16b0974b0103b723481245b05ccb34a3.ppt

- Количество слайдов: 21

EMEA Distributor Meeting 17 September 2007

Features and benefits The CPS control unit is a addressable gas detection system designed for continuous monitoring for toxic (CO, NO or NO 2) or flammable gases in underground car parks capable of monitoring 256 slaves. It complies with the demanding VDI 2053 regulation and has been approved by TUV Rheinland notified body. Installation and ownership cost reduction. The CPS uses a four wire 0. 22 mm 2 (24 AWG) core size cable, all values are transmitted in one second so fans only run during the required time, far better than old fashioned pump systems. Easier to maintain, no pump, no filters.

Overview CPS is a 8 channel digital controller able to monitor up to 256 slaves Slaves are gas detectors, relays, logic inputs, analog output modules CPS RM 4/8 CPS DI 16 CPS AO 4 CPS 10 4 or 8 Relay Module 16 Digital logic Input module 4 Analog Output module CO, NO 2, LPG, NGV or H 2

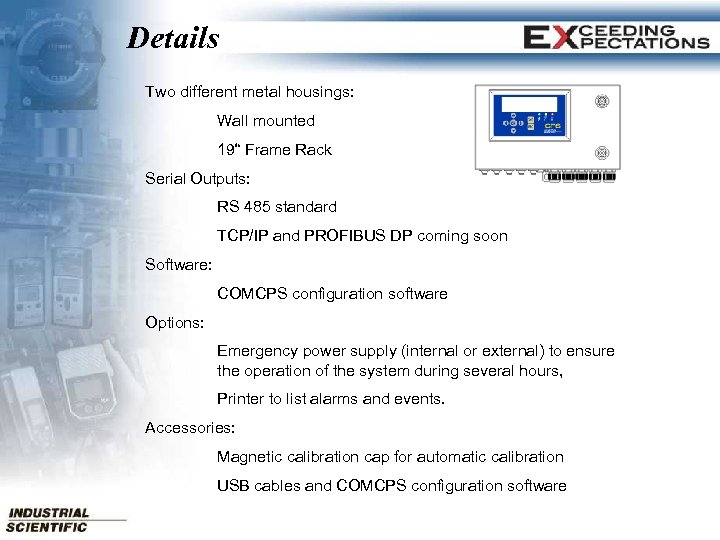

Details Two different metal housings: Wall mounted 19“ Frame Rack Serial Outputs: RS 485 standard TCP/IP and PROFIBUS DP coming soon Software: COMCPS configuration software Options: Emergency power supply (internal or external) to ensure the operation of the system during several hours, Printer to list alarms and events. Accessories: Magnetic calibration cap for automatic calibration USB cables and COMCPS configuration software

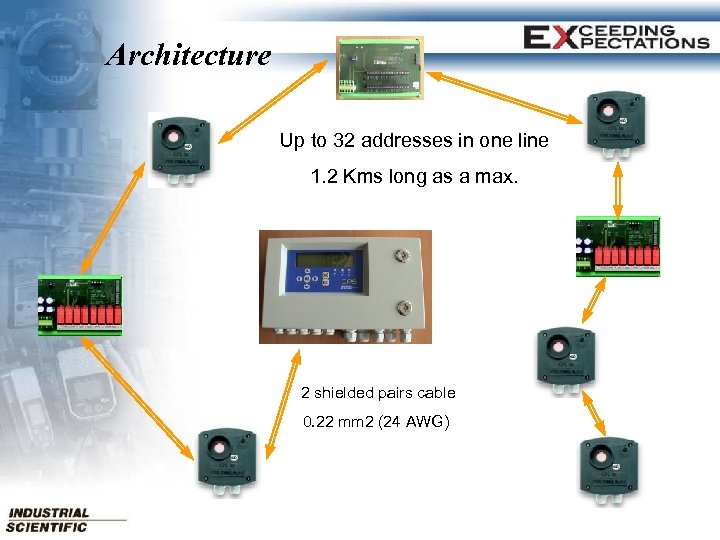

Architecture Up to 32 addresses in one line 1. 2 Kms long as a max. 2 shielded pairs cable 0. 22 mm 2 (24 AWG)

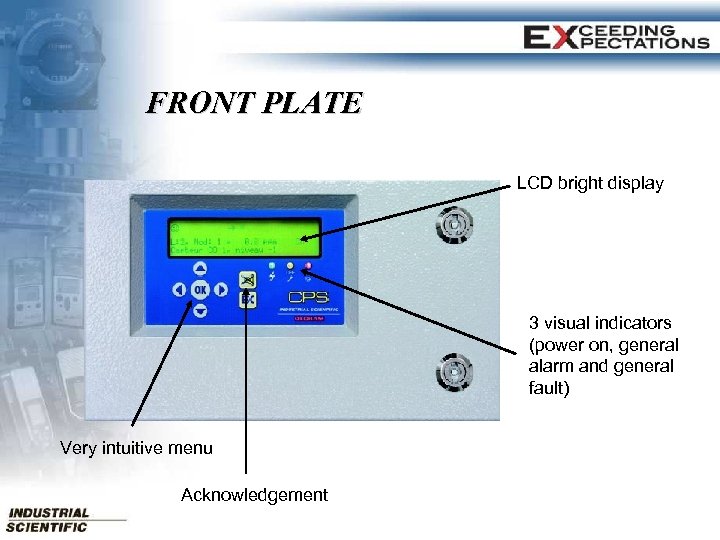

FRONT PLATE LCD bright display 3 visual indicators (power on, general alarm and general fault) Very intuitive menu Acknowledgement

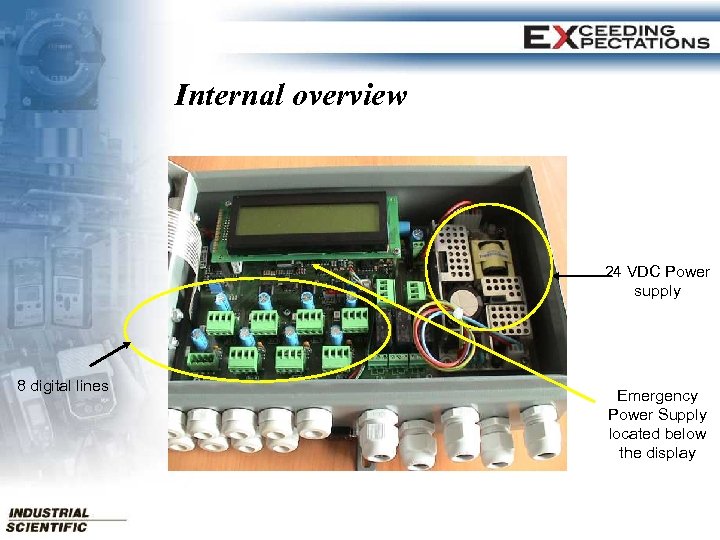

Internal overview 24 VDC Power supply 8 digital lines Emergency Power Supply located below the display

Addressable slave modules

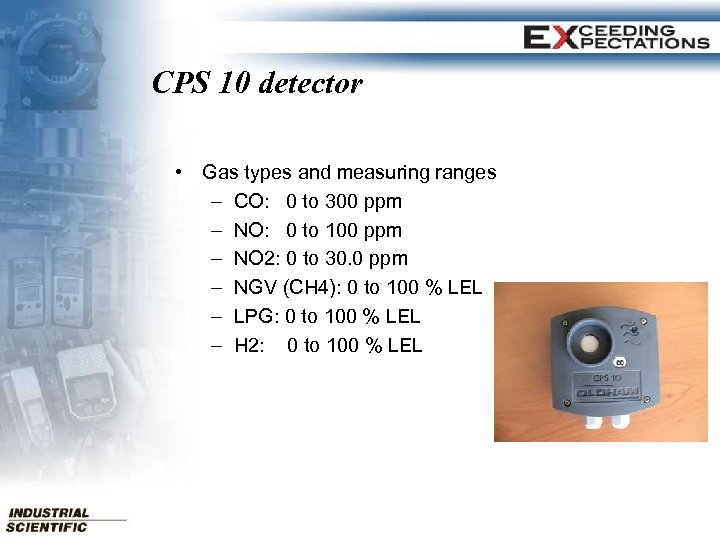

CPS 10 detector • Gas types and measuring ranges – CO: 0 to 300 ppm – NO: 0 to 100 ppm – NO 2: 0 to 30. 0 ppm – NGV (CH 4): 0 to 100 % LEL – LPG: 0 to 100 % LEL – H 2: 0 to 100 % LEL

CPS 10 calibration • Automatic mode • One man calibration • Non intrusive calibration by using a magnetic calibration cap • Up to 5 detectors simultaneously • Printing reports • Manual mode Open the detector and set the zero and span potentiometers • Service Sensor replacement can be done without switching off the line

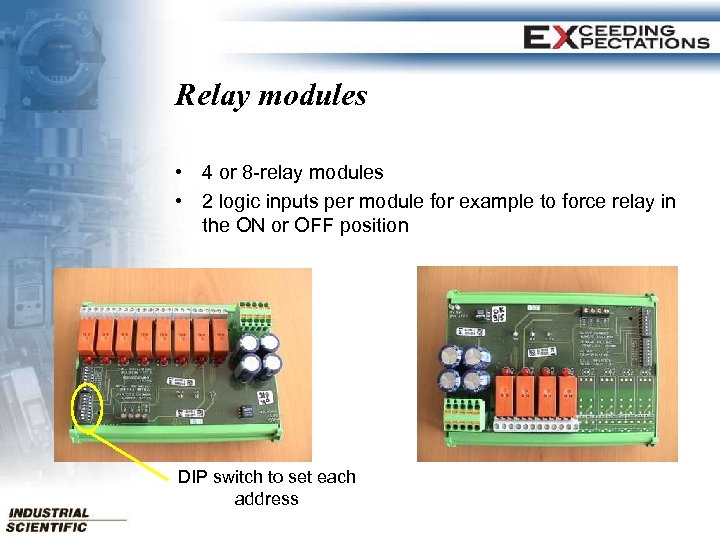

Relay modules • 4 or 8 -relay modules • 2 logic inputs per module for example to force relay in the ON or OFF position DIP switch to set each address

Relay configuration • 4 different modes : - Low speed - High speed - Normal - Buzzer

Alarms • 6 alarm events are available: alarm levels 1 to 4, over range and fault. • Alarms 1 to 4 can be delayed from 0 to 60 min or averaged to delay from 15 to 480 minutes for STEL and TWA. • The on-board buzzer is configurable and can be used to alert for a power supply failure, a gas alarm or a fault.

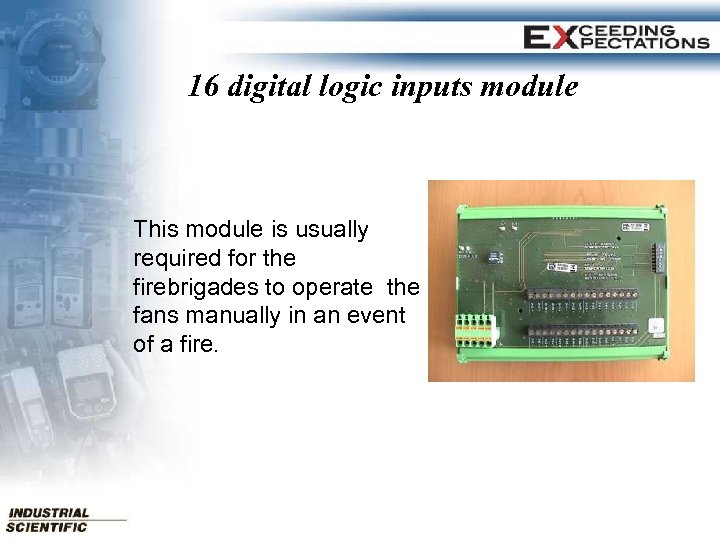

16 digital logic inputs module This module is usually required for the firebrigades to operate the fans manually in an event of a fire.

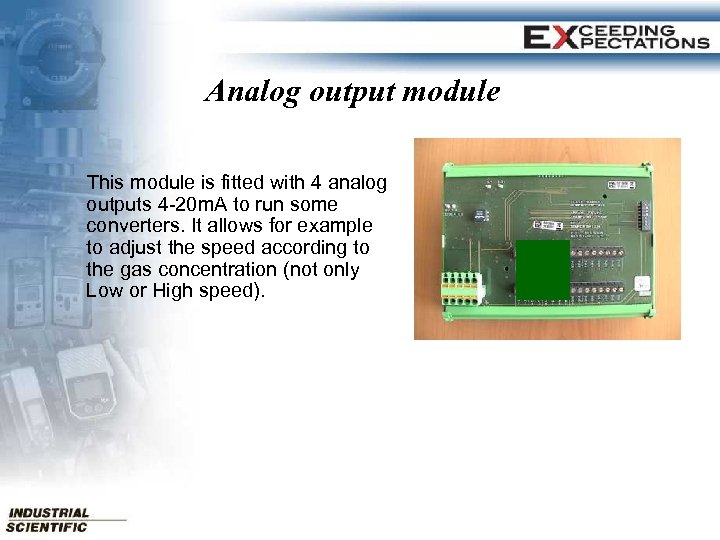

Analog output module This module is fitted with 4 analog outputs 4 -20 m. A to run some converters. It allows for example to adjust the speed according to the gas concentration (not only Low or High speed).

CPS System

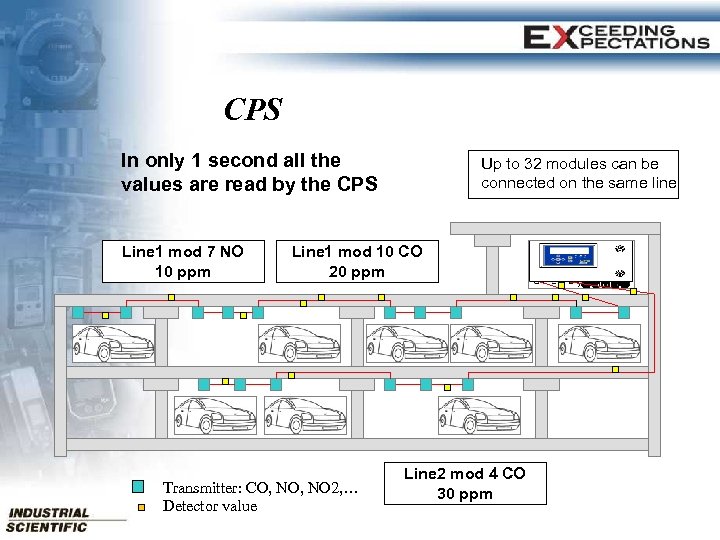

CPS In only 1 second all the values are read by the CPS Line 1 mod 7 NO 10 ppm Up to 32 modules can be connected on the same line Line 1 mod 10 CO 20 ppm Transmitter: CO, NO 2, … Detector value Line 2 mod 4 CO 30 ppm

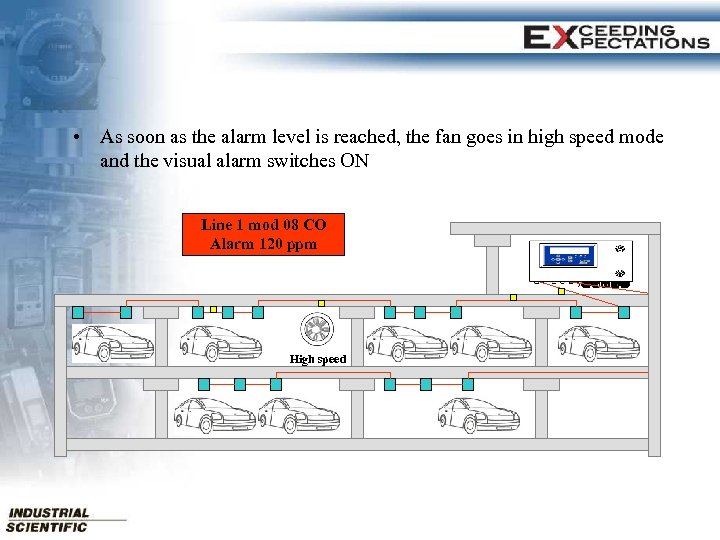

• As soon as the alarm level is reached, the fan goes in high speed mode and the visual alarm switches ON Line 1 mod 08 CO Alarm 120 ppm High speed

COMCPS software With the COMCPS software, you can set: - STEL and TWA calculations - Frequency of printings - Configuration of the internal buzzer - Transmitter configuration (label, location, type, alarm levels, etc. ) - Relay configuration (program, delay, state, low speed and high speed mode, etc. ) - Over range readings for flammable gases…

Questions ?

Thank You Vielen dank

16b0974b0103b723481245b05ccb34a3.ppt