588590587dbb59ebd4d1a298461c7e48.ppt

- Количество слайдов: 43

Emerging Research Opportunities in Energy Manufacturing G. Glenn Lipscomb Chemical & Environmental Engineering, University of Toledo NSF CMMI Research and Innovation Conference Membrane and Module Manufacture Tuesday, 4 January 2011 Atlanta, GA

Emerging Research Opportunities in Energy Manufacturing G. Glenn Lipscomb Chemical & Environmental Engineering, University of Toledo NSF CMMI Research and Innovation Conference Membrane and Module Manufacture Tuesday, 4 January 2011 Atlanta, GA

Outline Membrane Separations u Flat Sheet/Spiral Wound Modules u Hollow Fiber/Module Manufacture u Module Efficiencies u Large Applications u

Outline Membrane Separations u Flat Sheet/Spiral Wound Modules u Hollow Fiber/Module Manufacture u Module Efficiencies u Large Applications u

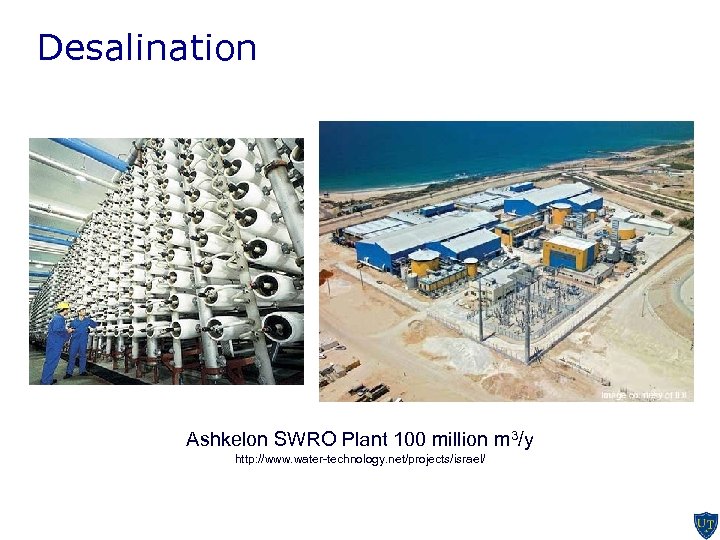

Desalination Ashkelon SWRO Plant 100 million m 3/y http: //www. water-technology. net/projects/israel/

Desalination Ashkelon SWRO Plant 100 million m 3/y http: //www. water-technology. net/projects/israel/

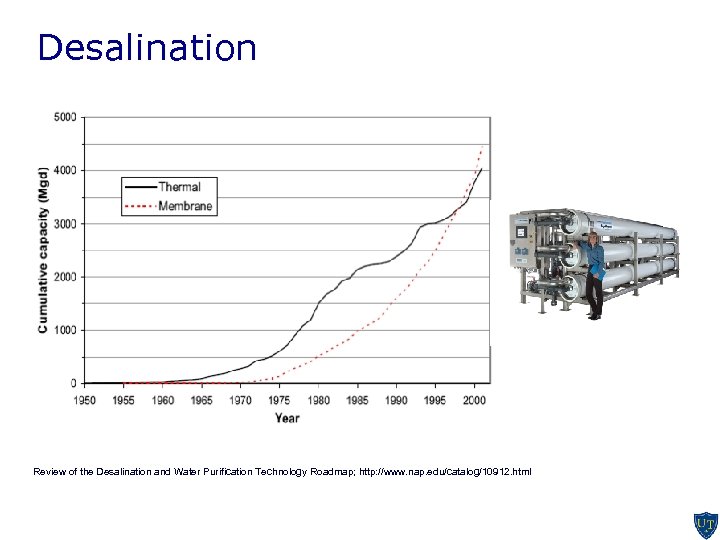

Desalination Review of the Desalination and Water Purification Technology Roadmap; http: //www. nap. edu/catalog/10912. html

Desalination Review of the Desalination and Water Purification Technology Roadmap; http: //www. nap. edu/catalog/10912. html

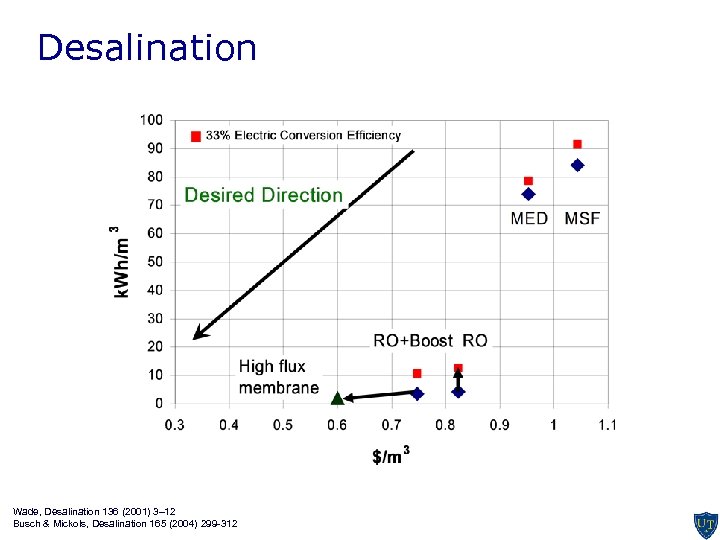

Desalination Wade, Desalination 136 (2001) 3– 12 Busch & Mickols, Desalination 165 (2004) 299 -312

Desalination Wade, Desalination 136 (2001) 3– 12 Busch & Mickols, Desalination 165 (2004) 299 -312

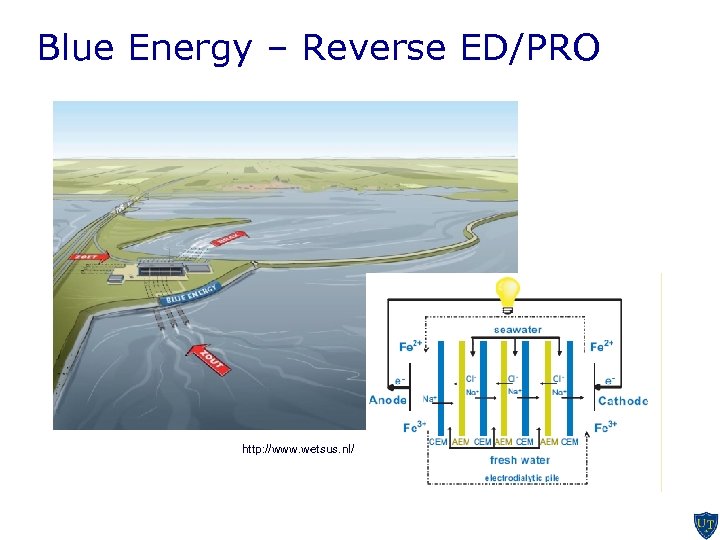

Blue Energy – Reverse ED/PRO http: //www. wetsus. nl/

Blue Energy – Reverse ED/PRO http: //www. wetsus. nl/

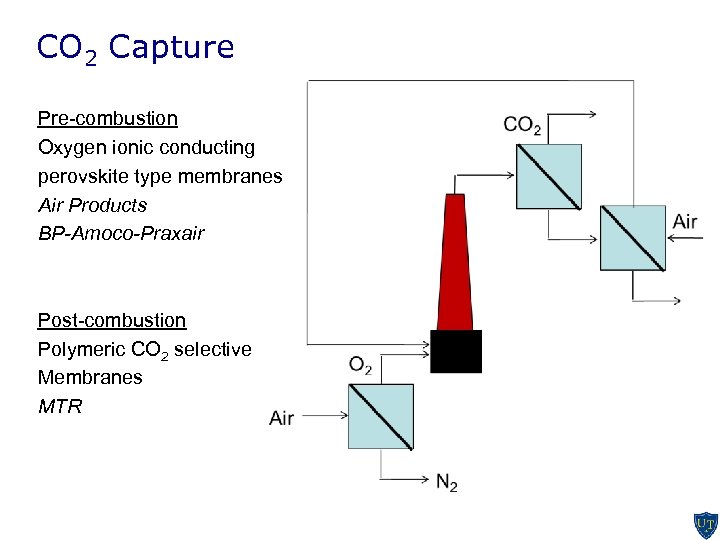

CO 2 Capture Pre-combustion Oxygen ionic conducting perovskite type membranes Air Products BP-Amoco-Praxair Post-combustion Polymeric CO 2 selective Membranes MTR

CO 2 Capture Pre-combustion Oxygen ionic conducting perovskite type membranes Air Products BP-Amoco-Praxair Post-combustion Polymeric CO 2 selective Membranes MTR

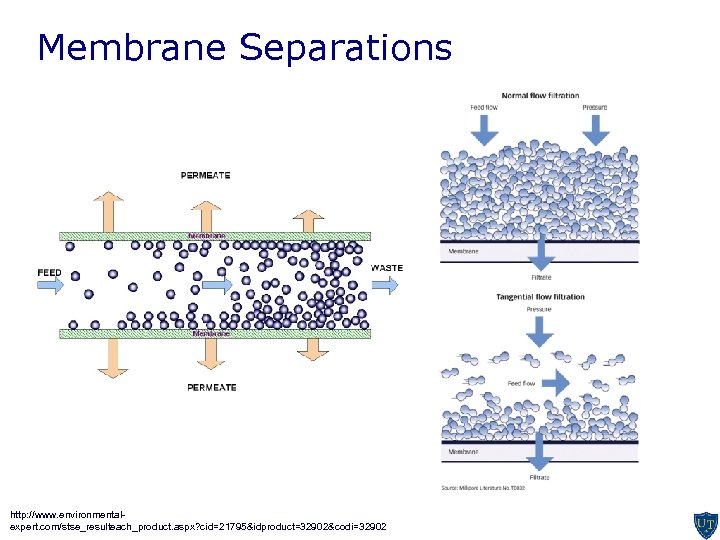

Membrane Separations http: //www. environmentalexpert. com/stse_resulteach_product. aspx? cid=21795&idproduct=32902&codi=32902

Membrane Separations http: //www. environmentalexpert. com/stse_resulteach_product. aspx? cid=21795&idproduct=32902&codi=32902

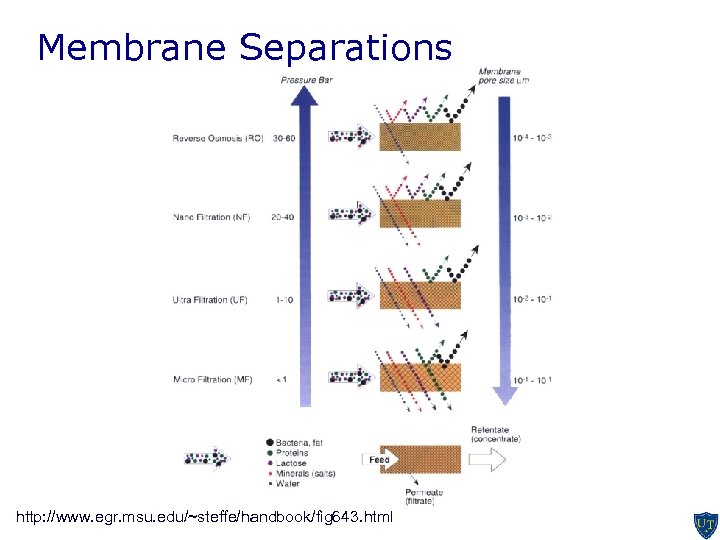

Membrane Separations http: //www. egr. msu. edu/~steffe/handbook/fig 643. html

Membrane Separations http: //www. egr. msu. edu/~steffe/handbook/fig 643. html

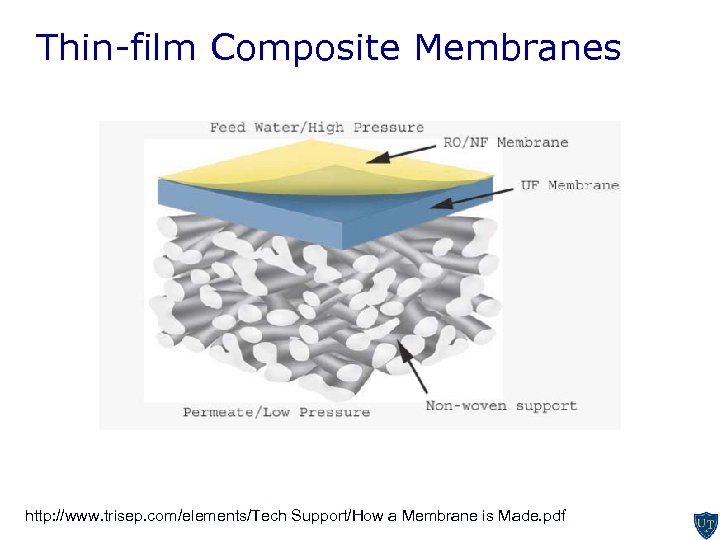

Thin-film Composite Membranes http: //www. trisep. com/elements/Tech Support/How a Membrane is Made. pdf

Thin-film Composite Membranes http: //www. trisep. com/elements/Tech Support/How a Membrane is Made. pdf

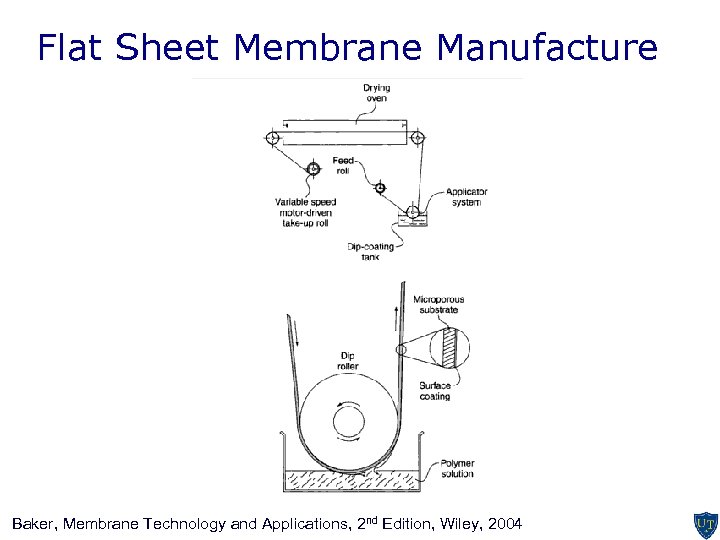

Flat Sheet Membrane Manufacture Baker, Membrane Technology and Applications, 2 nd Edition, Wiley, 2004

Flat Sheet Membrane Manufacture Baker, Membrane Technology and Applications, 2 nd Edition, Wiley, 2004

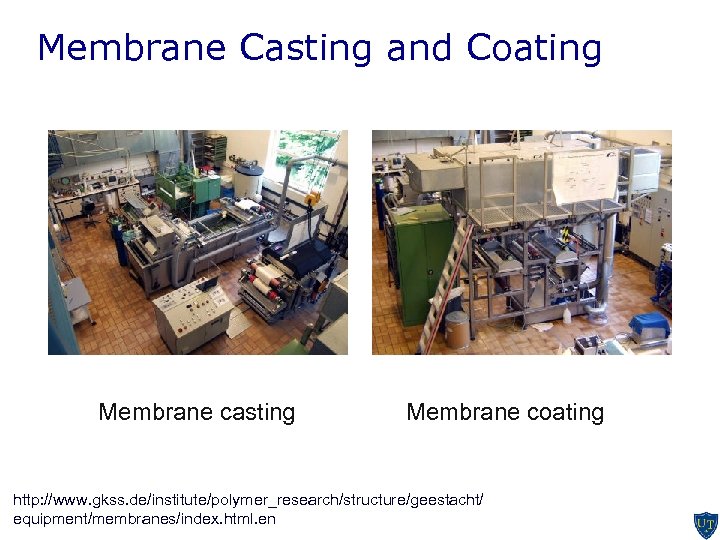

Membrane Casting and Coating Membrane casting Membrane coating http: //www. gkss. de/institute/polymer_research/structure/geestacht/ equipment/membranes/index. html. en

Membrane Casting and Coating Membrane casting Membrane coating http: //www. gkss. de/institute/polymer_research/structure/geestacht/ equipment/membranes/index. html. en

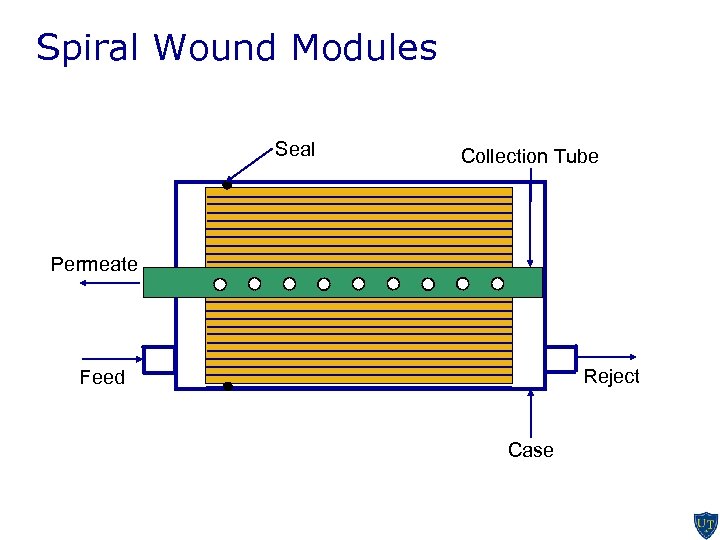

Spiral Wound Modules Seal Collection Tube Permeate Reject Feed Case

Spiral Wound Modules Seal Collection Tube Permeate Reject Feed Case

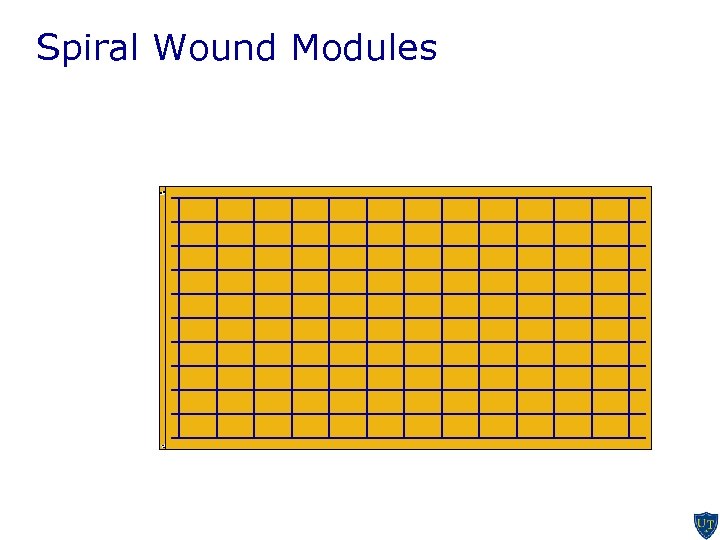

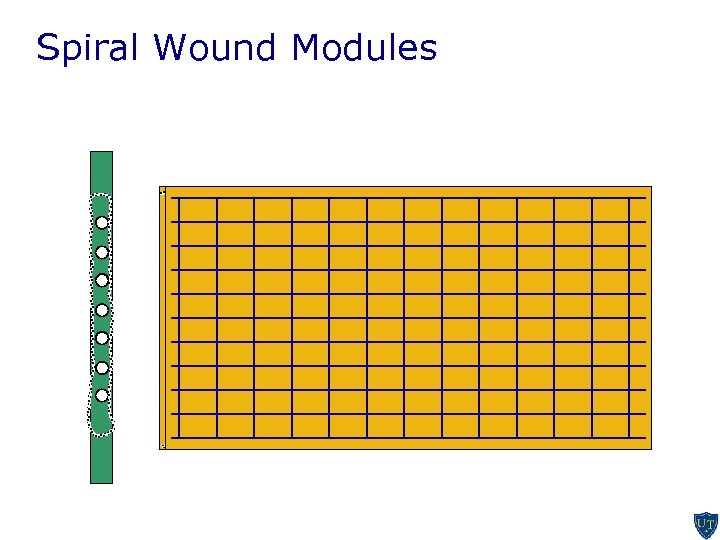

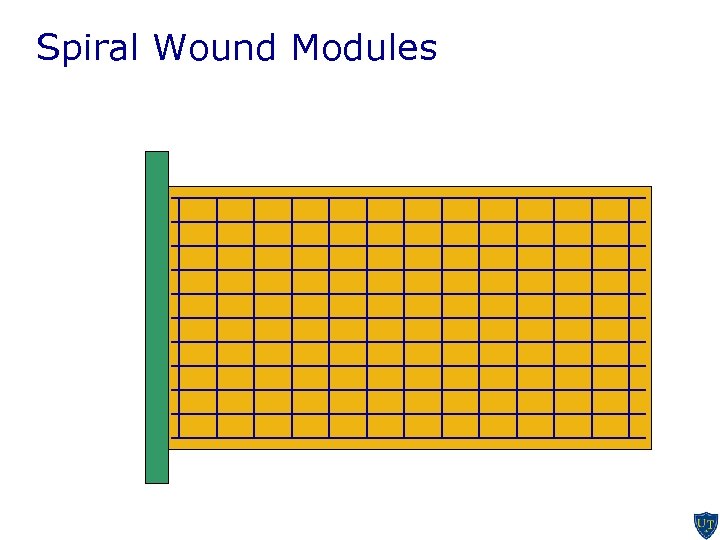

Spiral Wound Modules

Spiral Wound Modules

Spiral Wound Modules

Spiral Wound Modules

Spiral Wound Modules

Spiral Wound Modules

Spiral Wound Modules “Leaf” or “Envelope”

Spiral Wound Modules “Leaf” or “Envelope”

Spiral Wound Modules

Spiral Wound Modules

Spiral Wound Modules

Spiral Wound Modules

Spiral Wound Modules

Spiral Wound Modules

Spiral Wound Modules

Spiral Wound Modules

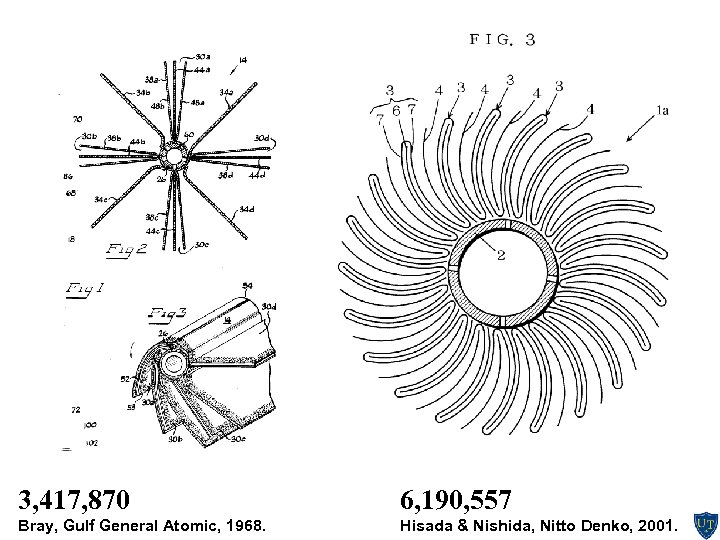

3, 417, 870 6, 190, 557 Bray, Gulf General Atomic, 1968. Hisada & Nishida, Nitto Denko, 2001.

3, 417, 870 6, 190, 557 Bray, Gulf General Atomic, 1968. Hisada & Nishida, Nitto Denko, 2001.

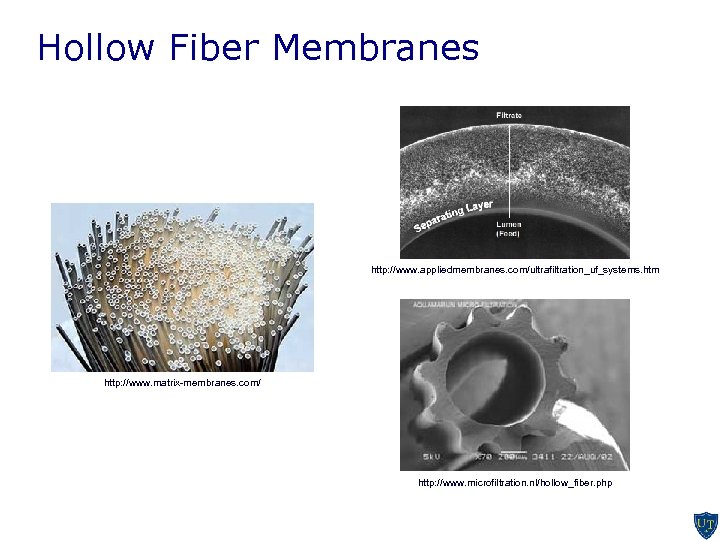

Hollow Fiber Membranes http: //www. appliedmembranes. com/ultrafiltration_uf_systems. htm http: //www. matrix-membranes. com/ http: //www. microfiltration. nl/hollow_fiber. php

Hollow Fiber Membranes http: //www. appliedmembranes. com/ultrafiltration_uf_systems. htm http: //www. matrix-membranes. com/ http: //www. microfiltration. nl/hollow_fiber. php

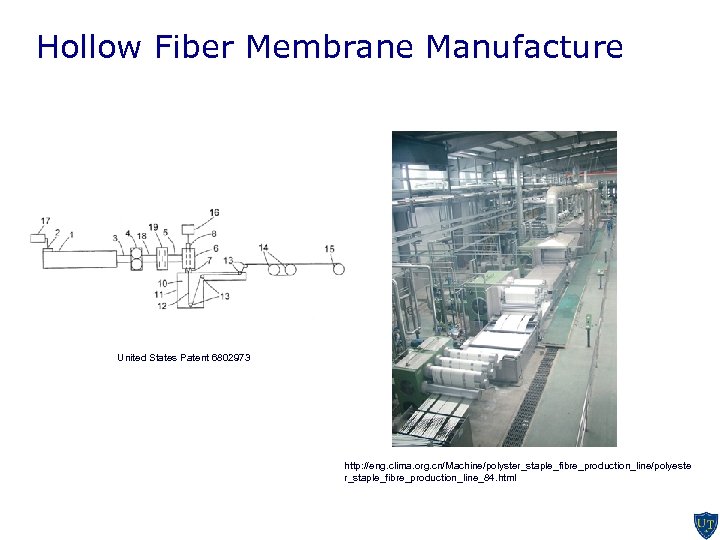

Hollow Fiber Membrane Manufacture United States Patent 6802973 http: //eng. clima. org. cn/Machine/polyster_staple_fibre_production_line/polyeste r_staple_fibre_production_line_84. html

Hollow Fiber Membrane Manufacture United States Patent 6802973 http: //eng. clima. org. cn/Machine/polyster_staple_fibre_production_line/polyeste r_staple_fibre_production_line_84. html

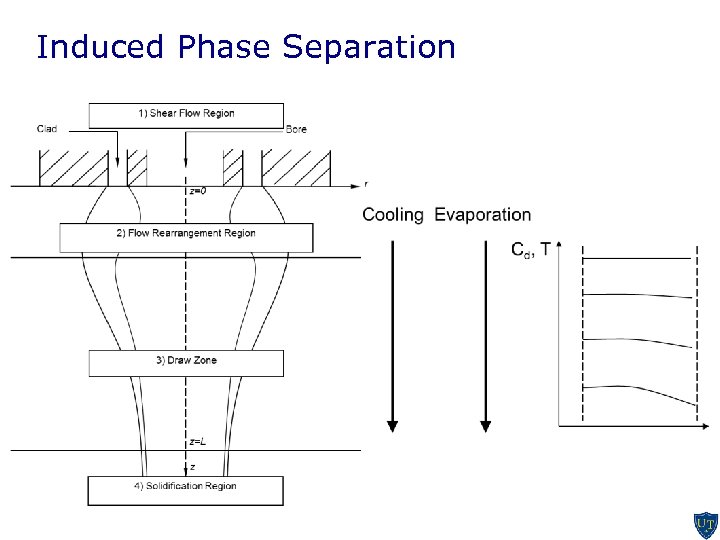

Induced Phase Separation Cooling Evaporation Cd , T Ri Ro

Induced Phase Separation Cooling Evaporation Cd , T Ri Ro

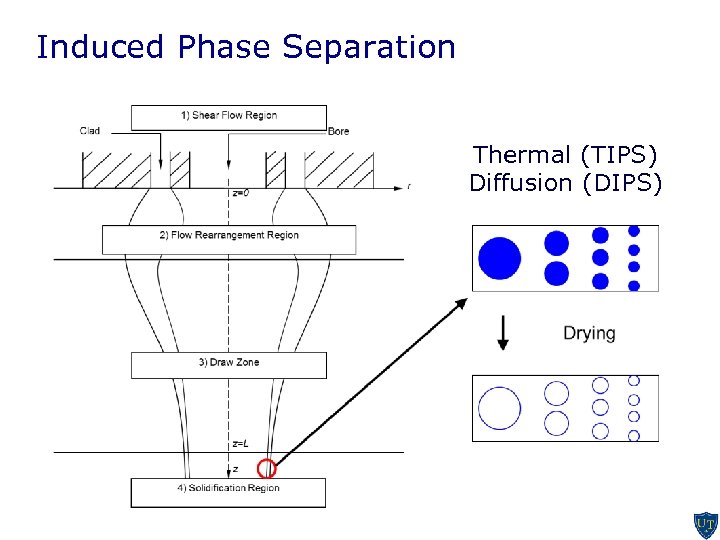

Induced Phase Separation Thermal (TIPS) Diffusion (DIPS) Hypothesis: Concentration gradient predictor of pore size and porosity asymmetry

Induced Phase Separation Thermal (TIPS) Diffusion (DIPS) Hypothesis: Concentration gradient predictor of pore size and porosity asymmetry

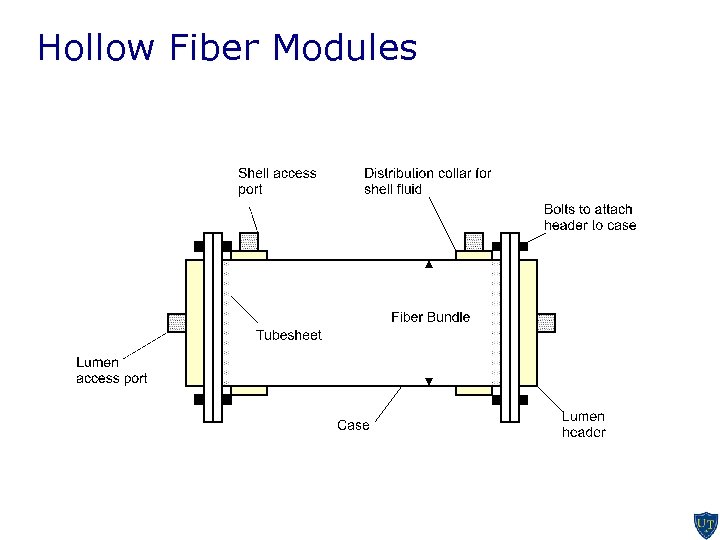

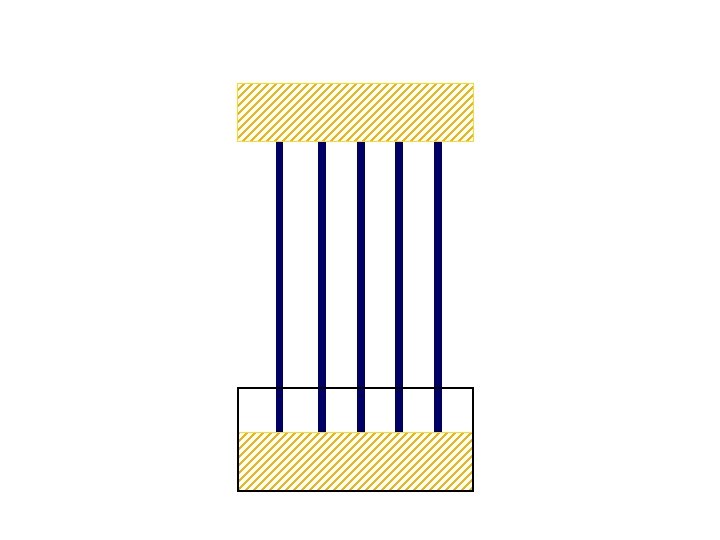

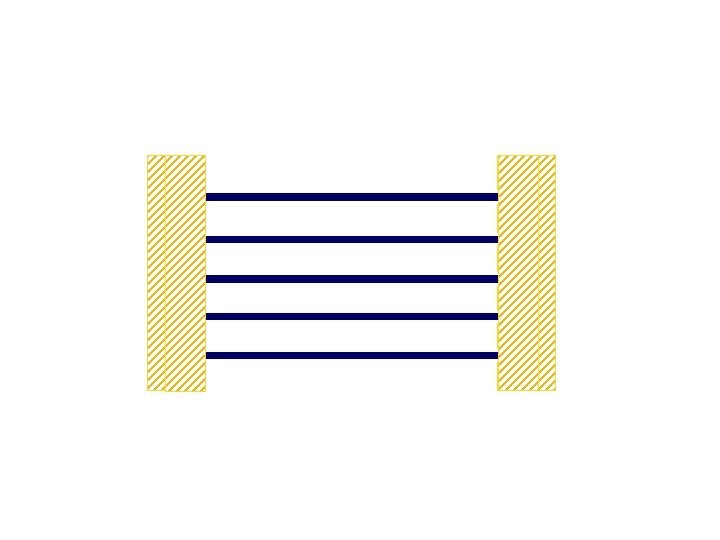

Hollow Fiber Modules

Hollow Fiber Modules

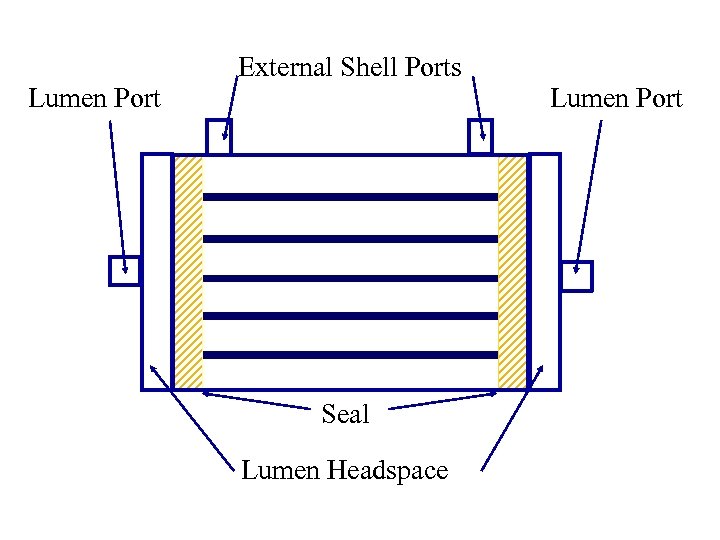

Lumen Port External Shell Ports Seal Lumen Headspace Lumen Port

Lumen Port External Shell Ports Seal Lumen Headspace Lumen Port

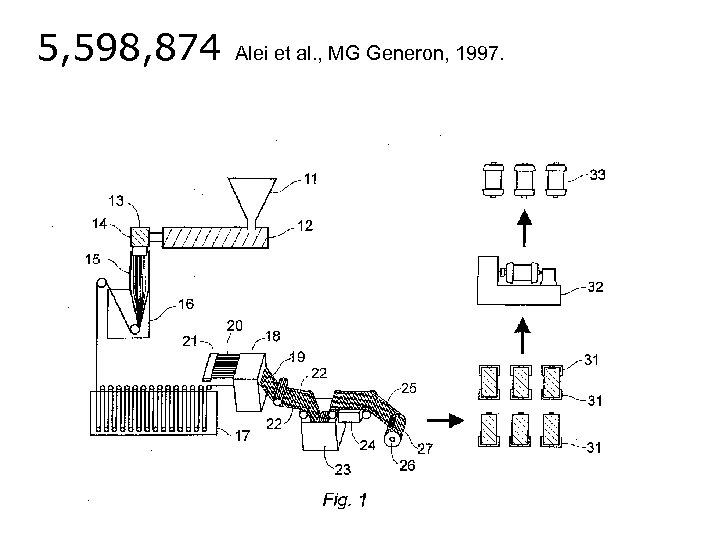

5, 598, 874 Alei et al. , MG Generon, 1997.

5, 598, 874 Alei et al. , MG Generon, 1997.

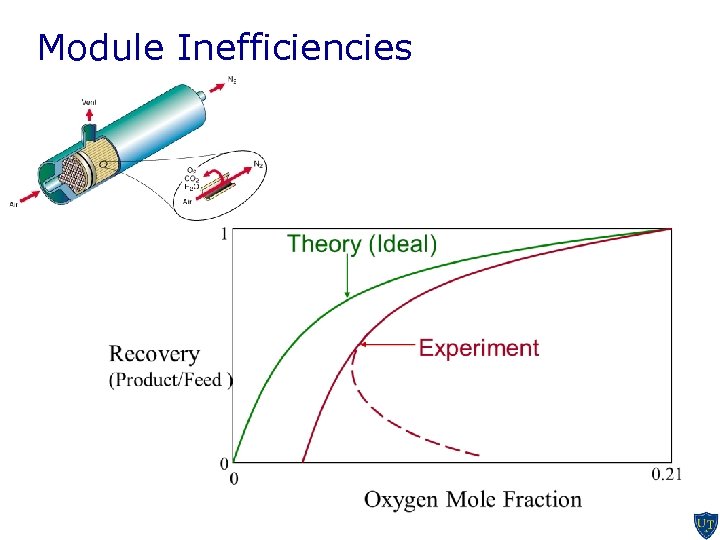

Module Inefficiencies

Module Inefficiencies

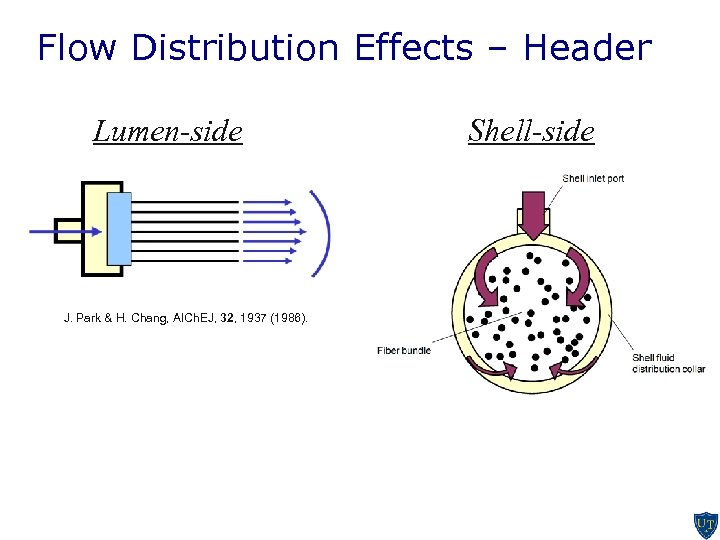

Flow Distribution Effects – Header Lumen-side J. Park & H. Chang, AICh. EJ, 32, 1937 (1986). Shell-side

Flow Distribution Effects – Header Lumen-side J. Park & H. Chang, AICh. EJ, 32, 1937 (1986). Shell-side

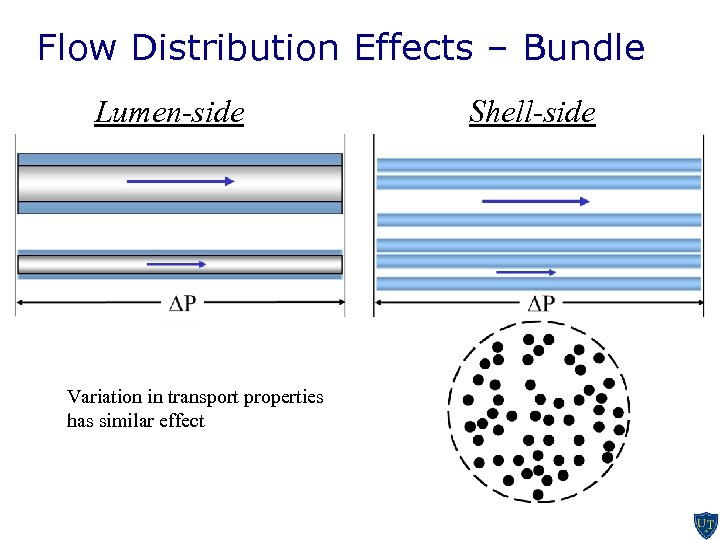

Flow Distribution Effects – Bundle Lumen-side Variation in transport properties has similar effect Shell-side

Flow Distribution Effects – Bundle Lumen-side Variation in transport properties has similar effect Shell-side

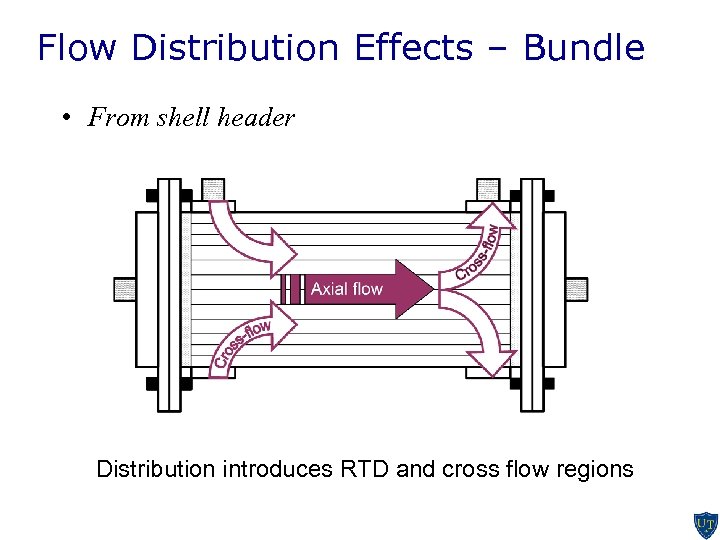

Flow Distribution Effects – Bundle • From shell header Distribution introduces RTD and cross flow regions

Flow Distribution Effects – Bundle • From shell header Distribution introduces RTD and cross flow regions

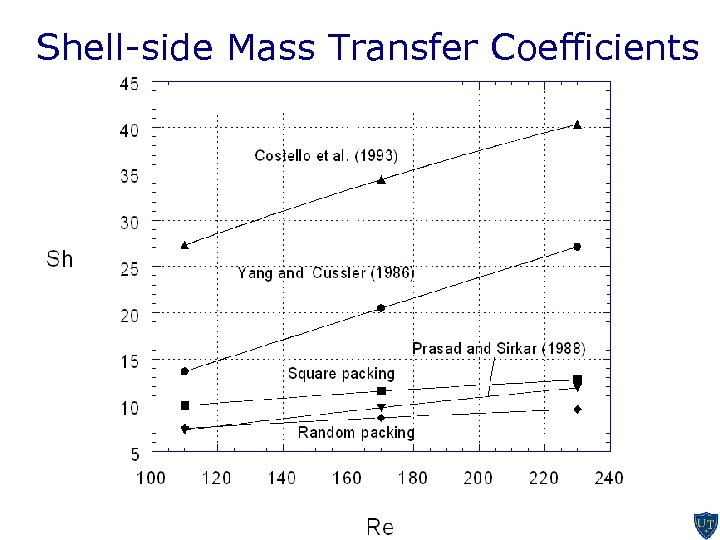

Shell-side Mass Transfer Coefficients packing fraction=0. 26, Sc=1000

Shell-side Mass Transfer Coefficients packing fraction=0. 26, Sc=1000

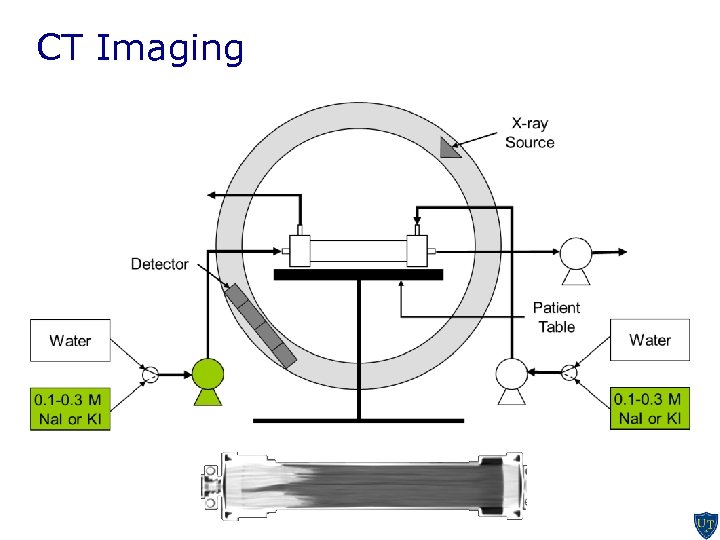

CT Imaging

CT Imaging

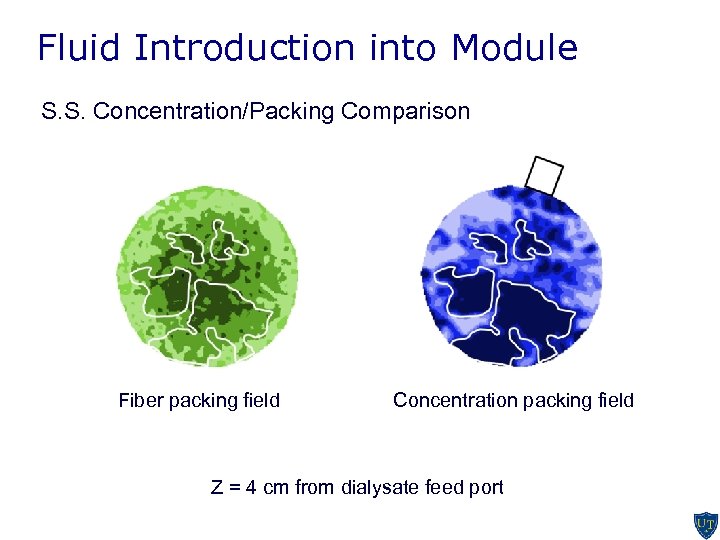

Fluid Introduction into Module S. S. Concentration/Packing Comparison Fiber packing field Concentration packing field Z = 4 cm from dialysate feed port

Fluid Introduction into Module S. S. Concentration/Packing Comparison Fiber packing field Concentration packing field Z = 4 cm from dialysate feed port

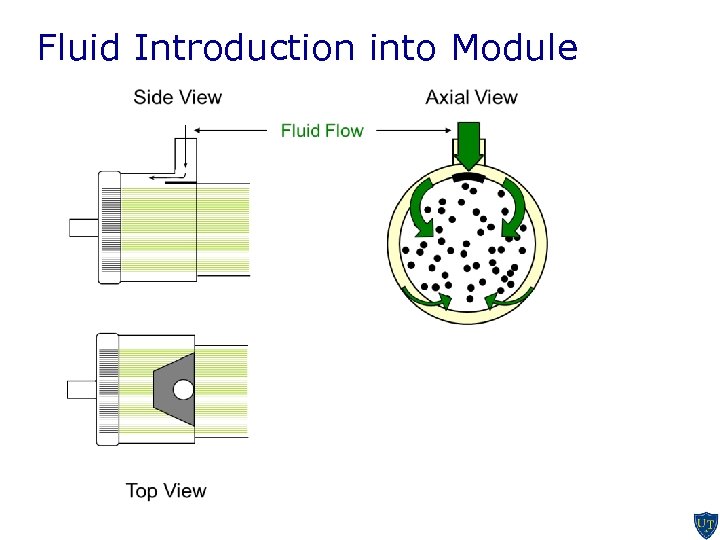

Fluid Introduction into Module

Fluid Introduction into Module

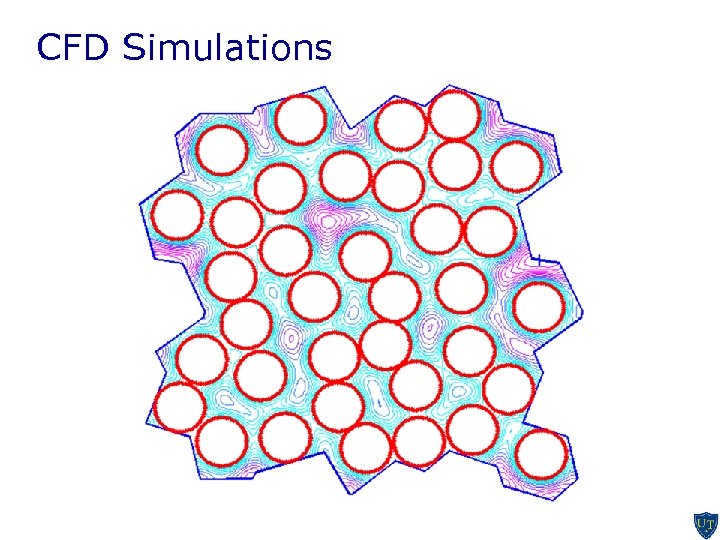

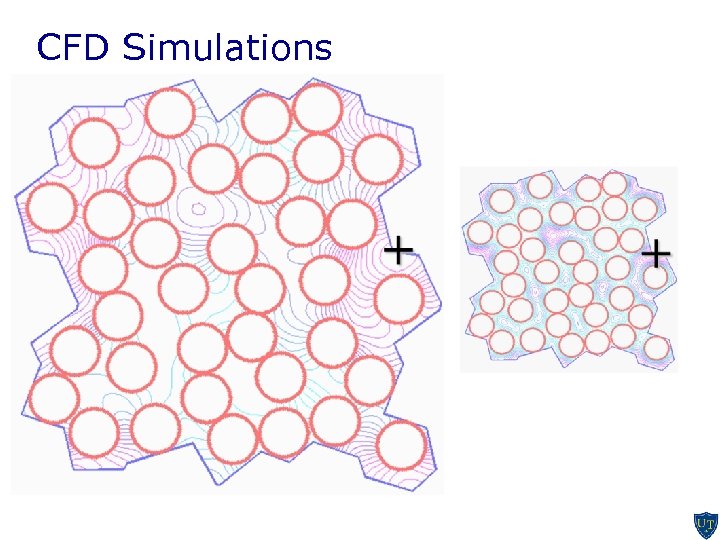

CFD Simulations

CFD Simulations

CFD Simulations

CFD Simulations

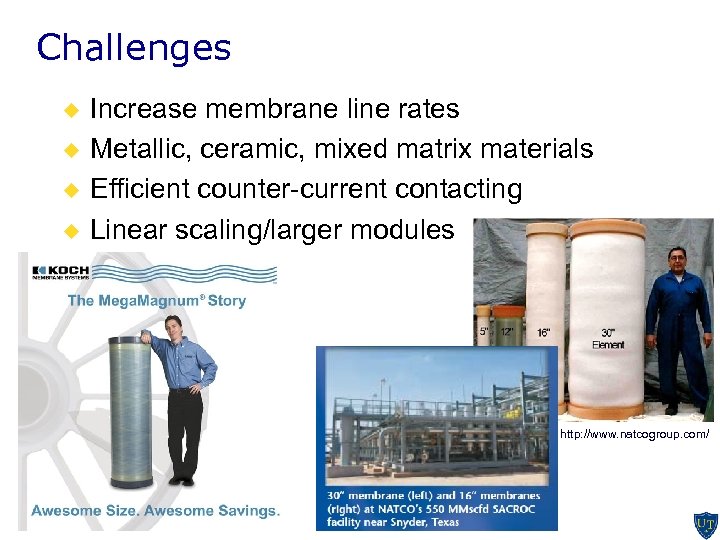

Challenges u u Increase membrane line rates Metallic, ceramic, mixed matrix materials Efficient counter-current contacting Linear scaling/larger modules http: //www. natcogroup. com/

Challenges u u Increase membrane line rates Metallic, ceramic, mixed matrix materials Efficient counter-current contacting Linear scaling/larger modules http: //www. natcogroup. com/