7f1d329398a06774aa28f1f575c831a0.ppt

- Количество слайдов: 32

ENCE 710 Design of Steel Structures VI. Plate Girders C. C. Fu, Ph. D. , P. E. Civil and Environmental Engineering Department University of Maryland

ENCE 710 Design of Steel Structures VI. Plate Girders C. C. Fu, Ph. D. , P. E. Civil and Environmental Engineering Department University of Maryland

Introduction Following subjects are covered: n Moment strength n Shear strength n Intermediate transverse stiffener n Bearing stiffener Reading: n Chapters 11 of Salmon & Johnson n AISC LRFD Specification Chapters B (Design Requirements) and F (Design of Members for Flexure) and G (Design of Members for Shear) 2

Introduction Following subjects are covered: n Moment strength n Shear strength n Intermediate transverse stiffener n Bearing stiffener Reading: n Chapters 11 of Salmon & Johnson n AISC LRFD Specification Chapters B (Design Requirements) and F (Design of Members for Flexure) and G (Design of Members for Shear) 2

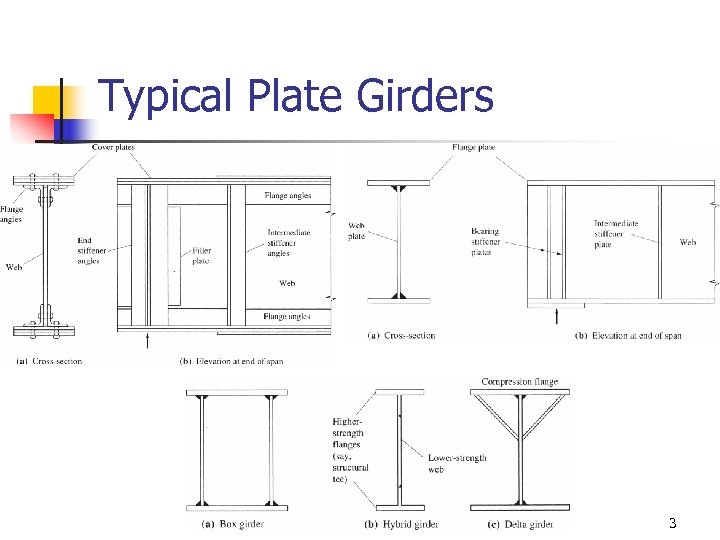

Typical Plate Girders 3

Typical Plate Girders 3

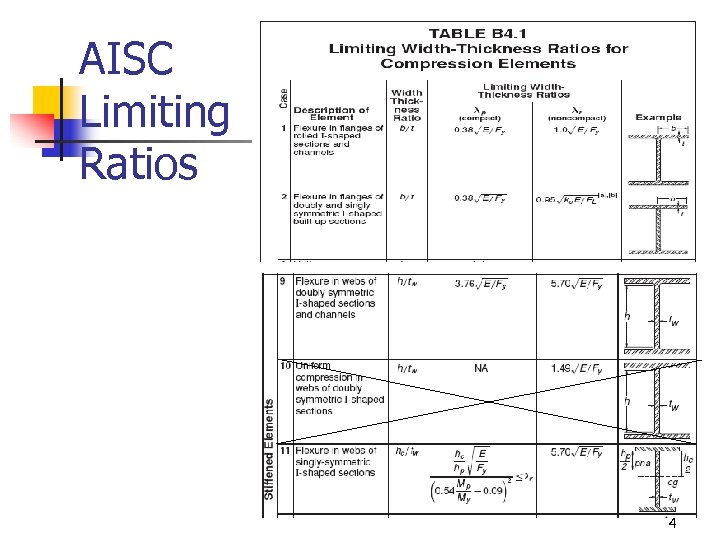

AISC Limiting Ratios 4

AISC Limiting Ratios 4

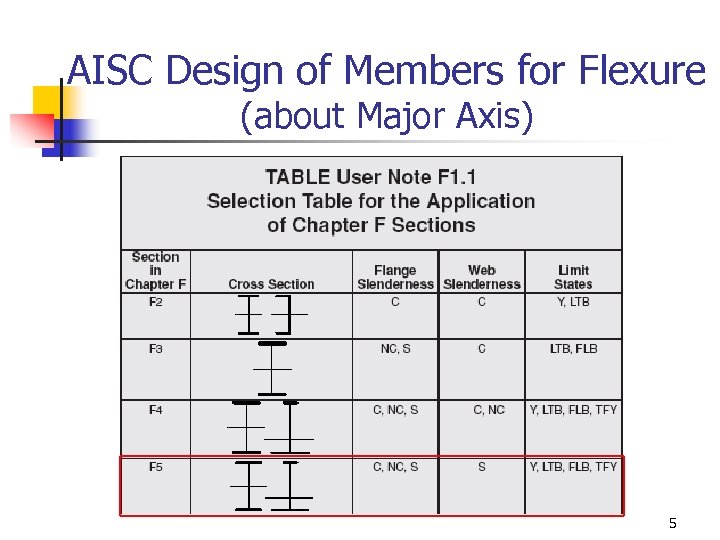

AISC Design of Members for Flexure (about Major Axis) 5

AISC Design of Members for Flexure (about Major Axis) 5

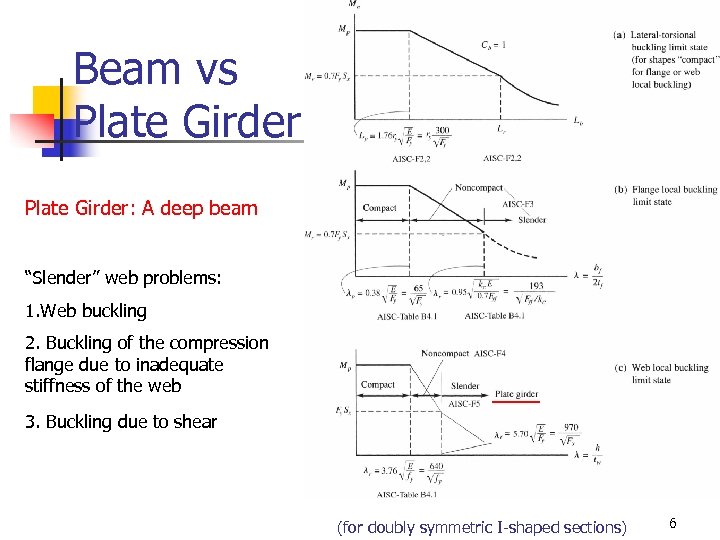

Beam vs Plate Girder: A deep beam “Slender” web problems: 1. Web buckling 2. Buckling of the compression flange due to inadequate stiffness of the web 3. Buckling due to shear (for doubly symmetric I-shaped sections) 6

Beam vs Plate Girder: A deep beam “Slender” web problems: 1. Web buckling 2. Buckling of the compression flange due to inadequate stiffness of the web 3. Buckling due to shear (for doubly symmetric I-shaped sections) 6

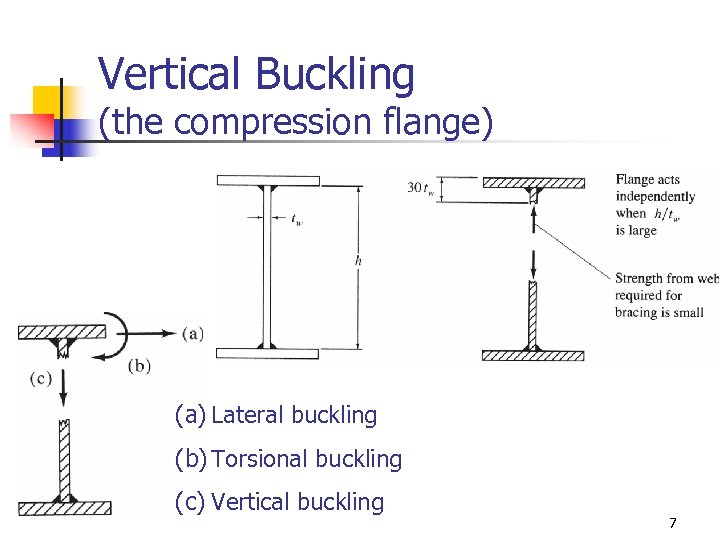

Vertical Buckling (the compression flange) (a) Lateral buckling (b) Torsional buckling (c) Vertical buckling 7

Vertical Buckling (the compression flange) (a) Lateral buckling (b) Torsional buckling (c) Vertical buckling 7

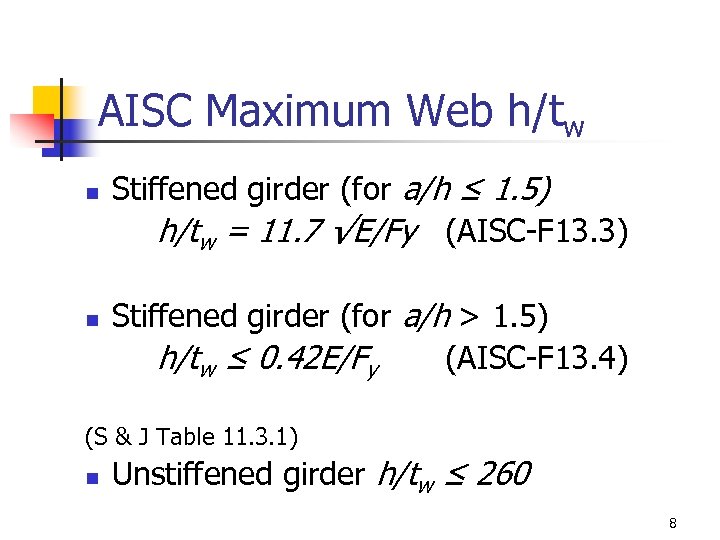

AISC Maximum Web h/tw n n Stiffened girder (for a/h ≤ 1. 5) h/tw = 11. 7 √E/Fy (AISC-F 13. 3) Stiffened girder (for a/h > 1. 5) h/tw ≤ 0. 42 E/Fy (AISC-F 13. 4) (S & J Table 11. 3. 1) n Unstiffened girder h/tw ≤ 260 8

AISC Maximum Web h/tw n n Stiffened girder (for a/h ≤ 1. 5) h/tw = 11. 7 √E/Fy (AISC-F 13. 3) Stiffened girder (for a/h > 1. 5) h/tw ≤ 0. 42 E/Fy (AISC-F 13. 4) (S & J Table 11. 3. 1) n Unstiffened girder h/tw ≤ 260 8

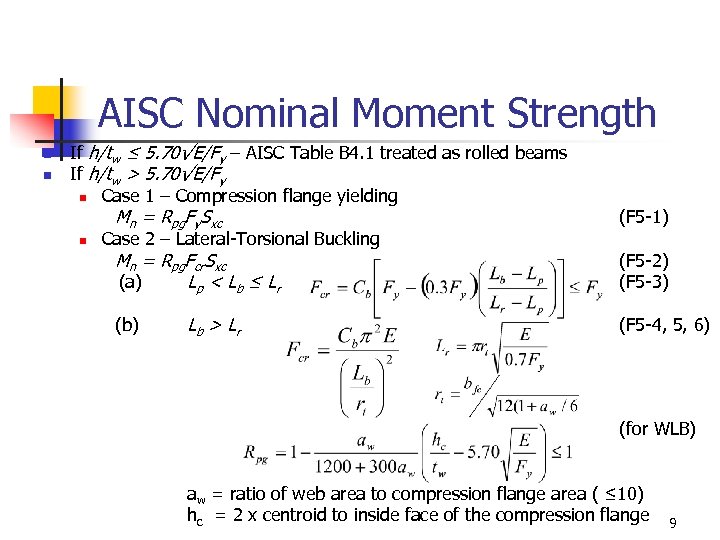

AISC Nominal Moment Strength n n If h/tw ≤ 5. 70√E/Fy – AISC Table B 4. 1 treated as rolled beams If h/tw > 5. 70√E/Fy n Case 1 – Compression flange yielding Mn = Rpg. Fy. Sxc n (F 5 -1) Mn = Rpg. Fcr. Sxc (a) Lp < L b ≤ Lr (F 5 -2) (F 5 -3) Case 2 – Lateral-Torsional Buckling (b) Lb > Lr (F 5 -4, 5, 6) (for WLB) aw = ratio of web area to compression flange area ( ≤ 10) hc = 2 x centroid to inside face of the compression flange 9

AISC Nominal Moment Strength n n If h/tw ≤ 5. 70√E/Fy – AISC Table B 4. 1 treated as rolled beams If h/tw > 5. 70√E/Fy n Case 1 – Compression flange yielding Mn = Rpg. Fy. Sxc n (F 5 -1) Mn = Rpg. Fcr. Sxc (a) Lp < L b ≤ Lr (F 5 -2) (F 5 -3) Case 2 – Lateral-Torsional Buckling (b) Lb > Lr (F 5 -4, 5, 6) (for WLB) aw = ratio of web area to compression flange area ( ≤ 10) hc = 2 x centroid to inside face of the compression flange 9

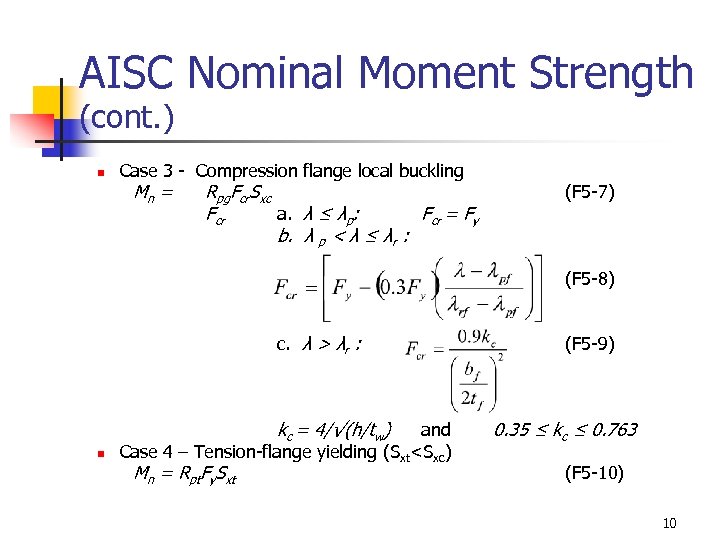

AISC Nominal Moment Strength (cont. ) n Case 3 - Compression flange local buckling Mn = Rpg. Fcr. Sxc Fcr a. λ ≤ λp: Fcr = Fy b. λ p < λ ≤ λr : (F 5 -7) (F 5 -8) c. λ > λr : kc = 4/√(h/tw) n and Case 4 – Tension-flange yielding (Sxt

AISC Nominal Moment Strength (cont. ) n Case 3 - Compression flange local buckling Mn = Rpg. Fcr. Sxc Fcr a. λ ≤ λp: Fcr = Fy b. λ p < λ ≤ λr : (F 5 -7) (F 5 -8) c. λ > λr : kc = 4/√(h/tw) n and Case 4 – Tension-flange yielding (Sxt

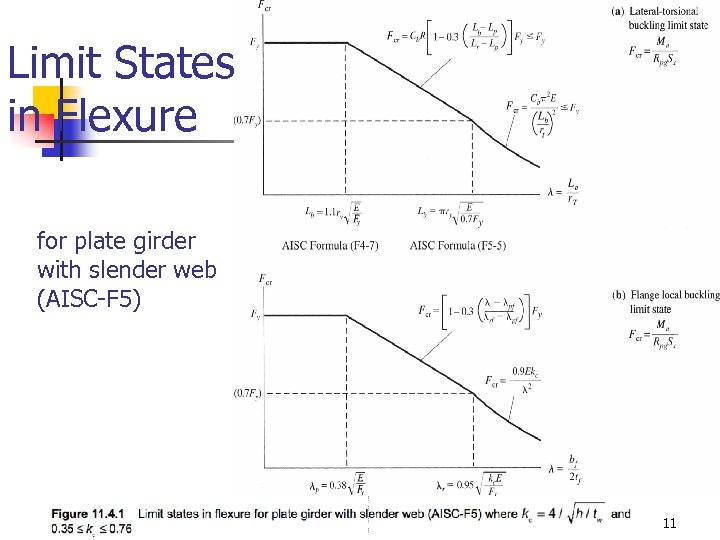

Limit States in Flexure for plate girder with slender web (AISC-F 5) 11

Limit States in Flexure for plate girder with slender web (AISC-F 5) 11

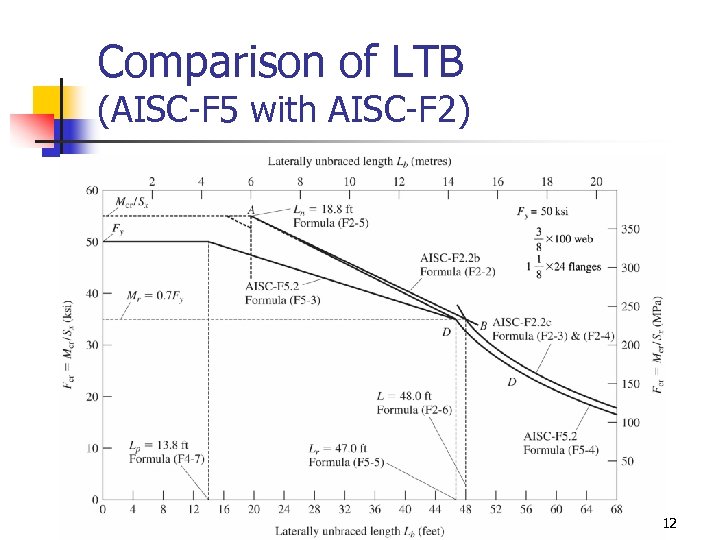

Comparison of LTB (AISC-F 5 with AISC-F 2) 12

Comparison of LTB (AISC-F 5 with AISC-F 2) 12

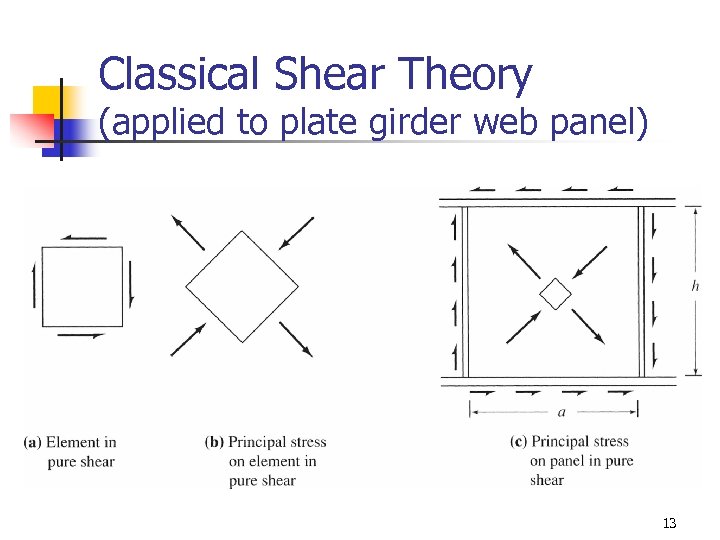

Classical Shear Theory (applied to plate girder web panel) 13

Classical Shear Theory (applied to plate girder web panel) 13

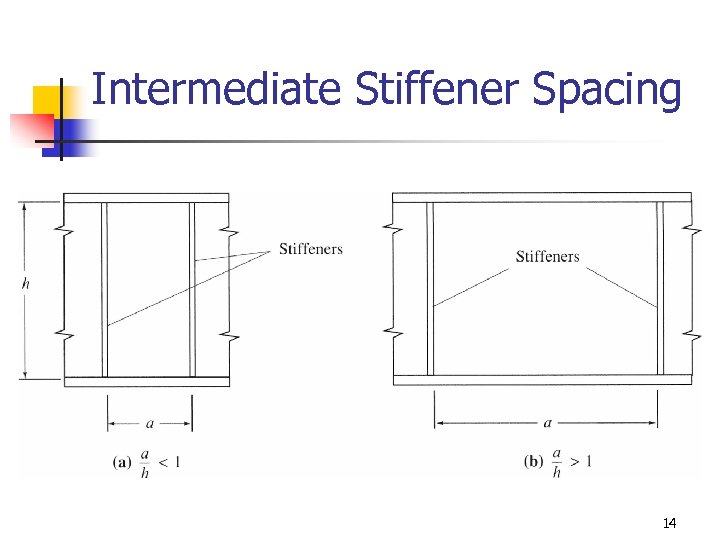

Intermediate Stiffener Spacing 14

Intermediate Stiffener Spacing 14

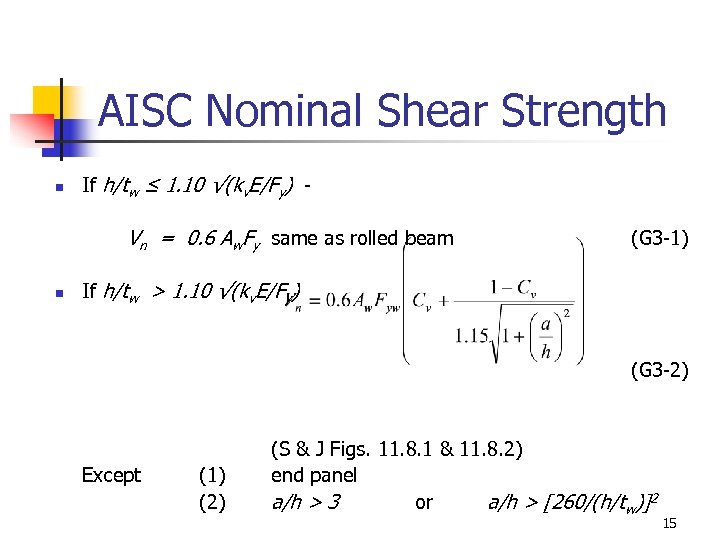

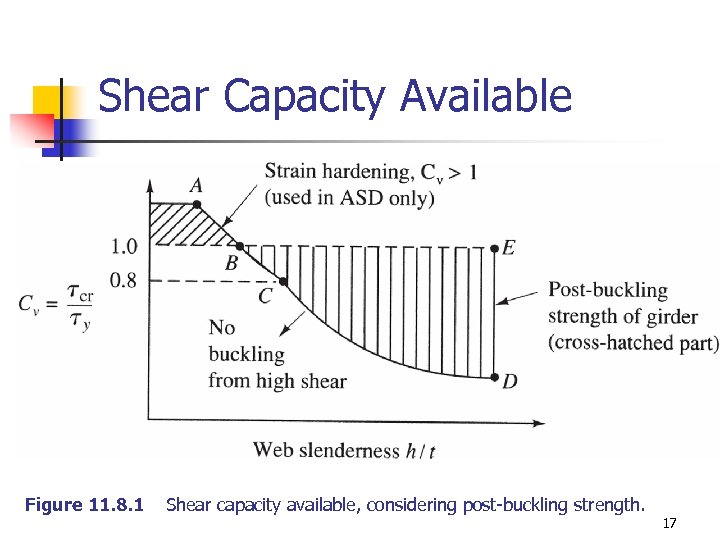

AISC Nominal Shear Strength n If h/tw ≤ 1. 10 √(kv. E/Fy) - Vn = 0. 6 Aw. Fy same as rolled beam n (G 3 -1) If h/tw > 1. 10 √(kv. E/Fy) (G 3 -2) Except (1) (2) (S & J Figs. 11. 8. 1 & 11. 8. 2) end panel a/h > 3 or a/h > [260/(h/tw)]2 15

AISC Nominal Shear Strength n If h/tw ≤ 1. 10 √(kv. E/Fy) - Vn = 0. 6 Aw. Fy same as rolled beam n (G 3 -1) If h/tw > 1. 10 √(kv. E/Fy) (G 3 -2) Except (1) (2) (S & J Figs. 11. 8. 1 & 11. 8. 2) end panel a/h > 3 or a/h > [260/(h/tw)]2 15

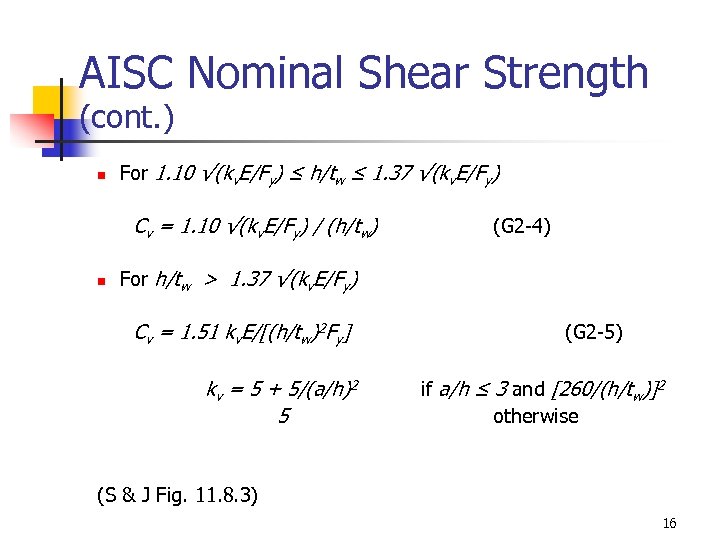

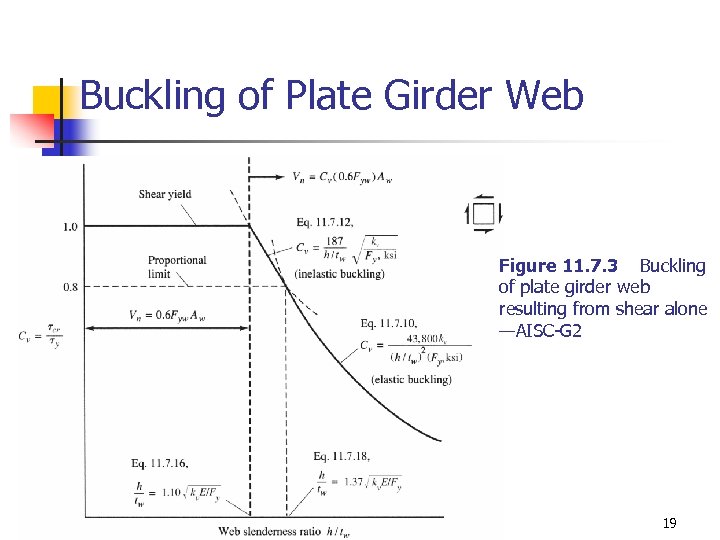

AISC Nominal Shear Strength (cont. ) n For 1. 10 √(kv. E/Fy) ≤ h/tw ≤ 1. 37 √(kv. E/Fy) Cv = 1. 10 √(kv. E/Fy) / (h/tw) n (G 2 -4) For h/tw > 1. 37 √(kv. E/Fy) Cv = 1. 51 kv. E/[(h/tw)2 Fy] kv = 5 + 5/(a/h)2 5 (G 2 -5) if a/h ≤ 3 and [260/(h/tw)]2 otherwise (S & J Fig. 11. 8. 3) 16

AISC Nominal Shear Strength (cont. ) n For 1. 10 √(kv. E/Fy) ≤ h/tw ≤ 1. 37 √(kv. E/Fy) Cv = 1. 10 √(kv. E/Fy) / (h/tw) n (G 2 -4) For h/tw > 1. 37 √(kv. E/Fy) Cv = 1. 51 kv. E/[(h/tw)2 Fy] kv = 5 + 5/(a/h)2 5 (G 2 -5) if a/h ≤ 3 and [260/(h/tw)]2 otherwise (S & J Fig. 11. 8. 3) 16

Shear Capacity Available Figure 11. 8. 1 Shear capacity available, considering post-buckling strength. 17

Shear Capacity Available Figure 11. 8. 1 Shear capacity available, considering post-buckling strength. 17

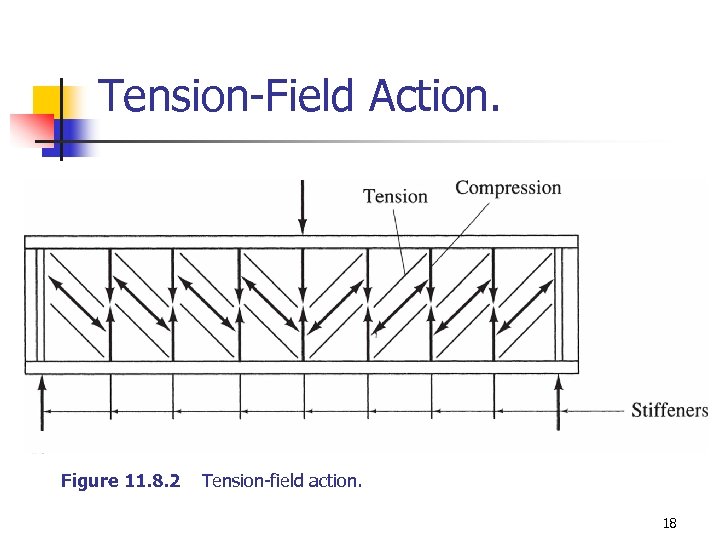

Tension-Field Action. Figure 11. 8. 2 Tension-field action. 18

Tension-Field Action. Figure 11. 8. 2 Tension-field action. 18

Buckling of Plate Girder Web Figure 11. 7. 3 Buckling of plate girder web resulting from shear alone —AISC-G 2 19

Buckling of Plate Girder Web Figure 11. 7. 3 Buckling of plate girder web resulting from shear alone —AISC-G 2 19

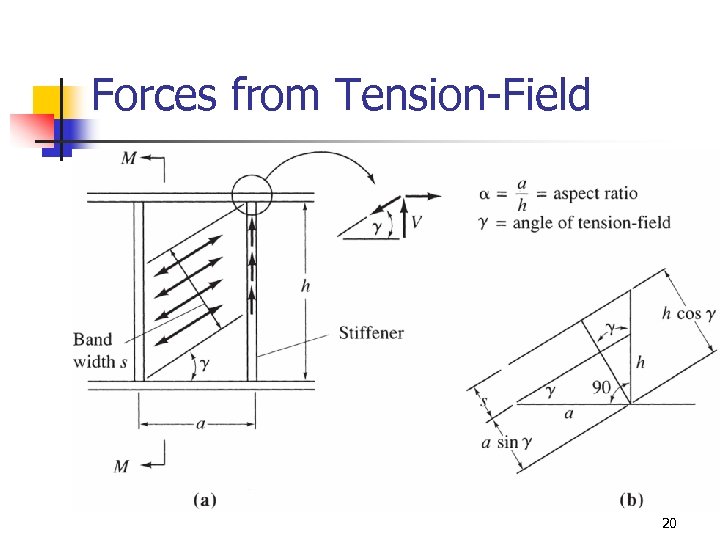

Forces from Tension-Field 20

Forces from Tension-Field 20

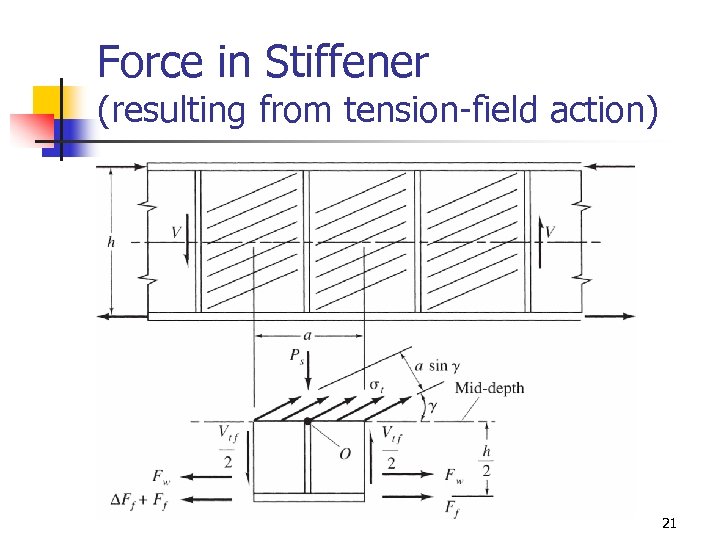

Force in Stiffener (resulting from tension-field action) 21

Force in Stiffener (resulting from tension-field action) 21

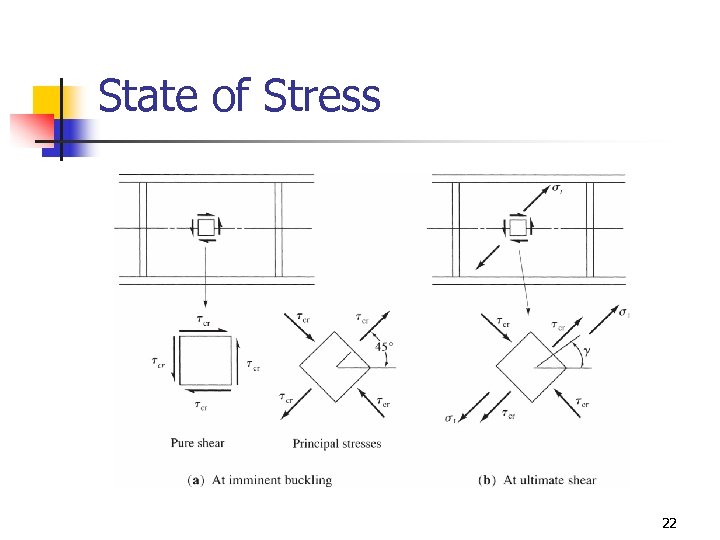

State of Stress 22

State of Stress 22

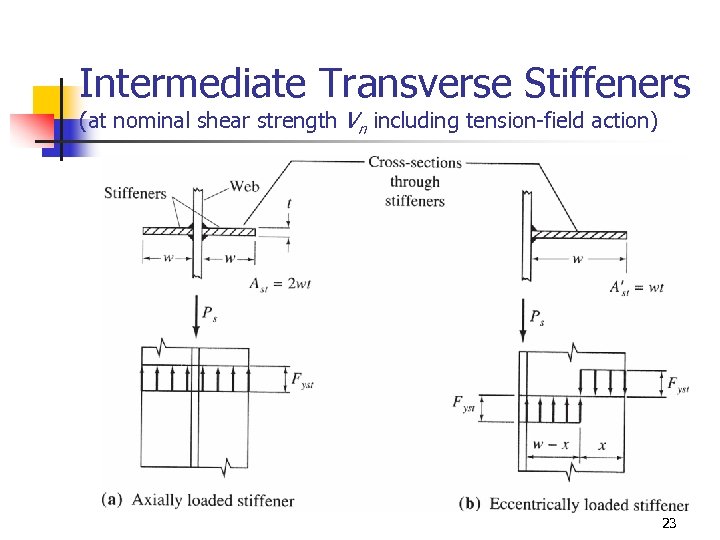

Intermediate Transverse Stiffeners (at nominal shear strength Vn including tension-field action) 23

Intermediate Transverse Stiffeners (at nominal shear strength Vn including tension-field action) 23

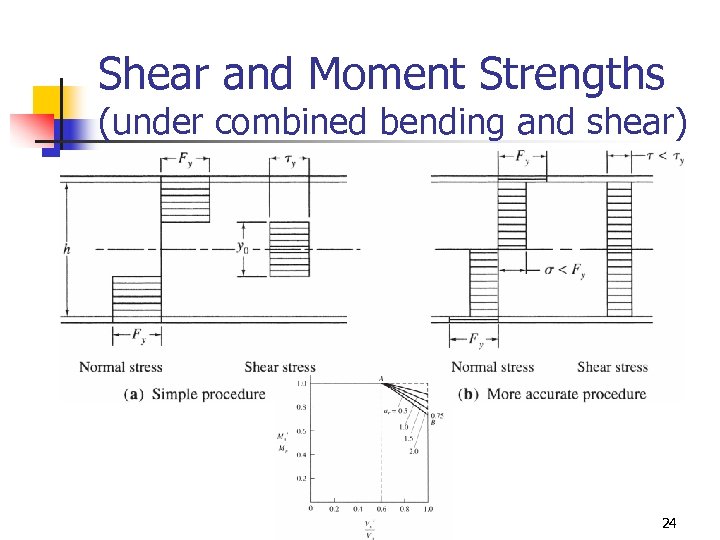

Shear and Moment Strengths (under combined bending and shear) 24

Shear and Moment Strengths (under combined bending and shear) 24

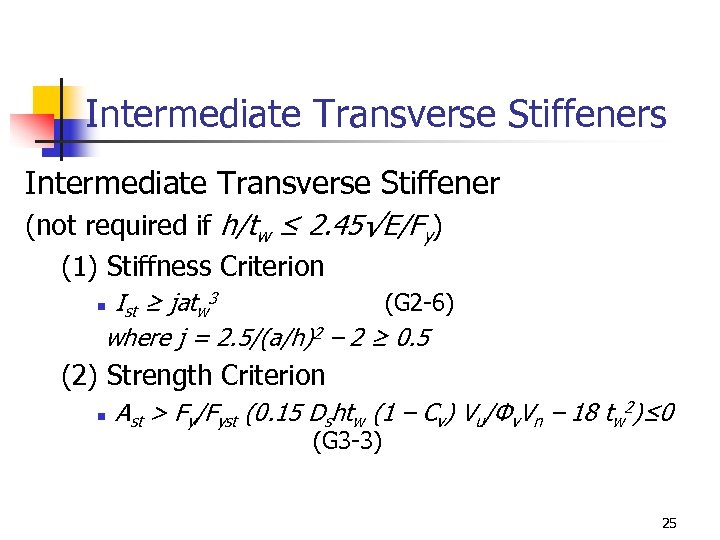

Intermediate Transverse Stiffeners Intermediate Transverse Stiffener (not required if h/tw ≤ 2. 45√E/Fy) (1) Stiffness Criterion Ist ≥ jatw 3 (G 2 -6) where j = 2. 5/(a/h)2 – 2 ≥ 0. 5 n (2) Strength Criterion n Ast > Fy/Fyst (0. 15 Dshtw (1 – Cv) Vu/Φv. Vn – 18 tw 2)≤ 0 (G 3 -3) 25

Intermediate Transverse Stiffeners Intermediate Transverse Stiffener (not required if h/tw ≤ 2. 45√E/Fy) (1) Stiffness Criterion Ist ≥ jatw 3 (G 2 -6) where j = 2. 5/(a/h)2 – 2 ≥ 0. 5 n (2) Strength Criterion n Ast > Fy/Fyst (0. 15 Dshtw (1 – Cv) Vu/Φv. Vn – 18 tw 2)≤ 0 (G 3 -3) 25

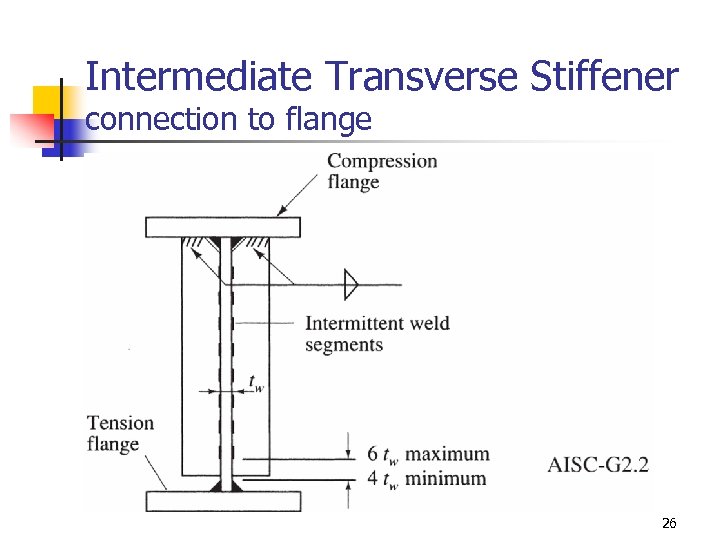

Intermediate Transverse Stiffener connection to flange 26

Intermediate Transverse Stiffener connection to flange 26

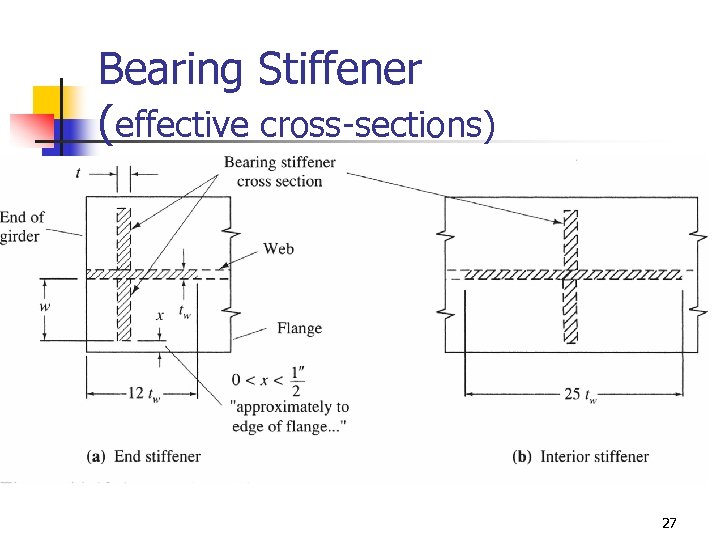

Bearing Stiffener (effective cross-sections) 27

Bearing Stiffener (effective cross-sections) 27

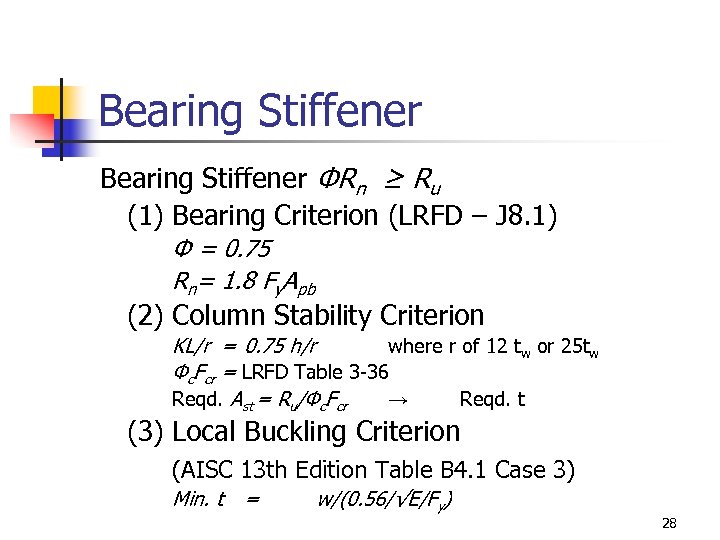

Bearing Stiffener ΦRn ≥ Ru (1) Bearing Criterion (LRFD – J 8. 1) Φ = 0. 75 Rn= 1. 8 Fy. Apb (2) Column Stability Criterion KL/r = 0. 75 h/r where r of 12 tw or 25 tw Φc. Fcr = LRFD Table 3 -36 Reqd. Ast = Ru/Φc. Fcr → Reqd. t (3) Local Buckling Criterion (AISC 13 th Edition Table B 4. 1 Case 3) Min. t = w/(0. 56/√E/Fy) 28

Bearing Stiffener ΦRn ≥ Ru (1) Bearing Criterion (LRFD – J 8. 1) Φ = 0. 75 Rn= 1. 8 Fy. Apb (2) Column Stability Criterion KL/r = 0. 75 h/r where r of 12 tw or 25 tw Φc. Fcr = LRFD Table 3 -36 Reqd. Ast = Ru/Φc. Fcr → Reqd. t (3) Local Buckling Criterion (AISC 13 th Edition Table B 4. 1 Case 3) Min. t = w/(0. 56/√E/Fy) 28

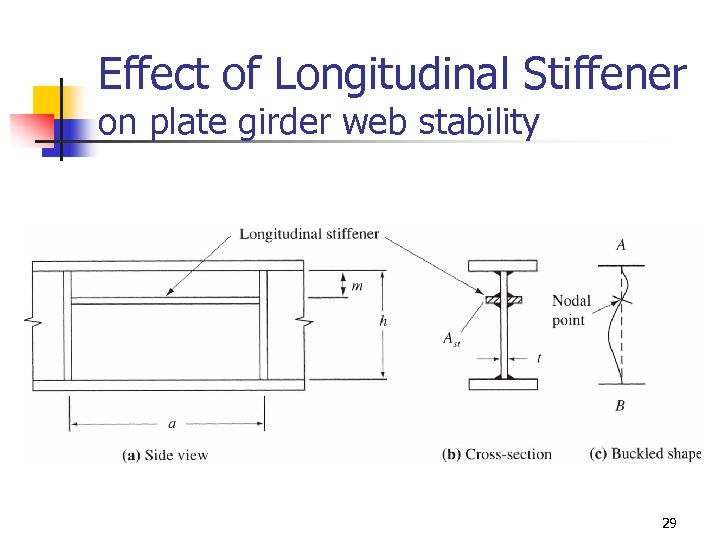

Effect of Longitudinal Stiffener on plate girder web stability 29

Effect of Longitudinal Stiffener on plate girder web stability 29

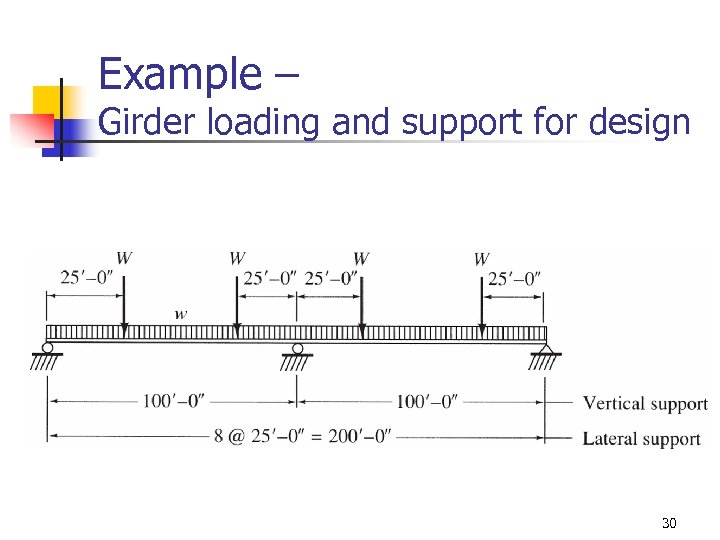

Example – Girder loading and support for design 30

Example – Girder loading and support for design 30

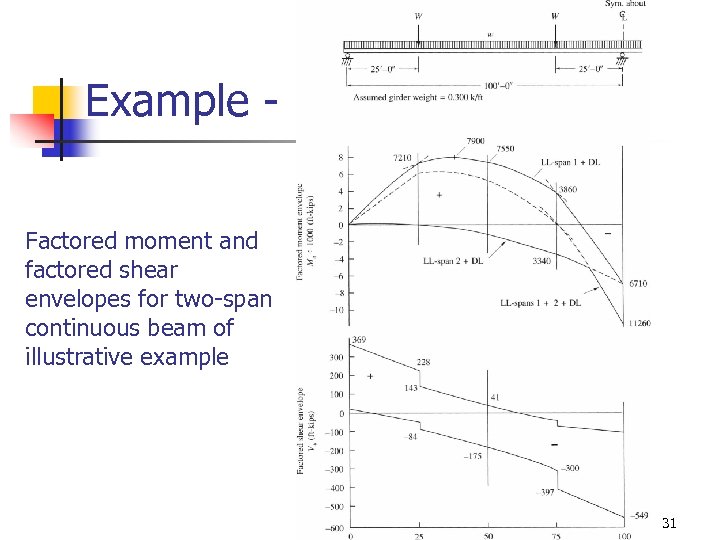

Example Factored moment and factored shear envelopes for two-span continuous beam of illustrative example 31

Example Factored moment and factored shear envelopes for two-span continuous beam of illustrative example 31

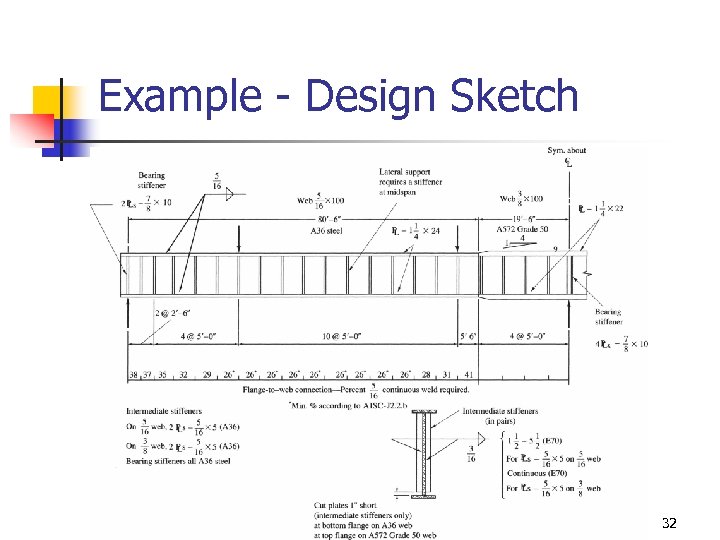

Example - Design Sketch 32

Example - Design Sketch 32