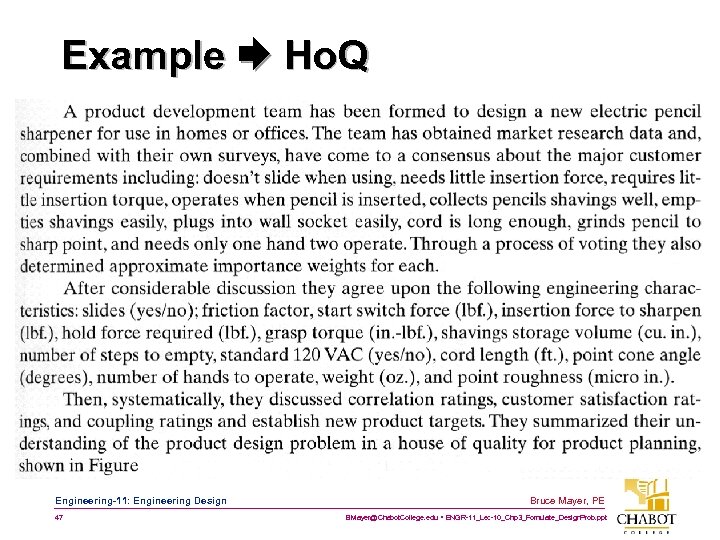

Example Ho. Q Engineering-11: Engineering Design 47 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

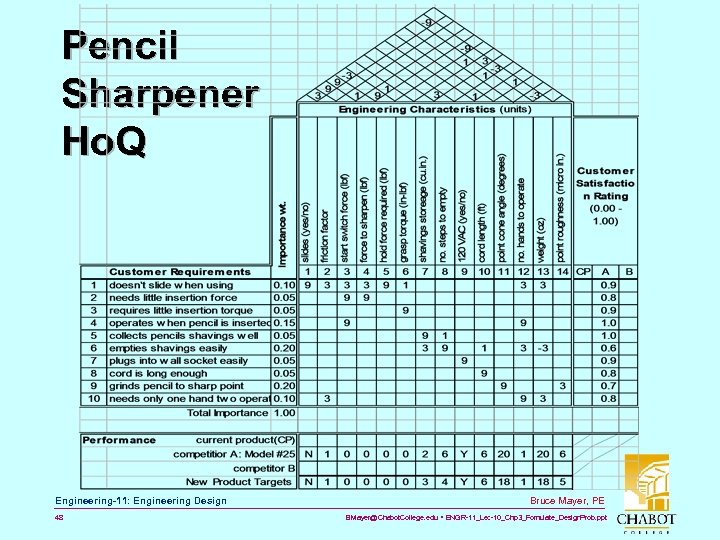

Pencil Sharpener Ho. Q Engineering-11: Engineering Design 48 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

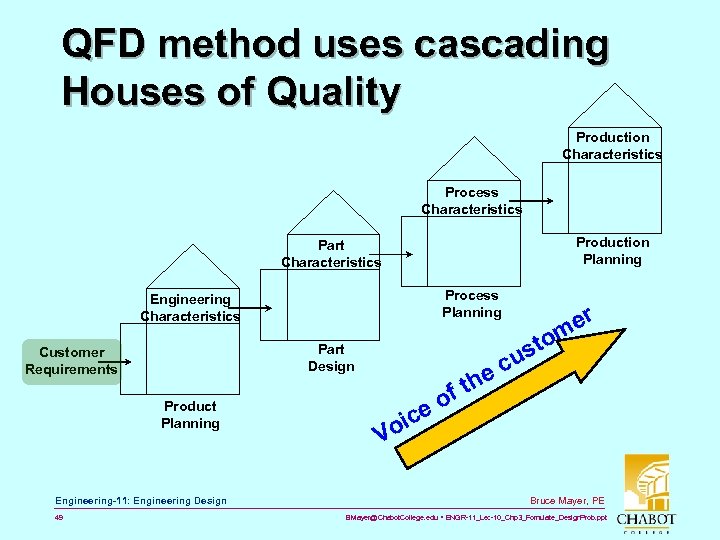

QFD method uses cascading Houses of Quality Production Characteristics Process Characteristics Production Planning Part Characteristics Process Planning Engineering Characteristics Product Planning Engineering-11: Engineering Design 49 us e c Part Design Customer Requirements er tom f th e o oic V Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

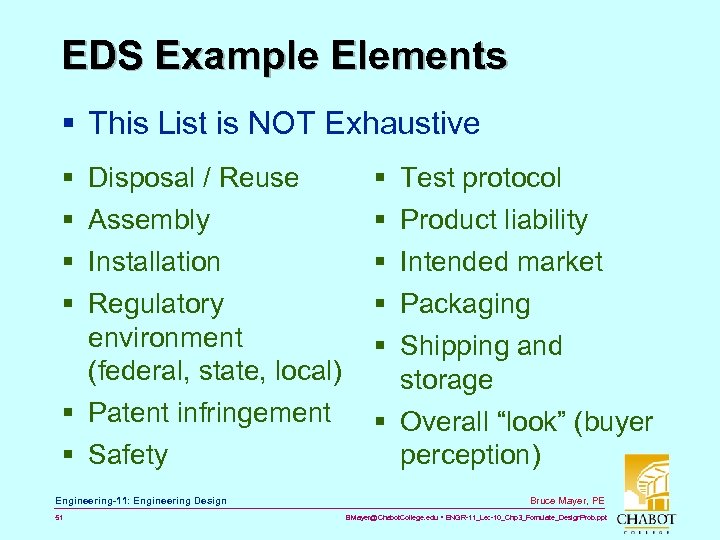

EDS Example Elements § These Items Might appear in an EDS § Intended market § Product cost(s) § Operating environment § Engineering performance § Product operators users § Ergonomics Engineering-11: Engineering Design 50 § § § § § User interface Dimensions Weight Materials Product life Service life Storage shelf life Reliability Mean time to failure Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

EDS Example Elements § This List is NOT Exhaustive § § Disposal / Reuse Assembly Installation Regulatory environment (federal, state, local) § Patent infringement § Safety Engineering-11: Engineering Design 51 § § § Test protocol Product liability Intended market Packaging Shipping and storage § Overall “look” (buyer perception) Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

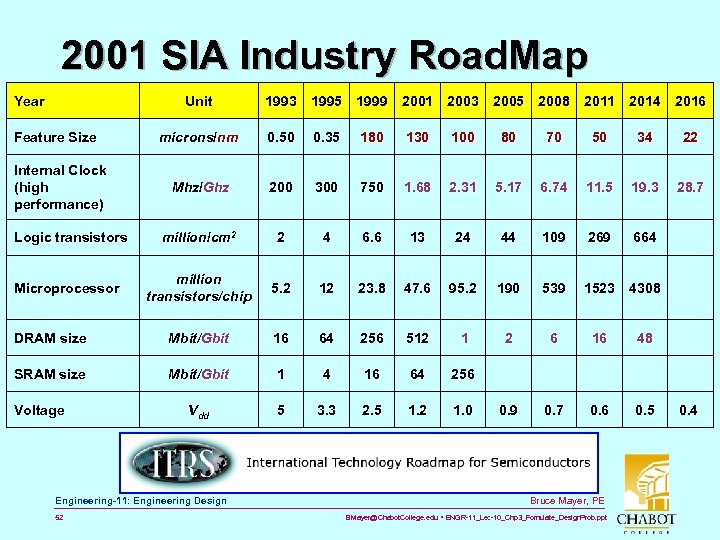

2001 SIA Industry Road. Map Year Unit 1993 1995 1999 2001 2003 2005 2008 2011 2014 2016 microns/nm 0. 50 0. 35 180 130 100 80 70 50 34 22 Mhz/Ghz 200 300 750 1. 68 2. 31 5. 17 6. 74 11. 5 19. 3 28. 7 million/cm 2 2 4 6. 6 13 24 44 109 269 664 million transistors/chip 5. 2 12 23. 8 47. 6 95. 2 190 539 1523 4308 DRAM size Mbit/Gbit 16 64 256 512 1 2 6 16 48 SRAM size Mbit/Gbit 1 4 16 64 256 Vdd 5 3. 3 2. 5 1. 2 1. 0 0. 7 0. 6 0. 5 0. 4 Feature Size Internal Clock (high performance) Logic transistors Microprocessor Voltage Engineering-11: Engineering Design 52 0. 9 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

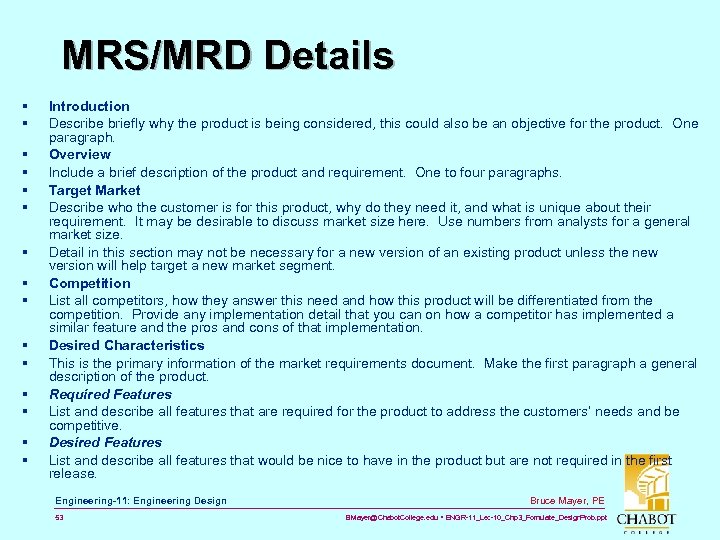

MRS/MRD Details § § § § Introduction Describe briefly why the product is being considered, this could also be an objective for the product. One paragraph. Overview Include a brief description of the product and requirement. One to four paragraphs. Target Market Describe who the customer is for this product, why do they need it, and what is unique about their requirement. It may be desirable to discuss market size here. Use numbers from analysts for a general market size. Detail in this section may not be necessary for a new version of an existing product unless the new version will help target a new market segment. Competition List all competitors, how they answer this need and how this product will be differentiated from the competition. Provide any implementation detail that you can on how a competitor has implemented a similar feature and the pros and cons of that implementation. Desired Characteristics This is the primary information of the market requirements document. Make the first paragraph a general description of the product. Required Features List and describe all features that are required for the product to address the customers’ needs and be competitive. Desired Features List and describe all features that would be nice to have in the product but are not required in the first release. Engineering-11: Engineering Design 53 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

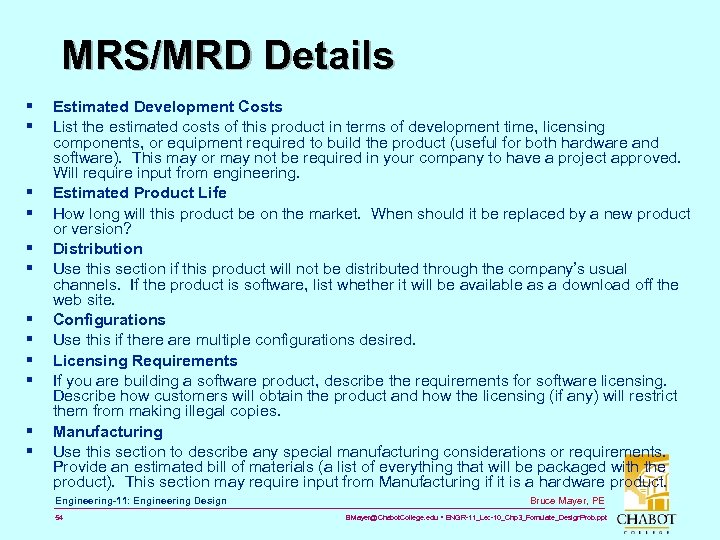

MRS/MRD Details § § § Estimated Development Costs List the estimated costs of this product in terms of development time, licensing components, or equipment required to build the product (useful for both hardware and software). This may or may not be required in your company to have a project approved. Will require input from engineering. Estimated Product Life How long will this product be on the market. When should it be replaced by a new product or version? Distribution Use this section if this product will not be distributed through the company’s usual channels. If the product is software, list whether it will be available as a download off the web site. Configurations Use this if there are multiple configurations desired. Licensing Requirements If you are building a software product, describe the requirements for software licensing. Describe how customers will obtain the product and how the licensing (if any) will restrict them from making illegal copies. Manufacturing Use this section to describe any special manufacturing considerations or requirements. Provide an estimated bill of materials (a list of everything that will be packaged with the product). This section may require input from Manufacturing if it is a hardware product. Engineering-11: Engineering Design 54 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

MRS/MRD Details § § § § Packaging For both software and hardware, describe how the product will be packaged. Maintenance This section is used (primarily for a hardware product) to describe any special maintenance requirements. May require input from customer service. Documentation Describe the types of documentation that are required including installation instructions, user manuals, administration manuals, quick start guides and tutorials. Specify whether the documentation will be online or hard copy. Forecast/Cost Estimate the sales for the product. This is required for cost justification as well as forecasts for inventory of product and or manuals. For hardware products you will need to estimate the preliminary costs of the product. For a software product you will need to estimate any potential royalties. In some companies, management wants the product manager to figure out the development costs of a product. If this is required, you will need to work closely with the finance department and the VP of Engineering to accurately estimate those costs. Impact on Other Products Use this section if this product will impact sales of or replace other products. Finance and sales will need this information forecasting purposes. Preliminary Schedule This will require input from engineering. It is needed for other departments to understand when the product will be available. Engineering-11: Engineering Design 55 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

In 10 min Discuss “Quality” Engineering-11: Engineering Design 56 Bruce Mayer, PE BMayer@Chabot. College. edu • ENGR-11_Lec-10_Chp 3_Fomulate_Design. Prob. ppt

d804446a9ef8eee1063421d61ca1b2b3.ppt