14b33d255b4c90401c8582870b5e4804.ppt

- Количество слайдов: 35

Engineered Improvements for Feed Pump Turbines FSRUG 2015 Presented by Jim Chalker

Safe Harbor Disclosure Some of the information contained in this document contains "forward-looking statements". In many cases, you can identify forward-looking statements by terminology such as "may, " "will, " "should, " "expects, " "plans, " "anticipates, " "believes, " "estimates, " "predicts, " "potential, " or "continue, " or the negative of such terms and other comparable terminology. These forward-looking statements are only predictions and as such inherently included risks and uncertainties. Actual events or results may differ materially as a result of risks facing Dresser-Rand Company (D-R) or actual results differing from the assumptions underlying such statements. These forward-looking statements are made only as of the date of this presentation, and D-R undertakes no obligation to update or revise the forward-looking statements, whether as a result of new information, future events or otherwise. All forward-looking statements are expressly qualified in their entirety by the "Risk Factors" and other cautionary statements included in D-R's annual, quarterly and special reports, proxy statements and other public filings with the Securities and Exchange Commission and other factors not known to D-R. Your decision to remain and receive the information about to be presented to you shall constitute your unconditional acceptance to the foregoing. Confidential & Proprietary Any person allowing themselves to directly or indirectly receive the information contained in this presentation (the "Receiver") agrees that this presentation and all information contained herein and/or in any way distributed to the Receiver with respect to the same (verbal or otherwise) is the confidential and proprietary property of Dresser-Rand Company and is being provided to and received by the Receiver in confidence. Receiver agrees not to divulge the contents hereof to any third party without the prior written approval of Dresser-Rand’s duly authorized representative. Receiver shall advise any permitted recipient of the confidential information of the nature of the same and obtain their agreement to be bound to these terms before such confidential information is disclosed to them. Receiver on behalf of its principal, representatives, employees and themselves individually to hereby unconditionally agree to the terms hereof and agree to defend, indemnify, and hold Dresser-Rand harmless from and against any and all damages that result from Receiver’s failure to strictly comply with these terms. Receiver further agrees that failure to comply with these terms will cause Dresser-Rand to suffer irreparable harm. Your decision to remain and receive the information about to be presented to you shall constitute your unconditional acceptance to the foregoing. Confidential & Proprietary Information

Definitions Revamps or Re-Rates u Change in Power u Change in Rotating Speed u Change in Steam Conditions u Resulting in a change in Nameplate Upgrades u Modernization u Reliability u Efficiency u Operability u Maintenance u Address Technical Concerns Confidential & Proprietary Information

Revamps or Re-Rates u Re-design of hardware for the new conditions of service. u Manufacture new steam path components using modern methods l l Quality Assurance l u Engineering Manufacturing Technology “Cookie cutter” vs. custom design Confidential & Proprietary Information

Upgrades u Address technical concerns discovered through operation or maintenance turnarounds. u Technical advisements from OEM or shared experiences from organizations like FSRUG Confidential & Proprietary Information

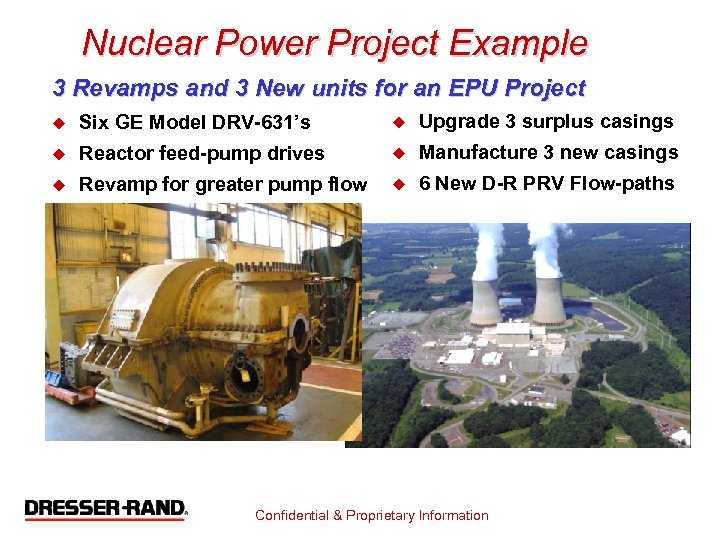

Nuclear Power Project Example 3 Revamps and 3 New units for an EPU Project u Six GE Model DRV-631’s u Upgrade 3 surplus casings u Reactor feed-pump drives u Manufacture 3 new casings u Revamp for greater pump flow u 6 New D-R PRV Flow-paths u Increase in power & speed Confidential & Proprietary Information

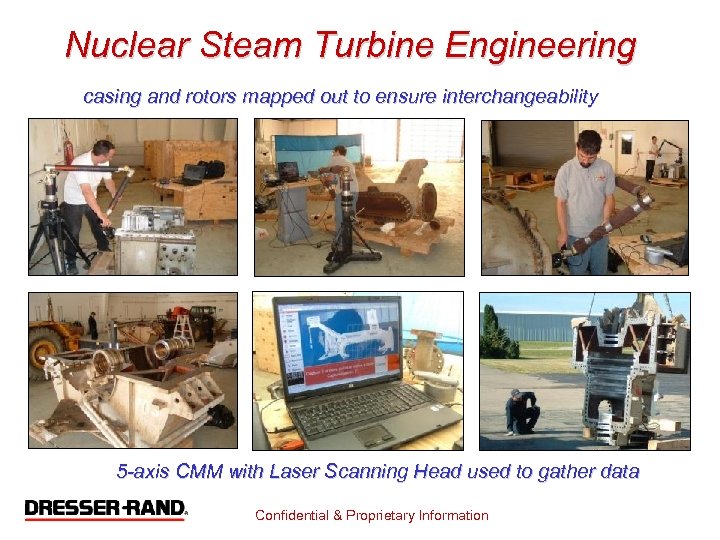

Nuclear Steam Turbine Engineering casing and rotors mapped out to ensure interchangeability 5 -axis CMM with Laser Scanning Head used to gather data Confidential & Proprietary Information

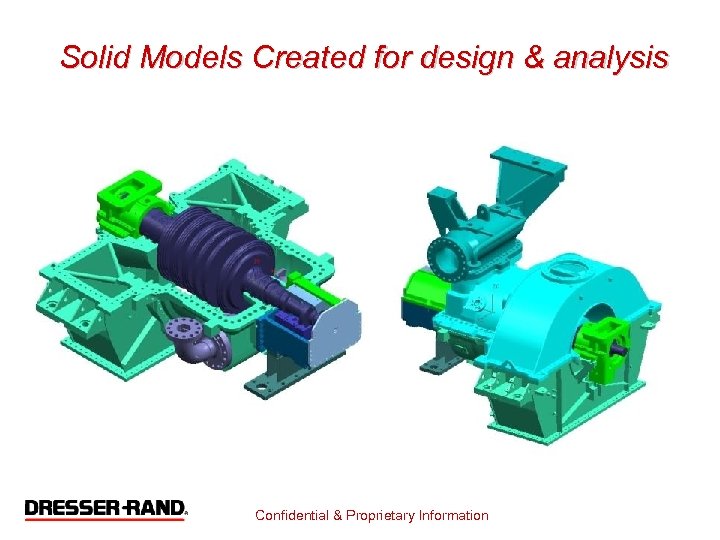

Solid Models Created for design & analysis Confidential & Proprietary Information

Engineering & Analysis The Solid models were used for design and analysis u Unit layout and design “form, fit & function” u Structural & Finite Element Analysis (FEA) u Aerodynamic / Computational Fluid Dynamics (CFD) u Manufacturing CNC codes “Art to part” u Improve the castings Mechanical design * Rotor dynamic analysis and design * Stress and vibration engineering * Thermodynamic engineering * Aerodynamic engineering * Metallurgical laboratory services * Manufacturing engineering Confidential & Proprietary Information

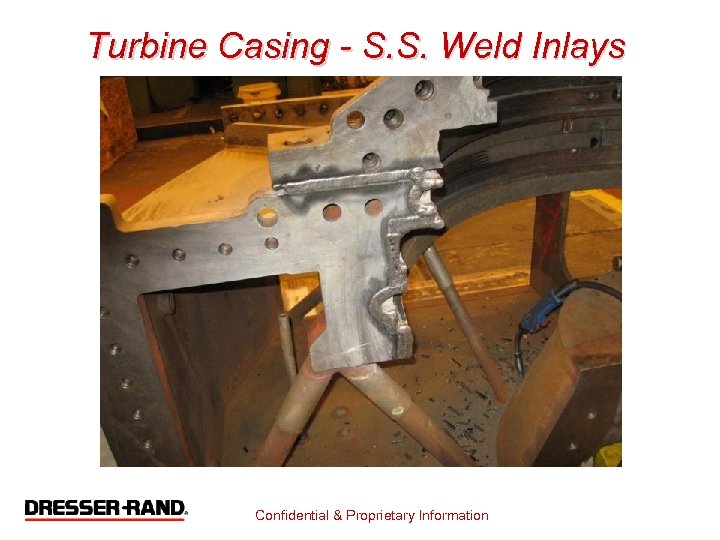

Turbine Casing - S. S. Weld Inlays Confidential & Proprietary Information

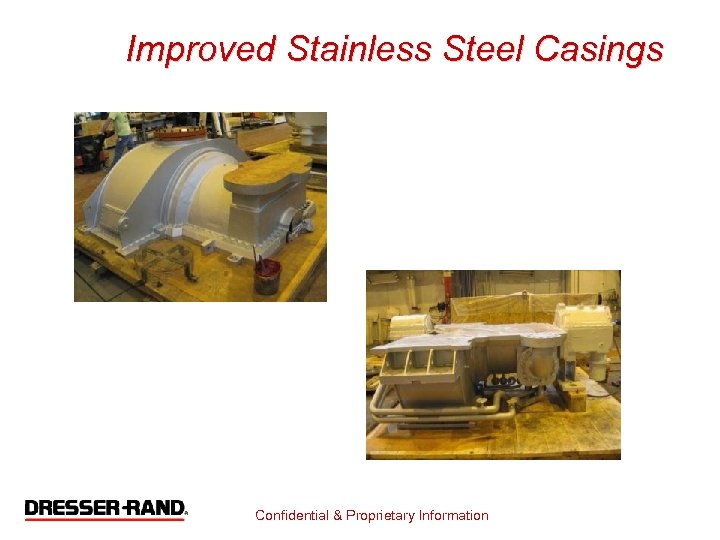

Improved Stainless Steel Casings Confidential & Proprietary Information

Confidential & Proprietary Information

Confidential & Proprietary Information

Confidential & Proprietary Information

Steam Product Improvements u Profile Ring and Vane (PRV) Diaphragms l Aero Performance improvements l Advanced manufacturing methods l Ability to hold tight tolerances l Less-Heat / Distortion Confidential & Proprietary Information

PRV and Modified PRV Design Confidential & Proprietary Information

Steam Turbine Revamps Cylindrical end-walls develop secondary flows in a cylindrical stator end-wall. Profiled end-walls develop a considerable reduction in secondary flows and pressure gradients in a profiled ring and vane (PRV) Note the old and new design construction stator end-wall. comparison. Confidential & Proprietary Information

Confidential & Proprietary Information

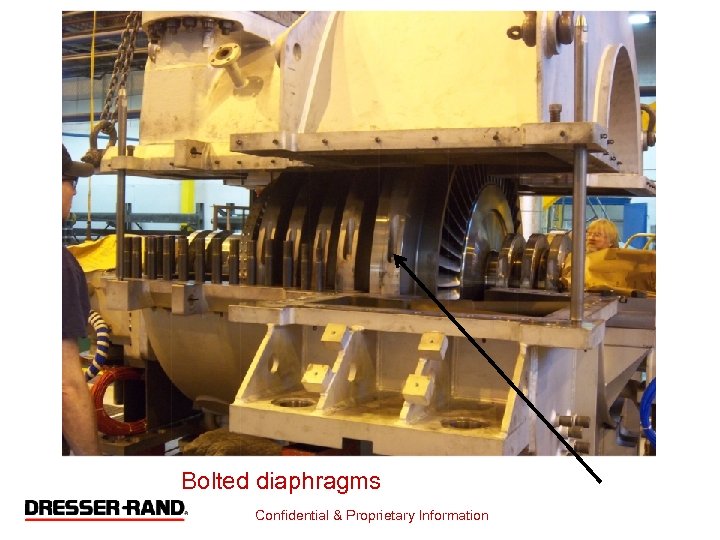

Bolted diaphragms Confidential & Proprietary Information

Confidential & Proprietary Information

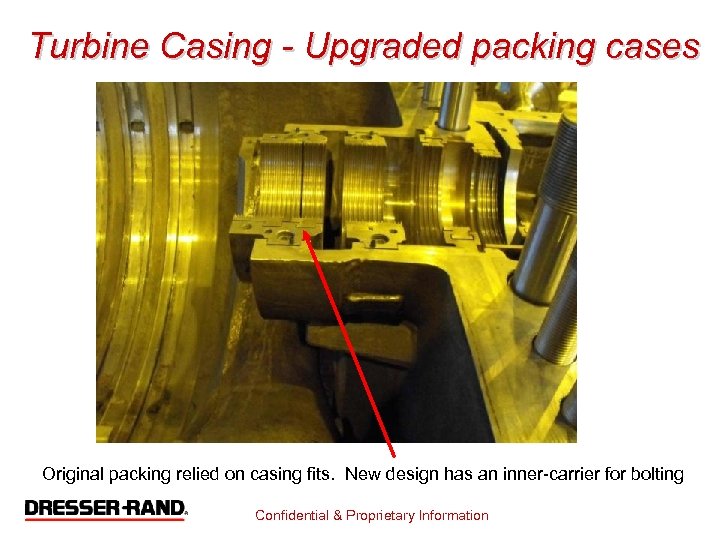

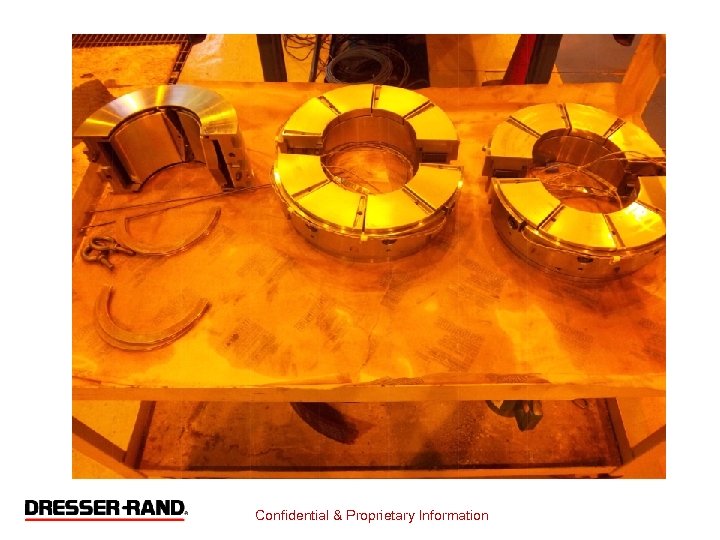

Turbine Casing - Upgraded packing cases Original packing relied on casing fits. New design has an inner-carrier for bolting Confidential & Proprietary Information

Improved bearing cases Capability for 2 out of 3 trip system Confidential & Proprietary Information

Confidential & Proprietary Information

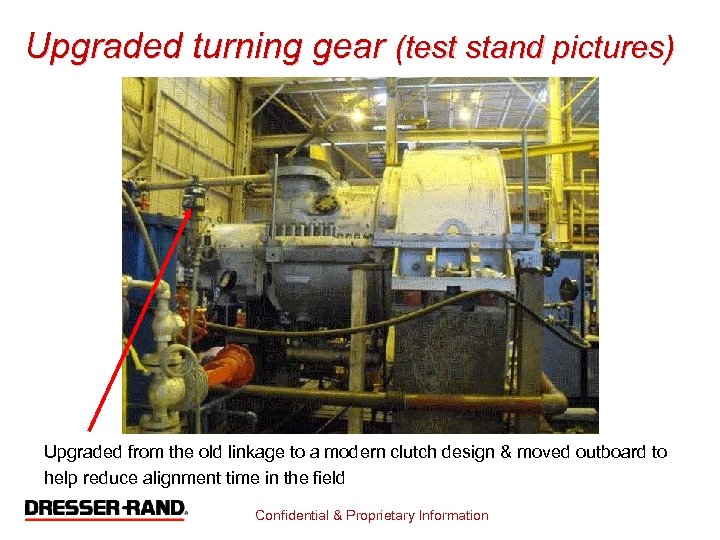

Original turning gear (field pictures) Original turning gear Coupling Tight space between the exhaust end & containment wall along with the location of the turning gear made it very difficult to align during turnarounds Confidential & Proprietary Information

Improved clutch type turning gear includes the shaft grounding brush Confidential & Proprietary Information

Confidential & Proprietary Information

Confidential & Proprietary Information

Upgraded turning gear (test stand pictures) Upgraded from the old linkage to a modern clutch design & moved outboard to help reduce alignment time in the field Confidential & Proprietary Information

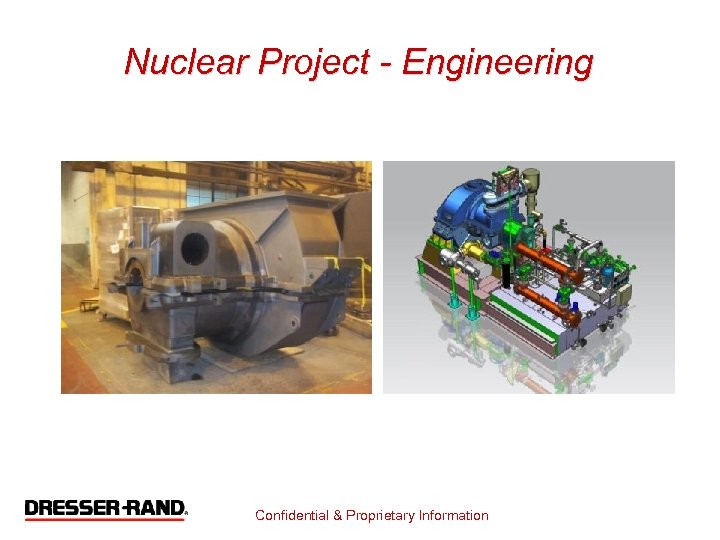

Nuclear Project - Engineering Confidential & Proprietary Information

Nuclear Project - Engineering u Engineering designed new components to meet our current design standards where applicable. u Adaptation Study - Know what needed to be done in the RCA before we start work and ensure compatibility with existing systems. u Engineering review meetings with client/user to ensure that all design and procedure changes receive proper approval. u Engineering to have ownership of turbine hardware components that were originally designed by others. Confidential & Proprietary Information

Nuclear Project - Engineering u Detailed Engineering and Analysis l Geometric Engineering • Develop blade/bucket root models • Develop casing diaphragm geometry • Develop rotor model • Layout existing steam path • Multi-unit dimensional comparison of critical dimensions l Thermodynamic Engineering and Design • Review existing unit performance model • Develop operational envelope • Design for new conditions • Review gland seal system • Performance curves Confidential & Proprietary Information

Nuclear Project - Engineering u Detailed Engineering and Analysis l Analytical Engineering • Review bucket and root selection for stress in operating range • Review for frequency interference • Campbell & Goodman Diagrams (blade & bucket stress) • Review shaft end stress at new conditions l Rotor Dynamic Analysis • Develop Mass Elastic model • Perform analysis and summarize • Review bearing design Confidential & Proprietary Information

Nuclear Project - Engineering u Detailed Engineering and Analysis l Design Engineering • Develop blade moisture protection plan • Review casing erosion issue and create repair or prevention plan • Create manufacturing drawings and specifications • DARS (Design Assessment Reports) • Control and protection valves • Bearing systems • Lubrication system Confidential & Proprietary Information

Project Objectives u Re-Rate for EPU conditions u Renew for life extension u Improve or maintain reliability u Improve operability l l u New controls & instrumentation Automated turning gear design Reduce maintenance requirements l u Remove from current weld repair schedule Remove from critical path during future refuel outages l Reduced alignment time Confidential & Proprietary Information

Questions? ? Thank You for your Time www. dresser-rand. com

14b33d255b4c90401c8582870b5e4804.ppt