5029f1c86bae957661338b9c43dce8d9.ppt

- Количество слайдов: 47

EMERGENCY RESPONSE & DISASTER MANAGEMENT PLAN EMERGENCY RESPONSE & DISASTER (ERDMP) MANAGEMENT PLAN (ERDMP) ESSAR OIL LIMITED By: Dr. Gopal Jayaraman by Dr. Gopal Jayaraman 1

EMERGENCY RESPONSE & DISASTER MANAGEMENT PLAN EMERGENCY RESPONSE & DISASTER (ERDMP) MANAGEMENT PLAN (ERDMP) ESSAR OIL LIMITED By: Dr. Gopal Jayaraman by Dr. Gopal Jayaraman 1

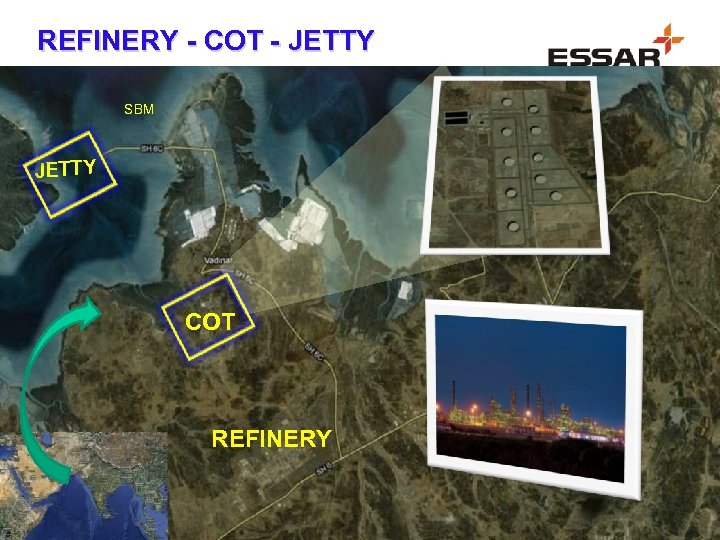

REFINERY - COT - JETTY SBM JETTY COT REFINERY

REFINERY - COT - JETTY SBM JETTY COT REFINERY

ESSAR ENERGY §Fully integrated Oil & Gas and Hydrocarbon Company §From exploration to production: Rig to Retail §Current refining capacity: 14. 0 MMTPA §Expansion to 36 MMTPA ; in 2 phases §Presently, 1250 ESSAR branded oil retails §Will open over 2500 ESSAR outlets; Countrywide.

ESSAR ENERGY §Fully integrated Oil & Gas and Hydrocarbon Company §From exploration to production: Rig to Retail §Current refining capacity: 14. 0 MMTPA §Expansion to 36 MMTPA ; in 2 phases §Presently, 1250 ESSAR branded oil retails §Will open over 2500 ESSAR outlets; Countrywide.

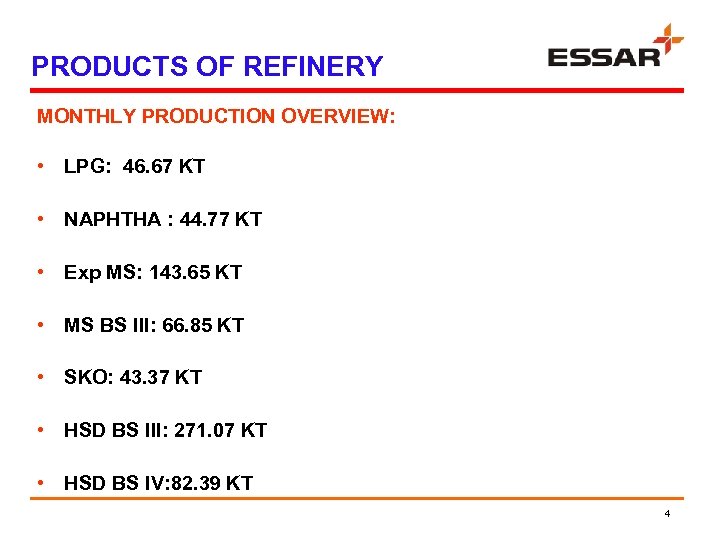

PRODUCTS OF REFINERY MONTHLY PRODUCTION OVERVIEW: • LPG: 46. 67 KT • NAPHTHA : 44. 77 KT • Exp MS: 143. 65 KT • MS BS III: 66. 85 KT • SKO: 43. 37 KT • HSD BS III: 271. 07 KT • HSD BS IV: 82. 39 KT 4

PRODUCTS OF REFINERY MONTHLY PRODUCTION OVERVIEW: • LPG: 46. 67 KT • NAPHTHA : 44. 77 KT • Exp MS: 143. 65 KT • MS BS III: 66. 85 KT • SKO: 43. 37 KT • HSD BS III: 271. 07 KT • HSD BS IV: 82. 39 KT 4

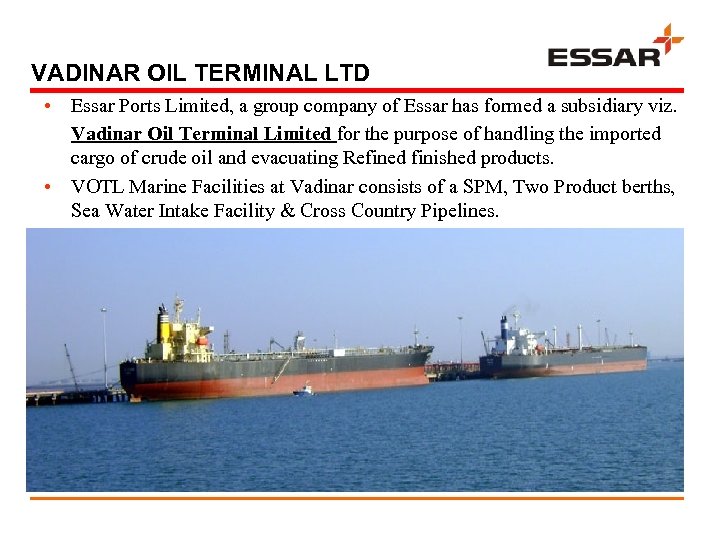

VADINAR OIL TERMINAL LTD • Essar Ports Limited, a group company of Essar has formed a subsidiary viz. Vadinar Oil Terminal Limited for the purpose of handling the imported cargo of crude oil and evacuating Refined finished products. • VOTL Marine Facilities at Vadinar consists of a SPM, Two Product berths, Sea Water Intake Facility & Cross Country Pipelines.

VADINAR OIL TERMINAL LTD • Essar Ports Limited, a group company of Essar has formed a subsidiary viz. Vadinar Oil Terminal Limited for the purpose of handling the imported cargo of crude oil and evacuating Refined finished products. • VOTL Marine Facilities at Vadinar consists of a SPM, Two Product berths, Sea Water Intake Facility & Cross Country Pipelines.

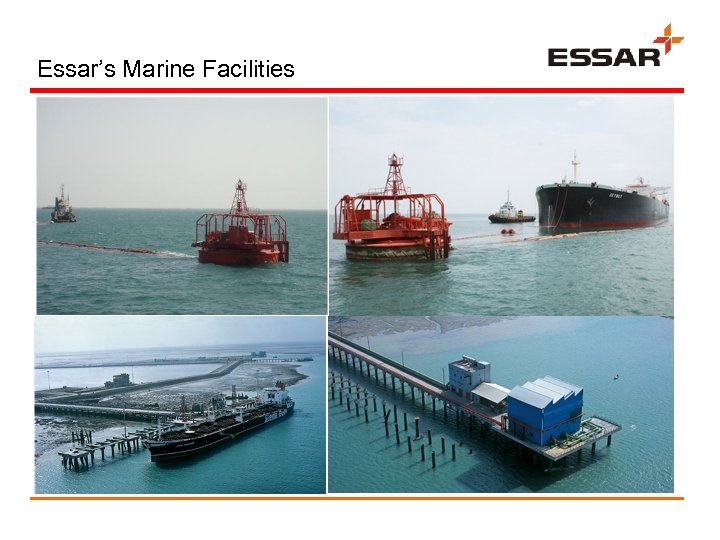

Essar’s Marine Facilities

Essar’s Marine Facilities

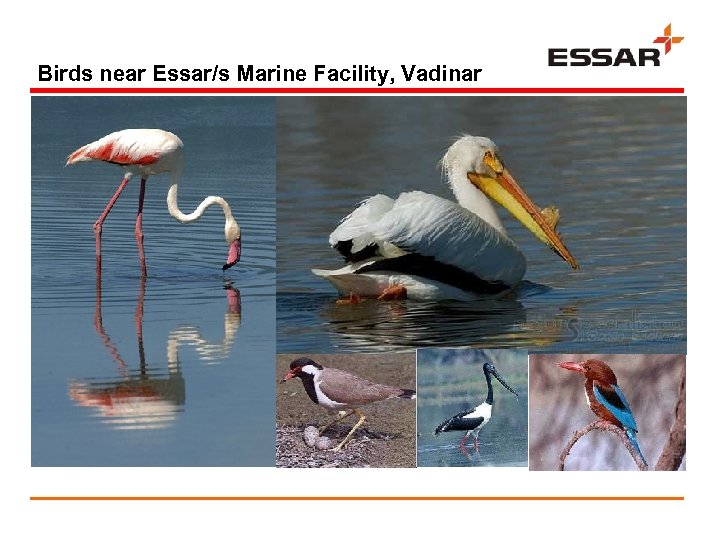

Birds near Essar/s Marine Facility, Vadinar

Birds near Essar/s Marine Facility, Vadinar

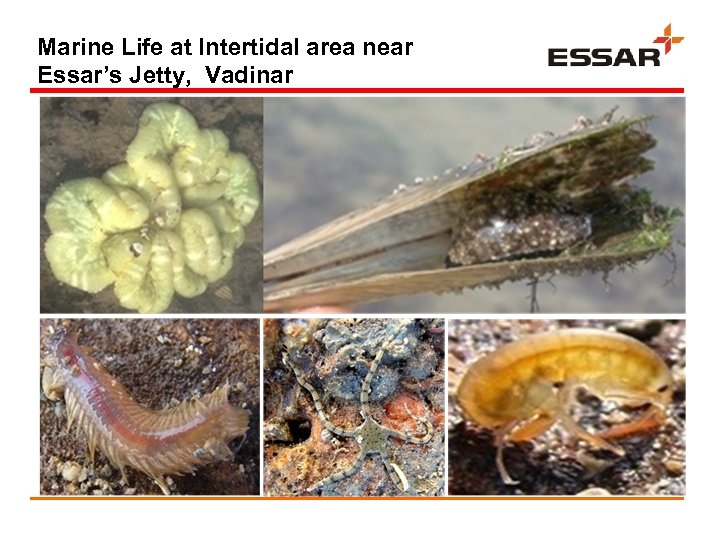

Marine Life at Intertidal area near Essar’s Jetty, Vadinar

Marine Life at Intertidal area near Essar’s Jetty, Vadinar

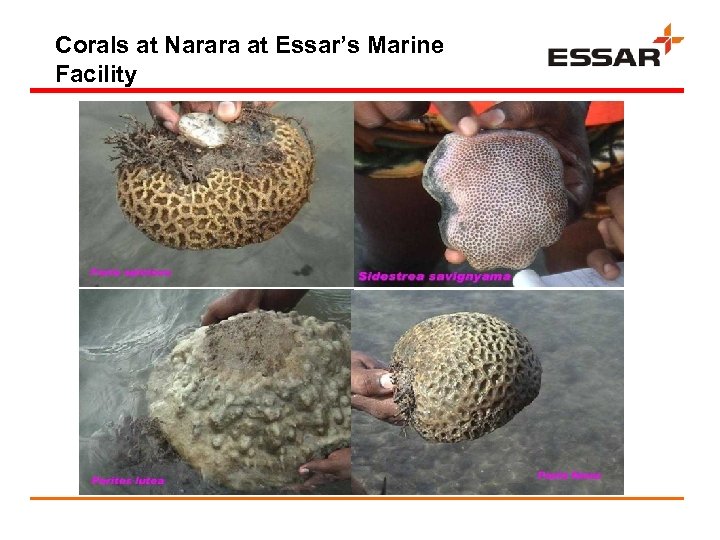

Corals at Narara at Essar’s Marine Facility

Corals at Narara at Essar’s Marine Facility

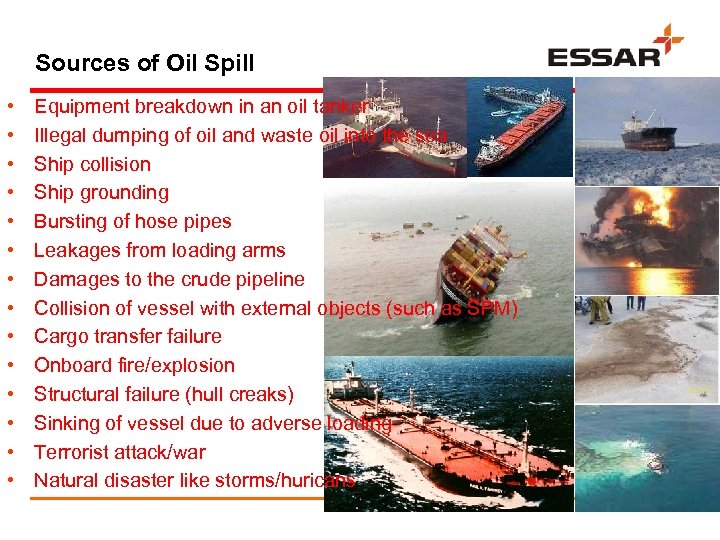

Sources of Oil Spill • • • • Equipment breakdown in an oil tanker Illegal dumping of oil and waste oil into the sea Ship collision Ship grounding Bursting of hose pipes Leakages from loading arms Damages to the crude pipeline Collision of vessel with external objects (such as SPM) Cargo transfer failure Onboard fire/explosion Structural failure (hull creaks) Sinking of vessel due to adverse loading Terrorist attack/war Natural disaster like storms/huricans

Sources of Oil Spill • • • • Equipment breakdown in an oil tanker Illegal dumping of oil and waste oil into the sea Ship collision Ship grounding Bursting of hose pipes Leakages from loading arms Damages to the crude pipeline Collision of vessel with external objects (such as SPM) Cargo transfer failure Onboard fire/explosion Structural failure (hull creaks) Sinking of vessel due to adverse loading Terrorist attack/war Natural disaster like storms/huricans

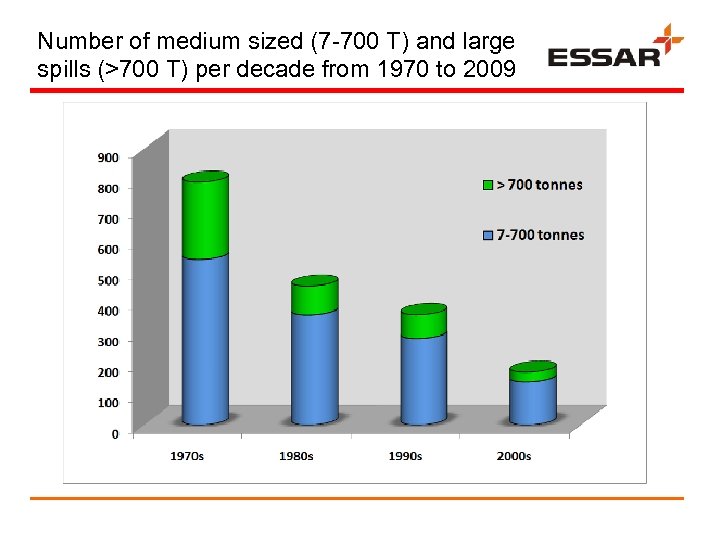

Number of medium sized (7 -700 T) and large spills (>700 T) per decade from 1970 to 2009

Number of medium sized (7 -700 T) and large spills (>700 T) per decade from 1970 to 2009

Contingency Planning ESSAR has developed following plans for various Emergencies • OSEMP : Onsite Site Emergency Management Plan identifies emergencies/contingencies measures for entire Vadinar site. • Contingency Manual: Contingency Manual identifies Marine Terminal Specific Emergency. • OSDCP: Oil Spill Disaster Contingency Plan is developed in line with NOSDCP and Vetted by Indian Coast Guard. • Verification and effectiveness of all the plans is being checked by carrying out frequent mock drills. • ESSAR carries out joint drills with other stake holders at frequent intervals

Contingency Planning ESSAR has developed following plans for various Emergencies • OSEMP : Onsite Site Emergency Management Plan identifies emergencies/contingencies measures for entire Vadinar site. • Contingency Manual: Contingency Manual identifies Marine Terminal Specific Emergency. • OSDCP: Oil Spill Disaster Contingency Plan is developed in line with NOSDCP and Vetted by Indian Coast Guard. • Verification and effectiveness of all the plans is being checked by carrying out frequent mock drills. • ESSAR carries out joint drills with other stake holders at frequent intervals

Classification of Oil Spill Risk • Tier One (upto 700 T) - Operational spillages which can be dealt with using the resources immediately available • Tier Two 700 – 10000 T - Medium sized spillages which exceed VOTL resources and which require District and/or Regional assistance. • Tier Three 10000 > T - Large spillages which exceed the full resources of the District/Region and which may require National assistance and /or the implementation of the NOS – DCP.

Classification of Oil Spill Risk • Tier One (upto 700 T) - Operational spillages which can be dealt with using the resources immediately available • Tier Two 700 – 10000 T - Medium sized spillages which exceed VOTL resources and which require District and/or Regional assistance. • Tier Three 10000 > T - Large spillages which exceed the full resources of the District/Region and which may require National assistance and /or the implementation of the NOS – DCP.

Our Preparedness • • • Tier I Oil spill combating capability based on Risk Assessment Trained Manpower to combat Tier I oil spill Pollution Control Vessel round the clock monitoring the operation Oil Spill Response Contingency Plan in place approved by ICG Implementation of OISD guidelines such as: OISD-STD-139 for Inspection of pipeline-offshore OISD-STD-140 for Inspection of jetty pipeline OISD-STD-188 for Corrosion monitoring of offshore and onshore pipelines OISD-GDN-200 Guidelines for preparation of Oil Spill Response Control Plan • Regular inspection of underwater/floating hose and subsea pipeline

Our Preparedness • • • Tier I Oil spill combating capability based on Risk Assessment Trained Manpower to combat Tier I oil spill Pollution Control Vessel round the clock monitoring the operation Oil Spill Response Contingency Plan in place approved by ICG Implementation of OISD guidelines such as: OISD-STD-139 for Inspection of pipeline-offshore OISD-STD-140 for Inspection of jetty pipeline OISD-STD-188 for Corrosion monitoring of offshore and onshore pipelines OISD-GDN-200 Guidelines for preparation of Oil Spill Response Control Plan • Regular inspection of underwater/floating hose and subsea pipeline

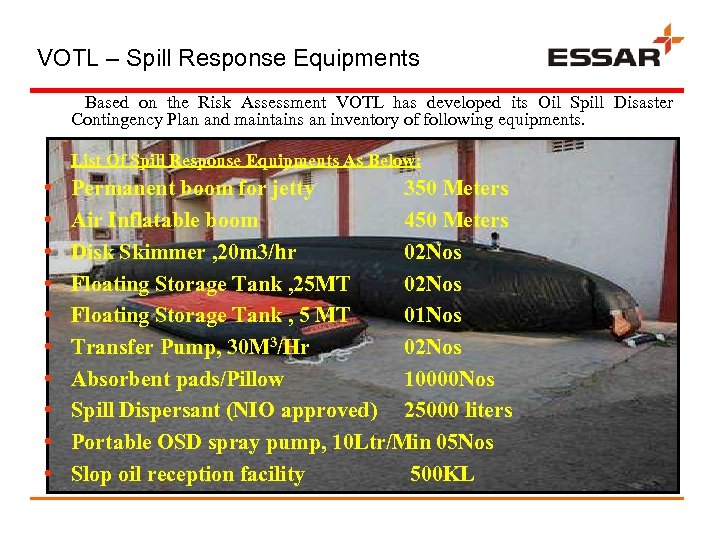

VOTL – Spill Response Equipments Based on the Risk Assessment VOTL has developed its Oil Spill Disaster Contingency Plan and maintains an inventory of following equipments. List Of Spill Response Equipments As Below: • • • Permanent boom for jetty 350 Meters Air Inflatable boom 450 Meters Disk Skimmer , 20 m 3/hr 02 Nos Floating Storage Tank , 25 MT 02 Nos Floating Storage Tank , 5 MT 01 Nos Transfer Pump, 30 M 3/Hr 02 Nos Absorbent pads/Pillow 10000 Nos Spill Dispersant (NIO approved) 25000 liters Portable OSD spray pump, 10 Ltr/Min 05 Nos Slop oil reception facility 500 KL

VOTL – Spill Response Equipments Based on the Risk Assessment VOTL has developed its Oil Spill Disaster Contingency Plan and maintains an inventory of following equipments. List Of Spill Response Equipments As Below: • • • Permanent boom for jetty 350 Meters Air Inflatable boom 450 Meters Disk Skimmer , 20 m 3/hr 02 Nos Floating Storage Tank , 25 MT 02 Nos Floating Storage Tank , 5 MT 01 Nos Transfer Pump, 30 M 3/Hr 02 Nos Absorbent pads/Pillow 10000 Nos Spill Dispersant (NIO approved) 25000 liters Portable OSD spray pump, 10 Ltr/Min 05 Nos Slop oil reception facility 500 KL

VOTL – Spill Response Equipments • Shore line clean up equipments. We are in the process of procurement of following oil spill response equipments to augment our OSR capabilities further: 1. 2. 3. 4. Intertidal Boom Air Inflatable Boom Shore Clean up vacuum System Absorbent Pads 1500 meters 450 meters 02 nos. 7000 nos. 5. 6. 7. 8. Absorbent Boom Absorbent Pillows Dispersant Spray unit Portable spray pump 300 mtrs. 100 nos. 01 nos. 04 nos.

VOTL – Spill Response Equipments • Shore line clean up equipments. We are in the process of procurement of following oil spill response equipments to augment our OSR capabilities further: 1. 2. 3. 4. Intertidal Boom Air Inflatable Boom Shore Clean up vacuum System Absorbent Pads 1500 meters 450 meters 02 nos. 7000 nos. 5. 6. 7. 8. Absorbent Boom Absorbent Pillows Dispersant Spray unit Portable spray pump 300 mtrs. 100 nos. 01 nos. 04 nos.

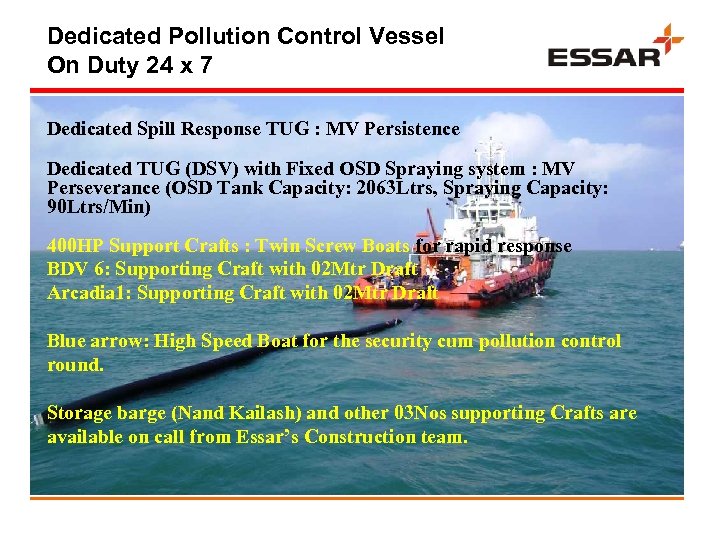

Dedicated Pollution Control Vessel On Duty 24 x 7 Dedicated Spill Response TUG : MV Persistence Dedicated TUG (DSV) with Fixed OSD Spraying system : MV Perseverance (OSD Tank Capacity: 2063 Ltrs, Spraying Capacity: 90 Ltrs/Min) 400 HP Support Crafts : Twin Screw Boats for rapid response BDV 6: Supporting Craft with 02 Mtr Draft Arcadia 1: Supporting Craft with 02 Mtr Draft Blue arrow: High Speed Boat for the security cum pollution control round. Storage barge (Nand Kailash) and other 03 Nos supporting Crafts are available on call from Essar’s Construction team.

Dedicated Pollution Control Vessel On Duty 24 x 7 Dedicated Spill Response TUG : MV Persistence Dedicated TUG (DSV) with Fixed OSD Spraying system : MV Perseverance (OSD Tank Capacity: 2063 Ltrs, Spraying Capacity: 90 Ltrs/Min) 400 HP Support Crafts : Twin Screw Boats for rapid response BDV 6: Supporting Craft with 02 Mtr Draft Arcadia 1: Supporting Craft with 02 Mtr Draft Blue arrow: High Speed Boat for the security cum pollution control round. Storage barge (Nand Kailash) and other 03 Nos supporting Crafts are available on call from Essar’s Construction team.

Pooling of Resources • At Regional level Essar (VOTL) has initiated and supported a need for mutual aid for Marine specific emergencies including Oil Spill. • The draft of Mutual Aid Agreement has been agreed by IOCL, BORL and ESSAR.

Pooling of Resources • At Regional level Essar (VOTL) has initiated and supported a need for mutual aid for Marine specific emergencies including Oil Spill. • The draft of Mutual Aid Agreement has been agreed by IOCL, BORL and ESSAR.

MOCK DRILL ( OIL SPILL)

MOCK DRILL ( OIL SPILL)

Deployed Spill Response Equipments

Deployed Spill Response Equipments

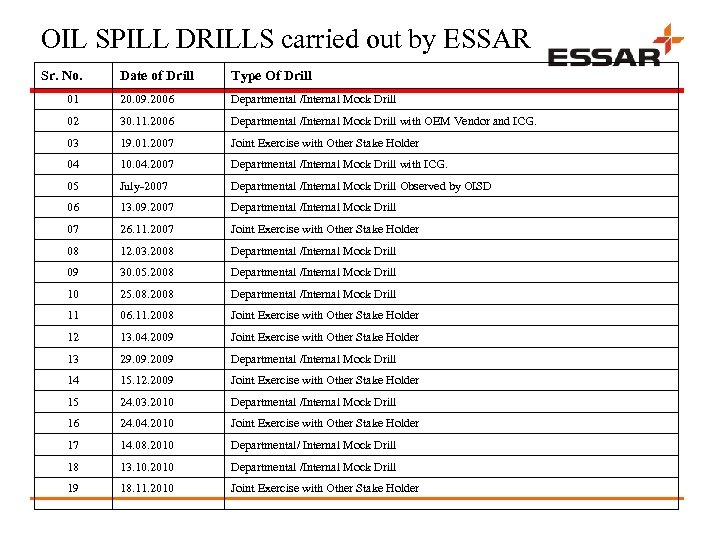

OIL SPILL DRILLS carried out by ESSAR Sr. No. Date of Drill Type Of Drill 01 20. 09. 2006 Departmental /Internal Mock Drill 02 30. 11. 2006 Departmental /Internal Mock Drill with OEM Vendor and ICG. 03 19. 01. 2007 Joint Exercise with Other Stake Holder 04 10. 04. 2007 Departmental /Internal Mock Drill with ICG. 05 July-2007 Departmental /Internal Mock Drill Observed by OISD 06 13. 09. 2007 Departmental /Internal Mock Drill 07 26. 11. 2007 Joint Exercise with Other Stake Holder 08 12. 03. 2008 Departmental /Internal Mock Drill 09 30. 05. 2008 Departmental /Internal Mock Drill 10 25. 08. 2008 Departmental /Internal Mock Drill 11 06. 11. 2008 Joint Exercise with Other Stake Holder 12 13. 04. 2009 Joint Exercise with Other Stake Holder 13 29. 09. 2009 Departmental /Internal Mock Drill 14 15. 12. 2009 Joint Exercise with Other Stake Holder 15 24. 03. 2010 Departmental /Internal Mock Drill 16 24. 04. 2010 Joint Exercise with Other Stake Holder 17 14. 08. 2010 Departmental/ Internal Mock Drill 18 13. 10. 2010 Departmental /Internal Mock Drill 19 18. 11. 2010 Joint Exercise with Other Stake Holder

OIL SPILL DRILLS carried out by ESSAR Sr. No. Date of Drill Type Of Drill 01 20. 09. 2006 Departmental /Internal Mock Drill 02 30. 11. 2006 Departmental /Internal Mock Drill with OEM Vendor and ICG. 03 19. 01. 2007 Joint Exercise with Other Stake Holder 04 10. 04. 2007 Departmental /Internal Mock Drill with ICG. 05 July-2007 Departmental /Internal Mock Drill Observed by OISD 06 13. 09. 2007 Departmental /Internal Mock Drill 07 26. 11. 2007 Joint Exercise with Other Stake Holder 08 12. 03. 2008 Departmental /Internal Mock Drill 09 30. 05. 2008 Departmental /Internal Mock Drill 10 25. 08. 2008 Departmental /Internal Mock Drill 11 06. 11. 2008 Joint Exercise with Other Stake Holder 12 13. 04. 2009 Joint Exercise with Other Stake Holder 13 29. 09. 2009 Departmental /Internal Mock Drill 14 15. 12. 2009 Joint Exercise with Other Stake Holder 15 24. 03. 2010 Departmental /Internal Mock Drill 16 24. 04. 2010 Joint Exercise with Other Stake Holder 17 14. 08. 2010 Departmental/ Internal Mock Drill 18 13. 10. 2010 Departmental /Internal Mock Drill 19 18. 11. 2010 Joint Exercise with Other Stake Holder

Highlights & Achievements • Terminal achieved BSC FIVE STAR in Health and Safety Standard followed by Sword of Honour - 2008. • Terminal has also achieved, Ø Ø Ø ISO 9001 -2008, ISO 14001: 2004, OHSAS 18001: 2007, ISO/TS 29001: 2007, ISO 28000: 2007, OCIMF certification. • SPM is Classed by ABS. • Terminal achieved BSC FIVE STAR in Environment Management -2010. • 90% People on Terminal are trained for IMO Level-I, Spill Response Training by ICG and OEM. (Figures as on 14. 02. 2011)

Highlights & Achievements • Terminal achieved BSC FIVE STAR in Health and Safety Standard followed by Sword of Honour - 2008. • Terminal has also achieved, Ø Ø Ø ISO 9001 -2008, ISO 14001: 2004, OHSAS 18001: 2007, ISO/TS 29001: 2007, ISO 28000: 2007, OCIMF certification. • SPM is Classed by ABS. • Terminal achieved BSC FIVE STAR in Environment Management -2010. • 90% People on Terminal are trained for IMO Level-I, Spill Response Training by ICG and OEM. (Figures as on 14. 02. 2011)

Ballast Water Information Exchange PRIOR ARRIVAL SHIP’S MASTER HAS TO GIVE FOLLOWING UNDERTAKING, • BALLAST WATER HAS BEEN EXCHANGED AS PER IMO GUIDELINES (FOR EXPORT TANKERS) • ALL BALLAST TANKS HAVE BEEN INSPECTED & ARE FREE OF OIL TRACES ON ARRIVAL AT TERMINAL FOLLOWING DECLARATION IS BEING TAKEN FROM SHIP’S MASTER AND SAME IS BEING INSPECTED BY TERMINAL’S REPS: • “This to certify that we have checked all the ballast tanks and the same are found to be free from Oil. ”

Ballast Water Information Exchange PRIOR ARRIVAL SHIP’S MASTER HAS TO GIVE FOLLOWING UNDERTAKING, • BALLAST WATER HAS BEEN EXCHANGED AS PER IMO GUIDELINES (FOR EXPORT TANKERS) • ALL BALLAST TANKS HAVE BEEN INSPECTED & ARE FREE OF OIL TRACES ON ARRIVAL AT TERMINAL FOLLOWING DECLARATION IS BEING TAKEN FROM SHIP’S MASTER AND SAME IS BEING INSPECTED BY TERMINAL’S REPS: • “This to certify that we have checked all the ballast tanks and the same are found to be free from Oil. ”

Highlights & Achievements • Total 726 No's Ship Handled at Jetty. • Total 28. 03 MMT of Cargo evacuated through Jetty. • Total 334 No's Ship Handled at SPM. • Total 47. 14 MMT of Cargo handled through SPM. • Total 1060 Shipment handled safely at VOTL Marine Terminal. • 1603 Days completed without LTI (Figures as on 14. 02. 2011)

Highlights & Achievements • Total 726 No's Ship Handled at Jetty. • Total 28. 03 MMT of Cargo evacuated through Jetty. • Total 334 No's Ship Handled at SPM. • Total 47. 14 MMT of Cargo handled through SPM. • Total 1060 Shipment handled safely at VOTL Marine Terminal. • 1603 Days completed without LTI (Figures as on 14. 02. 2011)

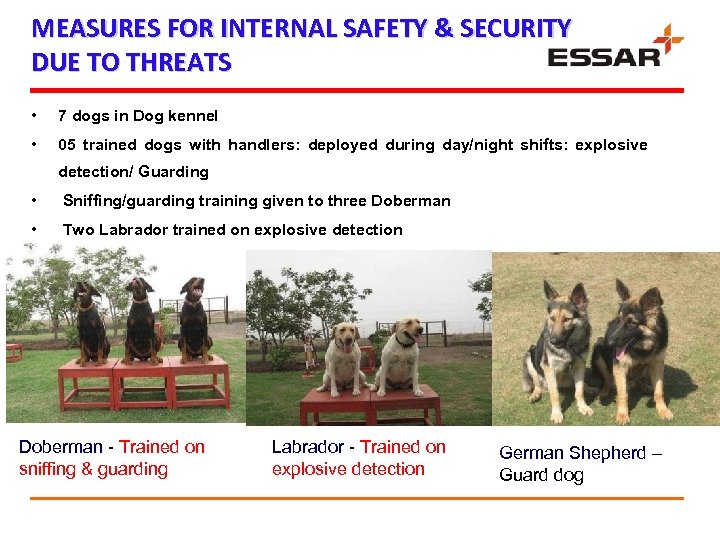

MEASURES FOR INTERNAL SAFETY & SECURITY DUE TO THREATS • 7 dogs in Dog kennel • 05 trained dogs with handlers: deployed during day/night shifts: explosive detection/ Guarding • Sniffing/guarding training given to three Doberman • Two Labrador trained on explosive detection • 02 German Shepard pups are under training. Doberman - Trained on sniffing & guarding 15 -Mar-18 Labrador - Trained on explosive detection German Shepherd – Guard dog 25

MEASURES FOR INTERNAL SAFETY & SECURITY DUE TO THREATS • 7 dogs in Dog kennel • 05 trained dogs with handlers: deployed during day/night shifts: explosive detection/ Guarding • Sniffing/guarding training given to three Doberman • Two Labrador trained on explosive detection • 02 German Shepard pups are under training. Doberman - Trained on sniffing & guarding 15 -Mar-18 Labrador - Trained on explosive detection German Shepherd – Guard dog 25

OBJECTIVES OF ON-SITE EMERGENCY MANAGEMENT PLAN AT REFINERY • To define and assess emergencies, including risk and environmental impact assessment. • To contain and control emergency incidents. • To safeguard employees and people in vicinity. • To provide maximum possible safety for the emergency response personnel. • To minimize damage to the environment. • To minimize damage to company installations and public property. • To inform employees, the general public and the authority about the hazards / risk assessed • Mutual Aid. • To effect rescue and treatment of casualties. To count injured. • To identify and list any fatalities. To inform and help relatives. • To secure the safe rehabilitation of affected areas / people and to restore normalcy. • To provide authentic information to the news media. • To dovetail properly to a similar plan of the local government for an offsite emergency arising out of an on-site emergency. • Ensure business continuity following an emergency event. • Minimize the effects of the emergency event on the company image. 27

OBJECTIVES OF ON-SITE EMERGENCY MANAGEMENT PLAN AT REFINERY • To define and assess emergencies, including risk and environmental impact assessment. • To contain and control emergency incidents. • To safeguard employees and people in vicinity. • To provide maximum possible safety for the emergency response personnel. • To minimize damage to the environment. • To minimize damage to company installations and public property. • To inform employees, the general public and the authority about the hazards / risk assessed • Mutual Aid. • To effect rescue and treatment of casualties. To count injured. • To identify and list any fatalities. To inform and help relatives. • To secure the safe rehabilitation of affected areas / people and to restore normalcy. • To provide authentic information to the news media. • To dovetail properly to a similar plan of the local government for an offsite emergency arising out of an on-site emergency. • Ensure business continuity following an emergency event. • Minimize the effects of the emergency event on the company image. 27

EMERGENCY SCENARIOS Ø Ø Ø Ø Ø Fire / explosion Major release of flammable/toxic chemical Oil spill Cyclonic Storm / Hurricane Earthquake Floods War Bomb Threat Industrial Unrest Transportation Accident involving Hazardous Material 28

EMERGENCY SCENARIOS Ø Ø Ø Ø Ø Fire / explosion Major release of flammable/toxic chemical Oil spill Cyclonic Storm / Hurricane Earthquake Floods War Bomb Threat Industrial Unrest Transportation Accident involving Hazardous Material 28

Categorization of Emergencies - Level - 01 MINOR ONSITE EMERGENCY This is an emergency or an incident which • Can be effectively and safely managed, and contained within the location of origin • Is unlikely to spread to other areas • Is unlikely to cause major upset in other process units • Has no impact outside the site, location or installation • Is unlikely to cause major business interruption • Can be effectively managed with the available resources • Is unlikely to endanger life, environment, company assets or reputation 29

Categorization of Emergencies - Level - 01 MINOR ONSITE EMERGENCY This is an emergency or an incident which • Can be effectively and safely managed, and contained within the location of origin • Is unlikely to spread to other areas • Is unlikely to cause major upset in other process units • Has no impact outside the site, location or installation • Is unlikely to cause major business interruption • Can be effectively managed with the available resources • Is unlikely to endanger life, environment, company assets or reputation 29

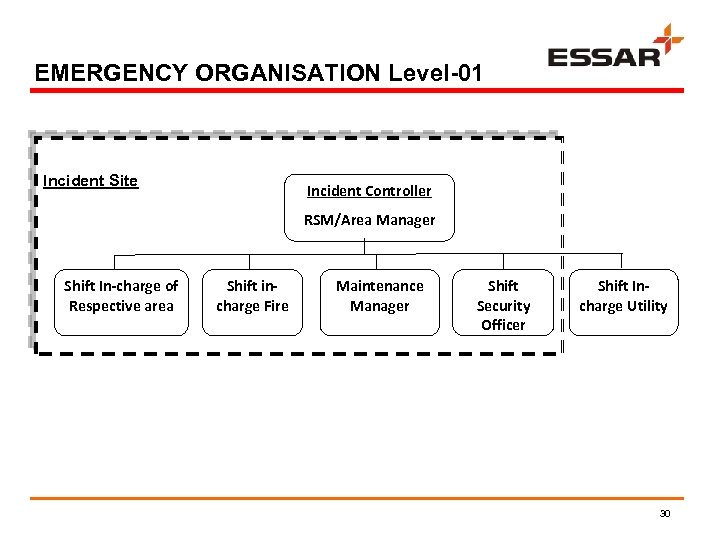

EMERGENCY ORGANISATION Level-01 Incident Site Incident Controller RSM/Area Manager Shift In-charge of Respective area Shift incharge Fire Maintenance Manager Shift Security Officer Shift Incharge Utility 30

EMERGENCY ORGANISATION Level-01 Incident Site Incident Controller RSM/Area Manager Shift In-charge of Respective area Shift incharge Fire Maintenance Manager Shift Security Officer Shift Incharge Utility 30

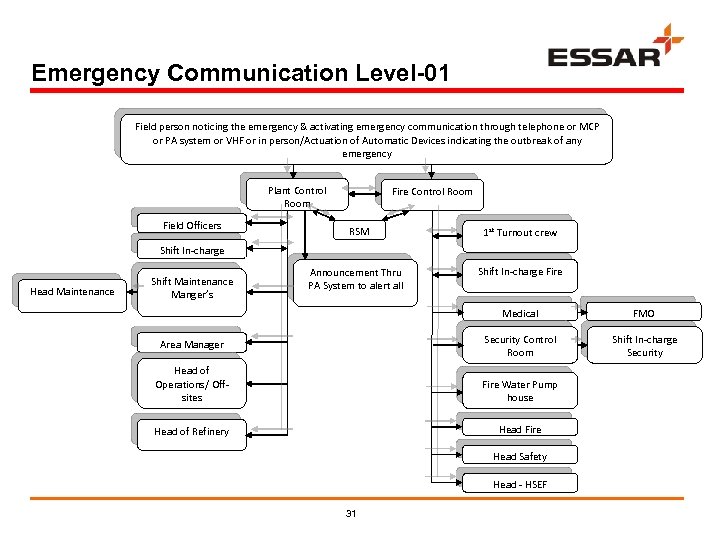

Emergency Communication Level-01 Field person noticing the emergency & activating emergency communication through telephone or MCP or PA system or VHF or in person/Actuation of Automatic Devices indicating the outbreak of any emergency Plant Control Room Field Officers Fire Control Room RSM 1 st Turnout crew Shift In-charge Head Maintenance Shift Maintenance Manger’s Announcement Thru PA System to alert all Shift In-charge Fire Medical Security Control Room Area Manager FMO Shift In-charge Security Head of Operations/ Offsites Fire Water Pump house Head of Refinery Head Fire Head Safety Head - HSEF 31

Emergency Communication Level-01 Field person noticing the emergency & activating emergency communication through telephone or MCP or PA system or VHF or in person/Actuation of Automatic Devices indicating the outbreak of any emergency Plant Control Room Field Officers Fire Control Room RSM 1 st Turnout crew Shift In-charge Head Maintenance Shift Maintenance Manger’s Announcement Thru PA System to alert all Shift In-charge Fire Medical Security Control Room Area Manager FMO Shift In-charge Security Head of Operations/ Offsites Fire Water Pump house Head of Refinery Head Fire Head Safety Head - HSEF 31

Categorization of Emergencies - Level - 02 MAJOR ONSITE EMERGENCY: This is an emergency or an incident which • Cannot be effectively and safely managed or contained at the location of origin • Is having the potential to spread to other areas • Is likely to cause major upsets in other process units • Is likely to cause business interruption • Is likely to have potential to effect beyond the site • Is likely to require full site emergency resources as well as mutual aid resources • Is likely to endanger life, environment, company assets or reputation 32

Categorization of Emergencies - Level - 02 MAJOR ONSITE EMERGENCY: This is an emergency or an incident which • Cannot be effectively and safely managed or contained at the location of origin • Is having the potential to spread to other areas • Is likely to cause major upsets in other process units • Is likely to cause business interruption • Is likely to have potential to effect beyond the site • Is likely to require full site emergency resources as well as mutual aid resources • Is likely to endanger life, environment, company assets or reputation 32

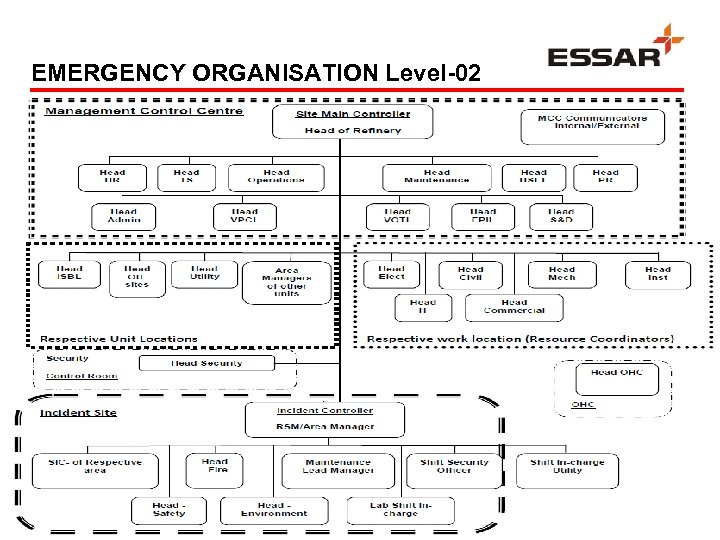

EMERGENCY ORGANISATION Level-02 33

EMERGENCY ORGANISATION Level-02 33

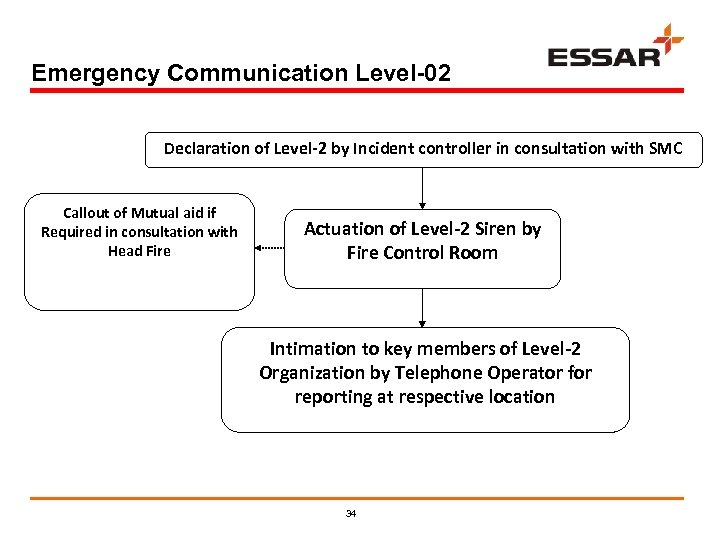

Emergency Communication Level-02 Declaration of Level-2 by Incident controller in consultation with SMC Callout of Mutual aid if Required in consultation with Head Fire Actuation of Level-2 Siren by Fire Control Room Intimation to key members of Level-2 Organization by Telephone Operator for reporting at respective location 34

Emergency Communication Level-02 Declaration of Level-2 by Incident controller in consultation with SMC Callout of Mutual aid if Required in consultation with Head Fire Actuation of Level-2 Siren by Fire Control Room Intimation to key members of Level-2 Organization by Telephone Operator for reporting at respective location 34

Categorization of Emergencies - Level - 03 OFFSITE IMPACT EMERGENCY An emergency or an incident • With offsite impact which could be catastrophic and is likely to affect the population, property and environment inside and outside the installation. • Calls for the activation of full site resources, mutual aid resources and resources from other installations of Essar. Management & control of such incidents having outside impact is done by District Administration. 35

Categorization of Emergencies - Level - 03 OFFSITE IMPACT EMERGENCY An emergency or an incident • With offsite impact which could be catastrophic and is likely to affect the population, property and environment inside and outside the installation. • Calls for the activation of full site resources, mutual aid resources and resources from other installations of Essar. Management & control of such incidents having outside impact is done by District Administration. 35

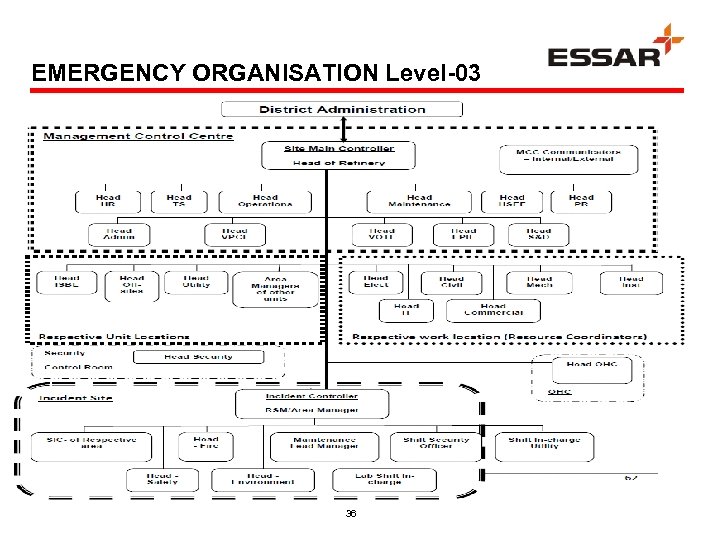

EMERGENCY ORGANISATION Level-03 36

EMERGENCY ORGANISATION Level-03 36

Emergency Communication Level-03 Information to District administration for activating the Level-3 emergency shall be initiated by SMC after thoroughly evaluating the situation with IC & MCC team. 37

Emergency Communication Level-03 Information to District administration for activating the Level-3 emergency shall be initiated by SMC after thoroughly evaluating the situation with IC & MCC team. 37

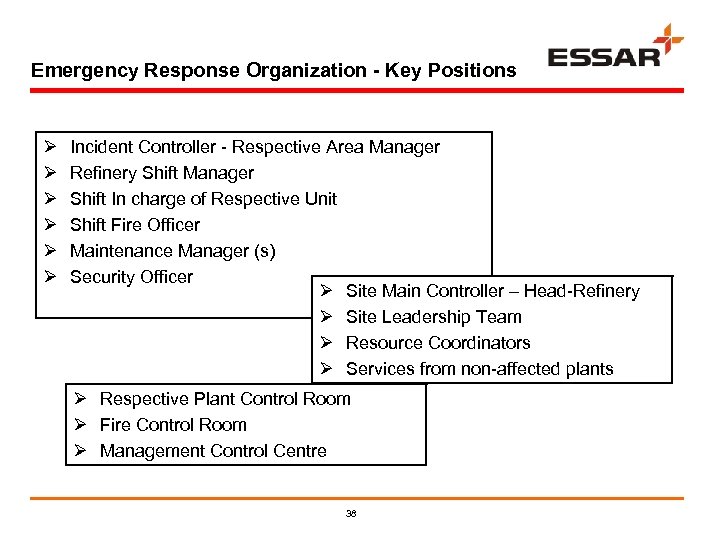

Emergency Response Organization - Key Positions Ø Ø Ø Incident Controller - Respective Area Manager Refinery Shift Manager Shift In charge of Respective Unit Shift Fire Officer Maintenance Manager (s) Security Officer Ø Site Main Controller – Head-Refinery Ø Site Leadership Team Ø Resource Coordinators Ø Services from non-affected plants Ø Respective Plant Control Room Ø Fire Control Room Ø Management Control Centre 38

Emergency Response Organization - Key Positions Ø Ø Ø Incident Controller - Respective Area Manager Refinery Shift Manager Shift In charge of Respective Unit Shift Fire Officer Maintenance Manager (s) Security Officer Ø Site Main Controller – Head-Refinery Ø Site Leadership Team Ø Resource Coordinators Ø Services from non-affected plants Ø Respective Plant Control Room Ø Fire Control Room Ø Management Control Centre 38

Action Initiated by the incident reporting person • Shall break the Manual Call Point • Shall call the following emergency numbers v Fire : 1111, Mobile: 99251 50927 v Medical : 1333, Mobile: 99252 06254 v Security : 1770, Mobile: 99798 68484 v RSM : 1723, Mobile: 99798 91330 v SIC of affected area • Shall communicate loudly – fire or help • Shall mitigate the incident- if trained • Should get away from the area & go to the assembly point 39

Action Initiated by the incident reporting person • Shall break the Manual Call Point • Shall call the following emergency numbers v Fire : 1111, Mobile: 99251 50927 v Medical : 1333, Mobile: 99252 06254 v Security : 1770, Mobile: 99798 68484 v RSM : 1723, Mobile: 99798 91330 v SIC of affected area • Shall communicate loudly – fire or help • Shall mitigate the incident- if trained • Should get away from the area & go to the assembly point 39

Means of Communication Ø Fire and Gas detection system Ø PA system Ø Hotline telephones Ø Intercom telephones / Flam proof mobile/ CUG mobile phones (not permitted in ISBL / Operation areas) Ø Messengers 40

Means of Communication Ø Fire and Gas detection system Ø PA system Ø Hotline telephones Ø Intercom telephones / Flam proof mobile/ CUG mobile phones (not permitted in ISBL / Operation areas) Ø Messengers 40

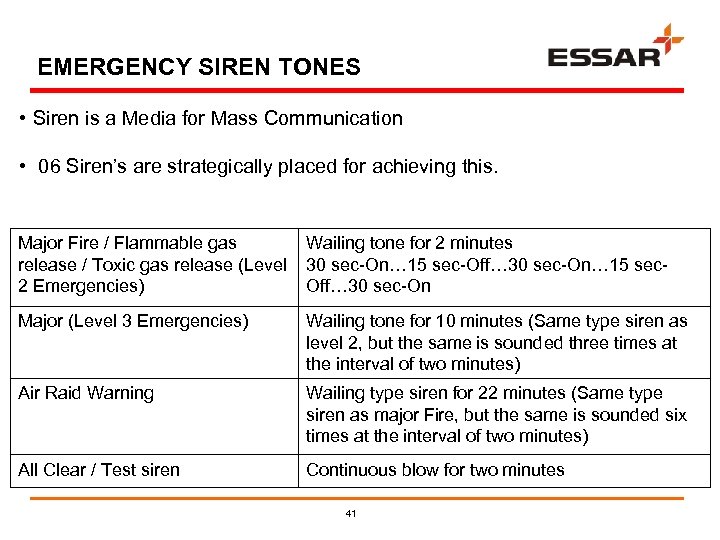

EMERGENCY SIREN TONES • Siren is a Media for Mass Communication • 06 Siren’s are strategically placed for achieving this. Major Fire / Flammable gas release / Toxic gas release (Level 2 Emergencies) Wailing tone for 2 minutes 30 sec-On… 15 sec-Off… 30 sec-On… 15 sec. Off… 30 sec-On Major (Level 3 Emergencies) Wailing tone for 10 minutes (Same type siren as level 2, but the same is sounded three times at the interval of two minutes) Air Raid Warning Wailing type siren for 22 minutes (Same type siren as major Fire, but the same is sounded six times at the interval of two minutes) All Clear / Test siren Continuous blow for two minutes 41

EMERGENCY SIREN TONES • Siren is a Media for Mass Communication • 06 Siren’s are strategically placed for achieving this. Major Fire / Flammable gas release / Toxic gas release (Level 2 Emergencies) Wailing tone for 2 minutes 30 sec-On… 15 sec-Off… 30 sec-On… 15 sec. Off… 30 sec-On Major (Level 3 Emergencies) Wailing tone for 10 minutes (Same type siren as level 2, but the same is sounded three times at the interval of two minutes) Air Raid Warning Wailing type siren for 22 minutes (Same type siren as major Fire, but the same is sounded six times at the interval of two minutes) All Clear / Test siren Continuous blow for two minutes 41

ASSEMBLY POINTS Ø Assembly Points are located at a safe place, well away from area of risk and least affected by the down wind direction. Ø Each assembly Point shall be marked by a conspicuous notices & provided with an identification e. g. Assembly Point. Ø Each Assembly Point shall be coordinated by Security Person. Ø Area Evacuation will be coordinated by Group Warden Ø Major evacuation shall be carried out by. Evacuation coordinator (Security) upon instruction of SMC. Ø Final head count shall be carried out by Security Coordinator at Master Assembly Point (Helipad). 42

ASSEMBLY POINTS Ø Assembly Points are located at a safe place, well away from area of risk and least affected by the down wind direction. Ø Each assembly Point shall be marked by a conspicuous notices & provided with an identification e. g. Assembly Point. Ø Each Assembly Point shall be coordinated by Security Person. Ø Area Evacuation will be coordinated by Group Warden Ø Major evacuation shall be carried out by. Evacuation coordinator (Security) upon instruction of SMC. Ø Final head count shall be carried out by Security Coordinator at Master Assembly Point (Helipad). 42

MANAGEMENT CONTROL CENTER (MCC) Ø Ø Ø Central point for information gathering, processing and decision making Alternate MCC is also available Activated in Level-02/03 Emergencies Equipped with Communication Gadgets/ PPE’s/Relevant Drawings/etc The SMC takes charge at the MCC and commands the emergency operations as per the emergency organization charts. Ø In & Out communication of MCC shall be done by MCC Communicator. Mutual Aid Ø Jamnagar district is having a Mutual aid scheme under the Chairmanship of Honorable District Collector. Ø Essar Oil is an active member of this Mutual Aid Organization. Ø Mutual aid conducts regular mock drills 43

MANAGEMENT CONTROL CENTER (MCC) Ø Ø Ø Central point for information gathering, processing and decision making Alternate MCC is also available Activated in Level-02/03 Emergencies Equipped with Communication Gadgets/ PPE’s/Relevant Drawings/etc The SMC takes charge at the MCC and commands the emergency operations as per the emergency organization charts. Ø In & Out communication of MCC shall be done by MCC Communicator. Mutual Aid Ø Jamnagar district is having a Mutual aid scheme under the Chairmanship of Honorable District Collector. Ø Essar Oil is an active member of this Mutual Aid Organization. Ø Mutual aid conducts regular mock drills 43

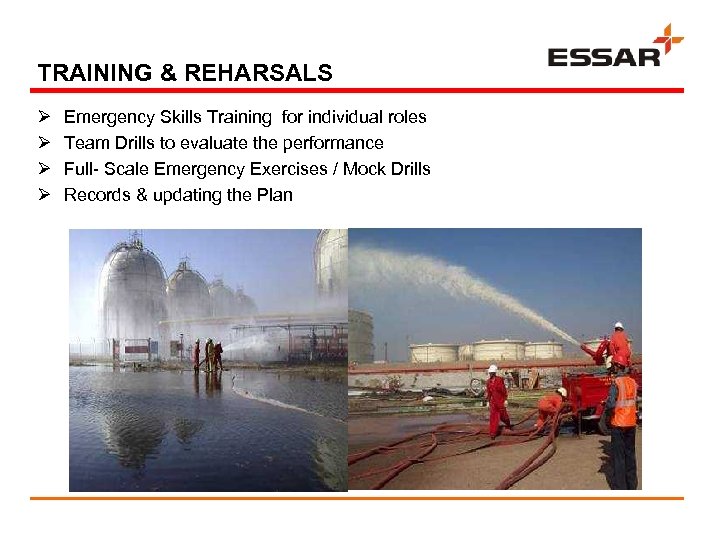

TRAINING & REHARSALS Ø Ø Emergency Skills Training for individual roles Team Drills to evaluate the performance Full- Scale Emergency Exercises / Mock Drills Records & updating the Plan

TRAINING & REHARSALS Ø Ø Emergency Skills Training for individual roles Team Drills to evaluate the performance Full- Scale Emergency Exercises / Mock Drills Records & updating the Plan

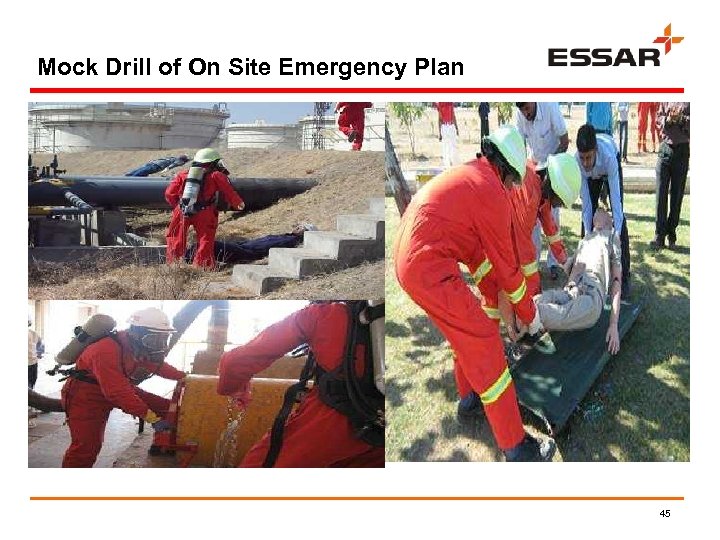

Mock Drill of On Site Emergency Plan 45

Mock Drill of On Site Emergency Plan 45

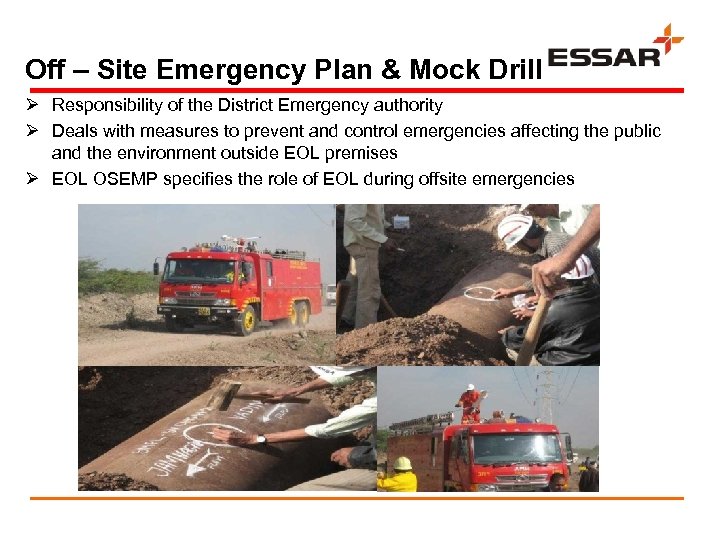

Off – Site Emergency Plan & Mock Drill Ø Responsibility of the District Emergency authority Ø Deals with measures to prevent and control emergencies affecting the public and the environment outside EOL premises Ø EOL OSEMP specifies the role of EOL during offsite emergencies

Off – Site Emergency Plan & Mock Drill Ø Responsibility of the District Emergency authority Ø Deals with measures to prevent and control emergencies affecting the public and the environment outside EOL premises Ø EOL OSEMP specifies the role of EOL during offsite emergencies

THANK YOU

THANK YOU