67f4044de94fd4c624809642e0882e74.ppt

- Количество слайдов: 40

EMC for Semiconductor Manufacturing Facility, Equipment Electromagnetic Compatibility and E 33 Directions Industrial Equipment EMC Regulation & SEMI E 33 Mark Frankfurth, NCE, CLSO Engineering Manager Product Safety & Regulatory Compliance Cymer Inc. mfrankfurth@cymer. com Ph 858 -385 -6558 13 July 2006 SEMICON West 2006 EMC STEP Course

Agenda • What is Electromagnetic Regulatory Compliance? • U. S. FCC and Similar Regulations • The New European EMC Directive • SEMI E 33 Directions and Current Status • Steps Every Company Should Take to be EMC Compliant 2 13 July 2006 SEMICON West 2006 EMC STEP Course

EMC & EM Compliance EMC = Electro. Magnetic Compatibility This is the ability of equipment to operate in its electromagnetic environment. EMC is a “performance-based” measure. EM “Compliance” is conformance to the rules of electromagnetic control regulation. This is based on Limits, Standards, Codes, Directives, and Laws. “Prescriptive” measures. These are not the same! 3 13 July 2006 SEMICON West 2006 EMC STEP Course

Categories of EM Compliance There a few levels of rigor in EM Compliance, these are represented by: • Verification/Self-Declaration – Industrial equipment • Certification & Authorization – Consumer electronics, radios, transmitters • Mission-critical – Medical, military, etc. 4 13 July 2006 SEMICON West 2006 EMC STEP Course

Approaches to EM Regulation There are 2 main courses for EM regulation & compliance: • U. S. Federal Communications Commission – Code of Federal Regulations (47 CFR Part 15) – Emissions only (radiated & conducted) • European EMC Directive – Directive & EU Member Country Legislation – Emissions & Immunity (radiated & conducted) – Part of CE Mark customs enforcement 5 13 July 2006 SEMICON West 2006 EMC STEP Course

Industrial Equipment EM Compliance The focus of this presentation is Industrial Equipment for the Semiconductor Manufacturing Industry. This means good news & bad news: • Industrial equipment EM regulation is a pretty flexible and lenient compliance environment. • Industrial equipment EM compliance is not well understood. 6 13 July 2006 SEMICON West 2006 EMC STEP Course

EM Compliance & SEMI E 33 • The goal of SEMI E 33 revision is to provide EMC guidance to the suppliers and users of equipment while leveraging existing EM regulatory compliance approaches. • Compliance with the applicable legal EMC requirements for the target market will equate to conformance with SEMI E 33 as currently written. 7 13 July 2006 SEMICON West 2006 EMC STEP Course

FCC – U. S. & Canada • FCC = Federal Communications Commission • For industrial equipment, typically falling under the designation “Class A”, compliance is pretty simple: • • 8 Test to ensure emissions are under limits Take data to develop a report Label the product according to the FCC rules File the data/report for later 13 July 2006 SEMICON West 2006 EMC STEP Course

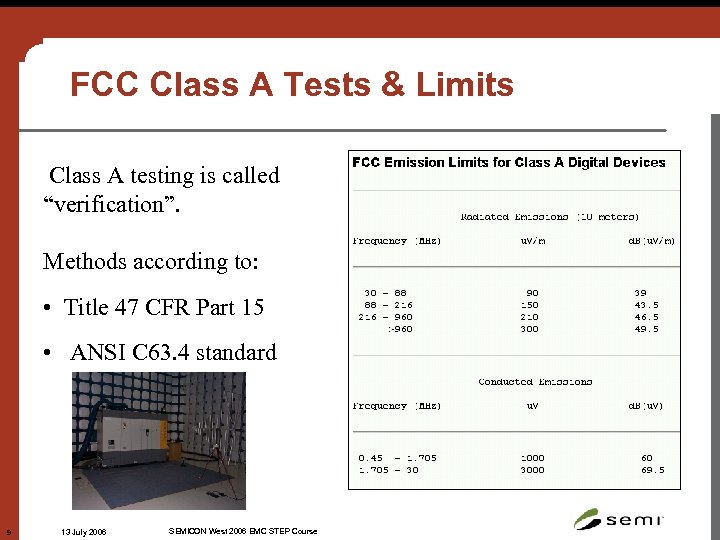

FCC Class A Tests & Limits Class A testing is called “verification”. Methods according to: • Title 47 CFR Part 15 • ANSI C 63. 4 standard 9 13 July 2006 SEMICON West 2006 EMC STEP Course

The FCC Class A Label Text The product would be labeled with the following exact wording: This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device shall not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation. And that is pretty much it for the FCC approach. 10 13 July 2006 SEMICON West 2006 EMC STEP Course

Europe & International Markets The rest of the globe concerned about EMC subscribes to the European approach and standards: • EMC Directive & Member Country Laws • Current EMC Directive 89/336/EEC • New EMC Directive 2004/108 • CISPR, IEC, and EN Technical Standards We will concentrate on the “New” EMC Directive 11 13 July 2006 SEMICON West 2006 EMC STEP Course

The New EMC Directive The newly published EMC Directive 2004/108 resulted from the SLIM and New Approach efforts to revise European Directives. Published in the Official Journal on 31 December 2004, this revision of the Directive came into force on 20 January 2005. Member states must implement it by 20 July 2007. 12 13 July 2006 SEMICON West 2006 EMC STEP Course

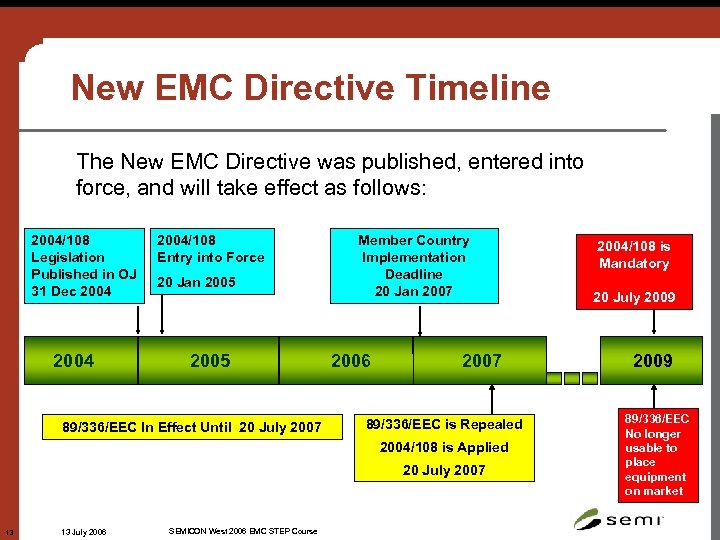

New EMC Directive Timeline The New EMC Directive was published, entered into force, and will take effect as follows: 2004/108 Legislation Published in OJ 31 Dec 2004/108 Entry into Force 20 Jan 2005 89/336/EEC In Effect Until 20 July 2007 Member Country Implementation Deadline 20 Jan 2007 2006 2007 89/336/EEC is Repealed 2004/108 is Applied 20 July 2007 13 13 July 2006 SEMICON West 2006 EMC STEP Course 2004/108 is Mandatory 20 July 2009 89/336/EEC No longer usable to place equipment on market

More Background • The new Directive may be referred to as “ 2004/108”, “Edition 2”, or “ 2 nd Edition”. • The 89/336/EEC Directive is in effect until 20 July 2007 when the old EMC Directive is repealed. • A transition period extends to 20 July 2009 before exclusive compliance to 2004/108 is required. 14 13 July 2006 SEMICON West 2006 EMC STEP Course

More Background What is a “Directive”? • High-level goals for European Union. • Instructions for member countries to create consistent legislation. • Hint: We are required to follow the laws of the countries! • Can’t declare to the new directive yet because country legislation is not in place. (e. g. Ro. HS) 15 13 July 2006 SEMICON West 2006 EMC STEP Course

Interpretations = Opinions There will be a couple of years of pontificating on the meaning of the changes. Every interpretation is just an opinion until… • Official European Commission guidance is issued or • Courts rule to set precedents Be careful who and what you believe ! (An updated interpretation “Guidance Document” is expected in late 2006 – will it be official? ) 16 13 July 2006 SEMICON West 2006 EMC STEP Course

EMC Directive Purpose • To ensure the function of the Internal European Market. • To ensure and adequate level of electromagnetic compatibility among products in the European Market. • Estimated to affect 800 Million products 17 13 July 2006 SEMICON West 2006 EMC STEP Course

New Approach Directives • State Essential Requirements. • Are supported by harmonized standards. • The big presumption: Conformance to harmonized standards equates to meeting the essential requirements. • Conformity assessment approach is used when these boundaries are exceeded. 18 13 July 2006 SEMICON West 2006 EMC STEP Course

Strategy As with all regulatory compliance rule changes, it is important to study the text of the rules and understand the potential impact for your products and business. Fortunately, the changes to the Directive are not large for most companies and appear to be beneficial overall. 19 13 July 2006 SEMICON West 2006 EMC STEP Course

Outside of EMC Directive Scope • • Telecom equipment under R&TTED Aviation/Aeronautical Products Amateur Radio Equipment – ITU Specificity Clause (Article 4. 1) – Where EMC specified in another Directive – Example = Medical Devices Directive 20 13 July 2006 SEMICON West 2006 EMC STEP Course

Protection Requirements • Equipment shall be so designed and manufactured, having regard to the state of the art, as to ensure that: • The electromagnetic disturbance generated does not exceed the level above which radio and telecommunication equipment or other equipment cannot operate as intended. • It has a level of immunity to the electromagnetic disturbance to be expected in its intended use which allows it to operate without unacceptable degradation of its intended use. 21 13 July 2006 SEMICON West 2006 EMC STEP Course

All in the Definitions • Equipment = apparatus or fixed installation • Apparatus = finished appliance or combination thereof made commercially available as a single functional unit, intended for the end-user… • Fixed Installation – particular combination of several types of apparatus and, where applicable, other devices, which are assembled, installed, and intended to be permanently used at a predefined location. 22 13 July 2006 SEMICON West 2006 EMC STEP Course

All in the Definitions continued • Apparatus includes components or subassemblies intended for incorporation into apparatus by the end-users… • Apparatus also includes Mobile Installations… • Key discrimination factor: Apparatus are made commercially available to end-users as a single functional unit. 23 13 July 2006 SEMICON West 2006 EMC STEP Course

How Does This Apply? Large-scale, integrated equipment can potentially qualify as a “Fixed Installation” This could prove very beneficial to the shipment and installation of leading-edge technology demonstration systems where individual elements are not yet conforming to the Directive. Most equipment will be classified “Apparatus”. 24 13 July 2006 SEMICON West 2006 EMC STEP Course

Brief List of Changes • Increased emphasis on Essential Requirements for Protection, and “good engineering practice” • Competent Bodies no longer exist in the Directive. Notified Bodies can be used. • Independent conformity assessment review of EMC compliance documentation is now purely voluntary. 25 13 July 2006 SEMICON West 2006 EMC STEP Course

Brief List of Changes continued • Technical Construction File (TCF) has been renamed Technical Documentation that all must assemble and make available to provide evidence of conformity assessment. A 10 year document retention requirement is defined. • Non-conforming equipment may be displayed or demonstrated at exhibits, trade shows, etc. provided that: – Markings indicate equipment may not be placed on the market until conformity is achieved. – EM Disturbances from demonstrations are controlled. 26 13 July 2006 SEMICON West 2006 EMC STEP Course

Brief List of Changes continued • Emphasis on testing different equipment configurations that could normally occur, or a known inclusive “worst-case” configuration. • Permanent custom systems are addressed as “Fixed Installations” which we will address further in this presentation. • Definitions have been updated and added to clarify terminology and interpretations. 27 13 July 2006 SEMICON West 2006 EMC STEP Course

What is NOT There • Changes to underlying Standards – Standards are technology-driven. • Definitions of “Place on the market” or “Put into service” as triggers for required conformance. – This still must come from supplemental interpretations e. g. “Blue Book”. Guidance document planned for 2006. • Onerous cable testing provisions discussed in the development of the revision. • Involvement in Safety of products or systems – e. g. “Functional Safety” considerations 28 13 July 2006 SEMICON West 2006 EMC STEP Course

Fixed Installations Do Not Require: Do Require: • Compliance with Essential Requirements • EMC Assessment for Protection • Declaration of Conformity • Attention to EMC-related • CE Mark Affixed installation requirements • Documentation of “good engineering practices” • Responsible Person holding the Technical Documentation 29 13 July 2006 SEMICON West 2006 EMC STEP Course

EMC Directive vs. WEEE Definitions The exception identified in WEEE for Largescale stationary industrial tools appears to have little in common with the Fixed Installation definition in the New EMC Directive. Although elements of the Fixed Installation wording could be used to support a WEEE exception argument, it does not appear to be a strong case. Use caution when borrowing definitions! 30 13 July 2006 SEMICON West 2006 EMC STEP Course

Conclusions of 2004/108 Review • Benefits are provided by New EMC Directive: – – – Reduced evaluation requirements under TCF Route Notified Body oversight is voluntary Better coverage of Fixed Installations Trade-show provisions Improved definitions and descriptions • Drawbacks: – Potential multiple configuration assessment requirement – Narrow scope of Fixed Installation category 31 13 July 2006 SEMICON West 2006 EMC STEP Course

Coming EMCD Guidance Document • • Contains 60+ pages to explain 14 page Directive 5 useful Flowcharts for Classification Process Presently undergoing refinement by Working Group Explanations of each section: – Scope of EMCD – Essential Requirements – Rules for Apparatus – Rules for Fixed Installations – Enforcement 32 13 July 2006 SEMICON West 2006 EMC STEP Course – Role of Notified Bodies – EMC-Benign Equipment – Areas Where EMCD Not Applicable – Spare Parts/Repair Activities – Technical Documentation

Apparatus versus Fixed Installation Bad news: Almost all products will be categorized as “apparatus”. • Definitions and interpretations of Fixed Installations very narrow, and direction is not supportive of Semiconductor Manufacturing Equipment (SME). • Fixed Installations oriented toward geographically large systems (railway systems, power-plants, etc. ) or • Equipment that is built-into a physical plant, e. g. elevators, overhead cranes, communications wiring. So SME is unlikely to enjoy Fixed Installation flexibility. 33 13 July 2006 SEMICON West 2006 EMC STEP Course

Spare Parts & Service • Much like safety guidance, if equipment is returned to the original compliant condition then no new compliance requirements are triggered. • If the equipment is changed or upgraded in a way that could change the EMC characteristics, the equipment must conform to the requirements of the New EMC Directive. • Components & subassemblies EMCD provisions apply here as well. More explanation is expected in this area. 34 13 July 2006 SEMICON West 2006 EMC STEP Course

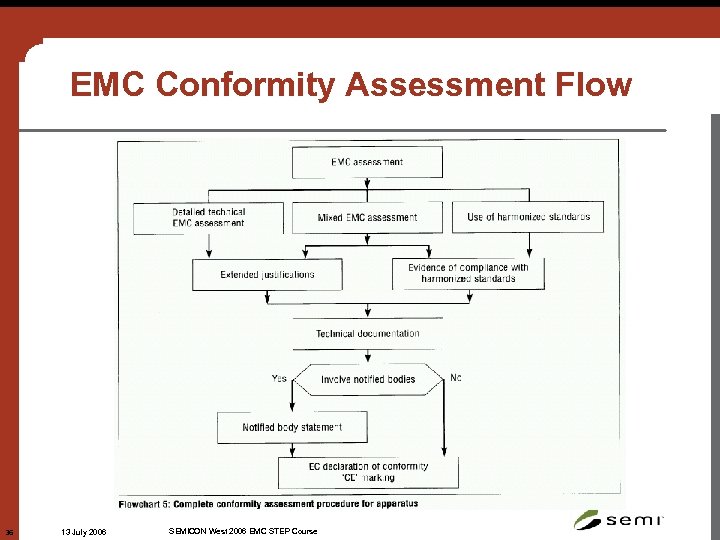

Conformity Assessment Options A flowchart details the potential methods for assessing EMC conformance: • Conform to Harmonized Standards • Detailed Technical EMC Assessment • Mixed EMC Assessment Much more detail expected in this area when the Guidance Document is finalized. 35 13 July 2006 SEMICON West 2006 EMC STEP Course

EMC Conformity Assessment Flow 36 13 July 2006 SEMICON West 2006 EMC STEP Course

SEMI E 33 Directions • The SEMI E 33 revision seeks to update references and overlay semiconductor industryspecific information on top of existing EMC compliance systems. • For example, conformance with the processes and requirements of the EU EMC Directive is intended to satisfy the requirements of SEMI E 33. • The goal of E 33 revision is improved information & awareness of EMC without increased compliance requirements for equipment. 37 13 July 2006 SEMICON West 2006 EMC STEP Course

Steps a Company Should Take To ensure EMC and EM compliance, the following steps are recommended: • Become familiar with the New EMC Directive via self-study or available courses. • Learn pre-compliance methods and test instrument usage to improve EMC before the test lab phase. • Take advantage of EMC expertise when needed to resolve problems or interpretation issues. • Address customer EMC concerns effectively. 38 13 July 2006 SEMICON West 2006 EMC STEP Course

Helpful References & Links New EMC Directive. pdf http: //europa. eu. int/eur-lex/Lex. Uri. Serv/site/en/oj/2004/l_39020041231 en 00240037. pdf EMCD Guidance Document Preview Article from Conformity Magazine: http: //www. conformity. com/0606_F 01. html Link to Cherry-Clough/Keith Armstrong’s Fixed Installation Presentation for interesting interpretations: http: //www. reo. co. uk/files/kbase/emc 2 c_Installations_under_EMCD 2. pdf Credits to Isador Straus & Gary Fenical for their Conformity articles. Credit to Dan Hoolihan for his TUV-America New EMC Directive slides. Credit to Keith Armstrong for his thoughts on Functional Safety & EMC. 39 13 July 2006 SEMICON West 2006 EMC STEP Course

Author/Presenter – Mark Frankfurth Mark S. Frankfurth is a graduate of Virginia Polytechnic Institute and State University (VPI & SU "Virginia Tech") in Blacksburg, Virginia, receiving a bachelor's degree in Electrical Engineering in 1988. Presently holding an engineering management position at Cymer Inc. overseeing Product Safety & Regulatory Compliance Engineering, Mark assists in the development of high-power industrial laser systems for semiconductor industry photolithography processes. Background expertise in product safety, electromagnetic compatibility (EMC), and quality engineering resulted from 5 years as a Senior EMC Engineer at AST Research Inc. of Irvine, California, where Mark contributed to the development of personal computer systems from an EMC, safety, and reliability engineering perspective. Prior to this Mark participated in the development and installation of optical fire detection systems detecting UV and IR signatures. Mark is a Certified Laser Safety Officer (CLSO) by the Laser Institute of America (LIA) Board of Laser Safety, a NARTE certified EMC Engineer, and formerly was an ASQ Certified Quality Engineer. A member of IEEE for 20 years, Mark has served in Chapter and Section officer roles including San Diego EMC Chapter Chairman and Section Secretary. Organizations Mark supports as officer or member include SESHA, ASSE, NFPA, SEMI, NARTE, and IEEE. Mark is continuing his professional development by pursuing a professional certificate in Occupational Health & Safety and Certified Safety Professional credentials. Contact Info – email: mfrankfurth@cymer. com phone: 858 -385 -6558 40 13 July 2006 SEMICON West 2006 EMC STEP Course

67f4044de94fd4c624809642e0882e74.ppt