2ae3296e38b694a1af1e6e483d2cf5c6.ppt

- Количество слайдов: 29

ENERGY STAR Multifamily High Rise Program Testing and Verification Protocols Webinar – Part II August 2011

ENERGY STAR Multifamily High Rise Program Testing and Verification Protocols Webinar – Part II August 2011

Testing and Verification Protocols • • • 1. 0 2. 0 3. 0 4. 0 5. 0 Appliances Domestic Water Heating Envelope Garages Heating and Cooling 2

Testing and Verification Protocols • • • 1. 0 2. 0 3. 0 4. 0 5. 0 Appliances Domestic Water Heating Envelope Garages Heating and Cooling 2

1. 1 ENERGY STAR Appliances Visual Inspection Data Sheet Test Procedure Instrumented Measurement Third-Party Commissioning Sampling: • One representative photo of each appliance type, make and model 3

1. 1 ENERGY STAR Appliances Visual Inspection Data Sheet Test Procedure Instrumented Measurement Third-Party Commissioning Sampling: • One representative photo of each appliance type, make and model 3

2. 0 & 5. 0 DHW, Heating and Cooling Systems • • • Visual Inspection Data Sheet Test Procedure Instrumented Measurement Third-Party Commissioning Sampling: • 100% of central primary equipment • RESNET for distributed systems, plumbing fixtures and delivery temperatures DHW/Heating/Cooling Plant: System size, type, design, and rated efficiency, sizing calculations Distribution System: Piping and/or ductwork configuration, mixing valves, zoning, insulation requirements Controls: System controls and settings Terminal Units (Heating & Cooling): Type, size, design, location, controls Heat Rejection (Cooling): Type, size, location and efficiency 4

2. 0 & 5. 0 DHW, Heating and Cooling Systems • • • Visual Inspection Data Sheet Test Procedure Instrumented Measurement Third-Party Commissioning Sampling: • 100% of central primary equipment • RESNET for distributed systems, plumbing fixtures and delivery temperatures DHW/Heating/Cooling Plant: System size, type, design, and rated efficiency, sizing calculations Distribution System: Piping and/or ductwork configuration, mixing valves, zoning, insulation requirements Controls: System controls and settings Terminal Units (Heating & Cooling): Type, size, design, location, controls Heat Rejection (Cooling): Type, size, location and efficiency 4

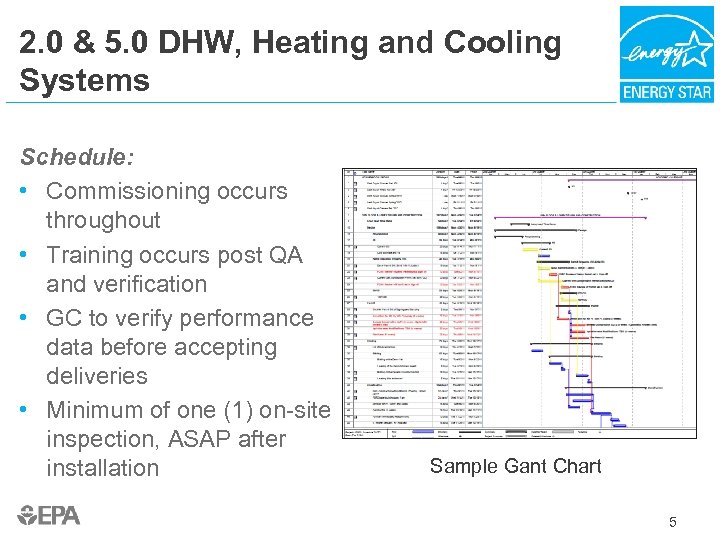

2. 0 & 5. 0 DHW, Heating and Cooling Systems Schedule: • Commissioning occurs throughout • Training occurs post QA and verification • GC to verify performance data before accepting deliveries • Minimum of one (1) on-site inspection, ASAP after installation Sample Gant Chart 5

2. 0 & 5. 0 DHW, Heating and Cooling Systems Schedule: • Commissioning occurs throughout • Training occurs post QA and verification • GC to verify performance data before accepting deliveries • Minimum of one (1) on-site inspection, ASAP after installation Sample Gant Chart 5

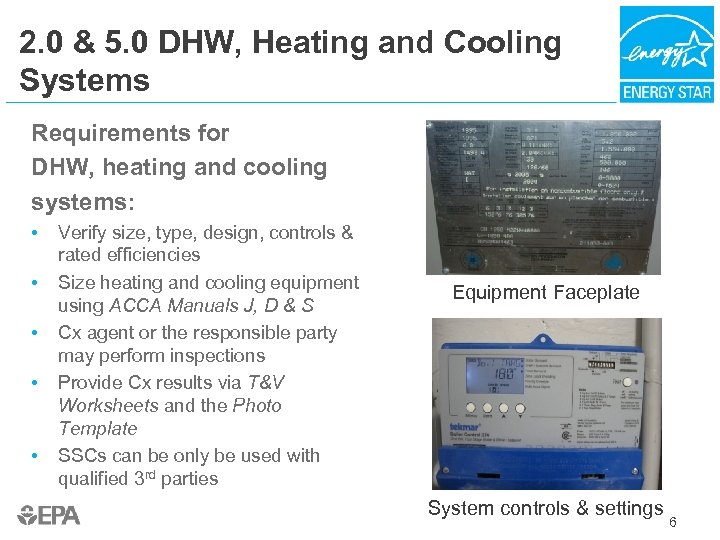

2. 0 & 5. 0 DHW, Heating and Cooling Systems Requirements for DHW, heating and cooling systems: • • • Verify size, type, design, controls & rated efficiencies Size heating and cooling equipment using ACCA Manuals J, D & S Cx agent or the responsible party may perform inspections Provide Cx results via T&V Worksheets and the Photo Template SSCs can be only be used with qualified 3 rd parties Equipment Faceplate System controls & settings 6

2. 0 & 5. 0 DHW, Heating and Cooling Systems Requirements for DHW, heating and cooling systems: • • • Verify size, type, design, controls & rated efficiencies Size heating and cooling equipment using ACCA Manuals J, D & S Cx agent or the responsible party may perform inspections Provide Cx results via T&V Worksheets and the Photo Template SSCs can be only be used with qualified 3 rd parties Equipment Faceplate System controls & settings 6

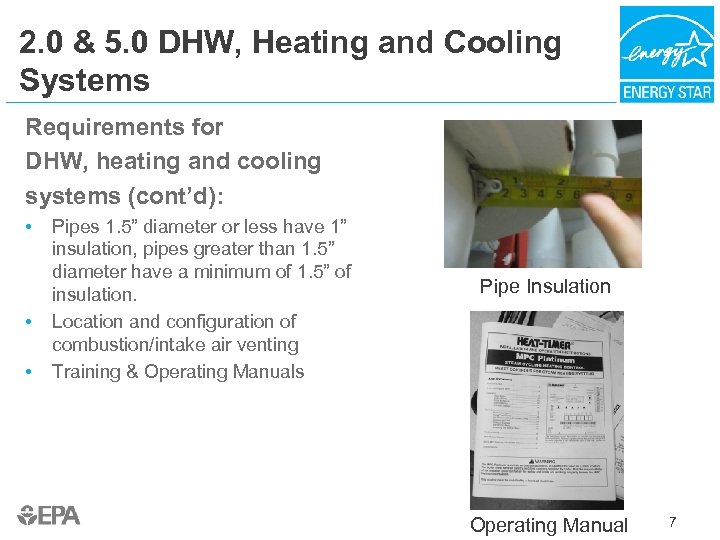

2. 0 & 5. 0 DHW, Heating and Cooling Systems Requirements for DHW, heating and cooling systems (cont’d): • • • Pipes 1. 5” diameter or less have 1” insulation, pipes greater than 1. 5” diameter have a minimum of 1. 5” of insulation. Location and configuration of combustion/intake air venting Training & Operating Manuals Pipe Insulation Operating Manual 7

2. 0 & 5. 0 DHW, Heating and Cooling Systems Requirements for DHW, heating and cooling systems (cont’d): • • • Pipes 1. 5” diameter or less have 1” insulation, pipes greater than 1. 5” diameter have a minimum of 1. 5” of insulation. Location and configuration of combustion/intake air venting Training & Operating Manuals Pipe Insulation Operating Manual 7

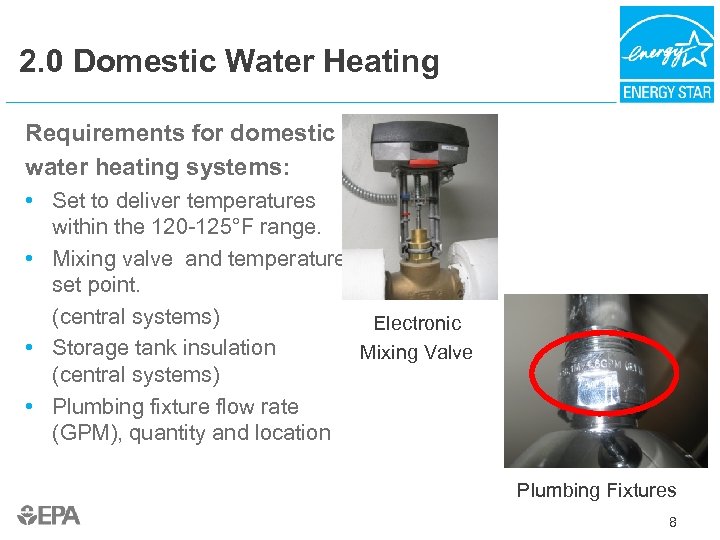

2. 0 Domestic Water Heating Requirements for domestic water heating systems: • Set to deliver temperatures within the 120 -125°F range. • Mixing valve and temperature set point. (central systems) Electronic • Storage tank insulation Mixing Valve (central systems) • Plumbing fixture flow rate (GPM), quantity and location Plumbing Fixtures 8

2. 0 Domestic Water Heating Requirements for domestic water heating systems: • Set to deliver temperatures within the 120 -125°F range. • Mixing valve and temperature set point. (central systems) Electronic • Storage tank insulation Mixing Valve (central systems) • Plumbing fixture flow rate (GPM), quantity and location Plumbing Fixtures 8

5. 0 All Heating and Cooling Systems Requirements for heating and cooling systems: • • R-6 duct insulation in unconditioned space, R-8 for Prescriptive Path Duct sealing details must go in CDs! Visual inspection Flex duct must meet SMACNA standards (see Appendix C) Non-continuous OA systems must have motorized damper Outdoor Air Damper 9

5. 0 All Heating and Cooling Systems Requirements for heating and cooling systems: • • R-6 duct insulation in unconditioned space, R-8 for Prescriptive Path Duct sealing details must go in CDs! Visual inspection Flex duct must meet SMACNA standards (see Appendix C) Non-continuous OA systems must have motorized damper Outdoor Air Damper 9

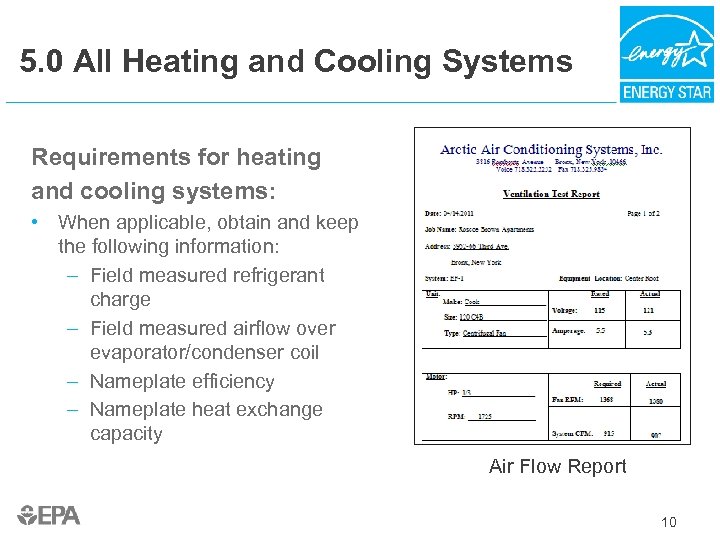

5. 0 All Heating and Cooling Systems Requirements for heating and cooling systems: • When applicable, obtain and keep the following information: – Field measured refrigerant charge – Field measured airflow over evaporator/condenser coil – Nameplate efficiency – Nameplate heat exchange capacity Air Flow Report 10

5. 0 All Heating and Cooling Systems Requirements for heating and cooling systems: • When applicable, obtain and keep the following information: – Field measured refrigerant charge – Field measured airflow over evaporator/condenser coil – Nameplate efficiency – Nameplate heat exchange capacity Air Flow Report 10

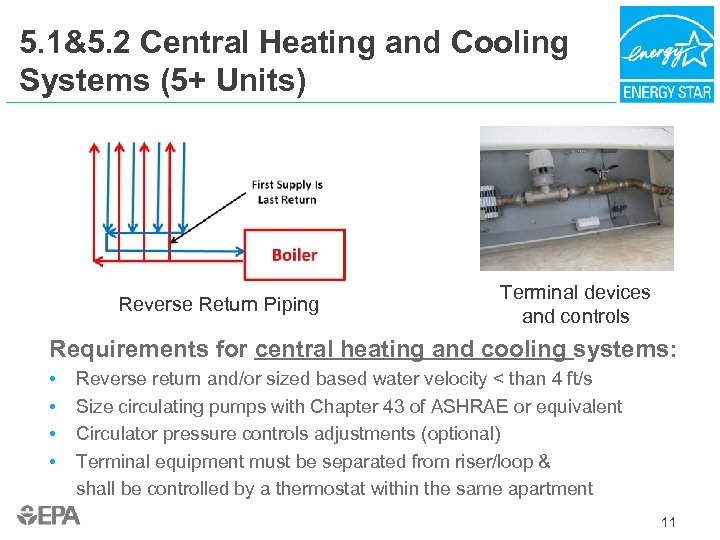

5. 1&5. 2 Central Heating and Cooling Systems (5+ Units) Reverse Return Piping Terminal devices and controls Requirements for central heating and cooling systems: • • Reverse return and/or sized based water velocity < than 4 ft/s Size circulating pumps with Chapter 43 of ASHRAE or equivalent Circulator pressure controls adjustments (optional) Terminal equipment must be separated from riser/loop & shall be controlled by a thermostat within the same apartment 11

5. 1&5. 2 Central Heating and Cooling Systems (5+ Units) Reverse Return Piping Terminal devices and controls Requirements for central heating and cooling systems: • • Reverse return and/or sized based water velocity < than 4 ft/s Size circulating pumps with Chapter 43 of ASHRAE or equivalent Circulator pressure controls adjustments (optional) Terminal equipment must be separated from riser/loop & shall be controlled by a thermostat within the same apartment 11

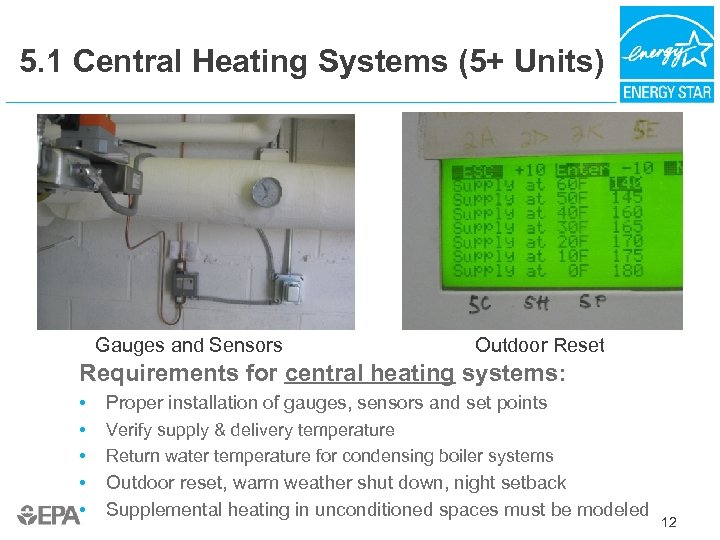

5. 1 Central Heating Systems (5+ Units) Gauges and Sensors Outdoor Reset Requirements for central heating systems: • Proper installation of gauges, sensors and set points • • Verify supply & delivery temperature Return water temperature for condensing boiler systems • • Outdoor reset, warm weather shut down, night setback Supplemental heating in unconditioned spaces must be modeled 12

5. 1 Central Heating Systems (5+ Units) Gauges and Sensors Outdoor Reset Requirements for central heating systems: • Proper installation of gauges, sensors and set points • • Verify supply & delivery temperature Return water temperature for condensing boiler systems • • Outdoor reset, warm weather shut down, night setback Supplemental heating in unconditioned spaces must be modeled 12

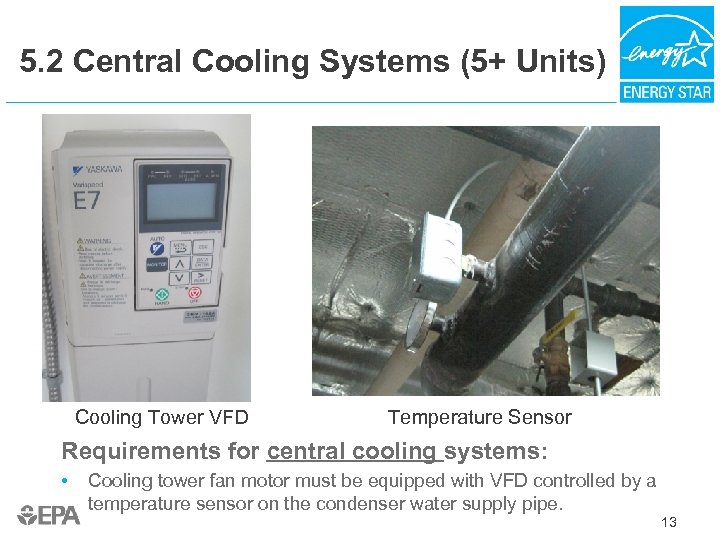

5. 2 Central Cooling Systems (5+ Units) Cooling Tower VFD Temperature Sensor Requirements for central cooling systems: • Cooling tower fan motor must be equipped with VFD controlled by a temperature sensor on the condenser water supply pipe. 13

5. 2 Central Cooling Systems (5+ Units) Cooling Tower VFD Temperature Sensor Requirements for central cooling systems: • Cooling tower fan motor must be equipped with VFD controlled by a temperature sensor on the condenser water supply pipe. 13

5. 3&5. 4 Distributed (Individual Apt) Heating and Cooling Systems Requirements for distributed heating & cooling systems: • Design to ACCA Manuals J, D and S or equivalent procedure • ENERGY STAR Home Rater and Contractor HVAC Checklists (optional) • Verify bedrooms have been provided with pressurebalancing solution • Duct leakage testing Duct Leakage Testing 14

5. 3&5. 4 Distributed (Individual Apt) Heating and Cooling Systems Requirements for distributed heating & cooling systems: • Design to ACCA Manuals J, D and S or equivalent procedure • ENERGY STAR Home Rater and Contractor HVAC Checklists (optional) • Verify bedrooms have been provided with pressurebalancing solution • Duct leakage testing Duct Leakage Testing 14

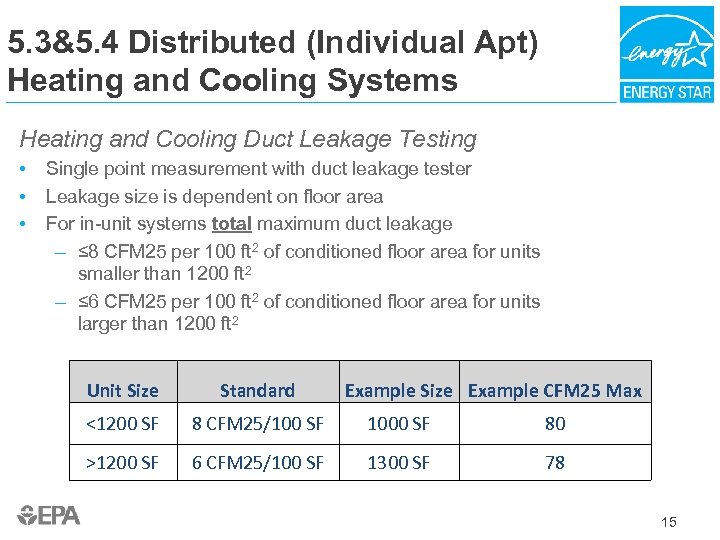

5. 3&5. 4 Distributed (Individual Apt) Heating and Cooling Systems Heating and Cooling Duct Leakage Testing • • • Single point measurement with duct leakage tester Leakage size is dependent on floor area For in-unit systems total maximum duct leakage – ≤ 8 CFM 25 per 100 ft 2 of conditioned floor area for units smaller than 1200 ft 2 – ≤ 6 CFM 25 per 100 ft 2 of conditioned floor area for units larger than 1200 ft 2 Unit Size Standard Example Size Example CFM 25 Max <1200 SF 8 CFM 25/100 SF 1000 SF 80 >1200 SF 6 CFM 25/100 SF 1300 SF 78 15

5. 3&5. 4 Distributed (Individual Apt) Heating and Cooling Systems Heating and Cooling Duct Leakage Testing • • • Single point measurement with duct leakage tester Leakage size is dependent on floor area For in-unit systems total maximum duct leakage – ≤ 8 CFM 25 per 100 ft 2 of conditioned floor area for units smaller than 1200 ft 2 – ≤ 6 CFM 25 per 100 ft 2 of conditioned floor area for units larger than 1200 ft 2 Unit Size Standard Example Size Example CFM 25 Max <1200 SF 8 CFM 25/100 SF 1000 SF 80 >1200 SF 6 CFM 25/100 SF 1300 SF 78 15

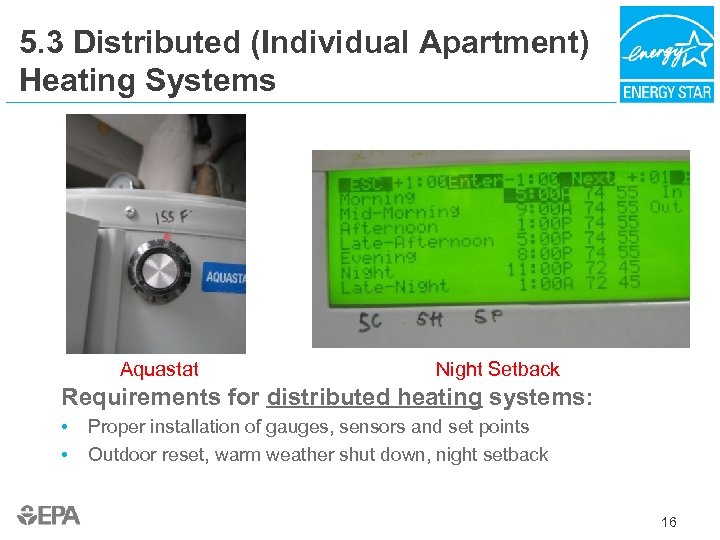

5. 3 Distributed (Individual Apartment) Heating Systems Aquastat Night Setback Requirements for distributed heating systems: • • Proper installation of gauges, sensors and set points Outdoor reset, warm weather shut down, night setback 16

5. 3 Distributed (Individual Apartment) Heating Systems Aquastat Night Setback Requirements for distributed heating systems: • • Proper installation of gauges, sensors and set points Outdoor reset, warm weather shut down, night setback 16

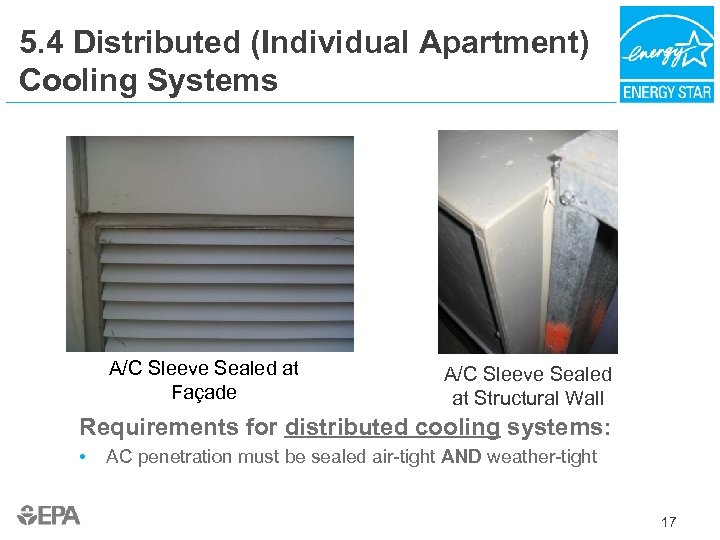

5. 4 Distributed (Individual Apartment) Cooling Systems A/C Sleeve Sealed at Façade A/C Sleeve Sealed at Structural Wall Requirements for distributed cooling systems: • AC penetration must be sealed air-tight AND weather-tight 17

5. 4 Distributed (Individual Apartment) Cooling Systems A/C Sleeve Sealed at Façade A/C Sleeve Sealed at Structural Wall Requirements for distributed cooling systems: • AC penetration must be sealed air-tight AND weather-tight 17

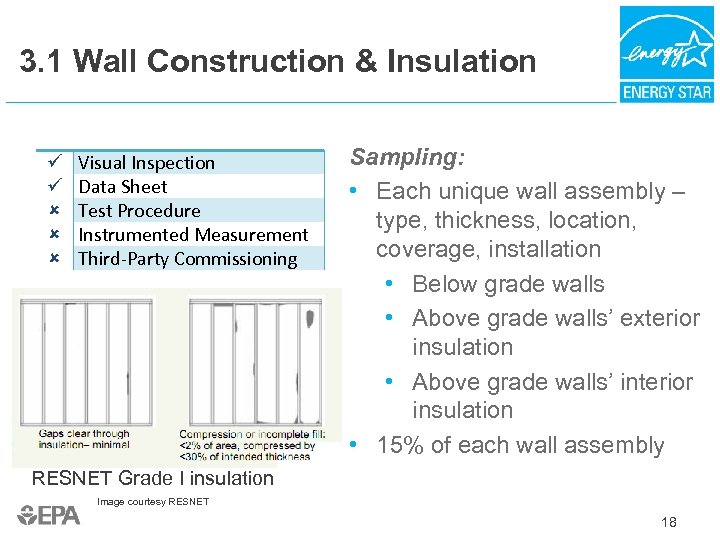

3. 1 Wall Construction & Insulation Visual Inspection Data Sheet Test Procedure Instrumented Measurement Third-Party Commissioning Sampling: • Each unique wall assembly – type, thickness, location, coverage, installation • Below grade walls • Above grade walls’ exterior insulation • Above grade walls’ interior insulation • 15% of each wall assembly RESNET Grade I insulation Image courtesy RESNET 18

3. 1 Wall Construction & Insulation Visual Inspection Data Sheet Test Procedure Instrumented Measurement Third-Party Commissioning Sampling: • Each unique wall assembly – type, thickness, location, coverage, installation • Below grade walls • Above grade walls’ exterior insulation • Above grade walls’ interior insulation • 15% of each wall assembly RESNET Grade I insulation Image courtesy RESNET 18

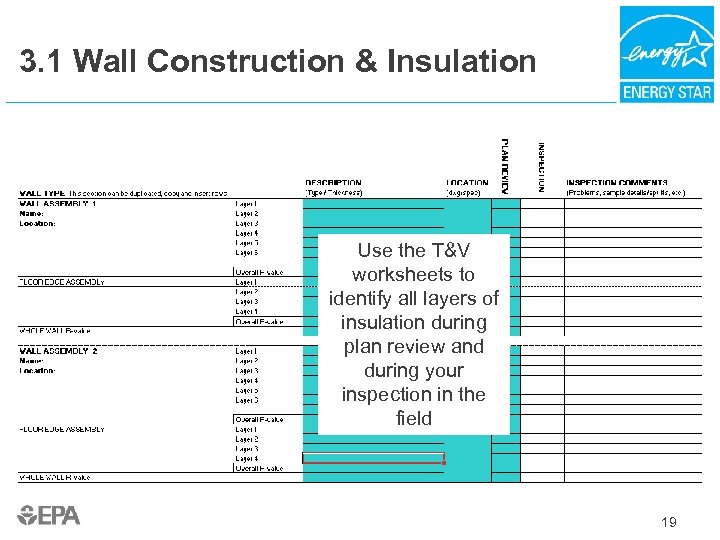

3. 1 Wall Construction & Insulation Use the T&V worksheets to identify all layers of insulation during plan review and during your inspection in the field 19

3. 1 Wall Construction & Insulation Use the T&V worksheets to identify all layers of insulation during plan review and during your inspection in the field 19

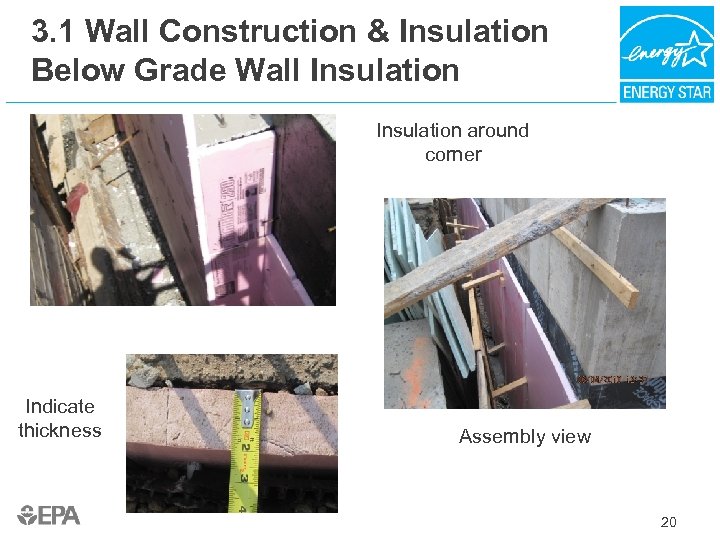

3. 1 Wall Construction & Insulation Below Grade Wall Insulation around corner Indicate thickness Assembly view 20

3. 1 Wall Construction & Insulation Below Grade Wall Insulation around corner Indicate thickness Assembly view 20

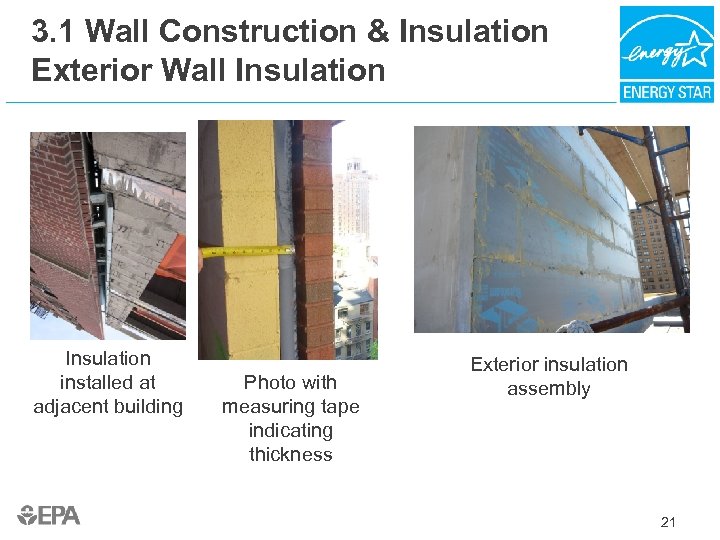

3. 1 Wall Construction & Insulation Exterior Wall Insulation installed at adjacent building Photo with measuring tape indicating thickness Exterior insulation assembly 21

3. 1 Wall Construction & Insulation Exterior Wall Insulation installed at adjacent building Photo with measuring tape indicating thickness Exterior insulation assembly 21

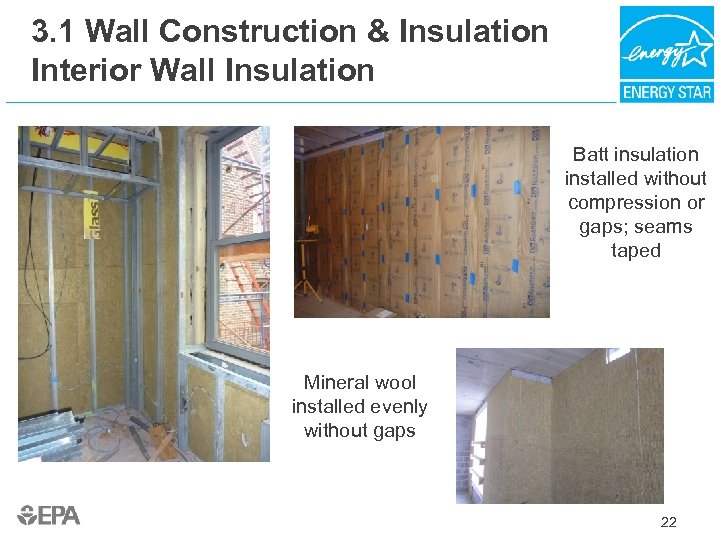

3. 1 Wall Construction & Insulation Interior Wall Insulation Batt insulation installed without compression or gaps; seams taped Mineral wool installed evenly without gaps 22

3. 1 Wall Construction & Insulation Interior Wall Insulation Batt insulation installed without compression or gaps; seams taped Mineral wool installed evenly without gaps 22

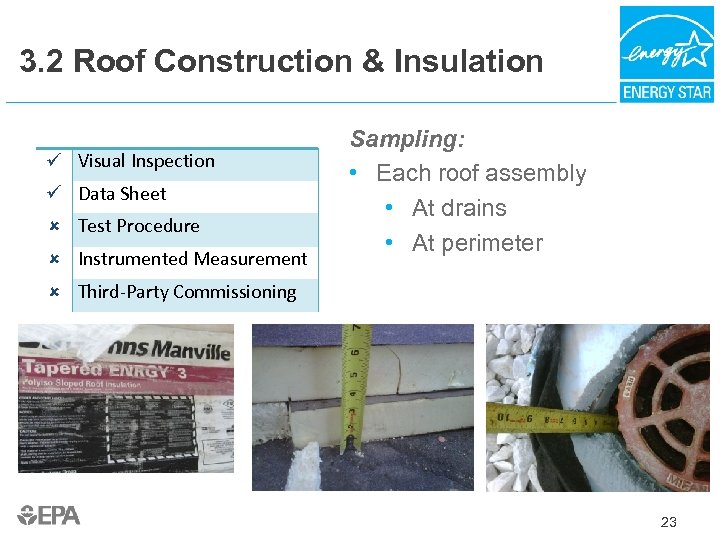

3. 2 Roof Construction & Insulation Visual Inspection Data Sheet Test Procedure Instrumented Measurement Sampling: • Each roof assembly • At drains • At perimeter Third-Party Commissioning 23

3. 2 Roof Construction & Insulation Visual Inspection Data Sheet Test Procedure Instrumented Measurement Sampling: • Each roof assembly • At drains • At perimeter Third-Party Commissioning 23

3. 3 Floor Construction & Insulation Visual Inspection Data Sheet Test Procedure Instrumented Measurement Third-Party Commissioning Sampling: • At least 15% of each unique floor assembly - insulation type, thickness, location, coverage, installation • Above unconditioned space • Below grade slab floor insulation • Slab-on-grade insulation 24

3. 3 Floor Construction & Insulation Visual Inspection Data Sheet Test Procedure Instrumented Measurement Third-Party Commissioning Sampling: • At least 15% of each unique floor assembly - insulation type, thickness, location, coverage, installation • Above unconditioned space • Below grade slab floor insulation • Slab-on-grade insulation 24

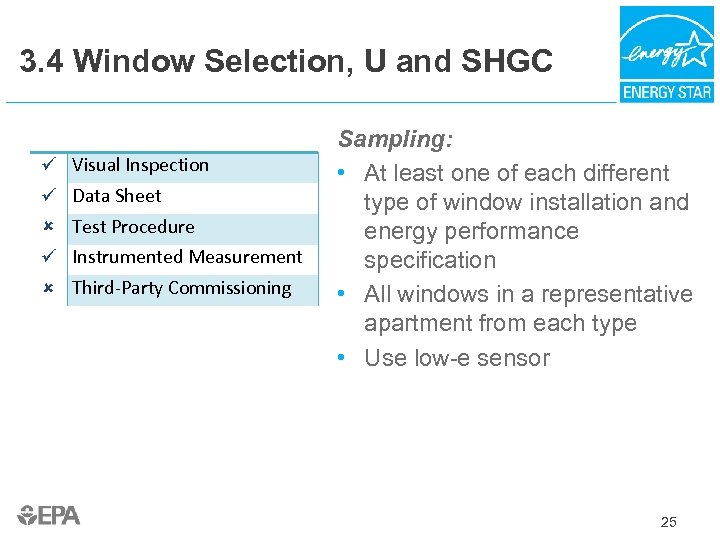

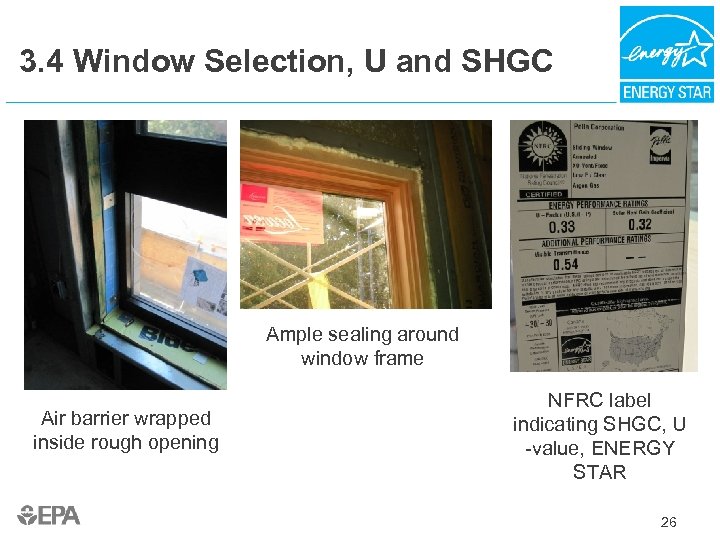

3. 4 Window Selection, U and SHGC Visual Inspection Data Sheet Test Procedure Instrumented Measurement Third-Party Commissioning Sampling: • At least one of each different type of window installation and energy performance specification • All windows in a representative apartment from each type • Use low-e sensor 25

3. 4 Window Selection, U and SHGC Visual Inspection Data Sheet Test Procedure Instrumented Measurement Third-Party Commissioning Sampling: • At least one of each different type of window installation and energy performance specification • All windows in a representative apartment from each type • Use low-e sensor 25

3. 4 Window Selection, U and SHGC Ample sealing around window frame Air barrier wrapped inside rough opening NFRC label indicating SHGC, U -value, ENERGY STAR 26

3. 4 Window Selection, U and SHGC Ample sealing around window frame Air barrier wrapped inside rough opening NFRC label indicating SHGC, U -value, ENERGY STAR 26

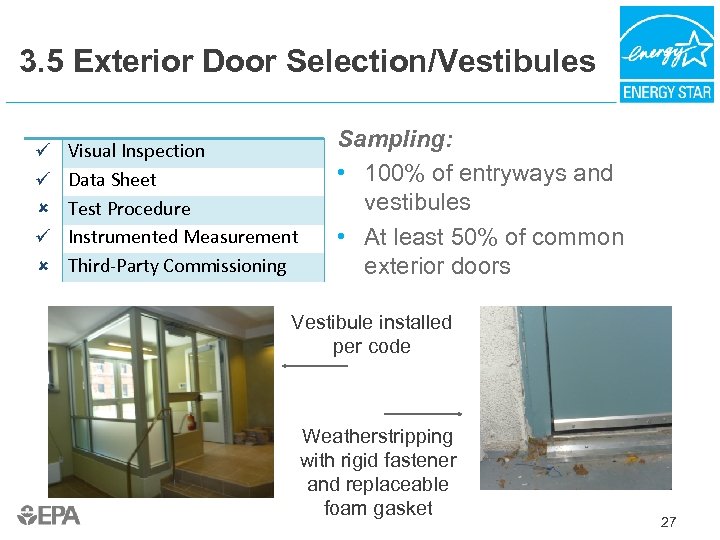

3. 5 Exterior Door Selection/Vestibules Visual Inspection Data Sheet Test Procedure Instrumented Measurement Third-Party Commissioning Sampling: • 100% of entryways and vestibules • At least 50% of common exterior doors Vestibule installed per code Weatherstripping with rigid fastener and replaceable foam gasket 27

3. 5 Exterior Door Selection/Vestibules Visual Inspection Data Sheet Test Procedure Instrumented Measurement Third-Party Commissioning Sampling: • 100% of entryways and vestibules • At least 50% of common exterior doors Vestibule installed per code Weatherstripping with rigid fastener and replaceable foam gasket 27

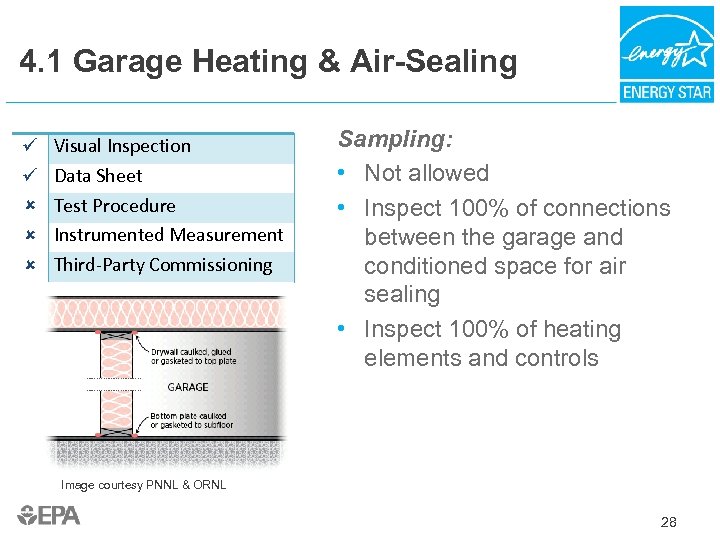

4. 1 Garage Heating & Air-Sealing Visual Inspection Data Sheet Test Procedure Instrumented Measurement Third-Party Commissioning Sampling: • Not allowed • Inspect 100% of connections between the garage and conditioned space for air sealing • Inspect 100% of heating elements and controls Image courtesy PNNL & ORNL 28

4. 1 Garage Heating & Air-Sealing Visual Inspection Data Sheet Test Procedure Instrumented Measurement Third-Party Commissioning Sampling: • Not allowed • Inspect 100% of connections between the garage and conditioned space for air sealing • Inspect 100% of heating elements and controls Image courtesy PNNL & ORNL 28

The End Questions? Contact: MFHR@energystar. gov 29

The End Questions? Contact: MFHR@energystar. gov 29