9eeba09137bff44e4ccbd3753d6c086f.ppt

- Количество слайдов: 84

ELECTRONICS MANUFACTURING PROCESSES Assembly Raw Materials R. Thompson March 2, 2000

Surface Mount Adhesives R. Thompson March 2, 2000

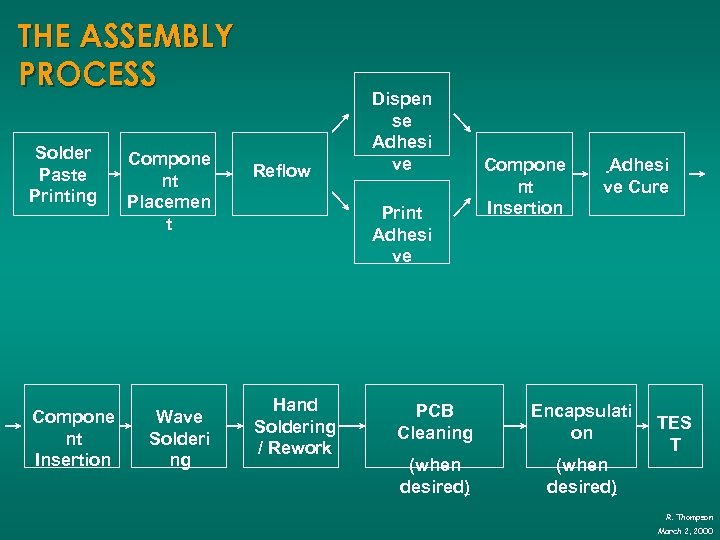

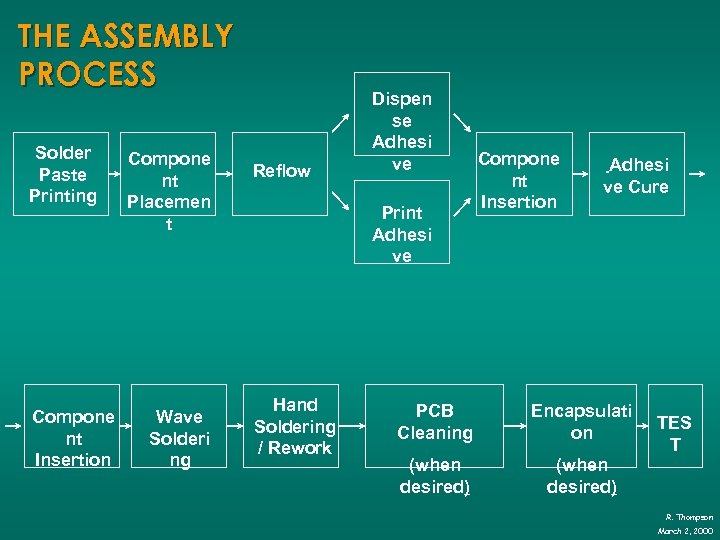

THE ASSEMBLY PROCESS Solder Paste Printing Compone nt Insertion Compone nt Placemen t Wave Solderi ng Reflow Dispen se Adhesi ve Print Adhesi ve Hand Soldering / Rework Compone nt Insertion Adhesi ve Cure PCB Cleaning Encapsulati on (when desired) TES T R. Thompson March 2, 2000

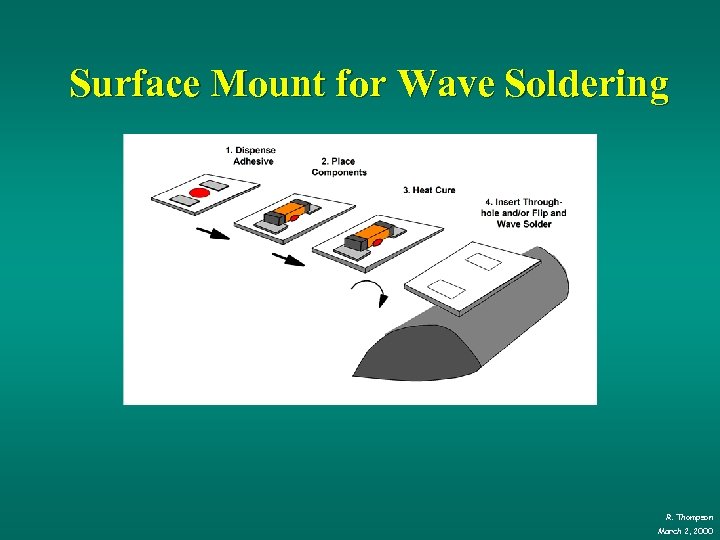

Surface Mount for Wave Soldering R. Thompson March 2, 2000

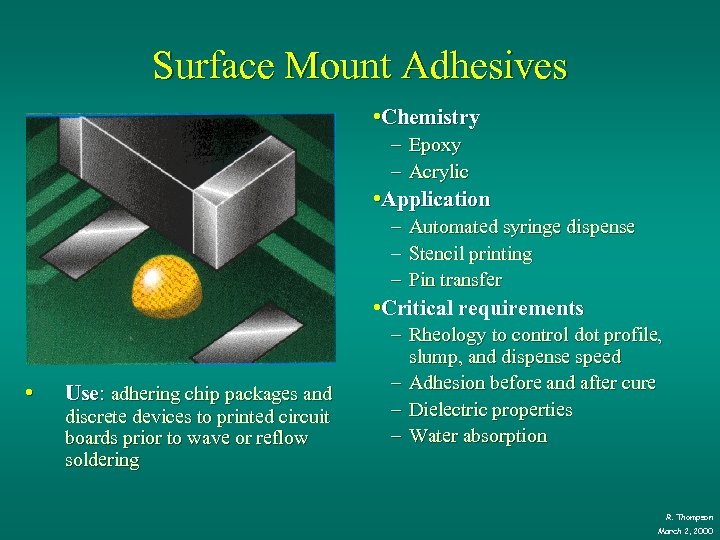

Surface Mount Adhesives • Chemistry – Epoxy – Acrylic • Application – – – Automated syringe dispense Stencil printing Pin transfer • Critical requirements • Use: adhering chip packages and discrete devices to printed circuit boards prior to wave or reflow soldering – Rheology to control dot profile, slump, and dispense speed – Adhesion before and after cure – Dielectric properties – Water absorption R. Thompson March 2, 2000

Epoxy Adhesives • Advantages – Low shrinkage – High “Green Strength” – Good adhesion to a wide variety of substrates – Excellent dielectric – Good chemical resistance • Limitations – Require refrigeration – Short “Pot Life” R. Thompson March 2, 2000

Acrylic Adhesives • Advantages – – Very high-speed dispense Low modulus Fast fixturing time No refrigeration • Limitations – High-temperature cure – UV-assisted cure – Limited solvent resistance R. Thompson March 2, 2000

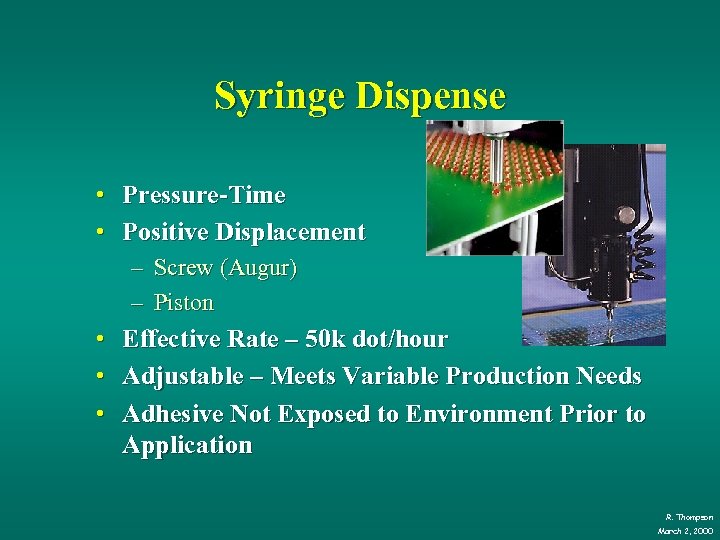

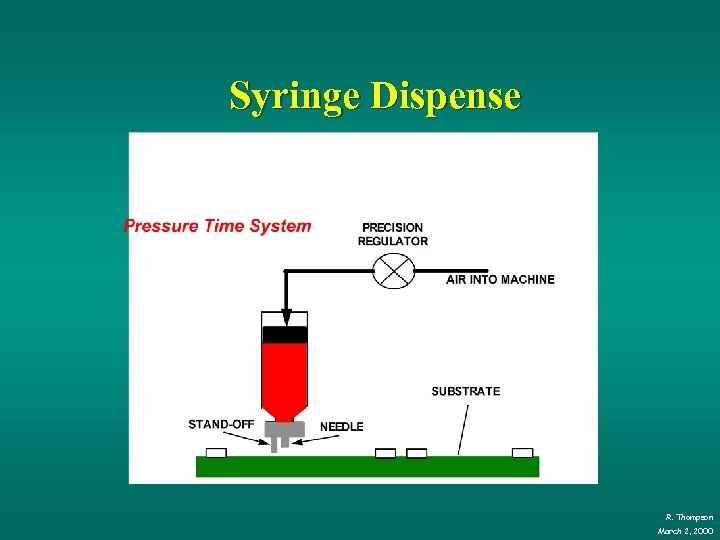

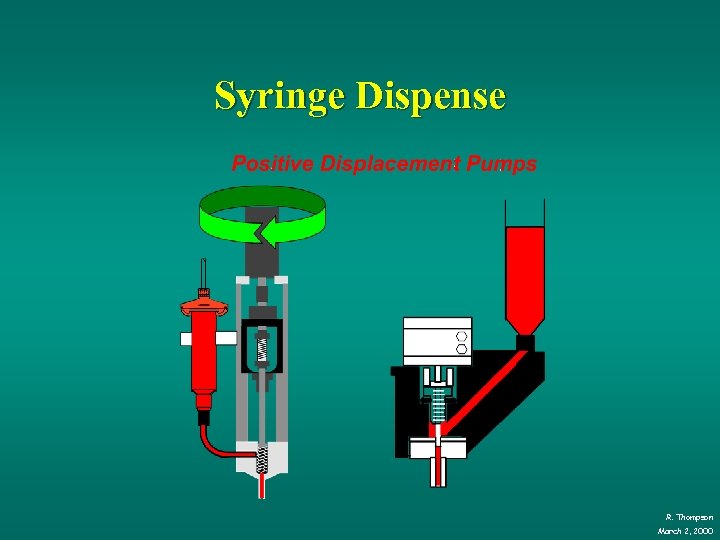

Syringe Dispense • Pressure-Time • Positive Displacement – Screw (Augur) – Piston • Effective Rate – 50 k dot/hour • Adjustable – Meets Variable Production Needs • Adhesive Not Exposed to Environment Prior to Application R. Thompson March 2, 2000

Syringe Dispense R. Thompson March 2, 2000

Syringe Dispense R. Thompson March 2, 2000

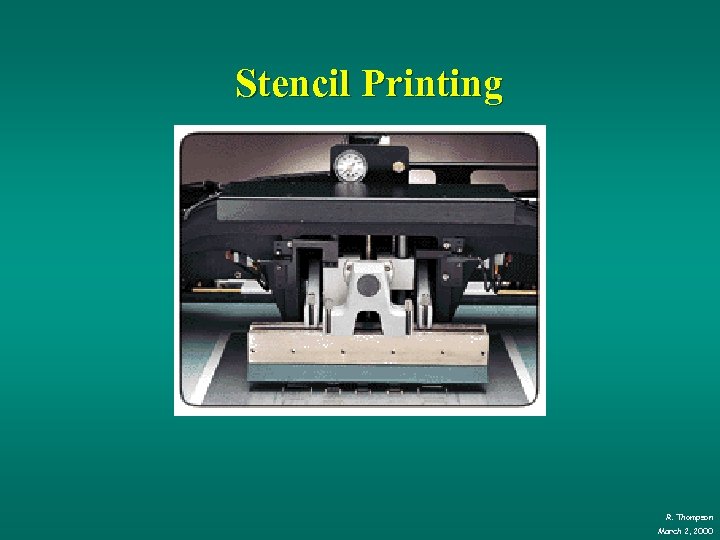

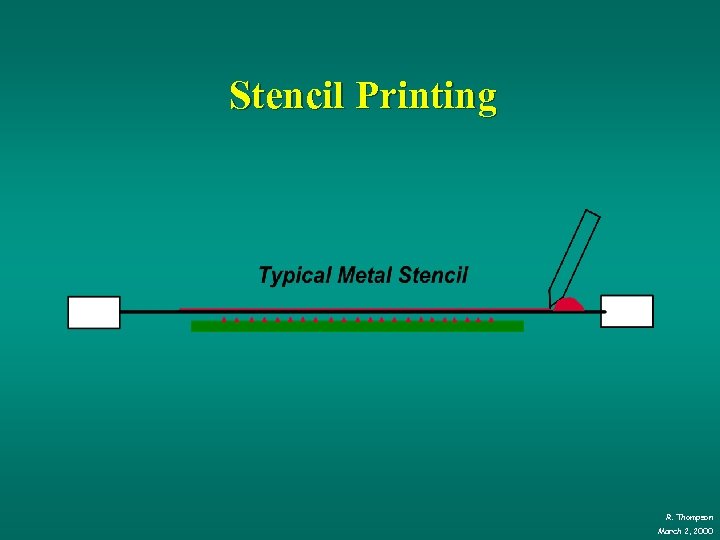

Stencil Printing R. Thompson March 2, 2000

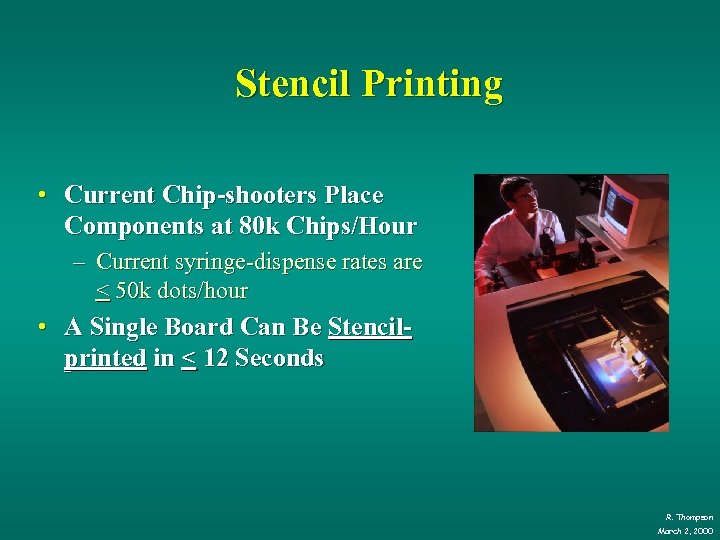

Stencil Printing • Current Chip-shooters Place Components at 80 k Chips/Hour – Current syringe-dispense rates are < 50 k dots/hour • A Single Board Can Be Stencilprinted in < 12 Seconds R. Thompson March 2, 2000

Stencil Printing R. Thompson March 2, 2000

Stencil Printing • Advantages – Fast cycle time – All adhesive dots placed simultaneously – All dots are the same height • Limitations – Typically limited to small-standoff components – Stencil cleanliness essential – Adhesive open to environment R. Thompson March 2, 2000

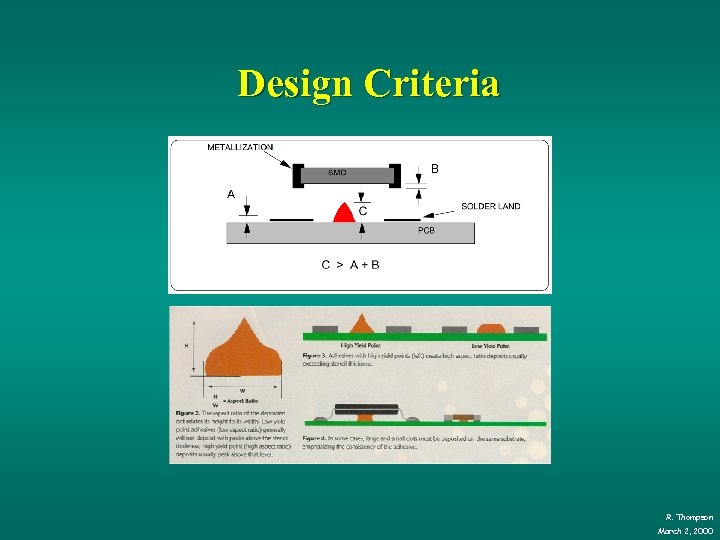

Design Criteria R. Thompson March 2, 2000

Electrically Conductive Adhesives R. Thompson March 2, 2000

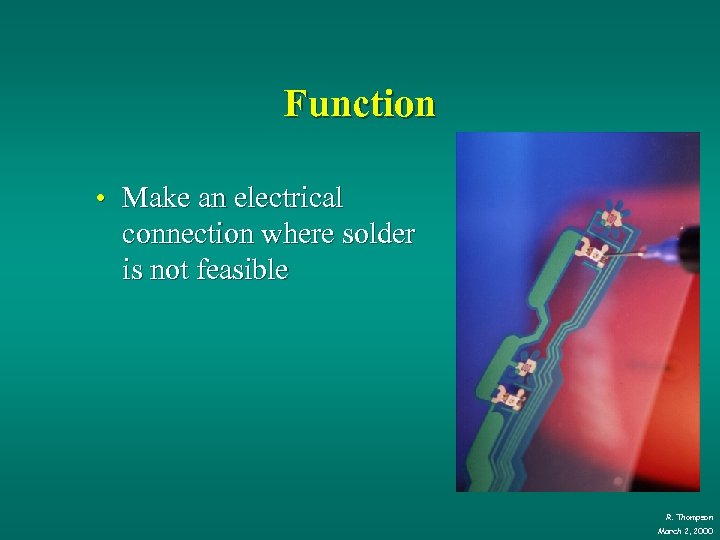

Function • Make an electrical connection where solder is not feasible R. Thompson March 2, 2000

Advantages of Conductive Adhesives • Reduced Joint Stress – Reduced thermal mismatch – Adhesive able to “absorb” mechanical joint stress • Process Costs (not material costs) • Bond Non-Solderable Substrates • “Low Temperature” Cure – Reduced stress on temperature-sensitive components • Environmental Aspects – Lead Free R. Thompson March 2, 2000

Electrically Conductive Adhesives • Electrically Conductive Fillers • 2 Main Adhesive Types – II. Isotropic Anisotropic R. Thompson March 2, 2000

Electrically Conductive Filler Types • Silver – – – Most commonly used Moderate cost Best combination of thermal and electrical conductivity • Gold – High Cost – Good thermal and electrical conductivity R. Thompson March 2, 2000

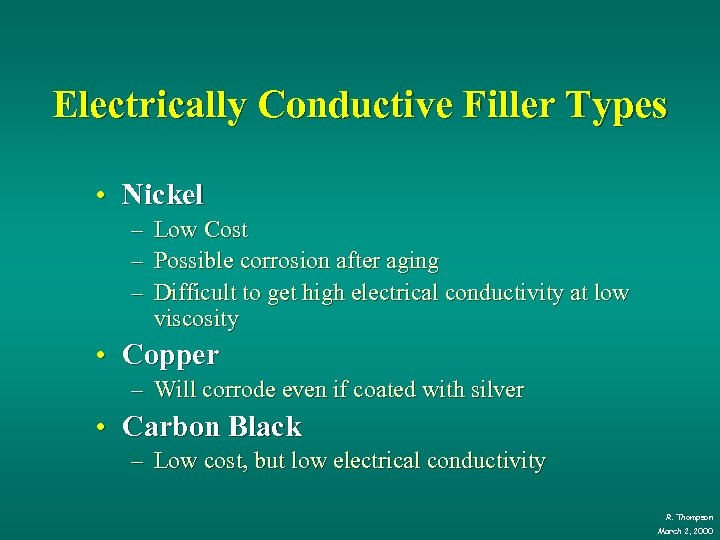

Electrically Conductive Filler Types • Nickel – Low Cost – Possible corrosion after aging – Difficult to get high electrical conductivity at low viscosity • Copper – Will corrode even if coated with silver • Carbon Black – Low cost, but low electrical conductivity R. Thompson March 2, 2000

Isotropic Adhesives • Conductive In All Material Axes • Solder “Replacement” R. Thompson March 2, 2000

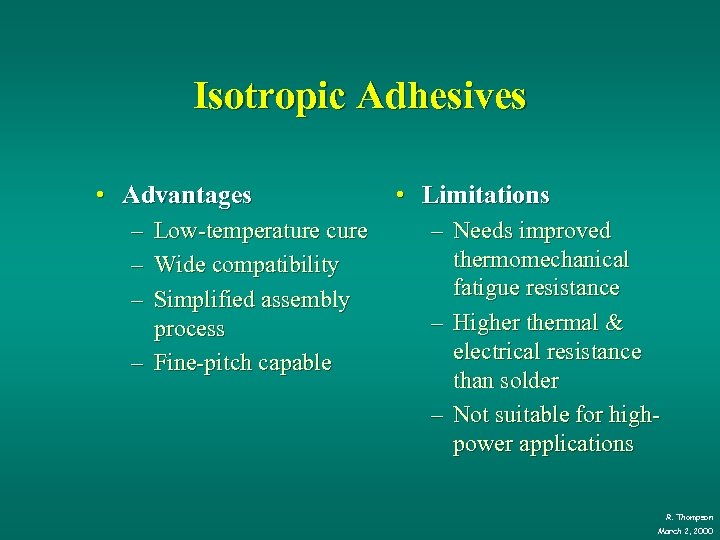

Isotropic Adhesives • Advantages – Low-temperature cure – Wide compatibility – Simplified assembly process – Fine-pitch capable • Limitations – Needs improved thermomechanical fatigue resistance – Higher thermal & electrical resistance than solder – Not suitable for highpower applications R. Thompson March 2, 2000

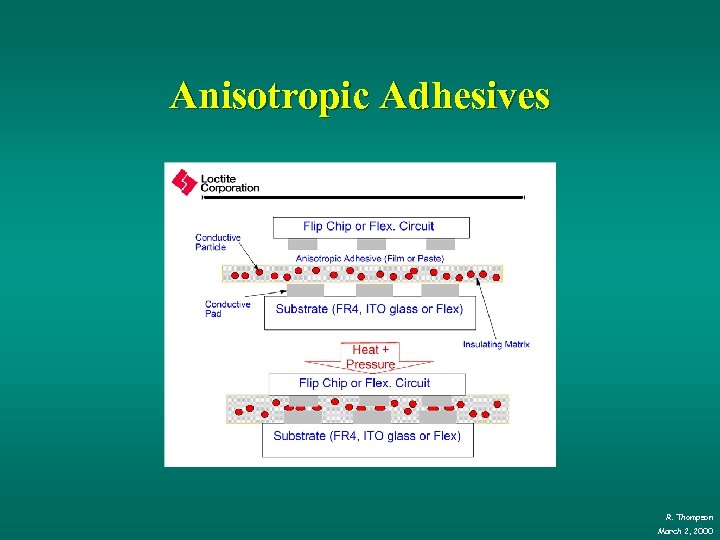

Anisotropic Adhesives • • “Z-axis” Conduction Heat and Pressure Cure UV Fixture, Then Heat Films - Ordered Array R. Thompson March 2, 2000

Anisotropic Adhesives R. Thompson March 2, 2000

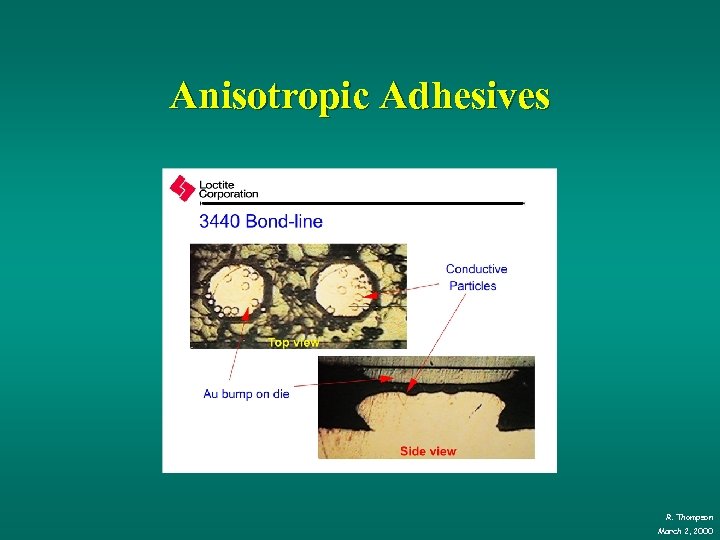

Anisotropic Adhesives R. Thompson March 2, 2000

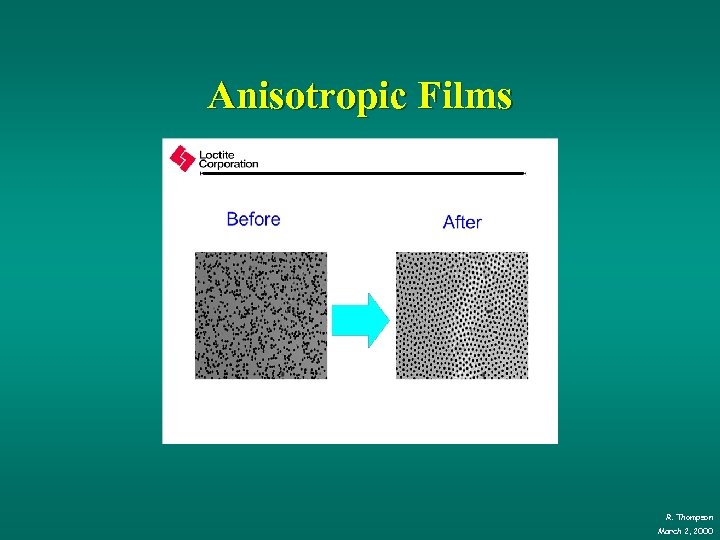

Anisotropic Adhesives • The primary limitation is that the resistance for each I/O will vary based on the dispersion of the particles • This can be overcome with ordered anisotropic conductive adhesive films (ACAF) R. Thompson March 2, 2000

Anisotropic Films R. Thompson March 2, 2000

Material Types • Epoxies • Silicones R. Thompson March 2, 2000

Epoxy Adhesives • Benefits – – – Good adhesion to a wide variety of substrates High cohesive strength Low shrinkage Good thermal and chemical resistance High Tg possible R. Thompson March 2, 2000

Silicone Adhesives • Benefits – – – Low Tg (< -60°C) Consistent performance over wide temp range Excellent high-temperature performance Low modulus Good resistance to polar solvents R. Thompson March 2, 2000

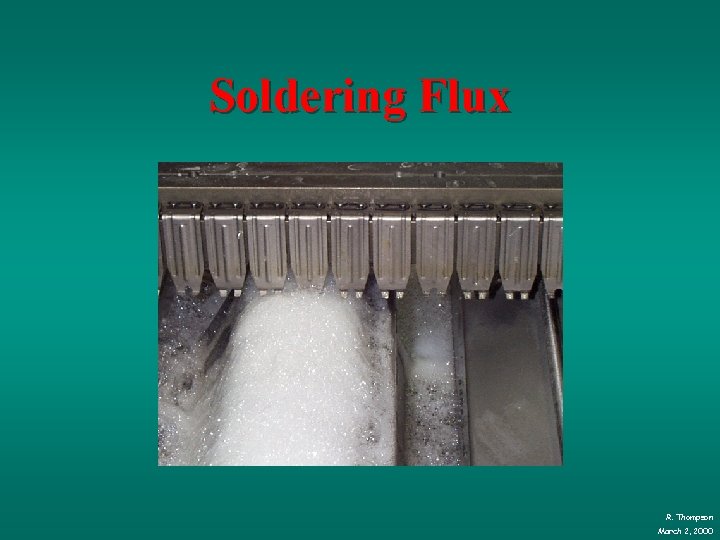

Soldering Flux R. Thompson March 2, 2000

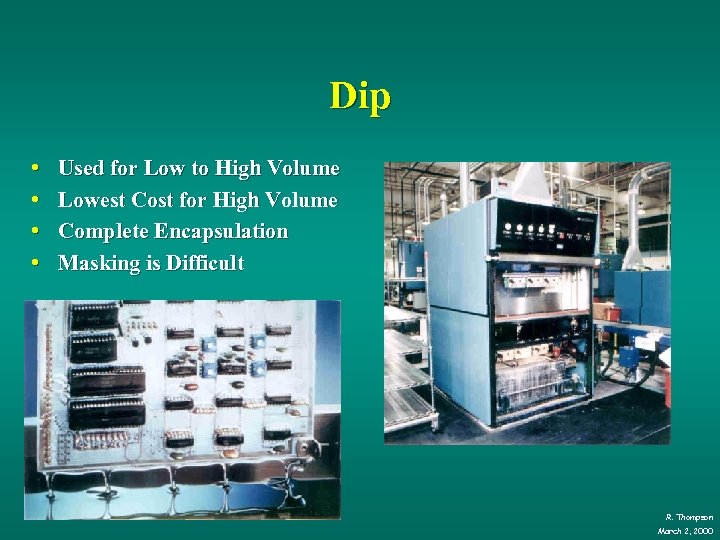

Dip • • Used for Low to High Volume Lowest Cost for High Volume Complete Encapsulation Masking is Difficult R. Thompson March 2, 2000

Fluxes • • • Types of Fluxes Flux Components J-STD-004 Classifications Packaging Application Methods Evaluation R. Thompson March 2, 2000

Types of Fluxes • Rosin/Resin – Abietic and Pimaric acid – Relatively non-corrosive – Hard to pin test • Water-soluble – Very corrosive • Low Solids (“No-clean”) – – – Dicarboxylic acid activators Easier to pin test IPA-based and water-based (VOC-free) R. Thompson March 2, 2000

Flux Components • Solvent – Alcohol, water, etc. • Activator – Amine hydrohalides, organic acids, bases – Reacts with metal oxides • Carrier – Rosin/resin, polyols, high boiling solvents – Coats metal surface, removes oxides & prevents reoxidation, allows heat transfer • Additives – Surfactants, thixotropes, biocide, anti-corrosion etc. R. Thompson March 2, 2000

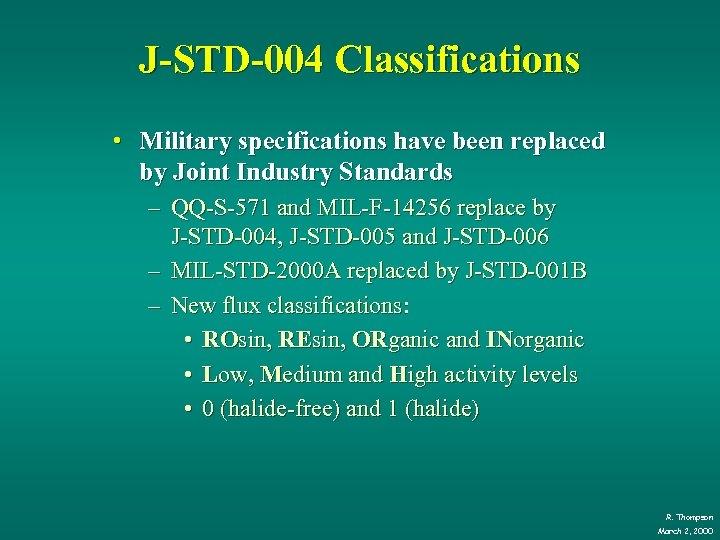

J-STD-004 Classifications • Military specifications have been replaced by Joint Industry Standards – QQ-S-571 and MIL-F-14256 replace by J-STD-004, J-STD-005 and J-STD-006 – MIL-STD-2000 A replaced by J-STD-001 B – New flux classifications: • ROsin, REsin, ORganic and INorganic • Low, Medium and High activity levels • 0 (halide-free) and 1 (halide) R. Thompson March 2, 2000

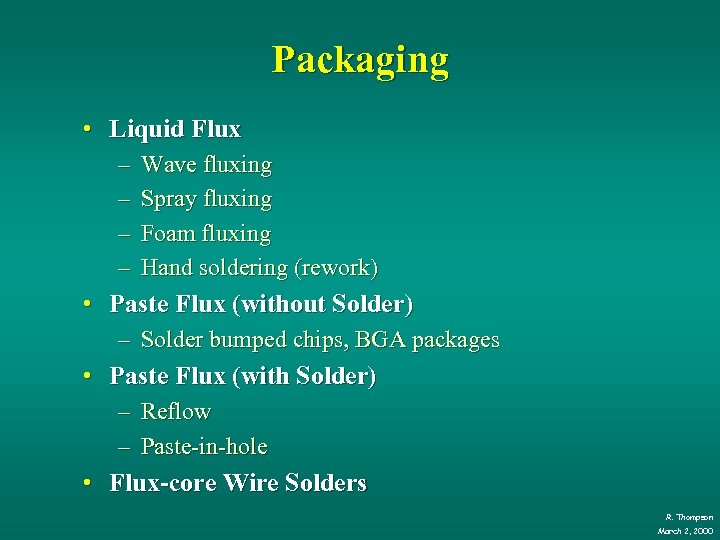

Packaging • Liquid Flux – – Wave fluxing Spray fluxing Foam fluxing Hand soldering (rework) • Paste Flux (without Solder) – Solder bumped chips, BGA packages • Paste Flux (with Solder) – Reflow – Paste-in-hole • Flux-core Wire Solders R. Thompson March 2, 2000

Spray Fluxing • Ultrasonic • Pulse R. Thompson March 2, 2000

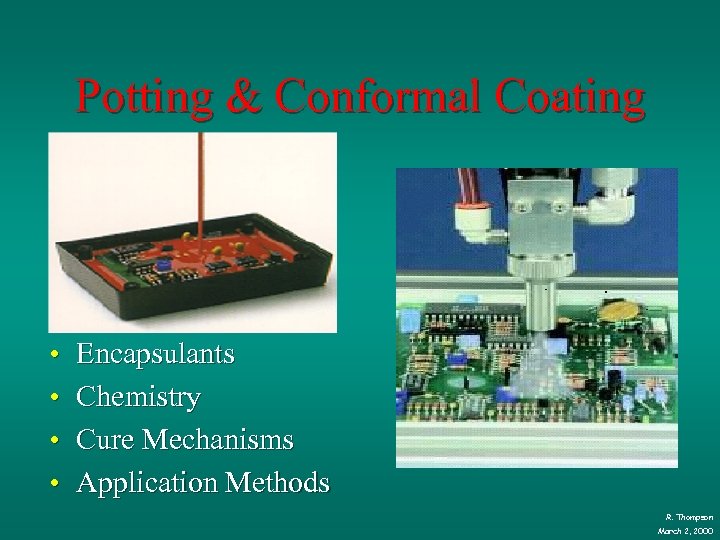

Potting & Conformal Coating • • Encapsulants Chemistry Cure Mechanisms Application Methods R. Thompson March 2, 2000

THE ASSEMBLY PROCESS Solder Paste Printing Compone nt Insertion Compone nt Placemen t Wave Solderi ng Reflow Dispen se Adhesi ve Print Adhesi ve Hand Soldering / Rework Compone nt Insertion Adhesi ve Cure PCB Cleaning Encapsulati on (when desired) TES T R. Thompson March 2, 2000

Encapsulants • Conformal Coating – Applied in a thin layer (5 to 10 mils) – Minimal stress relief and vibration damping • Potting – Applied in a thick layer (over 125 mils) – Used for stress relief and vibration damping R. Thompson March 2, 2000

Critical Requirements • Electrically Insulating – Good dielectric • Thermally Conductive – “Better than air” • Low-to-Moderate CTE and Low Modulus – Distribute solder joint stress – Necessary for fine-pitch • Good Adhesion To Each Interface Material R. Thompson March 2, 2000

What They Do • • • Dielectric Environmental (Moisture) Barrier Encapsulant Conductor Protectant Solder Joint Stress Relief Vibration Damping R. Thompson March 2, 2000

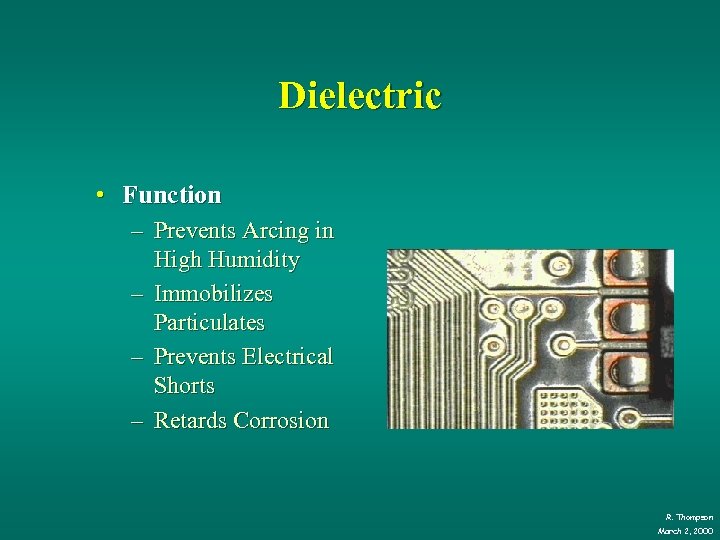

Dielectric • Function – Prevents Arcing in High Humidity – Immobilizes Particulates – Prevents Electrical Shorts – Retards Corrosion R. Thompson March 2, 2000

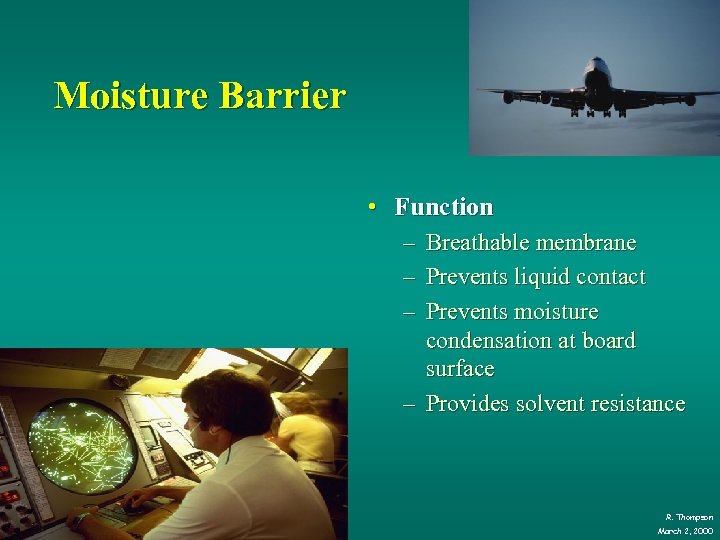

Moisture Barrier • Function – Breathable membrane – Prevents liquid contact – Prevents moisture condensation at board surface – Provides solvent resistance R. Thompson March 2, 2000

Encapsulant • Function – – Immobilized device Immobilizes debris Supports Components Provides solder joints stress distribution R. Thompson March 2, 2000

Protects Conductors • Function – Insulative coating – Shields bare conductors – Reduces high-voltage arcing R. Thompson March 2, 2000

Chemistry • • • Acrylics Epoxy Urethanes Silicones Parylene (Paraxylylene) R. Thompson March 2, 2000

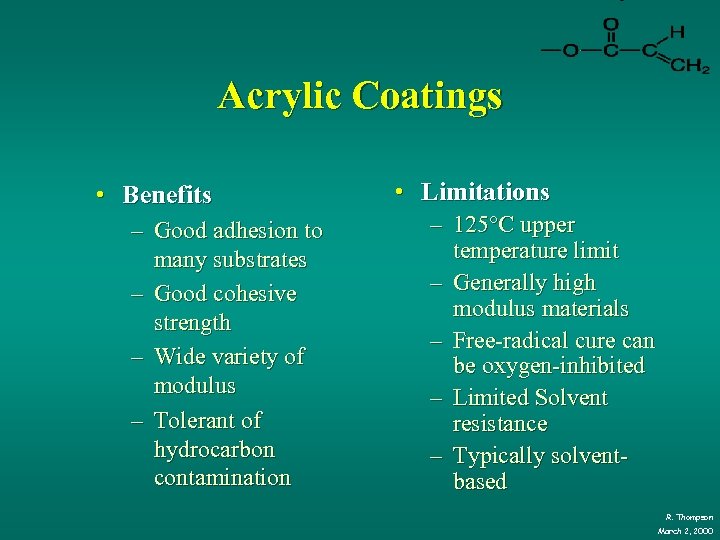

Acrylic Coatings • Benefits – Good adhesion to many substrates – Good cohesive strength – Wide variety of modulus – Tolerant of hydrocarbon contamination • Limitations – 125°C upper temperature limit – Generally high modulus materials – Free-radical cure can be oxygen-inhibited – Limited Solvent resistance – Typically solventbased R. Thompson March 2, 2000

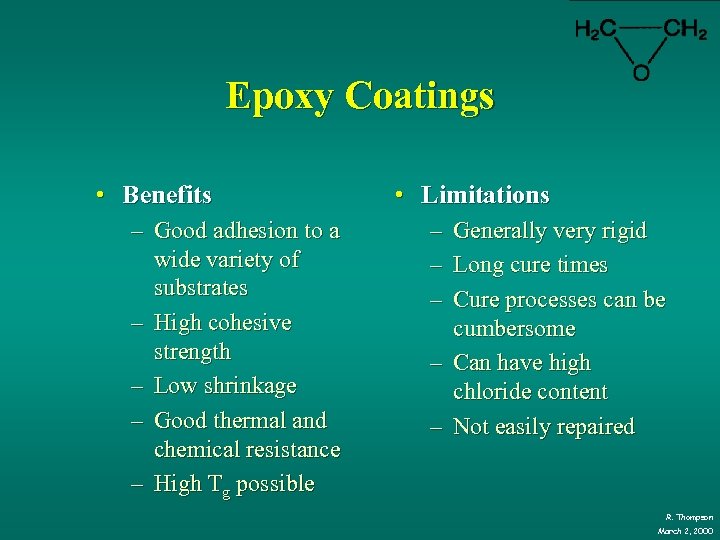

Epoxy Coatings • Benefits – Good adhesion to a wide variety of substrates – High cohesive strength – Low shrinkage – Good thermal and chemical resistance – High Tg possible • Limitations – Generally very rigid – Long cure times – Cure processes can be cumbersome – Can have high chloride content – Not easily repaired R. Thompson March 2, 2000

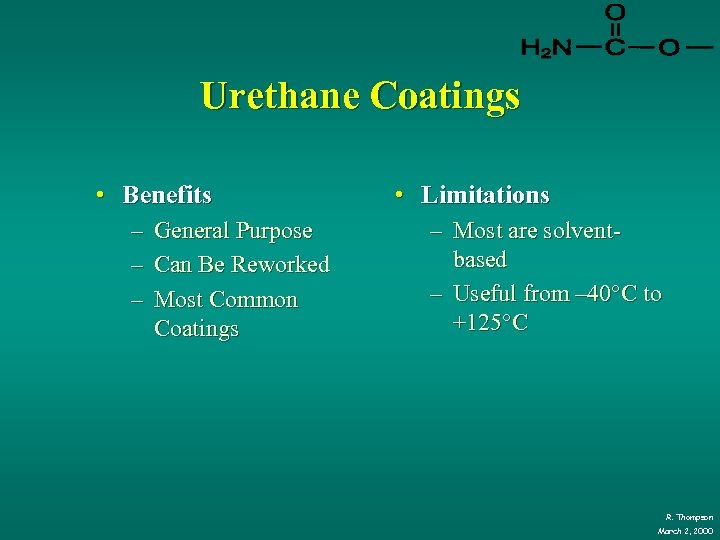

Urethane Coatings • Benefits – General Purpose – Can Be Reworked – Most Common Coatings • Limitations – Most are solventbased – Useful from – 40°C to +125°C R. Thompson March 2, 2000

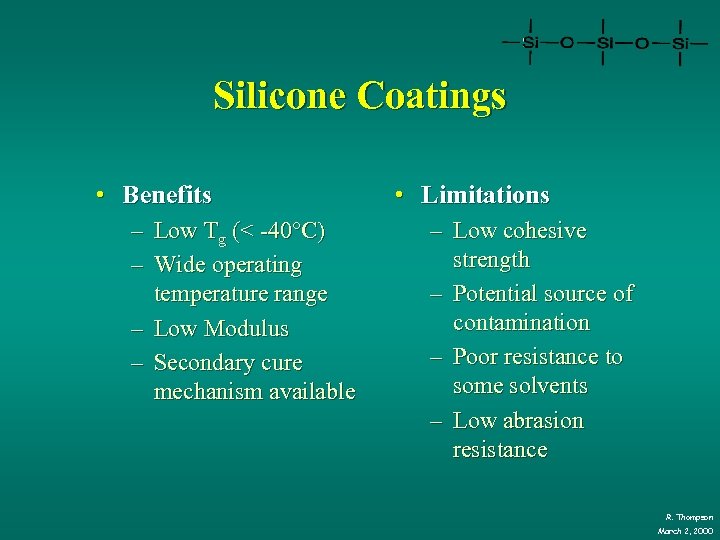

Silicone Coatings • Benefits – Low Tg (< -40°C) – Wide operating temperature range – Low Modulus – Secondary cure mechanism available • Limitations – Low cohesive strength – Potential source of contamination – Poor resistance to some solvents – Low abrasion resistance R. Thompson March 2, 2000

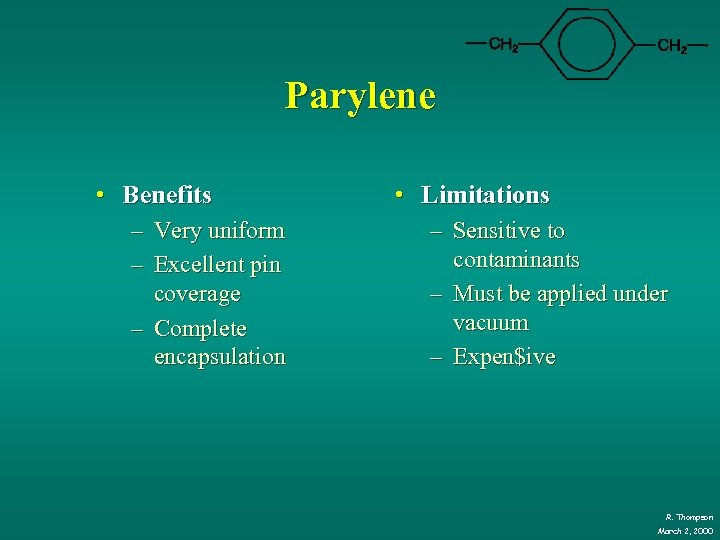

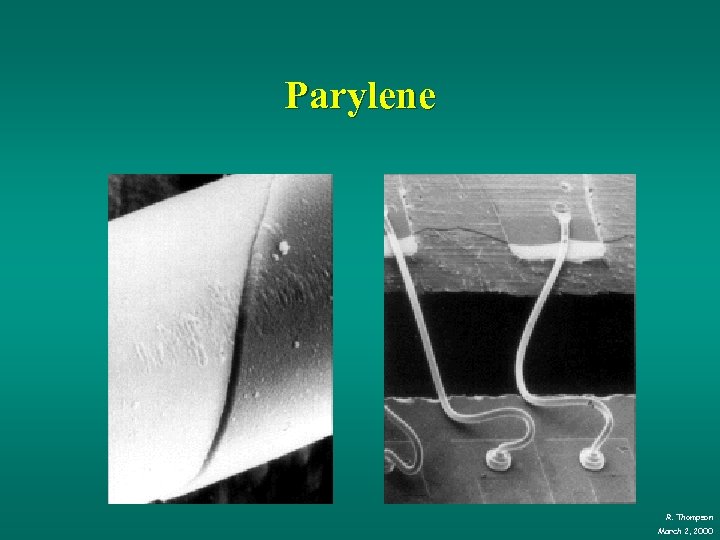

Parylene • Benefits – Very uniform – Excellent pin coverage – Complete encapsulation • Limitations – Sensitive to contaminants – Must be applied under vacuum – Expen$ive R. Thompson March 2, 2000

Parylene R. Thompson March 2, 2000

Cure Mechanisms • Air Dry – – – Most commonly used for aerosols Can take a long time Solvents/Odors (environmental concerns) R. Thompson March 2, 2000

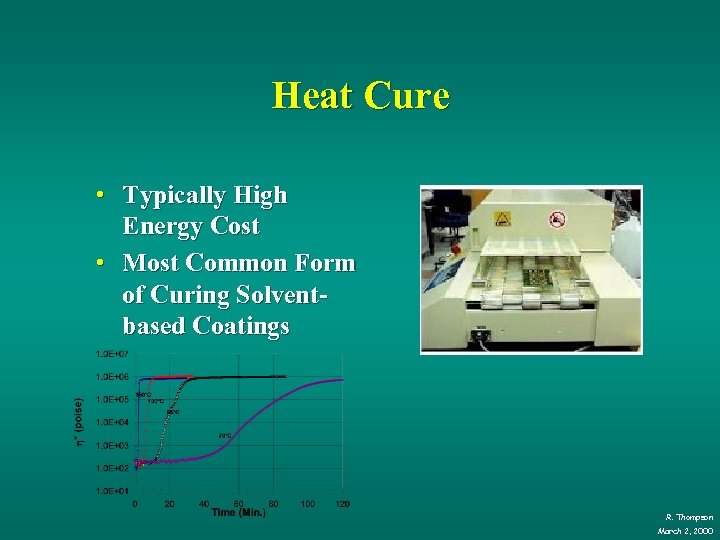

Heat Cure • Typically High Energy Cost • Most Common Form of Curing Solventbased Coatings R. Thompson March 2, 2000

UV Cure • High Speed / Very Efficient • Must Have Effective Secondary Cure for Shadowed Areas • Are Typically More Expensive R. Thompson March 2, 2000

Cure Mechanisms • Moisture – Uses ambient or forced moisture to initiate the cure reaction – Most commonly found in silicone family as primary or secondary mechanism R. Thompson March 2, 2000

Application Methods • Potting – Automated meter-mix – Hand-mix with vacuum de-air • Conformal Coating – – Manual spray Automated spray Dip Chemical vapor deposition (CVD) R. Thompson March 2, 2000

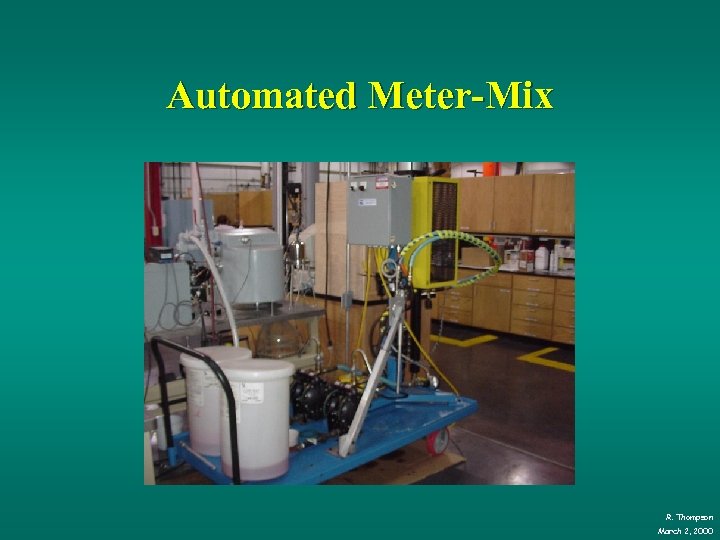

Automated Meter-Mix R. Thompson March 2, 2000

Manual Spray • Medium Volume Production • Low to Moderate Cost for High Volume • Does Not Coat Under Components • Masking Easier Than Dip Coat • Slightly More Maintenance Than Dip Coat • Parameters Affecting Thickness – Feed system – Line speed – Atomization pressure – Material temperature R. Thompson March 2, 2000

Automated Spray • Moderate to High Volume • Often Eliminates Masking • Most Expensive Equipment for High Volume • Higher Maintenance Than Dip or Spray R. Thompson March 2, 2000

Thermal Management R. Thompson March 2, 2000

Why is it Needed? • Packaging Reduction – – – Smaller components More power Tighter spacing • Heat Transfer Efficiency – Improve heat dissipation – Decrease thermal resistance • Component Effectiveness – – More efficient component output Longer working life, increased reliability R. Thompson March 2, 2000

Methods to Dissipate Heat • Mechanical Fasteners • Thermal Pads – With mechanical fasteners – With adhesives • Grease – With mechanical fasteners • Adhesives R. Thompson March 2, 2000

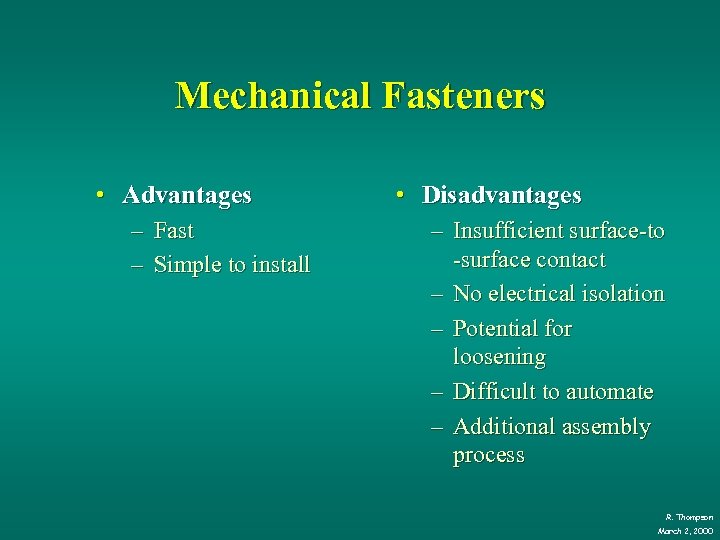

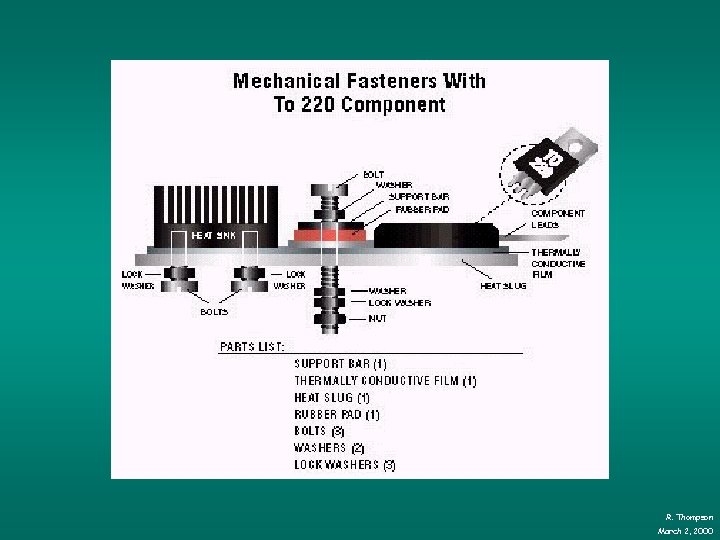

Mechanical Fasteners • Advantages – Fast – Simple to install • Disadvantages – Insufficient surface-to -surface contact – No electrical isolation – Potential for loosening – Difficult to automate – Additional assembly process R. Thompson March 2, 2000

R. Thompson March 2, 2000

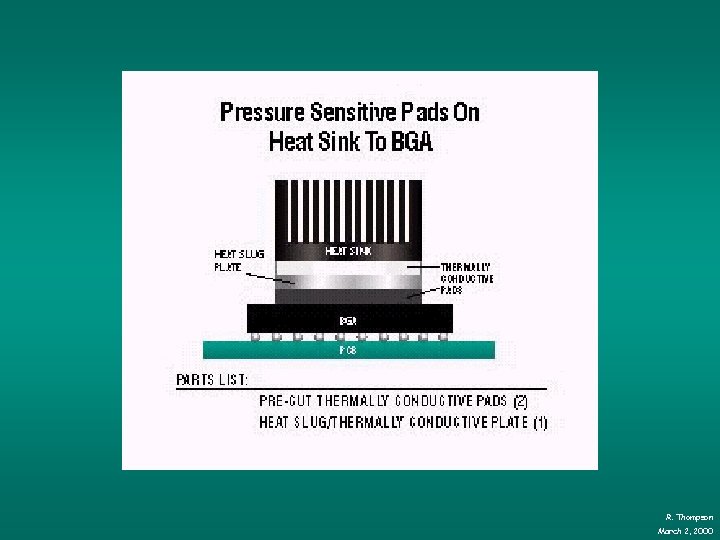

Thermal Pads • Advantages – Fairly good conductivity – Minimal void formation • Disadvantages – Fasteners required – Release film removal required – Pad relaxation – Labor intensive R. Thompson March 2, 2000

R. Thompson March 2, 2000

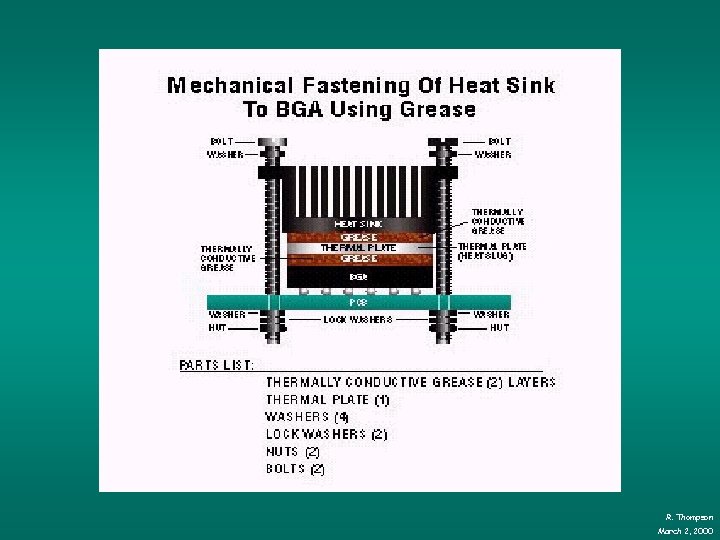

Thermal Grease • Advantages – Good conductivity – Minimal void formation • Disadvantages – Fasteners required – Poor electrical isolation – Collects debris – Matrix migration – Labor intensive R. Thompson March 2, 2000

R. Thompson March 2, 2000

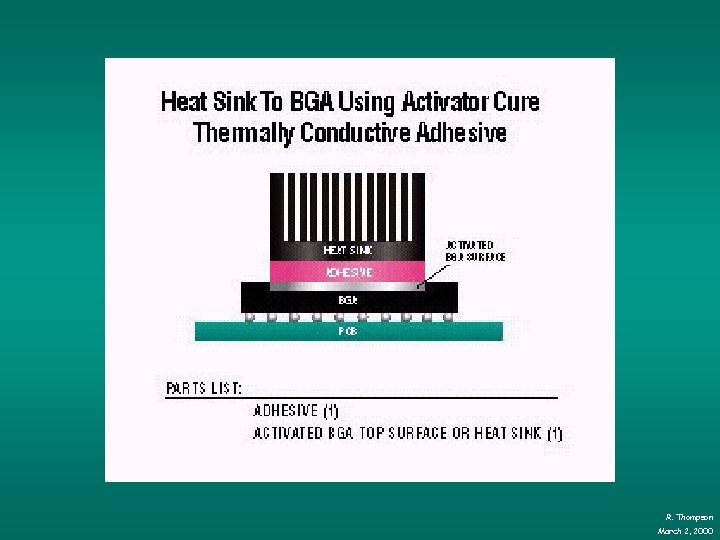

Adhesives • Advantages – Good conductivity – Good electrical isolation – Eliminates fasteners • Disadvantages – Accurate dispense required – Cure process required – Material storage required R. Thompson March 2, 2000

R. Thompson March 2, 2000

Curing Methods • Activator Cure – Fast fixture strength – Thick sections • UV Cure – Rapid cure – On-demand cure • Activator and UV – Rapid cure • Heat – Complete polymer cross-linking • Activator, Heat, and UV – Rapid fixture strength – Rapid cure R. Thompson March 2, 2000

Material Evaluation R. Thompson March 2, 2000

Material Evaluation • Characterization • Compatibility R. Thompson March 2, 2000

Characterization • Electrical Properties – Surface Insulation Resistance (SIR) – Electromigration (Dendritic growth) • Mechanical Properties – Bond strength (Peel, Shear) – Modulus of Elasticity (Young’s Modulus) – Coefficient of Thermal Expansion (CTE) • Performance Characteristics – – Out-gassing Moisture uptake R. Thompson March 2, 2000

Compatibility • • Flux Residue Solder Mask (if present) Component Mold-release Material Solder Materials (Sn/Pb, No-lead, etc. ) R. Thompson March 2, 2000

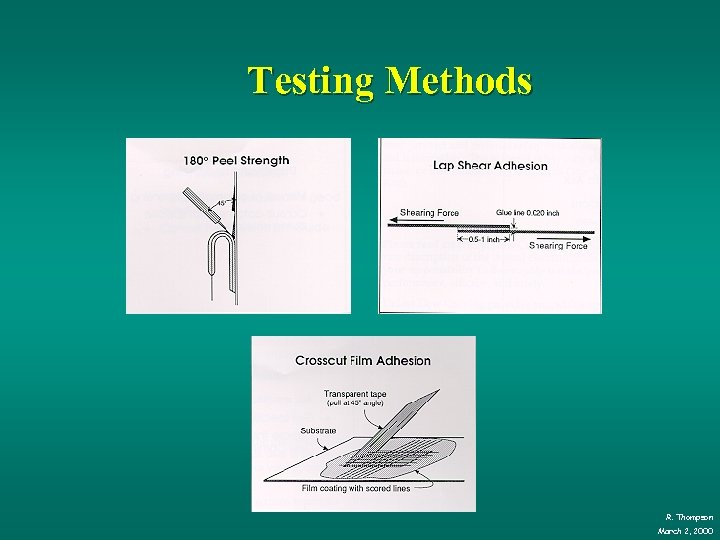

Testing Methods R. Thompson March 2, 2000

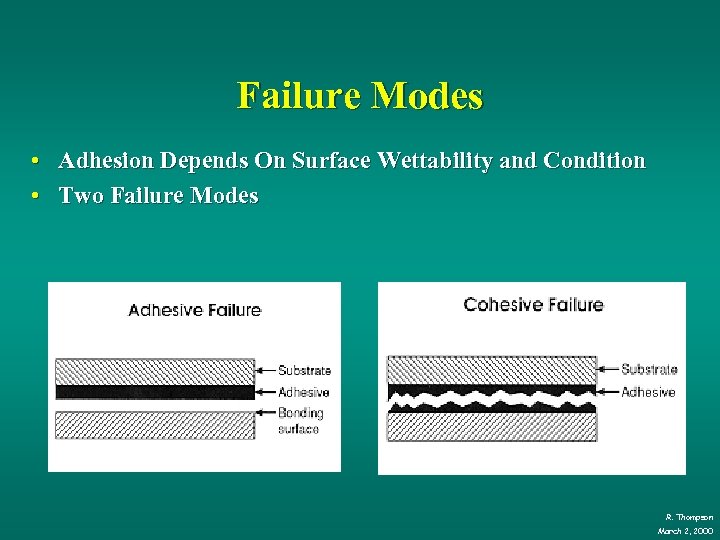

Failure Modes • Adhesion Depends On Surface Wettability and Condition • Two Failure Modes R. Thompson March 2, 2000

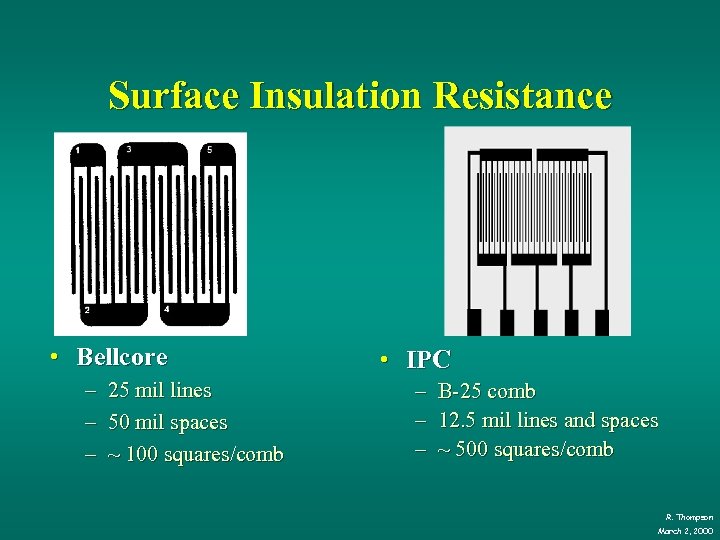

Surface Insulation Resistance • Bellcore – 25 mil lines – 50 mil spaces – ~ 100 squares/comb • IPC – – – B-25 comb 12. 5 mil lines and spaces ~ 500 squares/comb R. Thompson March 2, 2000

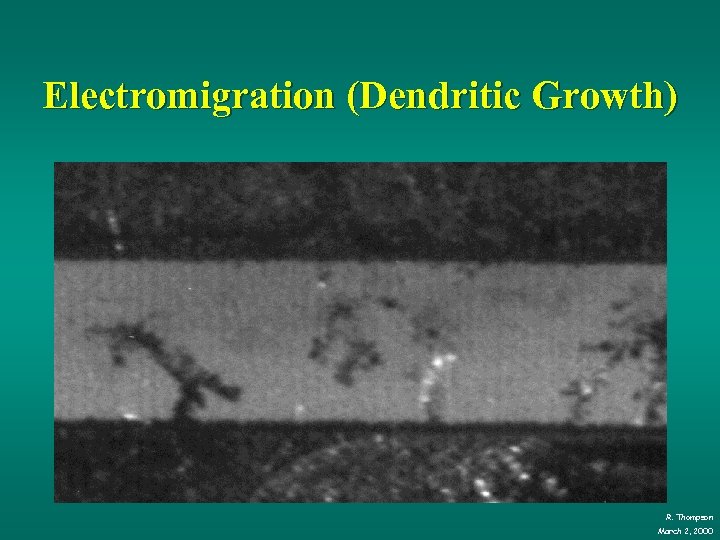

Electromigration (Dendritic Growth) R. Thompson March 2, 2000

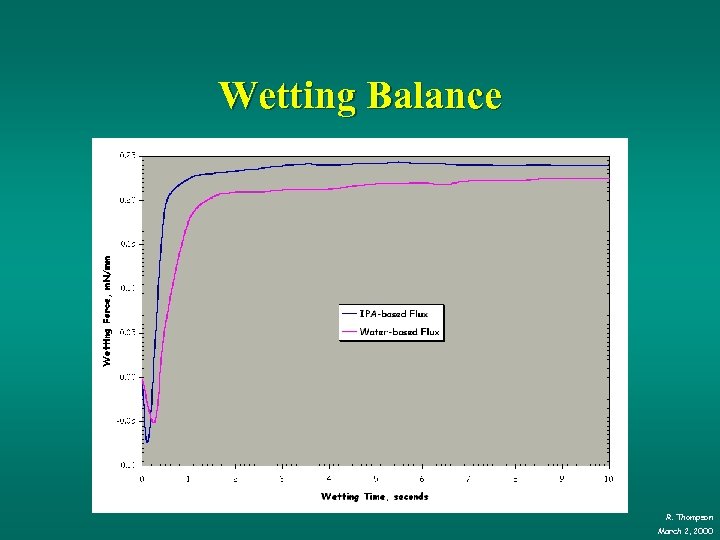

Wetting Balance R. Thompson March 2, 2000

9eeba09137bff44e4ccbd3753d6c086f.ppt