8cd9d7c135f8e43133ece9ad4b124b98.ppt

- Количество слайдов: 168

Energy and the New Reality, Volume 2: C-Free Energy Supply Chapter 2: Solar Energy L. D. Danny Harvey harvey@geog. utoronto. ca Publisher: Earthscan, UK Homepage: www. earthscan. co. uk/? tabid=101808 This material is intended for use in lectures, presentations and as handouts to students, and is provided in Powerpoint format so as to allow customization for the individual needs of course instructors. Permission of the author and publisher is required for any other usage. Please see www. earthscan. co. uk for contact details.

Energy and the New Reality, Volume 2: C-Free Energy Supply Chapter 2: Solar Energy L. D. Danny Harvey harvey@geog. utoronto. ca Publisher: Earthscan, UK Homepage: www. earthscan. co. uk/? tabid=101808 This material is intended for use in lectures, presentations and as handouts to students, and is provided in Powerpoint format so as to allow customization for the individual needs of course instructors. Permission of the author and publisher is required for any other usage. Please see www. earthscan. co. uk for contact details.

Framework • Solar flux density on a plane perpendicular to the sun’s rays at the mean Earth-Sun distance, Qs, is 1370 W/m 2 • The intercepted solar radiation flux (Qs x πRe 2) is about 11000 times the 2005 world primary power demand of 15. 3 TW • About 0. 8% of the world’s desert area (or 80, 700 km 2) covered with 10% efficient modules would be all that is required to generate the total world electricity consumption in 2005 of about 18000 TWh • However, cumulative installation of PV panels to date is only 25 km 2 • The solution is to directly use solar energy where-ever possible (for passive heating and ventilation, for thermaldriven cooling, and for daylighting), and to use solar electricity only where electricity really is needed.

Framework • Solar flux density on a plane perpendicular to the sun’s rays at the mean Earth-Sun distance, Qs, is 1370 W/m 2 • The intercepted solar radiation flux (Qs x πRe 2) is about 11000 times the 2005 world primary power demand of 15. 3 TW • About 0. 8% of the world’s desert area (or 80, 700 km 2) covered with 10% efficient modules would be all that is required to generate the total world electricity consumption in 2005 of about 18000 TWh • However, cumulative installation of PV panels to date is only 25 km 2 • The solution is to directly use solar energy where-ever possible (for passive heating and ventilation, for thermaldriven cooling, and for daylighting), and to use solar electricity only where electricity really is needed.

This chapter discusses: • Photovoltaic generation of electricity • Solar-thermal generation of electricity • Solar thermal energy for space heating and for hot water • Solar thermal energy for air conditioning • Industrial uses of solar thermal energy • Direct uses of solar energy for desalination, in agriculture and for cooking

This chapter discusses: • Photovoltaic generation of electricity • Solar-thermal generation of electricity • Solar thermal energy for space heating and for hot water • Solar thermal energy for air conditioning • Industrial uses of solar thermal energy • Direct uses of solar energy for desalination, in agriculture and for cooking

Chapter 4 (Buildings) of Volume 1 discusses passive (as opposed to active) uses of solar energy, with the building itself serving as a collector of solar energy. These passive uses are • Passive heating • Passive ventilation • Daylighting

Chapter 4 (Buildings) of Volume 1 discusses passive (as opposed to active) uses of solar energy, with the building itself serving as a collector of solar energy. These passive uses are • Passive heating • Passive ventilation • Daylighting

Chapter 11 (Community-Integrated Energy systems with Renewable Energy) of this volume discusses seasonal underground storage of solar thermal energy for space heating and for domestic hot water

Chapter 11 (Community-Integrated Energy systems with Renewable Energy) of this volume discusses seasonal underground storage of solar thermal energy for space heating and for domestic hot water

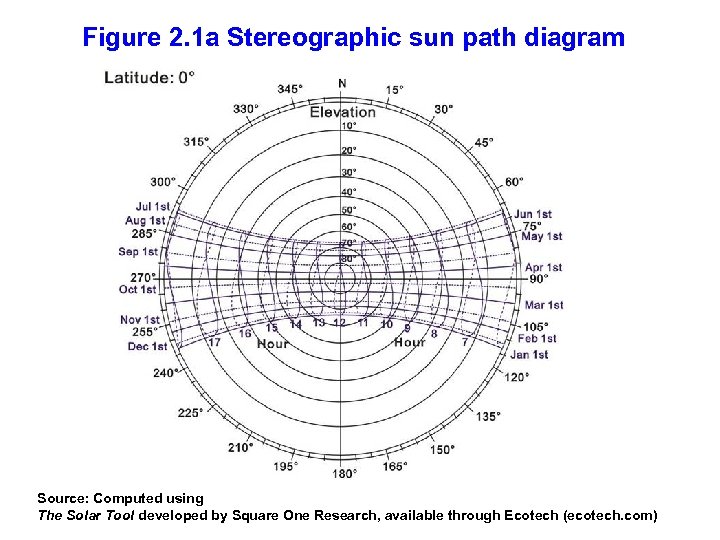

Figure 2. 1 a Stereographic sun path diagram Source: Computed using The Solar Tool developed by Square One Research, available through Ecotech (ecotech. com)

Figure 2. 1 a Stereographic sun path diagram Source: Computed using The Solar Tool developed by Square One Research, available through Ecotech (ecotech. com)

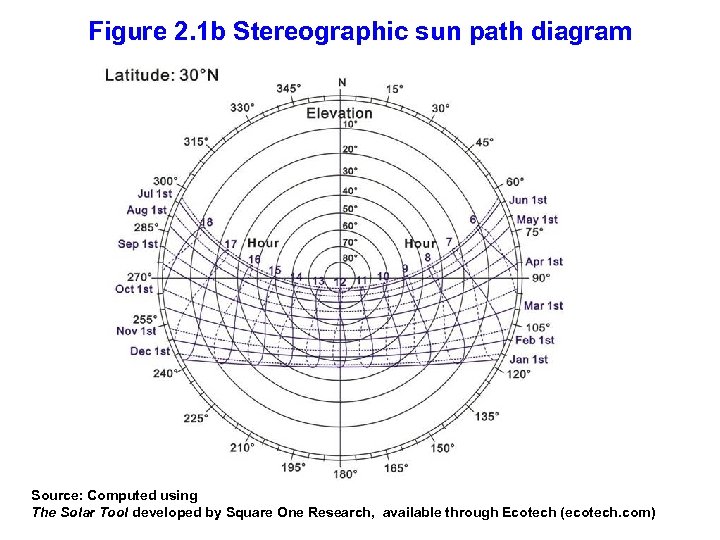

Figure 2. 1 b Stereographic sun path diagram Source: Computed using The Solar Tool developed by Square One Research, available through Ecotech (ecotech. com)

Figure 2. 1 b Stereographic sun path diagram Source: Computed using The Solar Tool developed by Square One Research, available through Ecotech (ecotech. com)

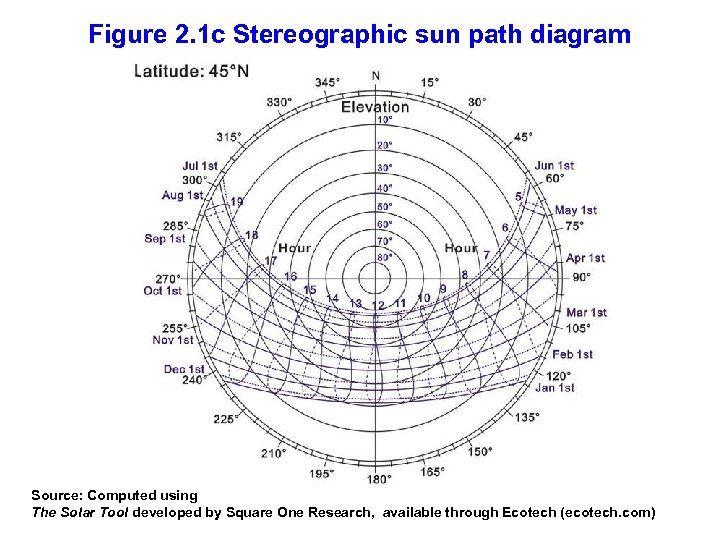

Figure 2. 1 c Stereographic sun path diagram Source: Computed using The Solar Tool developed by Square One Research, available through Ecotech (ecotech. com)

Figure 2. 1 c Stereographic sun path diagram Source: Computed using The Solar Tool developed by Square One Research, available through Ecotech (ecotech. com)

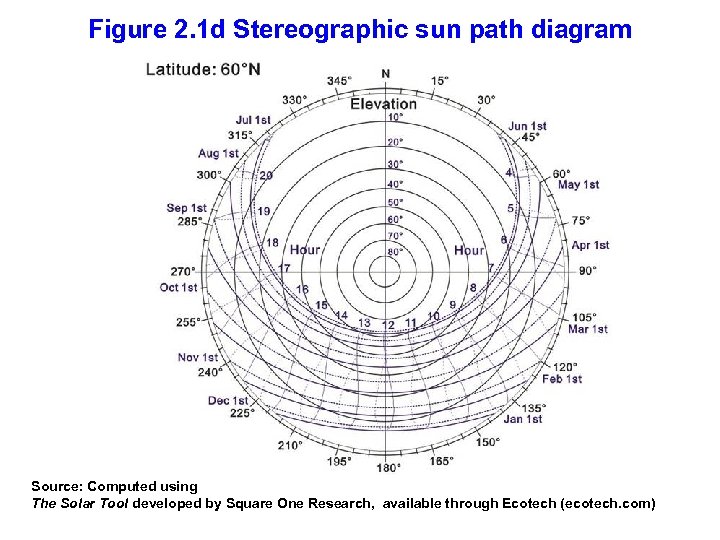

Figure 2. 1 d Stereographic sun path diagram Source: Computed using The Solar Tool developed by Square One Research, available through Ecotech (ecotech. com)

Figure 2. 1 d Stereographic sun path diagram Source: Computed using The Solar Tool developed by Square One Research, available through Ecotech (ecotech. com)

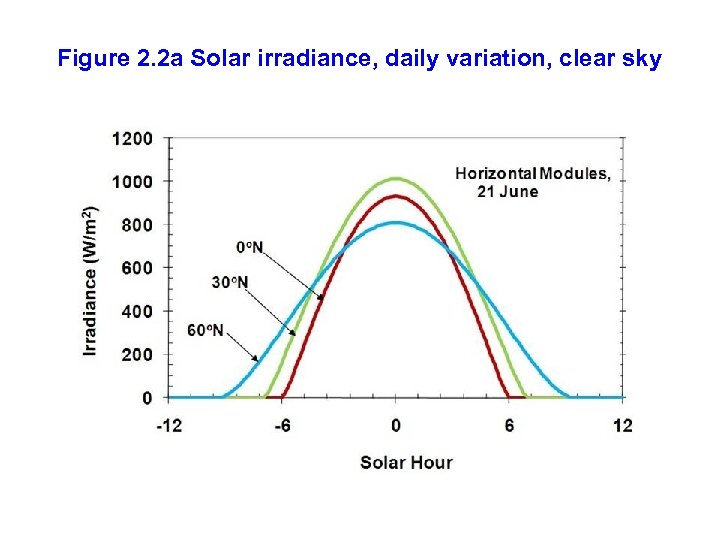

Figure 2. 2 a Solar irradiance, daily variation, clear sky

Figure 2. 2 a Solar irradiance, daily variation, clear sky

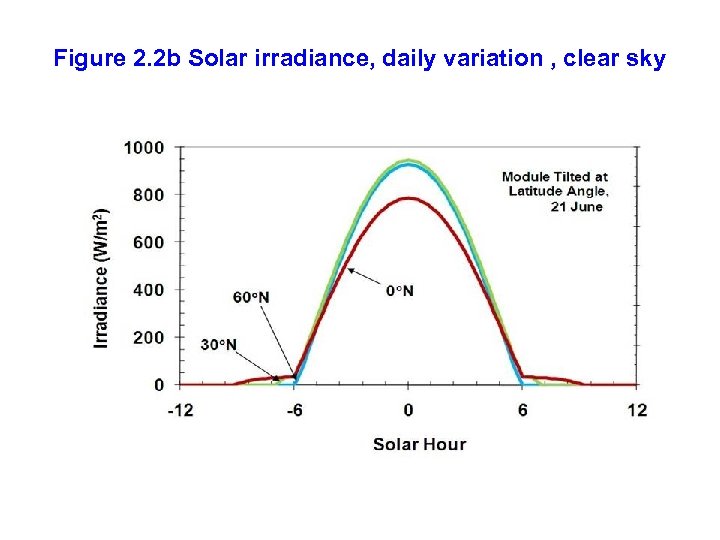

Figure 2. 2 b Solar irradiance, daily variation , clear sky

Figure 2. 2 b Solar irradiance, daily variation , clear sky

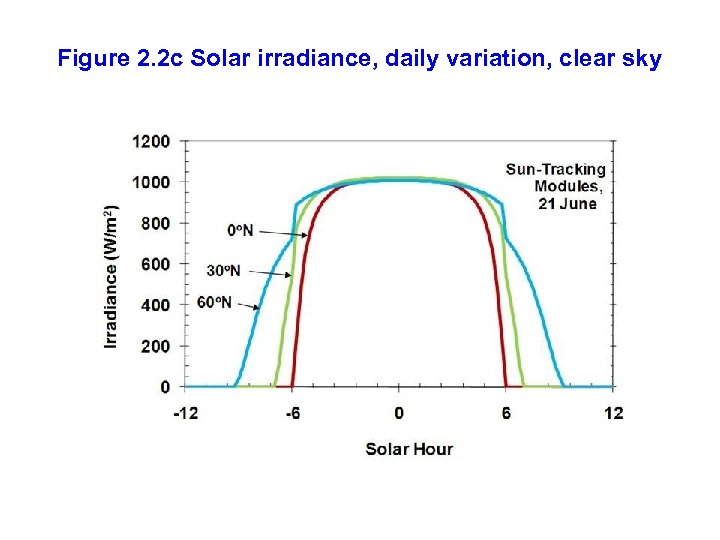

Figure 2. 2 c Solar irradiance, daily variation, clear sky

Figure 2. 2 c Solar irradiance, daily variation, clear sky

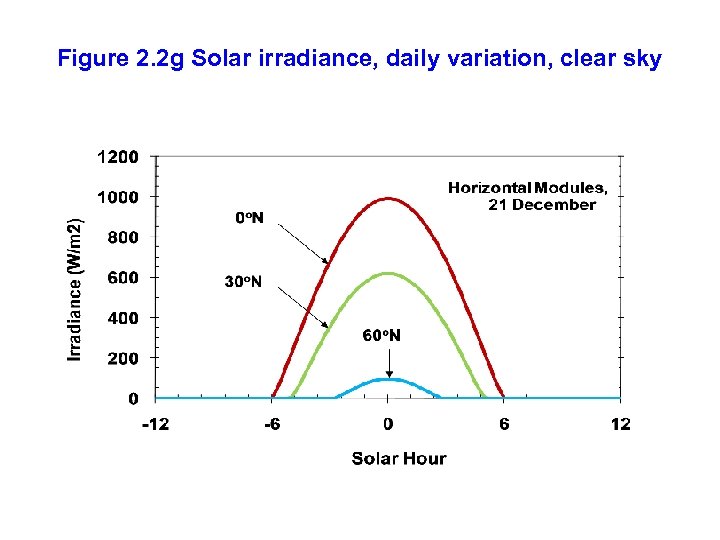

Figure 2. 2 g Solar irradiance, daily variation, clear sky

Figure 2. 2 g Solar irradiance, daily variation, clear sky

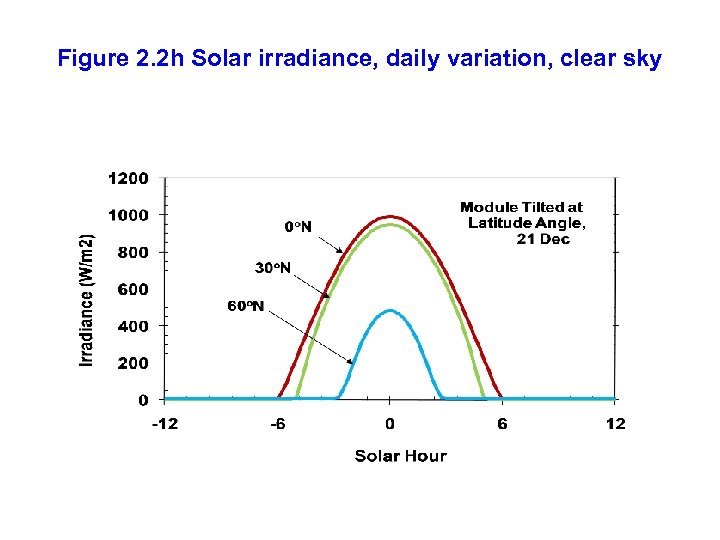

Figure 2. 2 h Solar irradiance, daily variation, clear sky

Figure 2. 2 h Solar irradiance, daily variation, clear sky

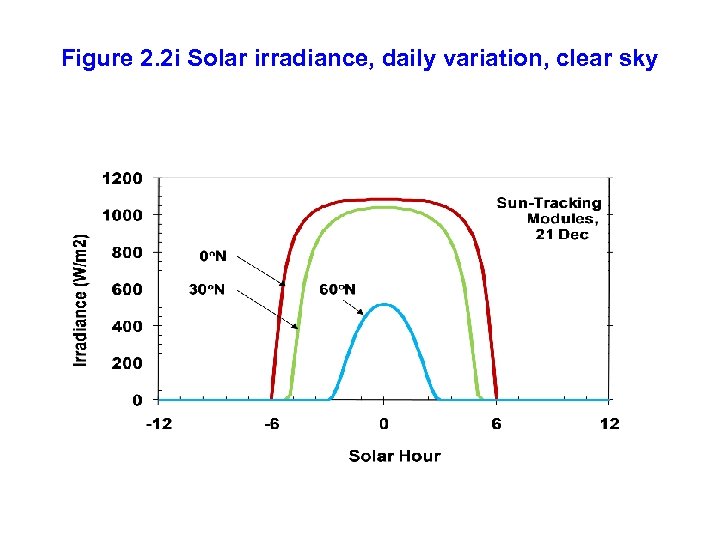

Figure 2. 2 i Solar irradiance, daily variation, clear sky

Figure 2. 2 i Solar irradiance, daily variation, clear sky

Observations on the diurnal variations (Fig 2. 2): • On June 21 - the further north, the longer the day and the less intense the noon peak - the differences in irradiance on a panel tilted at the latitude angle are smaller than on a horizontal panel - there is almost no difference in the irradiance on a sun-tracking PV panel within 5 hours of solar noon, but irradiance is less at other times at high latitudes because of the greater pathlength through the atmosphere (so more radiation is absorbed by the atmosphere) • On Dec 21 -- the further north, the shorter the day – differences are much greater, and sun tracking does not help much at high latitude (because even when pointed at the sun, the pathlength through the atmosphere is large)

Observations on the diurnal variations (Fig 2. 2): • On June 21 - the further north, the longer the day and the less intense the noon peak - the differences in irradiance on a panel tilted at the latitude angle are smaller than on a horizontal panel - there is almost no difference in the irradiance on a sun-tracking PV panel within 5 hours of solar noon, but irradiance is less at other times at high latitudes because of the greater pathlength through the atmosphere (so more radiation is absorbed by the atmosphere) • On Dec 21 -- the further north, the shorter the day – differences are much greater, and sun tracking does not help much at high latitude (because even when pointed at the sun, the pathlength through the atmosphere is large)

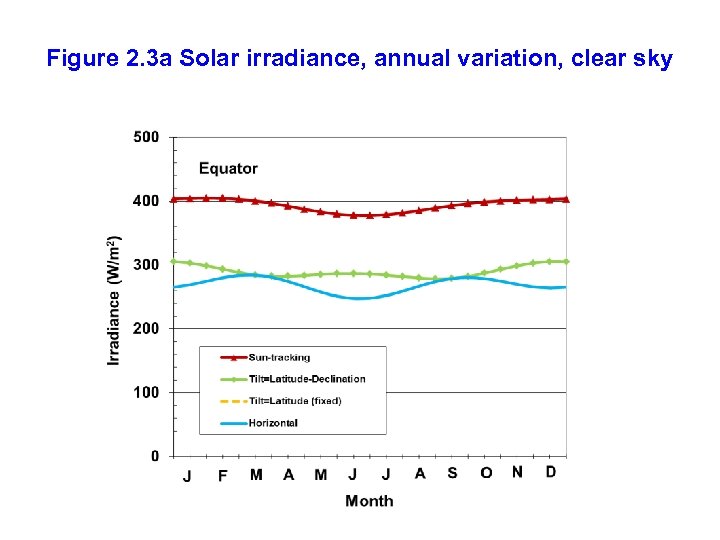

Figure 2. 3 a Solar irradiance, annual variation, clear sky

Figure 2. 3 a Solar irradiance, annual variation, clear sky

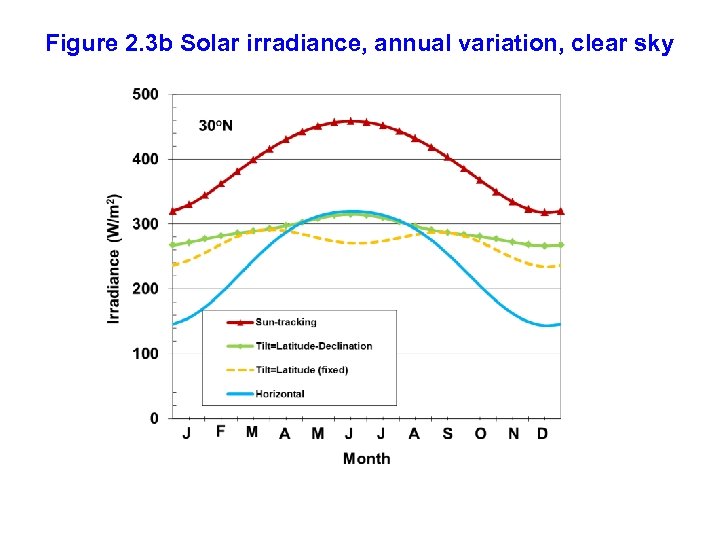

Figure 2. 3 b Solar irradiance, annual variation, clear sky

Figure 2. 3 b Solar irradiance, annual variation, clear sky

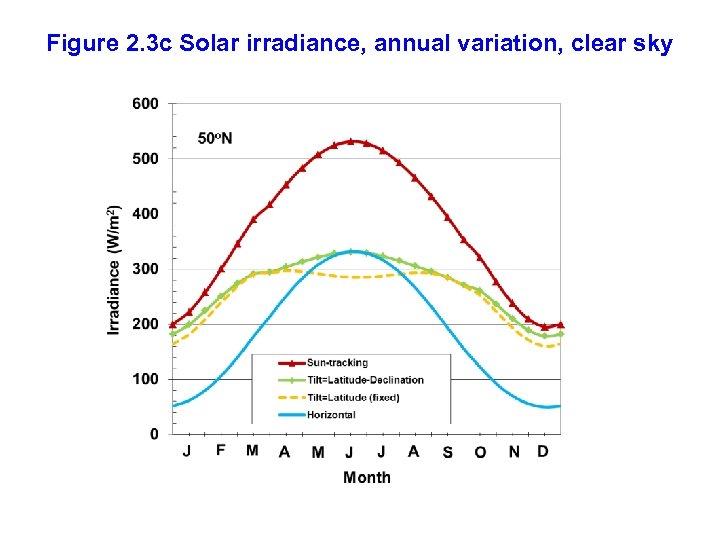

Figure 2. 3 c Solar irradiance, annual variation, clear sky

Figure 2. 3 c Solar irradiance, annual variation, clear sky

Observations on seasonal variation of diurnal average irradiance on a PV panel (Fig 2. 3) • If the panel has a fixed tilt equal to the latitude of the site, the result is greater irradiance in winter and less in summer compared to a horizontal panel • 1 -axis tracking, whereby the tilt is adjusted each day to equal the latitude minus solar declination, gives greater irradiance all year compared to fixed tilt • 2 -axis tracking is substantially better than 1 -axis tracking

Observations on seasonal variation of diurnal average irradiance on a PV panel (Fig 2. 3) • If the panel has a fixed tilt equal to the latitude of the site, the result is greater irradiance in winter and less in summer compared to a horizontal panel • 1 -axis tracking, whereby the tilt is adjusted each day to equal the latitude minus solar declination, gives greater irradiance all year compared to fixed tilt • 2 -axis tracking is substantially better than 1 -axis tracking

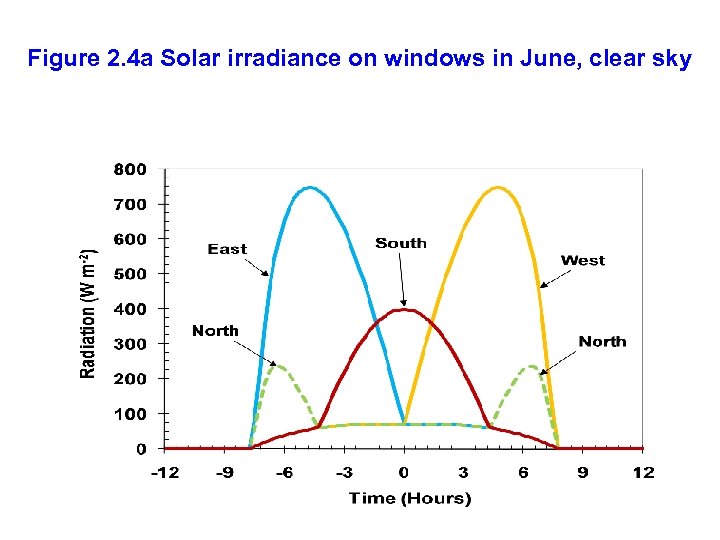

Figure 2. 4 a Solar irradiance on windows in June, clear sky

Figure 2. 4 a Solar irradiance on windows in June, clear sky

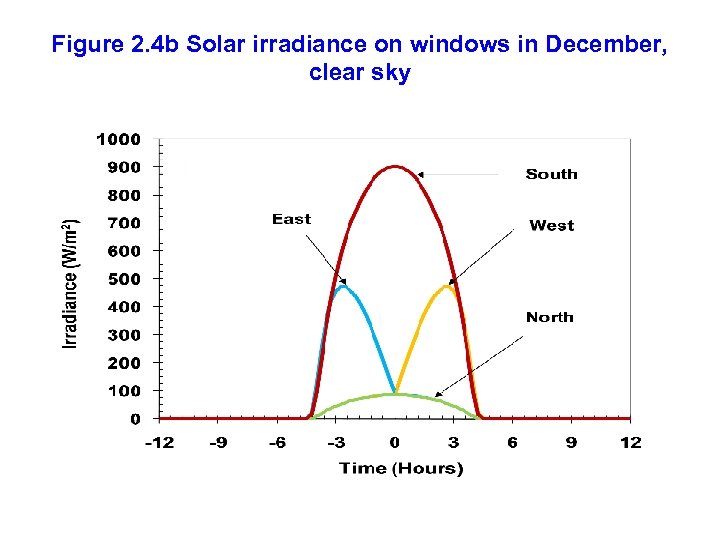

Figure 2. 4 b Solar irradiance on windows in December, clear sky

Figure 2. 4 b Solar irradiance on windows in December, clear sky

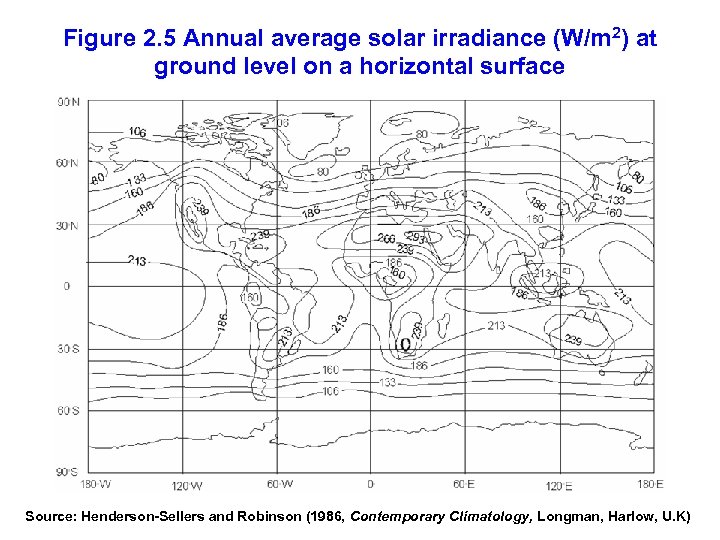

Figure 2. 5 Annual average solar irradiance (W/m 2) at ground level on a horizontal surface Source: Henderson-Sellers and Robinson (1986, Contemporary Climatology, Longman, Harlow, U. K)

Figure 2. 5 Annual average solar irradiance (W/m 2) at ground level on a horizontal surface Source: Henderson-Sellers and Robinson (1986, Contemporary Climatology, Longman, Harlow, U. K)

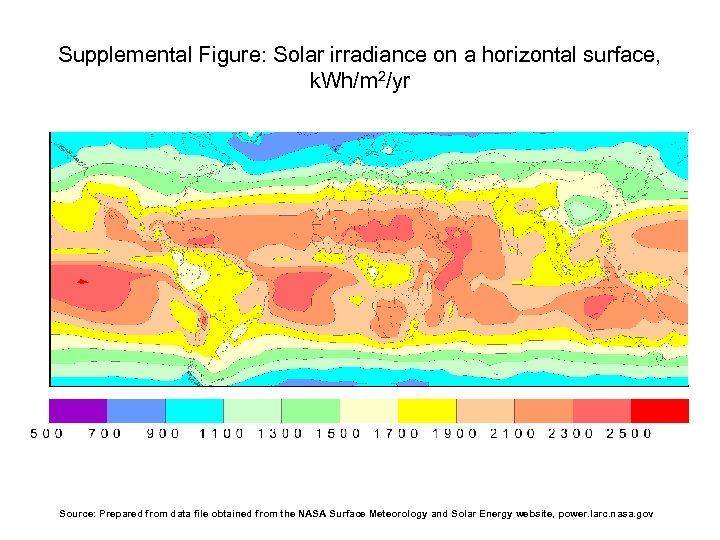

Supplemental Figure: Solar irradiance on a horizontal surface, k. Wh/m 2/yr Source: Prepared from data file obtained from the NASA Surface Meteorology and Solar Energy website, power. larc. nasa. gov

Supplemental Figure: Solar irradiance on a horizontal surface, k. Wh/m 2/yr Source: Prepared from data file obtained from the NASA Surface Meteorology and Solar Energy website, power. larc. nasa. gov

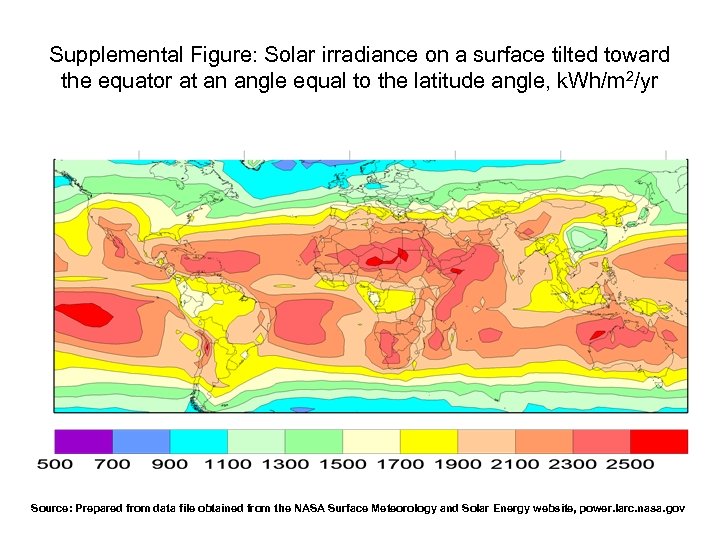

Supplemental Figure: Solar irradiance on a surface tilted toward the equator at an angle equal to the latitude angle, k. Wh/m 2/yr Source: Prepared from data file obtained from the NASA Surface Meteorology and Solar Energy website, power. larc. nasa. gov

Supplemental Figure: Solar irradiance on a surface tilted toward the equator at an angle equal to the latitude angle, k. Wh/m 2/yr Source: Prepared from data file obtained from the NASA Surface Meteorology and Solar Energy website, power. larc. nasa. gov

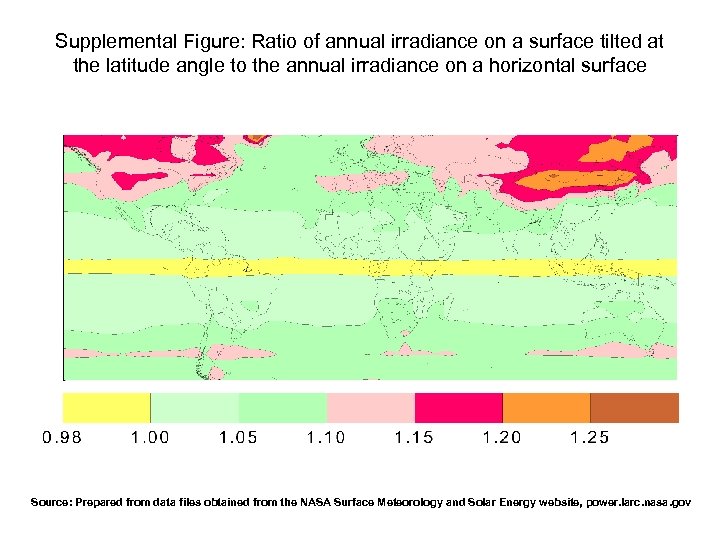

Supplemental Figure: Ratio of annual irradiance on a surface tilted at the latitude angle to the annual irradiance on a horizontal surface Source: Prepared from data files obtained from the NASA Surface Meteorology and Solar Energy website, power. larc. nasa. gov

Supplemental Figure: Ratio of annual irradiance on a surface tilted at the latitude angle to the annual irradiance on a horizontal surface Source: Prepared from data files obtained from the NASA Surface Meteorology and Solar Energy website, power. larc. nasa. gov

Two broad ways of making electricity from solar energy: • Photovoltaic (PV) • Solar thermal

Two broad ways of making electricity from solar energy: • Photovoltaic (PV) • Solar thermal

PV Electricity • Electromagnetic radiation (including light) comes in packets called photons, each with energy hv, where h=Plank’s constant and v is the frequency of the radiation • Electrons in an atom exist in different energy levels • A photon can bump an electron to a higher energy level if the energy of the photon exceeds the difference in energy from one level to the next

PV Electricity • Electromagnetic radiation (including light) comes in packets called photons, each with energy hv, where h=Plank’s constant and v is the frequency of the radiation • Electrons in an atom exist in different energy levels • A photon can bump an electron to a higher energy level if the energy of the photon exceeds the difference in energy from one level to the next

PV electricity (continued) • When a solid forms, two outer energy bands are formed, often separated by a gap in energy level (not a physical gap) • The lower energy band is called the valence band, the upper the conduction band • In a conductor, electrons occur in both bands and they overlap • In an insulator, the valence band is filled and the conduction band is empty, and the two bands do not overlap • In a semi-conductor, electrons occur in both bands and there is a small gap between the bands

PV electricity (continued) • When a solid forms, two outer energy bands are formed, often separated by a gap in energy level (not a physical gap) • The lower energy band is called the valence band, the upper the conduction band • In a conductor, electrons occur in both bands and they overlap • In an insulator, the valence band is filled and the conduction band is empty, and the two bands do not overlap • In a semi-conductor, electrons occur in both bands and there is a small gap between the bands

PV electricity (continued) • Silicon is a semi-conductor with a valence of 4 (4 electrons in the outer shell) • Two semiconductor layers are used – one layer (called the n-type layer) is doped with atoms have an valence of 5 (the extra electron is not taken up in the crystal lattice and so it is free to move), and the other layer (called the p-type layer) is doped with atoms having a valence of 3, so there are empty electron sites (called holes) • The juxtaposition of the n- and p layers is called a pn junction.

PV electricity (continued) • Silicon is a semi-conductor with a valence of 4 (4 electrons in the outer shell) • Two semiconductor layers are used – one layer (called the n-type layer) is doped with atoms have an valence of 5 (the extra electron is not taken up in the crystal lattice and so it is free to move), and the other layer (called the p-type layer) is doped with atoms having a valence of 3, so there are empty electron sites (called holes) • The juxtaposition of the n- and p layers is called a pn junction.

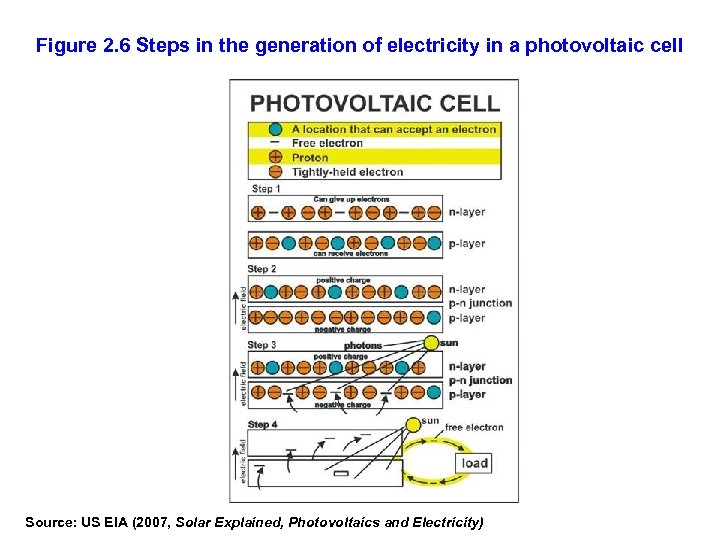

Figure 2. 6 Steps in the generation of electricity in a photovoltaic cell Source: US EIA (2007, Solar Explained, Photovoltaics and Electricity)

Figure 2. 6 Steps in the generation of electricity in a photovoltaic cell Source: US EIA (2007, Solar Explained, Photovoltaics and Electricity)

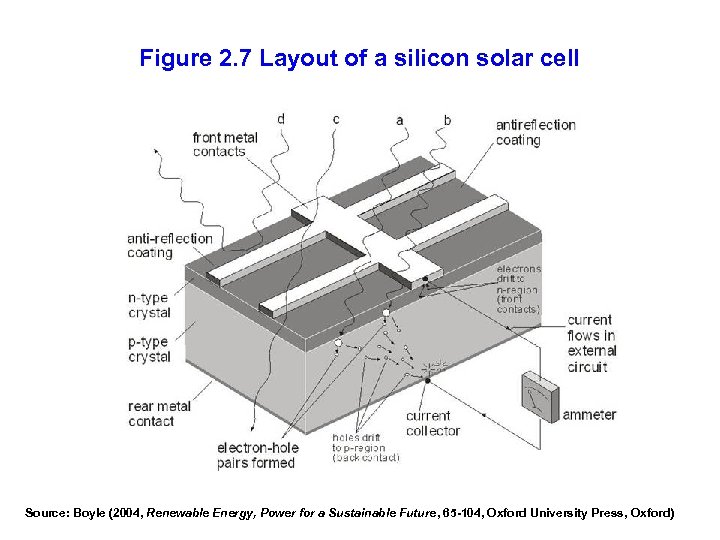

Figure 2. 7 Layout of a silicon solar cell Source: Boyle (2004, Renewable Energy, Power for a Sustainable Future, 65 -104, Oxford University Press, Oxford)

Figure 2. 7 Layout of a silicon solar cell Source: Boyle (2004, Renewable Energy, Power for a Sustainable Future, 65 -104, Oxford University Press, Oxford)

Components of a PV system • Module – consists of many cells wired together • Support structure • Inverter – converts DC module output to AC power at the right voltage and frequency for transfer to the grid • Concentrating mirrors or lens for concentrating PV systems

Components of a PV system • Module – consists of many cells wired together • Support structure • Inverter – converts DC module output to AC power at the right voltage and frequency for transfer to the grid • Concentrating mirrors or lens for concentrating PV systems

Types of PV cells • • Single-crystalline Multi-crystalline Thin-film amorphous silicon Thin-film compound semiconductors Thin-film multi-crystalline Nano-crystalline dye-sensitized cells Plastic cells

Types of PV cells • • Single-crystalline Multi-crystalline Thin-film amorphous silicon Thin-film compound semiconductors Thin-film multi-crystalline Nano-crystalline dye-sensitized cells Plastic cells

Thin-film compound semiconductors • • Cadmium telluride (Cd. Te) Copper-indium-diselenide (Cu. In. Se 2, CIS) Copper-indium-gallium-diselenide (CIGS) Gallium arsenide (Ga. As)

Thin-film compound semiconductors • • Cadmium telluride (Cd. Te) Copper-indium-diselenide (Cu. In. Se 2, CIS) Copper-indium-gallium-diselenide (CIGS) Gallium arsenide (Ga. As)

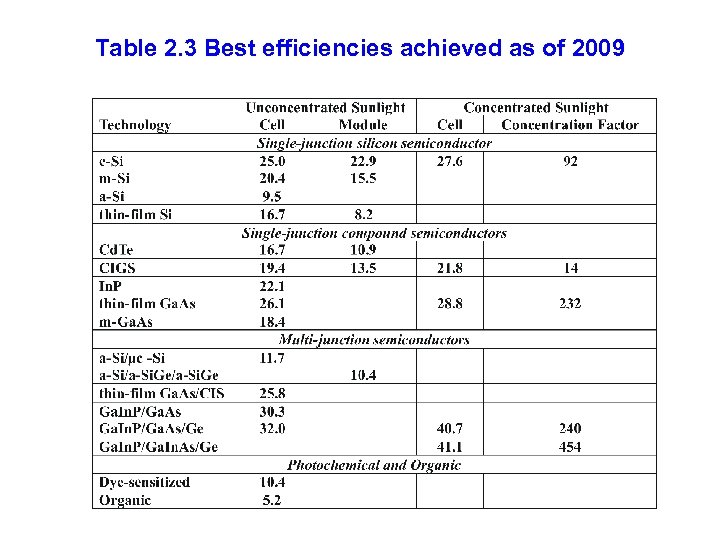

Table 2. 3 Best efficiencies achieved as of 2009

Table 2. 3 Best efficiencies achieved as of 2009

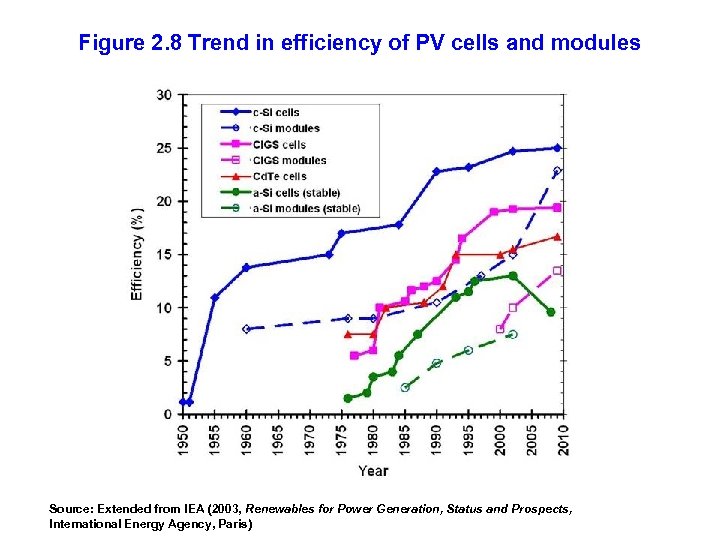

Figure 2. 8 Trend in efficiency of PV cells and modules Source: Extended from IEA (2003, Renewables for Power Generation, Status and Prospects, International Energy Agency, Paris)

Figure 2. 8 Trend in efficiency of PV cells and modules Source: Extended from IEA (2003, Renewables for Power Generation, Status and Prospects, International Energy Agency, Paris)

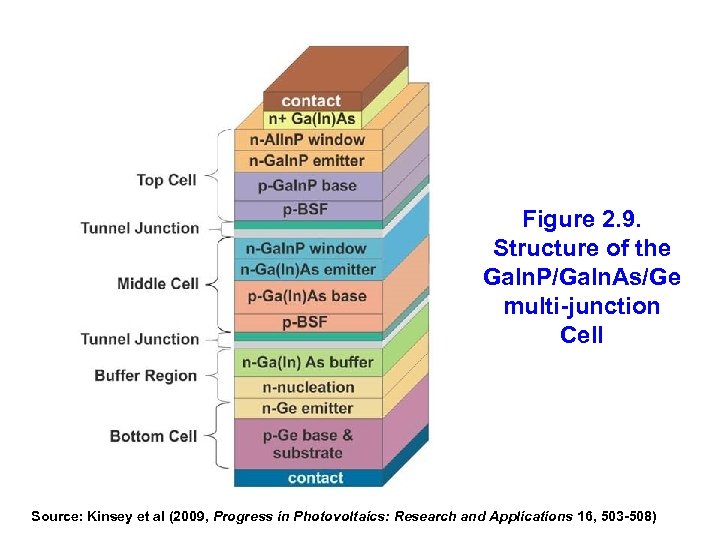

Figure 2. 9. Structure of the Ga. In. P/Ga. In. As/Ge multi-junction Cell Source: Kinsey et al (2009, Progress in Photovoltaics: Research and Applications 16, 503 -508)

Figure 2. 9. Structure of the Ga. In. P/Ga. In. As/Ge multi-junction Cell Source: Kinsey et al (2009, Progress in Photovoltaics: Research and Applications 16, 503 -508)

Compound semi-conductors • Have several pn junctions, each with a different band gap • Junctions are placed in the order of decreasing band gap, starting from the top • Efficiency is limited by that fact that • - if the photon energy is less than that of the band gap, nothing happens and the photon passes right through • - if the photon energy is greater than that of the band gap, the excess energy is wasted (turned into heat)

Compound semi-conductors • Have several pn junctions, each with a different band gap • Junctions are placed in the order of decreasing band gap, starting from the top • Efficiency is limited by that fact that • - if the photon energy is less than that of the band gap, nothing happens and the photon passes right through • - if the photon energy is greater than that of the band gap, the excess energy is wasted (turned into heat)

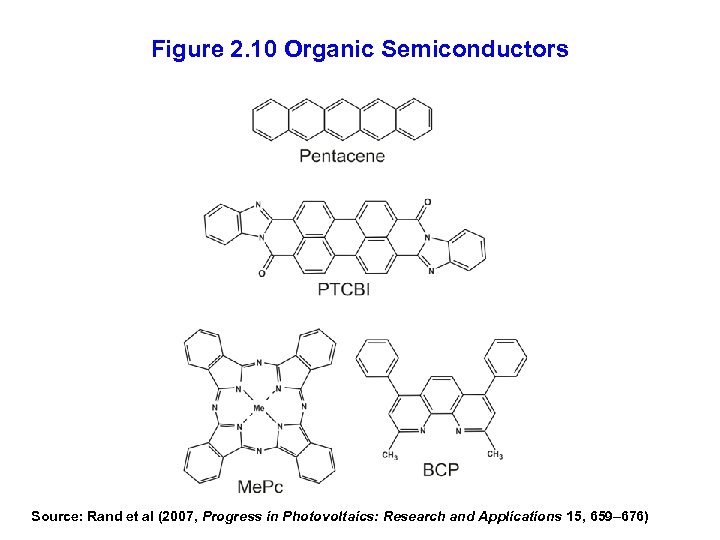

Figure 2. 10 Organic Semiconductors Source: Rand et al (2007, Progress in Photovoltaics: Research and Applications 15, 659– 676)

Figure 2. 10 Organic Semiconductors Source: Rand et al (2007, Progress in Photovoltaics: Research and Applications 15, 659– 676)

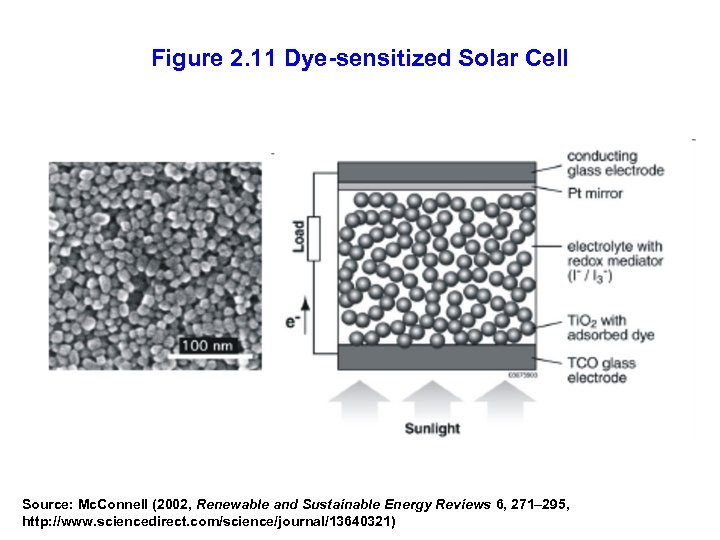

Figure 2. 11 Dye-sensitized Solar Cell Source: Mc. Connell (2002, Renewable and Sustainable Energy Reviews 6, 271– 295, http: //www. sciencedirect. com/science/journal/13640321)

Figure 2. 11 Dye-sensitized Solar Cell Source: Mc. Connell (2002, Renewable and Sustainable Energy Reviews 6, 271– 295, http: //www. sciencedirect. com/science/journal/13640321)

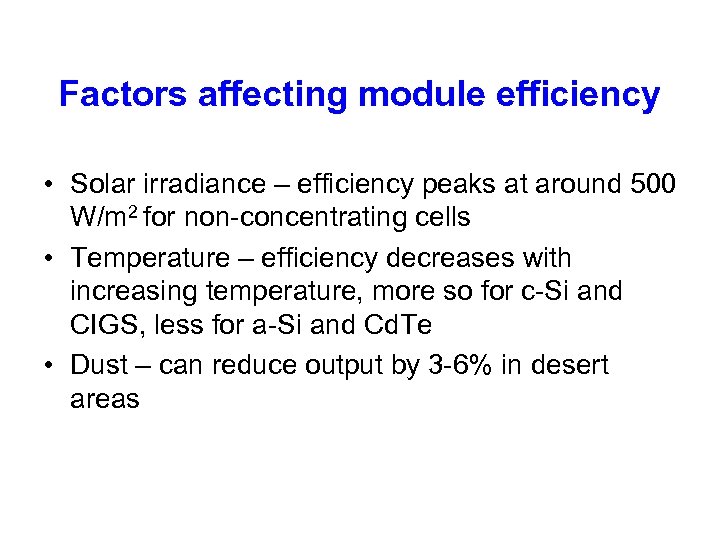

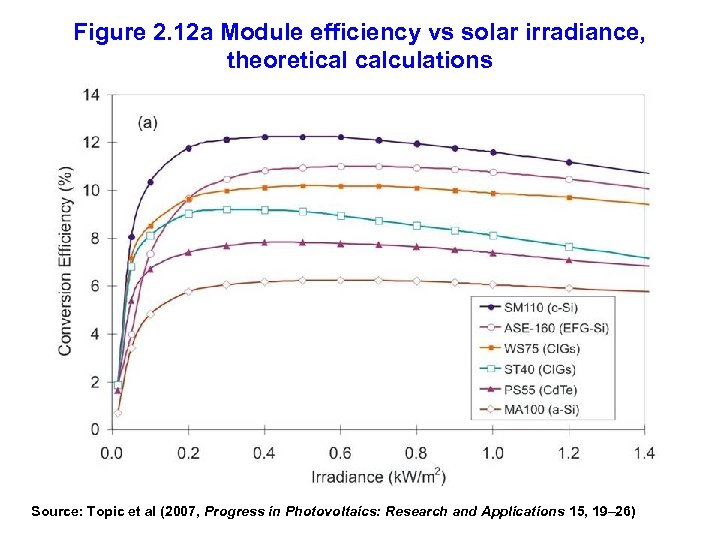

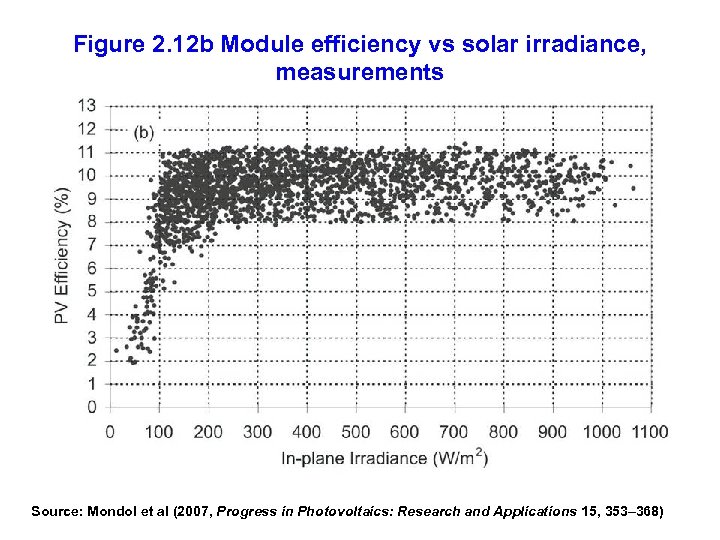

Factors affecting module efficiency • Solar irradiance – efficiency peaks at around 500 W/m 2 for non-concentrating cells • Temperature – efficiency decreases with increasing temperature, more so for c-Si and CIGS, less for a-Si and Cd. Te • Dust – can reduce output by 3 -6% in desert areas

Factors affecting module efficiency • Solar irradiance – efficiency peaks at around 500 W/m 2 for non-concentrating cells • Temperature – efficiency decreases with increasing temperature, more so for c-Si and CIGS, less for a-Si and Cd. Te • Dust – can reduce output by 3 -6% in desert areas

Figure 2. 12 a Module efficiency vs solar irradiance, theoretical calculations Source: Topic et al (2007, Progress in Photovoltaics: Research and Applications 15, 19– 26)

Figure 2. 12 a Module efficiency vs solar irradiance, theoretical calculations Source: Topic et al (2007, Progress in Photovoltaics: Research and Applications 15, 19– 26)

Figure 2. 12 b Module efficiency vs solar irradiance, measurements Source: Mondol et al (2007, Progress in Photovoltaics: Research and Applications 15, 353– 368)

Figure 2. 12 b Module efficiency vs solar irradiance, measurements Source: Mondol et al (2007, Progress in Photovoltaics: Research and Applications 15, 353– 368)

System efficiency is the product of • Module efficiency • Inverter efficiency • MPP-tracking efficiency

System efficiency is the product of • Module efficiency • Inverter efficiency • MPP-tracking efficiency

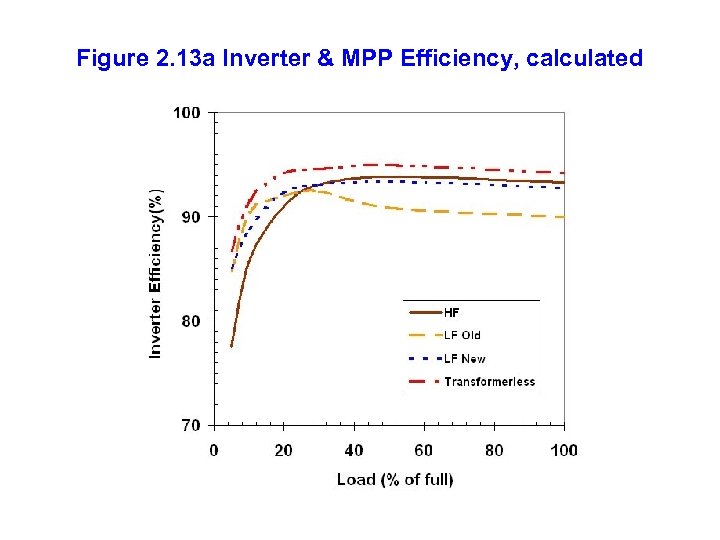

Figure 2. 13 a Inverter & MPP Efficiency, calculated

Figure 2. 13 a Inverter & MPP Efficiency, calculated

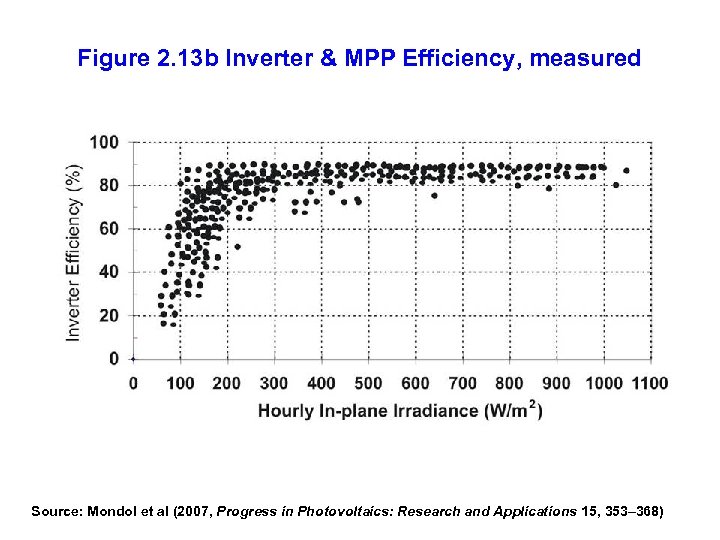

Figure 2. 13 b Inverter & MPP Efficiency, measured Source: Mondol et al (2007, Progress in Photovoltaics: Research and Applications 15, 353– 368)

Figure 2. 13 b Inverter & MPP Efficiency, measured Source: Mondol et al (2007, Progress in Photovoltaics: Research and Applications 15, 353– 368)

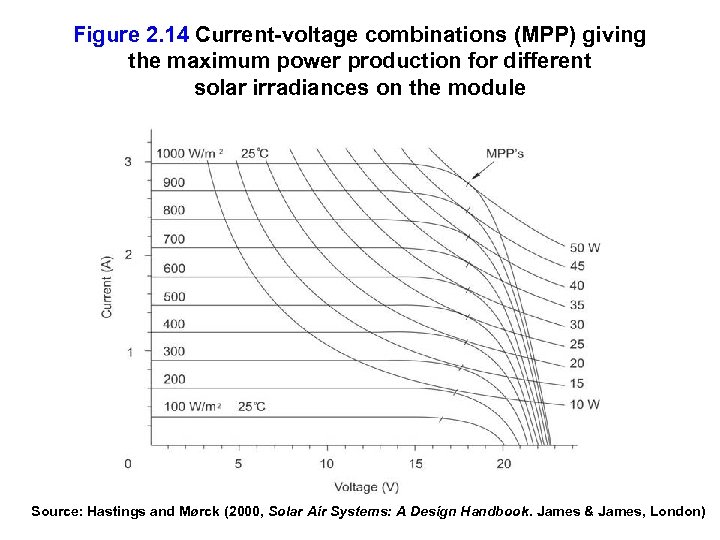

Figure 2. 14 Current-voltage combinations (MPP) giving the maximum power production for different solar irradiances on the module Source: Hastings and Mørck (2000, Solar Air Systems: A Design Handbook. James & James, London)

Figure 2. 14 Current-voltage combinations (MPP) giving the maximum power production for different solar irradiances on the module Source: Hastings and Mørck (2000, Solar Air Systems: A Design Handbook. James & James, London)

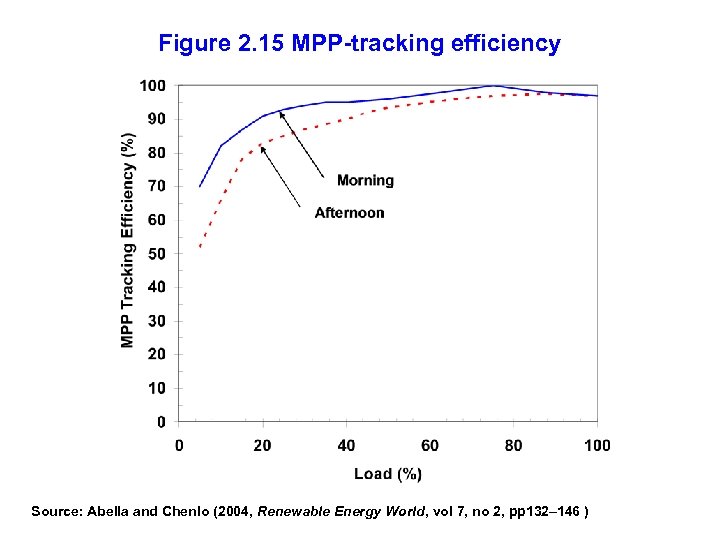

Figure 2. 15 MPP-tracking efficiency Source: Abella and Chenlo (2004, Renewable Energy World, vol 7, no 2, pp 132– 146 )

Figure 2. 15 MPP-tracking efficiency Source: Abella and Chenlo (2004, Renewable Energy World, vol 7, no 2, pp 132– 146 )

The net effect of all the losses is represented by the performance ratio: the ratio of actual k. Wh of generated AC electricity to k. Wh of DC electricity produced by the module Recent values have averaged around 75 -80%

The net effect of all the losses is represented by the performance ratio: the ratio of actual k. Wh of generated AC electricity to k. Wh of DC electricity produced by the module Recent values have averaged around 75 -80%

Building-Integrated PV (Bi. PV)

Building-Integrated PV (Bi. PV)

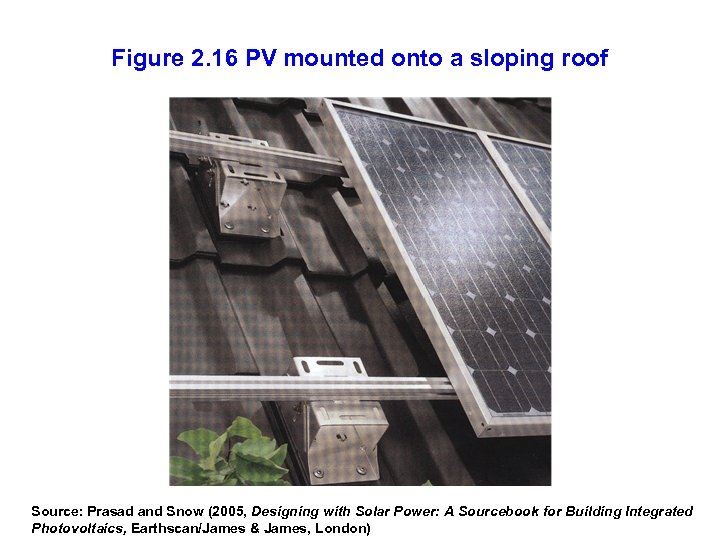

Figure 2. 16 PV mounted onto a sloping roof Source: Prasad and Snow (2005, Designing with Solar Power: A Sourcebook for Building Integrated Photovoltaics, Earthscan/James & James, London)

Figure 2. 16 PV mounted onto a sloping roof Source: Prasad and Snow (2005, Designing with Solar Power: A Sourcebook for Building Integrated Photovoltaics, Earthscan/James & James, London)

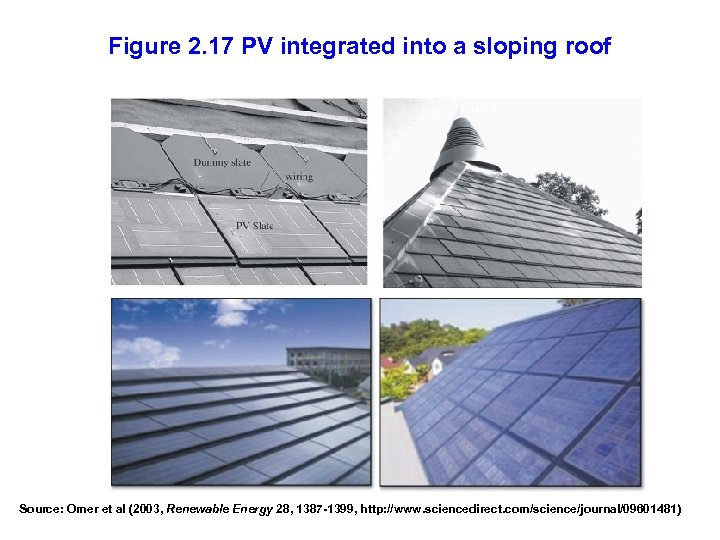

Figure 2. 17 PV integrated into a sloping roof Source: Omer et al (2003, Renewable Energy 28, 1387 -1399, http: //www. sciencedirect. com/science/journal/09601481)

Figure 2. 17 PV integrated into a sloping roof Source: Omer et al (2003, Renewable Energy 28, 1387 -1399, http: //www. sciencedirect. com/science/journal/09601481)

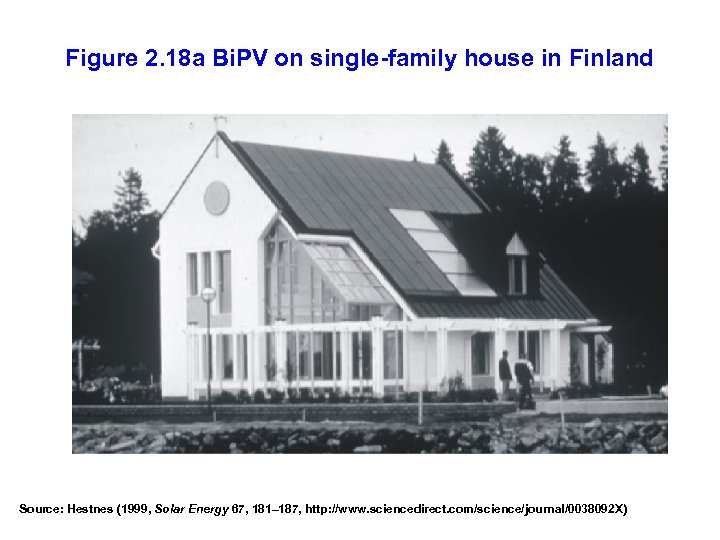

Figure 2. 18 a Bi. PV on single-family house in Finland Source: Hestnes (1999, Solar Energy 67, 181– 187, http: //www. sciencedirect. com/science/journal/0038092 X)

Figure 2. 18 a Bi. PV on single-family house in Finland Source: Hestnes (1999, Solar Energy 67, 181– 187, http: //www. sciencedirect. com/science/journal/0038092 X)

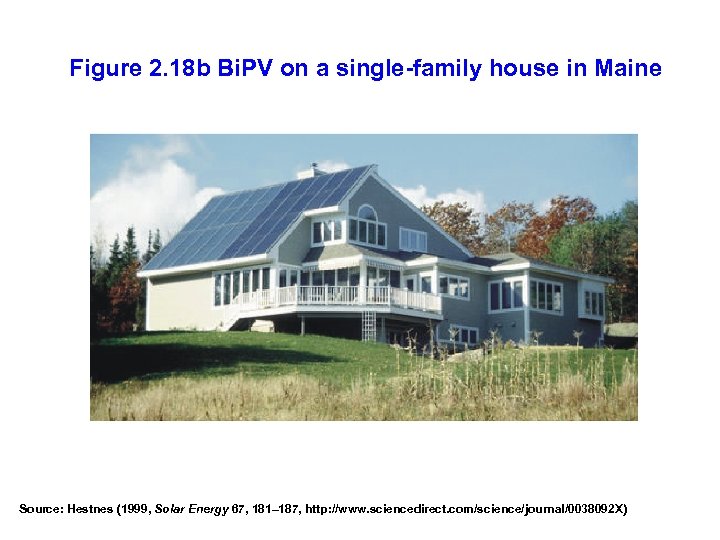

Figure 2. 18 b Bi. PV on a single-family house in Maine Source: Hestnes (1999, Solar Energy 67, 181– 187, http: //www. sciencedirect. com/science/journal/0038092 X)

Figure 2. 18 b Bi. PV on a single-family house in Maine Source: Hestnes (1999, Solar Energy 67, 181– 187, http: //www. sciencedirect. com/science/journal/0038092 X)

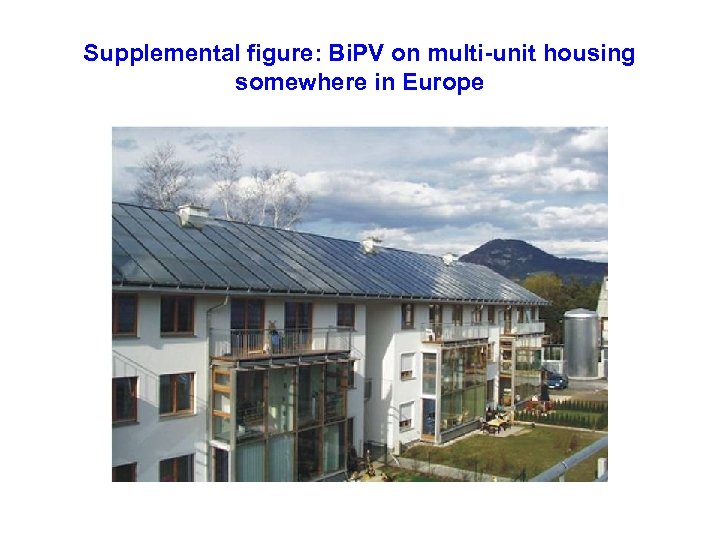

Supplemental figure: Bi. PV on multi-unit housing somewhere in Europe

Supplemental figure: Bi. PV on multi-unit housing somewhere in Europe

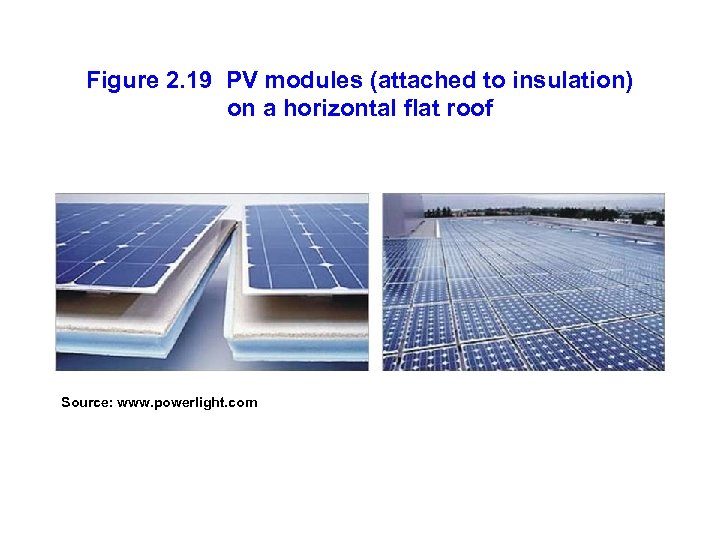

Figure 2. 19 PV modules (attached to insulation) on a horizontal flat roof Source: www. powerlight. com

Figure 2. 19 PV modules (attached to insulation) on a horizontal flat roof Source: www. powerlight. com

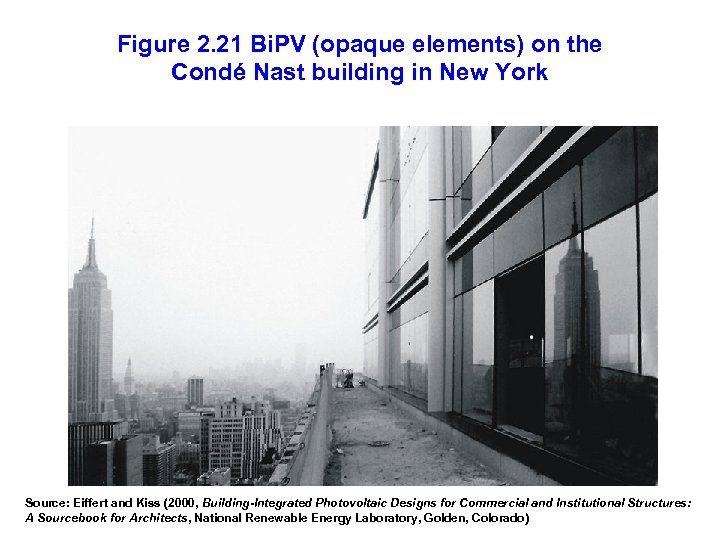

Figure 2. 21 Bi. PV (opaque elements) on the Condé Nast building in New York Source: Eiffert and Kiss (2000, Building-Integrated Photovoltaic Designs for Commercial and Institutional Structures: A Sourcebook for Architects, National Renewable Energy Laboratory, Golden, Colorado)

Figure 2. 21 Bi. PV (opaque elements) on the Condé Nast building in New York Source: Eiffert and Kiss (2000, Building-Integrated Photovoltaic Designs for Commercial and Institutional Structures: A Sourcebook for Architects, National Renewable Energy Laboratory, Golden, Colorado)

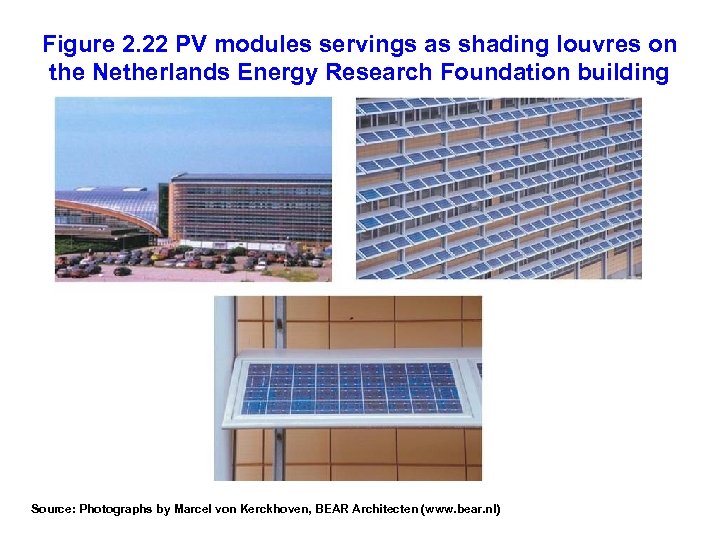

Figure 2. 22 PV modules servings as shading louvres on the Netherlands Energy Research Foundation building Source: Photographs by Marcel von Kerckhoven, BEAR Architecten (www. bear. nl)

Figure 2. 22 PV modules servings as shading louvres on the Netherlands Energy Research Foundation building Source: Photographs by Marcel von Kerckhoven, BEAR Architecten (www. bear. nl)

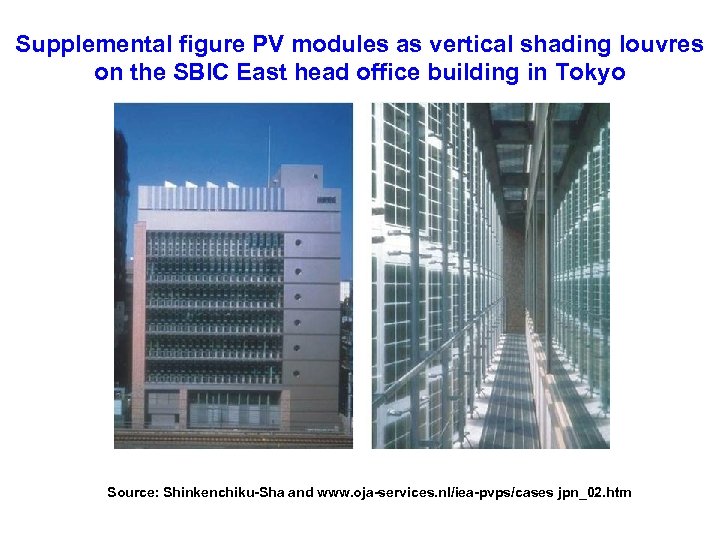

Supplemental figure PV modules as vertical shading louvres on the SBIC East head office building in Tokyo Source: Shinkenchiku-Sha and www. oja-services. nl/iea-pvps/cases jpn_02. htm

Supplemental figure PV modules as vertical shading louvres on the SBIC East head office building in Tokyo Source: Shinkenchiku-Sha and www. oja-services. nl/iea-pvps/cases jpn_02. htm

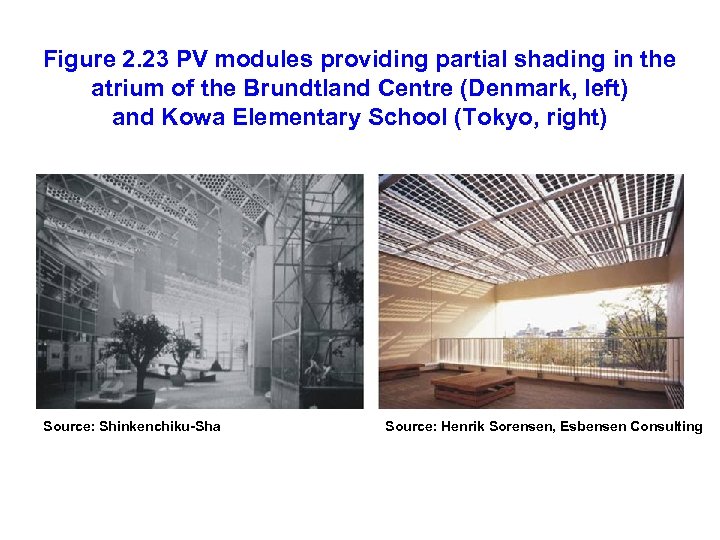

Figure 2. 23 PV modules providing partial shading in the atrium of the Brundtland Centre (Denmark, left) and Kowa Elementary School (Tokyo, right) Source: Shinkenchiku-Sha Source: Henrik Sorensen, Esbensen Consulting

Figure 2. 23 PV modules providing partial shading in the atrium of the Brundtland Centre (Denmark, left) and Kowa Elementary School (Tokyo, right) Source: Shinkenchiku-Sha Source: Henrik Sorensen, Esbensen Consulting

Supplemental figure: Amersfoort project, The Netherlands

Supplemental figure: Amersfoort project, The Netherlands

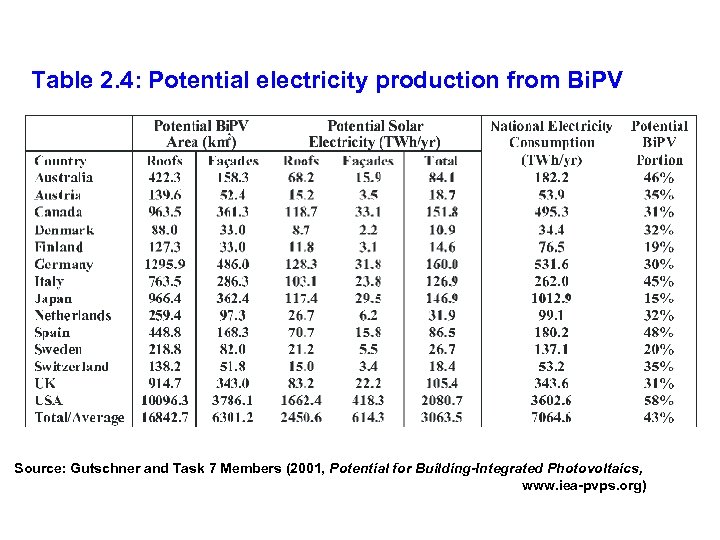

Table 2. 4: Potential electricity production from Bi. PV Source: Gutschner and Task 7 Members (2001, Potential for Building-Integrated Photovoltaics, www. iea-pvps. org)

Table 2. 4: Potential electricity production from Bi. PV Source: Gutschner and Task 7 Members (2001, Potential for Building-Integrated Photovoltaics, www. iea-pvps. org)

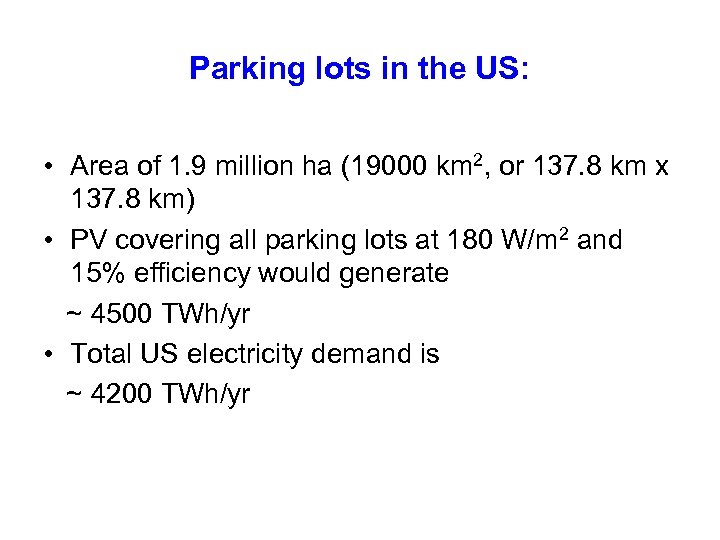

Parking lots in the US: • Area of 1. 9 million ha (19000 km 2, or 137. 8 km x 137. 8 km) • PV covering all parking lots at 180 W/m 2 and 15% efficiency would generate ~ 4500 TWh/yr • Total US electricity demand is ~ 4200 TWh/yr

Parking lots in the US: • Area of 1. 9 million ha (19000 km 2, or 137. 8 km x 137. 8 km) • PV covering all parking lots at 180 W/m 2 and 15% efficiency would generate ~ 4500 TWh/yr • Total US electricity demand is ~ 4200 TWh/yr

Concentrating PV • More sunlight on the expensive solar cell (by up to a factor of 500), using less expensive mirrors or lens • Cell efficiencies are greater under concentrated sunlight, compounding the benefit of greater solar irradiance • Works only with direct irradiance (not diffuse) • Requires 1 - or 2 -axis sun tracking • Passive or active heat removal required

Concentrating PV • More sunlight on the expensive solar cell (by up to a factor of 500), using less expensive mirrors or lens • Cell efficiencies are greater under concentrated sunlight, compounding the benefit of greater solar irradiance • Works only with direct irradiance (not diffuse) • Requires 1 - or 2 -axis sun tracking • Passive or active heat removal required

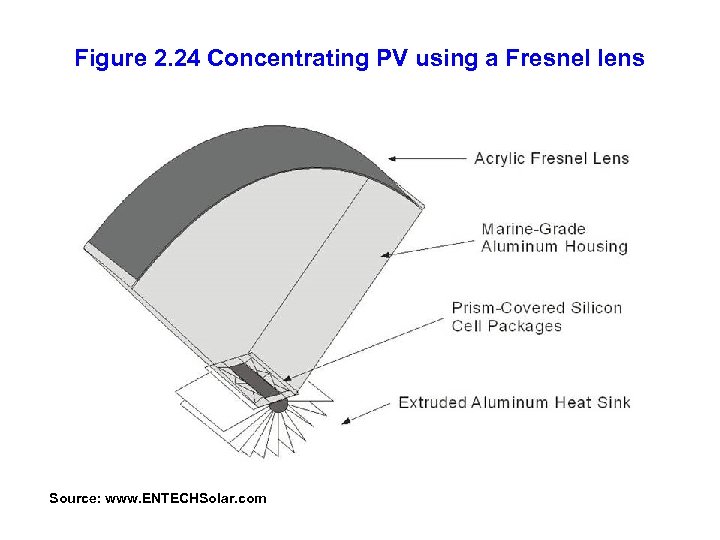

Figure 2. 24 Concentrating PV using a Fresnel lens Source: www. ENTECHSolar. com

Figure 2. 24 Concentrating PV using a Fresnel lens Source: www. ENTECHSolar. com

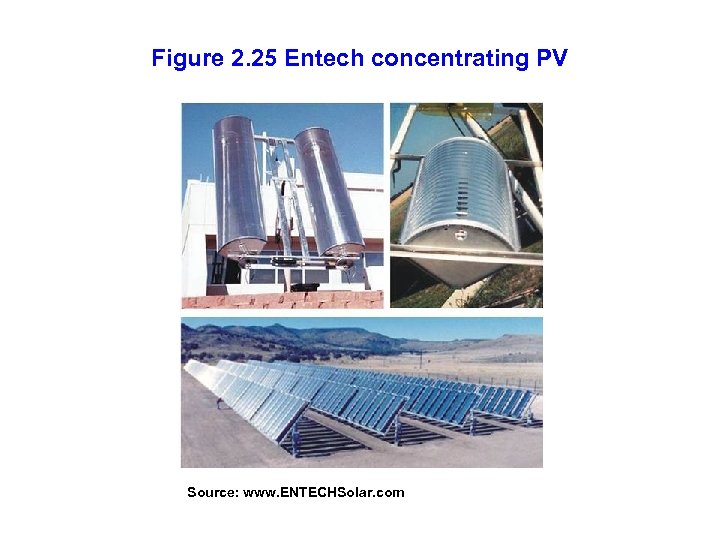

Figure 2. 25 Entech concentrating PV Source: www. ENTECHSolar. com

Figure 2. 25 Entech concentrating PV Source: www. ENTECHSolar. com

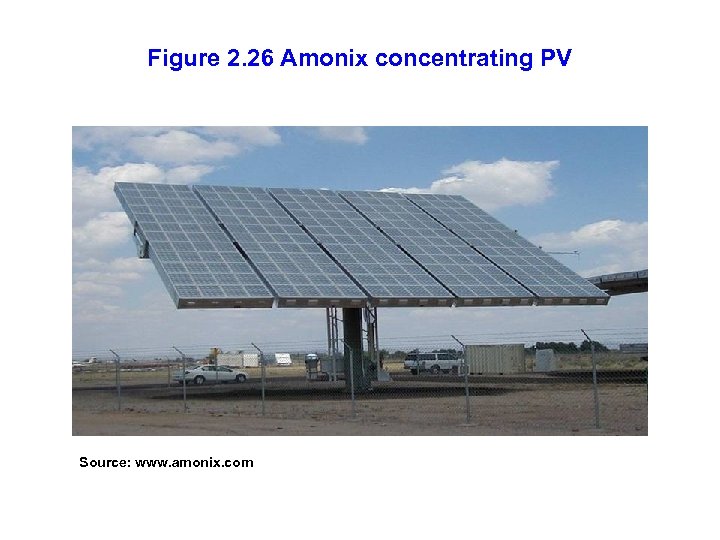

Figure 2. 26 Amonix concentrating PV Source: www. amonix. com

Figure 2. 26 Amonix concentrating PV Source: www. amonix. com

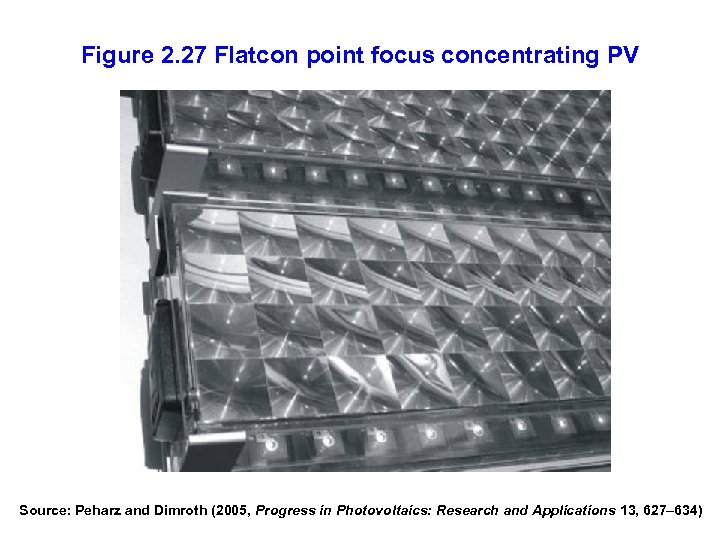

Figure 2. 27 Flatcon point focus concentrating PV Source: Peharz and Dimroth (2005, Progress in Photovoltaics: Research and Applications 13, 627– 634)

Figure 2. 27 Flatcon point focus concentrating PV Source: Peharz and Dimroth (2005, Progress in Photovoltaics: Research and Applications 13, 627– 634)

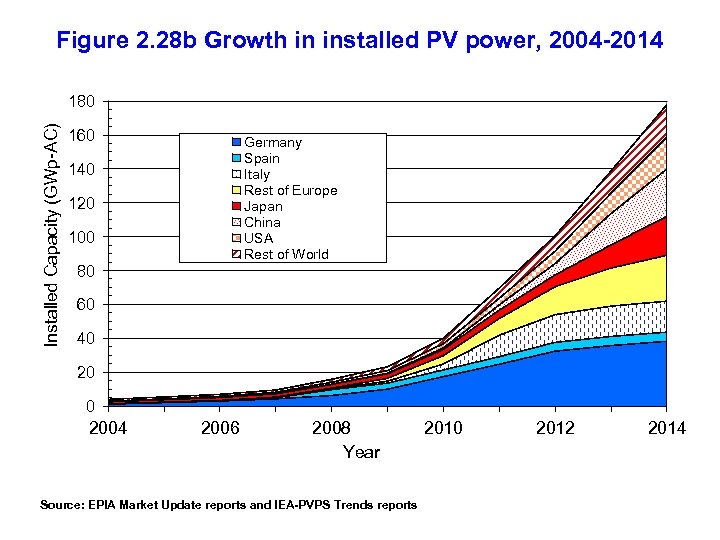

Figure 2. 28 b Growth in installed PV power, 2004 -2014 Installed Capacity (GWp-AC) 180 160 Germany Spain Italy Rest of Europe Japan China USA Rest of World 140 120 100 80 60 40 2004 2006 2008 Year Source: EPIA Market Update reports and IEA-PVPS Trends reports 2010 2012 2014

Figure 2. 28 b Growth in installed PV power, 2004 -2014 Installed Capacity (GWp-AC) 180 160 Germany Spain Italy Rest of Europe Japan China USA Rest of World 140 120 100 80 60 40 2004 2006 2008 Year Source: EPIA Market Update reports and IEA-PVPS Trends reports 2010 2012 2014

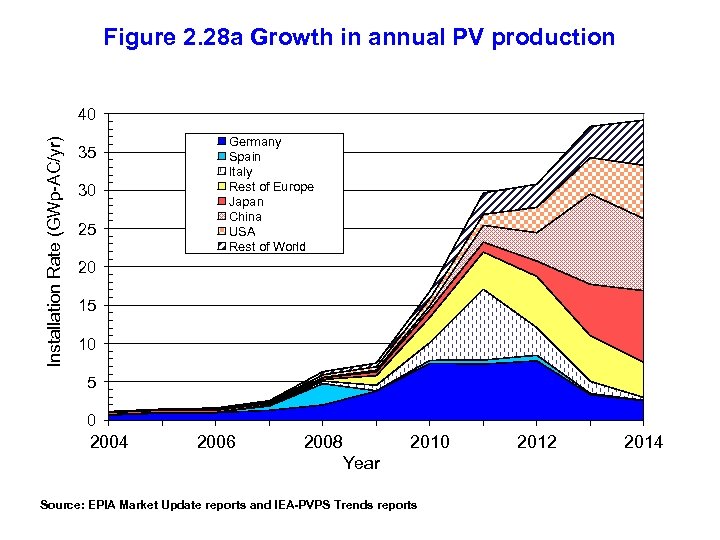

Figure 2. 28 a Growth in annual PV production Installation Rate (GWp-AC/yr) 40 35 30 25 Germany Spain Italy Rest of Europe Japan China USA Rest of World 20 15 10 5 0 2004 2006 2008 2010 Year Source: EPIA Market Update reports and IEA-PVPS Trends reports 2012 2014

Figure 2. 28 a Growth in annual PV production Installation Rate (GWp-AC/yr) 40 35 30 25 Germany Spain Italy Rest of Europe Japan China USA Rest of World 20 15 10 5 0 2004 2006 2008 2010 Year Source: EPIA Market Update reports and IEA-PVPS Trends reports 2012 2014

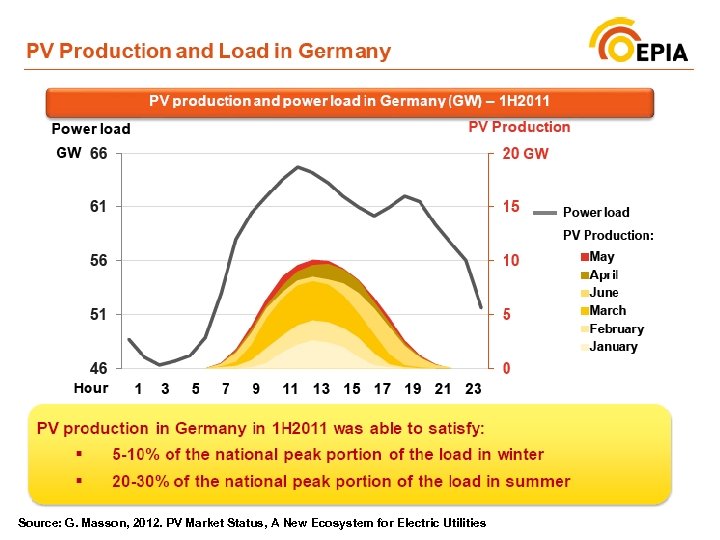

Source: G. Masson, 2012. PV Market Status, A New Ecosystem for Electric Utilities

Source: G. Masson, 2012. PV Market Status, A New Ecosystem for Electric Utilities

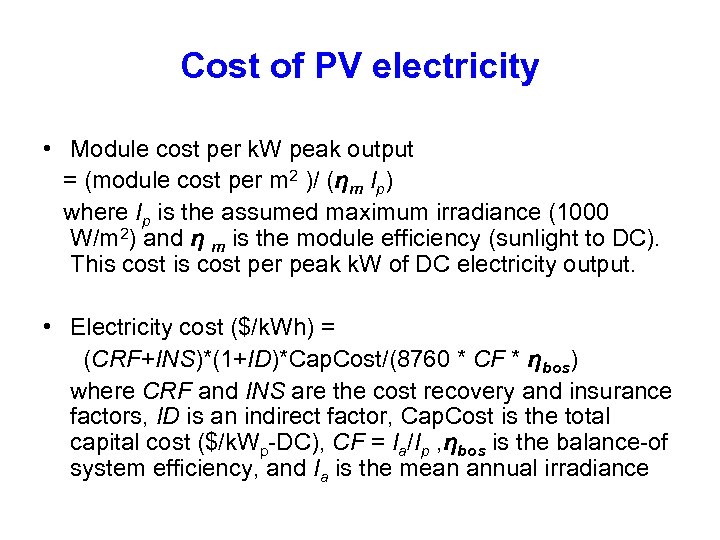

Cost of PV electricity • Module cost per k. W peak output = (module cost per m 2 )/ (ηm Ip) where Ip is the assumed maximum irradiance (1000 W/m 2) and η m is the module efficiency (sunlight to DC). This cost per peak k. W of DC electricity output. • Electricity cost ($/k. Wh) = (CRF+INS)*(1+ID)*Cap. Cost/(8760 * CF * ηbos) where CRF and INS are the cost recovery and insurance factors, ID is an indirect factor, Cap. Cost is the total capital cost ($/k. Wp-DC), CF = Ia/Ip , ηbos is the balance-of system efficiency, and Ia is the mean annual irradiance

Cost of PV electricity • Module cost per k. W peak output = (module cost per m 2 )/ (ηm Ip) where Ip is the assumed maximum irradiance (1000 W/m 2) and η m is the module efficiency (sunlight to DC). This cost per peak k. W of DC electricity output. • Electricity cost ($/k. Wh) = (CRF+INS)*(1+ID)*Cap. Cost/(8760 * CF * ηbos) where CRF and INS are the cost recovery and insurance factors, ID is an indirect factor, Cap. Cost is the total capital cost ($/k. Wp-DC), CF = Ia/Ip , ηbos is the balance-of system efficiency, and Ia is the mean annual irradiance

Component and installed costs (as of 2010) • Modules: ~ $400/m 2, or $4000/k. W-DC if the efficiency is 10% • Inverters: ~ $300 -600/k. W-DC (less for larger systems) • Total installed cost: ~ $6000 -9000/k. W-AC

Component and installed costs (as of 2010) • Modules: ~ $400/m 2, or $4000/k. W-DC if the efficiency is 10% • Inverters: ~ $300 -600/k. W-DC (less for larger systems) • Total installed cost: ~ $6000 -9000/k. W-AC

Costs of alternative cladding materials: • • Stainless steel: ~ $250 -350/m 2 Glass-wall systems: ~ $500 -750/m 2 Rough stone: ~ ≥ $750/m 2 Polished stone: ~ $2000 -2500/m 2

Costs of alternative cladding materials: • • Stainless steel: ~ $250 -350/m 2 Glass-wall systems: ~ $500 -750/m 2 Rough stone: ~ ≥ $750/m 2 Polished stone: ~ $2000 -2500/m 2

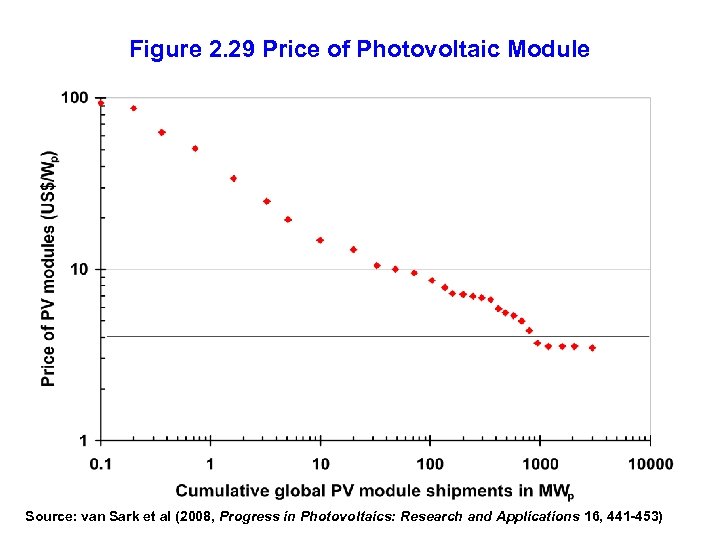

Projection of future costs • Extrapolation using the progress ratio concept • Engineering-based bottom-up analysis (Recall from the wind chapter: The progress ratio is the factor by which the cost is multiplied for each successive doubling in cumulative global production. It gives a good fit to the change in cost over time for a very wide range of technologies, although of course the progress ratio value varies from technology to technology, but is usually 0. 8 -0. 9)

Projection of future costs • Extrapolation using the progress ratio concept • Engineering-based bottom-up analysis (Recall from the wind chapter: The progress ratio is the factor by which the cost is multiplied for each successive doubling in cumulative global production. It gives a good fit to the change in cost over time for a very wide range of technologies, although of course the progress ratio value varies from technology to technology, but is usually 0. 8 -0. 9)

Figure 2. 29 Price of Photovoltaic Module Source: van Sark et al (2008, Progress in Photovoltaics: Research and Applications 16, 441 -453)

Figure 2. 29 Price of Photovoltaic Module Source: van Sark et al (2008, Progress in Photovoltaics: Research and Applications 16, 441 -453)

Results of bottom-up analyses: • A “bottom-up analysis” involves an item-by-item consideration of everything that affects cost, and how each could change over time or with economies of scale. • Projected near-term (2015) module costs of $1/Wp for both c-Si and a-Si, installed costs of $3/Wp or less with 1 GWp/yr manufacturing facilities

Results of bottom-up analyses: • A “bottom-up analysis” involves an item-by-item consideration of everything that affects cost, and how each could change over time or with economies of scale. • Projected near-term (2015) module costs of $1/Wp for both c-Si and a-Si, installed costs of $3/Wp or less with 1 GWp/yr manufacturing facilities

What actually happened?

What actually happened?

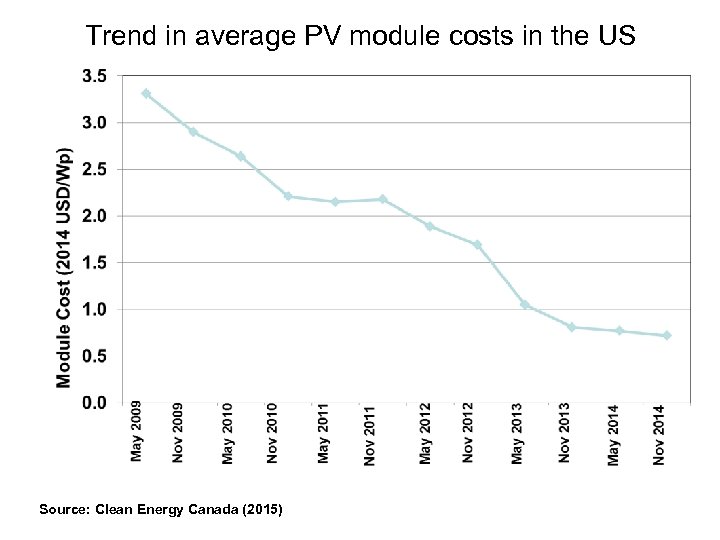

Trend in average PV module costs in the US Source: Clean Energy Canada (2015)

Trend in average PV module costs in the US Source: Clean Energy Canada (2015)

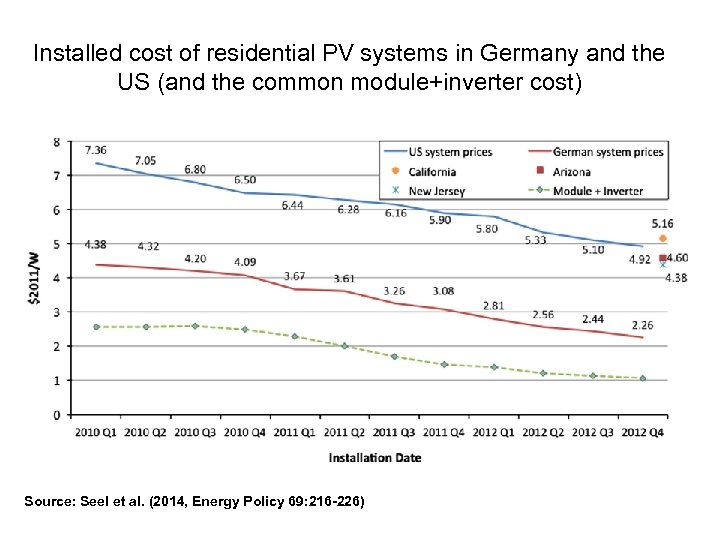

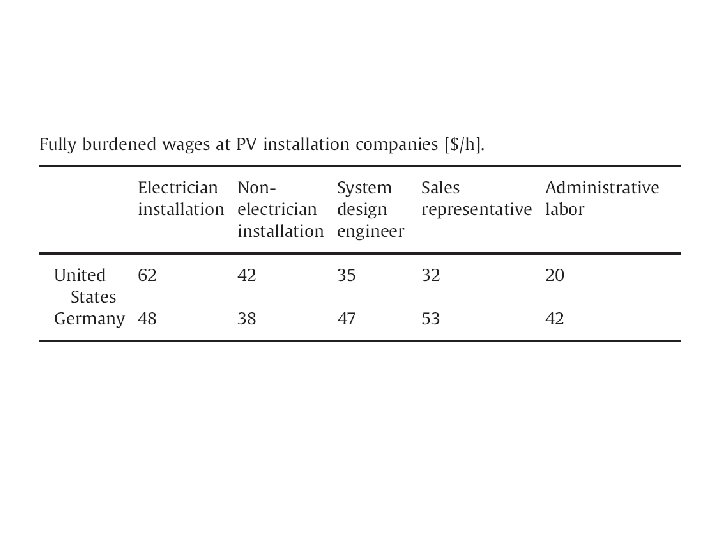

Installed cost of residential PV systems in Germany and the US (and the common module+inverter cost) Source: Seel et al. (2014, Energy Policy 69: 216 -226)

Installed cost of residential PV systems in Germany and the US (and the common module+inverter cost) Source: Seel et al. (2014, Energy Policy 69: 216 -226)

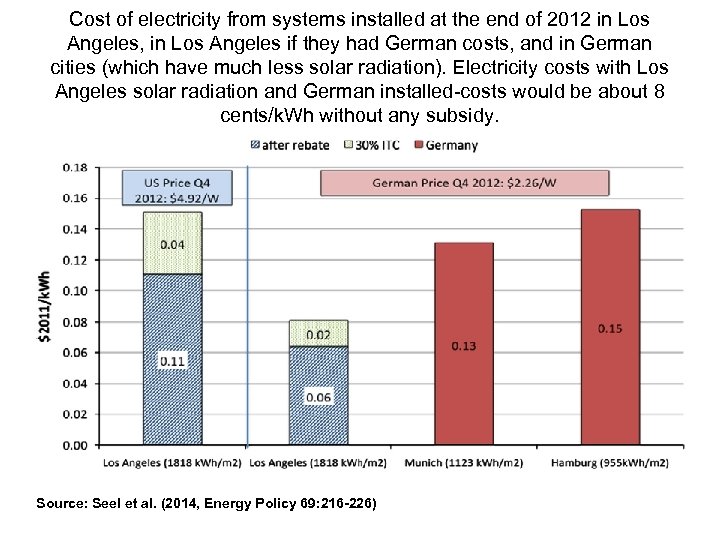

Cost of electricity from systems installed at the end of 2012 in Los Angeles, in Los Angeles if they had German costs, and in German cities (which have much less solar radiation). Electricity costs with Los Angeles solar radiation and German installed-costs would be about 8 cents/k. Wh without any subsidy. Source: Seel et al. (2014, Energy Policy 69: 216 -226)

Cost of electricity from systems installed at the end of 2012 in Los Angeles, in Los Angeles if they had German costs, and in German cities (which have much less solar radiation). Electricity costs with Los Angeles solar radiation and German installed-costs would be about 8 cents/k. Wh without any subsidy. Source: Seel et al. (2014, Energy Policy 69: 216 -226)

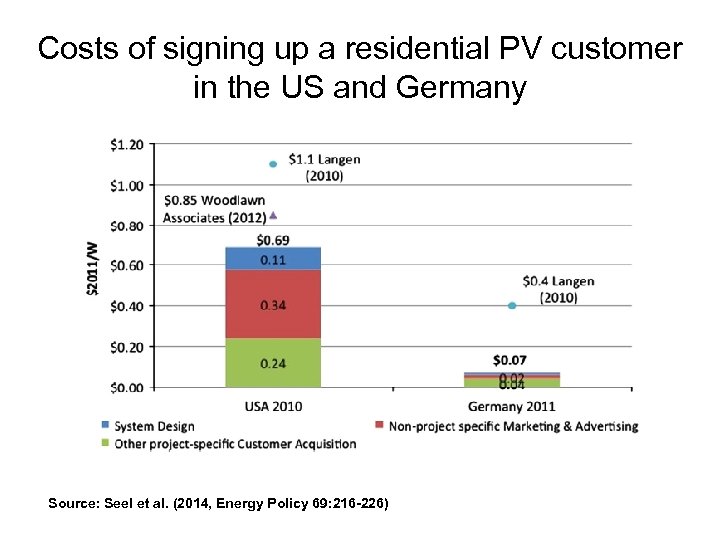

Costs of signing up a residential PV customer in the US and Germany Source: Seel et al. (2014, Energy Policy 69: 216 -226)

Costs of signing up a residential PV customer in the US and Germany Source: Seel et al. (2014, Energy Policy 69: 216 -226)

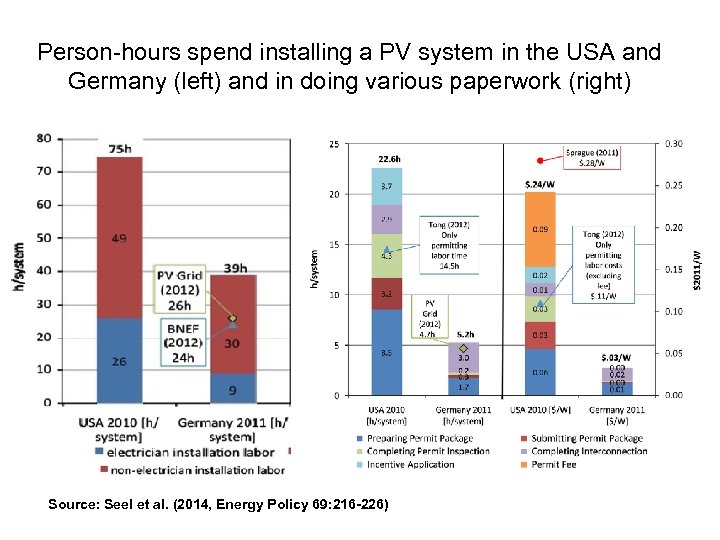

Person-hours spend installing a PV system in the USA and Germany (left) and in doing various paperwork (right) Source: Seel et al. (2014, Energy Policy 69: 216 -226)

Person-hours spend installing a PV system in the USA and Germany (left) and in doing various paperwork (right) Source: Seel et al. (2014, Energy Policy 69: 216 -226)

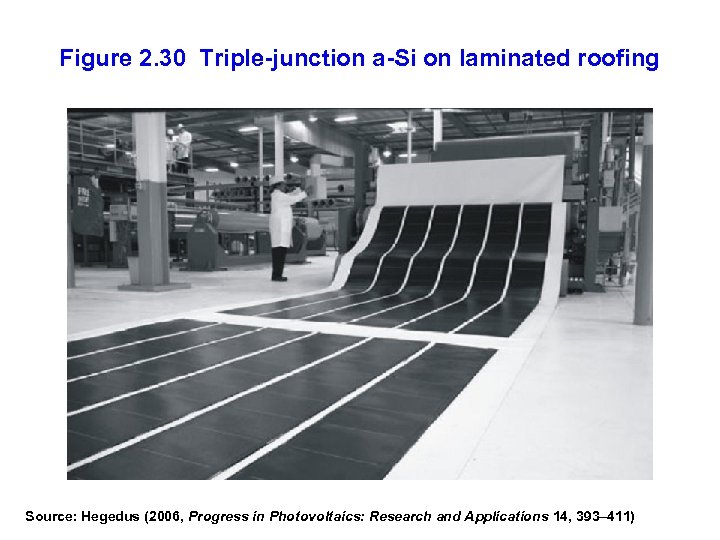

Figure 2. 30 Triple-junction a-Si on laminated roofing Source: Hegedus (2006, Progress in Photovoltaics: Research and Applications 14, 393– 411)

Figure 2. 30 Triple-junction a-Si on laminated roofing Source: Hegedus (2006, Progress in Photovoltaics: Research and Applications 14, 393– 411)

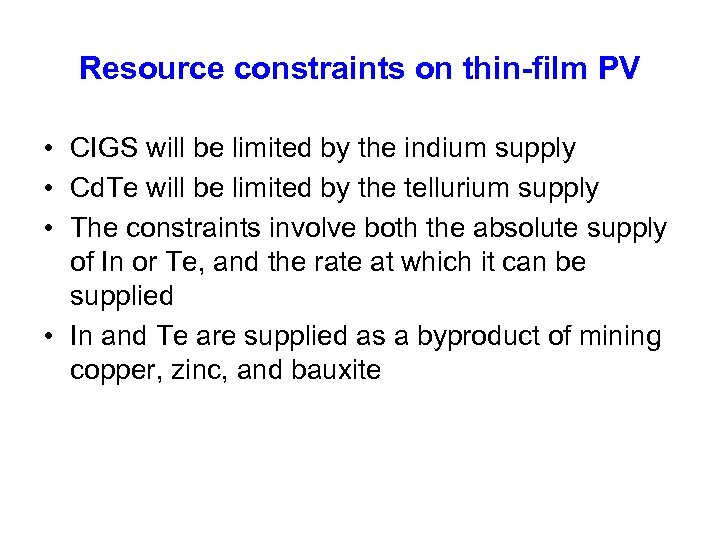

Resource constraints on thin-film PV • CIGS will be limited by the indium supply • Cd. Te will be limited by the tellurium supply • The constraints involve both the absolute supply of In or Te, and the rate at which it can be supplied • In and Te are supplied as a byproduct of mining copper, zinc, and bauxite

Resource constraints on thin-film PV • CIGS will be limited by the indium supply • Cd. Te will be limited by the tellurium supply • The constraints involve both the absolute supply of In or Te, and the rate at which it can be supplied • In and Te are supplied as a byproduct of mining copper, zinc, and bauxite

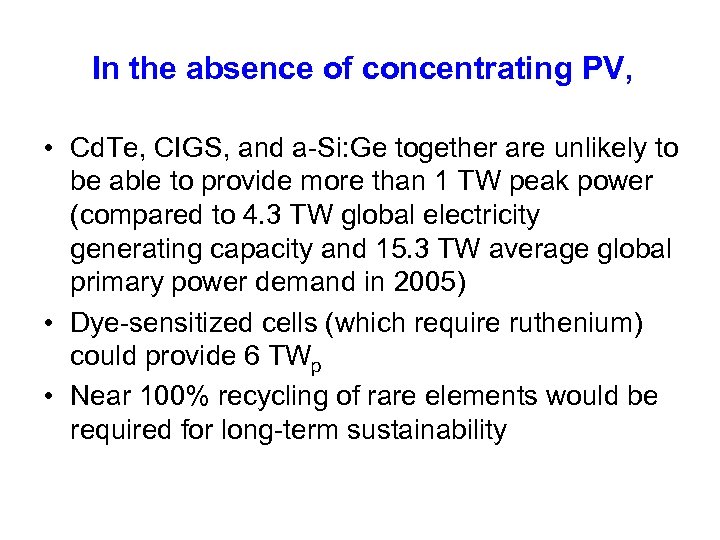

In the absence of concentrating PV, • Cd. Te, CIGS, and a-Si: Ge together are unlikely to be able to provide more than 1 TW peak power (compared to 4. 3 TW global electricity generating capacity and 15. 3 TW average global primary power demand in 2005) • Dye-sensitized cells (which require ruthenium) could provide 6 TWp • Near 100% recycling of rare elements would be required for long-term sustainability

In the absence of concentrating PV, • Cd. Te, CIGS, and a-Si: Ge together are unlikely to be able to provide more than 1 TW peak power (compared to 4. 3 TW global electricity generating capacity and 15. 3 TW average global primary power demand in 2005) • Dye-sensitized cells (which require ruthenium) could provide 6 TWp • Near 100% recycling of rare elements would be required for long-term sustainability

Solar Thermal Generation of Electricity • Mirrors are used to concentrate sunlight either onto a line focus or a point focus • Steam is generated, and then used in a steam turbine • In some cases, concentrated solar energy heats a storage medium (such as molten salt), so electricity can be generated 24 hours per day using stored heat at night • Best in desert or semi-desert regions, as only direct-beam solar radiation can be used

Solar Thermal Generation of Electricity • Mirrors are used to concentrate sunlight either onto a line focus or a point focus • Steam is generated, and then used in a steam turbine • In some cases, concentrated solar energy heats a storage medium (such as molten salt), so electricity can be generated 24 hours per day using stored heat at night • Best in desert or semi-desert regions, as only direct-beam solar radiation can be used

The radiation available for use by concentrating solar thermal power (CSTP) systems is referred to as the ‘direct normal’ radiation – the annual value is the irradiance on a surface that is always at 90 o to the sun’s rays As only the direct beam radiation can be used, the peak irradiance that can be used by CSTP is typically about 850 W/m 2, compared to 1000 W/m 2 for PV systems Thus, peak power capacity for CSTP is given assuming a direct beam irradiance of 850 W/m 2 rather than 1000 W/m 2 The annual capacity factor is equal to the annual average direct normal irradiance (in W/m 2) divided by 850 W/m 2 (in the same way that the annual capacity factor for PV is given by the annual average irradiance on the module divided by 1000 W/m 2)

The radiation available for use by concentrating solar thermal power (CSTP) systems is referred to as the ‘direct normal’ radiation – the annual value is the irradiance on a surface that is always at 90 o to the sun’s rays As only the direct beam radiation can be used, the peak irradiance that can be used by CSTP is typically about 850 W/m 2, compared to 1000 W/m 2 for PV systems Thus, peak power capacity for CSTP is given assuming a direct beam irradiance of 850 W/m 2 rather than 1000 W/m 2 The annual capacity factor is equal to the annual average direct normal irradiance (in W/m 2) divided by 850 W/m 2 (in the same way that the annual capacity factor for PV is given by the annual average irradiance on the module divided by 1000 W/m 2)

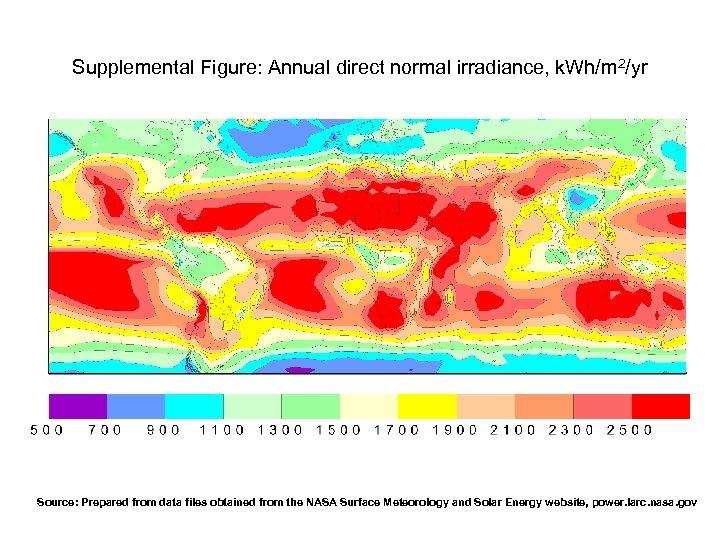

Supplemental Figure: Annual direct normal irradiance, k. Wh/m 2/yr Source: Prepared from data files obtained from the NASA Surface Meteorology and Solar Energy website, power. larc. nasa. gov

Supplemental Figure: Annual direct normal irradiance, k. Wh/m 2/yr Source: Prepared from data files obtained from the NASA Surface Meteorology and Solar Energy website, power. larc. nasa. gov

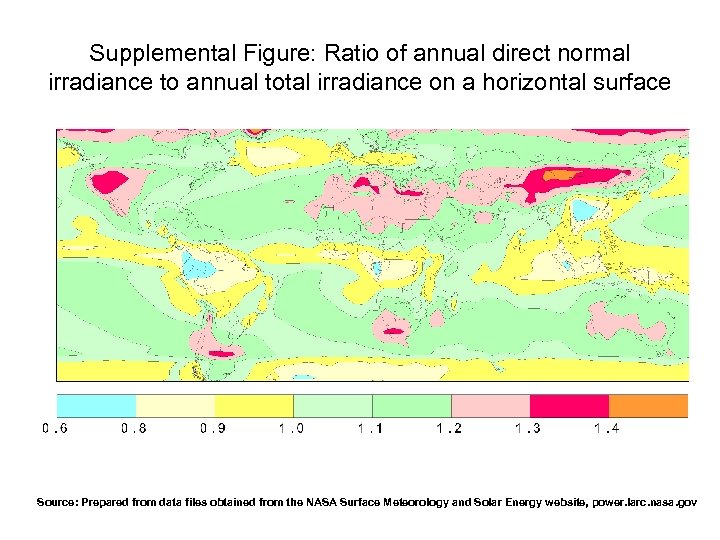

Supplemental Figure: Ratio of annual direct normal irradiance to annual total irradiance on a horizontal surface Source: Prepared from data files obtained from the NASA Surface Meteorology and Solar Energy website, power. larc. nasa. gov

Supplemental Figure: Ratio of annual direct normal irradiance to annual total irradiance on a horizontal surface Source: Prepared from data files obtained from the NASA Surface Meteorology and Solar Energy website, power. larc. nasa. gov

Types of Solar Thermal Systems: • Parabolic trough • Parabolic dish (Stirling engine) • Central tower

Types of Solar Thermal Systems: • Parabolic trough • Parabolic dish (Stirling engine) • Central tower

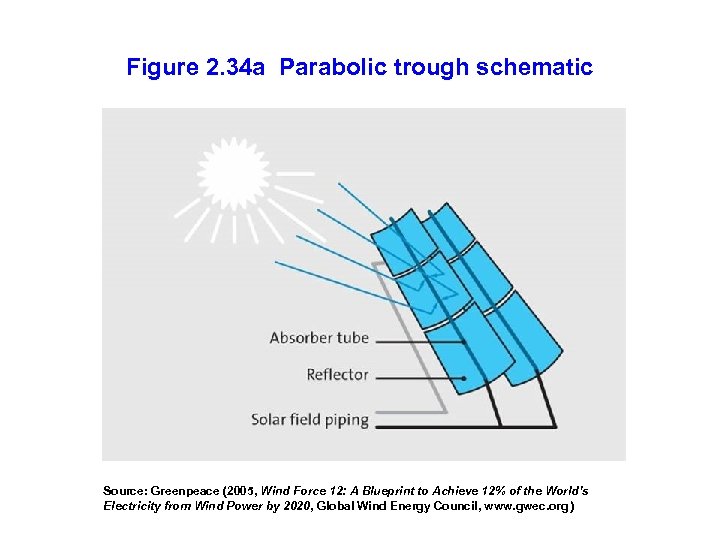

Figure 2. 34 a Parabolic trough schematic Source: Greenpeace (2005, Wind Force 12: A Blueprint to Achieve 12% of the World’s Electricity from Wind Power by 2020, Global Wind Energy Council, www. gwec. org )

Figure 2. 34 a Parabolic trough schematic Source: Greenpeace (2005, Wind Force 12: A Blueprint to Achieve 12% of the World’s Electricity from Wind Power by 2020, Global Wind Energy Council, www. gwec. org )

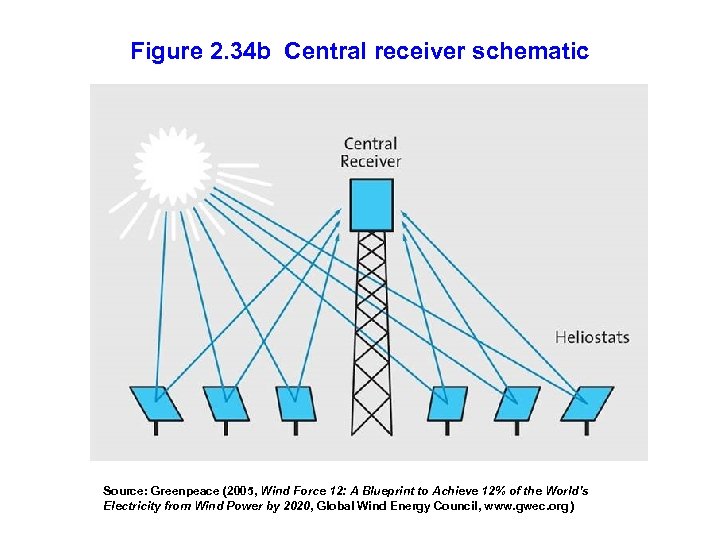

Figure 2. 34 b Central receiver schematic Source: Greenpeace (2005, Wind Force 12: A Blueprint to Achieve 12% of the World’s Electricity from Wind Power by 2020, Global Wind Energy Council, www. gwec. org )

Figure 2. 34 b Central receiver schematic Source: Greenpeace (2005, Wind Force 12: A Blueprint to Achieve 12% of the World’s Electricity from Wind Power by 2020, Global Wind Energy Council, www. gwec. org )

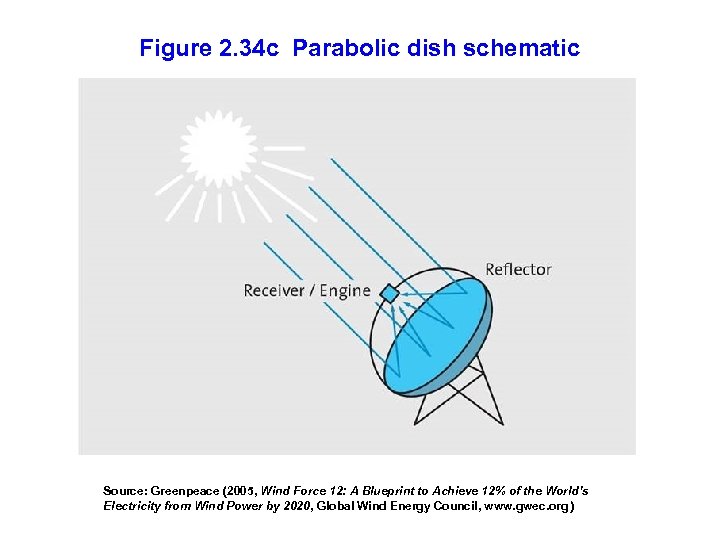

Figure 2. 34 c Parabolic dish schematic Source: Greenpeace (2005, Wind Force 12: A Blueprint to Achieve 12% of the World’s Electricity from Wind Power by 2020, Global Wind Energy Council, www. gwec. org )

Figure 2. 34 c Parabolic dish schematic Source: Greenpeace (2005, Wind Force 12: A Blueprint to Achieve 12% of the World’s Electricity from Wind Power by 2020, Global Wind Energy Council, www. gwec. org )

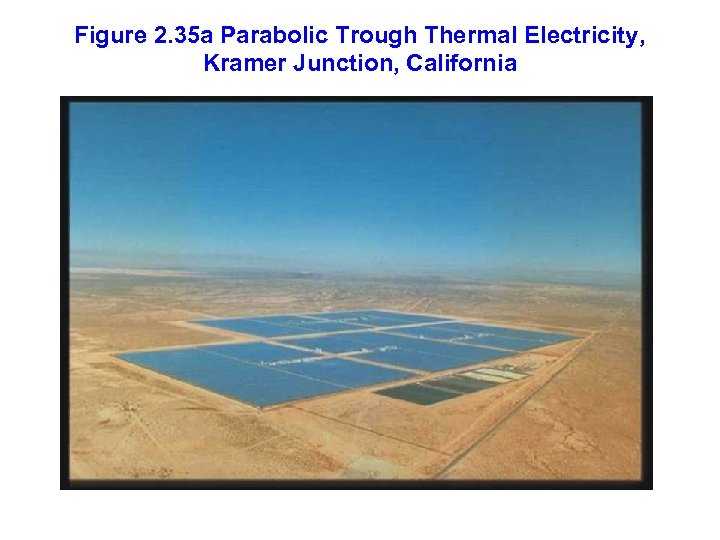

Figure 2. 35 a Parabolic Trough Thermal Electricity, Kramer Junction, California

Figure 2. 35 a Parabolic Trough Thermal Electricity, Kramer Junction, California

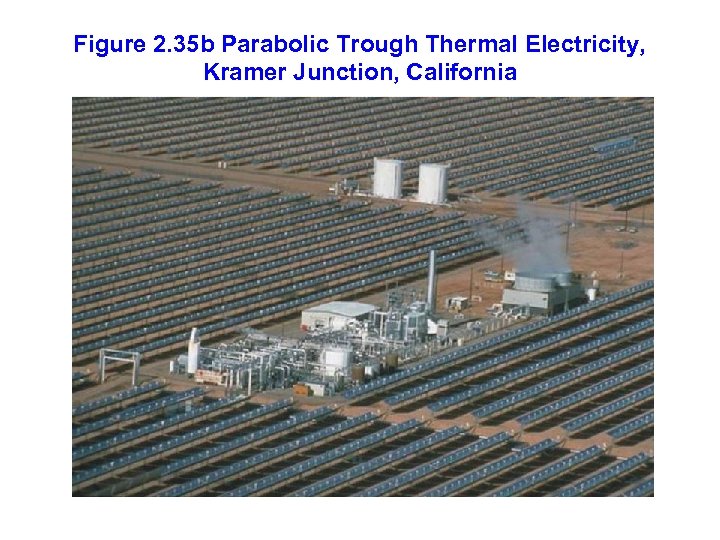

Figure 2. 35 b Parabolic Trough Thermal Electricity, Kramer Junction, California

Figure 2. 35 b Parabolic Trough Thermal Electricity, Kramer Junction, California

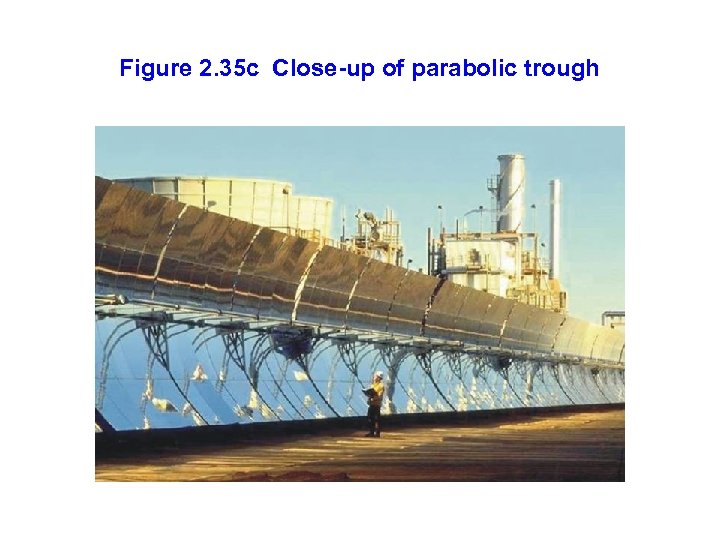

Figure 2. 35 c Close-up of parabolic trough

Figure 2. 35 c Close-up of parabolic trough

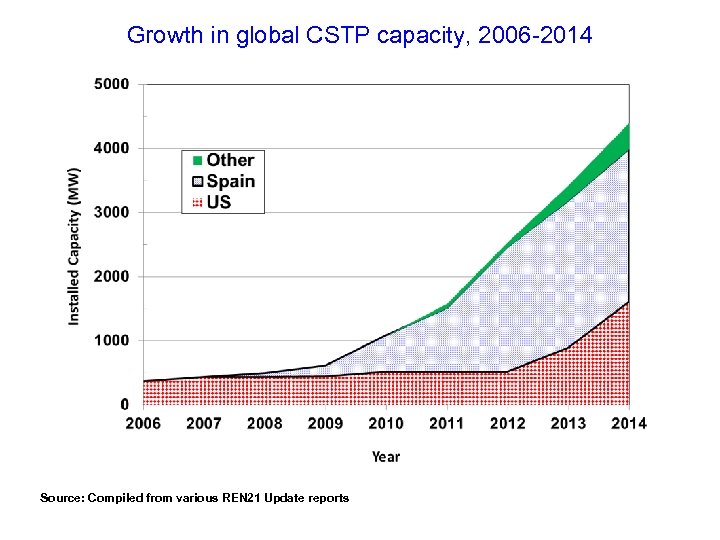

Growth in global CSTP capacity, 2006 -2014 Source: Compiled from various REN 21 Update reports

Growth in global CSTP capacity, 2006 -2014 Source: Compiled from various REN 21 Update reports

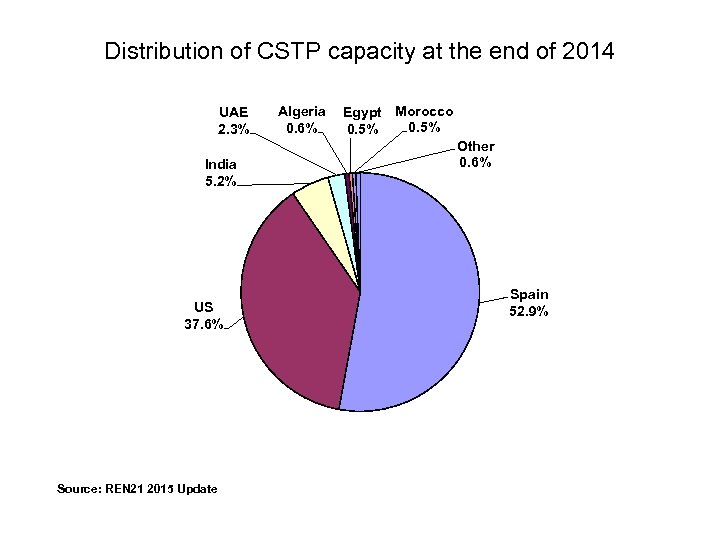

Distribution of CSTP capacity at the end of 2014 UAE 2. 3% India 5. 2% US 37. 6% Source: REN 21 2015 Update Algeria 0. 6% Egypt Morocco 0. 5% Other 0. 6% Spain 52. 9%

Distribution of CSTP capacity at the end of 2014 UAE 2. 3% India 5. 2% US 37. 6% Source: REN 21 2015 Update Algeria 0. 6% Egypt Morocco 0. 5% Other 0. 6% Spain 52. 9%

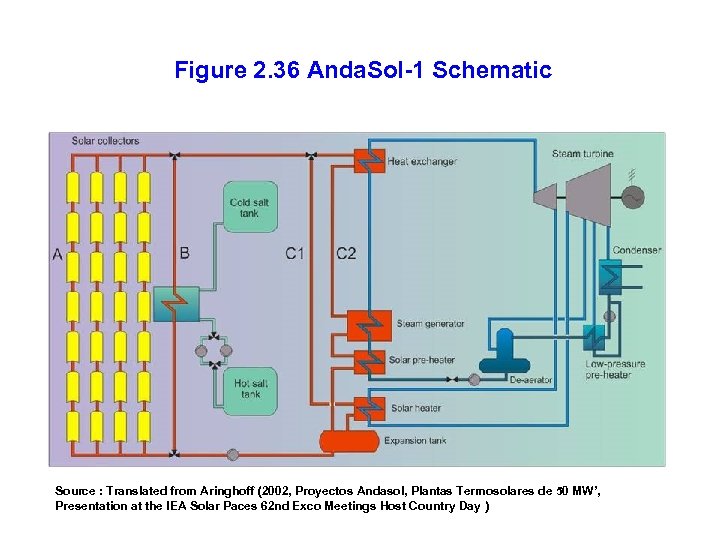

The latest parabolic trough systems either • Directly heat the water that will be used in the steam turbine, or • Directly heat water that in turn is circulated through a hot tank of molten salts (40% K-nitrate and 60% Na-nitrate), with the molten salts storing heat and in turn heating the steam that is used in a steam turbine, as illustrated in the following diagram

The latest parabolic trough systems either • Directly heat the water that will be used in the steam turbine, or • Directly heat water that in turn is circulated through a hot tank of molten salts (40% K-nitrate and 60% Na-nitrate), with the molten salts storing heat and in turn heating the steam that is used in a steam turbine, as illustrated in the following diagram

Figure 2. 36 Anda. Sol-1 Schematic Source : Translated from Aringhoff (2002, Proyectos Andasol, Plantas Termosolares de 50 MW’, Presentation at the IEA Solar Paces 62 nd Exco Meetings Host Country Day )

Figure 2. 36 Anda. Sol-1 Schematic Source : Translated from Aringhoff (2002, Proyectos Andasol, Plantas Termosolares de 50 MW’, Presentation at the IEA Solar Paces 62 nd Exco Meetings Host Country Day )

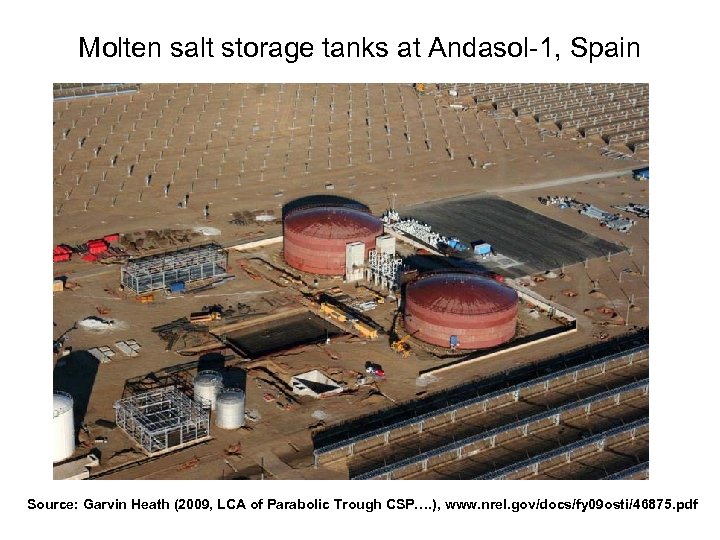

Molten salt storage tanks at Andasol-1, Spain Source: Garvin Heath (2009, LCA of Parabolic Trough CSP…. ), www. nrel. gov/docs/fy 09 osti/46875. pdf

Molten salt storage tanks at Andasol-1, Spain Source: Garvin Heath (2009, LCA of Parabolic Trough CSP…. ), www. nrel. gov/docs/fy 09 osti/46875. pdf

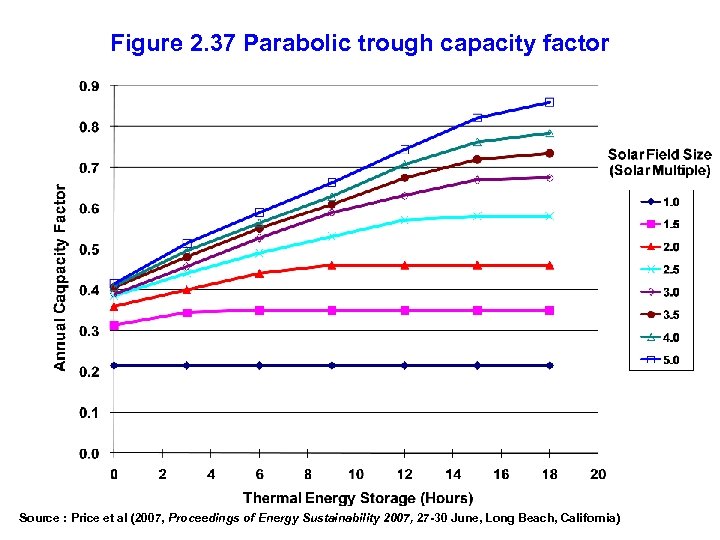

With thermal storage, • Electricity can be generated 24 hours per day • The capacity factor (average output over peak output) can reach 85%

With thermal storage, • Electricity can be generated 24 hours per day • The capacity factor (average output over peak output) can reach 85%

Figure 2. 37 Parabolic trough capacity factor Source : Price et al (2007, Proceedings of Energy Sustainability 2007, 27 -30 June, Long Beach, California)

Figure 2. 37 Parabolic trough capacity factor Source : Price et al (2007, Proceedings of Energy Sustainability 2007, 27 -30 June, Long Beach, California)

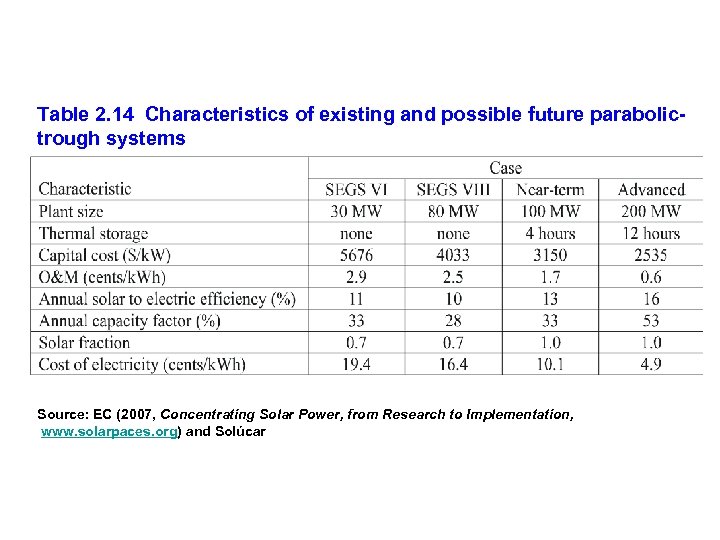

Table 2. 14 Characteristics of existing and possible future parabolictrough systems Source: EC (2007, Concentrating Solar Power, from Research to Implementation, www. solarpaces. org) and Solúcar

Table 2. 14 Characteristics of existing and possible future parabolictrough systems Source: EC (2007, Concentrating Solar Power, from Research to Implementation, www. solarpaces. org) and Solúcar

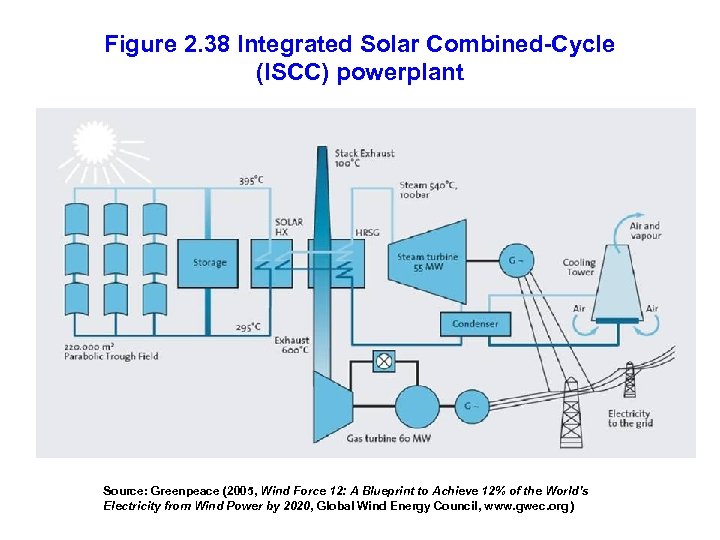

Figure 2. 38 Integrated Solar Combined-Cycle (ISCC) powerplant Source: Greenpeace (2005, Wind Force 12: A Blueprint to Achieve 12% of the World’s Electricity from Wind Power by 2020, Global Wind Energy Council, www. gwec. org )

Figure 2. 38 Integrated Solar Combined-Cycle (ISCC) powerplant Source: Greenpeace (2005, Wind Force 12: A Blueprint to Achieve 12% of the World’s Electricity from Wind Power by 2020, Global Wind Energy Council, www. gwec. org )

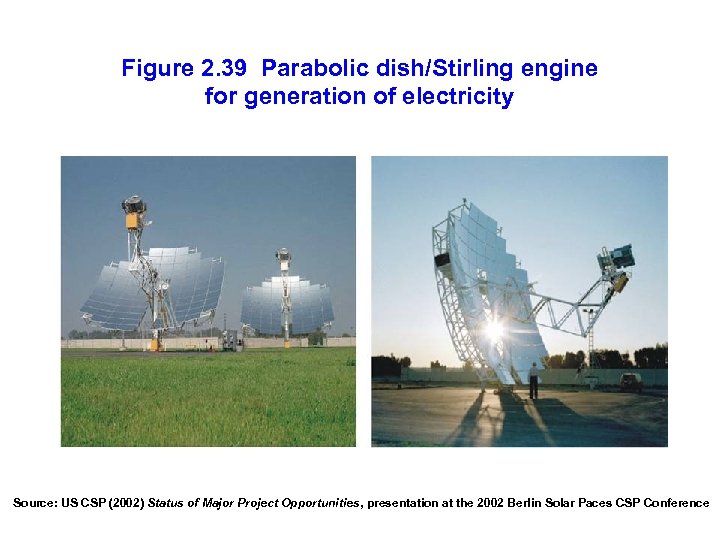

Figure 2. 39 Parabolic dish/Stirling engine for generation of electricity Source: US CSP (2002) Status of Major Project Opportunities, presentation at the 2002 Berlin Solar Paces CSP Conference

Figure 2. 39 Parabolic dish/Stirling engine for generation of electricity Source: US CSP (2002) Status of Major Project Opportunities, presentation at the 2002 Berlin Solar Paces CSP Conference

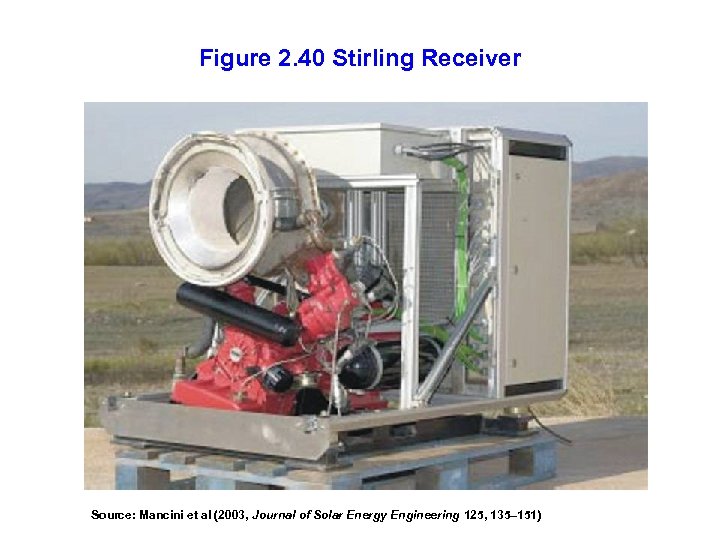

Figure 2. 40 Stirling Receiver Source: Mancini et al (2003, Journal of Solar Energy Engineering 125, 135– 151)

Figure 2. 40 Stirling Receiver Source: Mancini et al (2003, Journal of Solar Energy Engineering 125, 135– 151)

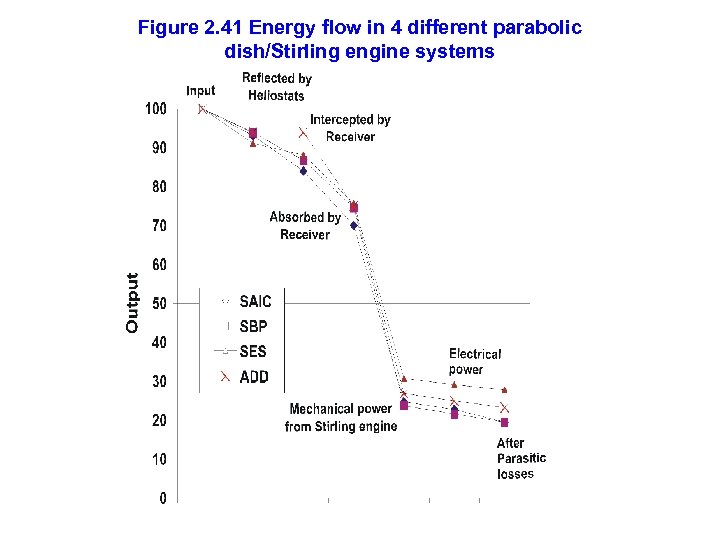

Figure 2. 41 Energy flow in 4 different parabolic dish/Stirling engine systems

Figure 2. 41 Energy flow in 4 different parabolic dish/Stirling engine systems

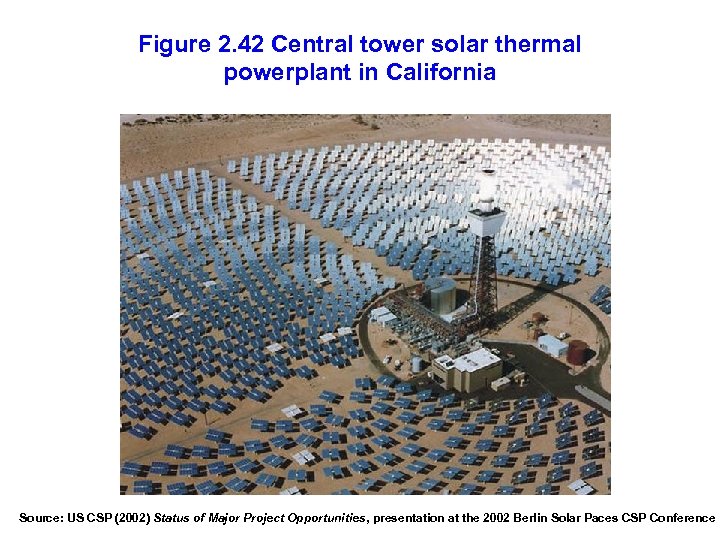

Figure 2. 42 Central tower solar thermal powerplant in California Source: US CSP (2002) Status of Major Project Opportunities, presentation at the 2002 Berlin Solar Paces CSP Conference

Figure 2. 42 Central tower solar thermal powerplant in California Source: US CSP (2002) Status of Major Project Opportunities, presentation at the 2002 Berlin Solar Paces CSP Conference

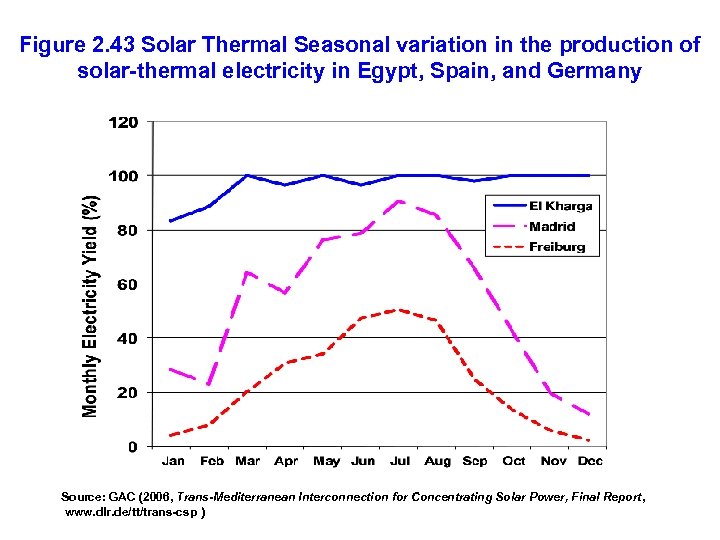

Figure 2. 43 Solar Thermal Seasonal variation in the production of solar-thermal electricity in Egypt, Spain, and Germany Source: GAC (2006, Trans-Mediterranean Interconnection for Concentrating Solar Power, Final Report, www. dlr. de/tt/trans-csp )

Figure 2. 43 Solar Thermal Seasonal variation in the production of solar-thermal electricity in Egypt, Spain, and Germany Source: GAC (2006, Trans-Mediterranean Interconnection for Concentrating Solar Power, Final Report, www. dlr. de/tt/trans-csp )

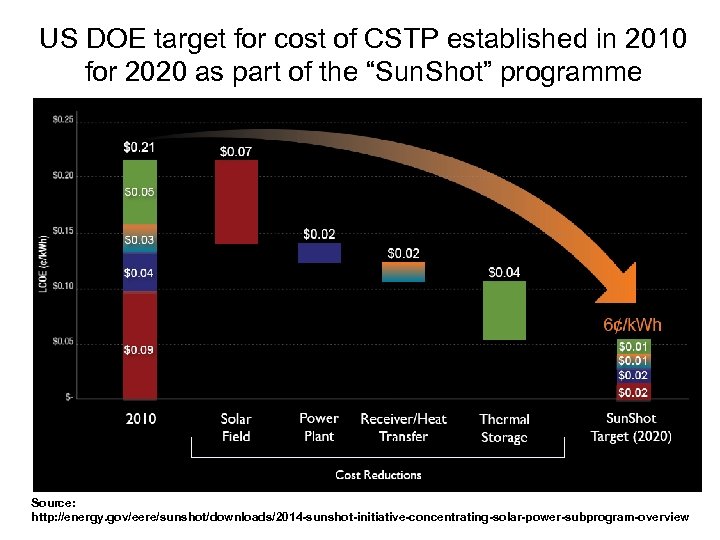

US DOE target for cost of CSTP established in 2010 for 2020 as part of the “Sun. Shot” programme Source: http: //energy. gov/eere/sunshot/downloads/2014 -sunshot-initiative-concentrating-solar-power-subprogram-overview

US DOE target for cost of CSTP established in 2010 for 2020 as part of the “Sun. Shot” programme Source: http: //energy. gov/eere/sunshot/downloads/2014 -sunshot-initiative-concentrating-solar-power-subprogram-overview

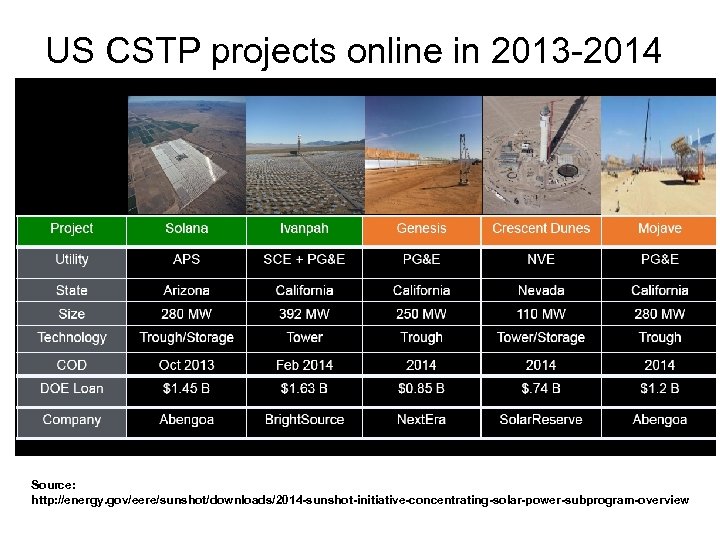

US CSTP projects online in 2013 -2014 Source: http: //energy. gov/eere/sunshot/downloads/2014 -sunshot-initiative-concentrating-solar-power-subprogram-overview

US CSTP projects online in 2013 -2014 Source: http: //energy. gov/eere/sunshot/downloads/2014 -sunshot-initiative-concentrating-solar-power-subprogram-overview

Progress toward 2020 cost goals Source: http: //energy. gov/eere/sunshot/downloads/2014 -sunshot-initiative-concentrating-solar-power-subprogram-overview

Progress toward 2020 cost goals Source: http: //energy. gov/eere/sunshot/downloads/2014 -sunshot-initiative-concentrating-solar-power-subprogram-overview

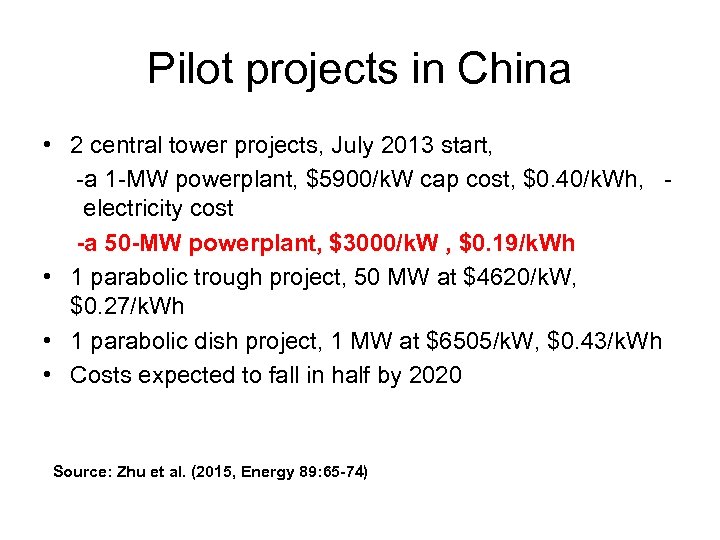

Pilot projects in China • 2 central tower projects, July 2013 start, -a 1 -MW powerplant, $5900/k. W cap cost, $0. 40/k. Wh, ___electricity cost -a 50 -MW powerplant, $3000/k. W , $0. 19/k. Wh • 1 parabolic trough project, 50 MW at $4620/k. W, $0. 27/k. Wh • 1 parabolic dish project, 1 MW at $6505/k. W, $0. 43/k. Wh • Costs expected to fall in half by 2020 Source: Zhu et al. (2015, Energy 89: 65 -74)

Pilot projects in China • 2 central tower projects, July 2013 start, -a 1 -MW powerplant, $5900/k. W cap cost, $0. 40/k. Wh, ___electricity cost -a 50 -MW powerplant, $3000/k. W , $0. 19/k. Wh • 1 parabolic trough project, 50 MW at $4620/k. W, $0. 27/k. Wh • 1 parabolic dish project, 1 MW at $6505/k. W, $0. 43/k. Wh • Costs expected to fall in half by 2020 Source: Zhu et al. (2015, Energy 89: 65 -74)

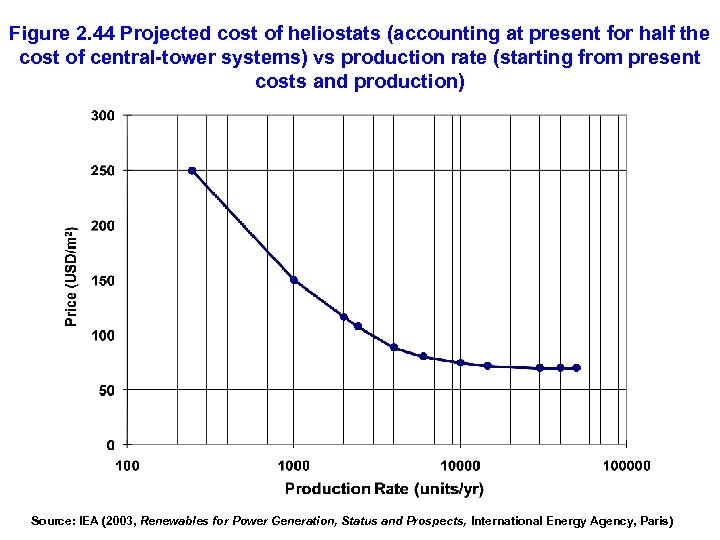

Figure 2. 44 Projected cost of heliostats (accounting at present for half the cost of central-tower systems) vs production rate (starting from present costs and production) Source: IEA (2003, Renewables for Power Generation, Status and Prospects, International Energy Agency, Paris)

Figure 2. 44 Projected cost of heliostats (accounting at present for half the cost of central-tower systems) vs production rate (starting from present costs and production) Source: IEA (2003, Renewables for Power Generation, Status and Prospects, International Energy Agency, Paris)

Overall projections for CSTP (applicable to all 3 types) • • $2000 -3000/k. W capital cost 5 -8 cents/k. Wh electricity cost 25% capacity factor without thermal storage 13 -15% overall conversion efficiency, sunlight on collectors to AC electricity output • Saudi Arabia had been planning to install 5 GW of CSTP (roughly doubling current global capacity), which would have driven costs down, but this is on hold due to the self-induced collapse of oil prices (and hence, in the country’s oil revenue) • Planned projects in Tunisia and Egypt are also on hold because of unrest in the region • Spain has pulled back for budgetary reasons • For now, its seems that the US and China will be driving the costs down through learning-by-doing

Overall projections for CSTP (applicable to all 3 types) • • $2000 -3000/k. W capital cost 5 -8 cents/k. Wh electricity cost 25% capacity factor without thermal storage 13 -15% overall conversion efficiency, sunlight on collectors to AC electricity output • Saudi Arabia had been planning to install 5 GW of CSTP (roughly doubling current global capacity), which would have driven costs down, but this is on hold due to the self-induced collapse of oil prices (and hence, in the country’s oil revenue) • Planned projects in Tunisia and Egypt are also on hold because of unrest in the region • Spain has pulled back for budgetary reasons • For now, its seems that the US and China will be driving the costs down through learning-by-doing

Solar Thermal Energy For Heating and for Domestic Hot Water

Solar Thermal Energy For Heating and for Domestic Hot Water

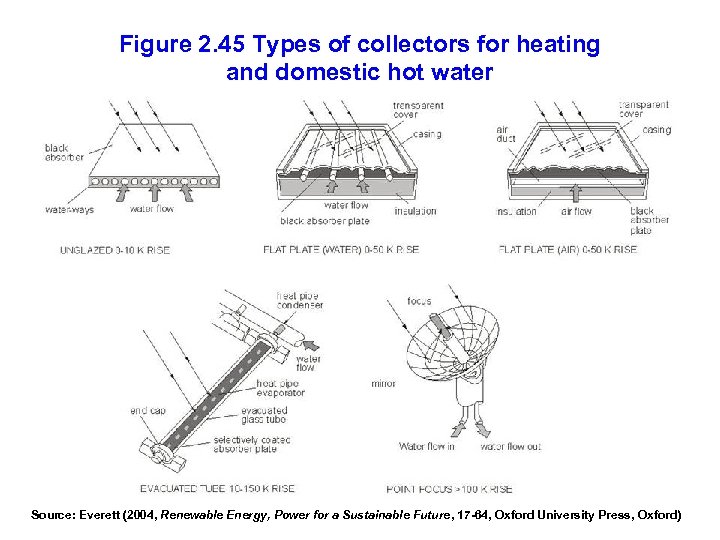

Figure 2. 45 Types of collectors for heating and domestic hot water Source: Everett (2004, Renewable Energy, Power for a Sustainable Future, 17 -64, Oxford University Press, Oxford)

Figure 2. 45 Types of collectors for heating and domestic hot water Source: Everett (2004, Renewable Energy, Power for a Sustainable Future, 17 -64, Oxford University Press, Oxford)

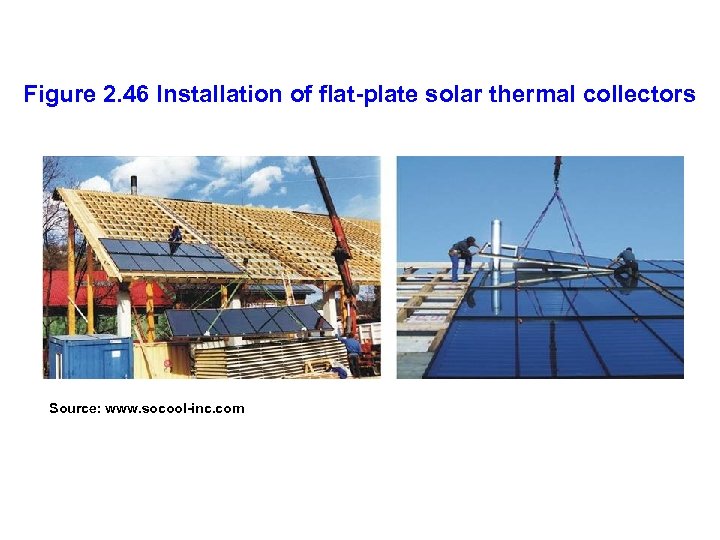

Figure 2. 46 Installation of flat-plate solar thermal collectors Source: www. socool-inc. com

Figure 2. 46 Installation of flat-plate solar thermal collectors Source: www. socool-inc. com

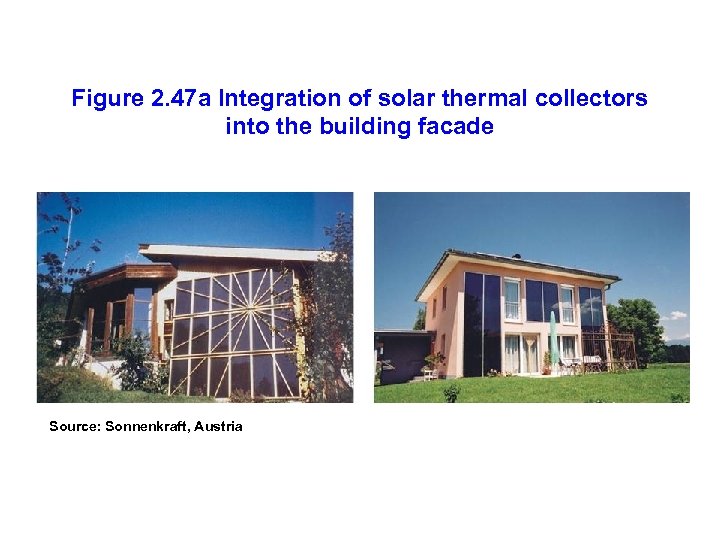

Figure 2. 47 a Integration of solar thermal collectors into the building facade Source: Sonnenkraft, Austria

Figure 2. 47 a Integration of solar thermal collectors into the building facade Source: Sonnenkraft, Austria

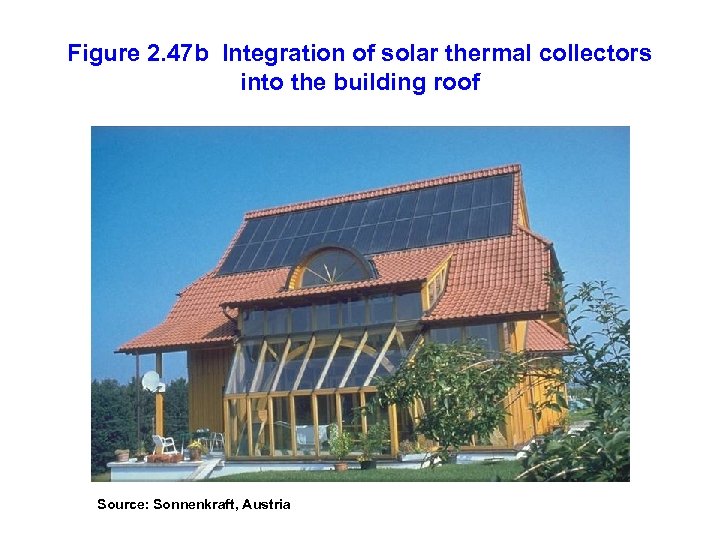

Figure 2. 47 b Integration of solar thermal collectors into the building roof Source: Sonnenkraft, Austria

Figure 2. 47 b Integration of solar thermal collectors into the building roof Source: Sonnenkraft, Austria

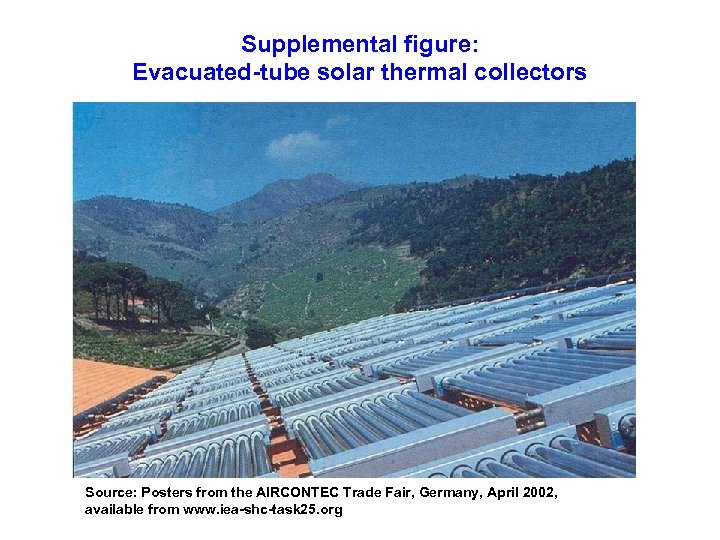

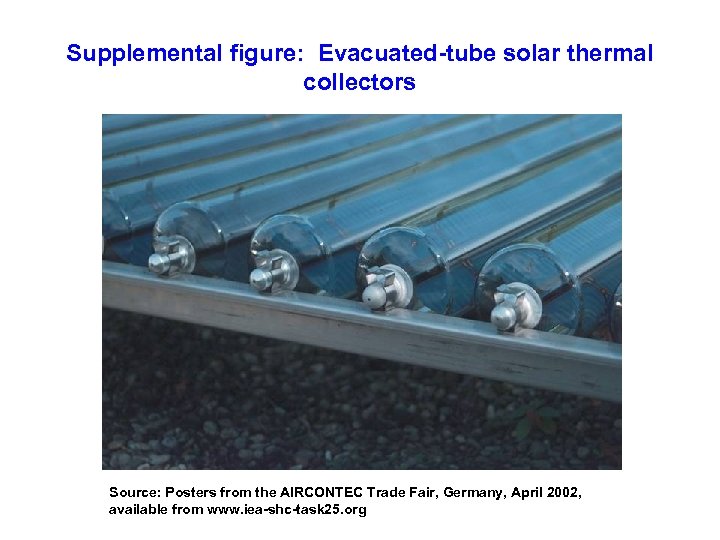

Supplemental figure: Evacuated-tube solar thermal collectors Source: Posters from the AIRCONTEC Trade Fair, Germany, April 2002, available from www. iea-shc-task 25. org

Supplemental figure: Evacuated-tube solar thermal collectors Source: Posters from the AIRCONTEC Trade Fair, Germany, April 2002, available from www. iea-shc-task 25. org

Supplemental figure: Evacuated-tube solar thermal collectors Source: Posters from the AIRCONTEC Trade Fair, Germany, April 2002, available from www. iea-shc-task 25. org

Supplemental figure: Evacuated-tube solar thermal collectors Source: Posters from the AIRCONTEC Trade Fair, Germany, April 2002, available from www. iea-shc-task 25. org

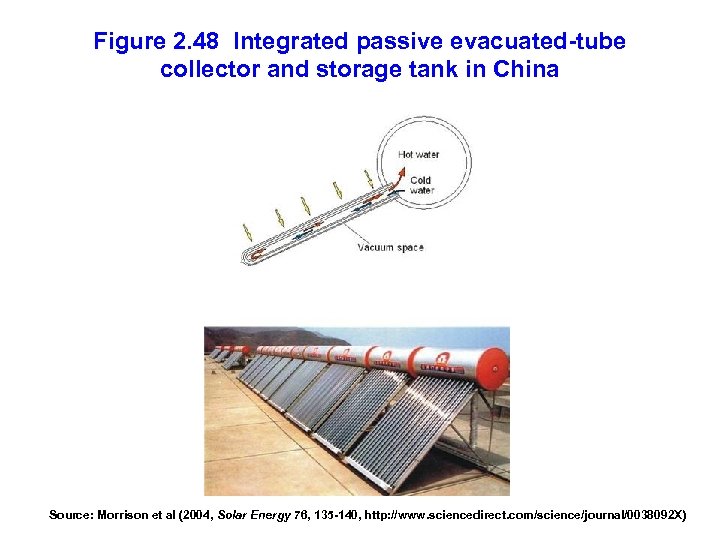

Figure 2. 48 Integrated passive evacuated-tube collector and storage tank in China Source: Morrison et al (2004, Solar Energy 76, 135 -140, http: //www. sciencedirect. com/science/journal/0038092 X)

Figure 2. 48 Integrated passive evacuated-tube collector and storage tank in China Source: Morrison et al (2004, Solar Energy 76, 135 -140, http: //www. sciencedirect. com/science/journal/0038092 X)

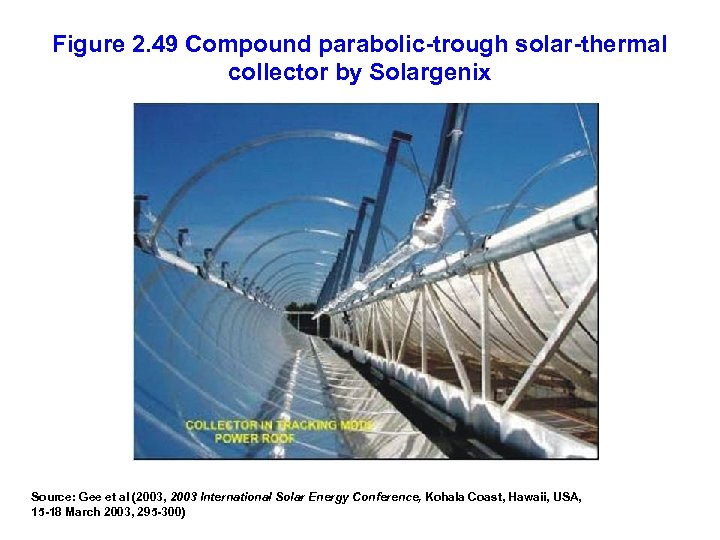

Figure 2. 49 Compound parabolic-trough solar-thermal collector by Solargenix Source: Gee et al (2003, 2003 International Solar Energy Conference, Kohala Coast, Hawaii, USA, 15 -18 March 2003, 295 -300)

Figure 2. 49 Compound parabolic-trough solar-thermal collector by Solargenix Source: Gee et al (2003, 2003 International Solar Energy Conference, Kohala Coast, Hawaii, USA, 15 -18 March 2003, 295 -300)

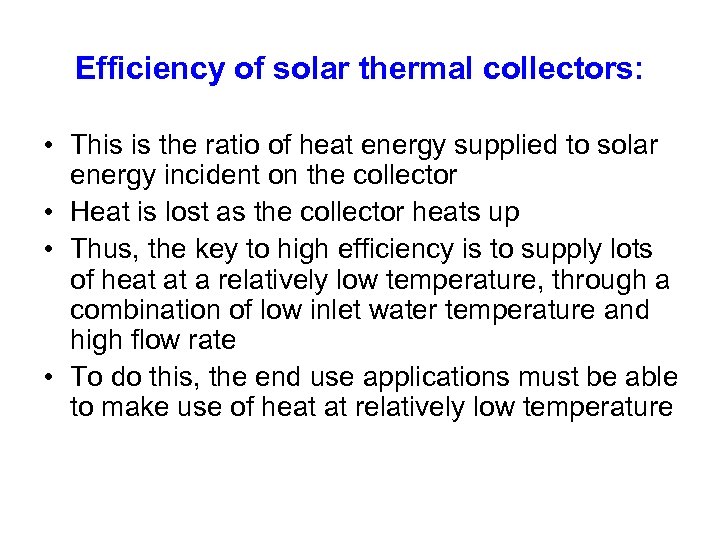

Efficiency of solar thermal collectors: • This is the ratio of heat energy supplied to solar energy incident on the collector • Heat is lost as the collector heats up • Thus, the key to high efficiency is to supply lots of heat at a relatively low temperature, through a combination of low inlet water temperature and high flow rate • To do this, the end use applications must be able to make use of heat at relatively low temperature

Efficiency of solar thermal collectors: • This is the ratio of heat energy supplied to solar energy incident on the collector • Heat is lost as the collector heats up • Thus, the key to high efficiency is to supply lots of heat at a relatively low temperature, through a combination of low inlet water temperature and high flow rate • To do this, the end use applications must be able to make use of heat at relatively low temperature

For space heating, this requires being able to use heat as it is generated in a radiant floor heating system, which in turn requires high thermal mass exposed to the inside (so that the building does not overheat) and a high-performance envelope (so that the building stays warm after sunset without having to store solar heat in a hot water tank) For domestic hot water, this requires use of a thermallystratified hot-water tank, with cold water from the bottom of the tank fed to the solar collector and hot water for use drawn from the top of the collector Phase-change materials (which store heat without a further increase in temperature) can also be used. Materials with melting points around 60 -70 o. C would be ideal for domestic hot water applications.

For space heating, this requires being able to use heat as it is generated in a radiant floor heating system, which in turn requires high thermal mass exposed to the inside (so that the building does not overheat) and a high-performance envelope (so that the building stays warm after sunset without having to store solar heat in a hot water tank) For domestic hot water, this requires use of a thermallystratified hot-water tank, with cold water from the bottom of the tank fed to the solar collector and hot water for use drawn from the top of the collector Phase-change materials (which store heat without a further increase in temperature) can also be used. Materials with melting points around 60 -70 o. C would be ideal for domestic hot water applications.

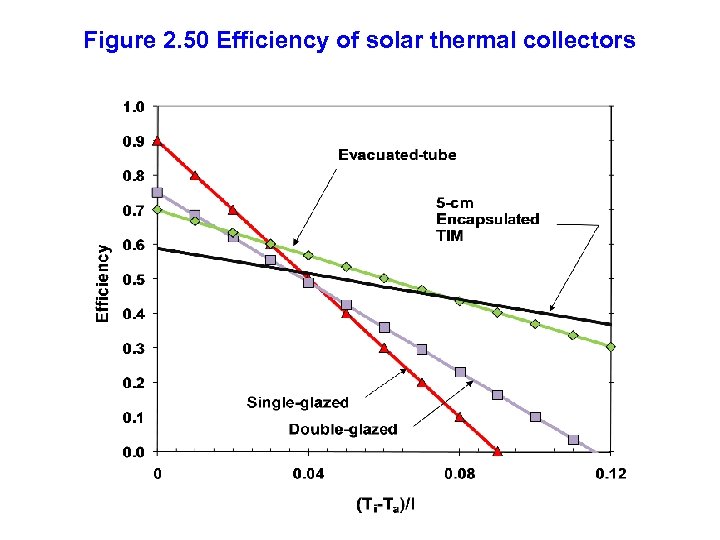

Figure 2. 50 Efficiency of solar thermal collectors

Figure 2. 50 Efficiency of solar thermal collectors

As seen in the previous slide, the efficiency of all collectors drops as the inlet temperature to air temperature increases. Domestic hot water might need to be at 70 C while air temperature is at 10 C; with 1000 W/m 2 solar irradiance, (Ti-Ta)/I = 0. 06, giving an efficiency range of 30 -50%. For space water, water at 40 C could be sufficient in a very well insulated house, giving (Ta-Ti)/I = 0. 03 and an efficiency range of 0. 55 -0. 65

As seen in the previous slide, the efficiency of all collectors drops as the inlet temperature to air temperature increases. Domestic hot water might need to be at 70 C while air temperature is at 10 C; with 1000 W/m 2 solar irradiance, (Ti-Ta)/I = 0. 06, giving an efficiency range of 30 -50%. For space water, water at 40 C could be sufficient in a very well insulated house, giving (Ta-Ti)/I = 0. 03 and an efficiency range of 0. 55 -0. 65

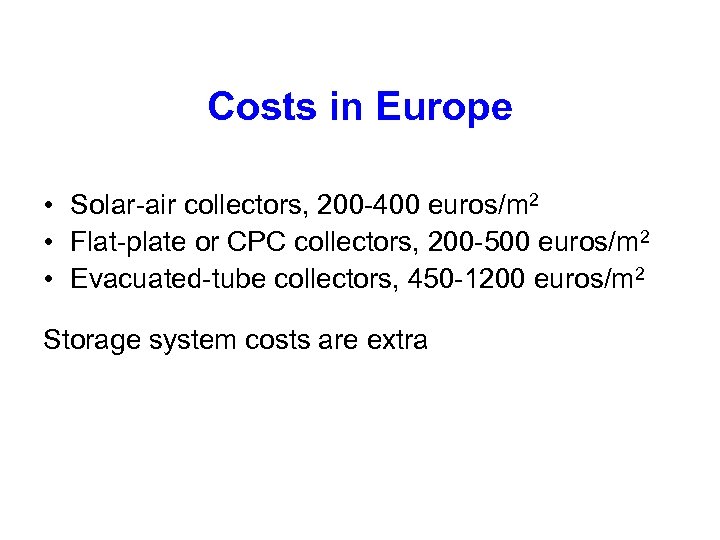

Costs in Europe • Solar-air collectors, 200 -400 euros/m 2 • Flat-plate or CPC collectors, 200 -500 euros/m 2 • Evacuated-tube collectors, 450 -1200 euros/m 2 Storage system costs are extra

Costs in Europe • Solar-air collectors, 200 -400 euros/m 2 • Flat-plate or CPC collectors, 200 -500 euros/m 2 • Evacuated-tube collectors, 450 -1200 euros/m 2 Storage system costs are extra

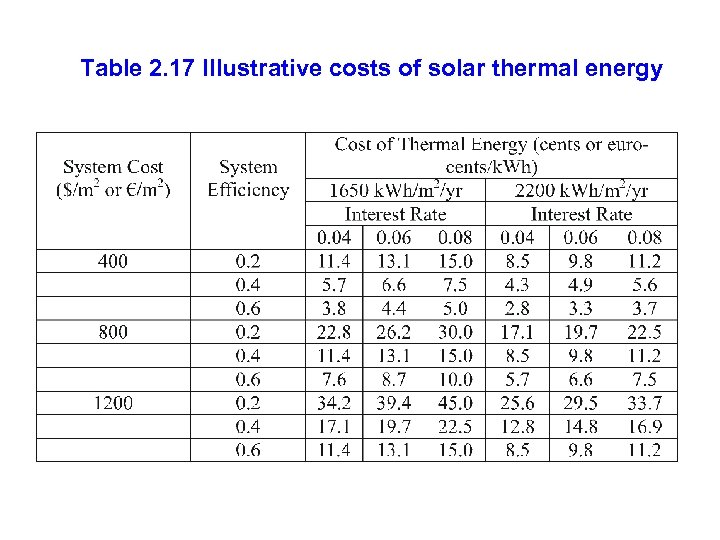

Table 2. 17 Illustrative costs of solar thermal energy

Table 2. 17 Illustrative costs of solar thermal energy

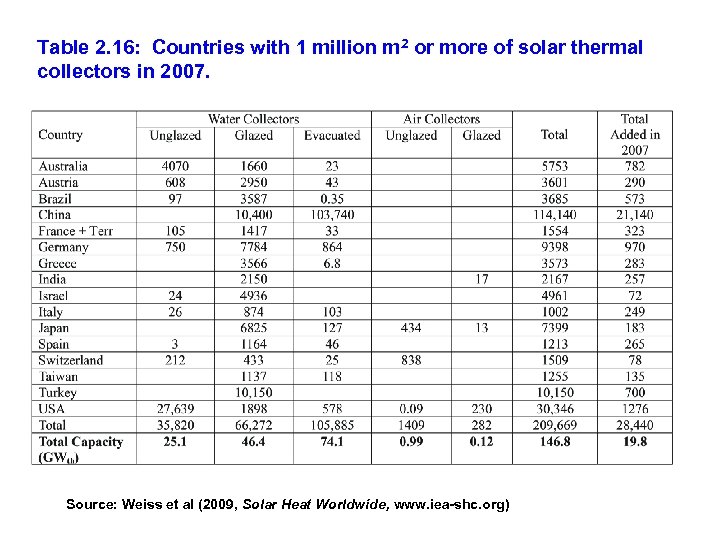

Table 2. 16: Countries with 1 million m 2 or more of solar thermal collectors in 2007. Source: Weiss et al (2009, Solar Heat Worldwide, www. iea-shc. org)

Table 2. 16: Countries with 1 million m 2 or more of solar thermal collectors in 2007. Source: Weiss et al (2009, Solar Heat Worldwide, www. iea-shc. org)

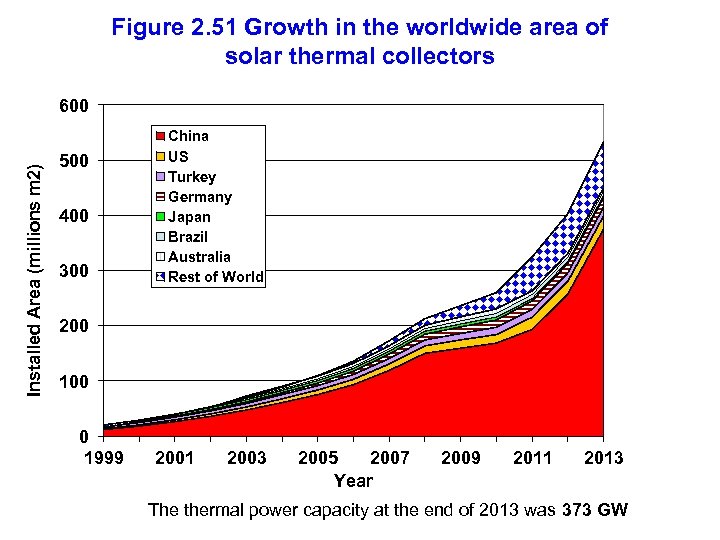

Figure 2. 51 Growth in the worldwide area of solar thermal collectors Installed Area (millions m 2) 600 500 400 300 China US Turkey Germany Japan Brazil Australia Rest of World 200 100 0 1999 2001 2003 2005 2007 Year 2009 2011 2013 The thermal power capacity at the end of 2013 was 373 GW

Figure 2. 51 Growth in the worldwide area of solar thermal collectors Installed Area (millions m 2) 600 500 400 300 China US Turkey Germany Japan Brazil Australia Rest of World 200 100 0 1999 2001 2003 2005 2007 Year 2009 2011 2013 The thermal power capacity at the end of 2013 was 373 GW

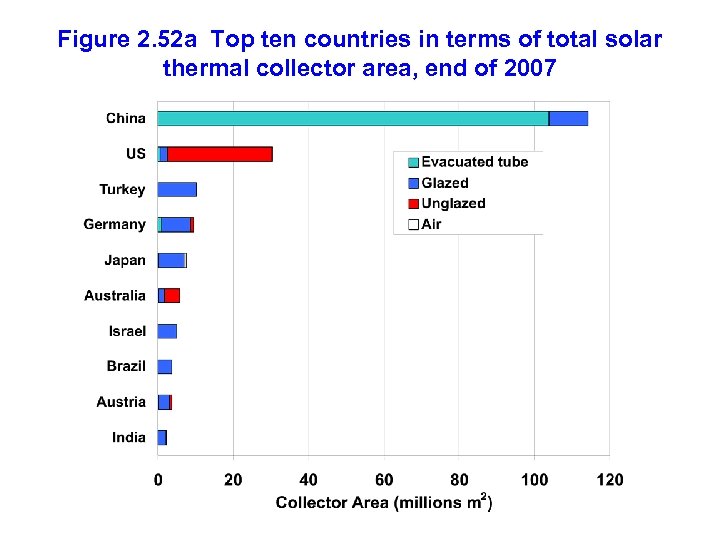

Figure 2. 52 a Top ten countries in terms of total solar thermal collector area, end of 2007

Figure 2. 52 a Top ten countries in terms of total solar thermal collector area, end of 2007

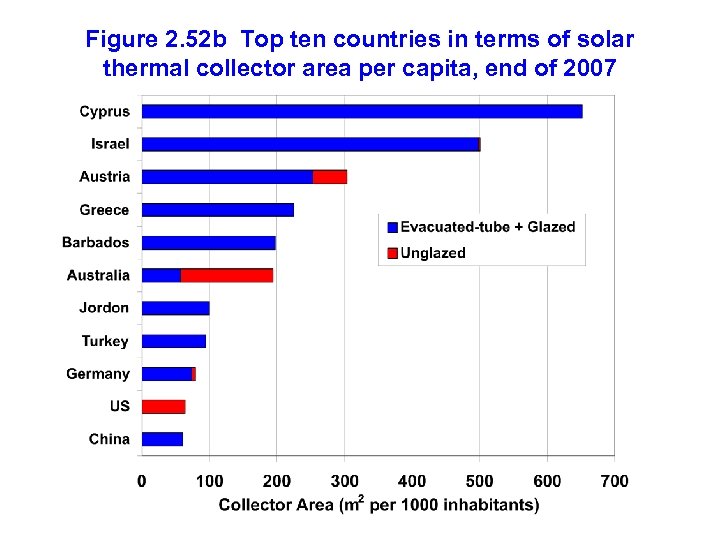

Figure 2. 52 b Top ten countries in terms of solar thermal collector area per capita, end of 2007

Figure 2. 52 b Top ten countries in terms of solar thermal collector area per capita, end of 2007

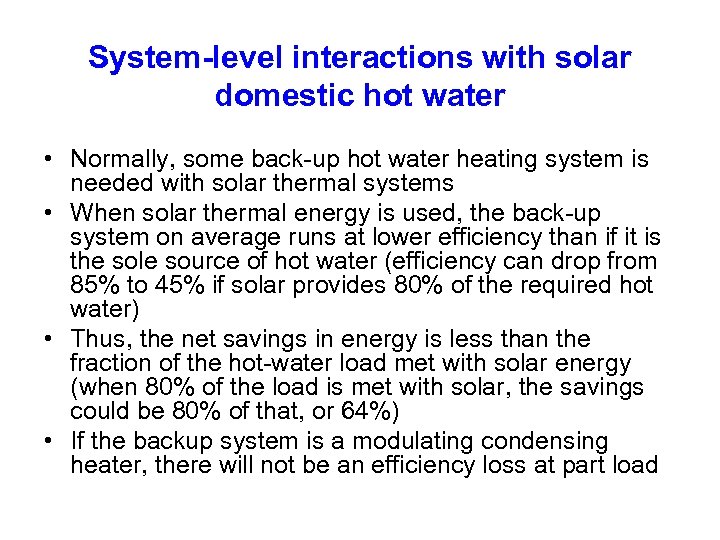

System-level interactions with solar domestic hot water • Normally, some back-up hot water heating system is needed with solar thermal systems • When solar thermal energy is used, the back-up system on average runs at lower efficiency than if it is the sole source of hot water (efficiency can drop from 85% to 45% if solar provides 80% of the required hot water) • Thus, the net savings in energy is less than the fraction of the hot-water load met with solar energy (when 80% of the load is met with solar, the savings could be 80% of that, or 64%) • If the backup system is a modulating condensing heater, there will not be an efficiency loss at part load

System-level interactions with solar domestic hot water • Normally, some back-up hot water heating system is needed with solar thermal systems • When solar thermal energy is used, the back-up system on average runs at lower efficiency than if it is the sole source of hot water (efficiency can drop from 85% to 45% if solar provides 80% of the required hot water) • Thus, the net savings in energy is less than the fraction of the hot-water load met with solar energy (when 80% of the load is met with solar, the savings could be 80% of that, or 64%) • If the backup system is a modulating condensing heater, there will not be an efficiency loss at part load

Solar Thermal Energy For Air Conditioning and Dehumidification • Absorption chillers • Solid desiccant systems • Liquid desiccant systems

Solar Thermal Energy For Air Conditioning and Dehumidification • Absorption chillers • Solid desiccant systems • Liquid desiccant systems

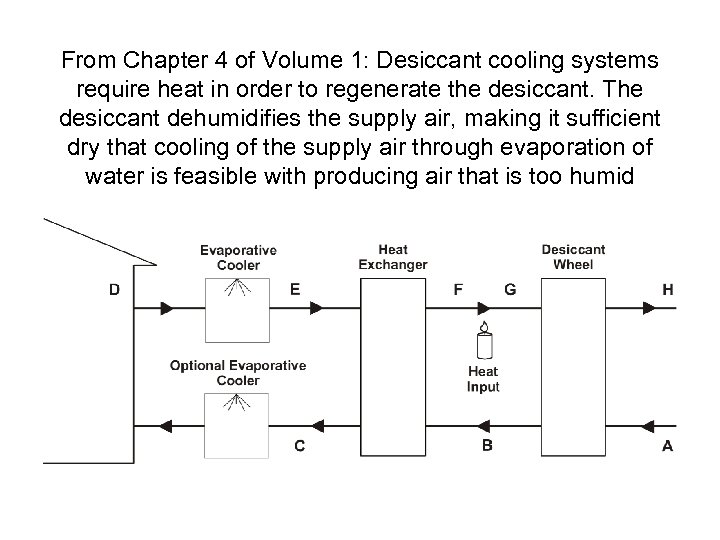

From Chapter 4 of Volume 1: Desiccant cooling systems require heat in order to regenerate the desiccant. The desiccant dehumidifies the supply air, making it sufficient dry that cooling of the supply air through evaporation of water is feasible with producing air that is too humid

From Chapter 4 of Volume 1: Desiccant cooling systems require heat in order to regenerate the desiccant. The desiccant dehumidifies the supply air, making it sufficient dry that cooling of the supply air through evaporation of water is feasible with producing air that is too humid

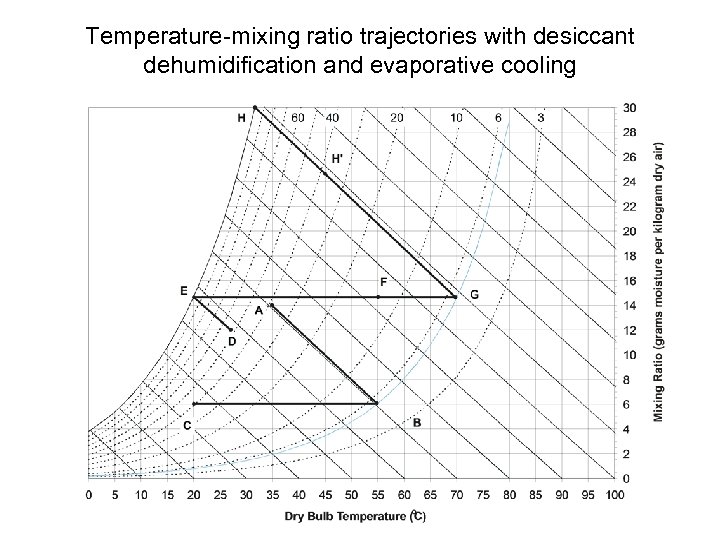

Temperature-mixing ratio trajectories with desiccant dehumidification and evaporative cooling

Temperature-mixing ratio trajectories with desiccant dehumidification and evaporative cooling

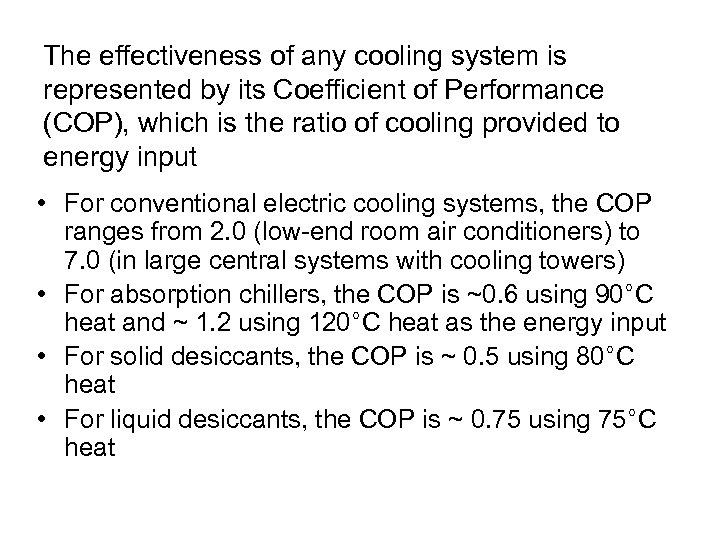

The effectiveness of any cooling system is represented by its Coefficient of Performance (COP), which is the ratio of cooling provided to energy input • For conventional electric cooling systems, the COP ranges from 2. 0 (low-end room air conditioners) to 7. 0 (in large central systems with cooling towers) • For absorption chillers, the COP is ~0. 6 using 90°C heat and ~ 1. 2 using 120°C heat as the energy input • For solid desiccants, the COP is ~ 0. 5 using 80°C heat • For liquid desiccants, the COP is ~ 0. 75 using 75°C heat

The effectiveness of any cooling system is represented by its Coefficient of Performance (COP), which is the ratio of cooling provided to energy input • For conventional electric cooling systems, the COP ranges from 2. 0 (low-end room air conditioners) to 7. 0 (in large central systems with cooling towers) • For absorption chillers, the COP is ~0. 6 using 90°C heat and ~ 1. 2 using 120°C heat as the energy input • For solid desiccants, the COP is ~ 0. 5 using 80°C heat • For liquid desiccants, the COP is ~ 0. 75 using 75°C heat

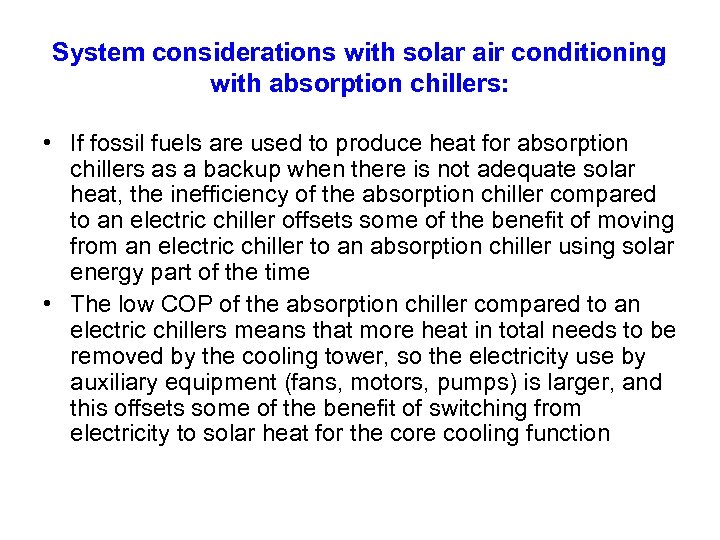

System considerations with solar air conditioning with absorption chillers: • If fossil fuels are used to produce heat for absorption chillers as a backup when there is not adequate solar heat, the inefficiency of the absorption chiller compared to an electric chiller offsets some of the benefit of moving from an electric chiller to an absorption chiller using solar energy part of the time • The low COP of the absorption chiller compared to an electric chillers means that more heat in total needs to be removed by the cooling tower, so the electricity use by auxiliary equipment (fans, motors, pumps) is larger, and this offsets some of the benefit of switching from electricity to solar heat for the core cooling function

System considerations with solar air conditioning with absorption chillers: • If fossil fuels are used to produce heat for absorption chillers as a backup when there is not adequate solar heat, the inefficiency of the absorption chiller compared to an electric chiller offsets some of the benefit of moving from an electric chiller to an absorption chiller using solar energy part of the time • The low COP of the absorption chiller compared to an electric chillers means that more heat in total needs to be removed by the cooling tower, so the electricity use by auxiliary equipment (fans, motors, pumps) is larger, and this offsets some of the benefit of switching from electricity to solar heat for the core cooling function

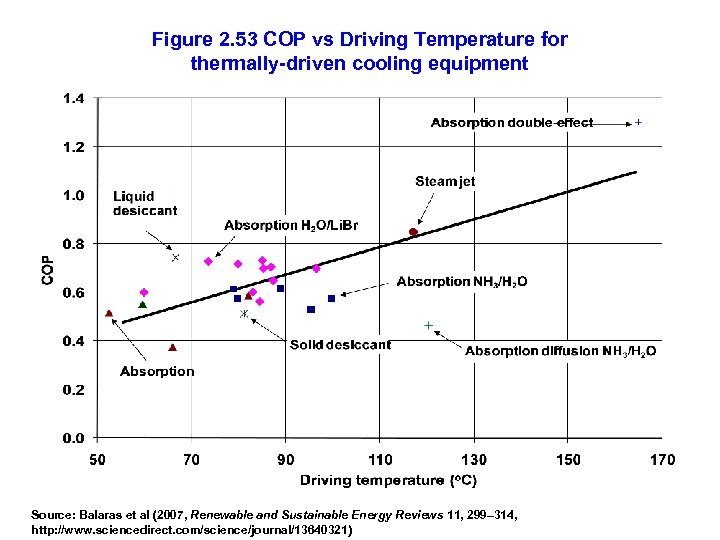

Figure 2. 53 COP vs Driving Temperature for thermally-driven cooling equipment Source: Balaras et al (2007, Renewable and Sustainable Energy Reviews 11, 299– 314, http: //www. sciencedirect. com/science/journal/13640321)

Figure 2. 53 COP vs Driving Temperature for thermally-driven cooling equipment Source: Balaras et al (2007, Renewable and Sustainable Energy Reviews 11, 299– 314, http: //www. sciencedirect. com/science/journal/13640321)

Costs • 1000 to 8000 euros per k. W of cooling capacity for solar thermal systems • 100 euros/k. W for large conventional cooling systems • The cost of solar systems is dominated by the cost of the collectors, so if collector costs come down, or the collectors are used for heating in the winter (so that only part of the collector cost need be ascribed to cooling), then the cooling cost will be smaller

Costs • 1000 to 8000 euros per k. W of cooling capacity for solar thermal systems • 100 euros/k. W for large conventional cooling systems • The cost of solar systems is dominated by the cost of the collectors, so if collector costs come down, or the collectors are used for heating in the winter (so that only part of the collector cost need be ascribed to cooling), then the cooling cost will be smaller

Solar cogeneration • Mount a PV module over a solar thermal collector, so that both electricity and useful heat are collected • By removing heat from the back of the module, the PV electrical efficiency increases • However, thermal collection efficiency will not be as large as for a dedicated solar thermal collector, and there might be an extra glazing over the PV panel, which reduces the production of electricity by absorbing some solar radiation

Solar cogeneration • Mount a PV module over a solar thermal collector, so that both electricity and useful heat are collected • By removing heat from the back of the module, the PV electrical efficiency increases • However, thermal collection efficiency will not be as large as for a dedicated solar thermal collector, and there might be an extra glazing over the PV panel, which reduces the production of electricity by absorbing some solar radiation

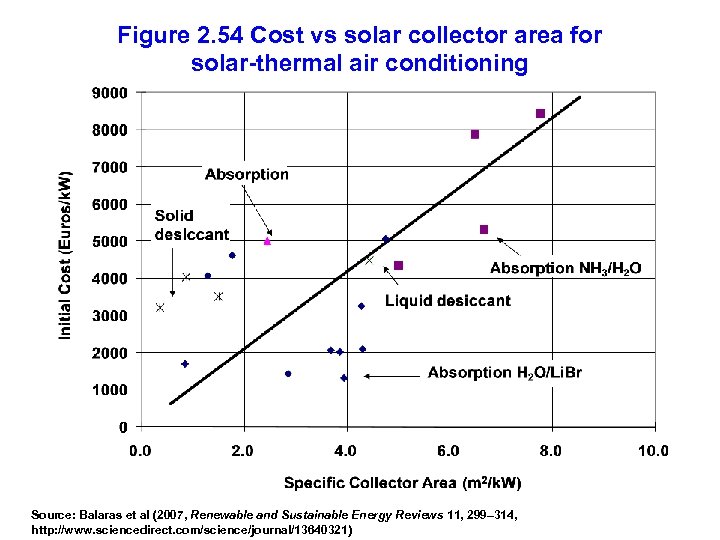

Figure 2. 54 Cost vs solar collector area for solar-thermal air conditioning Source: Balaras et al (2007, Renewable and Sustainable Energy Reviews 11, 299– 314, http: //www. sciencedirect. com/science/journal/13640321)

Figure 2. 54 Cost vs solar collector area for solar-thermal air conditioning Source: Balaras et al (2007, Renewable and Sustainable Energy Reviews 11, 299– 314, http: //www. sciencedirect. com/science/journal/13640321)

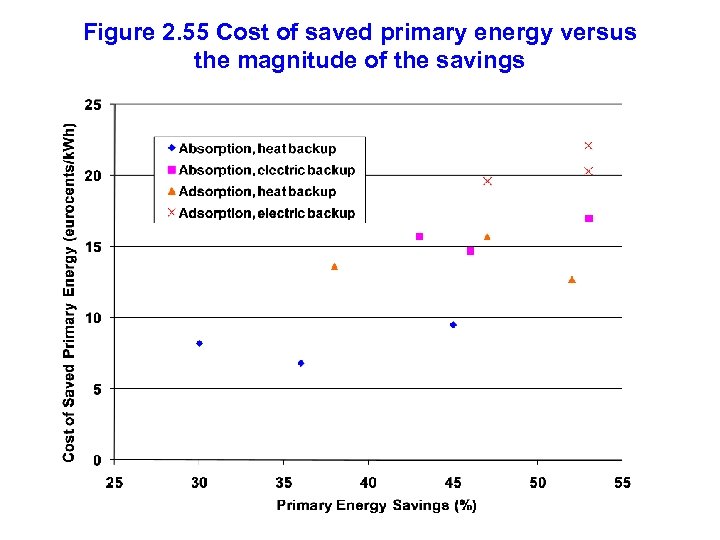

Figure 2. 55 Cost of saved primary energy versus the magnitude of the savings

Figure 2. 55 Cost of saved primary energy versus the magnitude of the savings

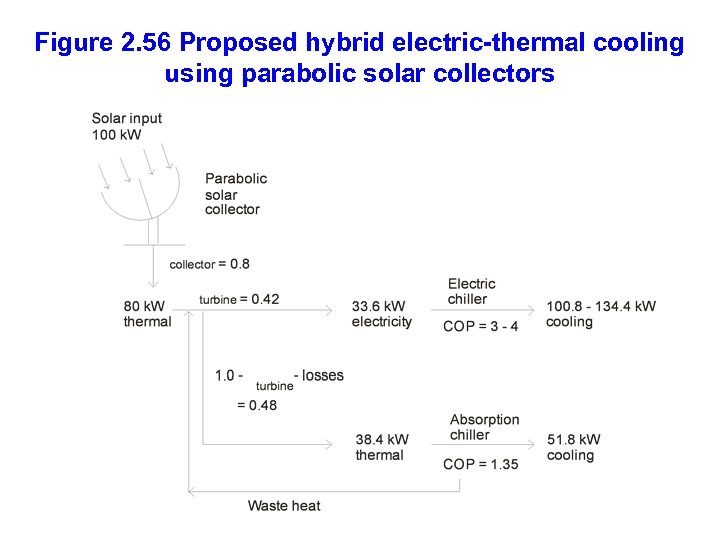

Figure 2. 56 Proposed hybrid electric-thermal cooling using parabolic solar collectors

Figure 2. 56 Proposed hybrid electric-thermal cooling using parabolic solar collectors

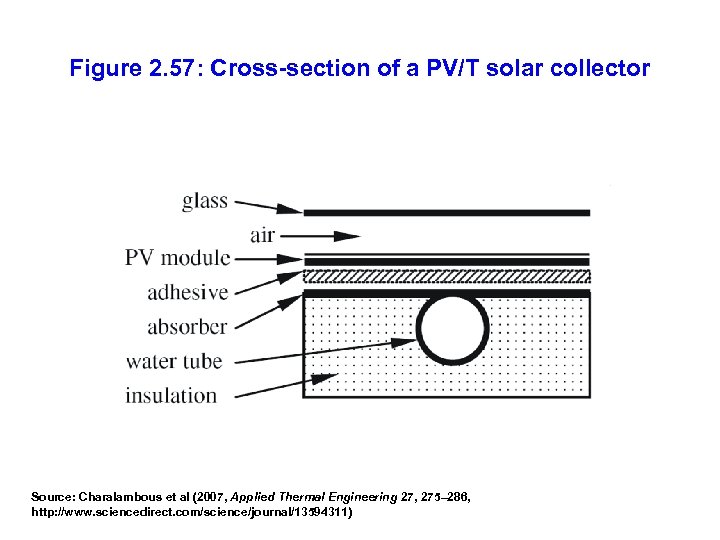

Figure 2. 57: Cross-section of a PV/T solar collector Source: Charalambous et al (2007, Applied Thermal Engineering 27, 275– 286, http: //www. sciencedirect. com/science/journal/13594311)

Figure 2. 57: Cross-section of a PV/T solar collector Source: Charalambous et al (2007, Applied Thermal Engineering 27, 275– 286, http: //www. sciencedirect. com/science/journal/13594311)

Industrial uses of Solar Energy • Low temperature (60 -260 o. C) Food processing – often at 80 -120 o. C Textiles Some chemical and plastics processes • High temperature (900 -2400 K, readily achieved with solar furnaces) reduction of metal ores

Industrial uses of Solar Energy • Low temperature (60 -260 o. C) Food processing – often at 80 -120 o. C Textiles Some chemical and plastics processes • High temperature (900 -2400 K, readily achieved with solar furnaces) reduction of metal ores

Other uses of solar energy: • Desalination of seawater • Fixation of nitrogen • Solar cooling of greenhouses (with desiccants and evaporation) • Crop drying • Cooking

Other uses of solar energy: • Desalination of seawater • Fixation of nitrogen • Solar cooling of greenhouses (with desiccants and evaporation) • Crop drying • Cooking

Desalination Options: • Solar electricity to power reverse osmosis desalination (80 MJ solar/m 3) • Solar heat to power multi-stage flash desalination (600 MJ solar/m 3) • Extraction from night air with desiccants, regeneration of desiccant with solar heat • Condensation from humidified air with cool seawater

Desalination Options: • Solar electricity to power reverse osmosis desalination (80 MJ solar/m 3) • Solar heat to power multi-stage flash desalination (600 MJ solar/m 3) • Extraction from night air with desiccants, regeneration of desiccant with solar heat • Condensation from humidified air with cool seawater

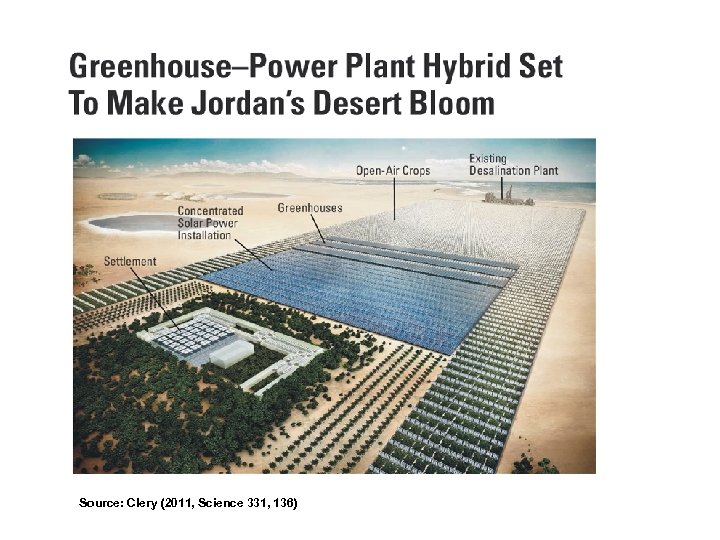

Source: Clery (2011, Science 331, 136)

Source: Clery (2011, Science 331, 136)

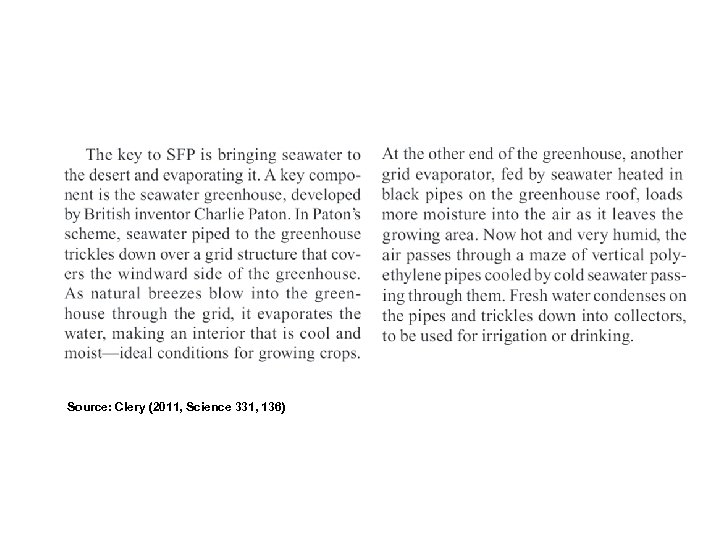

Source: Clery (2011, Science 331, 136)

Source: Clery (2011, Science 331, 136)

Dealing with intermittency • Use rapidly variable fossil backup • Aggregate geographically-dispersed PV arrays • Install energy storage (V 2 G plug-in hybrid cars in particular) and develop dispatchable loads • Link diverse renewable energy resources (especially if the variability of non-solar resources complements the solar variability)

Dealing with intermittency • Use rapidly variable fossil backup • Aggregate geographically-dispersed PV arrays • Install energy storage (V 2 G plug-in hybrid cars in particular) and develop dispatchable loads • Link diverse renewable energy resources (especially if the variability of non-solar resources complements the solar variability)

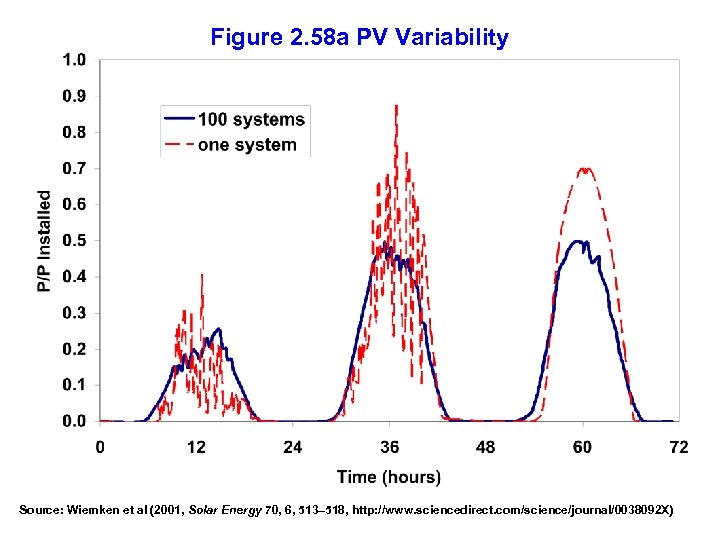

Figure 2. 58 a PV Variability Source: Wiemken et al (2001, Solar Energy 70, 6, 513– 518, http: //www. sciencedirect. com/science/journal/0038092 X)

Figure 2. 58 a PV Variability Source: Wiemken et al (2001, Solar Energy 70, 6, 513– 518, http: //www. sciencedirect. com/science/journal/0038092 X)

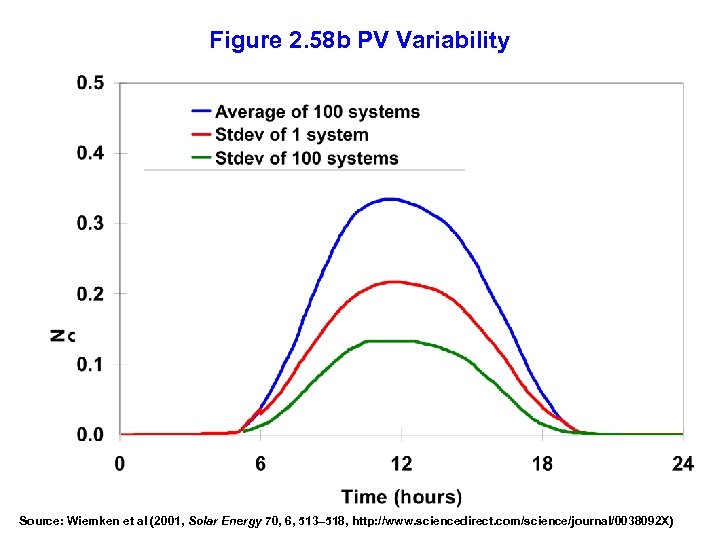

Figure 2. 58 b PV Variability Source: Wiemken et al (2001, Solar Energy 70, 6, 513– 518, http: //www. sciencedirect. com/science/journal/0038092 X)

Figure 2. 58 b PV Variability Source: Wiemken et al (2001, Solar Energy 70, 6, 513– 518, http: //www. sciencedirect. com/science/journal/0038092 X)

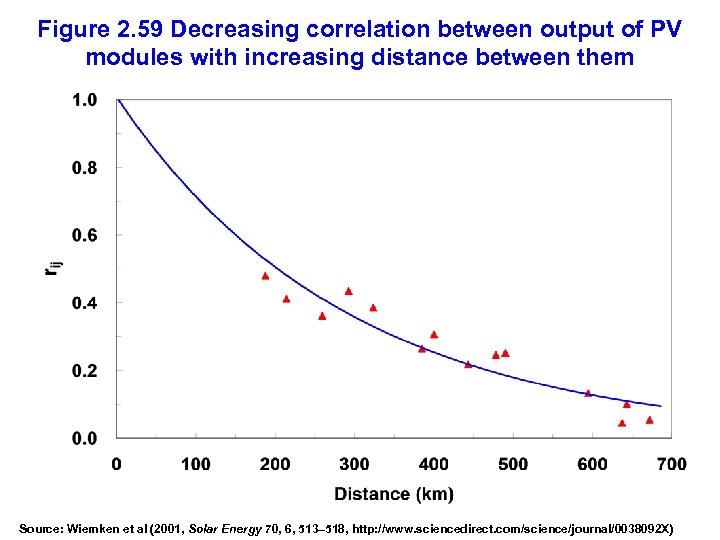

Figure 2. 59 Decreasing correlation between output of PV modules with increasing distance between them Source: Wiemken et al (2001, Solar Energy 70, 6, 513– 518, http: //www. sciencedirect. com/science/journal/0038092 X)

Figure 2. 59 Decreasing correlation between output of PV modules with increasing distance between them Source: Wiemken et al (2001, Solar Energy 70, 6, 513– 518, http: //www. sciencedirect. com/science/journal/0038092 X)

Concluding Comments • The solar energy resource is enormous but diffuse, so large land areas would be involved in capturing it • Many of our energy needs involve low-temperature heat (for space heating and hot water, and for some industrial processes), and so do not require the intermediary of expensive solar electricity • Thus, the first strategy in using solar energy should be to design buildings to make passive use of solar energy – for heating, ventilation, and cooling (which occurs when passive ventilation brings in outside air that is cooler than the temperature that the building would reach on its own)

Concluding Comments • The solar energy resource is enormous but diffuse, so large land areas would be involved in capturing it • Many of our energy needs involve low-temperature heat (for space heating and hot water, and for some industrial processes), and so do not require the intermediary of expensive solar electricity • Thus, the first strategy in using solar energy should be to design buildings to make passive use of solar energy – for heating, ventilation, and cooling (which occurs when passive ventilation brings in outside air that is cooler than the temperature that the building would reach on its own)

Concluding Comments (continued) • Two strategies for generating electricity for solar energy are photovoltaic (PV) and solar-thermal • PV electricity can be done centrally or on site as building-integrated PV (Bi. PV) • Bi. PV alone could provide 15 -60% of total electricity needs in various countries • Solar thermal electricity can be generated 24 hours per day but requires direct-beam solar radiation – so it is best in desert or semi-arid regions

Concluding Comments (continued) • Two strategies for generating electricity for solar energy are photovoltaic (PV) and solar-thermal • PV electricity can be done centrally or on site as building-integrated PV (Bi. PV) • Bi. PV alone could provide 15 -60% of total electricity needs in various countries • Solar thermal electricity can be generated 24 hours per day but requires direct-beam solar radiation – so it is best in desert or semi-arid regions

Concluding Comments (continued) • PV cells can use conventional materials (silicon) or various toxic (As, Cd) or rare (Ge, In, Te, Ru, Se) elements, with those using rare elements being most efficient (up to 30%, vs 10 -15% for crystalline silicon-based cells and 6 -8% for amorphous silicon) • Limits on the availability of the rare materials represent real constraints on how much electricity could be supplied with these cells • The limit can be increased by a factor of 100 or so using concentrating PV cells, and would no longer be an issue.

Concluding Comments (continued) • PV cells can use conventional materials (silicon) or various toxic (As, Cd) or rare (Ge, In, Te, Ru, Se) elements, with those using rare elements being most efficient (up to 30%, vs 10 -15% for crystalline silicon-based cells and 6 -8% for amorphous silicon) • Limits on the availability of the rare materials represent real constraints on how much electricity could be supplied with these cells • The limit can be increased by a factor of 100 or so using concentrating PV cells, and would no longer be an issue.

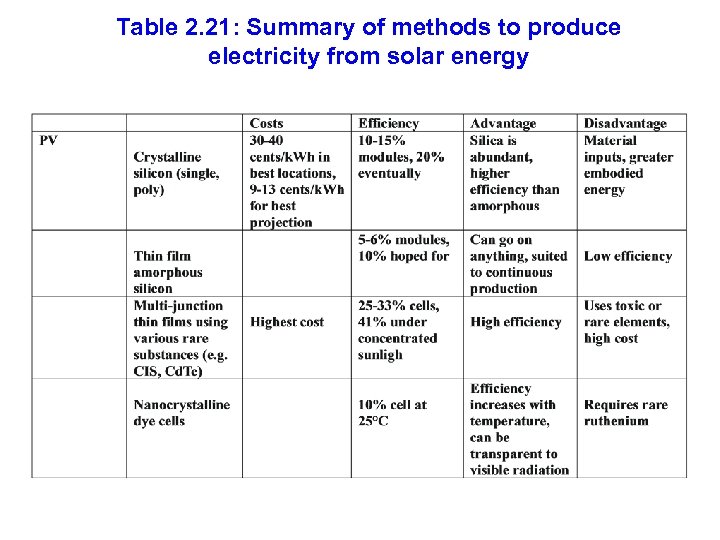

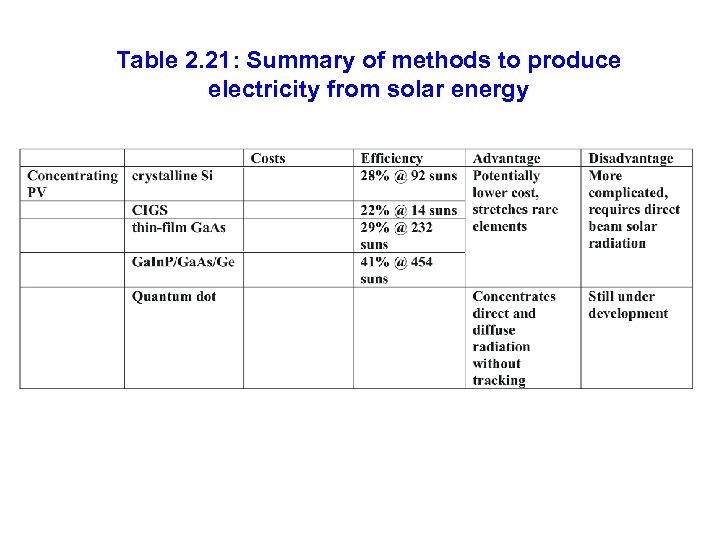

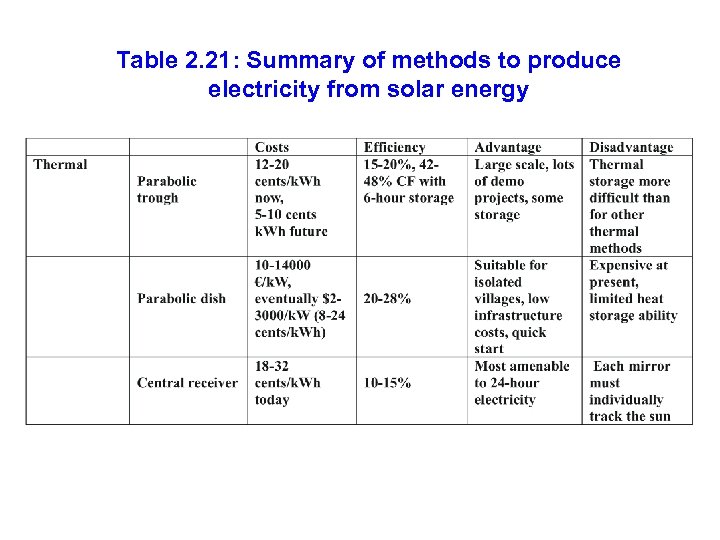

Table 2. 21: Summary of methods to produce electricity from solar energy

Table 2. 21: Summary of methods to produce electricity from solar energy

Table 2. 21: Summary of methods to produce electricity from solar energy

Table 2. 21: Summary of methods to produce electricity from solar energy

Table 2. 21: Summary of methods to produce electricity from solar energy

Table 2. 21: Summary of methods to produce electricity from solar energy

Concluding comments (continued) • PV electricity is currently expensive (~ 20 -25 cents/k. Wh in sunny locations, 45 -60 cents/k. Wh in midlatitude locations) but will likely fall in price by a factor of 2 or more during the next decade • This would make Bi. PV highly competitive with peak electricity, which can cost 15 -30 cents/k. Wh (retail price) • Parabolic-trough concentrating solar-thermal electricity is already in the 12 -20 cents/k. Wh range and could drop to as low as 5 cents/k. Wh

Concluding comments (continued) • PV electricity is currently expensive (~ 20 -25 cents/k. Wh in sunny locations, 45 -60 cents/k. Wh in midlatitude locations) but will likely fall in price by a factor of 2 or more during the next decade • This would make Bi. PV highly competitive with peak electricity, which can cost 15 -30 cents/k. Wh (retail price) • Parabolic-trough concentrating solar-thermal electricity is already in the 12 -20 cents/k. Wh range and could drop to as low as 5 cents/k. Wh

Other active uses of solar energy • • • Solar air conditioning Medium-temperature (60 -260 o. C) industrial heat High-temperature (1000 -2500 o. C) industrial heat Solar fixation of nitrogen Crop drying Cooking

Other active uses of solar energy • • • Solar air conditioning Medium-temperature (60 -260 o. C) industrial heat High-temperature (1000 -2500 o. C) industrial heat Solar fixation of nitrogen Crop drying Cooking