7c7fac3b62688c90ce8664db26649435.ppt

- Количество слайдов: 150

Elevator Training 2003 Content: ¨Elevator terminology and components ¨Types of elevators ¨Safety features ¨Types of Emergencies ¨Rescue methods 1

Elevator Training 2003 Content: ¨Elevator terminology and components ¨Types of elevators ¨Safety features ¨Types of Emergencies ¨Rescue methods 1

Elevator Training 2003 Please note: *Remember, all elevators are not built the same. *Elevators installed at different time periods conform to different requirements or codes. *Elevator features and operation may vary from one elevator to another. *Get to know the elevators in the buildings that you respond to during pre-fire inspections. 2

Elevator Training 2003 Please note: *Remember, all elevators are not built the same. *Elevators installed at different time periods conform to different requirements or codes. *Elevator features and operation may vary from one elevator to another. *Get to know the elevators in the buildings that you respond to during pre-fire inspections. 2

Elevator Training 2003 Counterweight A tracked weight that is suspended from cables and moves within its own set of guide rails along the hoistway walls. This counterweight will be equal to the dead weight of the car plus about 40% of the rated load. 3

Elevator Training 2003 Counterweight A tracked weight that is suspended from cables and moves within its own set of guide rails along the hoistway walls. This counterweight will be equal to the dead weight of the car plus about 40% of the rated load. 3

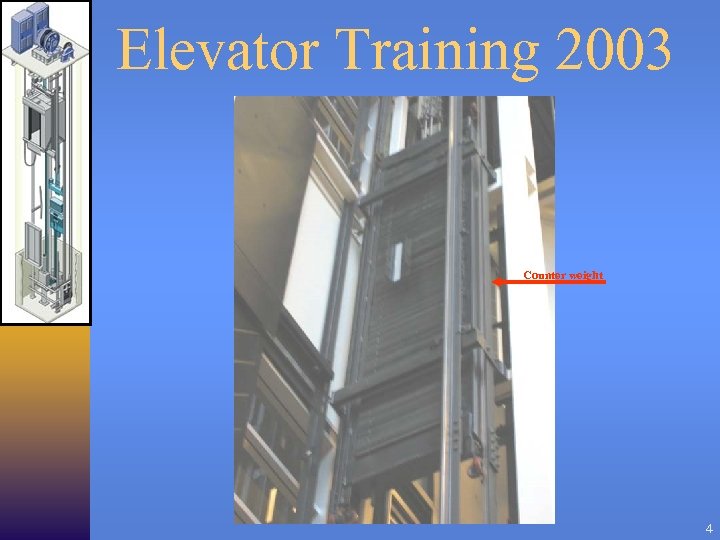

Elevator Training 2003 Counter weight 4

Elevator Training 2003 Counter weight 4

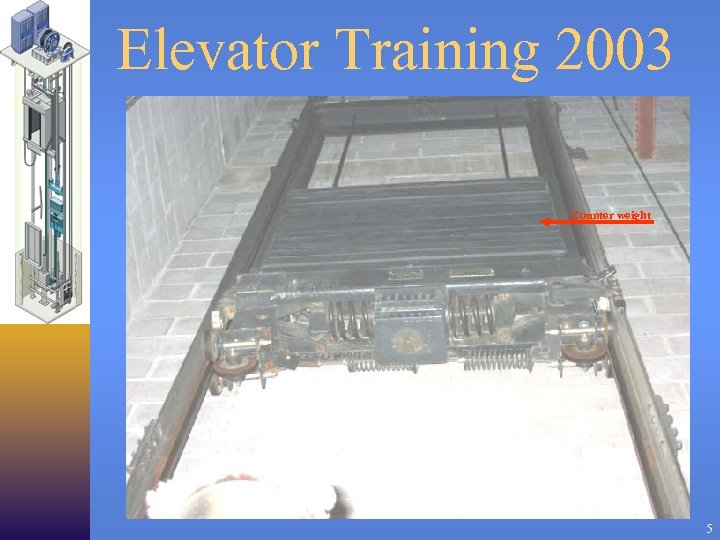

Elevator Training 2003 Counter weight 5

Elevator Training 2003 Counter weight 5

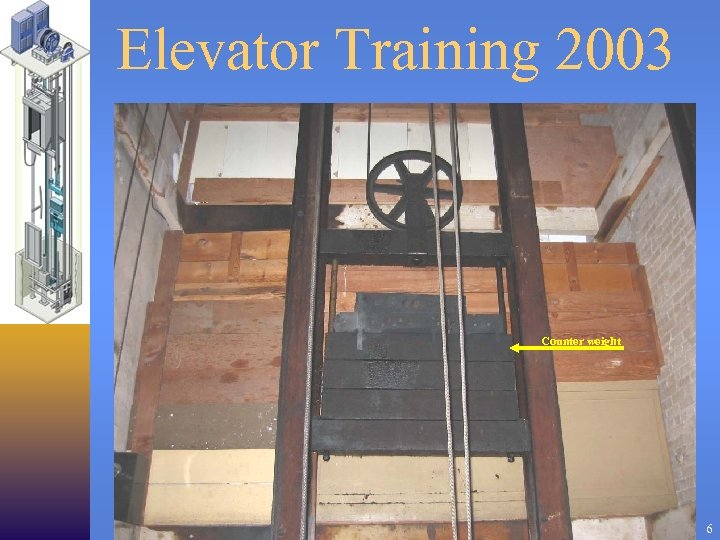

Elevator Training 2003 Counter weight 6

Elevator Training 2003 Counter weight 6

Elevator Training 2003 Hoistway The shaft that encompasses the elevator car. Generally serving all floors of the building. 7

Elevator Training 2003 Hoistway The shaft that encompasses the elevator car. Generally serving all floors of the building. 7

Elevator Training 2003 Hoistway In high-rise buildings hoistways may be banked. With specific hoistways serving only the lower floors and others serving only middle or upper floors while traveling in a blind hoistway until reaching the floors that it serves. A blind hoistway has no doors on the floors that it does not serve. 8

Elevator Training 2003 Hoistway In high-rise buildings hoistways may be banked. With specific hoistways serving only the lower floors and others serving only middle or upper floors while traveling in a blind hoistway until reaching the floors that it serves. A blind hoistway has no doors on the floors that it does not serve. 8

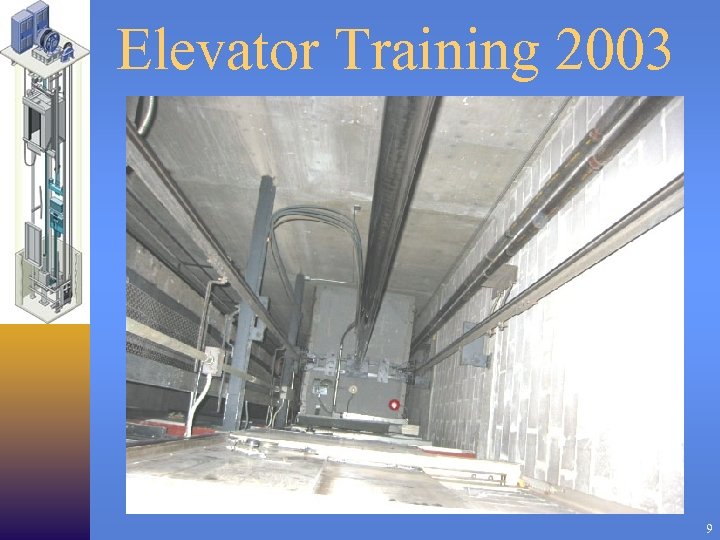

Elevator Training 2003 9

Elevator Training 2003 9

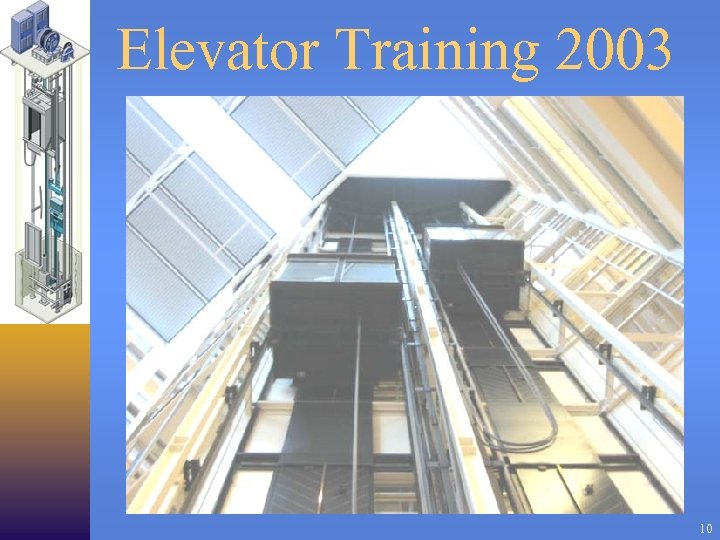

Elevator Training 2003 10

Elevator Training 2003 10

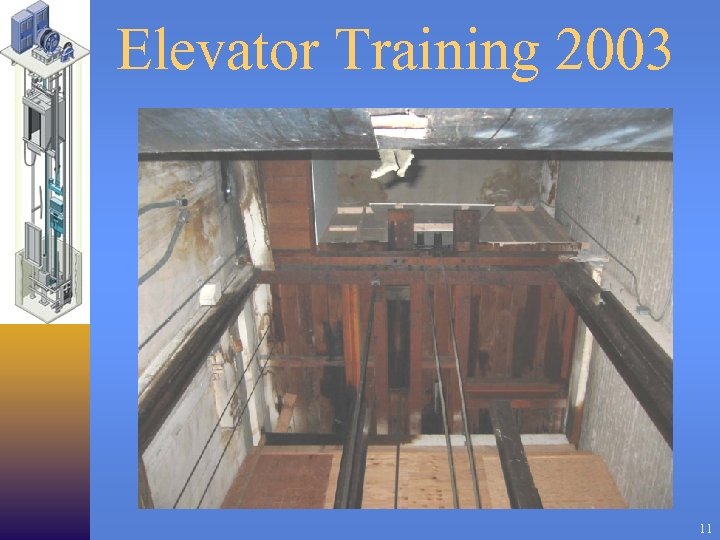

Elevator Training 2003 11

Elevator Training 2003 11

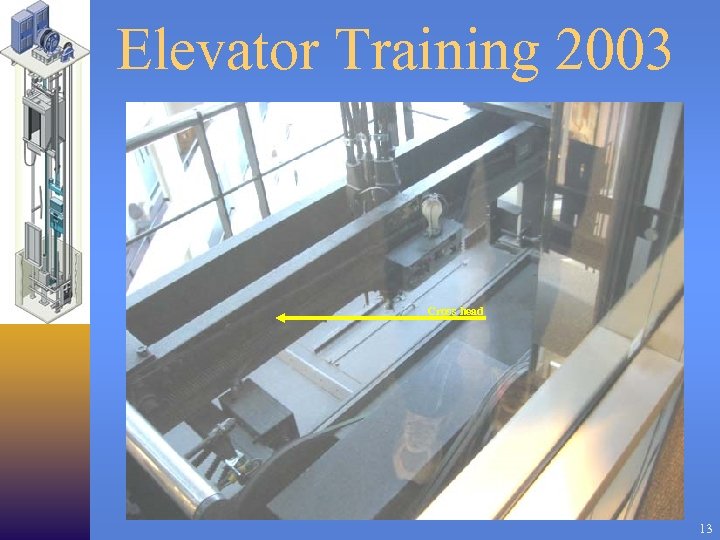

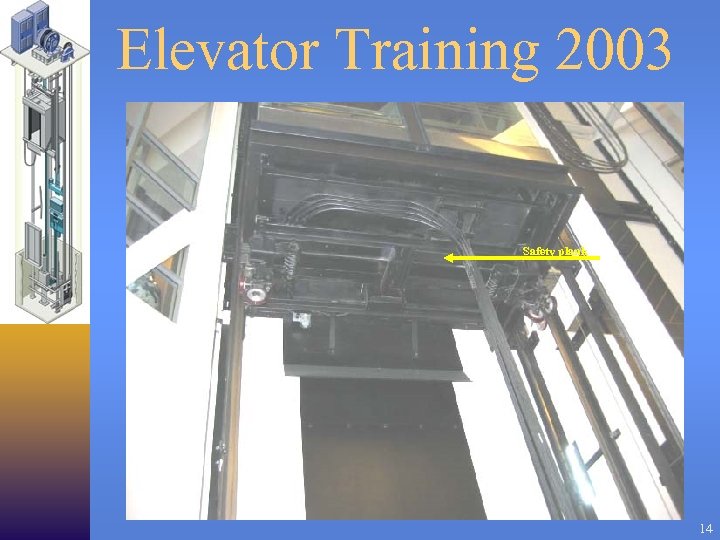

Elevator Training 2003 Elevator car A heavy steel frame surrounding a cage of metal and wood panels. The top of the car frame is called the “crosshead”. Cabled elevators are usually suspended from the crosshead. The bottom of the frame is usually referred to as the “safety plank”. 12

Elevator Training 2003 Elevator car A heavy steel frame surrounding a cage of metal and wood panels. The top of the car frame is called the “crosshead”. Cabled elevators are usually suspended from the crosshead. The bottom of the frame is usually referred to as the “safety plank”. 12

Elevator Training 2003 Cross head 13

Elevator Training 2003 Cross head 13

Elevator Training 2003 Safety plank 14

Elevator Training 2003 Safety plank 14

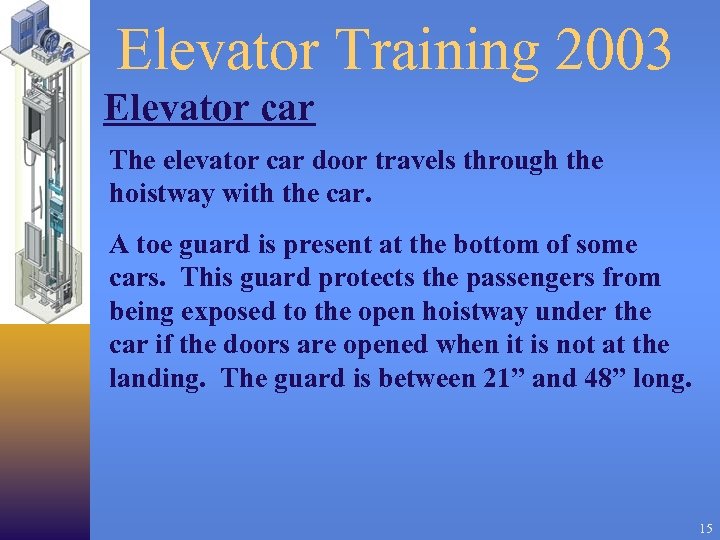

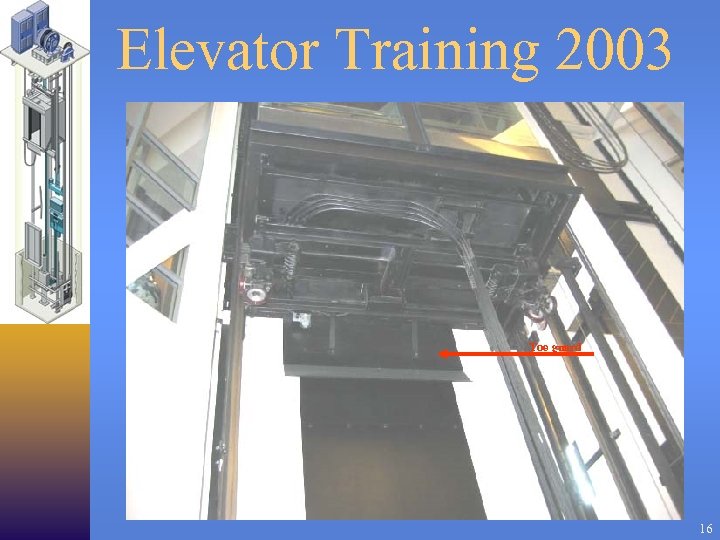

Elevator Training 2003 Elevator car The elevator car door travels through the hoistway with the car. A toe guard is present at the bottom of some cars. This guard protects the passengers from being exposed to the open hoistway under the car if the doors are opened when it is not at the landing. The guard is between 21” and 48” long. 15

Elevator Training 2003 Elevator car The elevator car door travels through the hoistway with the car. A toe guard is present at the bottom of some cars. This guard protects the passengers from being exposed to the open hoistway under the car if the doors are opened when it is not at the landing. The guard is between 21” and 48” long. 15

Elevator Training 2003 Toe guard 16

Elevator Training 2003 Toe guard 16

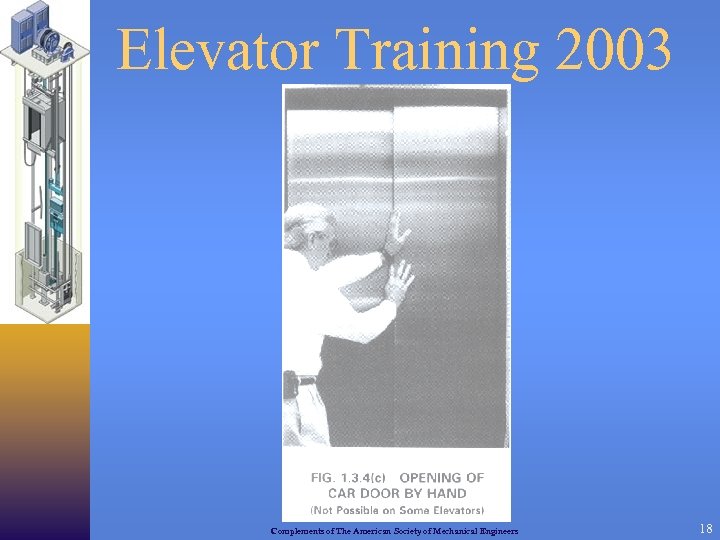

Elevator Training 2003 Elevator door These doors can sometimes opened on the inside by hand, except where anti-egress devices are installed. This will also break the electrical interlock which will cut the power to the car. 17

Elevator Training 2003 Elevator door These doors can sometimes opened on the inside by hand, except where anti-egress devices are installed. This will also break the electrical interlock which will cut the power to the car. 17

Elevator Training 2003 Complements of The American Society of Mechanical Engineers 18

Elevator Training 2003 Complements of The American Society of Mechanical Engineers 18

Elevator Training 2003 Anti-egress lock 19

Elevator Training 2003 Anti-egress lock 19

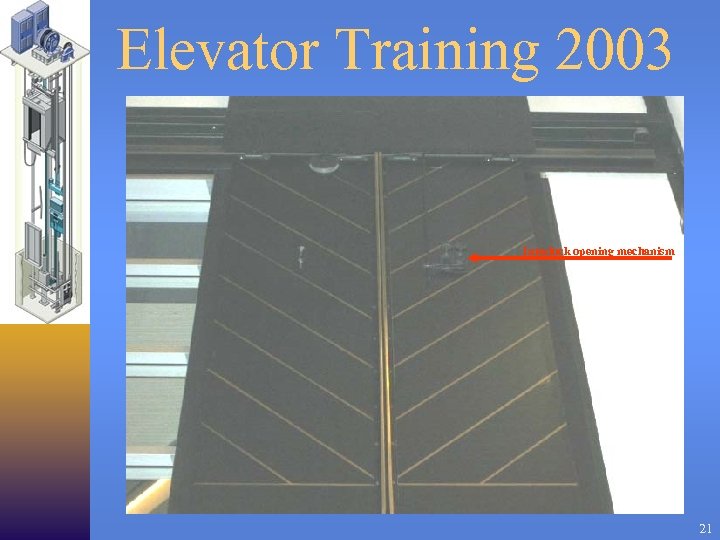

Elevator Training 2003 Hoistway doors Horizontal operating hoistway doors are generally hung from the top on rollers that run in a track, with the bottom of the door running in a slot. 20

Elevator Training 2003 Hoistway doors Horizontal operating hoistway doors are generally hung from the top on rollers that run in a track, with the bottom of the door running in a slot. 20

Elevator Training 2003 Interlock opening mechanism 21

Elevator Training 2003 Interlock opening mechanism 21

Elevator Training 2003 Hoistway doors Forcing these doors at the middle or at the bottom will cause damage to the doors and their mounting hardware. The doors can also be knocked out of their track and fall into the hoistway. 22

Elevator Training 2003 Hoistway doors Forcing these doors at the middle or at the bottom will cause damage to the doors and their mounting hardware. The doors can also be knocked out of their track and fall into the hoistway. 22

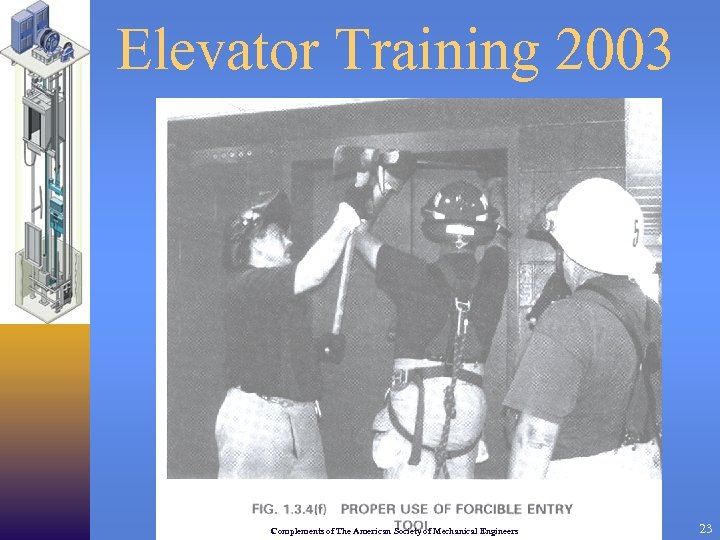

Elevator Training 2003 Complements of The American Society of Mechanical Engineers 23

Elevator Training 2003 Complements of The American Society of Mechanical Engineers 23

Elevator Training 2003 Hoistway door interlock The hoistway door locking mechanism provides a means to mechanically lock each hoistway door. They are also interconnected electrically to prevent operation of the elevator if any of the elevator’s hoistway doors are open. 24

Elevator Training 2003 Hoistway door interlock The hoistway door locking mechanism provides a means to mechanically lock each hoistway door. They are also interconnected electrically to prevent operation of the elevator if any of the elevator’s hoistway doors are open. 24

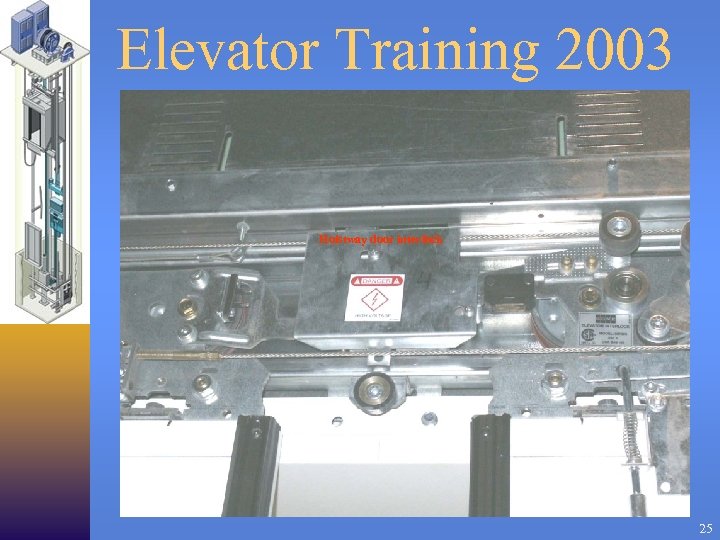

Elevator Training 2003 Hoistway door interlock 25

Elevator Training 2003 Hoistway door interlock 25

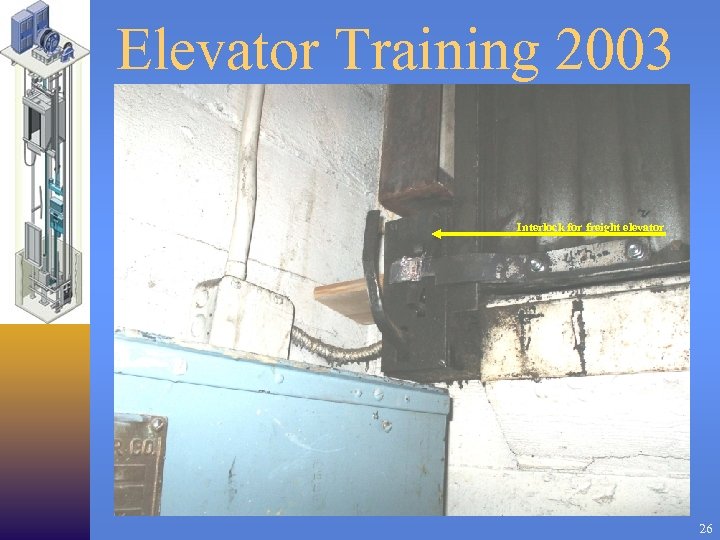

Elevator Training 2003 Interlock for freight elevator 26

Elevator Training 2003 Interlock for freight elevator 26

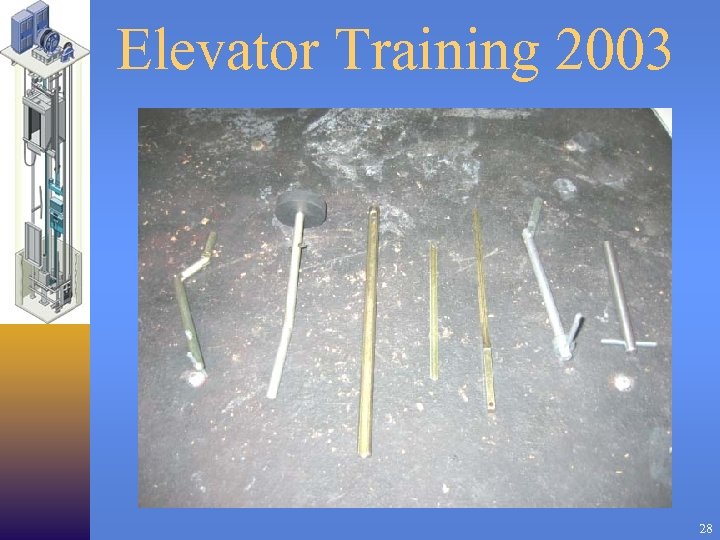

Elevator Training 2003 Hoistway emergency door keys Carried on trucks and the squad, permit the unlocking of the hoistway door interlock. 27

Elevator Training 2003 Hoistway emergency door keys Carried on trucks and the squad, permit the unlocking of the hoistway door interlock. 27

Elevator Training 2003 28

Elevator Training 2003 28

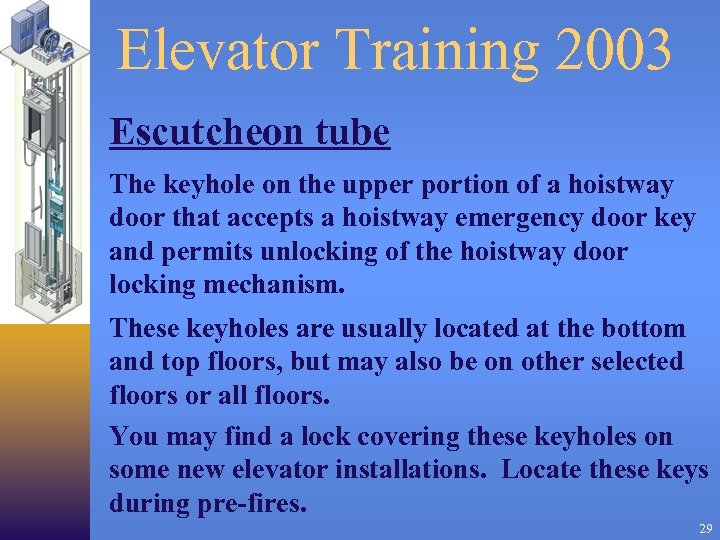

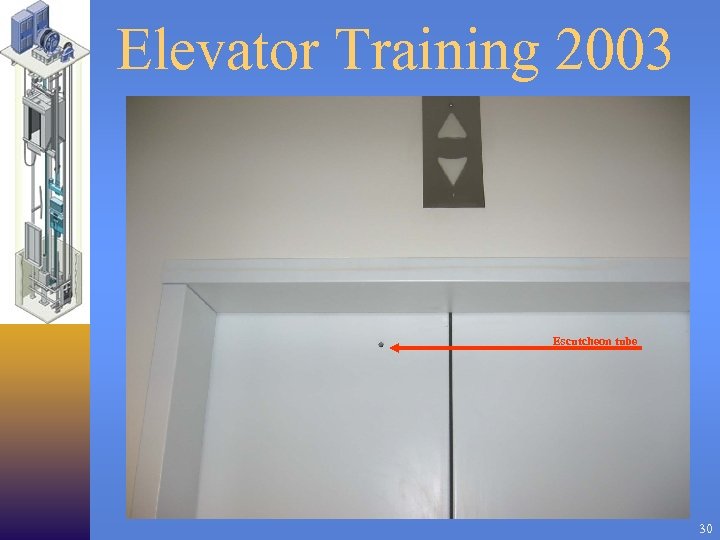

Elevator Training 2003 Escutcheon tube The keyhole on the upper portion of a hoistway door that accepts a hoistway emergency door key and permits unlocking of the hoistway door locking mechanism. These keyholes are usually located at the bottom and top floors, but may also be on other selected floors or all floors. You may find a lock covering these keyholes on some new elevator installations. Locate these keys during pre-fires. 29

Elevator Training 2003 Escutcheon tube The keyhole on the upper portion of a hoistway door that accepts a hoistway emergency door key and permits unlocking of the hoistway door locking mechanism. These keyholes are usually located at the bottom and top floors, but may also be on other selected floors or all floors. You may find a lock covering these keyholes on some new elevator installations. Locate these keys during pre-fires. 29

Elevator Training 2003 Escutcheon tube 30

Elevator Training 2003 Escutcheon tube 30

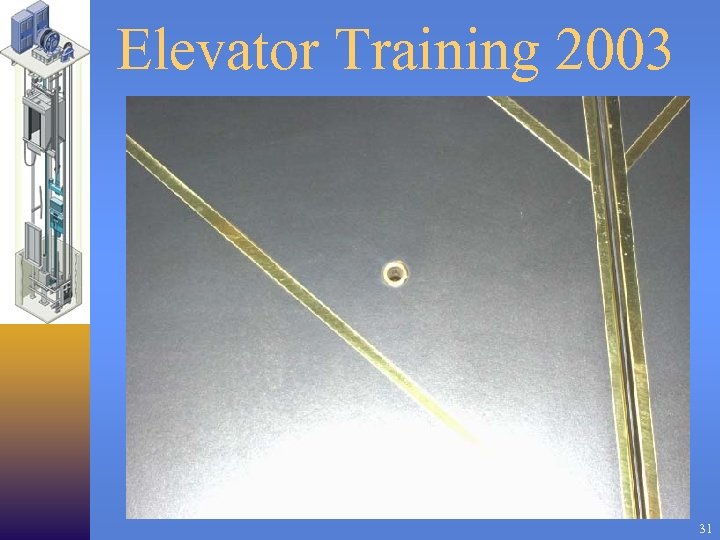

Elevator Training 2003 31

Elevator Training 2003 31

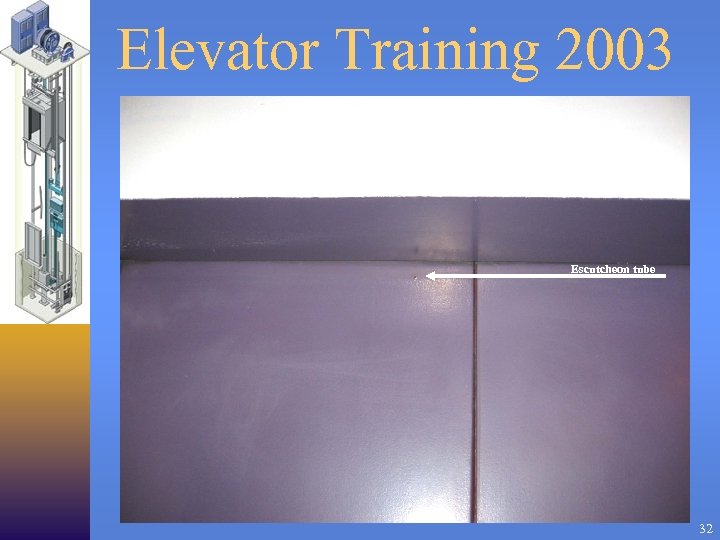

Elevator Training 2003 Escutcheon tube 32

Elevator Training 2003 Escutcheon tube 32

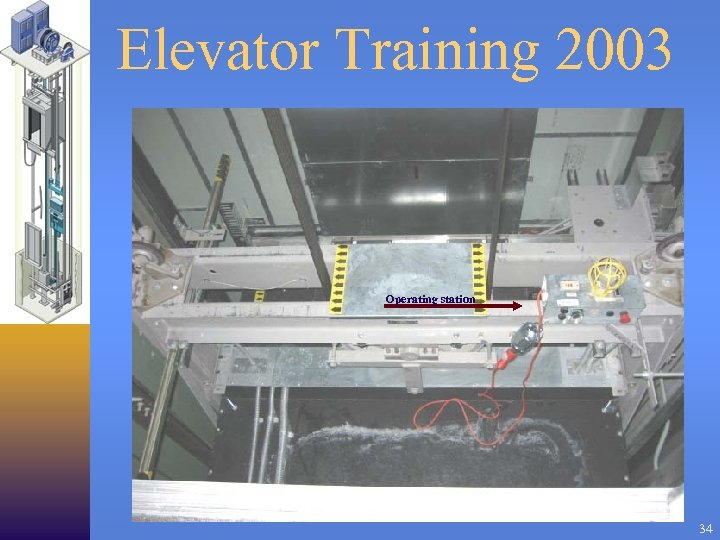

Elevator Training 2003 Car top operating station Provided on some cars for operating the car from the car top. To be used by the elevator technician when servicing the car. This station should only be operated under the direct supervision of the elevator technician. 33

Elevator Training 2003 Car top operating station Provided on some cars for operating the car from the car top. To be used by the elevator technician when servicing the car. This station should only be operated under the direct supervision of the elevator technician. 33

Elevator Training 2003 Operating station 34

Elevator Training 2003 Operating station 34

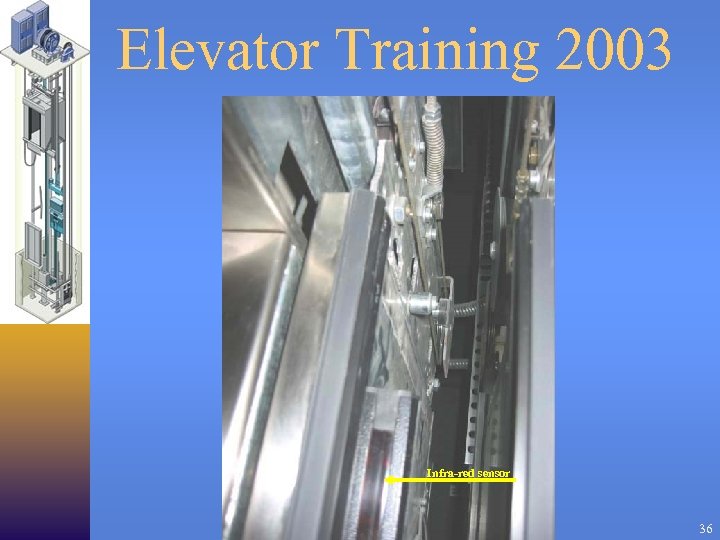

Elevator Training 2003 Photo-electric and infrared sensors A sensor between the hoistway and car doors that detects objects in their path and prevents the doors from closing. Photo-electric eyes were problematic and are being phased out. 35

Elevator Training 2003 Photo-electric and infrared sensors A sensor between the hoistway and car doors that detects objects in their path and prevents the doors from closing. Photo-electric eyes were problematic and are being phased out. 35

Elevator Training 2003 Infra-red sensor 36

Elevator Training 2003 Infra-red sensor 36

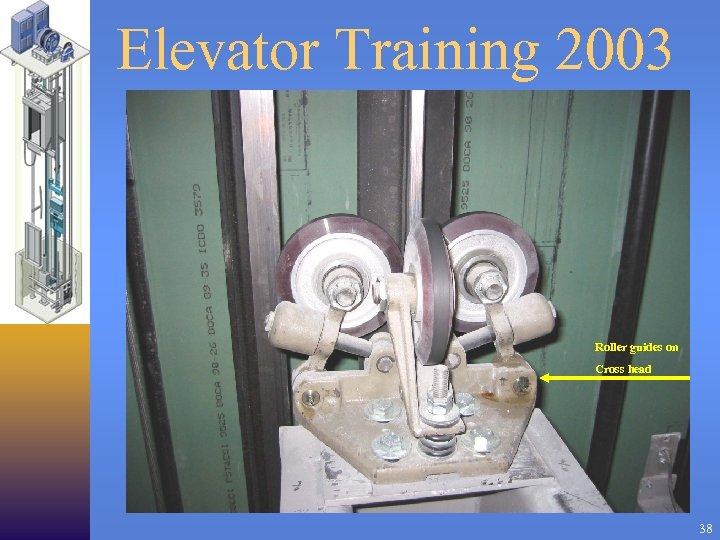

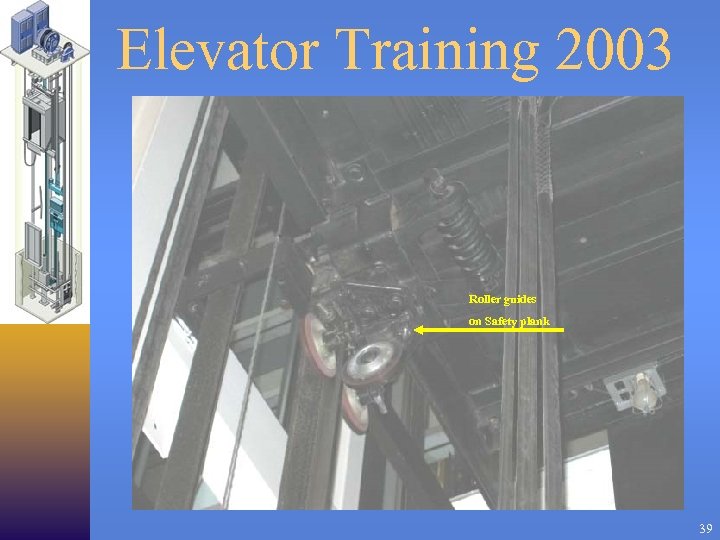

Elevator Training 2003 Roller guides A set of three wheels that roll against the guide rails. Usually mounted to the safety plank and crosshead. They keep the car in contact with the guide rails and prevent sway. 37

Elevator Training 2003 Roller guides A set of three wheels that roll against the guide rails. Usually mounted to the safety plank and crosshead. They keep the car in contact with the guide rails and prevent sway. 37

Elevator Training 2003 Roller guides on Cross head 38

Elevator Training 2003 Roller guides on Cross head 38

Elevator Training 2003 Roller guides on Safety plank 39

Elevator Training 2003 Roller guides on Safety plank 39

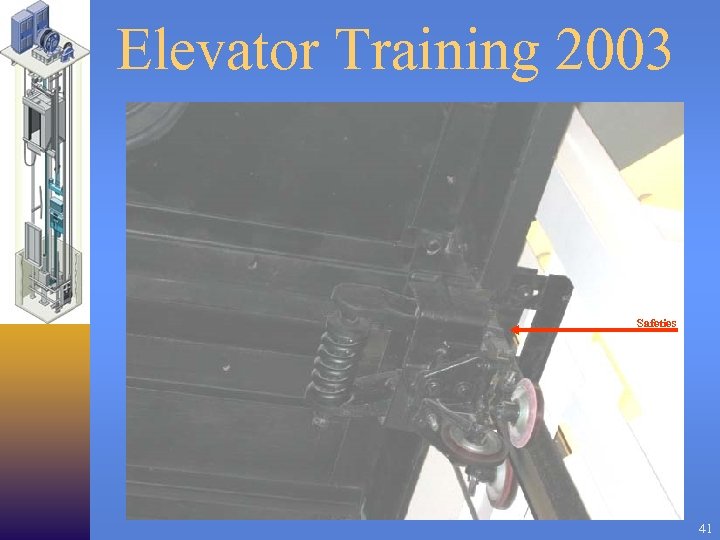

Elevator Training 2003 Safeties Emergency braking mechanism that stops the car by wedging into the guide rails when over speeding has occurred. It is activated by the speed governor sensing over speeding of the elevator car. 40

Elevator Training 2003 Safeties Emergency braking mechanism that stops the car by wedging into the guide rails when over speeding has occurred. It is activated by the speed governor sensing over speeding of the elevator car. 40

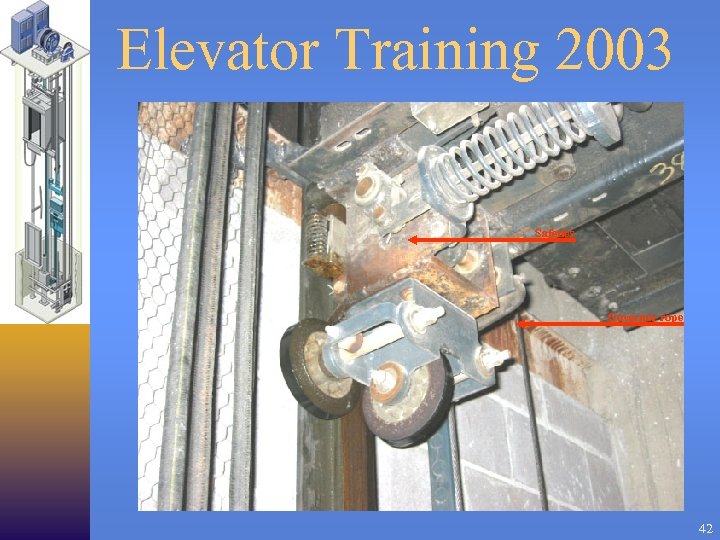

Elevator Training 2003 Safeties 41

Elevator Training 2003 Safeties 41

Elevator Training 2003 Safeties Governor rope 42

Elevator Training 2003 Safeties Governor rope 42

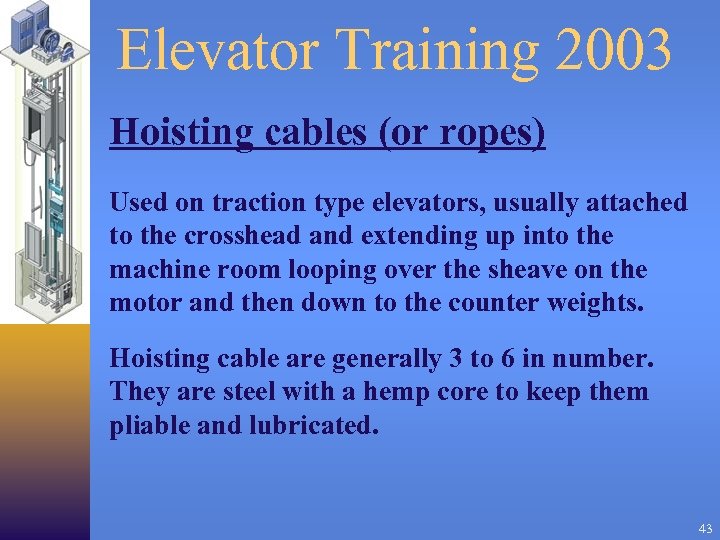

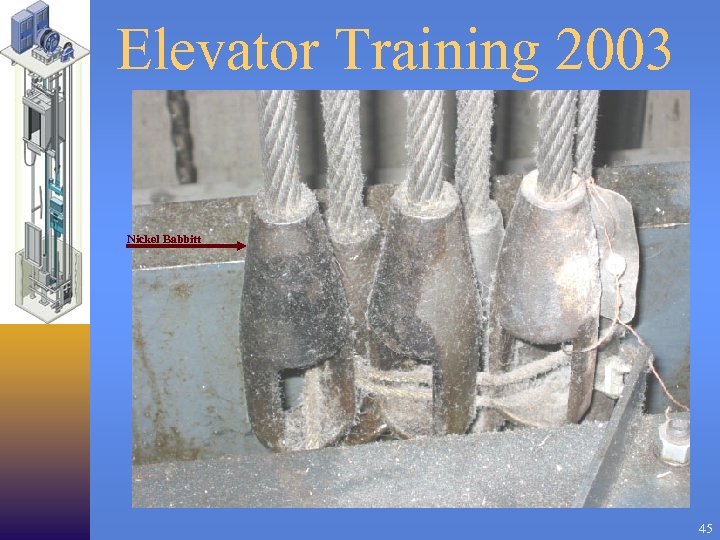

Elevator Training 2003 Hoisting cables (or ropes) Used on traction type elevators, usually attached to the crosshead and extending up into the machine room looping over the sheave on the motor and then down to the counter weights. Hoisting cable are generally 3 to 6 in number. They are steel with a hemp core to keep them pliable and lubricated. 43

Elevator Training 2003 Hoisting cables (or ropes) Used on traction type elevators, usually attached to the crosshead and extending up into the machine room looping over the sheave on the motor and then down to the counter weights. Hoisting cable are generally 3 to 6 in number. They are steel with a hemp core to keep them pliable and lubricated. 43

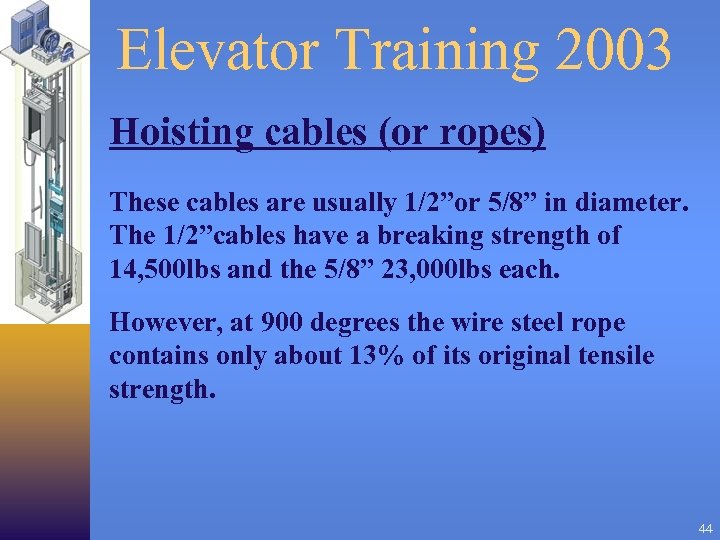

Elevator Training 2003 Hoisting cables (or ropes) These cables are usually 1/2”or 5/8” in diameter. The 1/2”cables have a breaking strength of 14, 500 lbs and the 5/8” 23, 000 lbs each. However, at 900 degrees the wire steel rope contains only about 13% of its original tensile strength. 44

Elevator Training 2003 Hoisting cables (or ropes) These cables are usually 1/2”or 5/8” in diameter. The 1/2”cables have a breaking strength of 14, 500 lbs and the 5/8” 23, 000 lbs each. However, at 900 degrees the wire steel rope contains only about 13% of its original tensile strength. 44

Elevator Training 2003 Nickel Babbitt 45

Elevator Training 2003 Nickel Babbitt 45

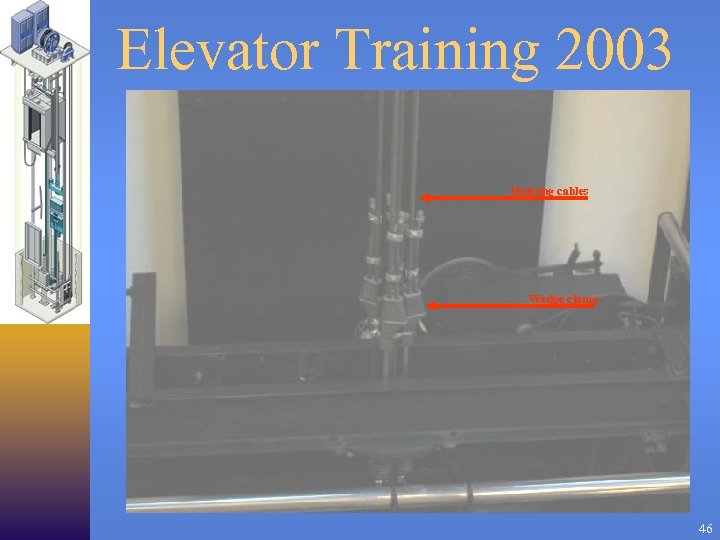

Elevator Training 2003 Hoisting cables Wedge clamp 46

Elevator Training 2003 Hoisting cables Wedge clamp 46

Elevator Training 2003 47

Elevator Training 2003 47

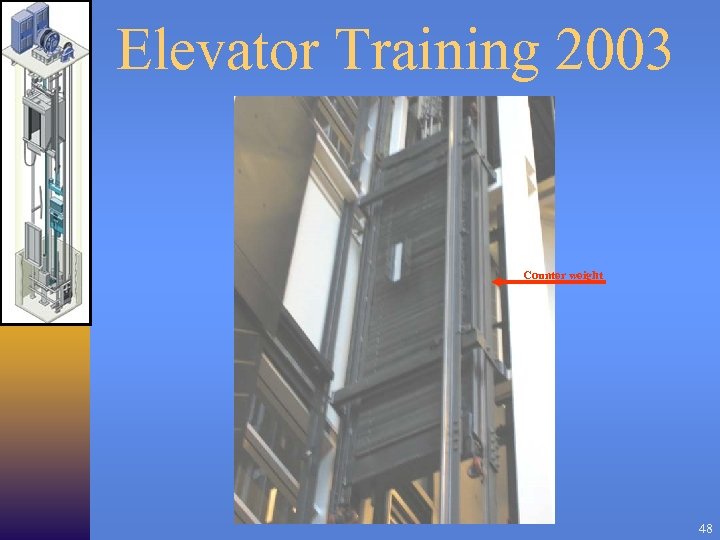

Elevator Training 2003 Counter weight 48

Elevator Training 2003 Counter weight 48

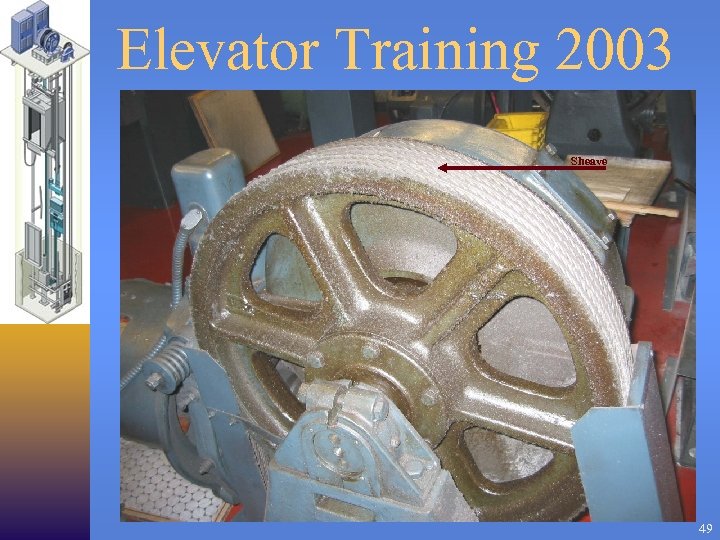

Elevator Training 2003 Sheave 49

Elevator Training 2003 Sheave 49

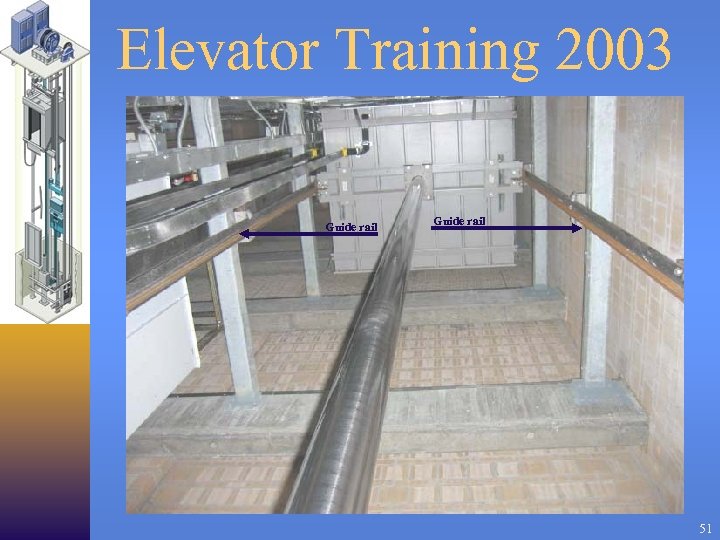

Elevator Training 2003 Guide rails Tracks in the form of a “T” that run the length of the hoistway, that guide the elevator car. Usually mounted to the sides of the hoistway, at the middle of the elevator car. 50

Elevator Training 2003 Guide rails Tracks in the form of a “T” that run the length of the hoistway, that guide the elevator car. Usually mounted to the sides of the hoistway, at the middle of the elevator car. 50

Elevator Training 2003 Guide rail 51

Elevator Training 2003 Guide rail 51

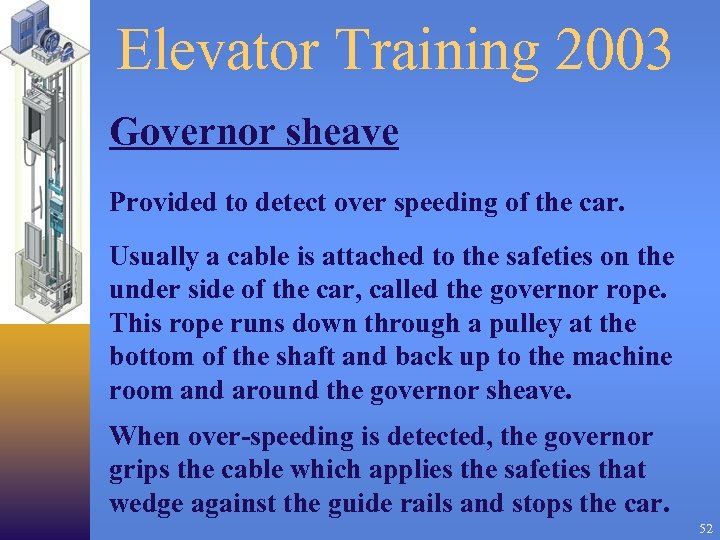

Elevator Training 2003 Governor sheave Provided to detect over speeding of the car. Usually a cable is attached to the safeties on the under side of the car, called the governor rope. This rope runs down through a pulley at the bottom of the shaft and back up to the machine room and around the governor sheave. When over-speeding is detected, the governor grips the cable which applies the safeties that wedge against the guide rails and stops the car. 52

Elevator Training 2003 Governor sheave Provided to detect over speeding of the car. Usually a cable is attached to the safeties on the under side of the car, called the governor rope. This rope runs down through a pulley at the bottom of the shaft and back up to the machine room and around the governor sheave. When over-speeding is detected, the governor grips the cable which applies the safeties that wedge against the guide rails and stops the car. 52

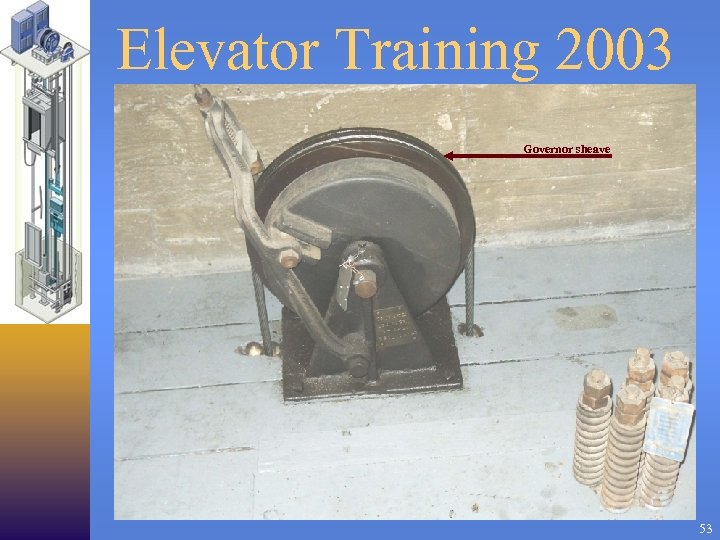

Elevator Training 2003 Governor sheave 53

Elevator Training 2003 Governor sheave 53

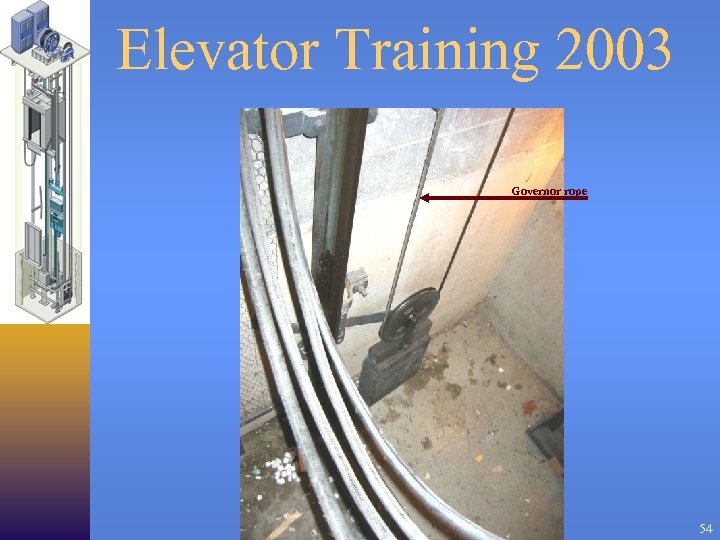

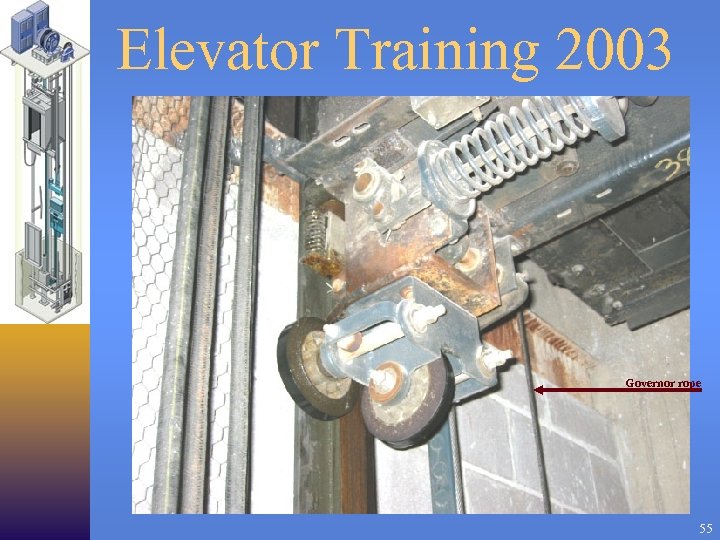

Elevator Training 2003 Governor rope 54

Elevator Training 2003 Governor rope 54

Elevator Training 2003 Governor rope 55

Elevator Training 2003 Governor rope 55

Elevator Training 2003 Car emergency exit Usually located at the top of the elevator cars, sometimes on the side, other times not present. Top exits open from outside the car. Side exits are extremely dangerous to use and are no longer being installed. Existing side exits have been disabled by being permanently bolted shut. 56

Elevator Training 2003 Car emergency exit Usually located at the top of the elevator cars, sometimes on the side, other times not present. Top exits open from outside the car. Side exits are extremely dangerous to use and are no longer being installed. Existing side exits have been disabled by being permanently bolted shut. 56

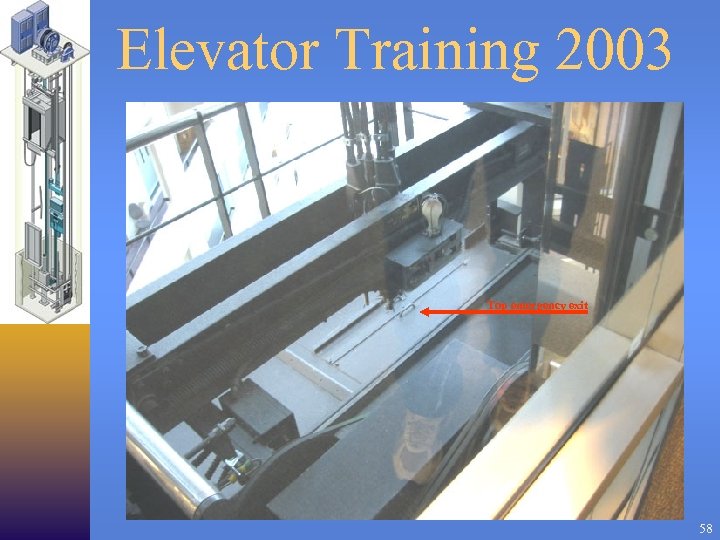

Elevator Training 2003 Top emergency exit 57

Elevator Training 2003 Top emergency exit 57

Elevator Training 2003 Top emergency exit 58

Elevator Training 2003 Top emergency exit 58

Elevator Training 2003 Machine room For electric traction type Usually located above the hoistway in a penthouse or two floors above the highest floor it serves, but may be in the basement if overhead space is unavailable. Generally containing hoisting machines, controllers, generator, speed governor and the main electrical disconnects to the elevators. 59

Elevator Training 2003 Machine room For electric traction type Usually located above the hoistway in a penthouse or two floors above the highest floor it serves, but may be in the basement if overhead space is unavailable. Generally containing hoisting machines, controllers, generator, speed governor and the main electrical disconnects to the elevators. 59

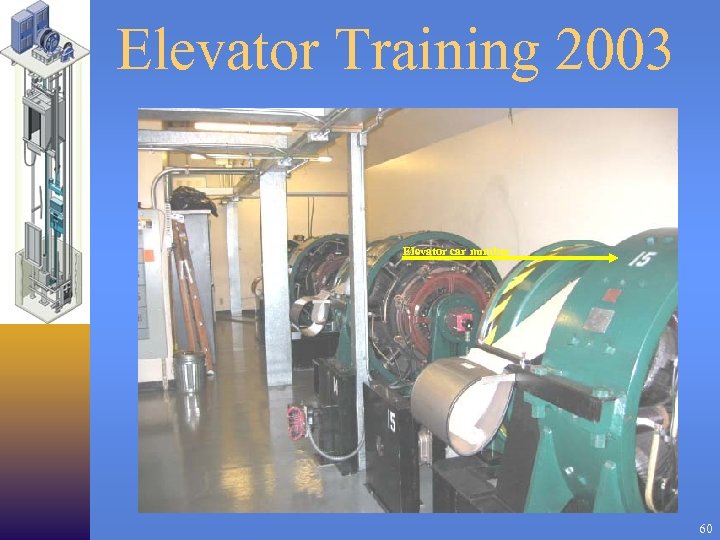

Elevator Training 2003 Elevator car number 60

Elevator Training 2003 Elevator car number 60

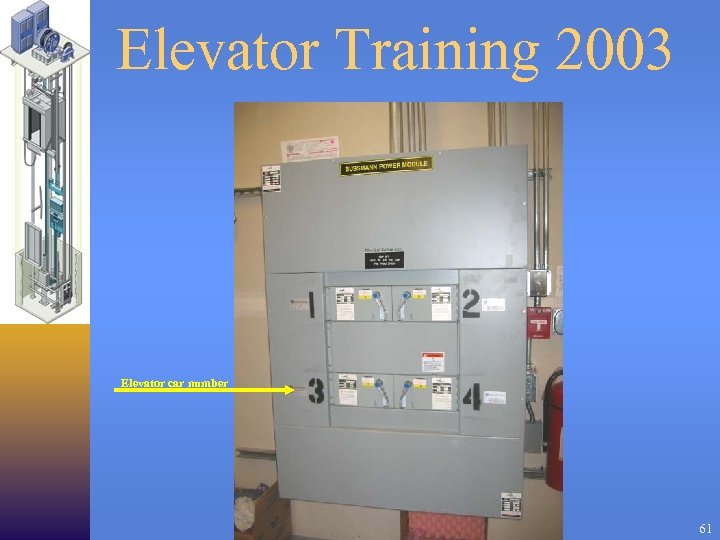

Elevator Training 2003 Elevator car number 61

Elevator Training 2003 Elevator car number 61

Elevator Training 2003 Elevator car number 62

Elevator Training 2003 Elevator car number 62

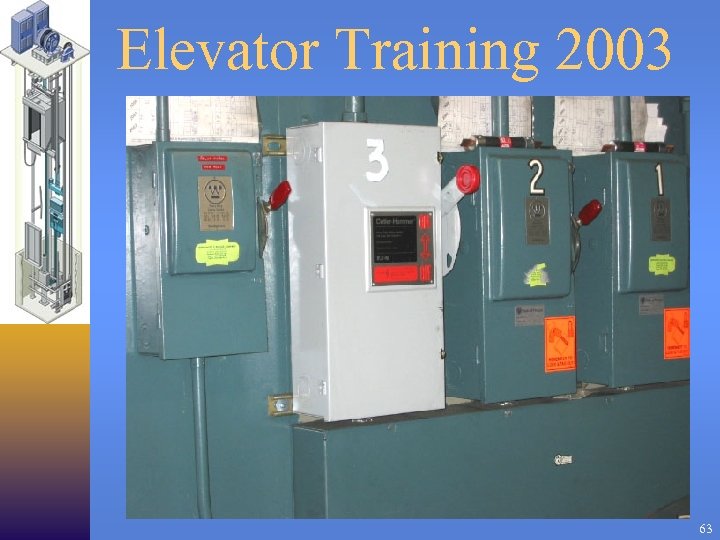

Elevator Training 2003 63

Elevator Training 2003 63

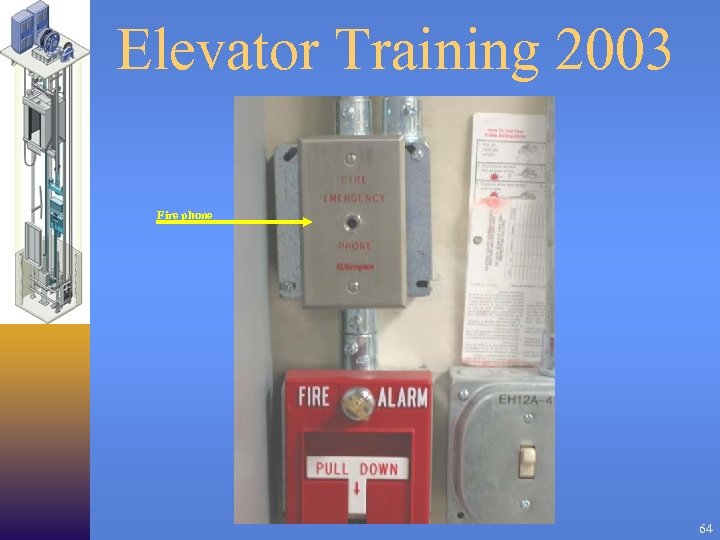

Elevator Training 2003 Fire phone 64

Elevator Training 2003 Fire phone 64

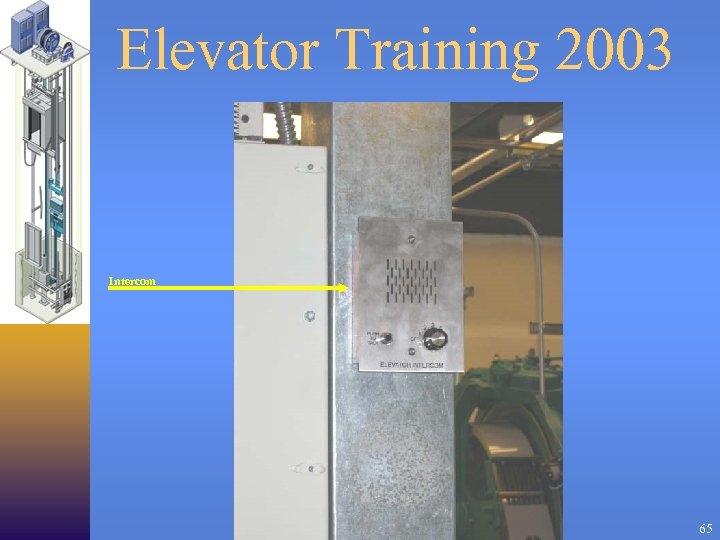

Elevator Training 2003 Intercom 65

Elevator Training 2003 Intercom 65

Elevator Training 2003 Machine room For hydraulic plunger type Usually located in the basement or first floor, but could be anywhere. Generally containing the electric motors, pumps, oil reservoirs, controllers and electrical disconnect to the elevators. 66

Elevator Training 2003 Machine room For hydraulic plunger type Usually located in the basement or first floor, but could be anywhere. Generally containing the electric motors, pumps, oil reservoirs, controllers and electrical disconnect to the elevators. 66

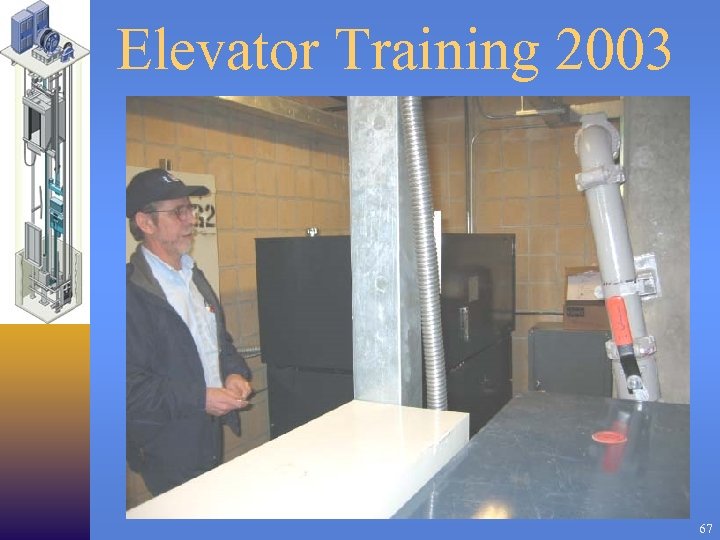

Elevator Training 2003 67

Elevator Training 2003 67

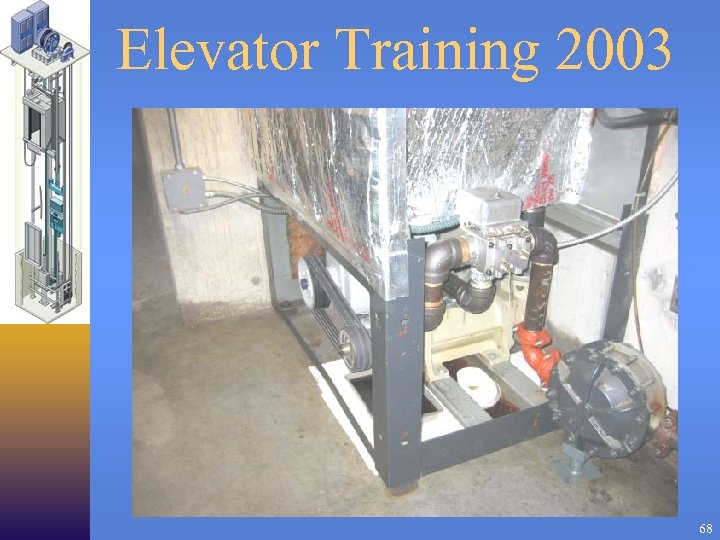

Elevator Training 2003 68

Elevator Training 2003 68

Elevator Training 2003 69

Elevator Training 2003 69

Elevator Training 2003 Phase I A mode of operation activated by a smoke detector located in an elevator lobby, elevator machine room, elevator hoistway or by a keyed recall switch. This activation returns all cars to the main egress lobby or an alternated designated landing, opens the elevator doors and removes the cars from service. If the car is on independent service, the elevator will revert to Phase I recall in about 60 seconds. 70

Elevator Training 2003 Phase I A mode of operation activated by a smoke detector located in an elevator lobby, elevator machine room, elevator hoistway or by a keyed recall switch. This activation returns all cars to the main egress lobby or an alternated designated landing, opens the elevator doors and removes the cars from service. If the car is on independent service, the elevator will revert to Phase I recall in about 60 seconds. 70

Elevator Training 2003 Phase I The keyed recall switch has an “On”, “Off” and sometimes a “Bypass” position. The key is removable in the “On” and “Off” positions only. 71

Elevator Training 2003 Phase I The keyed recall switch has an “On”, “Off” and sometimes a “Bypass” position. The key is removable in the “On” and “Off” positions only. 71

Elevator Training 2003 Phase I On - Puts elevators into phase I recall. Off - Puts elevator back into normal service. Bypass – Put elevator back into service regardless of whether the smoke detectors are reset. The key must be kept in switch when it is in the bypass position. 72

Elevator Training 2003 Phase I On - Puts elevators into phase I recall. Off - Puts elevator back into normal service. Bypass – Put elevator back into service regardless of whether the smoke detectors are reset. The key must be kept in switch when it is in the bypass position. 72

Elevator Training 2003 Phase I Note: The “bypass” feature is being replaced with a “reset” feature for elevators installed or altered under ASME A 17. 1 a, 2002. 73

Elevator Training 2003 Phase I Note: The “bypass” feature is being replaced with a “reset” feature for elevators installed or altered under ASME A 17. 1 a, 2002. 73

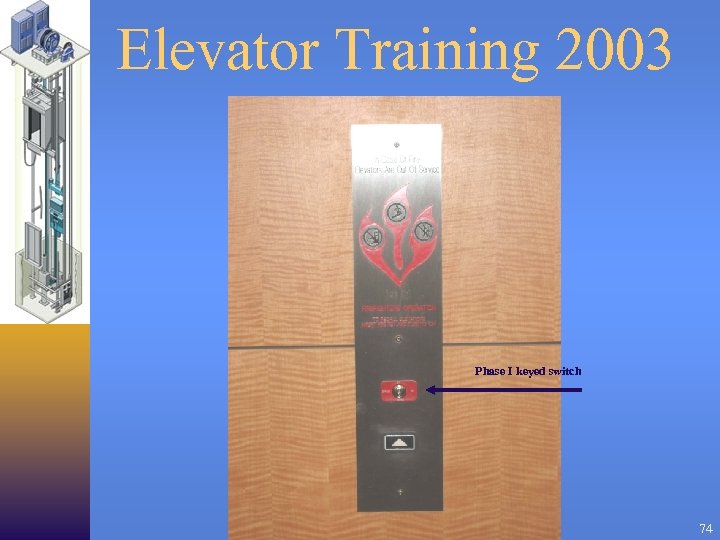

Elevator Training 2003 Phase I keyed switch 74

Elevator Training 2003 Phase I keyed switch 74

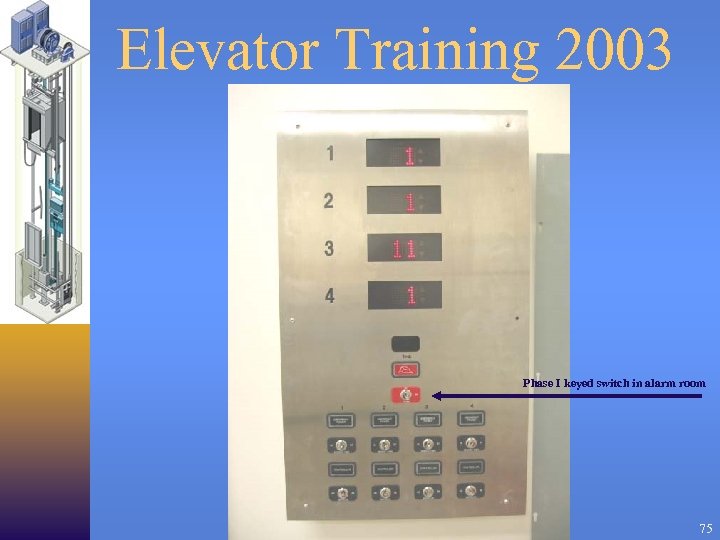

Elevator Training 2003 Phase I keyed switch in alarm room 75

Elevator Training 2003 Phase I keyed switch in alarm room 75

Elevator Training 2003 76

Elevator Training 2003 76

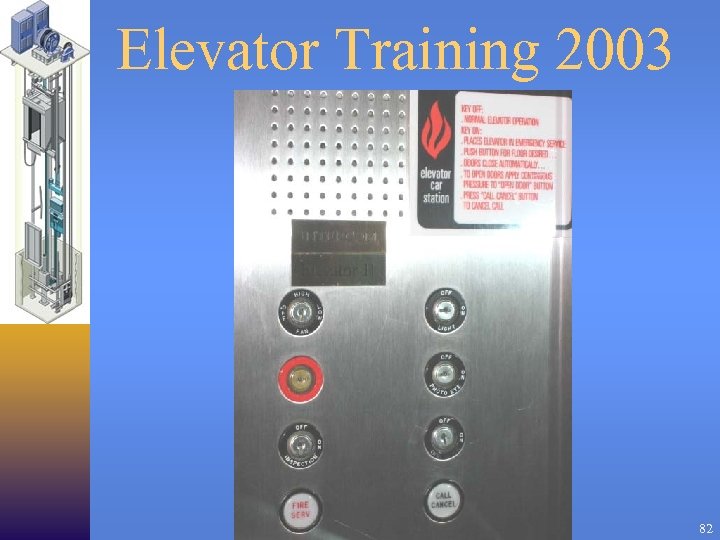

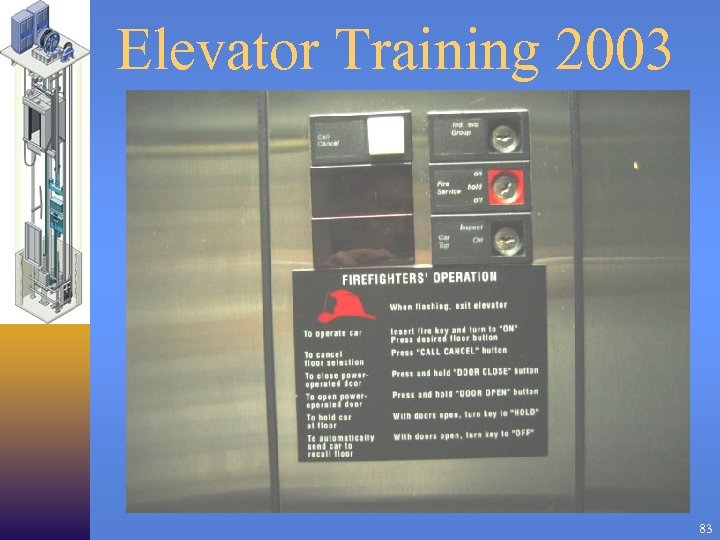

Elevator Training 2003 Phase II A mode of operation activated by the firefighters independent service key switch inside the elevator. This can only be activated when a phase I recall of the elevators is in effect and with the elevator at the lobby or designated floor with the doors open. 77

Elevator Training 2003 Phase II A mode of operation activated by the firefighters independent service key switch inside the elevator. This can only be activated when a phase I recall of the elevators is in effect and with the elevator at the lobby or designated floor with the doors open. 77

Elevator Training 2003 Phase II The Phase II keyed switch in the car has an “Off”, “On” and sometimes a “Hold” position. The “Hold” position allows fire personnel to remove the key and search a floor while the elevator car is waiting with the doors open. 78

Elevator Training 2003 Phase II The Phase II keyed switch in the car has an “Off”, “On” and sometimes a “Hold” position. The “Hold” position allows fire personnel to remove the key and search a floor while the elevator car is waiting with the doors open. 78

Elevator Training 2003 Phase II Off - Puts elevator back into phase I control, unless elevator is not in phase I, then the elevator will stay at that location with doors open until it is put into phase II again, returned to lobby and then switched to the off position. 79

Elevator Training 2003 Phase II Off - Puts elevator back into phase I control, unless elevator is not in phase I, then the elevator will stay at that location with doors open until it is put into phase II again, returned to lobby and then switched to the off position. 79

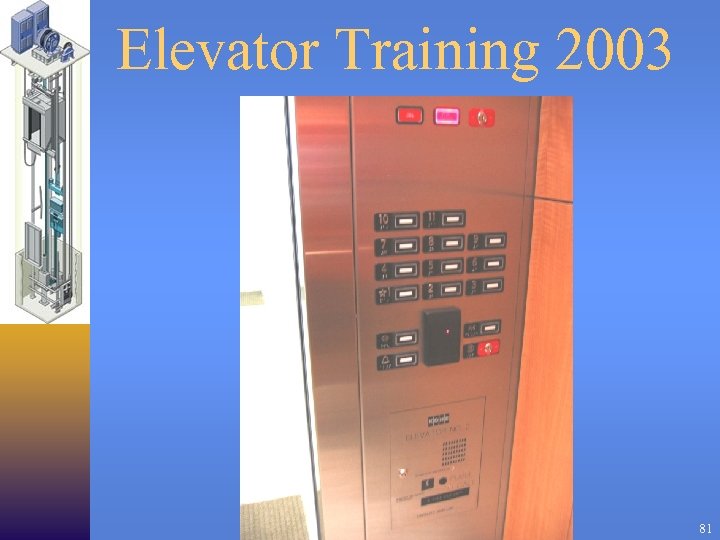

Elevator Training 2003 Phase II On - Puts the elevator into firefighter’s independent service. 80

Elevator Training 2003 Phase II On - Puts the elevator into firefighter’s independent service. 80

Elevator Training 2003 81

Elevator Training 2003 81

Elevator Training 2003 82

Elevator Training 2003 82

Elevator Training 2003 83

Elevator Training 2003 83

Elevator Training 2003 Types of elevators • Hydraulic • Electric traction • Drum 84

Elevator Training 2003 Types of elevators • Hydraulic • Electric traction • Drum 84

Elevator Training 2003 Hydraulic Found in two types: Plunger type and Roped hydraulic 85

Elevator Training 2003 Hydraulic Found in two types: Plunger type and Roped hydraulic 85

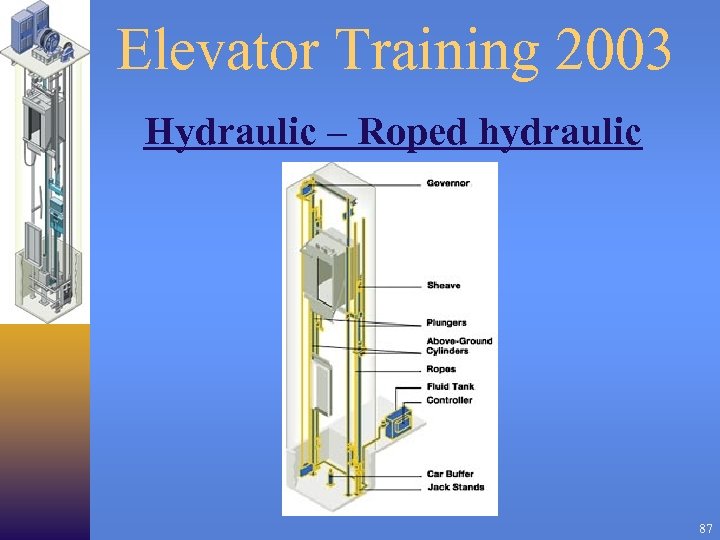

Elevator Training 2003 Hydraulic – Roped hydraulic This type is similar to the electric traction type but uses a hydraulic machine for power. 86

Elevator Training 2003 Hydraulic – Roped hydraulic This type is similar to the electric traction type but uses a hydraulic machine for power. 86

Elevator Training 2003 Hydraulic – Roped hydraulic 87

Elevator Training 2003 Hydraulic – Roped hydraulic 87

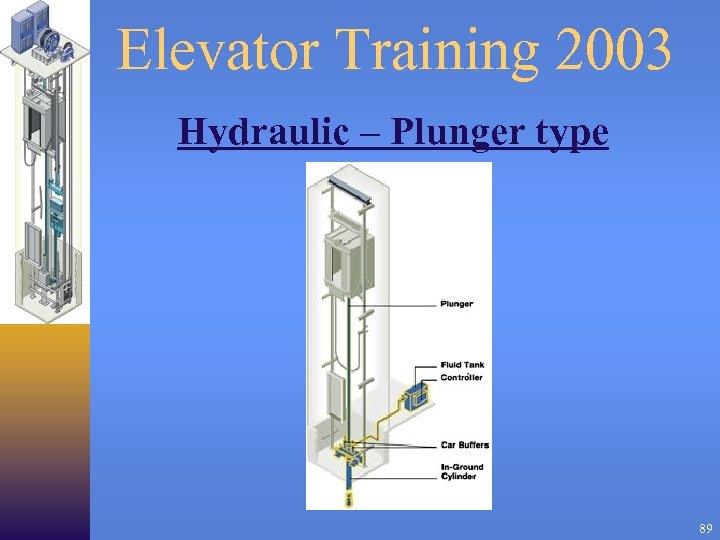

Elevator Training 2003 Hydraulic - Plunger type This type is the most common and consists of an elevator car mounted on top of a long hydraulic piston. The piston is generally not telescopic, so there must be a hole in the ground as long as the distance the elevator travels. 88

Elevator Training 2003 Hydraulic - Plunger type This type is the most common and consists of an elevator car mounted on top of a long hydraulic piston. The piston is generally not telescopic, so there must be a hole in the ground as long as the distance the elevator travels. 88

Elevator Training 2003 Hydraulic – Plunger type 89

Elevator Training 2003 Hydraulic – Plunger type 89

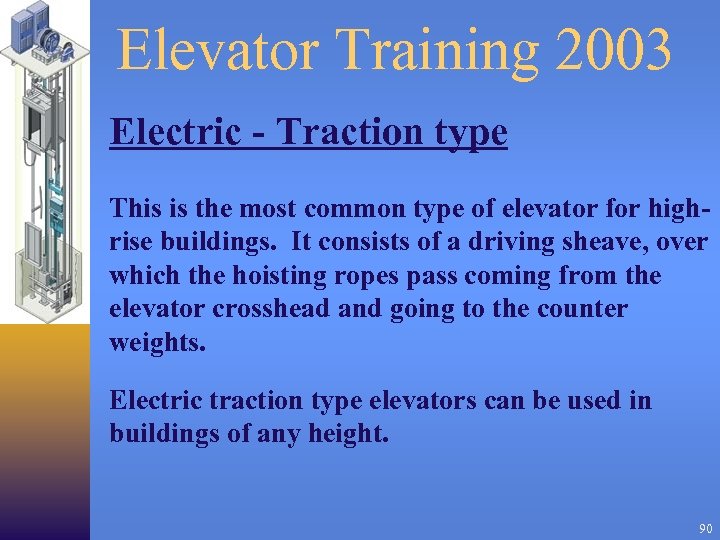

Elevator Training 2003 Electric - Traction type This is the most common type of elevator for highrise buildings. It consists of a driving sheave, over which the hoisting ropes pass coming from the elevator crosshead and going to the counter weights. Electric traction type elevators can be used in buildings of any height. 90

Elevator Training 2003 Electric - Traction type This is the most common type of elevator for highrise buildings. It consists of a driving sheave, over which the hoisting ropes pass coming from the elevator crosshead and going to the counter weights. Electric traction type elevators can be used in buildings of any height. 90

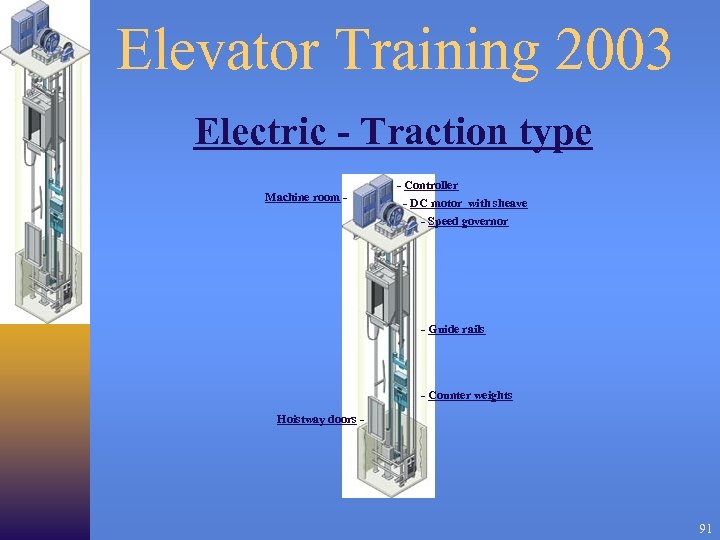

Elevator Training 2003 Electric - Traction type Machine room - - Controller - DC motor with sheave - Speed governor - Guide rails - Counter weights Hoistway doors - 91

Elevator Training 2003 Electric - Traction type Machine room - - Controller - DC motor with sheave - Speed governor - Guide rails - Counter weights Hoistway doors - 91

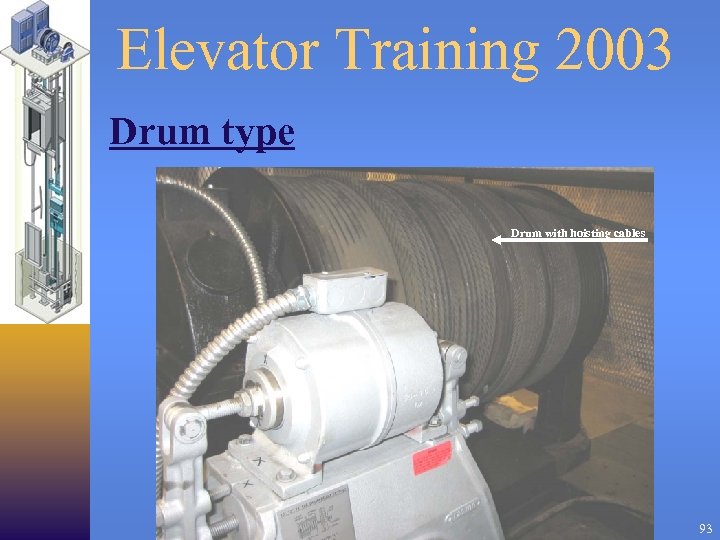

Elevator Training 2003 Drum type Drum – Consists of a large drum in the machine room around which hoisting cables and counter weights ropes are wound. Not used in tall buildings because of the large drum size that would be necessary. This is an old type of elevator and obsolete. The machine room for this type of elevator could be located on the first floor next to the shaft, in the basement or overhead. 92

Elevator Training 2003 Drum type Drum – Consists of a large drum in the machine room around which hoisting cables and counter weights ropes are wound. Not used in tall buildings because of the large drum size that would be necessary. This is an old type of elevator and obsolete. The machine room for this type of elevator could be located on the first floor next to the shaft, in the basement or overhead. 92

Elevator Training 2003 Drum type Drum with hoisting cables 93

Elevator Training 2003 Drum type Drum with hoisting cables 93

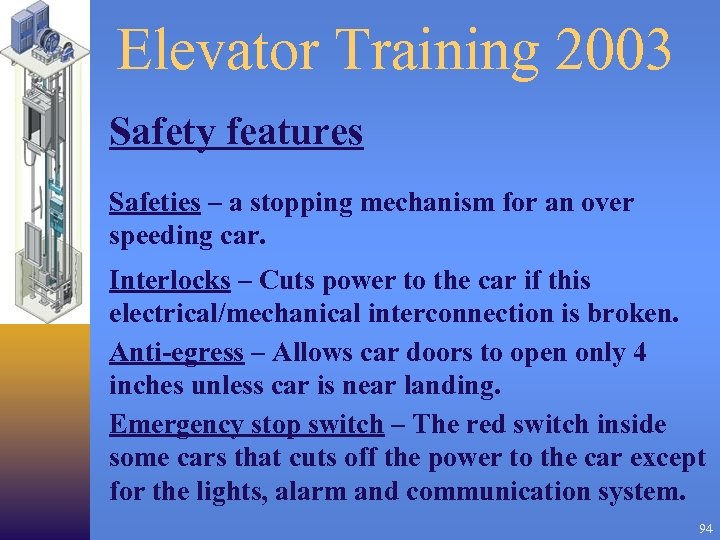

Elevator Training 2003 Safety features Safeties – a stopping mechanism for an over speeding car. Interlocks – Cuts power to the car if this electrical/mechanical interconnection is broken. Anti-egress – Allows car doors to open only 4 inches unless car is near landing. Emergency stop switch – The red switch inside some cars that cuts off the power to the car except for the lights, alarm and communication system. 94

Elevator Training 2003 Safety features Safeties – a stopping mechanism for an over speeding car. Interlocks – Cuts power to the car if this electrical/mechanical interconnection is broken. Anti-egress – Allows car doors to open only 4 inches unless car is near landing. Emergency stop switch – The red switch inside some cars that cuts off the power to the car except for the lights, alarm and communication system. 94

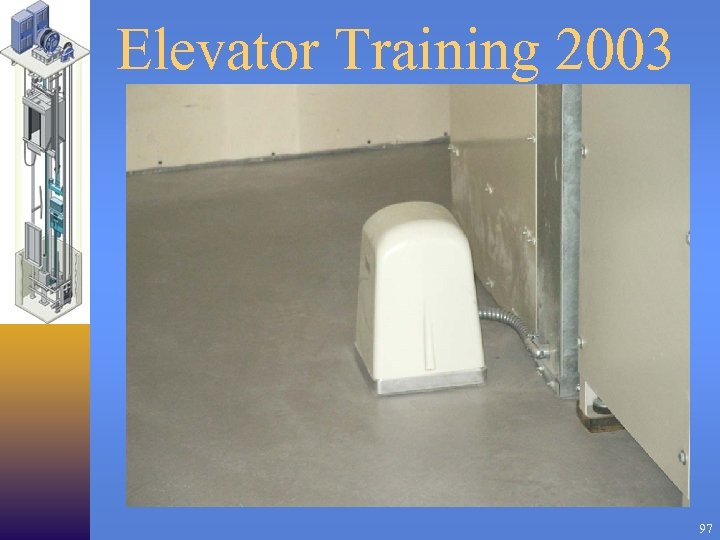

Elevator Training 2003 Safety features Seismic switch - A motion sensing device on some elevators installations. If it is activated the elevator will move away from the counter weights to the next landing with its doors open and inoperable. This device overrides phase I and phase II operation unless phase II operation is already in effect. 95

Elevator Training 2003 Safety features Seismic switch - A motion sensing device on some elevators installations. If it is activated the elevator will move away from the counter weights to the next landing with its doors open and inoperable. This device overrides phase I and phase II operation unless phase II operation is already in effect. 95

Elevator Training 2003 Safety features If this device has been activated it can mean that an unsafe structural condition exists. This device is located in the machine room. 96

Elevator Training 2003 Safety features If this device has been activated it can mean that an unsafe structural condition exists. This device is located in the machine room. 96

Elevator Training 2003 97

Elevator Training 2003 97

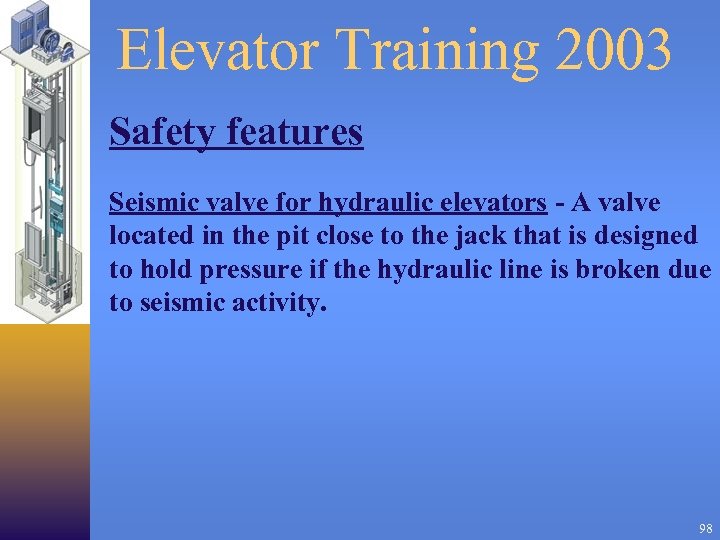

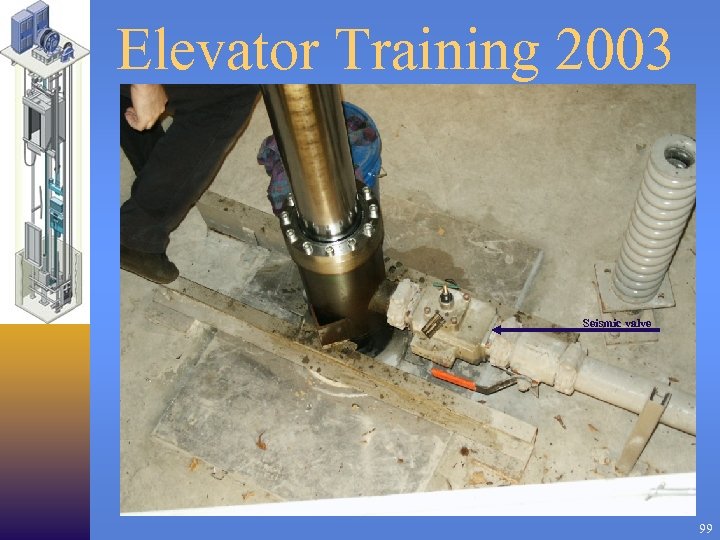

Elevator Training 2003 Safety features Seismic valve for hydraulic elevators - A valve located in the pit close to the jack that is designed to hold pressure if the hydraulic line is broken due to seismic activity. 98

Elevator Training 2003 Safety features Seismic valve for hydraulic elevators - A valve located in the pit close to the jack that is designed to hold pressure if the hydraulic line is broken due to seismic activity. 98

Elevator Training 2003 Seismic valve 99

Elevator Training 2003 Seismic valve 99

Elevator Training 2003 Elevator emergencies In many cases an elevator technician correct a problem faster than we can initiate a rescue. Elevator technicians are on call 24 hrs a day and can usually respond within an hour. When dispatched on a elevator emergency, verify that an elevator technician has been notified. 100

Elevator Training 2003 Elevator emergencies In many cases an elevator technician correct a problem faster than we can initiate a rescue. Elevator technicians are on call 24 hrs a day and can usually respond within an hour. When dispatched on a elevator emergency, verify that an elevator technician has been notified. 100

Elevator Training 2003 Types of emergencies • Person trapped in elevator car The 3 most common reasons: – Power failure – Malfunction of control components – Activation of safety equipment 101

Elevator Training 2003 Types of emergencies • Person trapped in elevator car The 3 most common reasons: – Power failure – Malfunction of control components – Activation of safety equipment 101

Elevator Training 2003 - Power failure If it’s going to be short term, its best not to attempt a rescue. Explain the situation to the occupant. Calm and reassure them and let them know that they are not in danger and steps are being taken to remove them safely. If emergency power is available, it can be used. 102

Elevator Training 2003 - Power failure If it’s going to be short term, its best not to attempt a rescue. Explain the situation to the occupant. Calm and reassure them and let them know that they are not in danger and steps are being taken to remove them safely. If emergency power is available, it can be used. 102

Elevator Training 2003 - Power failure Some newer elevators will return to the lobby one at a time where the doors will open automatically. 103

Elevator Training 2003 - Power failure Some newer elevators will return to the lobby one at a time where the doors will open automatically. 103

Elevator Training 2003 - Power failure If there is no emergency power, then shut off the power to that elevator in the machine room. This will prevent any unexpected movement of traction type elevators when the power is restored. 104

Elevator Training 2003 - Power failure If there is no emergency power, then shut off the power to that elevator in the machine room. This will prevent any unexpected movement of traction type elevators when the power is restored. 104

Elevator Training 2003 - Malfunction of control components Shut off the power to the elevator in the machine room. This will prevent any unexpected movement of the car when the power is restored. 105

Elevator Training 2003 - Malfunction of control components Shut off the power to the elevator in the machine room. This will prevent any unexpected movement of the car when the power is restored. 105

Elevator Training 2003 - Malfunction of control components However, if you have a true emergency, try a Phase I recall or turning the power off and on to see if the system will restart correctly. *Remember, do not restart an elevator without consulting an elevator technician. 106

Elevator Training 2003 - Malfunction of control components However, if you have a true emergency, try a Phase I recall or turning the power off and on to see if the system will restart correctly. *Remember, do not restart an elevator without consulting an elevator technician. 106

Elevator Training 2003 - Malfunction of control components If this does not work leave the power to the elevator off in the machine room. Whenever you turn the power off to an elevator, leave a member with a radio and fire phone (if available), to guard the switch. 107

Elevator Training 2003 - Malfunction of control components If this does not work leave the power to the elevator off in the machine room. Whenever you turn the power off to an elevator, leave a member with a radio and fire phone (if available), to guard the switch. 107

Elevator Training 2003 - Activation of safety equipment. If one of the elevator’s safety devices has been activated, it is often indicating a serious malfunction in the hoistway or operating machinery. 108

Elevator Training 2003 - Activation of safety equipment. If one of the elevator’s safety devices has been activated, it is often indicating a serious malfunction in the hoistway or operating machinery. 108

Elevator Training 2003 - Activation of safety equipment. In this situation you should wait for an elevator technician. Leave the power on to the elevator. This will help the technician in determining the problem. However, if you have to perform a rescue, turn off the main power to the elevator in the machine room. 109

Elevator Training 2003 - Activation of safety equipment. In this situation you should wait for an elevator technician. Leave the power on to the elevator. This will help the technician in determining the problem. However, if you have to perform a rescue, turn off the main power to the elevator in the machine room. 109

Elevator Training 2003 Remember: • Let your presence be known to the trapped occupant when you arrive. Calm and reassure them and let them know that there is no danger and steps are being taken to remove them safely. 110

Elevator Training 2003 Remember: • Let your presence be known to the trapped occupant when you arrive. Calm and reassure them and let them know that there is no danger and steps are being taken to remove them safely. 110

Elevator Training 2003 Rescue methods • Person trapped in elevator car Locate the stalled car by observing the floor indicator in the lobby or voice contact with occupant. Ask them which direction they were going and which floor they stopped at last. 111

Elevator Training 2003 Rescue methods • Person trapped in elevator car Locate the stalled car by observing the floor indicator in the lobby or voice contact with occupant. Ask them which direction they were going and which floor they stopped at last. 111

Elevator Training 2003 Rescue methods • Person trapped in elevator car Try sending a member to the last floor that the car came from to shake and physically make sure the hoistway doors are fully closed and that the interlock switch is making contact. All of the hoistway doors must be closed for the car to operate. 112

Elevator Training 2003 Rescue methods • Person trapped in elevator car Try sending a member to the last floor that the car came from to shake and physically make sure the hoistway doors are fully closed and that the interlock switch is making contact. All of the hoistway doors must be closed for the car to operate. 112

Elevator Training 2003 Rescue methods • Person trapped in elevator car If that does not work you can try calling the car to the floor above or below its location in the opposite direction it was traveling. Sometimes its necessary to try this on several floors to get the call to register. 113

Elevator Training 2003 Rescue methods • Person trapped in elevator car If that does not work you can try calling the car to the floor above or below its location in the opposite direction it was traveling. Sometimes its necessary to try this on several floors to get the call to register. 113

Elevator Training 2003 Rescue methods • Person trapped in elevator car *Remember, always shut off the power to the elevator in the machine room before attempting passenger removal and leave a member with a radio (and fire phone if available) guarding the switch. 114

Elevator Training 2003 Rescue methods • Person trapped in elevator car *Remember, always shut off the power to the elevator in the machine room before attempting passenger removal and leave a member with a radio (and fire phone if available) guarding the switch. 114

Elevator Training 2003 Rescue methods • Person trapped in elevator car *And after a rescue has been performed leave the power off and a member onscene to inform the elevator technician what measures were taken to remove the occupant. 115

Elevator Training 2003 Rescue methods • Person trapped in elevator car *And after a rescue has been performed leave the power off and a member onscene to inform the elevator technician what measures were taken to remove the occupant. 115

Elevator Training 2003 Rescue methods • Person trapped in elevator car If these attempts to correct the problem fail, shut off the main power to the elevator in the machine room and station a member with a radio (and a fire phone if available). Remember to maintain a 4’ clearance around the switching equipment with the radio. 116

Elevator Training 2003 Rescue methods • Person trapped in elevator car If these attempts to correct the problem fail, shut off the main power to the elevator in the machine room and station a member with a radio (and a fire phone if available). Remember to maintain a 4’ clearance around the switching equipment with the radio. 116

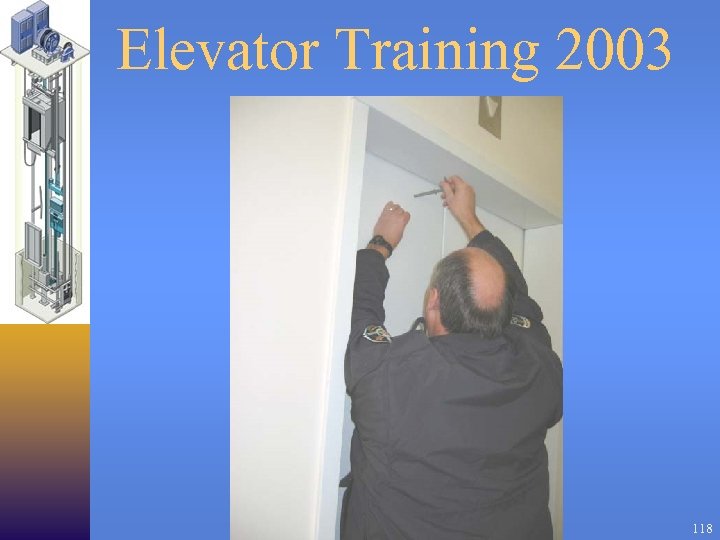

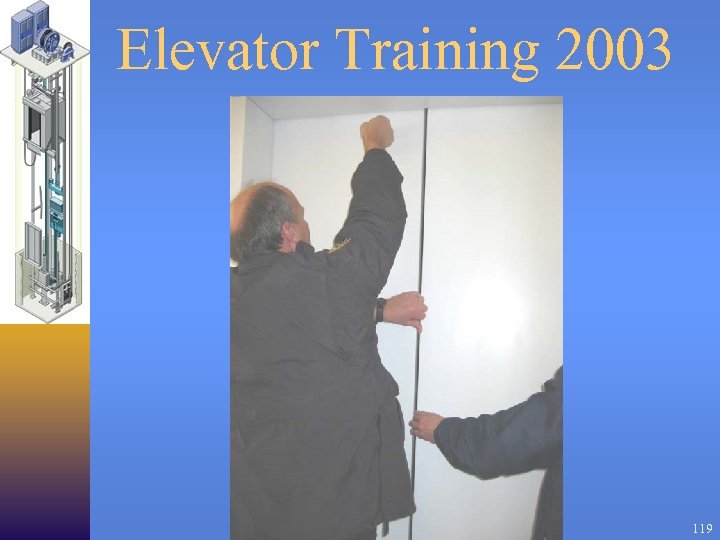

Elevator Training 2003 Rescue methods • Person trapped in elevator car If the occupant has activated the emergency stop switch, instruct them to turn it off. This will help to calm them. If the hoistway door has an escutcheon tube, insert the appropriate key and release the hoistway door interlock, and open the doors. 117

Elevator Training 2003 Rescue methods • Person trapped in elevator car If the occupant has activated the emergency stop switch, instruct them to turn it off. This will help to calm them. If the hoistway door has an escutcheon tube, insert the appropriate key and release the hoistway door interlock, and open the doors. 117

Elevator Training 2003 118

Elevator Training 2003 118

Elevator Training 2003 119

Elevator Training 2003 119

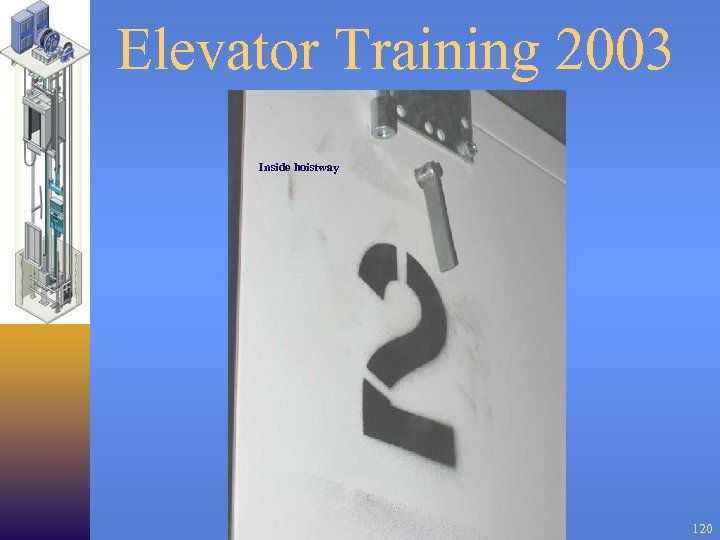

Elevator Training 2003 Inside hoistway 120

Elevator Training 2003 Inside hoistway 120

Elevator Training 2003 121

Elevator Training 2003 121

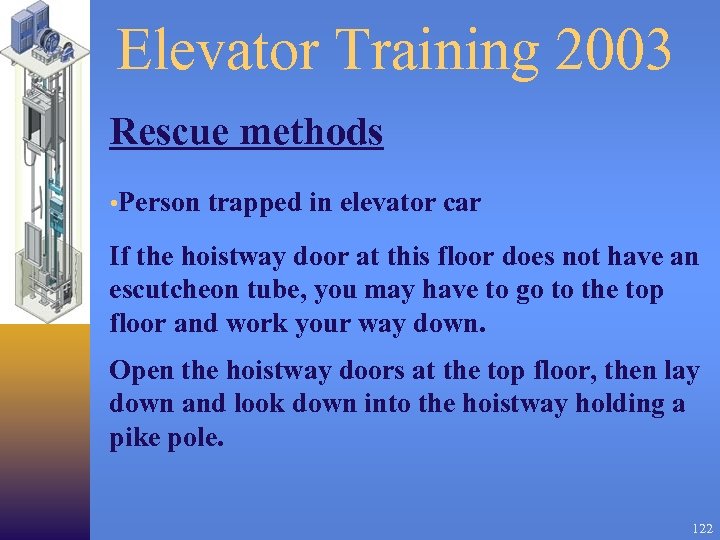

Elevator Training 2003 Rescue methods • Person trapped in elevator car If the hoistway door at this floor does not have an escutcheon tube, you may have to go to the top floor and work your way down. Open the hoistway doors at the top floor, then lay down and look down into the hoistway holding a pike pole. 122

Elevator Training 2003 Rescue methods • Person trapped in elevator car If the hoistway door at this floor does not have an escutcheon tube, you may have to go to the top floor and work your way down. Open the hoistway doors at the top floor, then lay down and look down into the hoistway holding a pike pole. 122

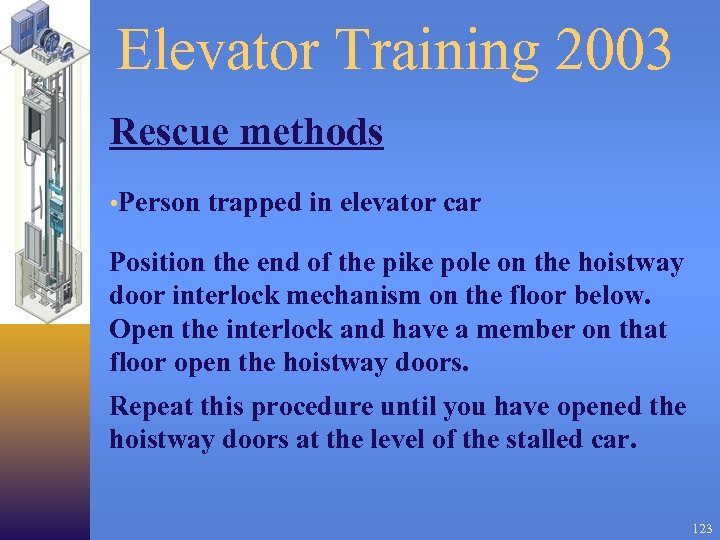

Elevator Training 2003 Rescue methods • Person trapped in elevator car Position the end of the pike pole on the hoistway door interlock mechanism on the floor below. Open the interlock and have a member on that floor open the hoistway doors. Repeat this procedure until you have opened the hoistway doors at the level of the stalled car. 123

Elevator Training 2003 Rescue methods • Person trapped in elevator car Position the end of the pike pole on the hoistway door interlock mechanism on the floor below. Open the interlock and have a member on that floor open the hoistway doors. Repeat this procedure until you have opened the hoistway doors at the level of the stalled car. 123

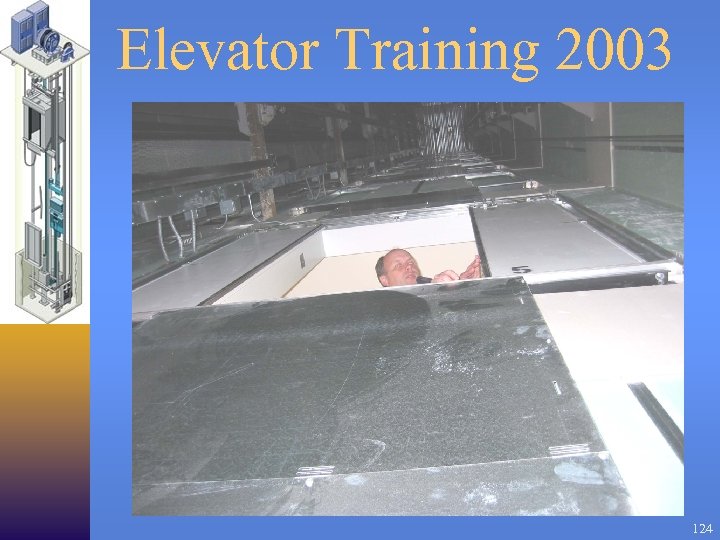

Elevator Training 2003 124

Elevator Training 2003 124

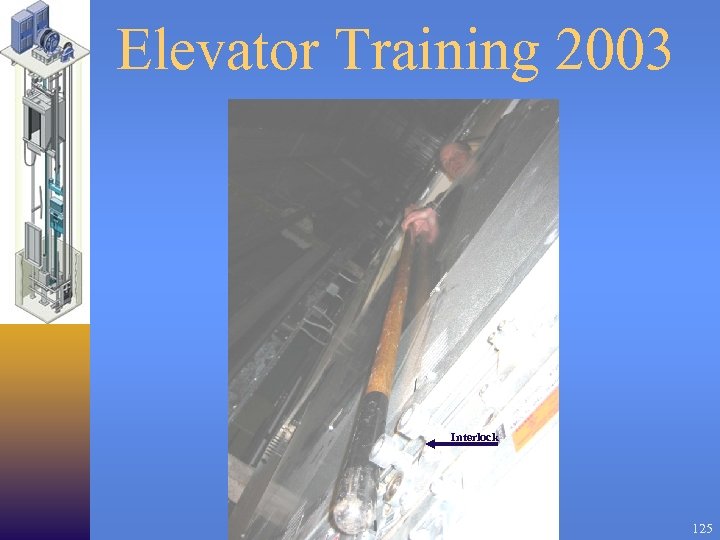

Elevator Training 2003 Interlock 125

Elevator Training 2003 Interlock 125

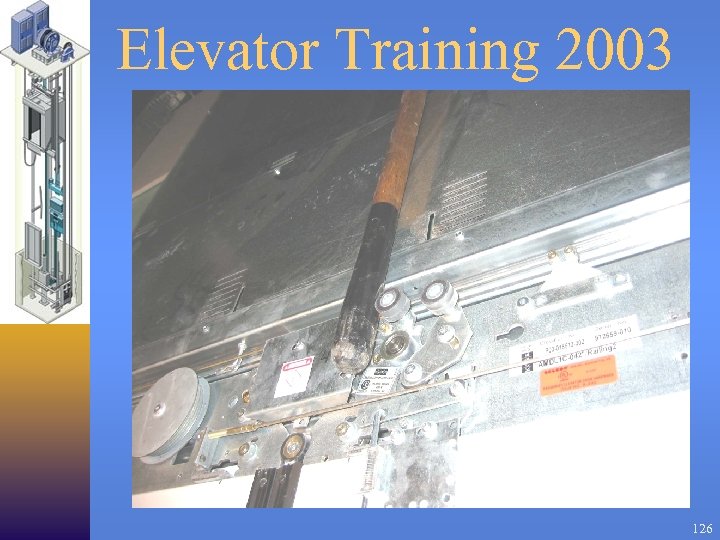

Elevator Training 2003 126

Elevator Training 2003 126

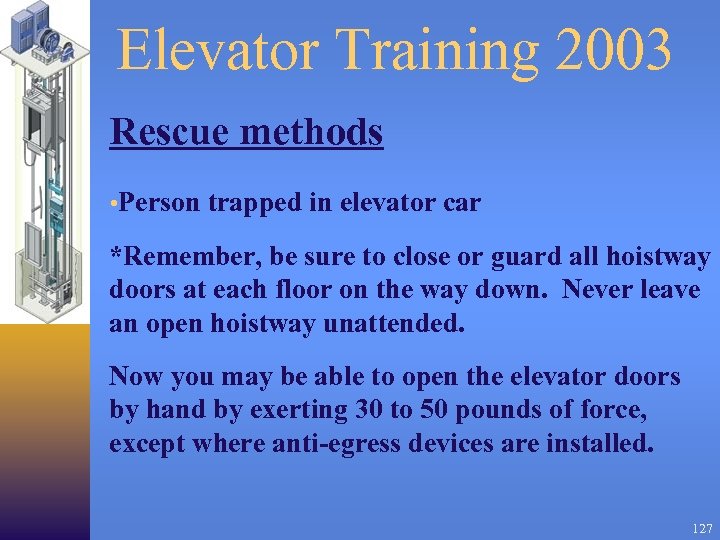

Elevator Training 2003 Rescue methods • Person trapped in elevator car *Remember, be sure to close or guard all hoistway doors at each floor on the way down. Never leave an open hoistway unattended. Now you may be able to open the elevator doors by hand by exerting 30 to 50 pounds of force, except where anti-egress devices are installed. 127

Elevator Training 2003 Rescue methods • Person trapped in elevator car *Remember, be sure to close or guard all hoistway doors at each floor on the way down. Never leave an open hoistway unattended. Now you may be able to open the elevator doors by hand by exerting 30 to 50 pounds of force, except where anti-egress devices are installed. 127

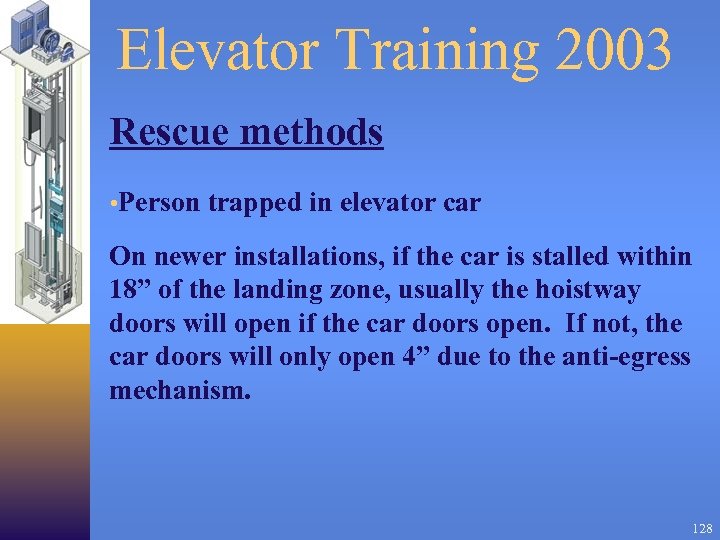

Elevator Training 2003 Rescue methods • Person trapped in elevator car On newer installations, if the car is stalled within 18” of the landing zone, usually the hoistway doors will open if the car doors open. If not, the car doors will only open 4” due to the anti-egress mechanism. 128

Elevator Training 2003 Rescue methods • Person trapped in elevator car On newer installations, if the car is stalled within 18” of the landing zone, usually the hoistway doors will open if the car doors open. If not, the car doors will only open 4” due to the anti-egress mechanism. 128

Elevator Training 2003 Rescue methods • Person trapped in elevator car In this case you may be able to release the mechanism from the outside. If this isn’t possible, you may have to force the doors with a port-a-power or rabbit tool toward the top of the doors. 129

Elevator Training 2003 Rescue methods • Person trapped in elevator car In this case you may be able to release the mechanism from the outside. If this isn’t possible, you may have to force the doors with a port-a-power or rabbit tool toward the top of the doors. 129

Elevator Training 2003 Anti-egress lock 130

Elevator Training 2003 Anti-egress lock 130

Elevator Training 2003 Rescue methods • Person trapped in elevator car If you use a rabbit tool to force the hoistway or elevator doors and anti-egress is present, you may need to use cribbing. Anti-egress allows the doors to open 4”, while the spreading capability of the rabbit tool is only 3 1/2”. 131

Elevator Training 2003 Rescue methods • Person trapped in elevator car If you use a rabbit tool to force the hoistway or elevator doors and anti-egress is present, you may need to use cribbing. Anti-egress allows the doors to open 4”, while the spreading capability of the rabbit tool is only 3 1/2”. 131

Elevator Training 2003 Rescue methods • Opening the hoistway doors from an adjacent car. -Bring the adjacent car to the floor nearest the stalled car and open its doors. 132

Elevator Training 2003 Rescue methods • Opening the hoistway doors from an adjacent car. -Bring the adjacent car to the floor nearest the stalled car and open its doors. 132

Elevator Training 2003 Rescue methods • Opening the hoistway doors from an adjacent car. -Set the main power switch in the machine room for both cars to the off position. 133

Elevator Training 2003 Rescue methods • Opening the hoistway doors from an adjacent car. -Set the main power switch in the machine room for both cars to the off position. 133

Elevator Training 2003 Rescue methods • Opening the hoistway doors from an adjacent car. -Extend a pike pole through the opening between the car and hoistway doors to the interlock roller of the stalled car. 134

Elevator Training 2003 Rescue methods • Opening the hoistway doors from an adjacent car. -Extend a pike pole through the opening between the car and hoistway doors to the interlock roller of the stalled car. 134

Elevator Training 2003 Rescue methods • Opening the hoistway doors from an adjacent car. -Activate the interlock mechanism while a member opens the hoistway doors. -Rescuer enter elevator and remove one occupant at a time. 135

Elevator Training 2003 Rescue methods • Opening the hoistway doors from an adjacent car. -Activate the interlock mechanism while a member opens the hoistway doors. -Rescuer enter elevator and remove one occupant at a time. 135

Elevator Training 2003 Rescue methods • Opening the hoistway doors from an adjacent car. *Guard any opening to the hoistway that exists. *Be careful not to extend the pike pole into the hoistway of an elevator still in service. 136

Elevator Training 2003 Rescue methods • Opening the hoistway doors from an adjacent car. *Guard any opening to the hoistway that exists. *Be careful not to extend the pike pole into the hoistway of an elevator still in service. 136

Elevator Training 2003 Rescue methods • Car more than 3’ from landing. *It is inadvisable to remove passengers through the elevator doors if it is more than 3’ above the landing, because of the possible danger of falling into the hoistway. 137

Elevator Training 2003 Rescue methods • Car more than 3’ from landing. *It is inadvisable to remove passengers through the elevator doors if it is more than 3’ above the landing, because of the possible danger of falling into the hoistway. 137

Elevator Training 2003 Rescue methods • Car more than 3’ from landing. *It is also inadvisable to remove passengers through the elevator doors if the car is more than 3’ below the landing because of the limited size of the access opening for rescue. 138

Elevator Training 2003 Rescue methods • Car more than 3’ from landing. *It is also inadvisable to remove passengers through the elevator doors if the car is more than 3’ below the landing because of the limited size of the access opening for rescue. 138

Elevator Training 2003 Rescue methods • Removal of occupants through the top emergency exit. *Do not use top emergency exits in unenclosed hoistways. Also, some elevators do not have these exits. *The preferred method is to have an elevator technician move the car to a landing level. 139

Elevator Training 2003 Rescue methods • Removal of occupants through the top emergency exit. *Do not use top emergency exits in unenclosed hoistways. Also, some elevators do not have these exits. *The preferred method is to have an elevator technician move the car to a landing level. 139

Elevator Training 2003 Rescue methods • Removal of occupants through the top emergency exit. *The following should only be performed if a real emergency exists. -Set the main power switch in the machine room to off and station a member to guard the switch with a radio (and a fire phone if available). -If there are elevators in adjoining shafts, set their power switches to off also. 140

Elevator Training 2003 Rescue methods • Removal of occupants through the top emergency exit. *The following should only be performed if a real emergency exists. -Set the main power switch in the machine room to off and station a member to guard the switch with a radio (and a fire phone if available). -If there are elevators in adjoining shafts, set their power switches to off also. 140

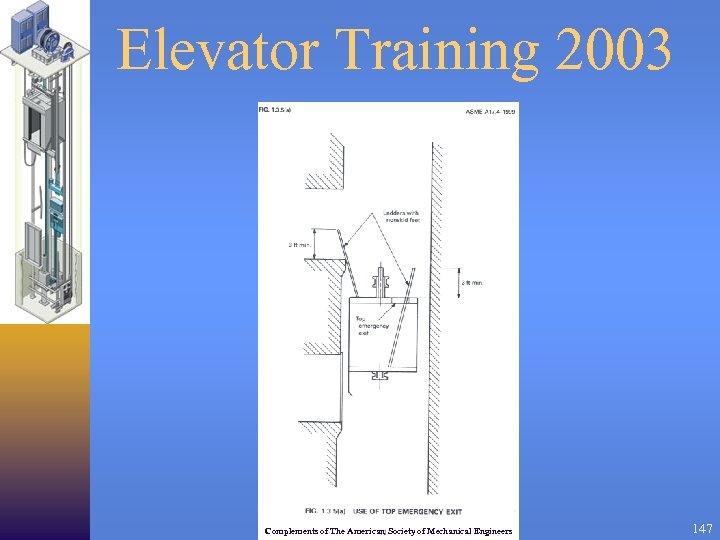

Elevator Training 2003 Rescue methods • Removal of occupants through the top emergency exit. -Open the hoistway doors at the nearest landing level above the stalled car. The opening of the hoistway doors can be accomplished as described previously. -A ladder with non-skid feet should be lowered and securely positioned to the car top. The ladder should be long enough to have at least 3 rungs above the landing. 141

Elevator Training 2003 Rescue methods • Removal of occupants through the top emergency exit. -Open the hoistway doors at the nearest landing level above the stalled car. The opening of the hoistway doors can be accomplished as described previously. -A ladder with non-skid feet should be lowered and securely positioned to the car top. The ladder should be long enough to have at least 3 rungs above the landing. 141

Elevator Training 2003 Rescue methods • Removal of occupants through the top emergency exit. -One member of the rescue team wearing a safety belt and properly tied off to a secure line descends to the top of the car. 142

Elevator Training 2003 Rescue methods • Removal of occupants through the top emergency exit. -One member of the rescue team wearing a safety belt and properly tied off to a secure line descends to the top of the car. 142

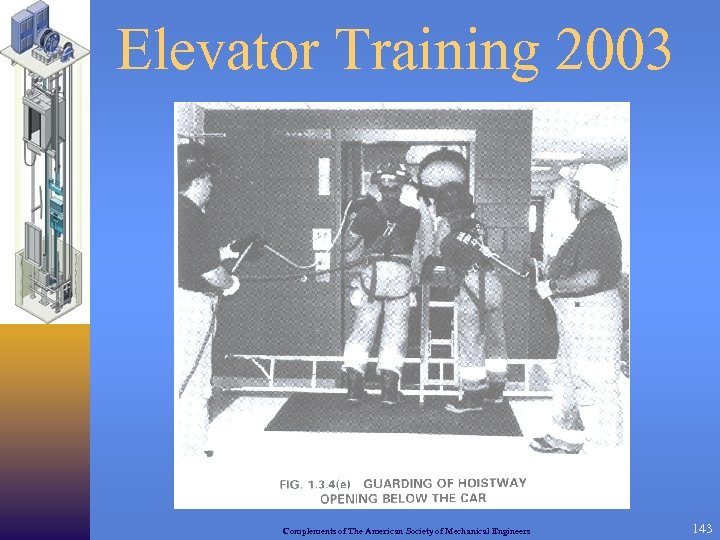

Elevator Training 2003 Complements of The American Society of Mechanical Engineers 143

Elevator Training 2003 Complements of The American Society of Mechanical Engineers 143

Elevator Training 2003 Rescue methods • Removal of occupants through the top emergency exit. -A second ladder should be lowered through the emergency top exit, long enough to extend at least 3 rungs above the car top. -A second rescuer should descend to the car top wearing a safety belt and a secured line. 144

Elevator Training 2003 Rescue methods • Removal of occupants through the top emergency exit. -A second ladder should be lowered through the emergency top exit, long enough to extend at least 3 rungs above the car top. -A second rescuer should descend to the car top wearing a safety belt and a secured line. 144

Elevator Training 2003 Rescue methods • Removal of occupants through the top emergency exit. -The second rescuer should carry a second safety belt for the victim. -One rescuer should enter the stalled car and set the emergency stop switch to off (if available), while the other stays on the car top. 145

Elevator Training 2003 Rescue methods • Removal of occupants through the top emergency exit. -The second rescuer should carry a second safety belt for the victim. -One rescuer should enter the stalled car and set the emergency stop switch to off (if available), while the other stays on the car top. 145

Elevator Training 2003 Rescue methods • Removal of occupants through the top emergency exit. -A third member should be at the landing used to gain access. -The occupants should then be assisted up the ladder from the car wearing the safety belt, one at a time. 146

Elevator Training 2003 Rescue methods • Removal of occupants through the top emergency exit. -A third member should be at the landing used to gain access. -The occupants should then be assisted up the ladder from the car wearing the safety belt, one at a time. 146

Elevator Training 2003 Complements of The American Society of Mechanical Engineers 147

Elevator Training 2003 Complements of The American Society of Mechanical Engineers 147

Elevator Training 2003 Rescue methods • Removal of occupants through the top emergency exit. -Remember, do not restore power to the stalled car. Have a member stand by to inform the elevator technician the measures that were taken to perform the rescue. 148

Elevator Training 2003 Rescue methods • Removal of occupants through the top emergency exit. -Remember, do not restore power to the stalled car. Have a member stand by to inform the elevator technician the measures that were taken to perform the rescue. 148

Elevator Training 2003 Elevators • The information covered in this presentation are some, but not all of the methods of elevator rescue. For more in-depth information on elevator function and methods of elevator rescue, refer to: 1. PF&R Training Bulletin #19, Elevators and Elevator Emergencies. 2. ASME A 17. 4, Guide for Emergency Personnel. 3. The Chief Elevator Inspector, Oregon Dept. of Consumer and Business Services. 149

Elevator Training 2003 Elevators • The information covered in this presentation are some, but not all of the methods of elevator rescue. For more in-depth information on elevator function and methods of elevator rescue, refer to: 1. PF&R Training Bulletin #19, Elevators and Elevator Emergencies. 2. ASME A 17. 4, Guide for Emergency Personnel. 3. The Chief Elevator Inspector, Oregon Dept. of Consumer and Business Services. 149

Elevator Training 2003 Thank you DRILL CODE: 20 -07. ELEV 150

Elevator Training 2003 Thank you DRILL CODE: 20 -07. ELEV 150