25aab014aab1feb5c6a57774be18cb53.ppt

- Количество слайдов: 34

Emission Standards for SI Marine Engines Mike Samulski Office of Transportation and Air Quality International Boat Builders’ Exhibition & Conference EMD Meeting October 6, 2008 1

Emission Standards for SI Marine Engines Mike Samulski Office of Transportation and Air Quality International Boat Builders’ Exhibition & Conference EMD Meeting October 6, 2008 1

Outline • • 2 Overview of new standards Spark-ignition marine engine categories Program details Not-to-exceed zone Small businesses Evaporative emissions Certification Questions

Outline • • 2 Overview of new standards Spark-ignition marine engine categories Program details Not-to-exceed zone Small businesses Evaporative emissions Certification Questions

Final Rule • On September 4, 2008, EPA Administrator Steve Johnson signed, into law, new exhaust and evaporative emission standards for spark-ignition marine engines and vessels. • These standards apply only to new engines and vessels sold for use in the United States. • The standards will help reduce harmful health effects of ozone and carbon monoxide from these products. 3

Final Rule • On September 4, 2008, EPA Administrator Steve Johnson signed, into law, new exhaust and evaporative emission standards for spark-ignition marine engines and vessels. • These standards apply only to new engines and vessels sold for use in the United States. • The standards will help reduce harmful health effects of ozone and carbon monoxide from these products. 3

Final Standards: Overview • HC+NOx exhaust emission standards for SI marine engines are similar in stringency to existing standards in California • New CO exhaust emission standards for all SI marine engines • New Not-to-Exceed provisions • New evaporative emission standards 4

Final Standards: Overview • HC+NOx exhaust emission standards for SI marine engines are similar in stringency to existing standards in California • New CO exhaust emission standards for all SI marine engines • New Not-to-Exceed provisions • New evaporative emission standards 4

Engine Categories SI Marine • Outboards/PWC • Sterndrive/Inboards – Jetboats – High performance – Air boats • Marine generators Small SI as well 5

Engine Categories SI Marine • Outboards/PWC • Sterndrive/Inboards – Jetboats – High performance – Air boats • Marine generators Small SI as well 5

Program Details OB/PWC Engines Certification SD/I Engines Jetboats High performance Evaporative Generator Sets Small business provisions 6 NTE zone

Program Details OB/PWC Engines Certification SD/I Engines Jetboats High performance Evaporative Generator Sets Small business provisions 6 NTE zone

![Outboards/PWC Pollutant Maximum Power (P) Standard [g/k. W-hr] Model Year HC+NOx ≤ 4. 3 Outboards/PWC Pollutant Maximum Power (P) Standard [g/k. W-hr] Model Year HC+NOx ≤ 4. 3](https://present5.com/presentation/25aab014aab1feb5c6a57774be18cb53/image-7.jpg) Outboards/PWC Pollutant Maximum Power (P) Standard [g/k. W-hr] Model Year HC+NOx ≤ 4. 3 k. W > 4. 3 k. W 30 2. 1 + 0. 09 × (151 +557/P 0. 9) 2010 CO ≤ 40 k. W > 40 k. W 500 – 5. 0 × P 300 2010 • Same HC+NOx standards as CARB 2008 • Can be achieved with existing technology – 2 -stroke direct injection engines – 4 -stroke engines • Will essentially phase-out carbureted 2 stroke engines 7

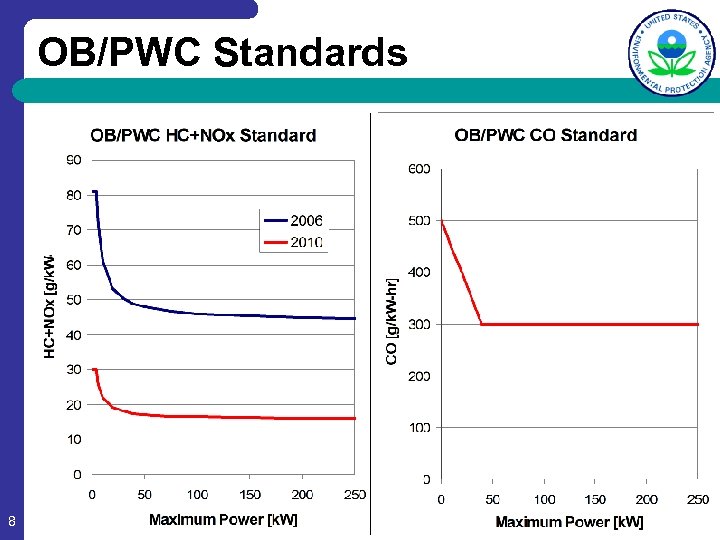

Outboards/PWC Pollutant Maximum Power (P) Standard [g/k. W-hr] Model Year HC+NOx ≤ 4. 3 k. W > 4. 3 k. W 30 2. 1 + 0. 09 × (151 +557/P 0. 9) 2010 CO ≤ 40 k. W > 40 k. W 500 – 5. 0 × P 300 2010 • Same HC+NOx standards as CARB 2008 • Can be achieved with existing technology – 2 -stroke direct injection engines – 4 -stroke engines • Will essentially phase-out carbureted 2 stroke engines 7

OB/PWC Standards 8

OB/PWC Standards 8

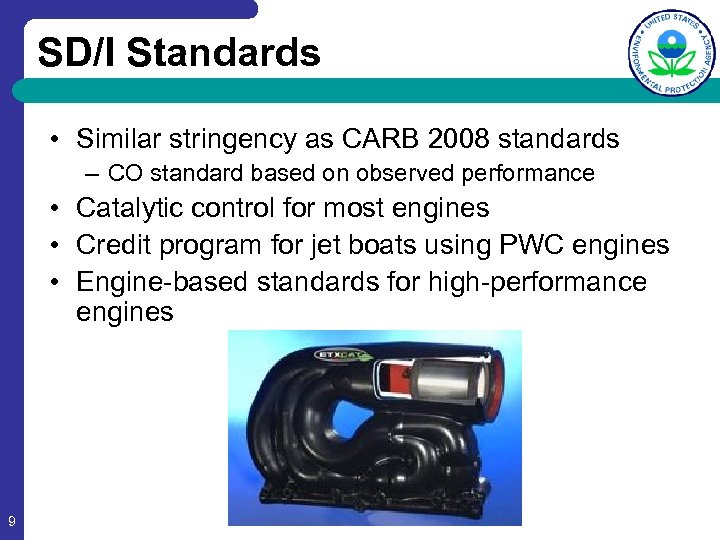

SD/I Standards • Similar stringency as CARB 2008 standards – CO standard based on observed performance • Catalytic control for most engines • Credit program for jet boats using PWC engines • Engine-based standards for high-performance engines 9

SD/I Standards • Similar stringency as CARB 2008 standards – CO standard based on observed performance • Catalytic control for most engines • Credit program for jet boats using PWC engines • Engine-based standards for high-performance engines 9

![SD/I Standards Maximum Power HC+NOx [g/k. W-hr] CO [g/k. W-hr] Model Year ≤ 373 SD/I Standards Maximum Power HC+NOx [g/k. W-hr] CO [g/k. W-hr] Model Year ≤ 373](https://present5.com/presentation/25aab014aab1feb5c6a57774be18cb53/image-10.jpg) SD/I Standards Maximum Power HC+NOx [g/k. W-hr] CO [g/k. W-hr] Model Year ≤ 373 k. Wa 5. 0 75 2010 b High performance enginesc ≤ 485 k. W 20. 0 16. 0 350 2011 High performance enginesc > 485 k. W 25. 0 22. 0 350 2011 This category also includes engines >373 k. W that do not otherwise meet the definition of “high-performance. ” b 2011 for small-businesses and for engines built using the 4. 3 L or 8. 1 L GM engine blocks. c For small businesses, the 2010 standards do not apply and the 2011 standards are delayed until 2013. a 10

SD/I Standards Maximum Power HC+NOx [g/k. W-hr] CO [g/k. W-hr] Model Year ≤ 373 k. Wa 5. 0 75 2010 b High performance enginesc ≤ 485 k. W 20. 0 16. 0 350 2011 High performance enginesc > 485 k. W 25. 0 22. 0 350 2011 This category also includes engines >373 k. W that do not otherwise meet the definition of “high-performance. ” b 2011 for small-businesses and for engines built using the 4. 3 L or 8. 1 L GM engine blocks. c For small businesses, the 2010 standards do not apply and the 2011 standards are delayed until 2013. a 10

SD/I Provisions • Many similar provisions as for OB/PWC – Averaging, banking, and trading – Closed crankcase – Emissions related warranty – Similar test procedures • Some differences 11 – Onboard diagnostics – No production line testing – No manufacturer run -use test program in

SD/I Provisions • Many similar provisions as for OB/PWC – Averaging, banking, and trading – Closed crankcase – Emissions related warranty – Similar test procedures • Some differences 11 – Onboard diagnostics – No production line testing – No manufacturer run -use test program in

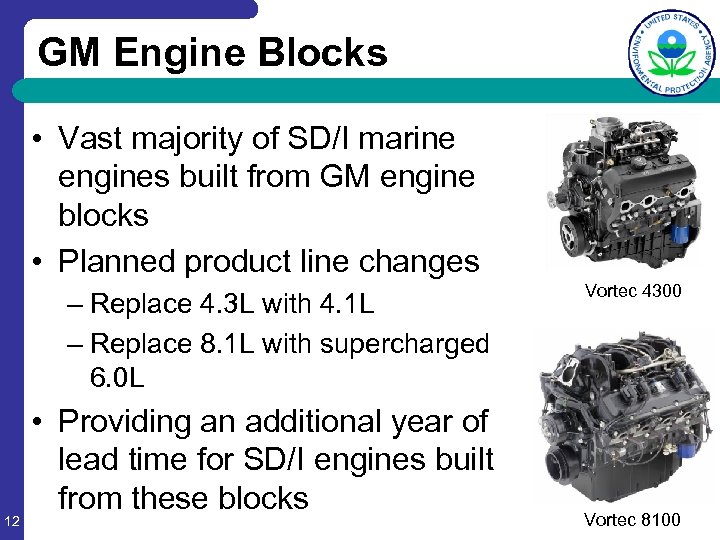

GM Engine Blocks • Vast majority of SD/I marine engines built from GM engine blocks • Planned product line changes – Replace 4. 3 L with 4. 1 L – Replace 8. 1 L with supercharged 6. 0 L 12 • Providing an additional year of lead time for SD/I engines built from these blocks Vortec 4300 Vortec 8100

GM Engine Blocks • Vast majority of SD/I marine engines built from GM engine blocks • Planned product line changes – Replace 4. 3 L with 4. 1 L – Replace 8. 1 L with supercharged 6. 0 L 12 • Providing an additional year of lead time for SD/I engines built from these blocks Vortec 4300 Vortec 8100

High Performance Engines • Short useful life and warranty periods • No NTE standards • Most manufacturers eligible for small business provisions • Assigned emission factors • 15% torque at idle during test • Simplified testing 13

High Performance Engines • Short useful life and warranty periods • No NTE standards • Most manufacturers eligible for small business provisions • Assigned emission factors • 15% torque at idle during test • Simplified testing 13

![Marine Generator Sets Engine Category Size HC+NOx [g/k. W-hr] CO [g/k. W-hr] Model Year Marine Generator Sets Engine Category Size HC+NOx [g/k. W-hr] CO [g/k. W-hr] Model Year](https://present5.com/presentation/25aab014aab1feb5c6a57774be18cb53/image-14.jpg) Marine Generator Sets Engine Category Size HC+NOx [g/k. W-hr] CO [g/k. W-hr] Model Year Generator Sets ≤ 19 k. W < 225 cc > 225 cc 10. 0 8. 0 5. 0 2012 2011 • Remain classified as small SI engines • Stringent CO standard based on new catalystequipped marine generators 14

Marine Generator Sets Engine Category Size HC+NOx [g/k. W-hr] CO [g/k. W-hr] Model Year Generator Sets ≤ 19 k. W < 225 cc > 225 cc 10. 0 8. 0 5. 0 2012 2011 • Remain classified as small SI engines • Stringent CO standard based on new catalystequipped marine generators 14

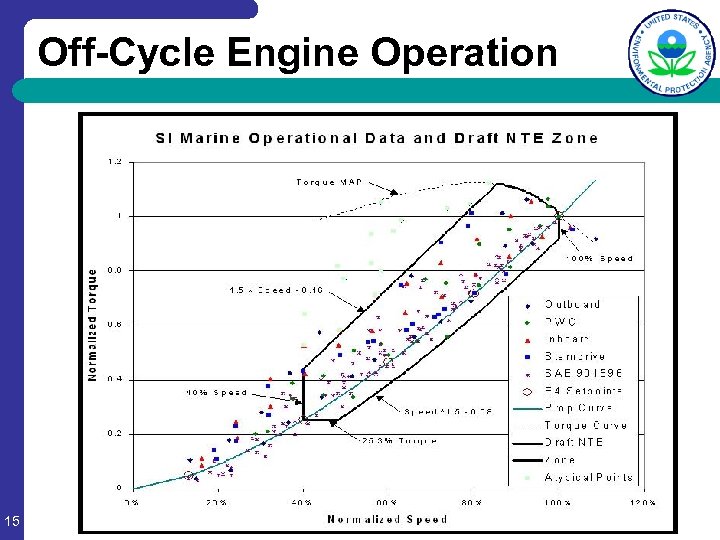

Off-Cycle Engine Operation 15

Off-Cycle Engine Operation 15

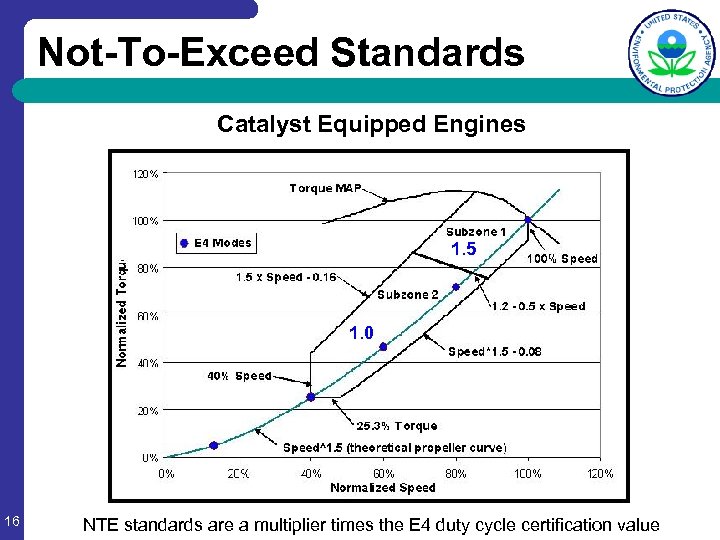

Not-To-Exceed Standards Catalyst Equipped Engines 1. 5 1. 0 16 NTE standards are a multiplier times the E 4 duty cycle certification value

Not-To-Exceed Standards Catalyst Equipped Engines 1. 5 1. 0 16 NTE standards are a multiplier times the E 4 duty cycle certification value

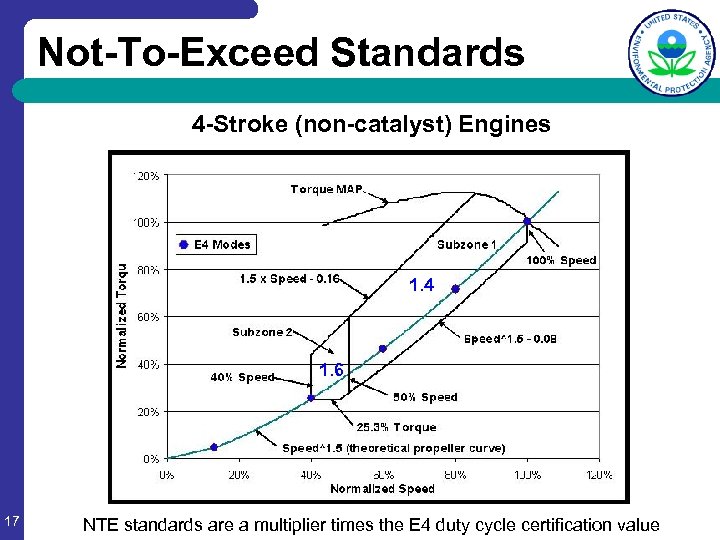

Not-To-Exceed Standards 4 -Stroke (non-catalyst) Engines 1. 4 1. 6 17 NTE standards are a multiplier times the E 4 duty cycle certification value

Not-To-Exceed Standards 4 -Stroke (non-catalyst) Engines 1. 4 1. 6 17 NTE standards are a multiplier times the E 4 duty cycle certification value

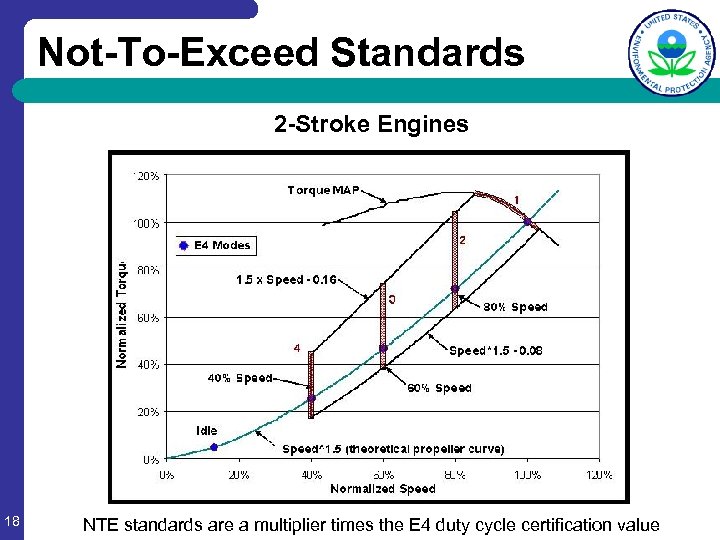

Not-To-Exceed Standards 2 -Stroke Engines 18 NTE standards are a multiplier times the E 4 duty cycle certification value

Not-To-Exceed Standards 2 -Stroke Engines 18 NTE standards are a multiplier times the E 4 duty cycle certification value

Small Business Provisions • • • 19 Broad engine families for high performance Additional lead time for SD/I Early ABT bonus credits for SD/I No production line testing Assigned deterioration factors Economic hardship relief

Small Business Provisions • • • 19 Broad engine families for high performance Additional lead time for SD/I Early ABT bonus credits for SD/I No production line testing Assigned deterioration factors Economic hardship relief

Evaporative Emissions • Portable tanks – Tank permeation – Self-sealing vent • Vessels – Hose and tank permeation – Diurnal emissions – Refueling spillage • Engines – Standards apply to hose & tanks directly mounted on engines 20 309 Boat Fuel Systems: Design and Compliance

Evaporative Emissions • Portable tanks – Tank permeation – Self-sealing vent • Vessels – Hose and tank permeation – Diurnal emissions – Refueling spillage • Engines – Standards apply to hose & tanks directly mounted on engines 20 309 Boat Fuel Systems: Design and Compliance

Certification Procedures The ABCs of getting a Certificate of Conformity with EPA emission regulations… 21

Certification Procedures The ABCs of getting a Certificate of Conformity with EPA emission regulations… 21

Certification Procedures • The basics: – If your product is subject to EPA emissions standards, you must obtain a Certificate of Conformity before you introduce it into US Commerce. • Must demonstrate compliance with the applicable regulation. – Certificates are issued by the Compliance and Innovative Solutions Division (CISD), Office of Transportation and Air Quality. • CISD’s Heavy-Duty and Nonroad Engines Group processes the Applications for Certification for Marine SI – You must certify every model year or production period 22

Certification Procedures • The basics: – If your product is subject to EPA emissions standards, you must obtain a Certificate of Conformity before you introduce it into US Commerce. • Must demonstrate compliance with the applicable regulation. – Certificates are issued by the Compliance and Innovative Solutions Division (CISD), Office of Transportation and Air Quality. • CISD’s Heavy-Duty and Nonroad Engines Group processes the Applications for Certification for Marine SI – You must certify every model year or production period 22

How do I certify? • To obtain a Certificate of Conformity: 1. Read the regulations! • • • SD/I & components: 40 CFR Parts 1045, 1060, 1065 and 1068 OB/PWC: add 40 CFR Part 91 http: //epa. gov/otaq/marinesi. htm 2. Request an EPA Manufacturer Code: • • http: //epa. gov/otaq/verify/mfr-code. htm Contact: Mr. Petersen, 734. 214. 4204; petersen. pete@epa. gov 3. Determine: • • 23 Engine Families/Permeation Families The type of Certificate you need: – Exhaust, Evaporative (fuel lines, fuel tanks), or both

How do I certify? • To obtain a Certificate of Conformity: 1. Read the regulations! • • • SD/I & components: 40 CFR Parts 1045, 1060, 1065 and 1068 OB/PWC: add 40 CFR Part 91 http: //epa. gov/otaq/marinesi. htm 2. Request an EPA Manufacturer Code: • • http: //epa. gov/otaq/verify/mfr-code. htm Contact: Mr. Petersen, 734. 214. 4204; petersen. pete@epa. gov 3. Determine: • • 23 Engine Families/Permeation Families The type of Certificate you need: – Exhaust, Evaporative (fuel lines, fuel tanks), or both

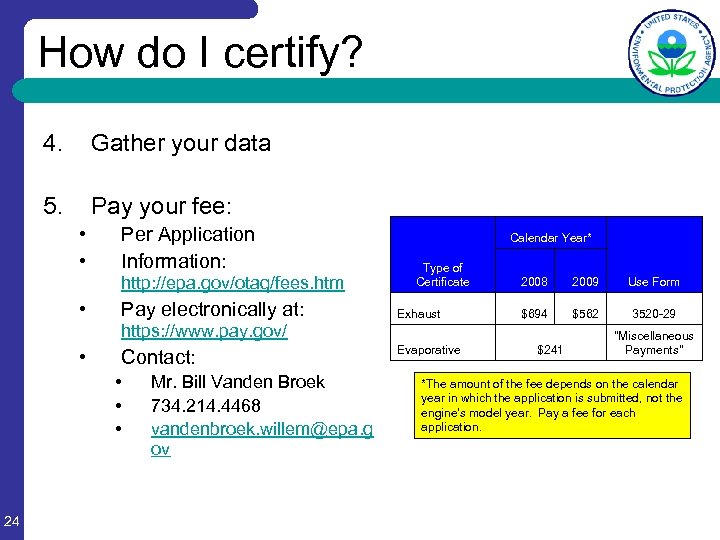

How do I certify? 4. Gather your data 5. Pay your fee: • • Per Application Information: http: //epa. gov/otaq/fees. htm • Pay electronically at: Calendar Year* Type of Certificate Exhaust 2008 2009 Use Form $694 $562 3520 -29 https: //www. pay. gov/ • Contact: • • • 24 Mr. Bill Vanden Broek 734. 214. 4468 vandenbroek. willem@epa. g ov Evaporative $241 "Miscellaneous Payments" *The amount of the fee depends on the calendar year in which the application is submitted, not the engine’s model year. Pay a fee for each application.

How do I certify? 4. Gather your data 5. Pay your fee: • • Per Application Information: http: //epa. gov/otaq/fees. htm • Pay electronically at: Calendar Year* Type of Certificate Exhaust 2008 2009 Use Form $694 $562 3520 -29 https: //www. pay. gov/ • Contact: • • • 24 Mr. Bill Vanden Broek 734. 214. 4468 vandenbroek. willem@epa. g ov Evaporative $241 "Miscellaneous Payments" *The amount of the fee depends on the calendar year in which the application is submitted, not the engine’s model year. Pay a fee for each application.

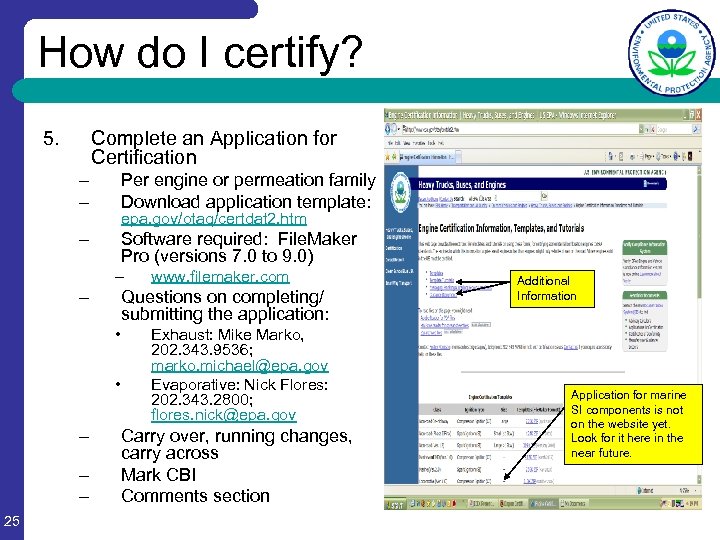

How do I certify? 5. Complete an Application for Certification – – Per engine or permeation family Download application template: – Software required: File. Maker Pro (versions 7. 0 to 9. 0) epa. gov/otaq/certdat 2. htm – – Questions on completing/ submitting the application: • • – – – 25 www. filemaker. com Exhaust: Mike Marko, 202. 343. 9536; marko. michael@epa. gov Evaporative: Nick Flores: 202. 343. 2800; flores. nick@epa. gov Carry over, running changes, carry across Mark CBI Comments section Additional Information Application for marine SI components is not on the website yet. Look for it here in the near future.

How do I certify? 5. Complete an Application for Certification – – Per engine or permeation family Download application template: – Software required: File. Maker Pro (versions 7. 0 to 9. 0) epa. gov/otaq/certdat 2. htm – – Questions on completing/ submitting the application: • • – – – 25 www. filemaker. com Exhaust: Mike Marko, 202. 343. 9536; marko. michael@epa. gov Evaporative: Nick Flores: 202. 343. 2800; flores. nick@epa. gov Carry over, running changes, carry across Mark CBI Comments section Additional Information Application for marine SI components is not on the website yet. Look for it here in the near future.

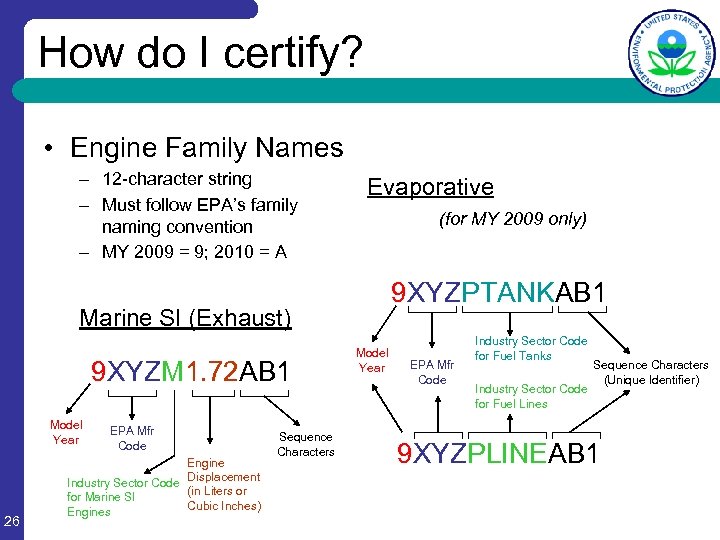

How do I certify? • Engine Family Names – 12 -character string – Must follow EPA’s family naming convention – MY 2009 = 9; 2010 = A Evaporative (for MY 2009 only) 9 XYZPTANKAB 1 Marine SI (Exhaust) 9 XYZM 1. 72 AB 1 Model Year 26 EPA Mfr Code Engine Industry Sector Code Displacement (in Liters or for Marine SI Cubic Inches) Engines Sequence Characters Model Year EPA Mfr Code Industry Sector Code for Fuel Tanks Industry Sector Code for Fuel Lines Sequence Characters (Unique Identifier) 9 XYZPLINEAB 1

How do I certify? • Engine Family Names – 12 -character string – Must follow EPA’s family naming convention – MY 2009 = 9; 2010 = A Evaporative (for MY 2009 only) 9 XYZPTANKAB 1 Marine SI (Exhaust) 9 XYZM 1. 72 AB 1 Model Year 26 EPA Mfr Code Engine Industry Sector Code Displacement (in Liters or for Marine SI Cubic Inches) Engines Sequence Characters Model Year EPA Mfr Code Industry Sector Code for Fuel Tanks Industry Sector Code for Fuel Lines Sequence Characters (Unique Identifier) 9 XYZPLINEAB 1

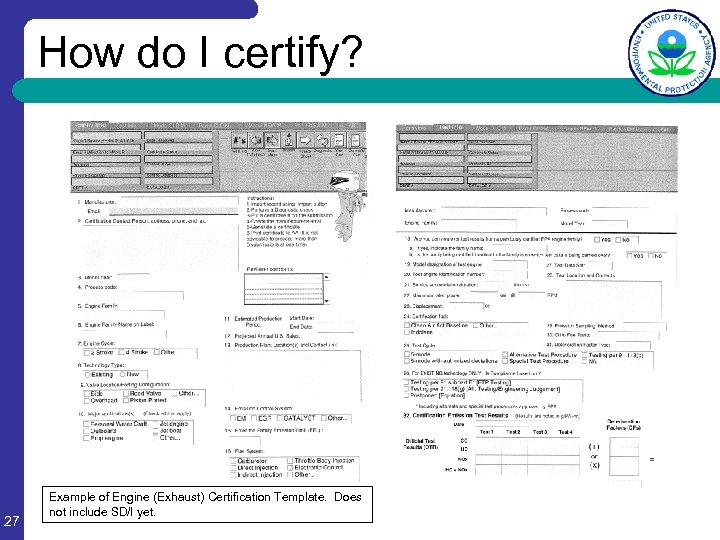

How do I certify? 27 Example of Engine (Exhaust) Certification Template. Does not include SD/I yet.

How do I certify? 27 Example of Engine (Exhaust) Certification Template. Does not include SD/I yet.

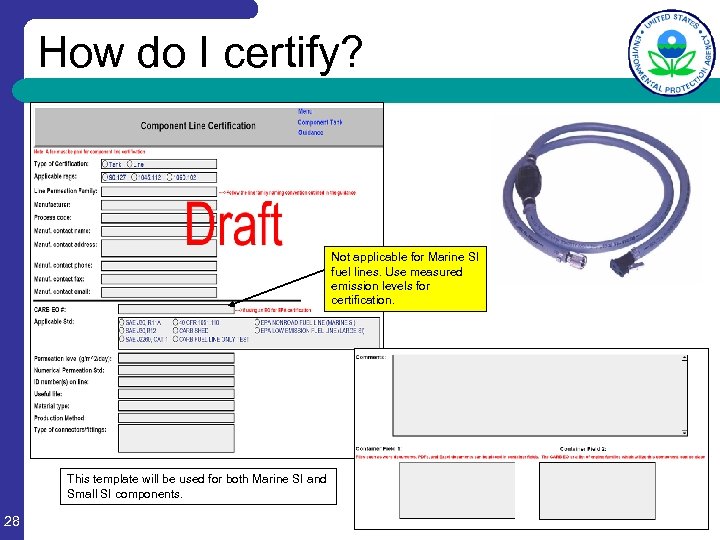

How do I certify? Not applicable for Marine SI fuel lines. Use measured emission levels for certification. This template will be used for both Marine SI and Small SI components. 28

How do I certify? Not applicable for Marine SI fuel lines. Use measured emission levels for certification. This template will be used for both Marine SI and Small SI components. 28

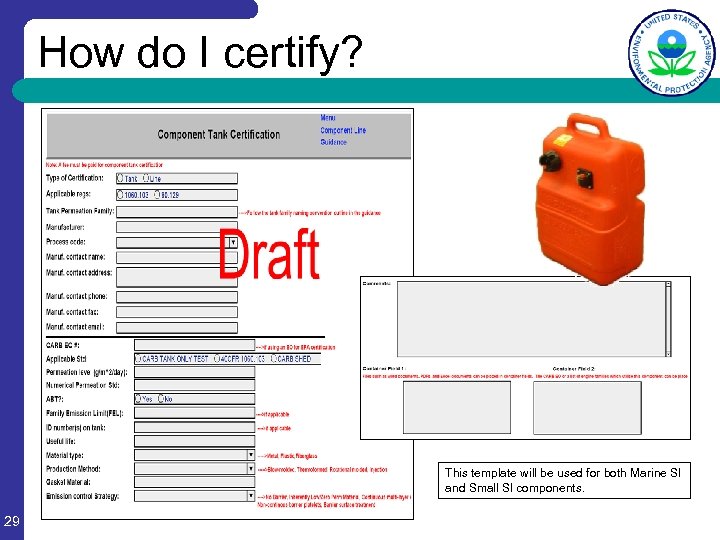

How do I certify? This template will be used for both Marine SI and Small SI components. 29

How do I certify? This template will be used for both Marine SI and Small SI components. 29

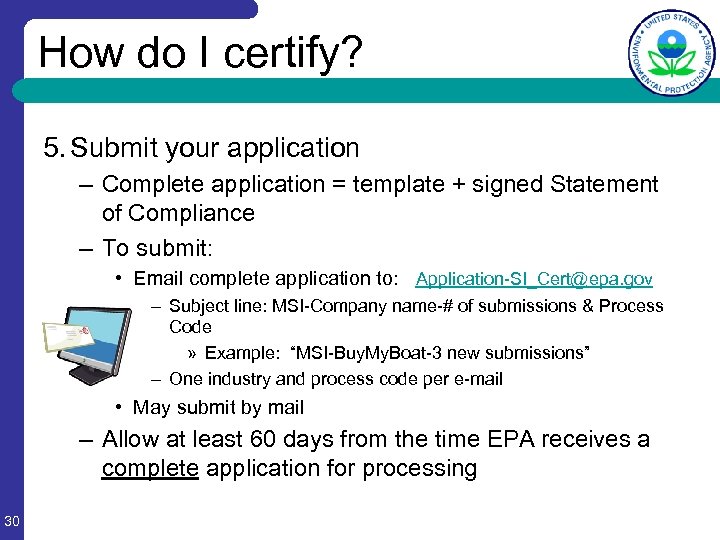

How do I certify? 5. Submit your application – Complete application = template + signed Statement of Compliance – To submit: • Email complete application to: Application-SI_Cert@epa. gov – Subject line: MSI-Company name-# of submissions & Process Code » Example: “MSI-Buy. My. Boat-3 new submissions” – One industry and process code per e-mail • May submit by mail – Allow at least 60 days from the time EPA receives a complete application for processing 30

How do I certify? 5. Submit your application – Complete application = template + signed Statement of Compliance – To submit: • Email complete application to: Application-SI_Cert@epa. gov – Subject line: MSI-Company name-# of submissions & Process Code » Example: “MSI-Buy. My. Boat-3 new submissions” – One industry and process code per e-mail • May submit by mail – Allow at least 60 days from the time EPA receives a complete application for processing 30

EPA Review • Mike Marko or Nick Flores receive the applications and check them for completeness – Contact them if you have questions about the templates or need to know where your cert is • If you have a question about Marine SI regulations, contact: Nydia Yanira Reyes – reyes-morales. nydia@epa. gov (e-mail preferred) – 202. 343. 9264 • Send special requests to: – Ms. Khesha Jennings, Manager, Heavy-Duty and Nonroad Engines Group • jennings. khesha@epa. gov 31

EPA Review • Mike Marko or Nick Flores receive the applications and check them for completeness – Contact them if you have questions about the templates or need to know where your cert is • If you have a question about Marine SI regulations, contact: Nydia Yanira Reyes – reyes-morales. nydia@epa. gov (e-mail preferred) – 202. 343. 9264 • Send special requests to: – Ms. Khesha Jennings, Manager, Heavy-Duty and Nonroad Engines Group • jennings. khesha@epa. gov 31

EPA Review • Please keep in mind that once you certify, you must comply with all parts of the regulation(s) that apply to your product, such as: – – – – – 32 Labeling Requirements Average, Banking and Trading (AB&T) Production-line Testing (PLT) In-use Testing Warranties Defect Reports & Recalls Owner’s Manual requirements Selective Enforcement Audits Recordkeeping, etc

EPA Review • Please keep in mind that once you certify, you must comply with all parts of the regulation(s) that apply to your product, such as: – – – – – 32 Labeling Requirements Average, Banking and Trading (AB&T) Production-line Testing (PLT) In-use Testing Warranties Defect Reports & Recalls Owner’s Manual requirements Selective Enforcement Audits Recordkeeping, etc

Other useful information Heavy-Duty and Nonroad Engines Group Regular Mail: US EPA 1200 Pennsylvania Avenue, NW Mail Code 6403 J Washington, DC 20460 Courier Address: US EPA 1310 L Street, NW, Mail Code 6405 J Washington, DC 20005 33 Fax: 202. 343. 2804 • • • To submit: – AB&T: abt_engine@epa. gov – PLT (OB/PWC): plt@epa. gov Cert data available @: www. epa. gov/otaq/certdata. htm Imports Line: 734. 214. 4100 – Email-imports@epa. gov Exemptions: David Hurlin – 734. 214. 4098 CBI: Robert Doyle, 202. 343. 9258 – Doyle. robert@epa. gov

Other useful information Heavy-Duty and Nonroad Engines Group Regular Mail: US EPA 1200 Pennsylvania Avenue, NW Mail Code 6403 J Washington, DC 20460 Courier Address: US EPA 1310 L Street, NW, Mail Code 6405 J Washington, DC 20005 33 Fax: 202. 343. 2804 • • • To submit: – AB&T: abt_engine@epa. gov – PLT (OB/PWC): plt@epa. gov Cert data available @: www. epa. gov/otaq/certdata. htm Imports Line: 734. 214. 4100 – Email-imports@epa. gov Exemptions: David Hurlin – 734. 214. 4098 CBI: Robert Doyle, 202. 343. 9258 – Doyle. robert@epa. gov

Questions http: //www. epa. gov/otaq/marinesi. htm For general program questions: Mike Samulski, Samulski. Michael@epa. gov 34 For questions regarding certification: Nydia Reyes-Morales, Reyes-Morales. Nydia@epa. gov

Questions http: //www. epa. gov/otaq/marinesi. htm For general program questions: Mike Samulski, Samulski. Michael@epa. gov 34 For questions regarding certification: Nydia Reyes-Morales, Reyes-Morales. Nydia@epa. gov